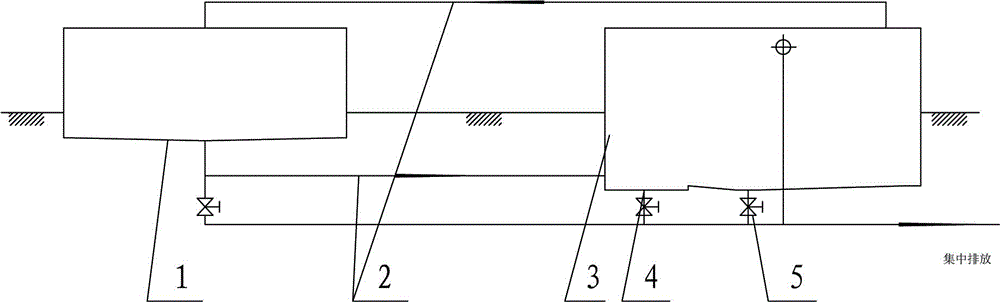

Prawn circulating aquaculture system and operation method

A technology for recirculating aquaculture and prawns, which is applied in fish farming, antifouling/underwater coatings, and biocide-containing paints to achieve safe silver ion concentration, good bacteriostatic effect, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

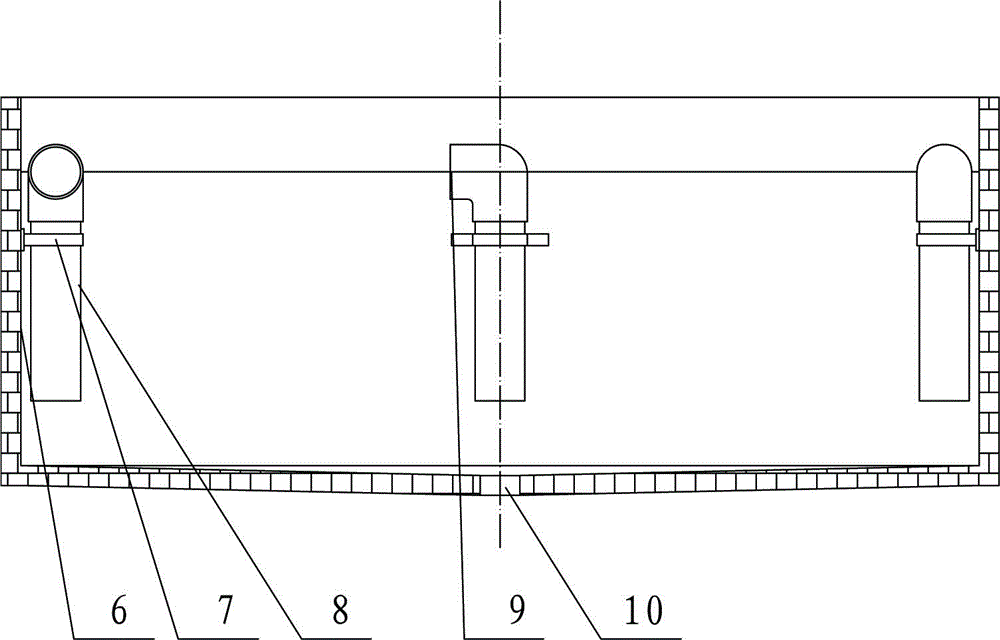

[0031] The inner wall of the breeding pond is coated with nano-functional coating 6; several aeration and water purification devices 8 positioned by hoops 7 are evenly arranged along the wall of the pond, and the water outlet 9 is arranged tangentially to the wall of the breeding pond; the bottom center of the breeding pond is provided with Sewage outlet 10;

[0032] The aeration combination device is composed of a right-angle elbow 81, a diversion standpipe 82, a suspension filler 83, and an aeration component 84; The filling rate of suspended filler in the riser is 65%.

[0033] The diversion riser also has a built-in aeration component 84, which is located in the suspended packing 83; the aeration component is composed of an air stone 85 and a soft air pipe 86; the air stone communicates with the soft air pipe through the end air port; The trachea is placed outside the water outlet of the right-angle elbow; the filter materials in the diversion standpipe are connected by a...

Embodiment 2

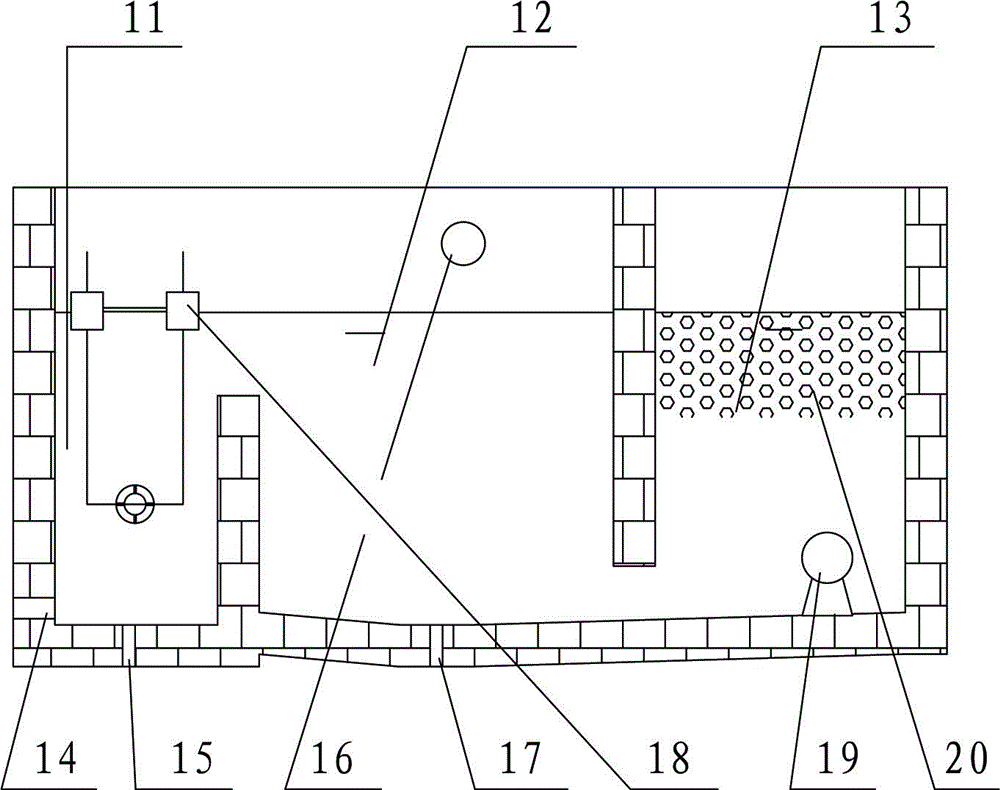

[0041] The air flotation chamber has a built-in air flotation machine 18 with a power of 0.75kw; the biological filter chamber has a built-in circulating water pump 19 and suspended filler 20 with a power of 3.0kw, and the filling rate of the suspended filler in the biological filter chamber is 30%.

[0042] Air flotation contact time: 2.5min, separation and sedimentation time: 30min.

[0043] Others are the same as embodiment 1.

[0044]According to the above-mentioned circulating aquaculture system for prawns, the operation method is to start the aeration component in the early stage of cultivation, and the water flow will form a micro-flow internal circulation under the promotion of air lift to maintain good water quality; in the middle and late stages of cultivation, the organic load will increase. On this basis, the circulating water pump is started again, and the water flows from the inside to the outside to complete the external circulation. This greatly reduces energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com