Graphene/titanate nanometer composite visible-light activated photocatalyst and preparation method thereof

A nanocomposite and photocatalyst technology, applied in the field of nanocomposite materials and photocatalysis, to achieve the effects of good surface morphology, enhanced visible light catalytic performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

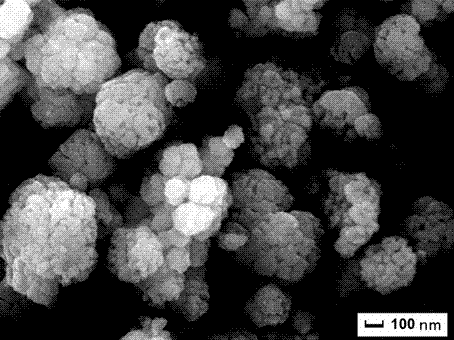

[0032]Dissolve 2.55 mL of tetrabutyl titanate in 20 mL of absolute ethanol, add ammonia solution while stirring, filter and wash to obtain precipitates of titanium oxyhydroxides. Dissolve 4.76 g of barium nitrate and 2.1 g of potassium hydroxide in 10 mL of deionized water, respectively. 20 mg graphene oxide was sonicated in 20 mL deionized water for 3 hours, then barium nitrate aqueous solution was added and stirred for another 8 hours. Mix and stir the titanium oxyhydroxide precipitation, barium nitrate and graphene oxide solution for 30 minutes, then add potassium hydroxide aqueous solution and stir for 10 minutes, then transfer to a 100 mL reactor liner, and adjust the reaction with deionized water The volume of the reaction material in the inner tank of the reactor reached 75% of the inner tank volume of the reactor, and then placed in a stainless steel jacket, sealed, and kept at 120°C for 10 hours for hydrothermal treatment, and then allowed the reactor to cool naturall...

Embodiment 2

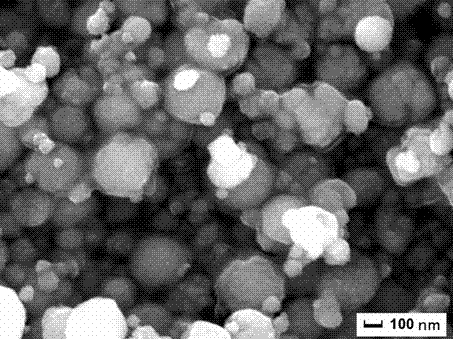

[0034] Dissolve 2.55 mL of tetrabutyl titanate in 20 mL of absolute ethanol, add ammonia solution while stirring, filter and wash to obtain precipitates of titanium oxyhydroxides. Dissolve 4.76 g of barium nitrate and 2.1 g of potassium hydroxide in 10 mL of deionized water, respectively. 50 mg graphene oxide was sonicated in 20 mL deionized water for 4 hours, then barium nitrate aqueous solution was added and stirred for another 10 hours. Mix and stir the titanium oxyhydroxide precipitation, barium nitrate and graphene oxide solution for 30 minutes, then add potassium hydroxide aqueous solution and stir for 10 minutes, then transfer to a 100 mL reactor liner, and adjust the reaction with deionized water The volume of the reaction material in the inner tank of the reactor reaches 75% of the inner tank volume of the reactor, and then placed in a stainless steel jacket, sealed, and kept at 140 ° C for 8 hours for hydrothermal treatment, and then allowed the reactor to cool natur...

Embodiment 3

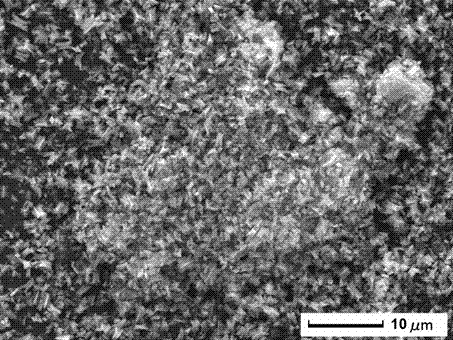

[0036] Dissolve 2.55 mL of tetrabutyl titanate in 20 mL of absolute ethanol, add ammonia solution while stirring, filter and wash to obtain precipitates of titanium oxyhydroxides. Dissolve 4.76 g of barium nitrate and 2.1 g of potassium hydroxide in 10 mL of deionized water, respectively. 100 mg graphene oxide was sonicated in 20 mL deionized water for 5 hours, then barium nitrate aqueous solution was added and stirred for another 10 hours. Mix and stir the titanium oxyhydroxide precipitation, barium nitrate and graphene oxide solution for 30 minutes, then add potassium hydroxide aqueous solution and stir for 10 minutes, then transfer to the inner tank of a 100 mL reactor, and adjust the reactor with deionized water The volume of the reaction material in the inner tank reaches 75% of the volume of the inner tank of the reactor, and then placed in a stainless steel jacket, sealed, and kept at 180°C for 6 hours to carry out hydrothermal treatment, then allowing the reactor to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com