Preparation method of superfine dolomite and application of superfine dolomite

A dolomite and fine powder technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve the problems of easy agglomeration of ultrafine powder, small application range, and difficulty in uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

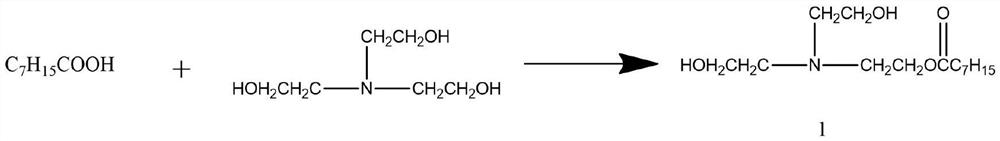

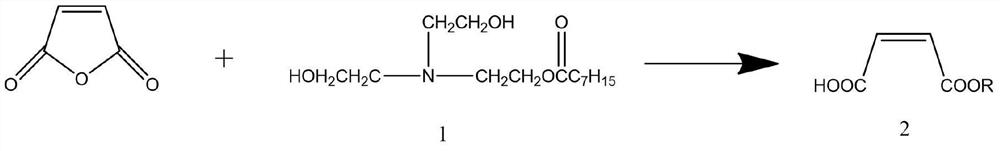

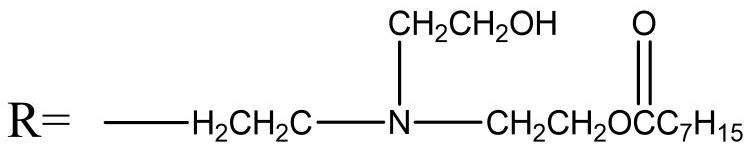

[0039] Present embodiment is a kind of grinding aid, and the preparation process of described grinding aid comprises the following steps:

[0040] S1: Add phenol to a three-necked flask equipped with a condenser and a stirrer, then add octanoic acid and triethanolamine, and place the three-necked flask in a constant temperature oil bath at a temperature of 130°C and a stirring speed of 100r / min Stirring and reacting for 7 hours until the water is completely discharged, the crude product of intermediate 1 is obtained; the molar ratio of octanoic acid and triethanolamine is 1.6:1.0, and the dosage ratio of octanoic acid and phenol is 1g:5mL;

[0041]S2: Dissolve the crude product of intermediate 1 in isooctane to obtain the crude product solution of intermediate 1, wash the crude product solution of intermediate 1 with aqueous sodium hydroxide solution and distilled water three times respectively, and remove unreacted octanoic acid, triethanolamine and phenol , and then the crud...

Embodiment 2

[0045] Present embodiment is a kind of grinding aid, and the preparation process of described grinding aid comprises the following steps:

[0046] S1: Add phenol to a three-necked flask equipped with a condenser and a stirrer, then add octanoic acid and triethanolamine, and place the three-necked flask in a constant temperature oil bath at a temperature of 135°C and a stirring speed of 150r / min Stirring and reacting for 8 hours, until the water is completely discharged, the crude product of intermediate 1 is obtained; the molar ratio of octanoic acid and triethanolamine is 1.6:1.0, and the dosage ratio of octanoic acid and phenol is 1g:8mL;

[0047] S2: Dissolve the crude product of intermediate 1 in isooctane to obtain the crude product solution of intermediate 1, wash the crude product solution of intermediate 1 with sodium hydroxide aqueous solution and distilled water 4 times respectively, and remove unreacted octanoic acid, triethanolamine and phenol , and then the crude ...

Embodiment 3

[0051] Present embodiment is a kind of grinding aid, and the preparation process of described grinding aid comprises the following steps:

[0052] S1: Add phenol to a three-necked flask equipped with a condenser and a stirrer, then add octanoic acid and triethanolamine, and place the three-necked flask in a constant temperature oil bath at a temperature of 140°C and a stirring speed of 200r / min Stirring and reacting for 9 hours until the water is completely discharged, the crude product of intermediate 1 is obtained; the molar ratio of octanoic acid and triethanolamine is 1.6:1.0, and the dosage ratio of octanoic acid and phenol is 1g:10mL;

[0053] S2: Dissolve the crude intermediate 1 in isooctane to obtain the crude intermediate 1 solution, wash the crude intermediate 1 solution with sodium hydroxide aqueous solution and distilled water 5 times respectively, and remove unreacted octanoic acid, triethanolamine and phenol , and then the crude product solution of Intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com