Patents

Literature

31 results about "Cargo handling gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cargo-Handling Gear of a Ship equipment for loading, unloading, and rearranging of freight. Usually a ship is equipped with cargo-handling gear of the periodic-motion type—loading booms, cranes, and sometimes elevators. The loading boom is the most common form of cargo-handling gear in freighters because of its simplicity of operation. Modern ships ...

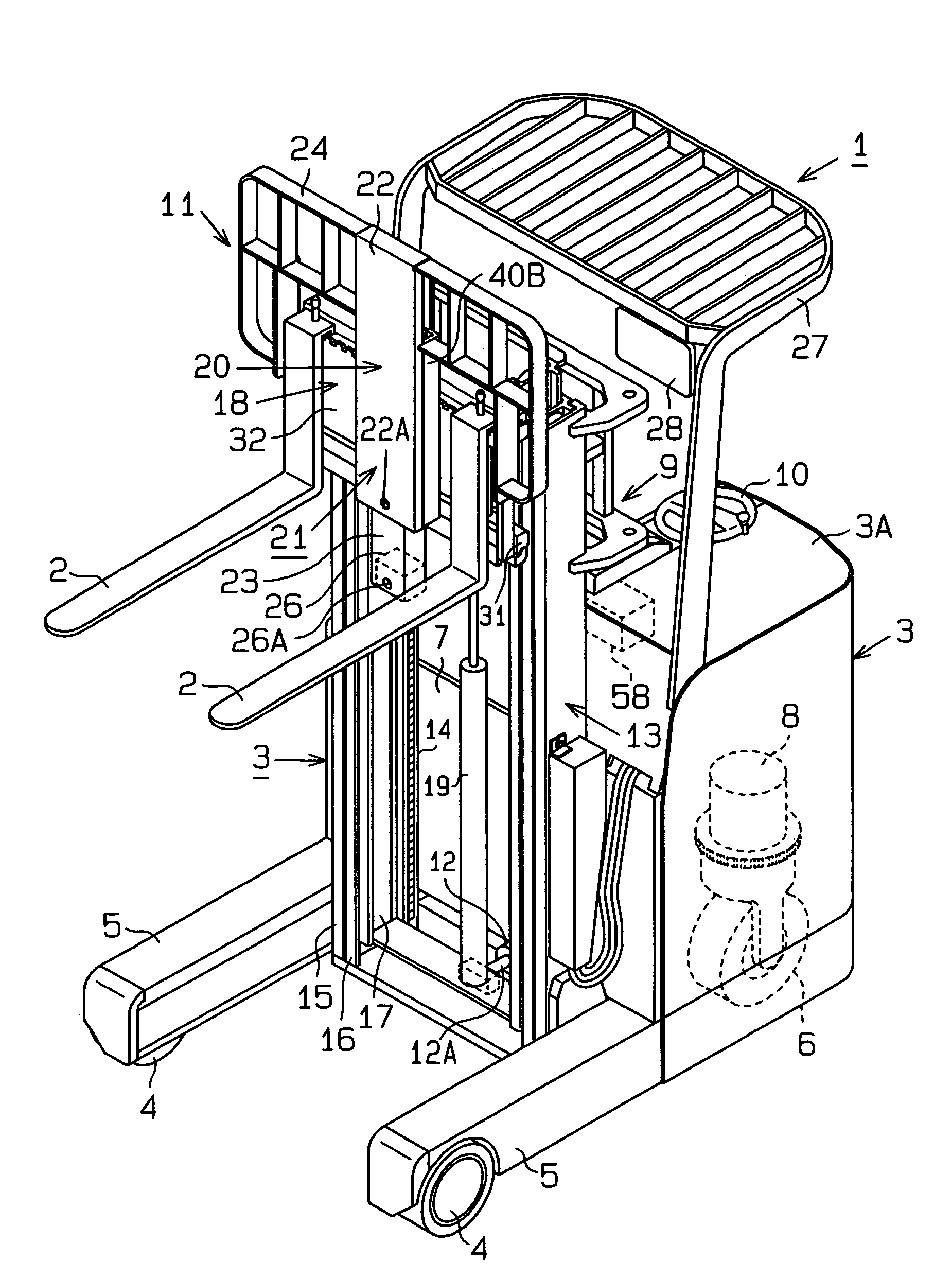

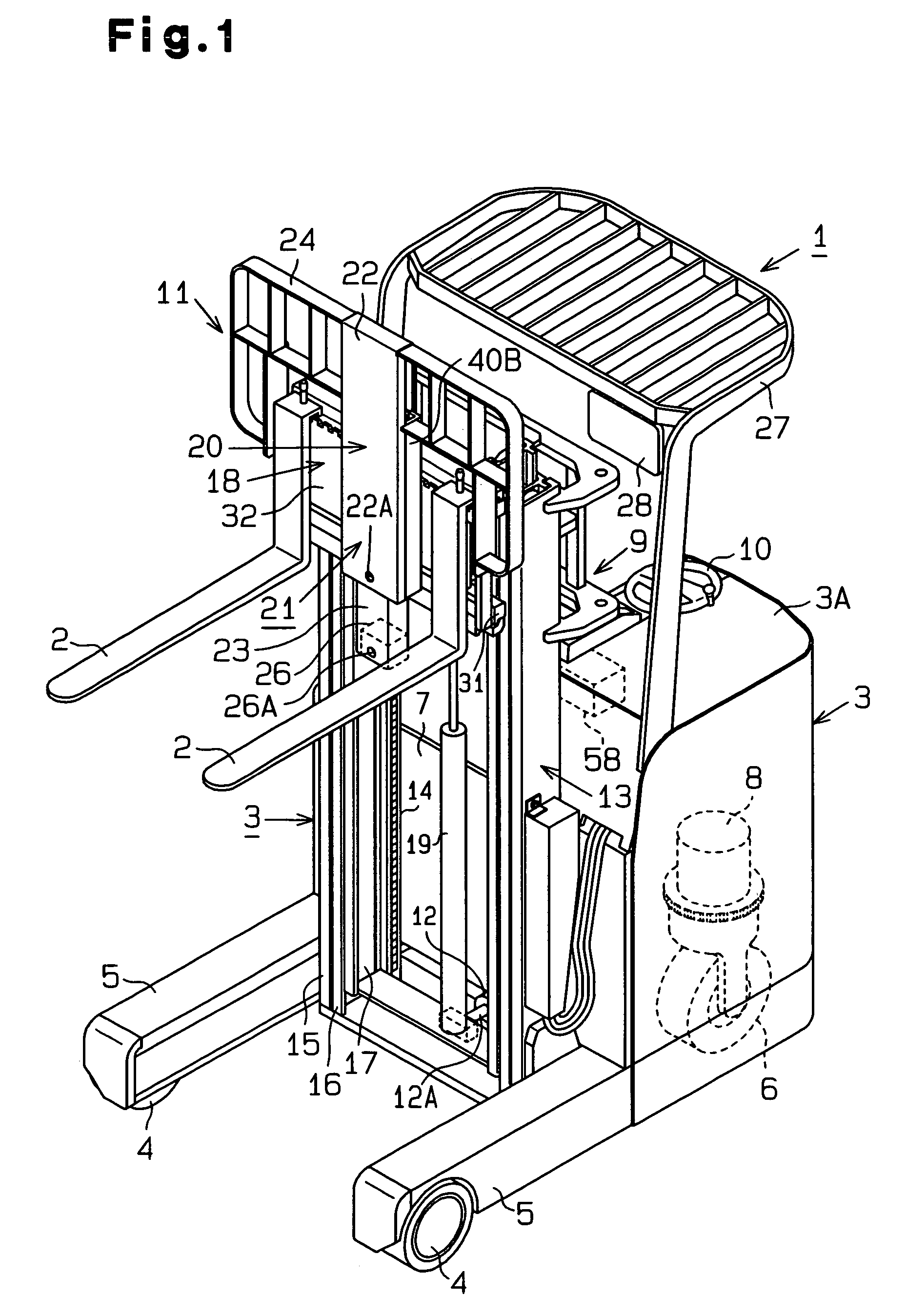

Camera lifting apparatus and cargo handling operation aiding apparatus in industrial vehicle and industrial vehicle

InactiveUS7320385B2Avoid spreadingEffective supportAnti-theft devicesLifting devicesCargo handling gearEngineering

A camera lifting apparatus is used in an industrial vehicle equipped with a cargo handling apparatus for lifting a cargo carrying carriage up and down along a mast provided on a vehicle body. The carriage has a cargo carrying apparatus. The camera lifting apparatus comprises a camera unit attached to the cargo carrying apparatus. The camera unit has a camera for picking up an image of a work area of the cargo carrying apparatus. A moving mechanism moves the camera unit relatively to the cargo carrying apparatus. An actuator drives the moving mechanism.

Owner:TOYOTA IND CORP

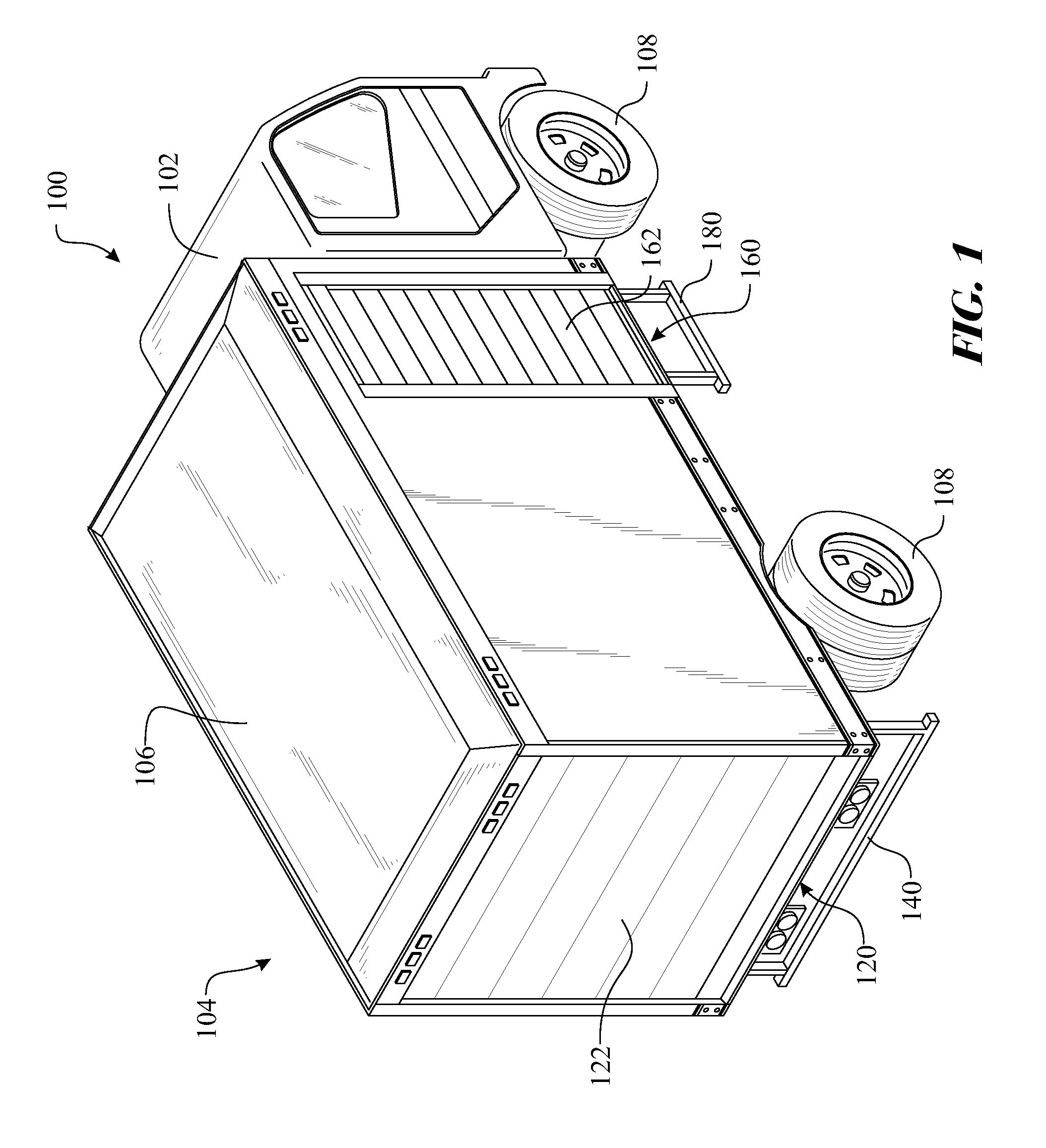

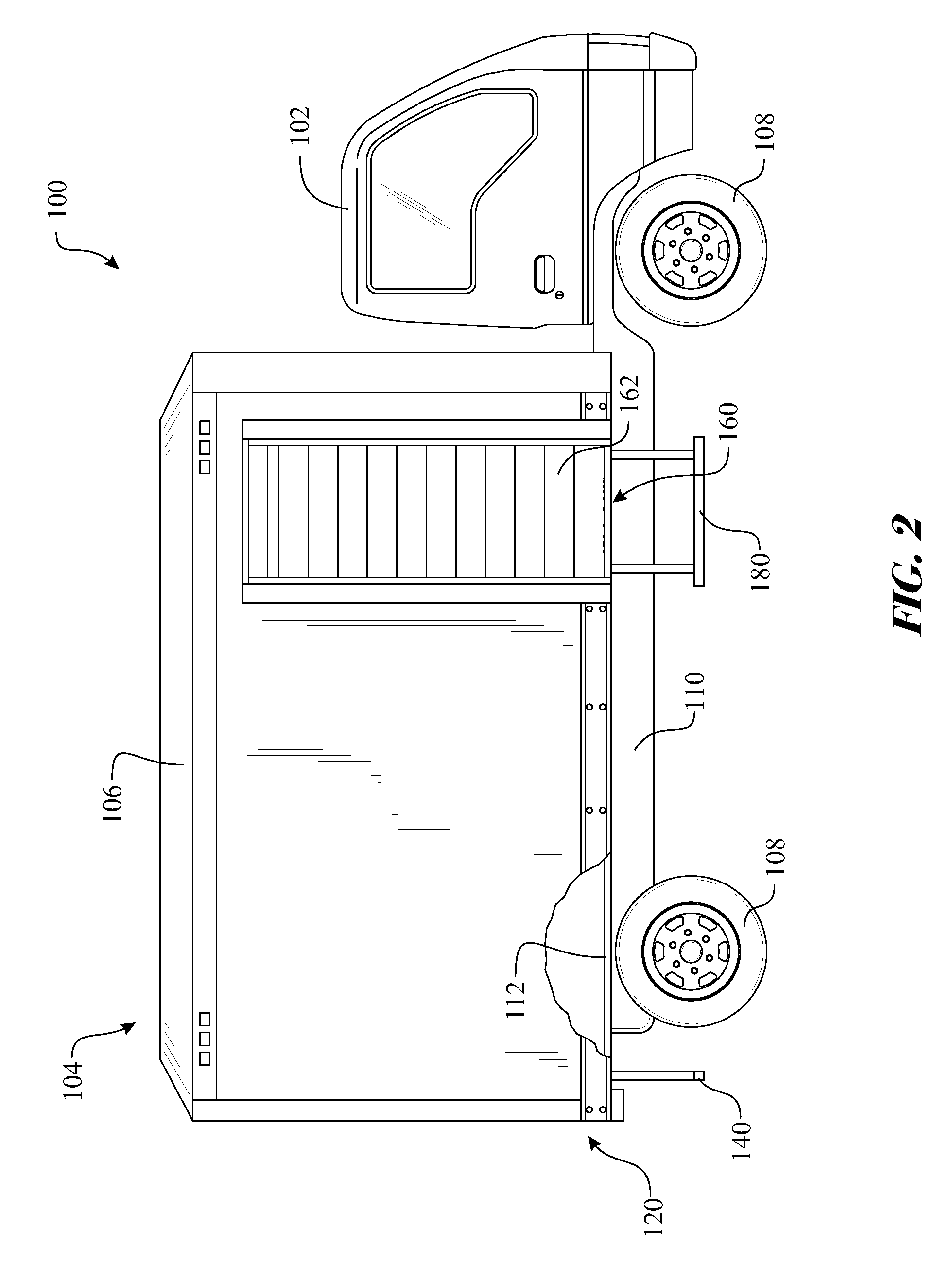

Cargo handling apparatus

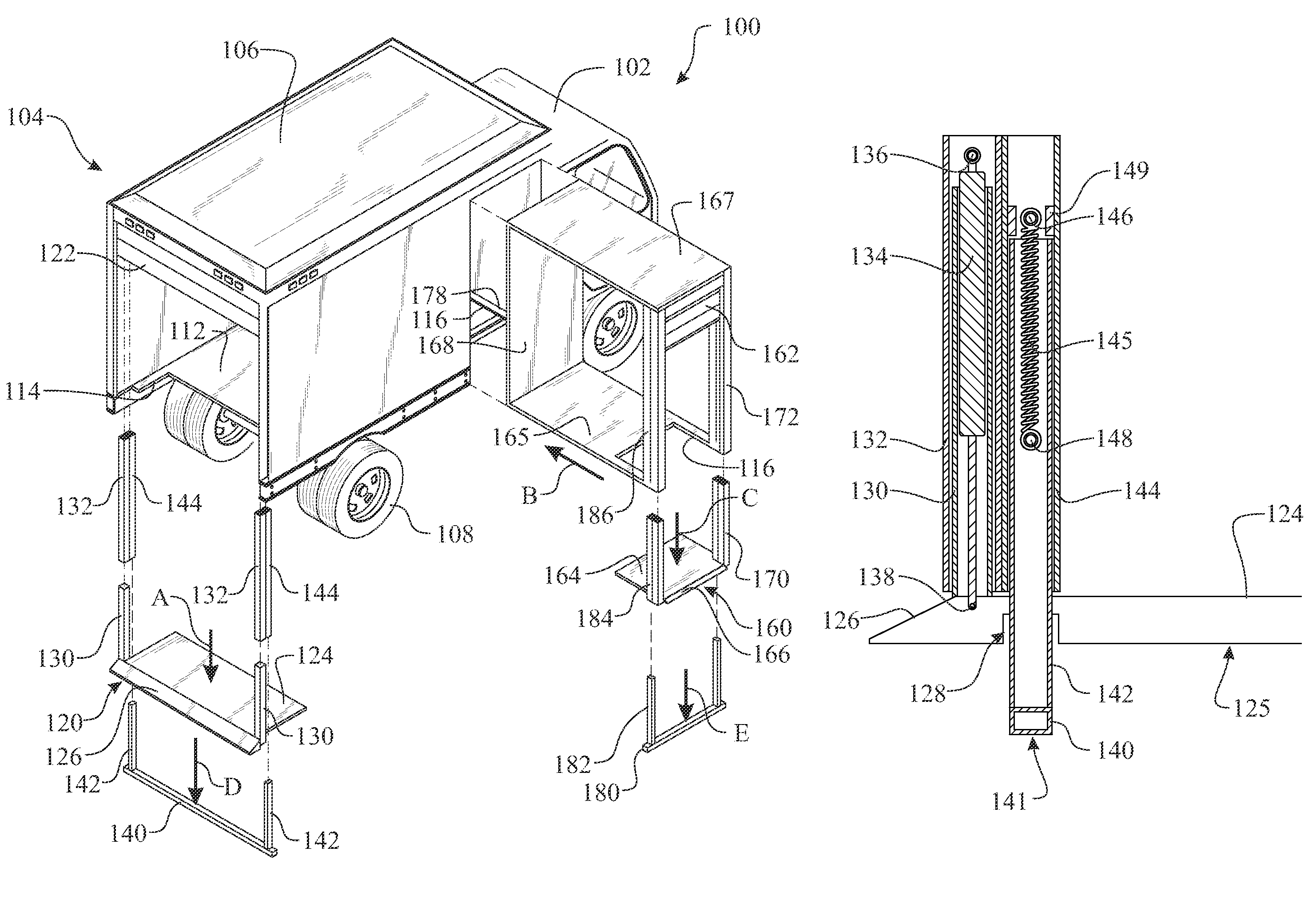

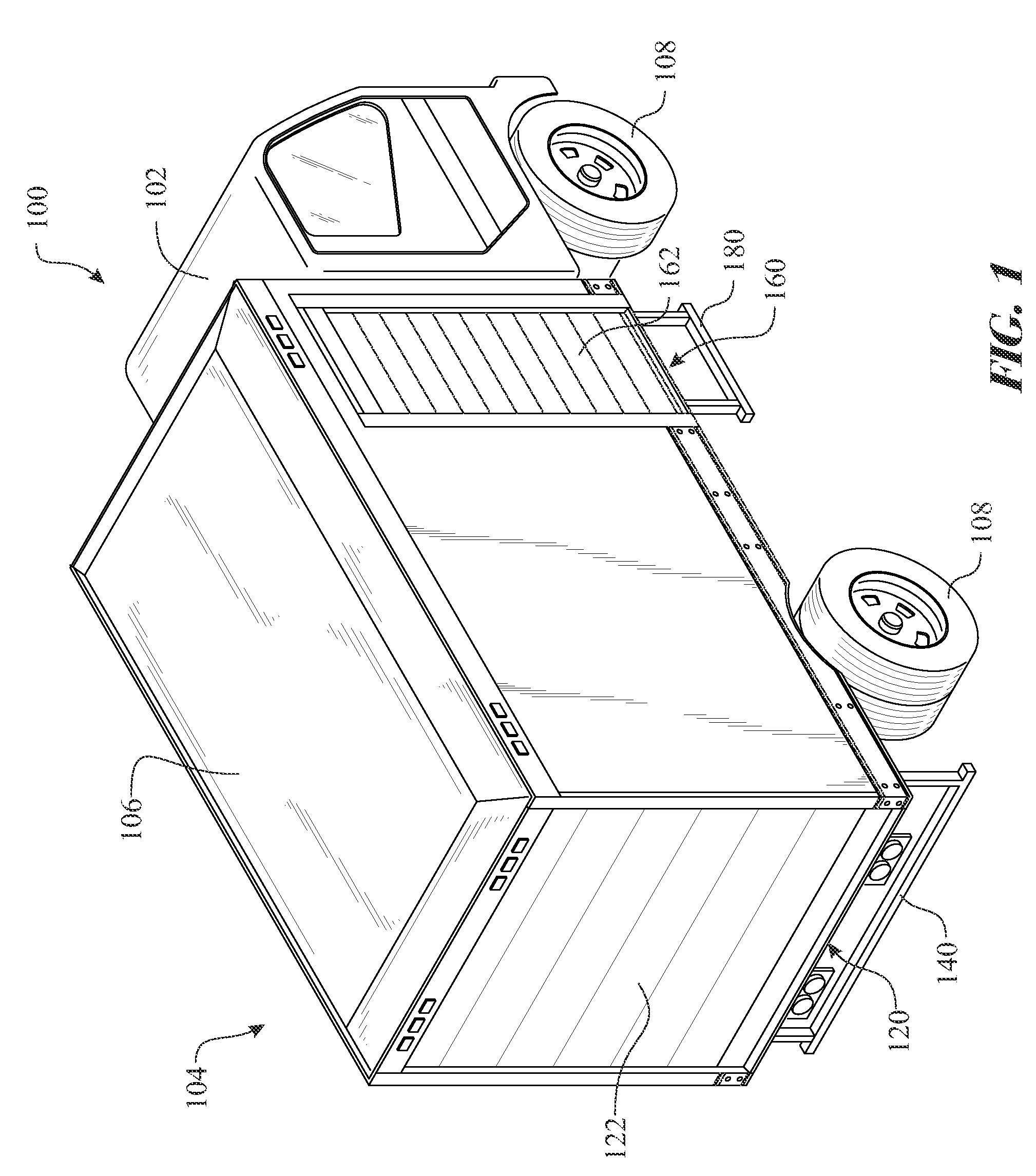

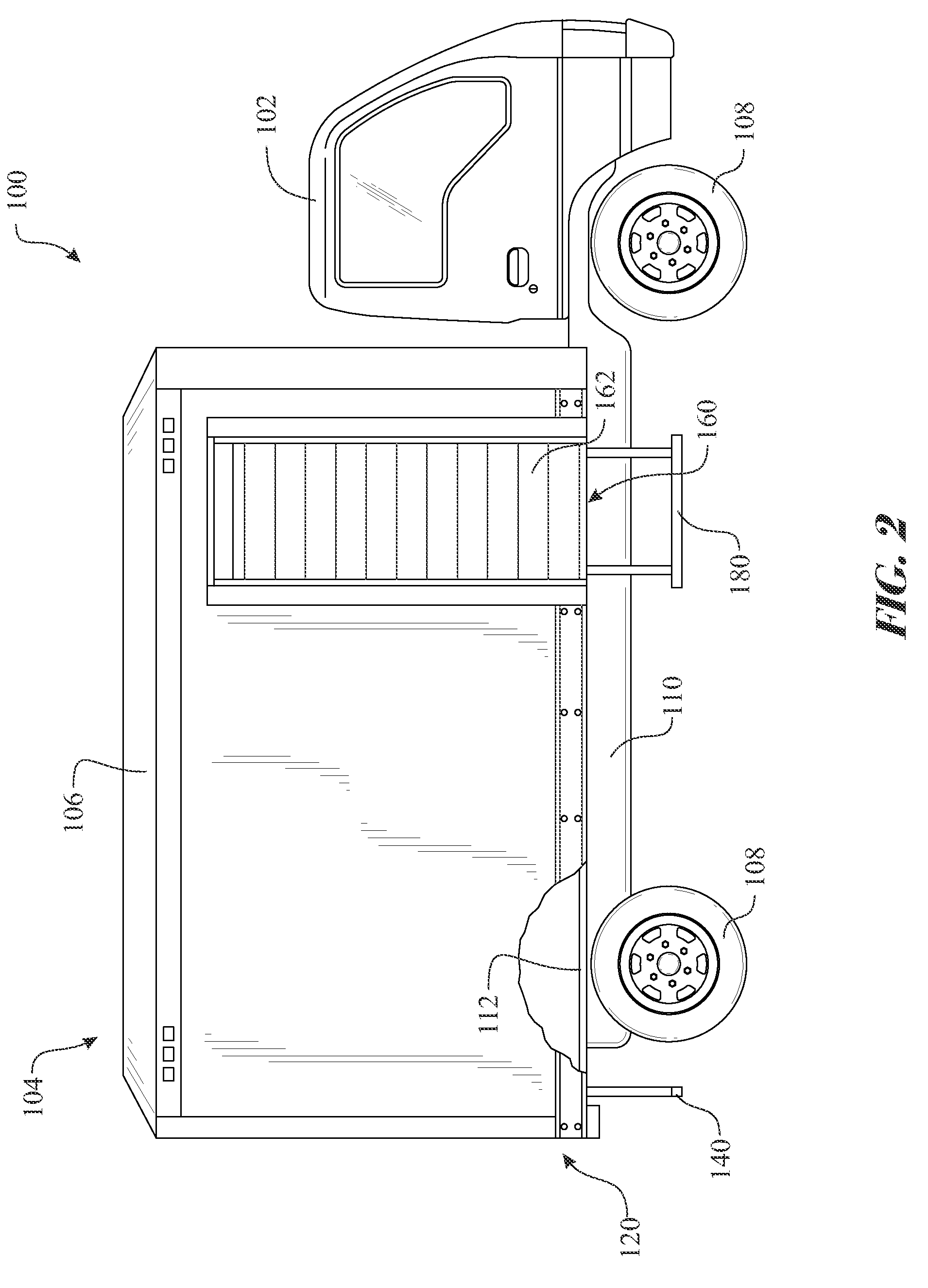

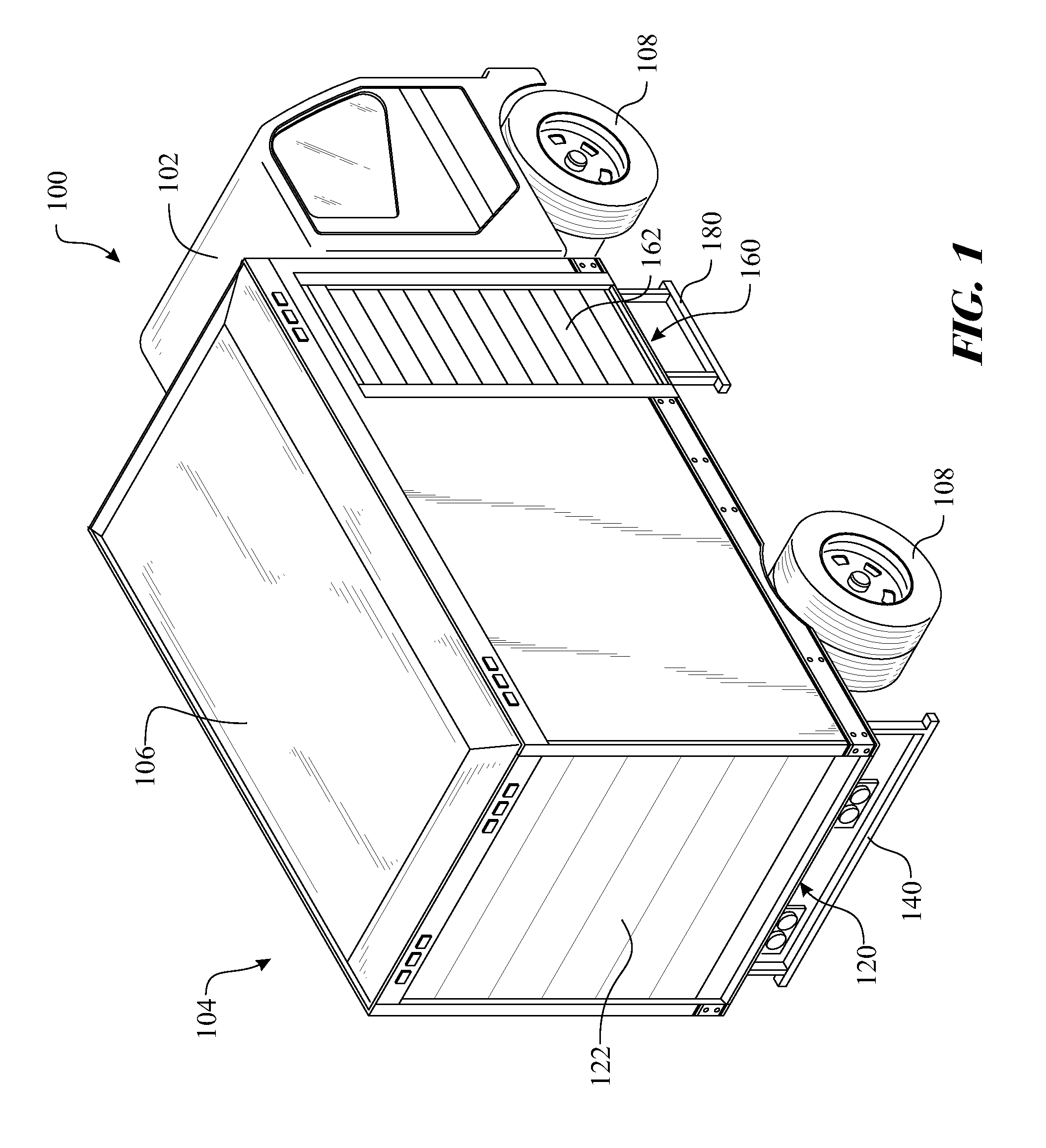

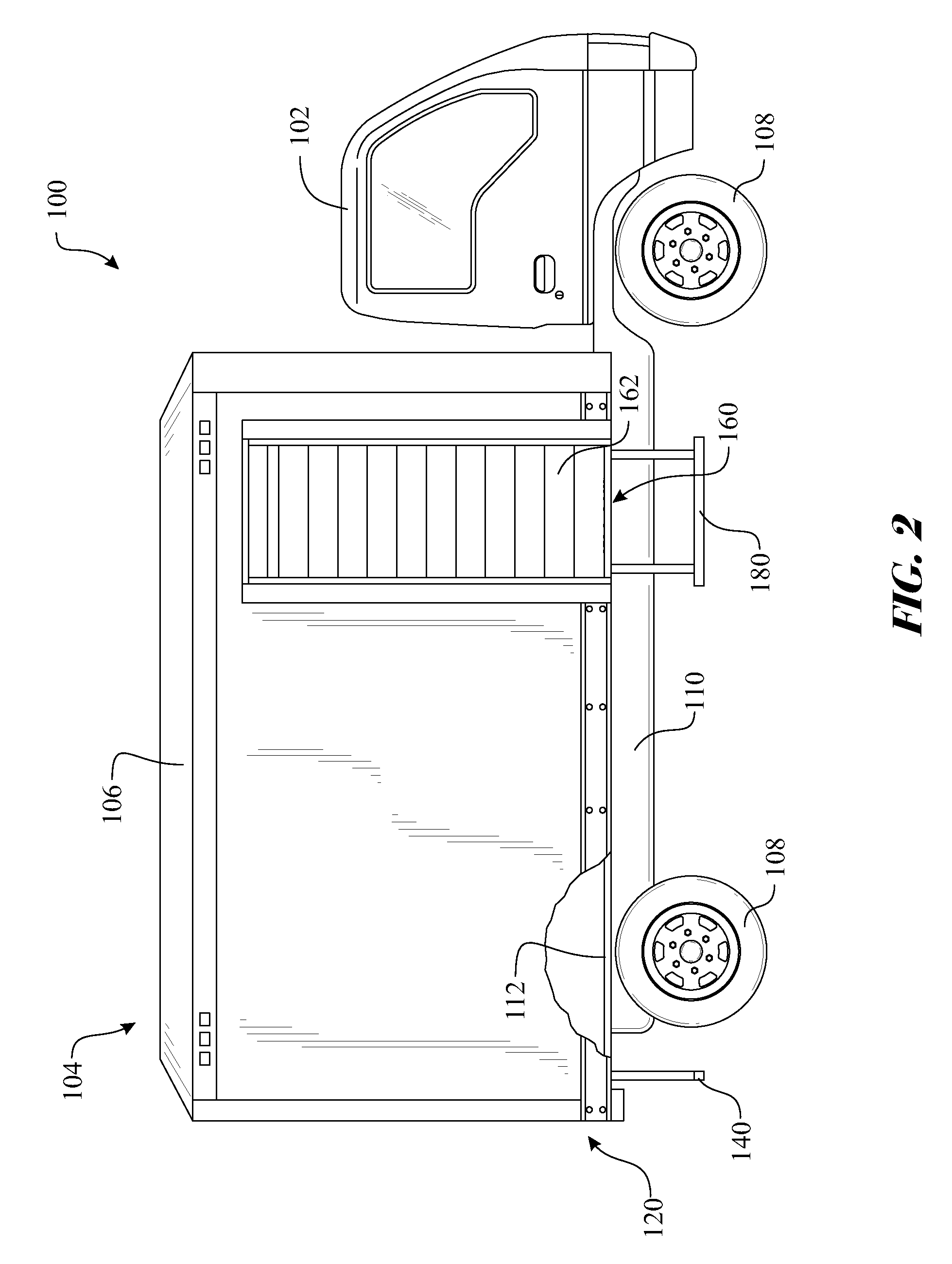

InactiveUS7568877B1Eliminate needMinimize additional working spaceRefuse receptaclesVehicle with parallel load movementCargo handling gearActuator

A goods handling apparatus for a cargo storage and transport trailer of, or connectable to, a vehicle. The preferred apparatus includes a movable cargo platform forming a separate part of, and continuous with, the trailer floor when the cargo platform is in an upper position whereupon cargo may be slid between the trailer floor and the cargo platform. A vertical actuator attached to the cargo platform raises and lowers the cargo platform between the upper position and a lower position atop the ground or other vehicle support surface whereupon cargo may be slid between the cargo platform and the ground or other vehicle support surface. The cargo platform is positioned substantially within the plan perimeter of the floor of the trailer when cargo on the cargo platform is lifted or lowered. A side module is also available.

Owner:NESPOR RONALD R

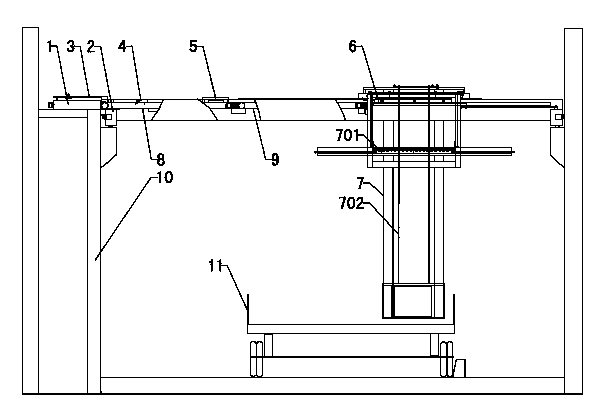

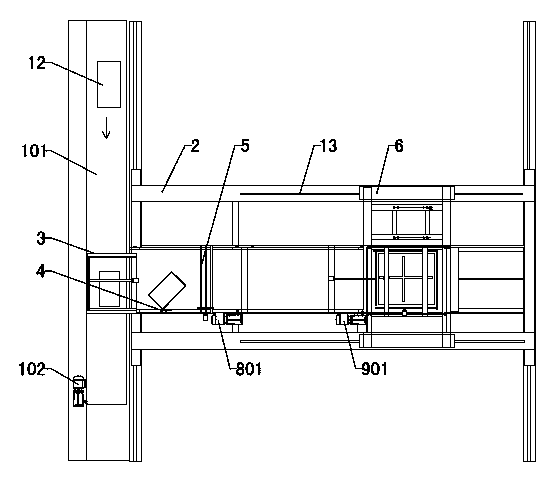

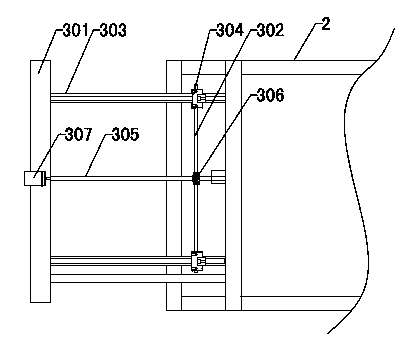

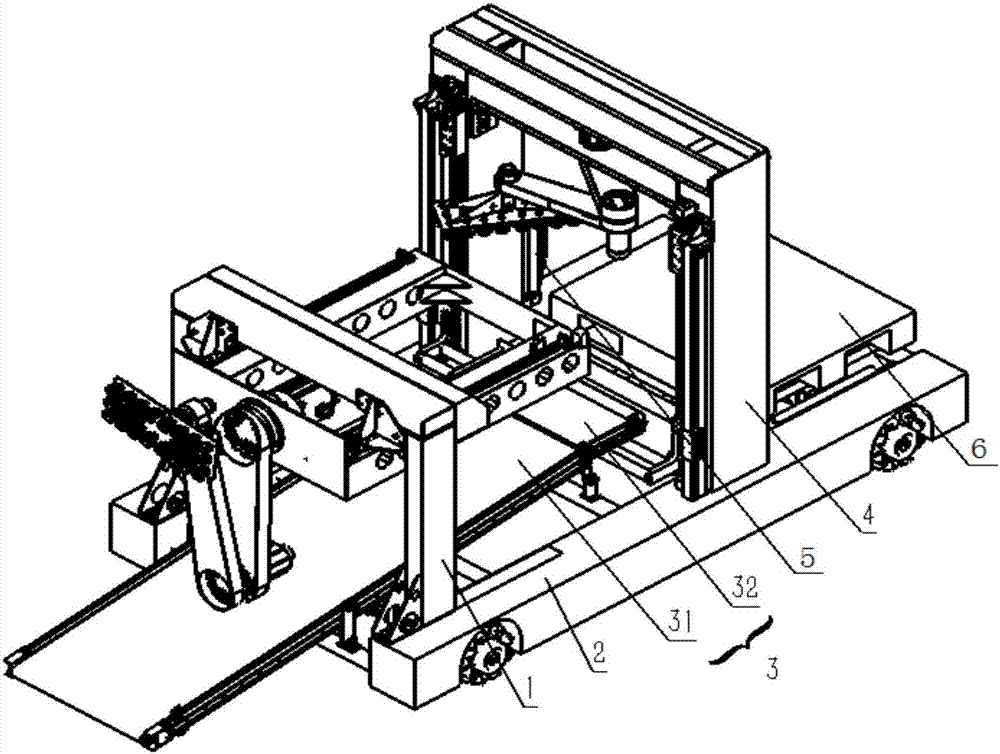

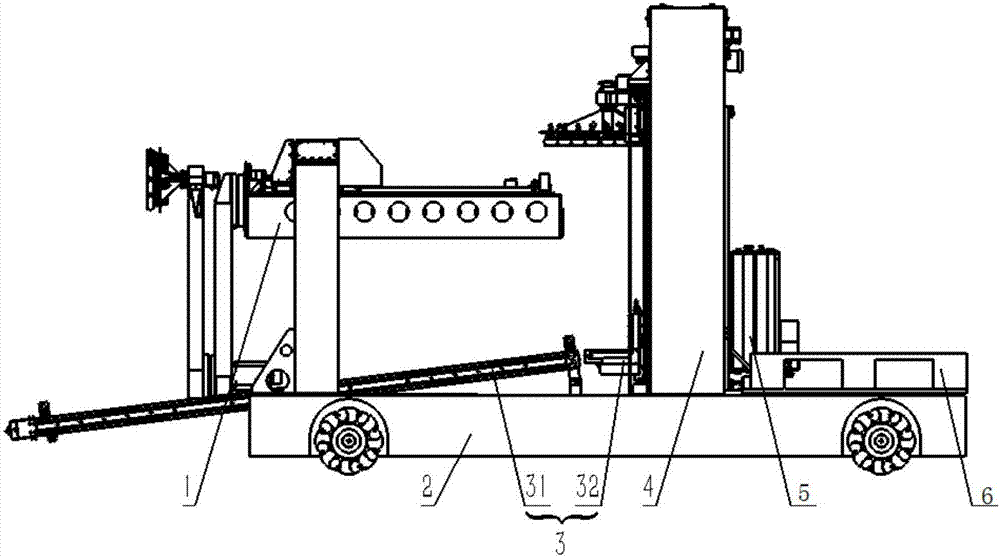

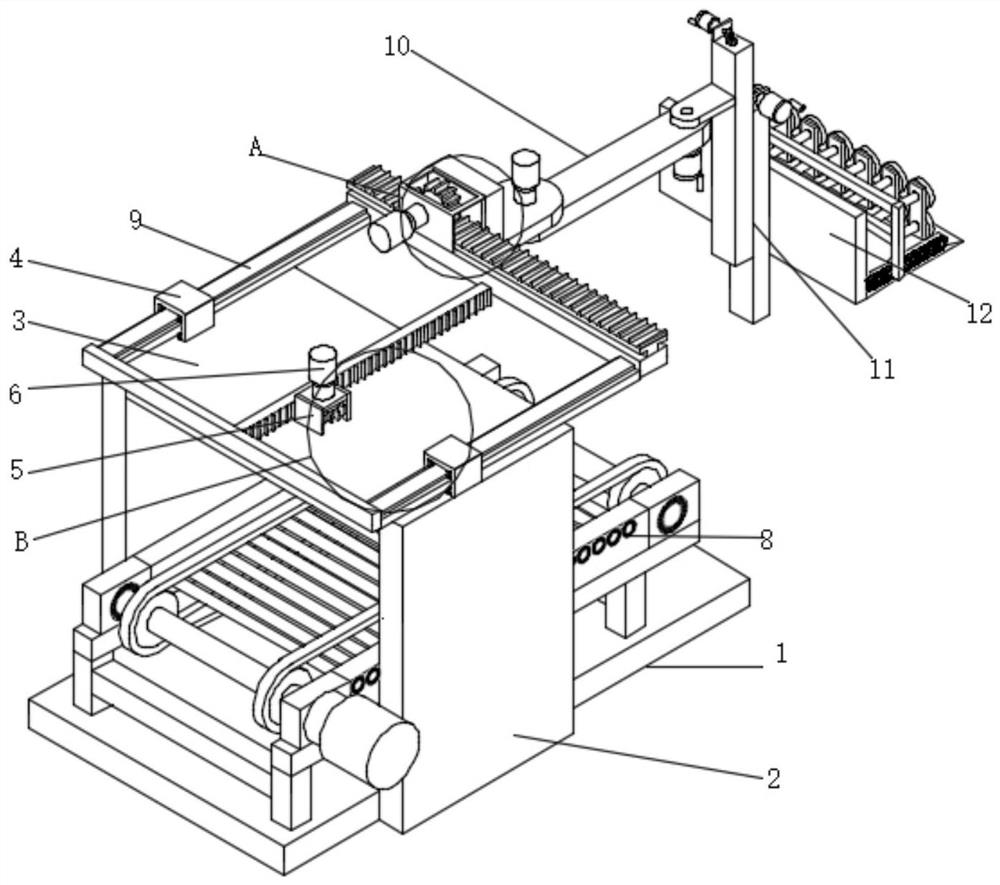

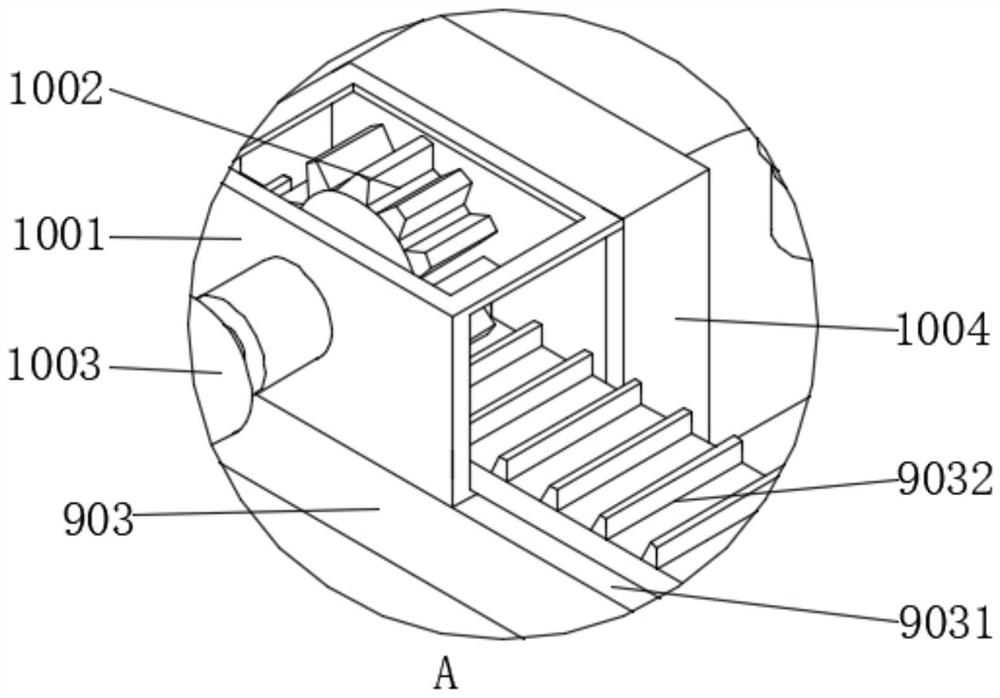

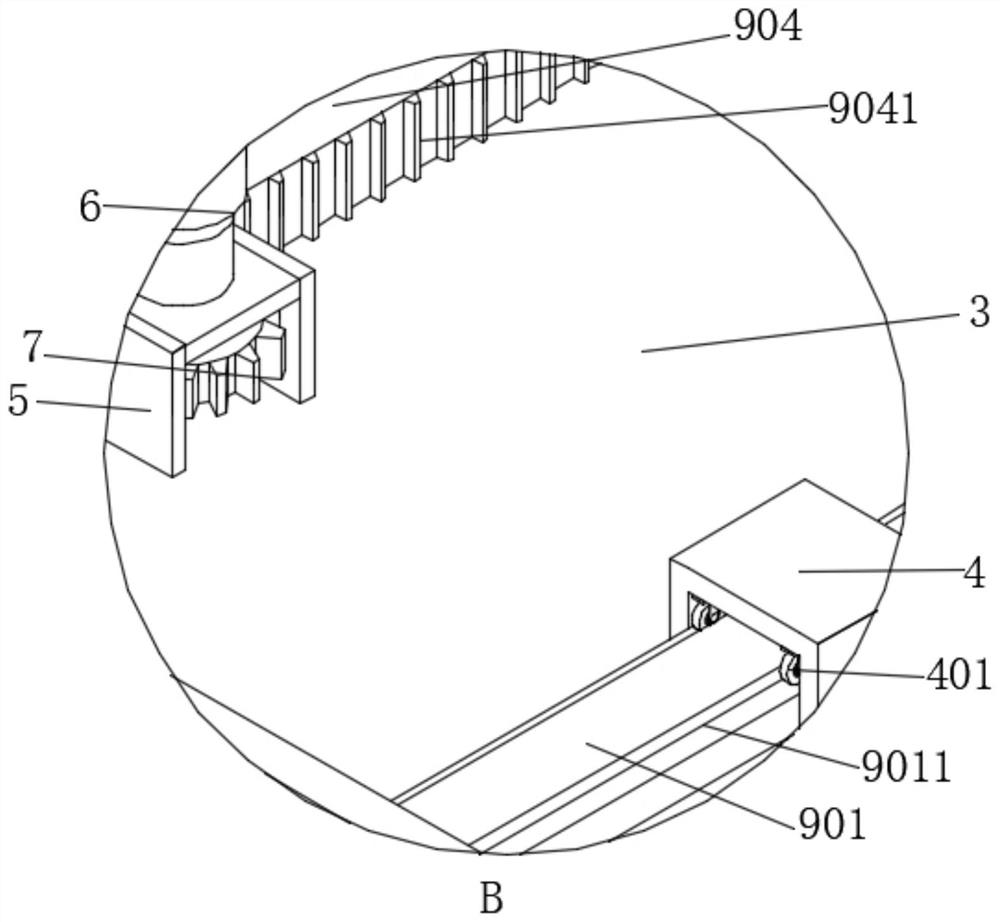

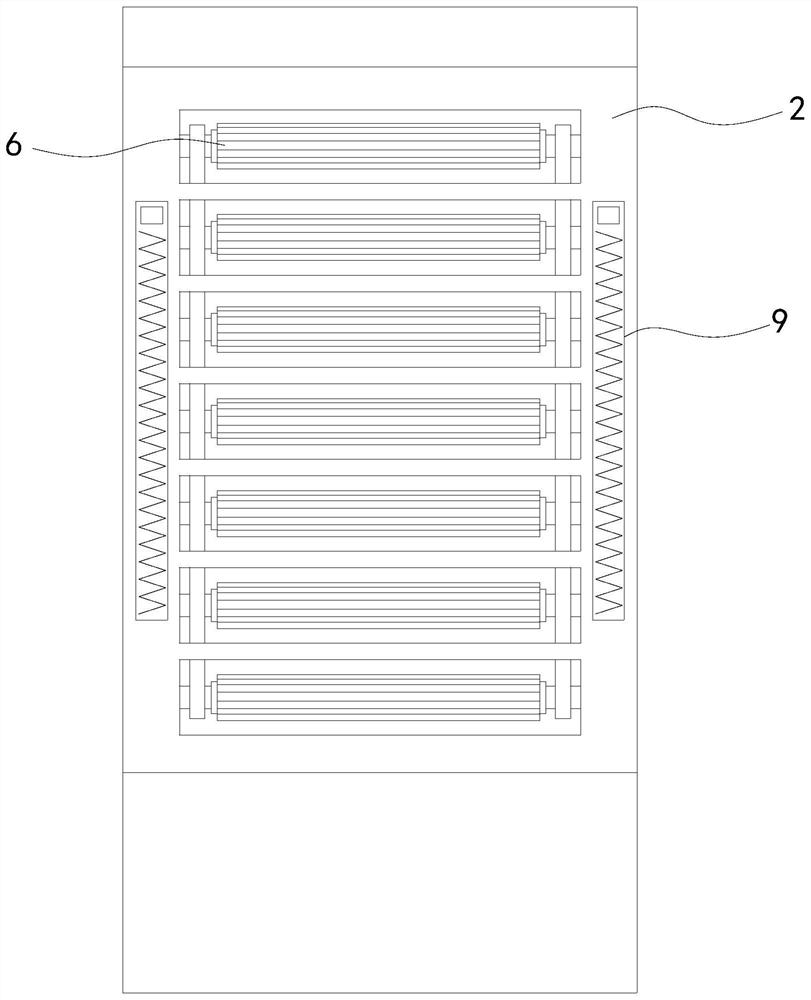

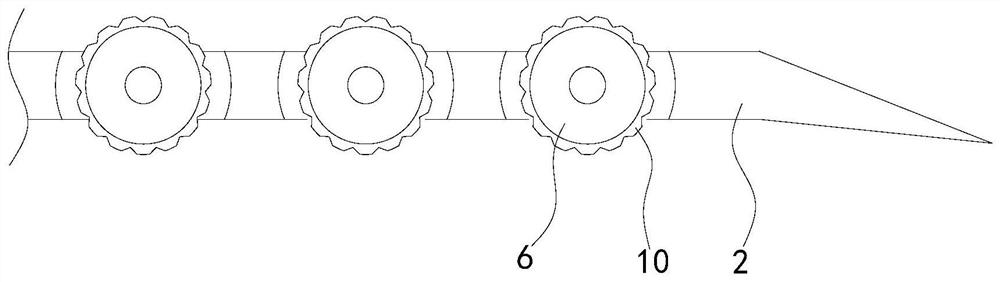

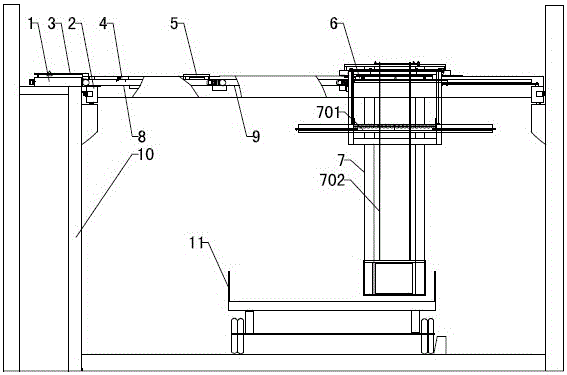

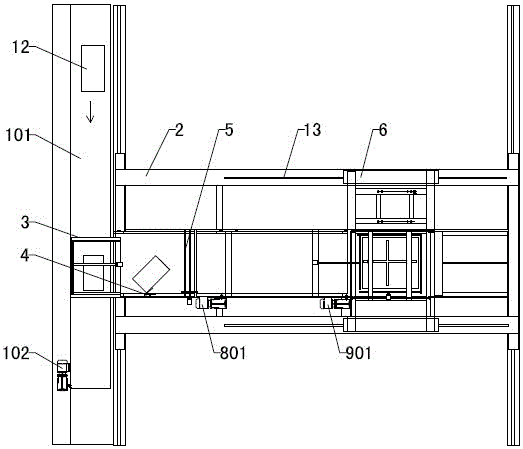

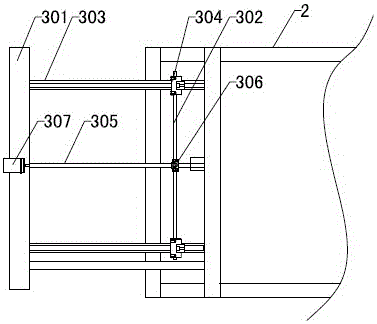

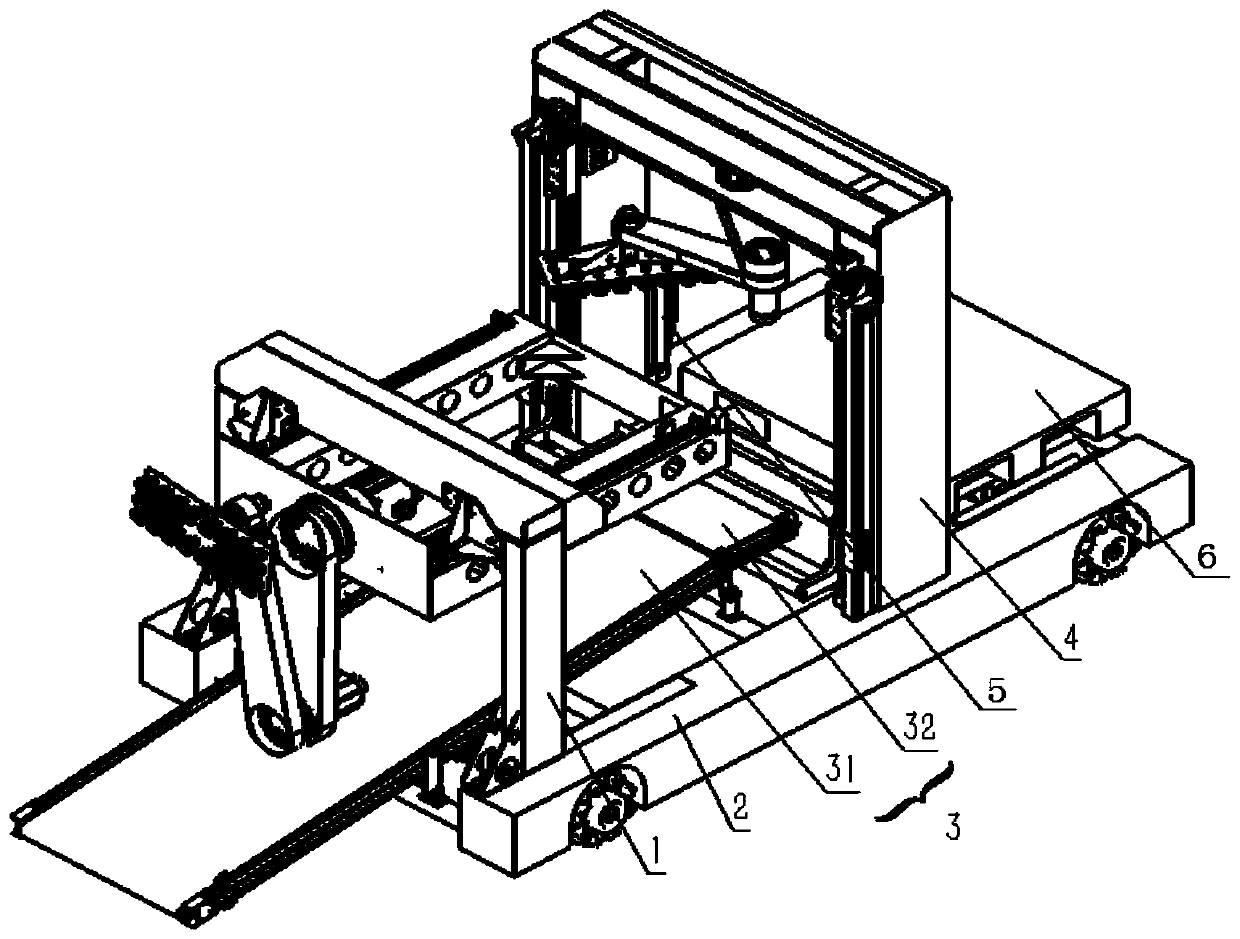

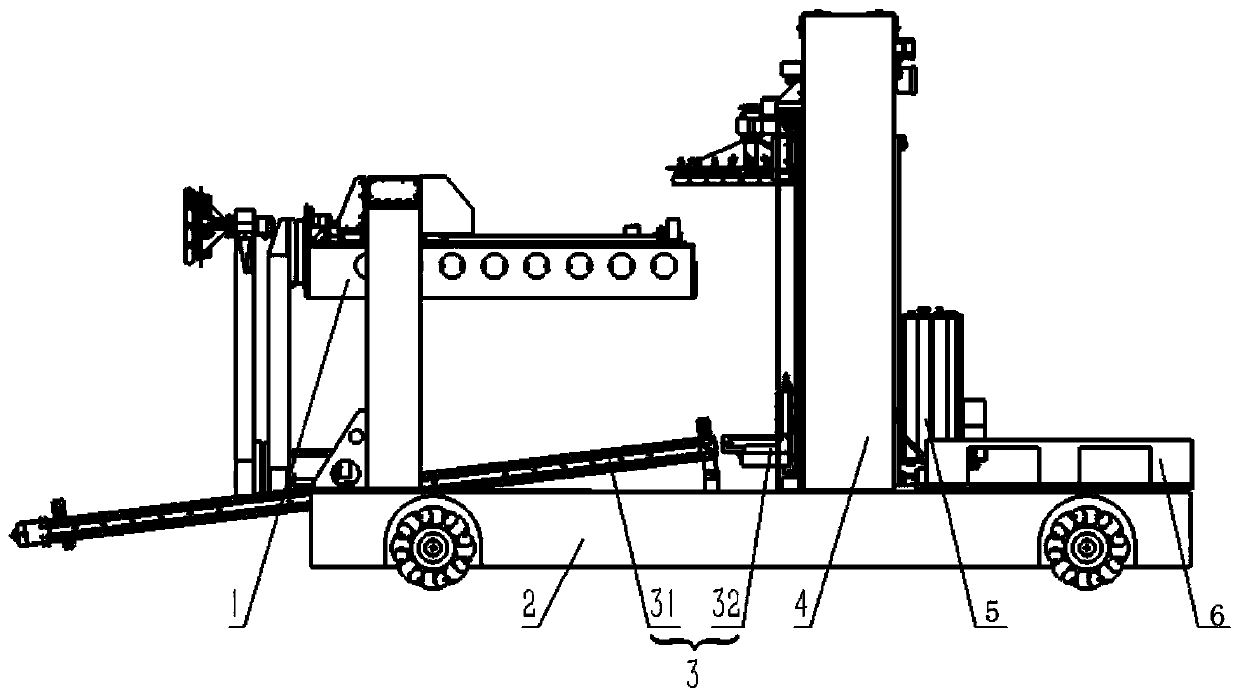

Automatic cargo loading all-in-one machine

ActiveCN103964222ARealize integrationIntegration and automatic realizationLoading/unloadingMechanical conveyorsCargo handling gearEngineering

The invention provides an automatic cargo loading all-in-one machine, belongs to the field of cargo loading and unloading devices and particularly relates to an all-in-one machine capable of achieving automatic truck loading and stacking. The automatic cargo loading all-in-one machine is characterized in that one side of a longitudinal belt conveying mechanism (1) is provided with a transverse conveying mechanism perpendicular to the longitudinal belt conveying mechanism, the transverse conveying mechanism comprises a transverse support (2) and a transverse conveying belt fixed on the transverse support (2), an adjusting mechanism (4) and a superposing and grouping device (5) are sequentially arranged above the transverse conveying belt, the rear portion of the transverse conveying belt is connected with a positioning mechanism, and a trucking loading and stacking mechanism (7) is connected under the positioning mechanism (6). Manual operation is not needed in the whole truck loading process, truck loading and stacking integration is achieved automatically, the loading efficiency is remarkably improved, an installing space is saved, and the cargo loading conveying demand at any position in a warehouse is achieved though match of the longitudinal conveying mechanism and the transverse conveying mechanism.

Owner:山东长江粮油仓储机械有限公司

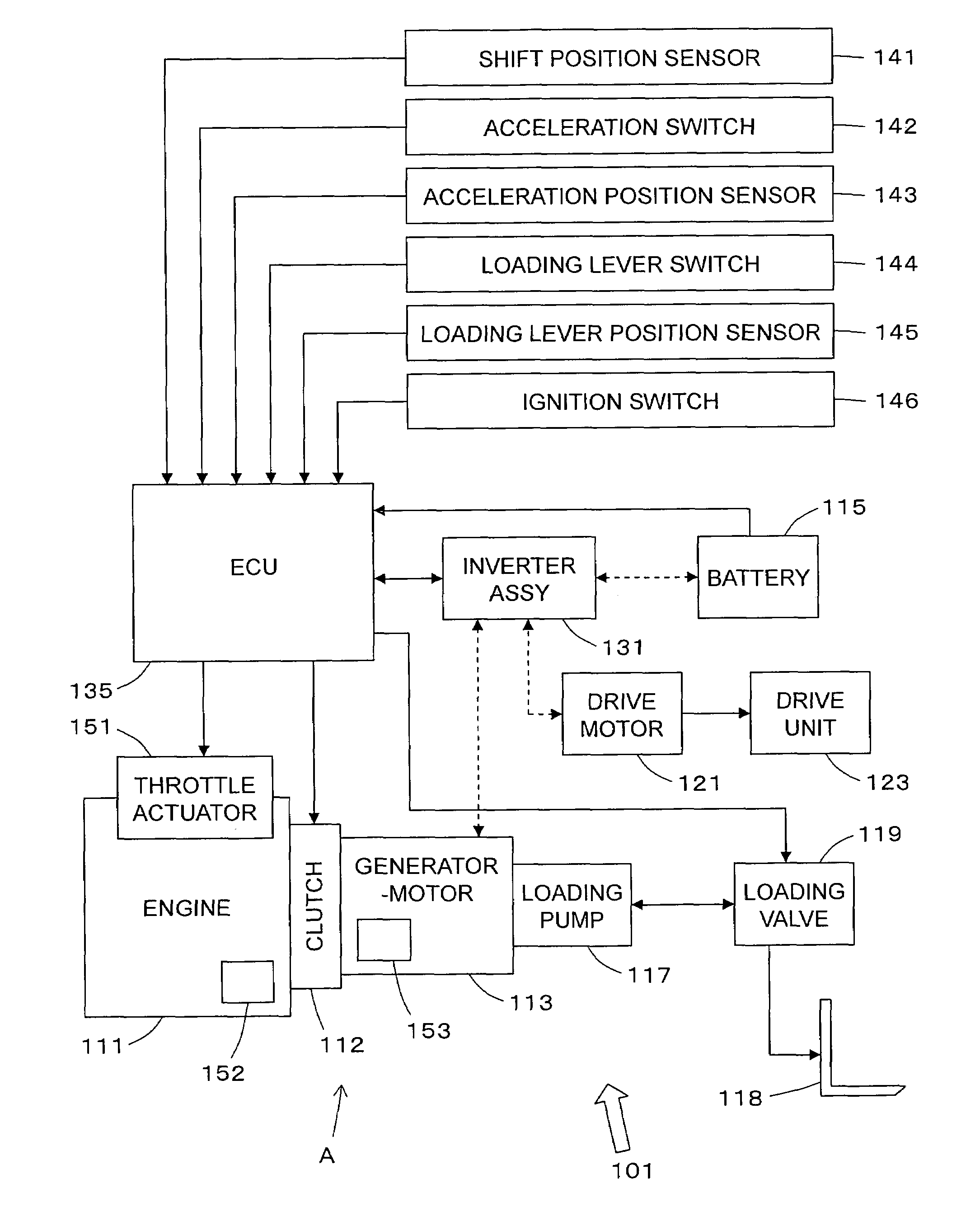

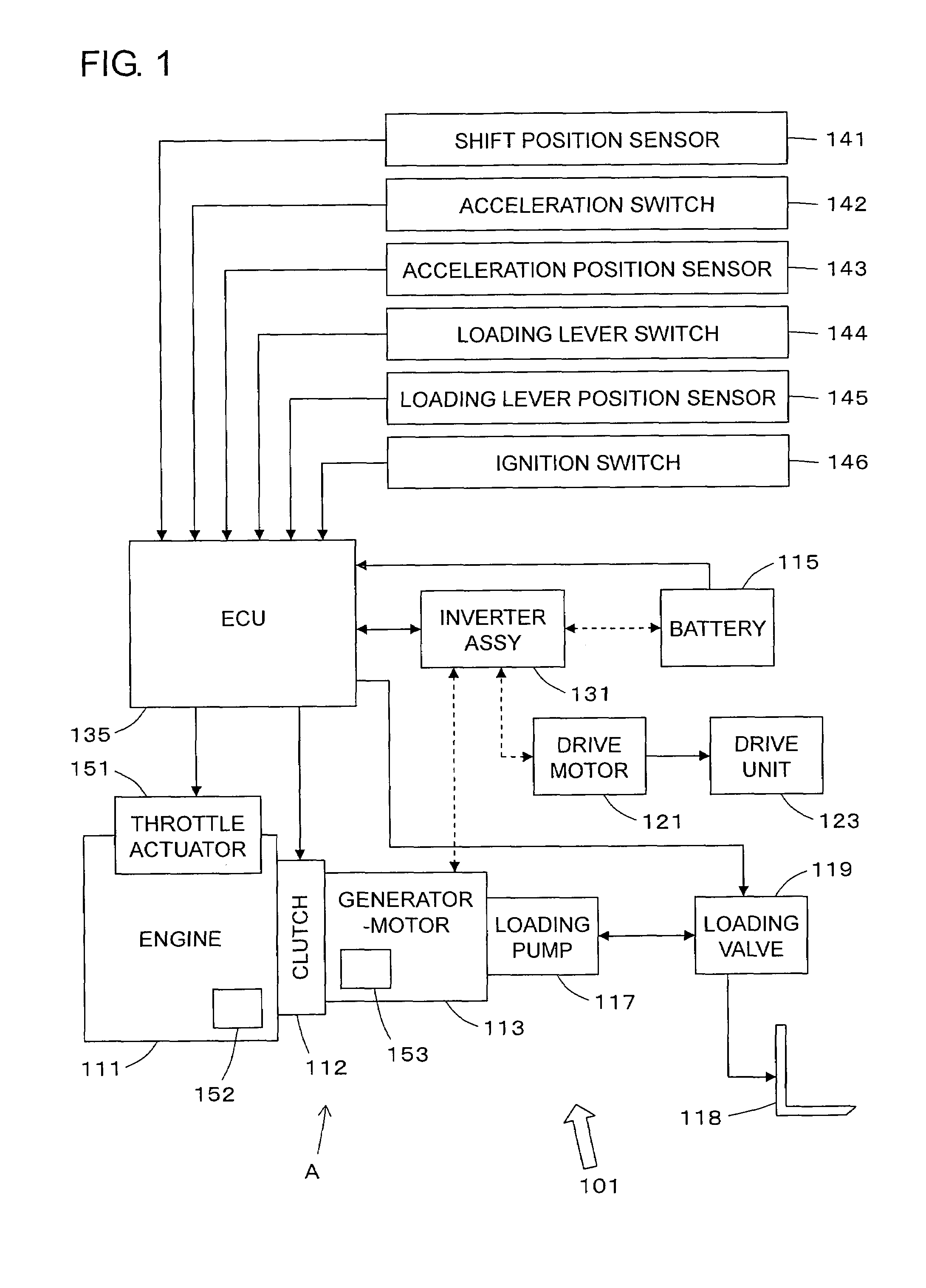

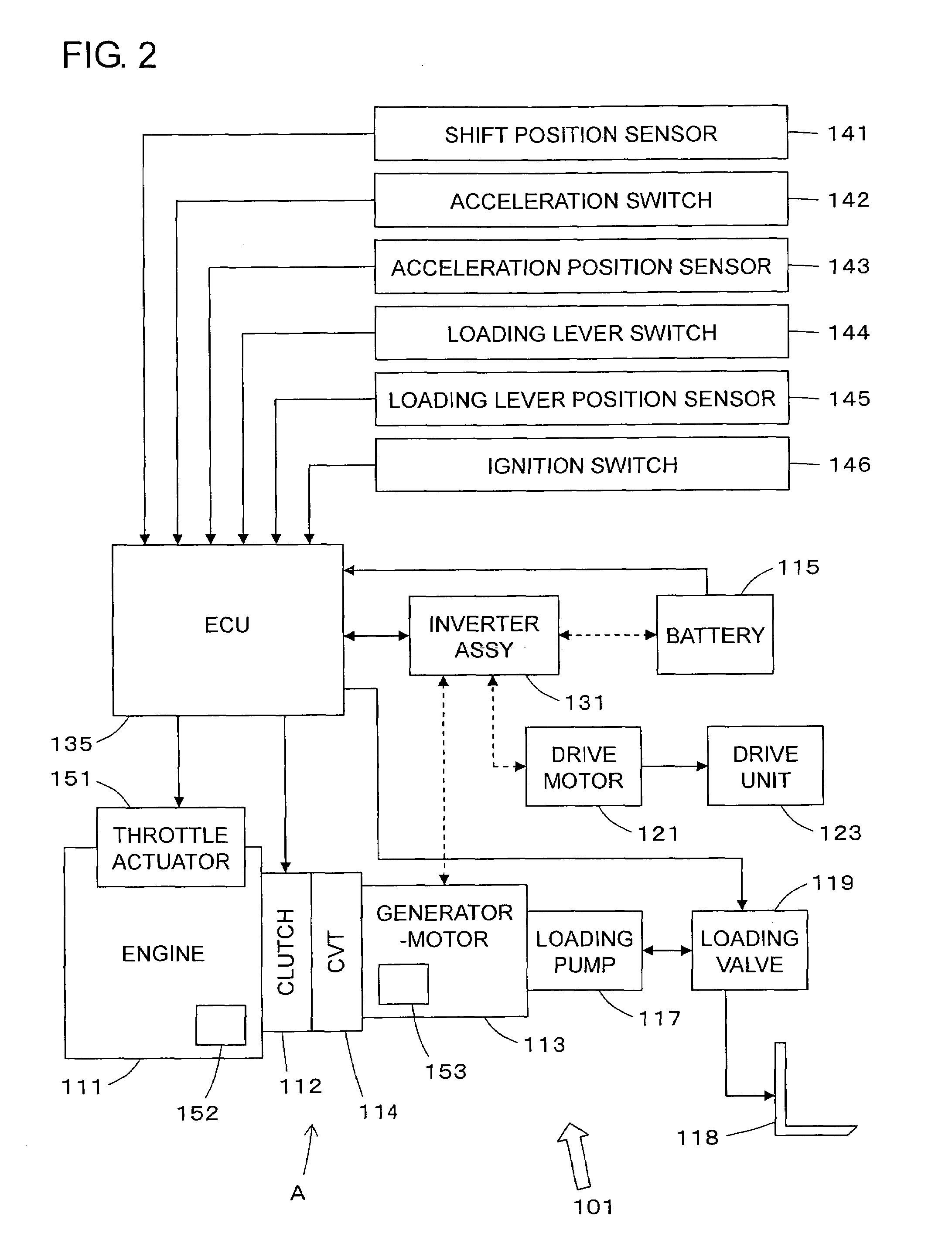

Cargo handling apparatus of cargo handling industrial vehicle

InactiveUS7464778B2Improve energy efficiencyEnsure responsivenessGearing controlPlural diverse prime-mover propulsion mountingCargo handling gearPosition sensor

Provided are an engine 111, a generator-motor 113, a clutch 112 connecting / disconnecting power therebetween, a battery 115, and a loading pump 117 for driving a fork 118. The generator-motor 113 is set either in a generator mode or in a motor mode. When a cargo handling load (detected by a loading lever position sensor 145 and the like) is smaller than a predetermined value, the clutch 112 is set to a disconnection state, the engine 111 is stopped or idled, and the loading pump 117 is driven by the generator-motor 113 in the motor mode. When the load is increased to the predetermined value or more during cargo handling work in a state where the clutch 112 is released, an increase of the number of revolution of the engine is started while an output of the generator-motor 113 is being increased. When the number of revolution of the engine 111 is made equal to the number of revolution of the generator-motor 113, the clutch 112 is set to a connected state, and the loading pump 117 is driven by the engine 111.

Owner:TOYOTA IND CORP

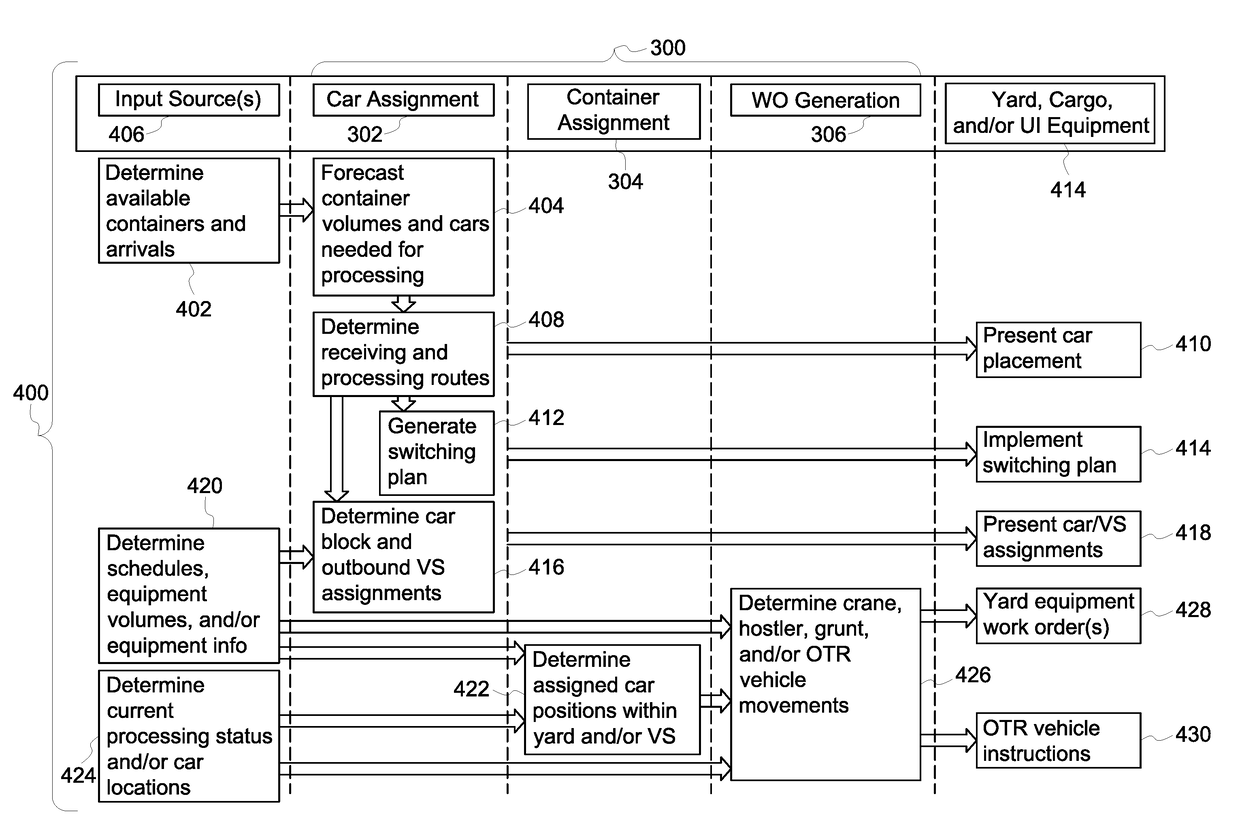

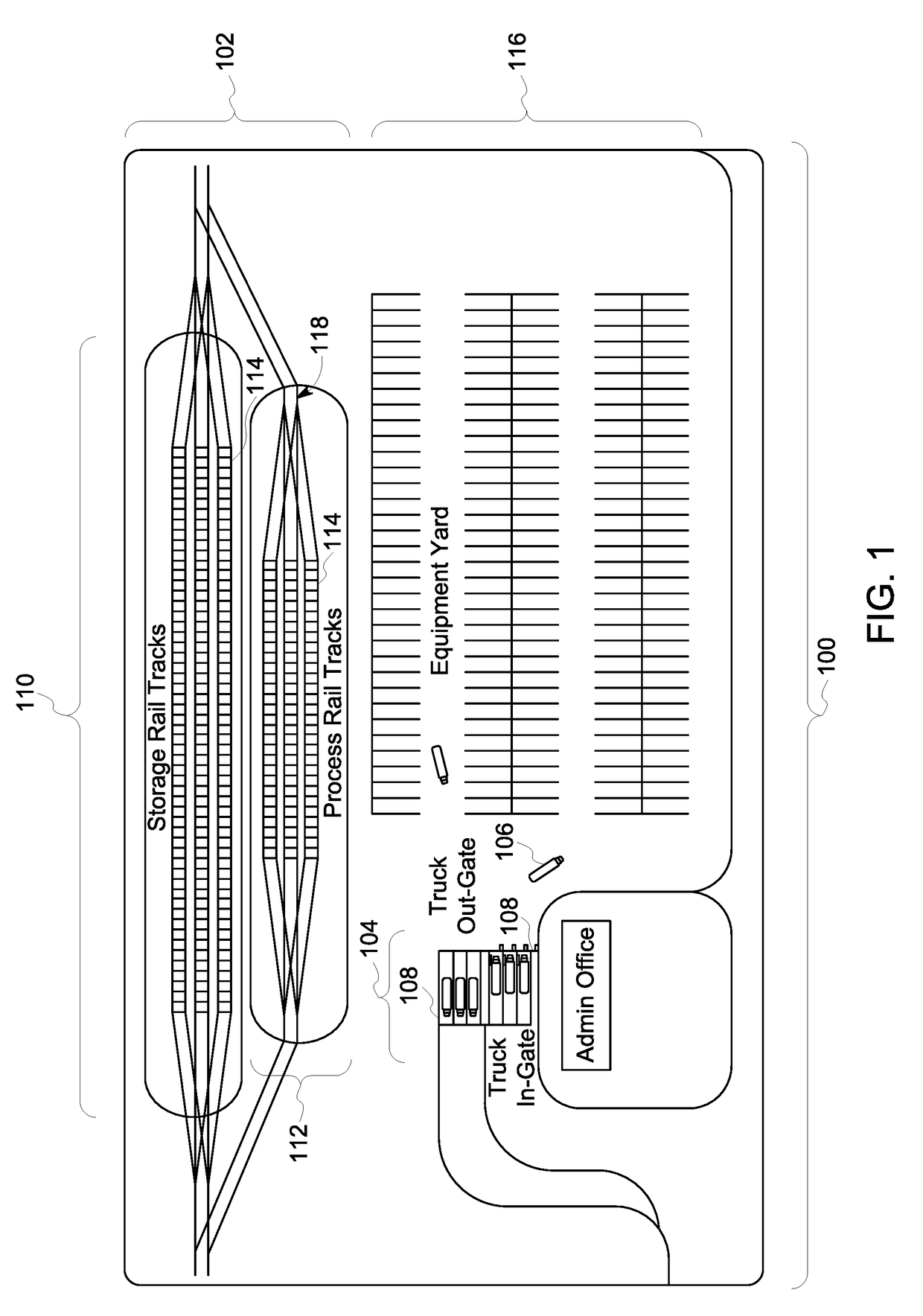

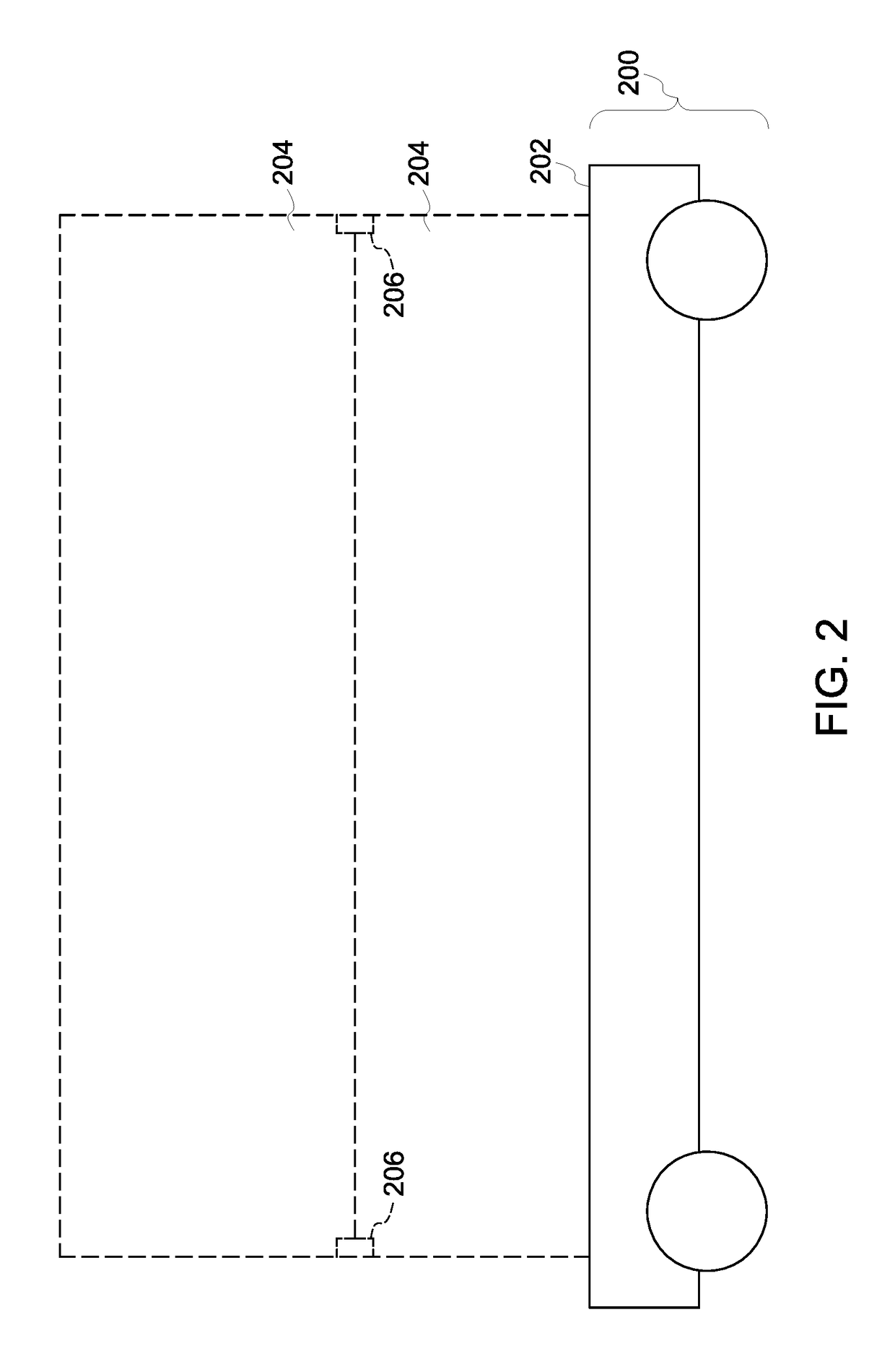

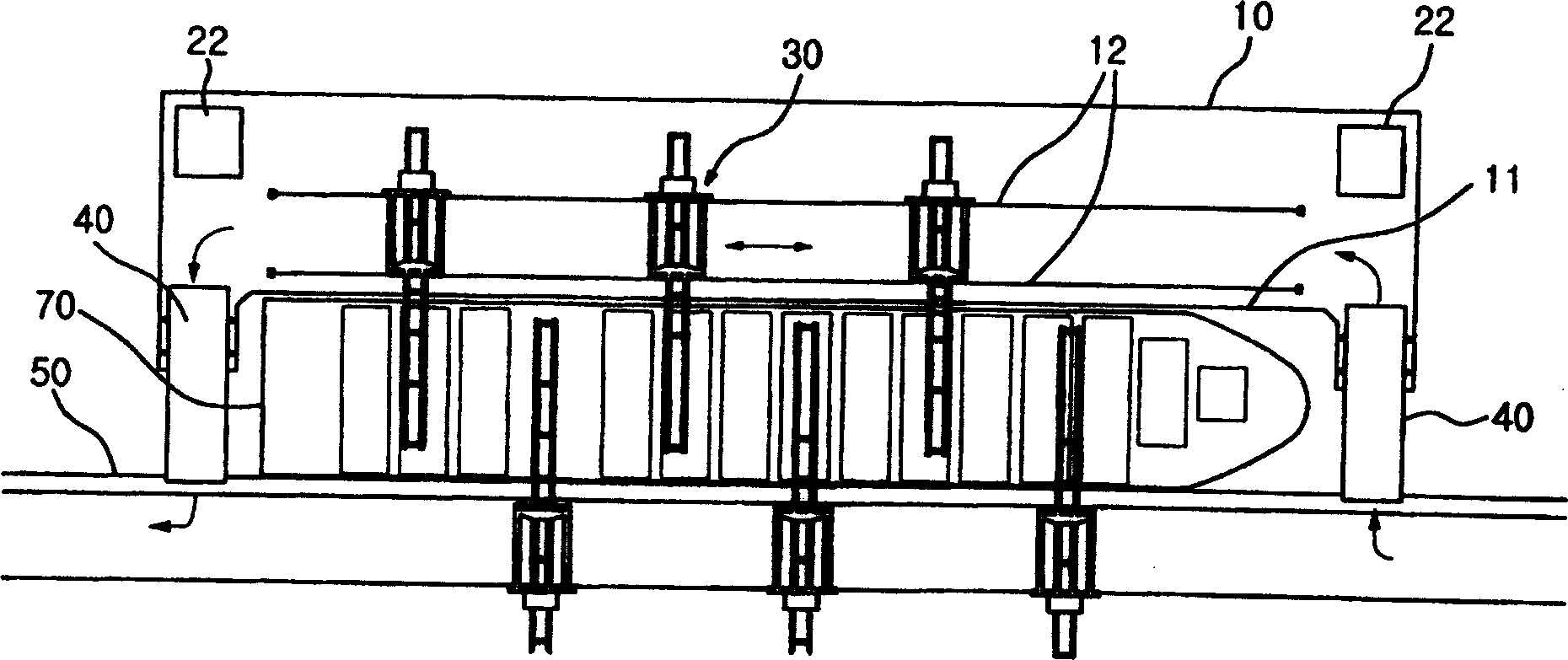

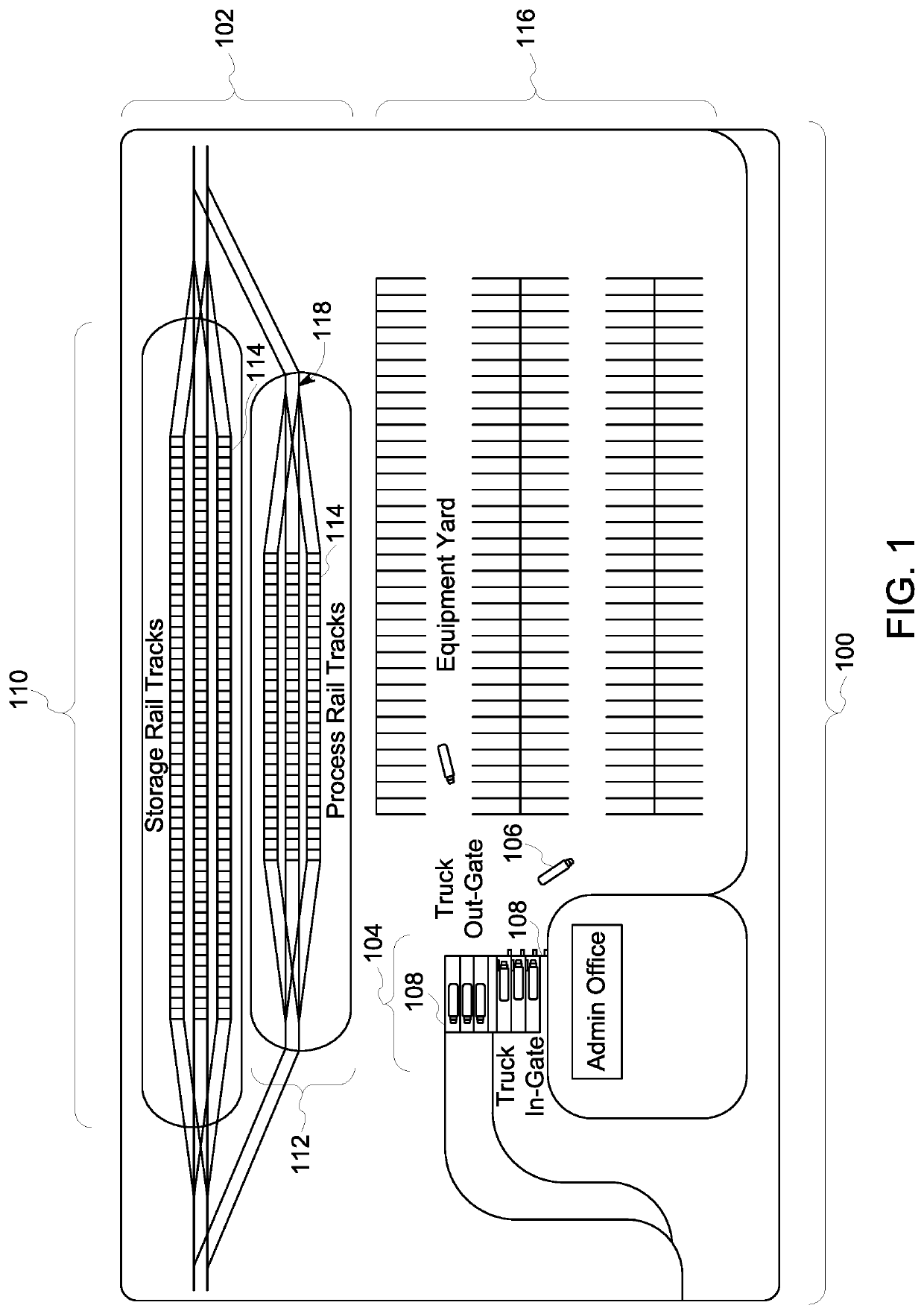

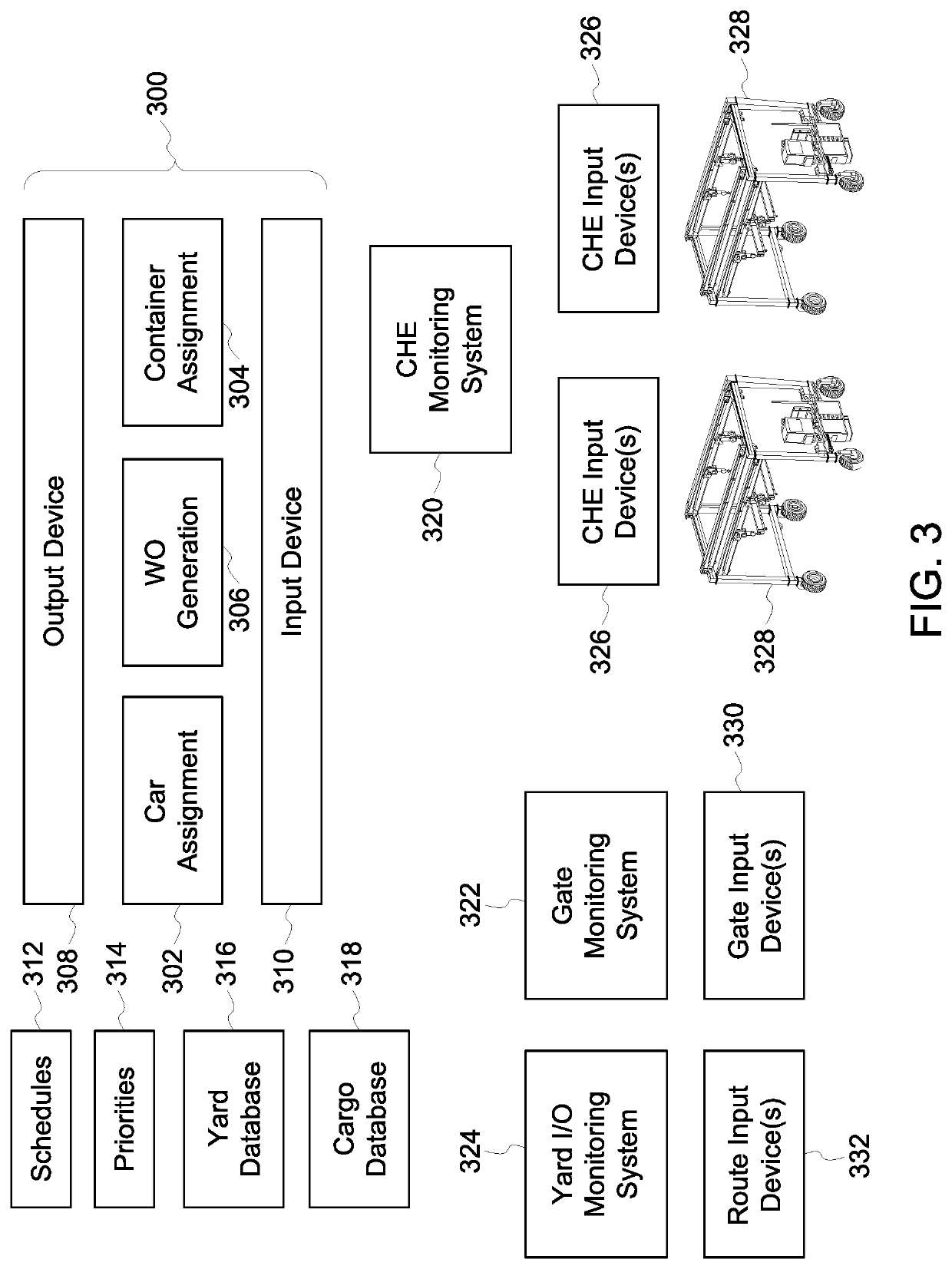

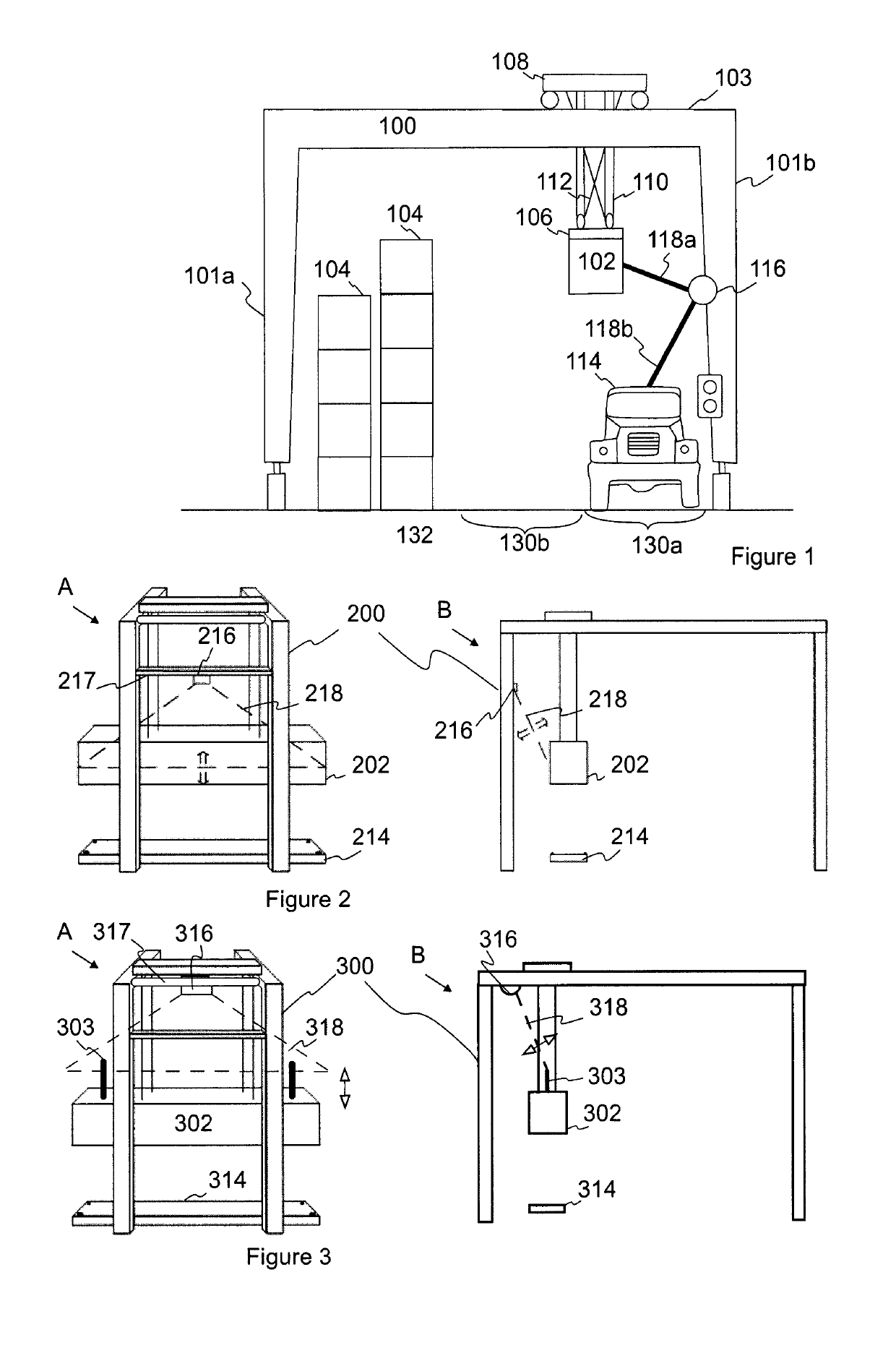

Intermodal transportation terminal control system and method

ActiveUS20170267267A1High operating costsReduce throughputTraffic regulationTrolley cranesProgram planningCargo handling gear

An intermodal terminal control system determines characteristics of cargo containers scheduled for receipt into and / or travel out of an intermodal terminal connected with both rail routes and automobile routes, determines characteristics of cargo handling equipment within the intermodal terminal, determines characteristics of rail vehicles scheduled for one or more of entry into or travel out of the intermodal terminal, and determines characteristics of automobile vehicles scheduled for entry into or travel out of the intermodal terminal. The system also determines constraints on cargo handling operations and a plan for the cargo handling equipment to transfer the cargo containers between the different modes of transportation within the intermodal terminal. The plan designates a sequence of operations to be performed in moving the cargo containers with the cargo handling equipment. The plan is based on the characteristics of the cargo containers, the cargo handling equipment, the rail vehicles, and the automobile vehicles.

Owner:TRANSPORTATION IP HLDG LLC

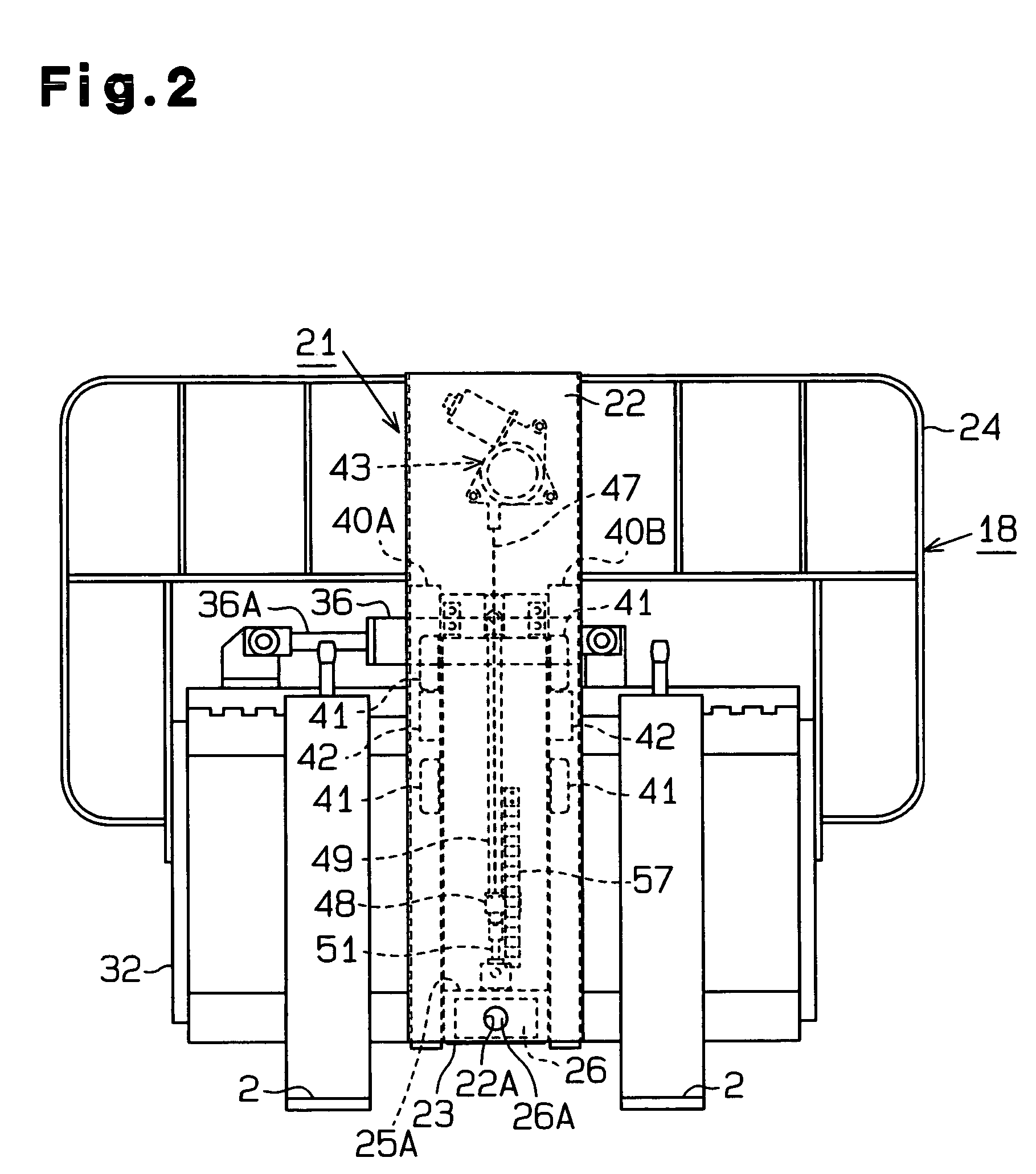

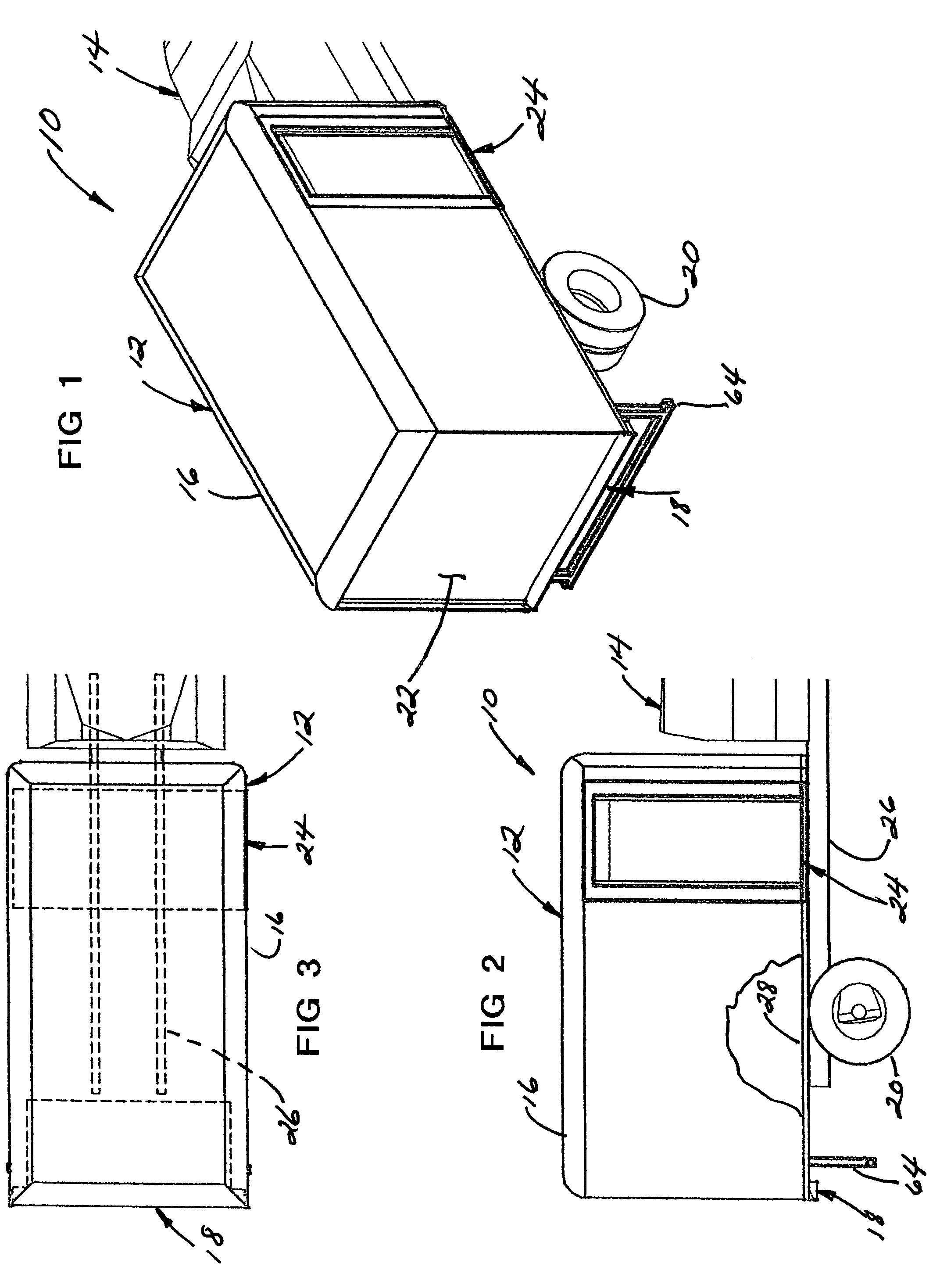

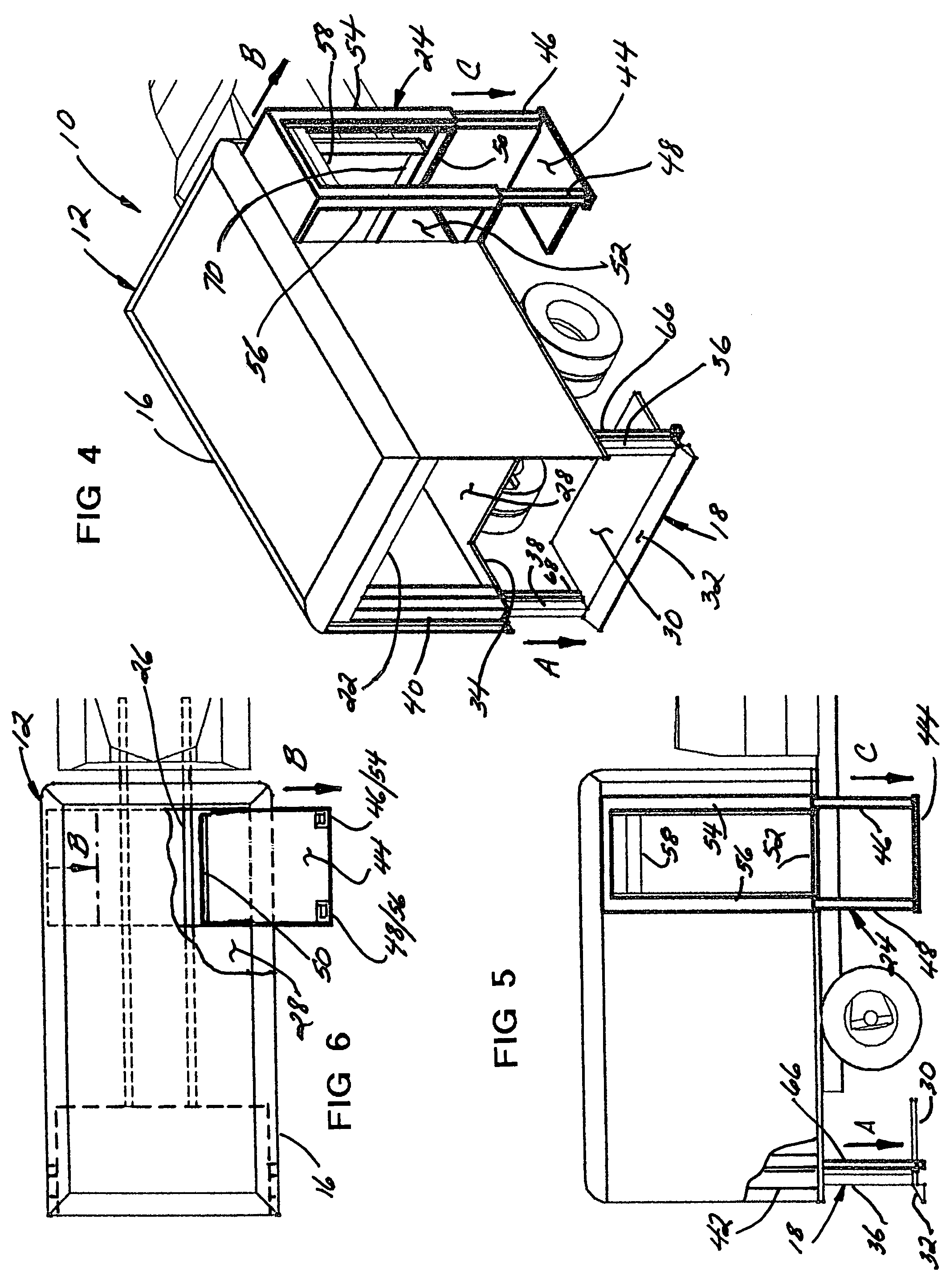

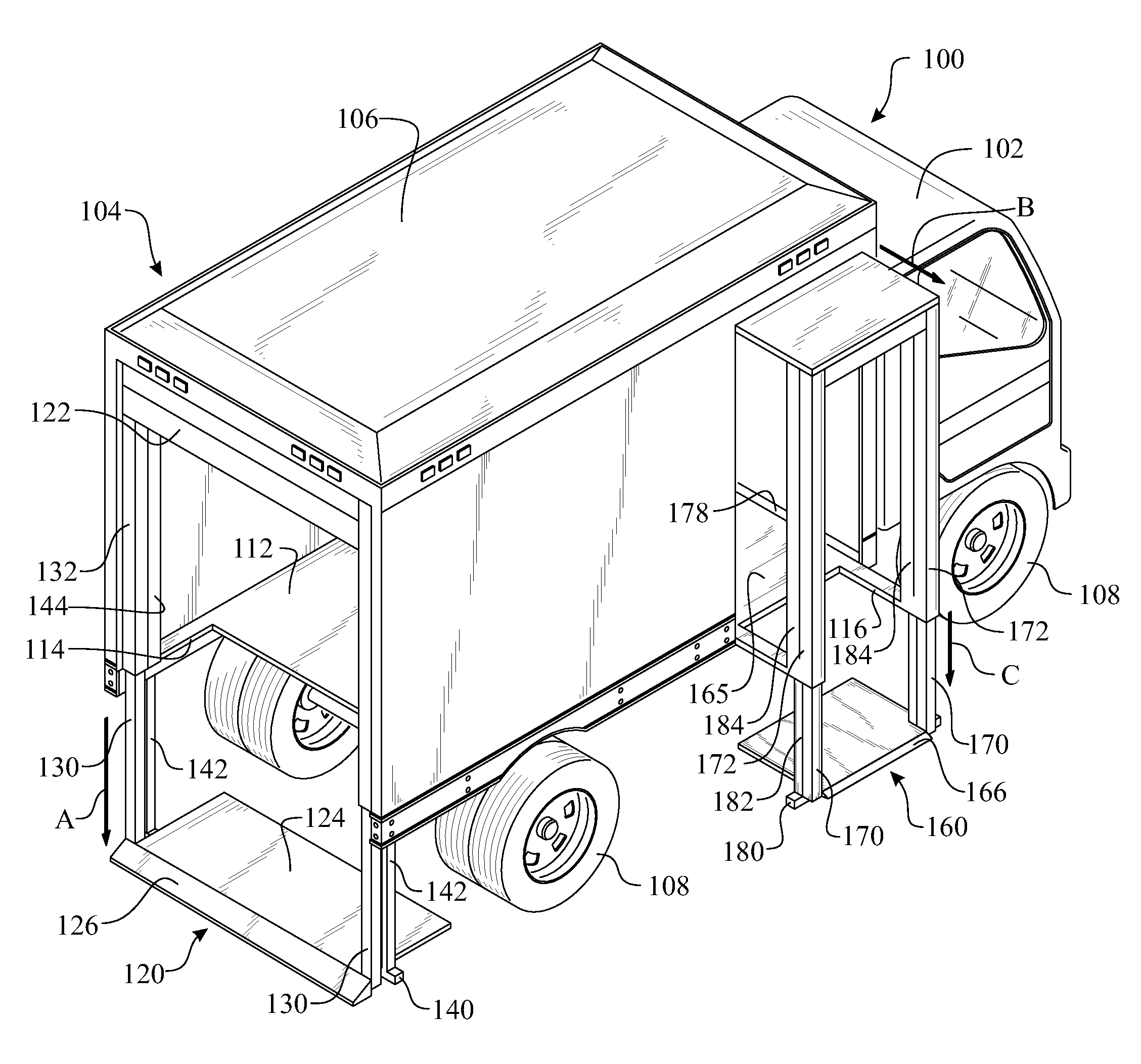

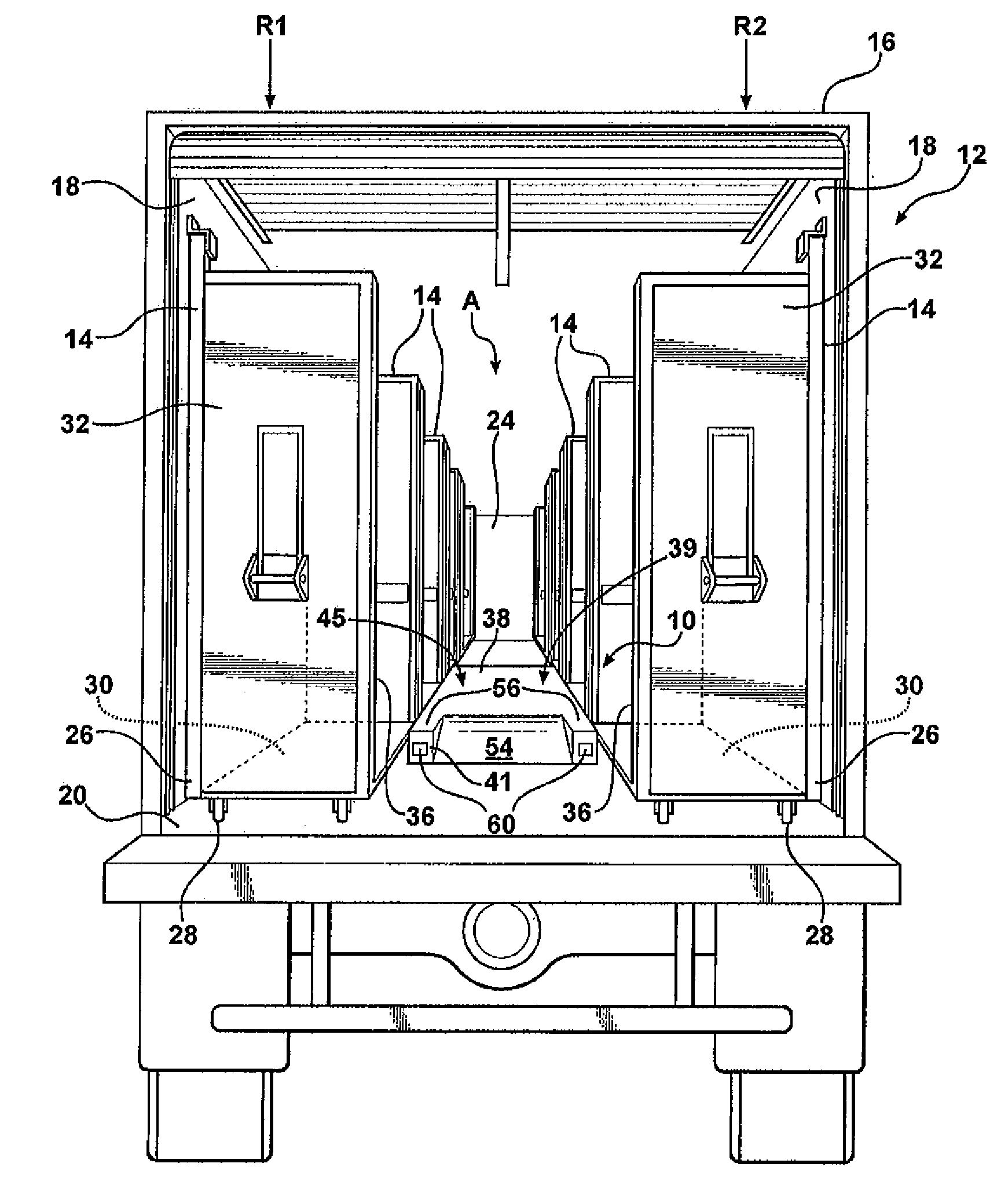

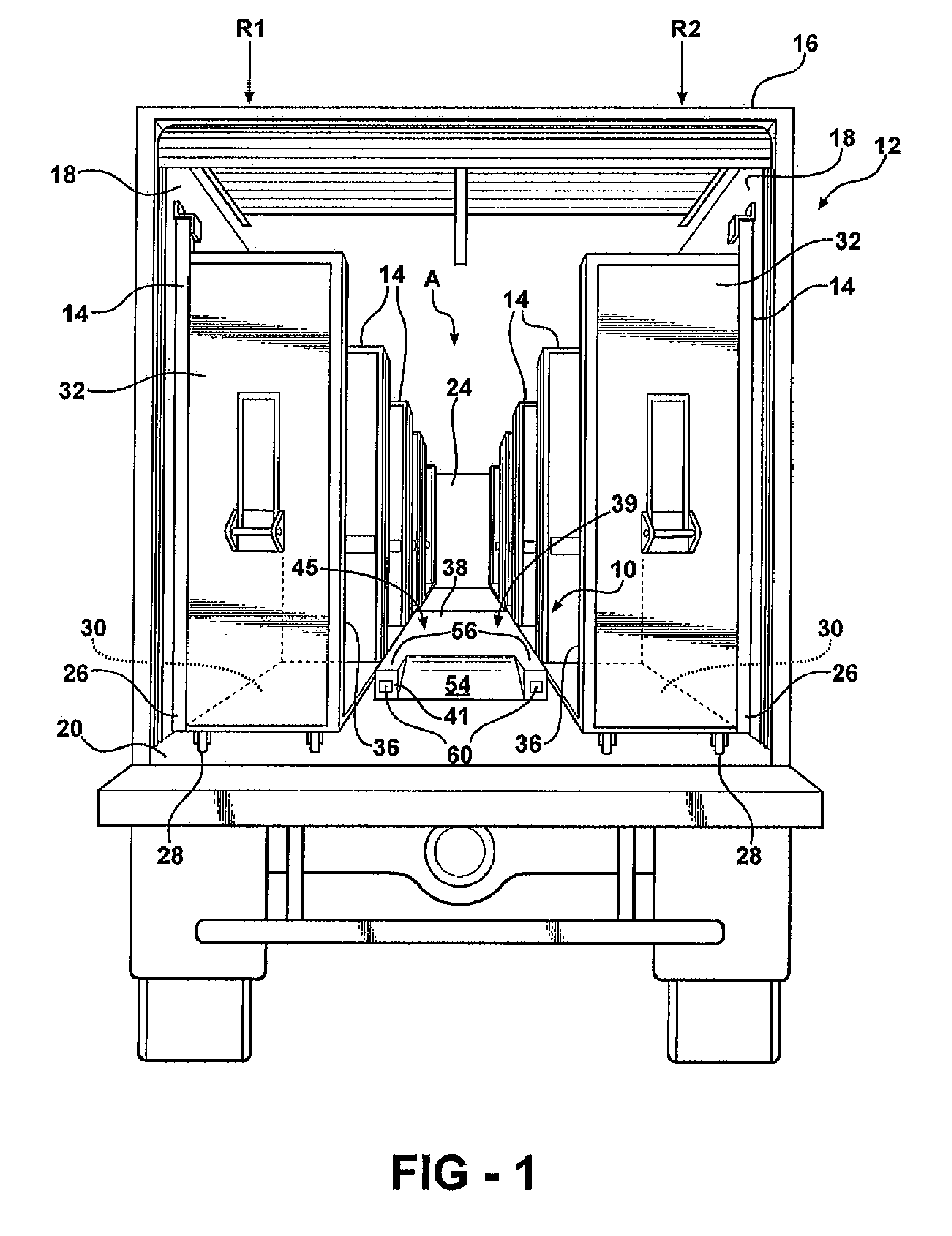

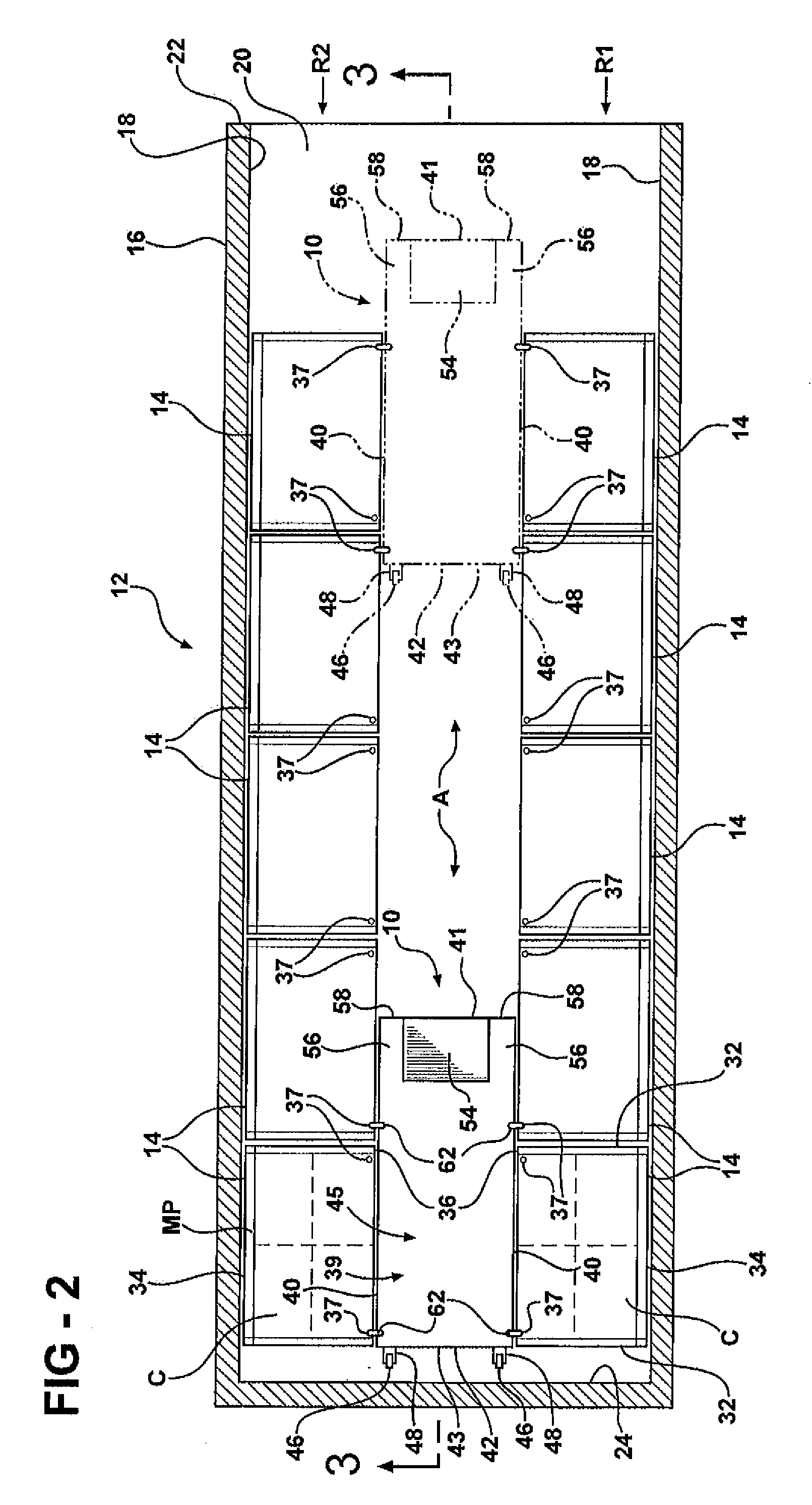

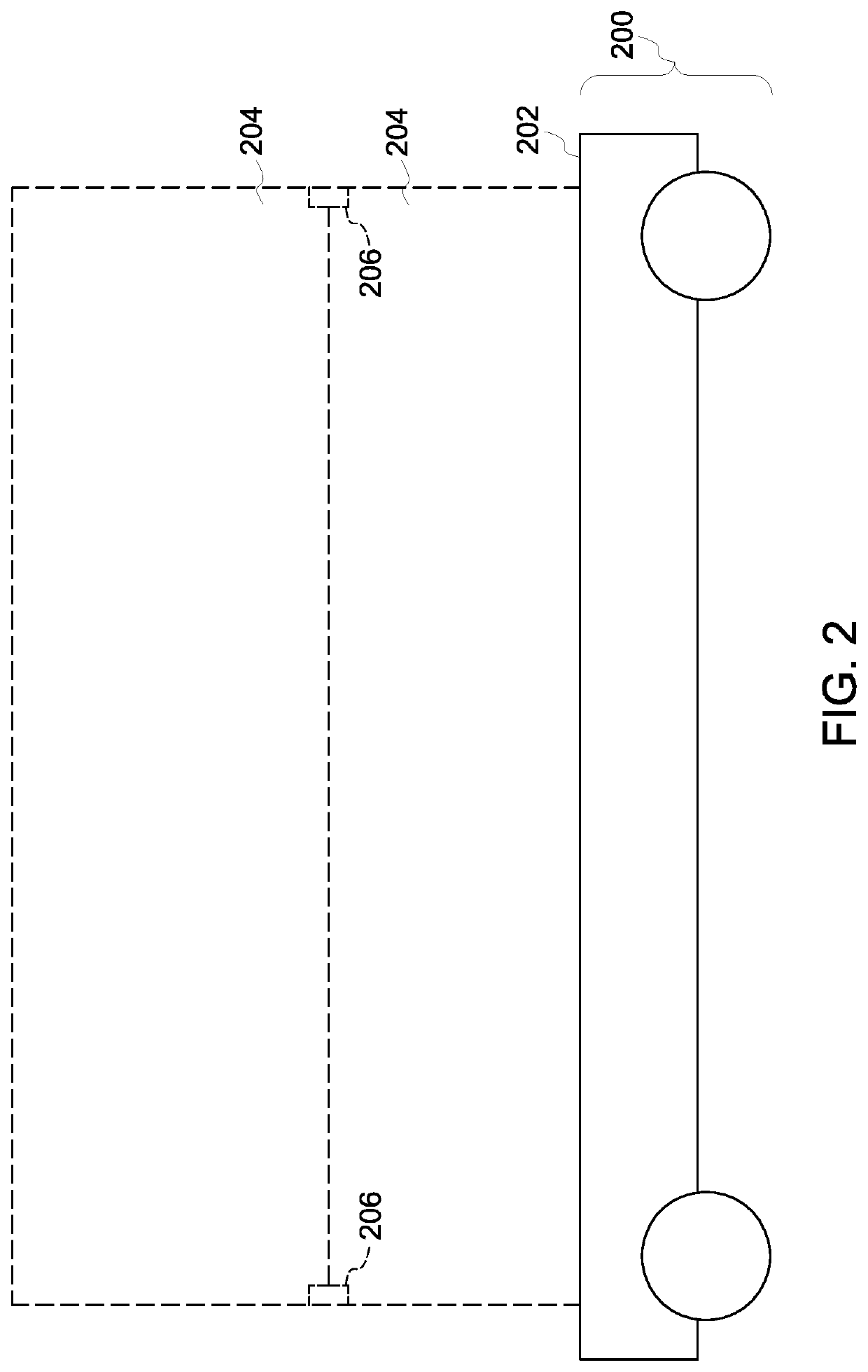

Cargo handling apparatus module

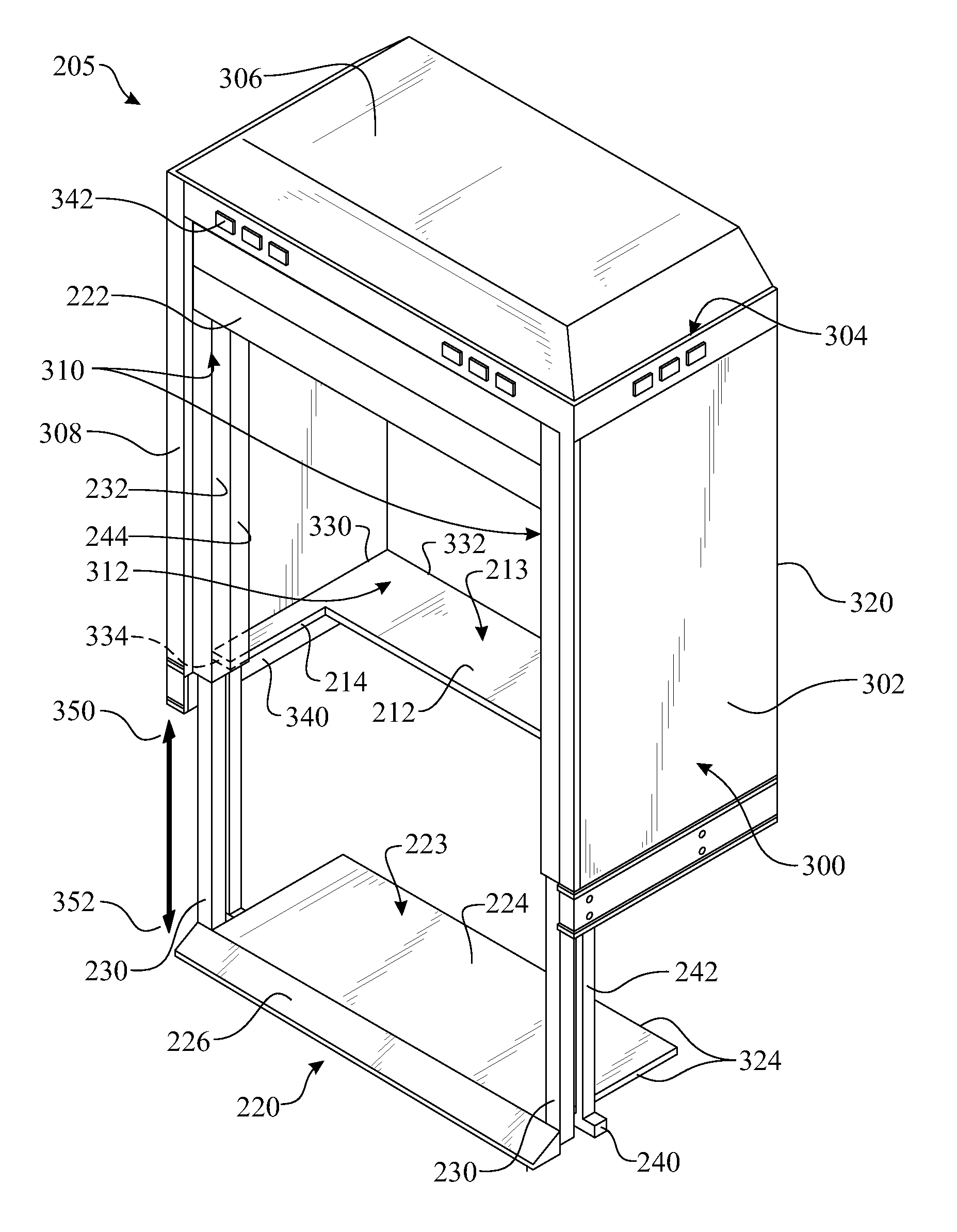

InactiveUS20120020764A1Eliminate needVehicle with raised loading platformRefuse receptaclesCargo handling gearActuator

A goods handling' apparatus for a cargo storage and transport vehicle includes a movable cargo platform continuous with a portion of cargo enclosure floor, when the cargo platform is in an upper position. Cargo may be slid between the trailer floor and the cargo platform. A vertical actuator raises and lowers the cargo platform between the upper position and a lower position atop the ground or other vehicle support surface whereupon cargo may be slid between the cargo platform and the ground or other positions. The cargo platform is disposed substantially within the plan perimeter of the floor of the cargo module during raising and lowering. A modular system may be integrated into the cargo enclosure, or may be incorporated into a modular enclosure for appending to a cargo box of the prior art. An underside is disposed in vertically adjusting communication with the cargo platform.

Owner:NESPOR RONALD R

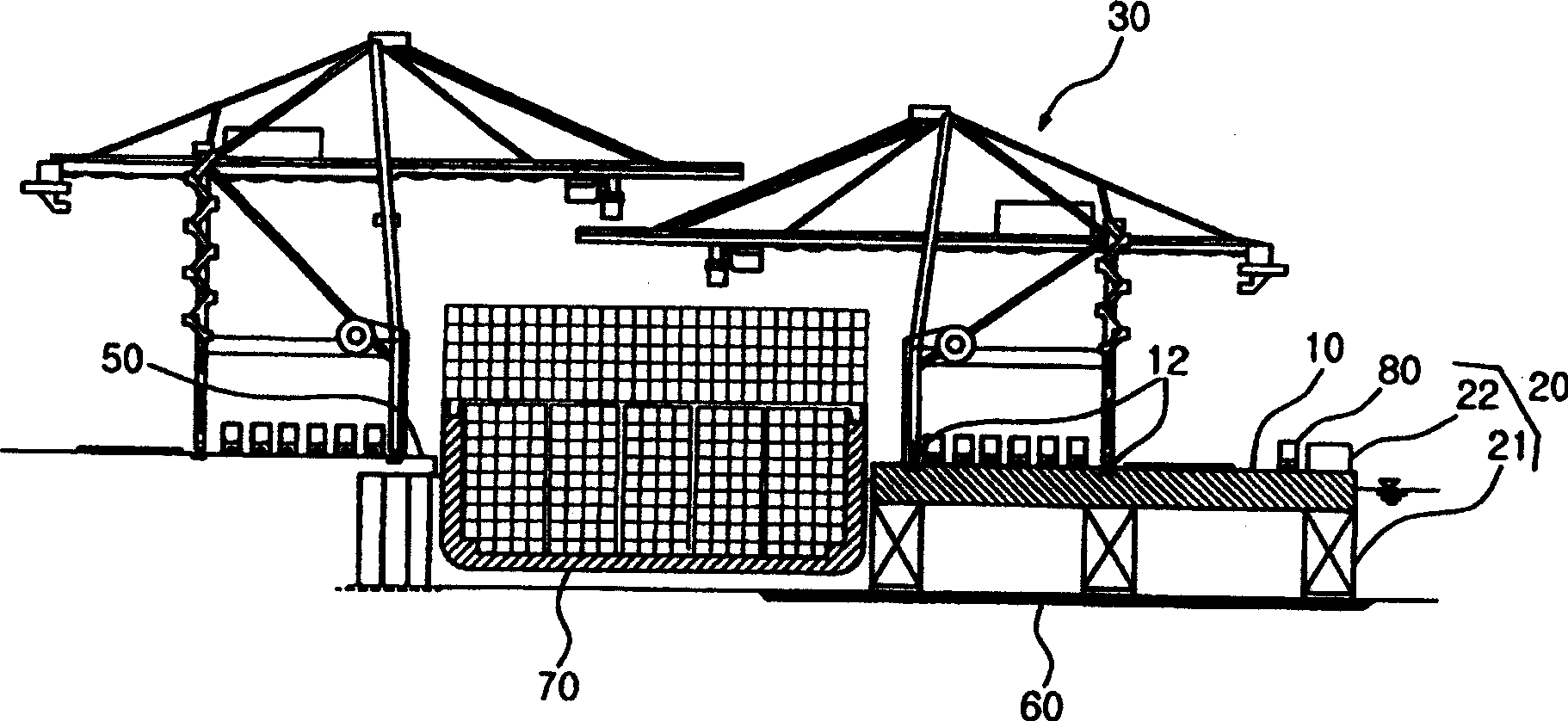

Apparatus for loading and unloading cargo at sea-side of ship

InactiveCN1576162AReduce shockQuick installationCargo handling apparatusBreakwatersCargo handling gearContainer crane

Owner:丁灴一 +1

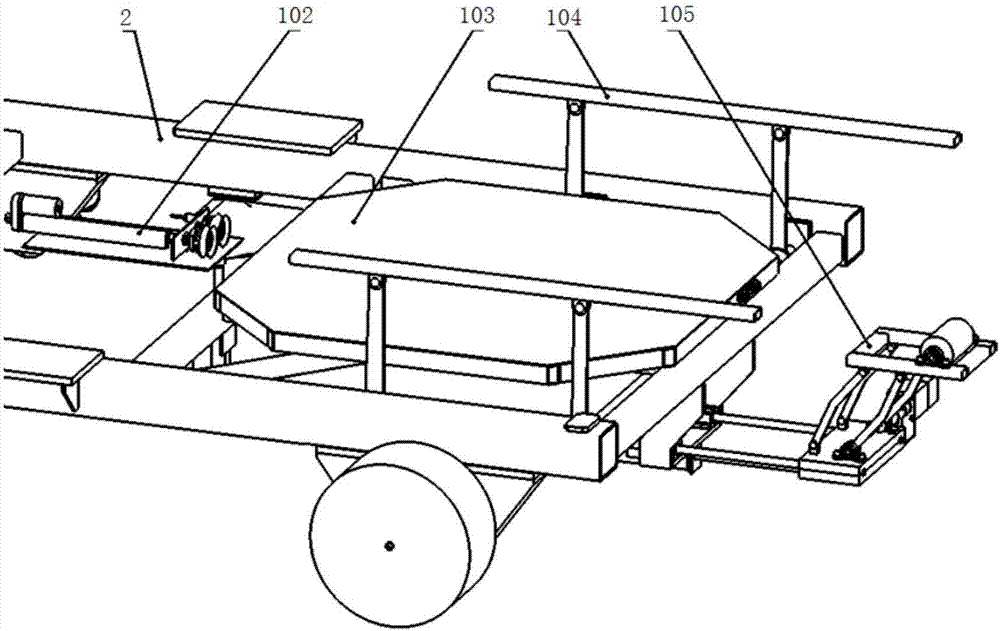

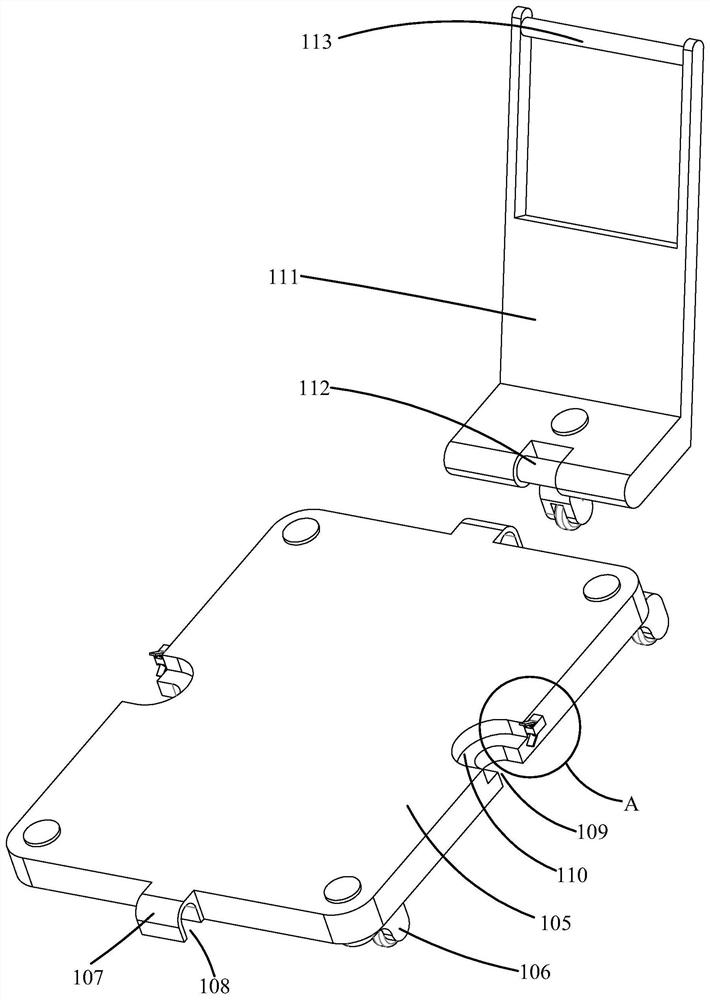

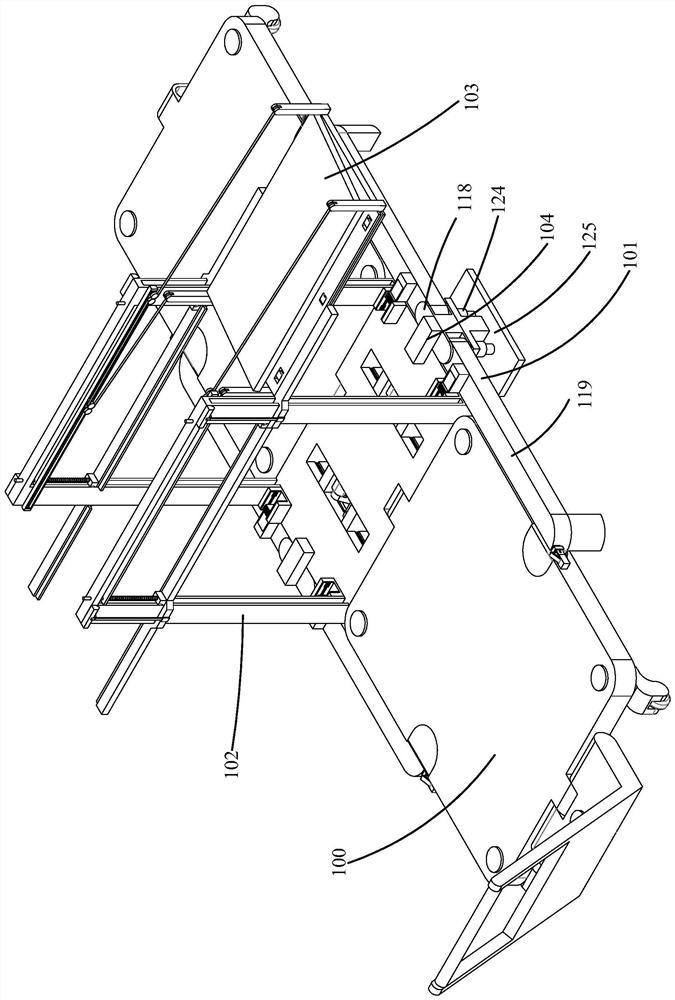

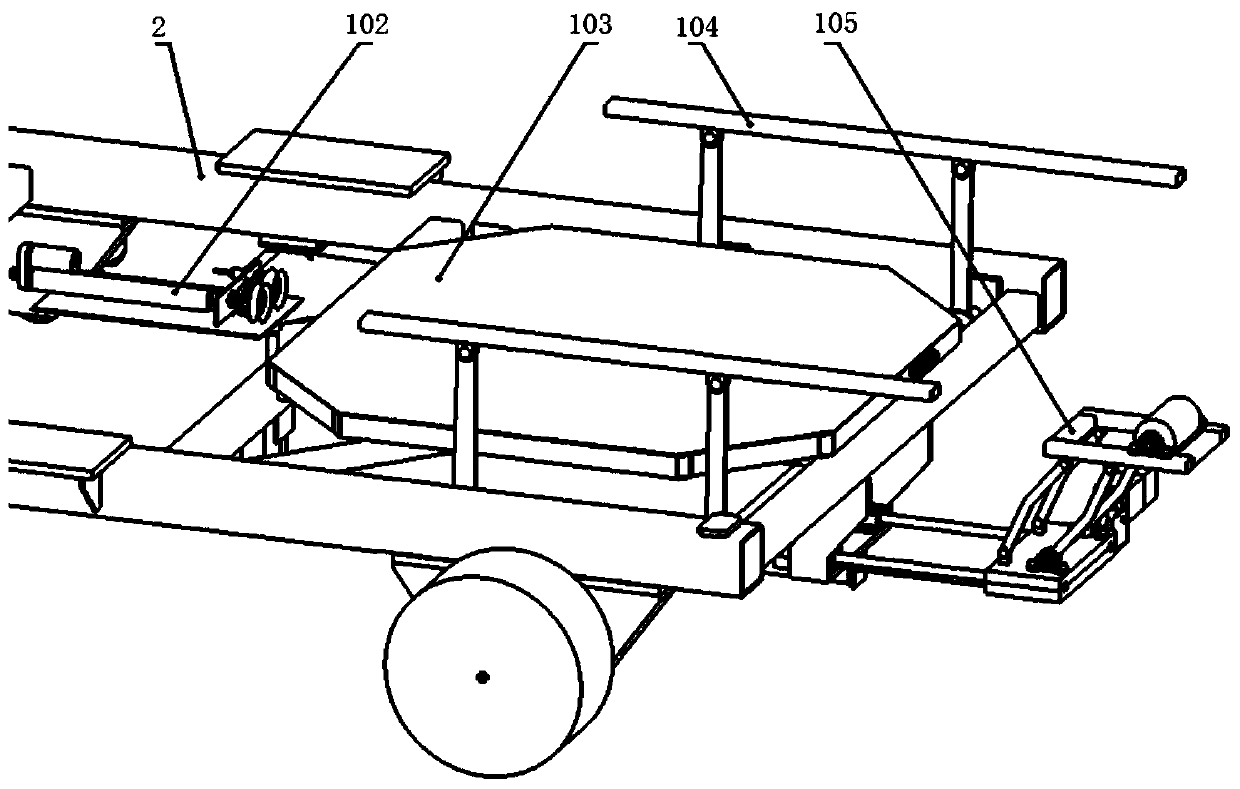

Mobile robot capable of achieving automatic cargo handling

ActiveCN107032141AWith automatic loadingFunctionalWrapping material feeding apparatusWrapping with article rotationCargo handling gearThin membrane

The invention belongs to the field of cargo handling equipment and particularly discloses a mobile robot capable of achieving automatic cargo handling. The mobile robot comprises a mobile platform, a grabbing mechanism, a conveying mechanism, a pallet exchanging mechanism and a film winding mechanism, wherein the grabbing mechanism comprises a front manipulator and a rear manipulator, the conveying mechanism is arranged between the front manipulator and the rear manipulator, and the pallet exchanging mechanism comprises a rotating plate module; the film winding mechanism comprises a film drawing module, a film clamping module and a film cutting module, the film drawing module, the film clamping module and the film cutting module are installed on the mobile platform, the film drawing module carries out up-and-down motion relative to the mobile platform in the film winding process, the film clamping module is a split film clamping mechanism, the film clamping module is fixedly connected with the rotating table module and rotates along with the rotating table module in the film winding process, and the film clamping module is separated from the rotating table module after the film is wound; the film cutting module is used for cutting off the film. The mobile robot can effectively solve the problem that an existing cargo handing robot is difficultly applied to narrow spaces, and has the advantages of being small in overall size, convenient to operate, high in applicability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Cargo handling apparatus and underride combination

A goods handling' apparatus for a cargo storage and transport vehicle includes a movable cargo platform continuous with a portion of cargo enclosure floor, when the cargo platform is in an upper position. Cargo may be slid between the trailer floor and the cargo platform. A vertical actuator raises and lowers the cargo platform between the upper position and a lower position atop the ground or other vehicle support surface whereupon cargo may be slid between the cargo platform and the ground or other positions. The cargo platform is disposed substantially within the plan perimeter of the floor of the cargo module during raising and lowering. A modular system may be integrated into the cargo enclosure, or may be incorporated into a modular enclosure for appending to a cargo box of the prior art. An underride is disposed in vertically adjusting communication with the cargo platform.

Owner:NESPOR RONALD R

Cargo handling apparatus module

InactiveUS8177471B2Eliminate needRefuse receptaclesVehicle with parallel load movementCargo handling gearActuator

Owner:NESPOR RONALD R

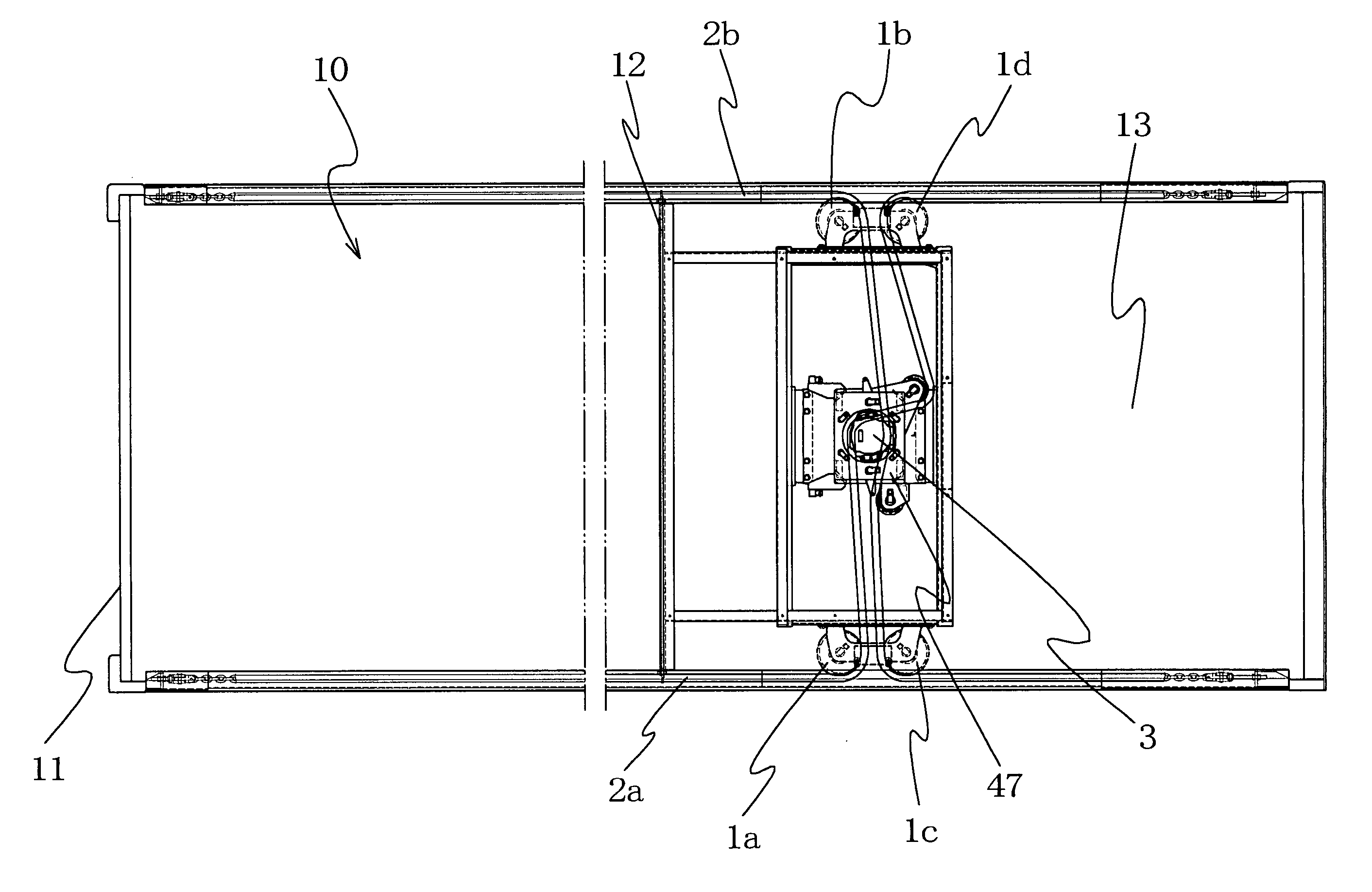

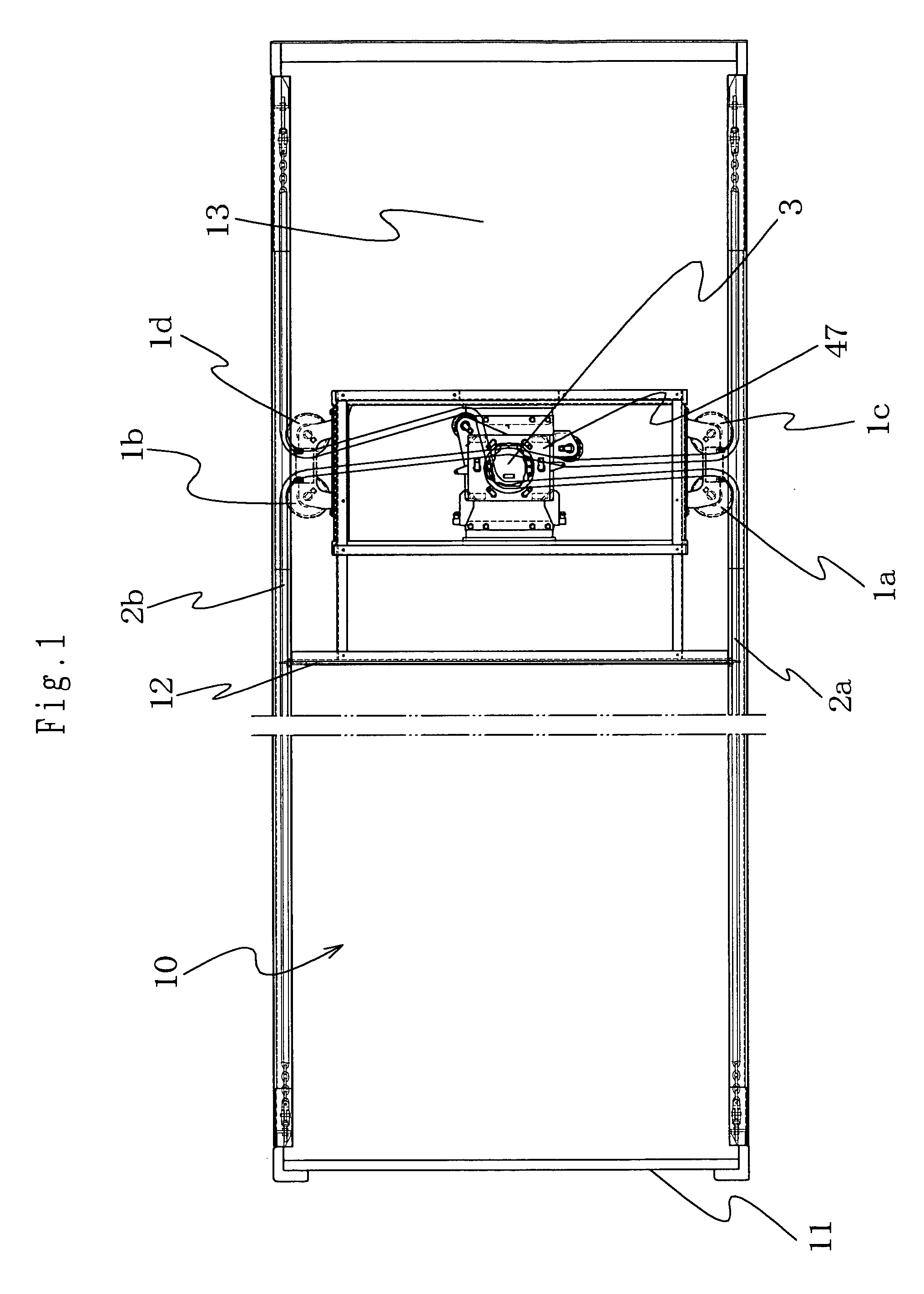

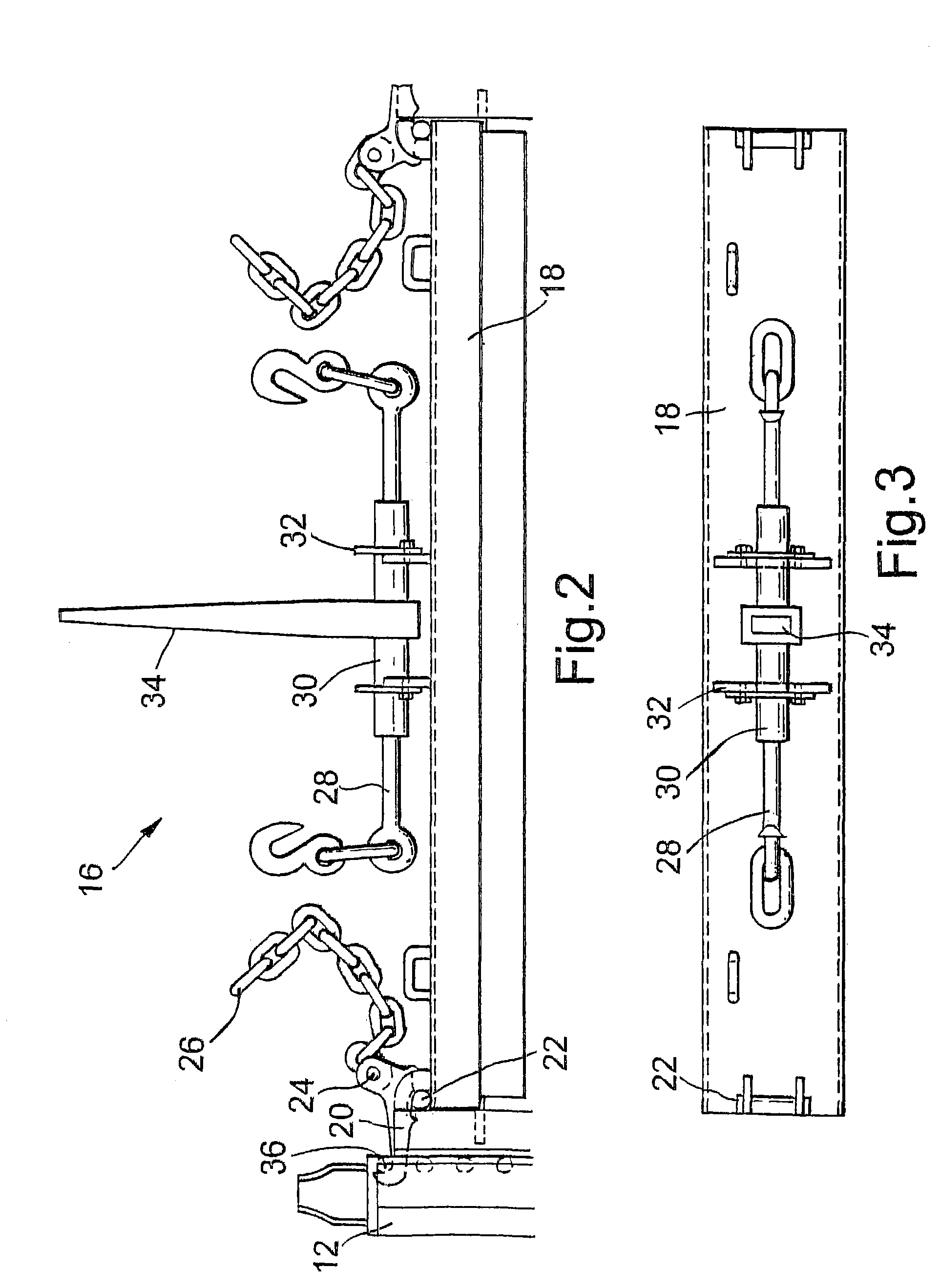

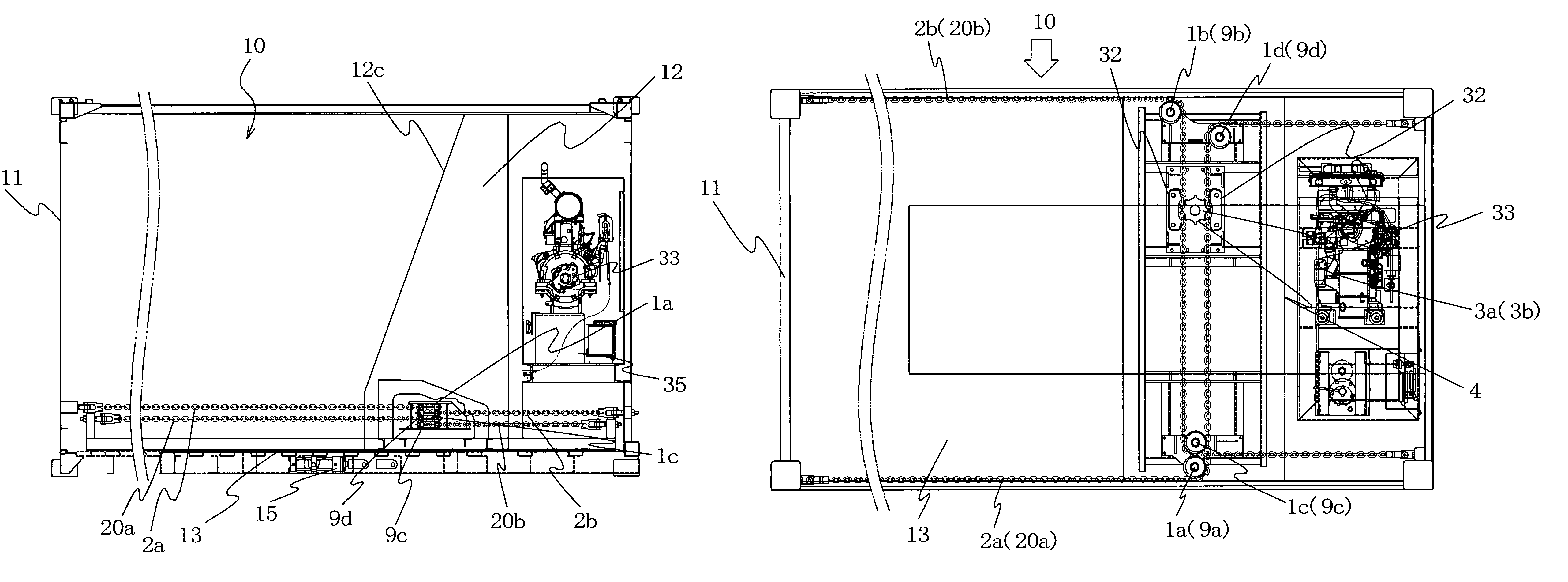

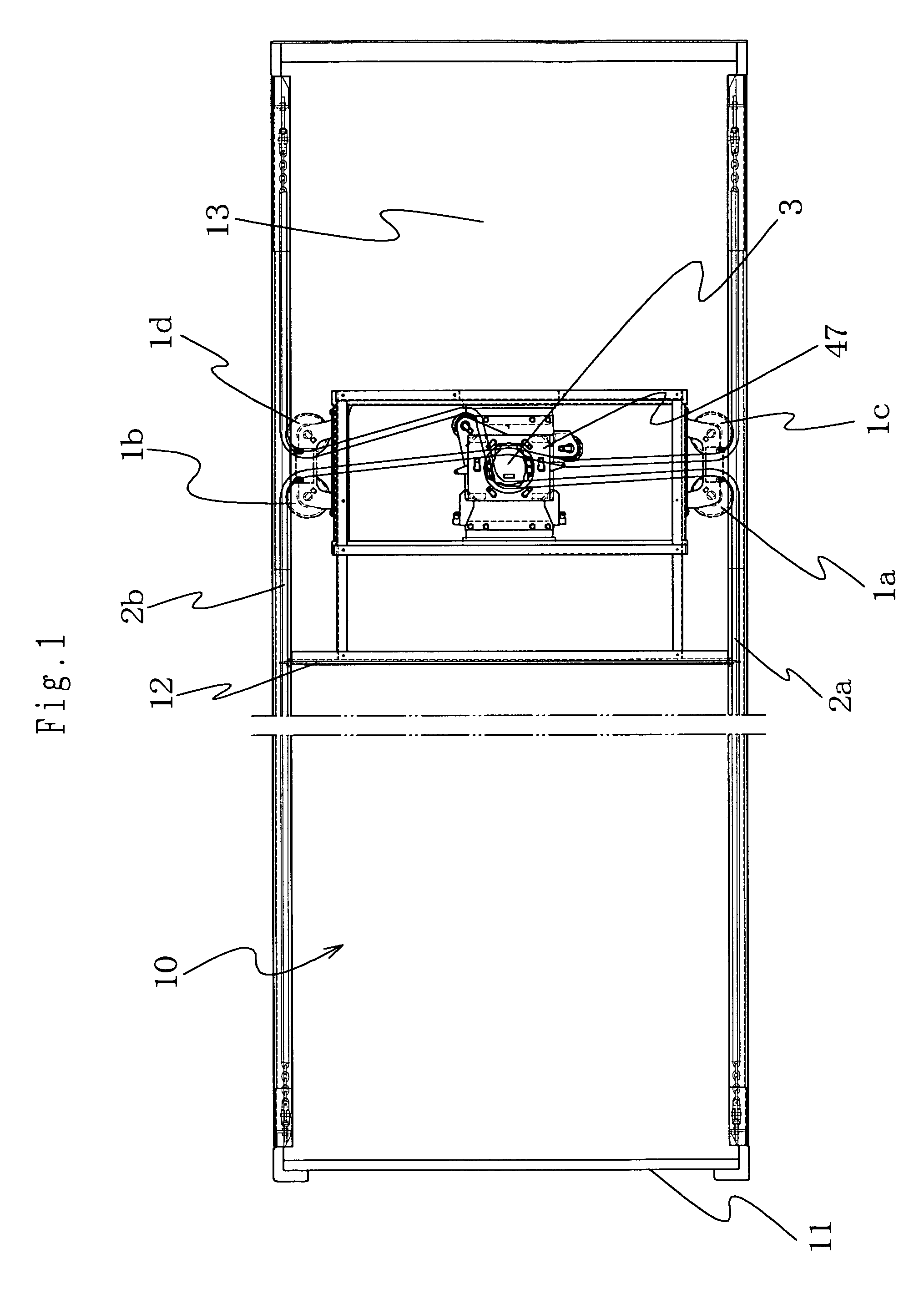

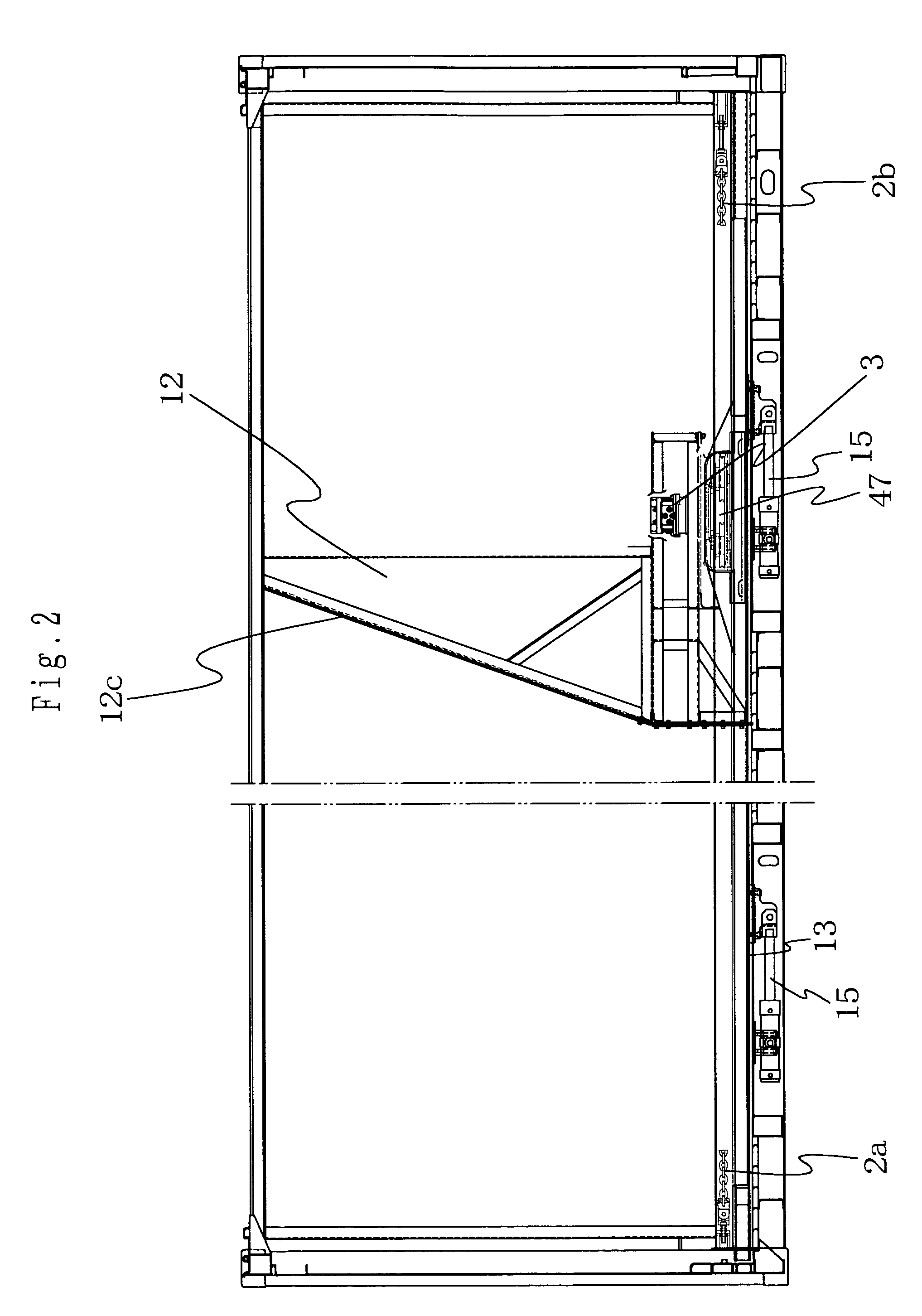

Cargo transportation box body with cargo handling device

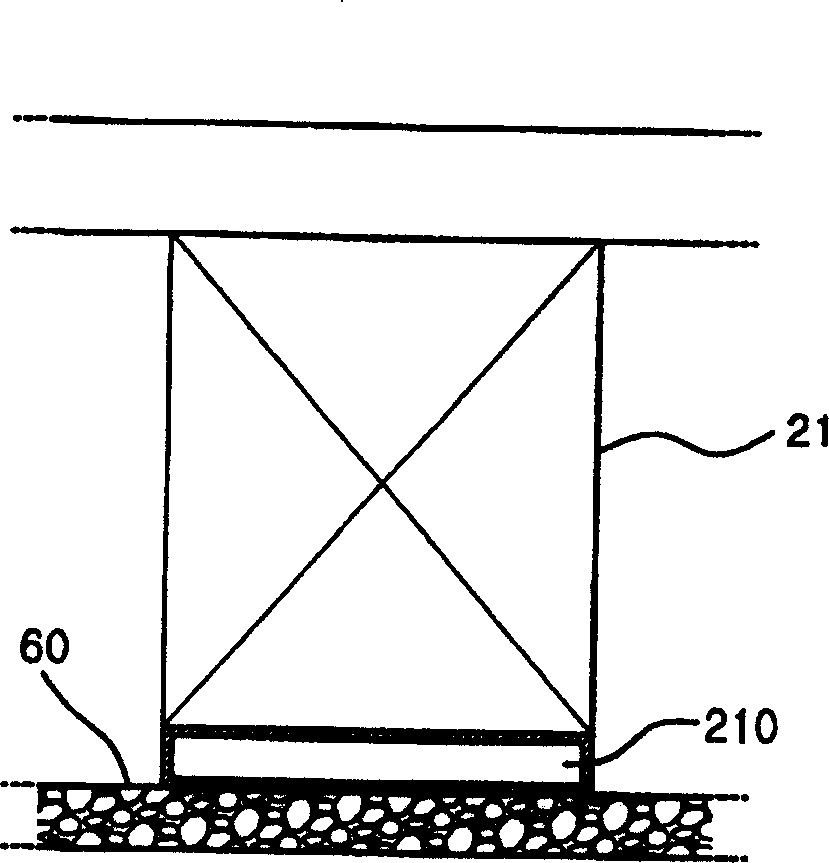

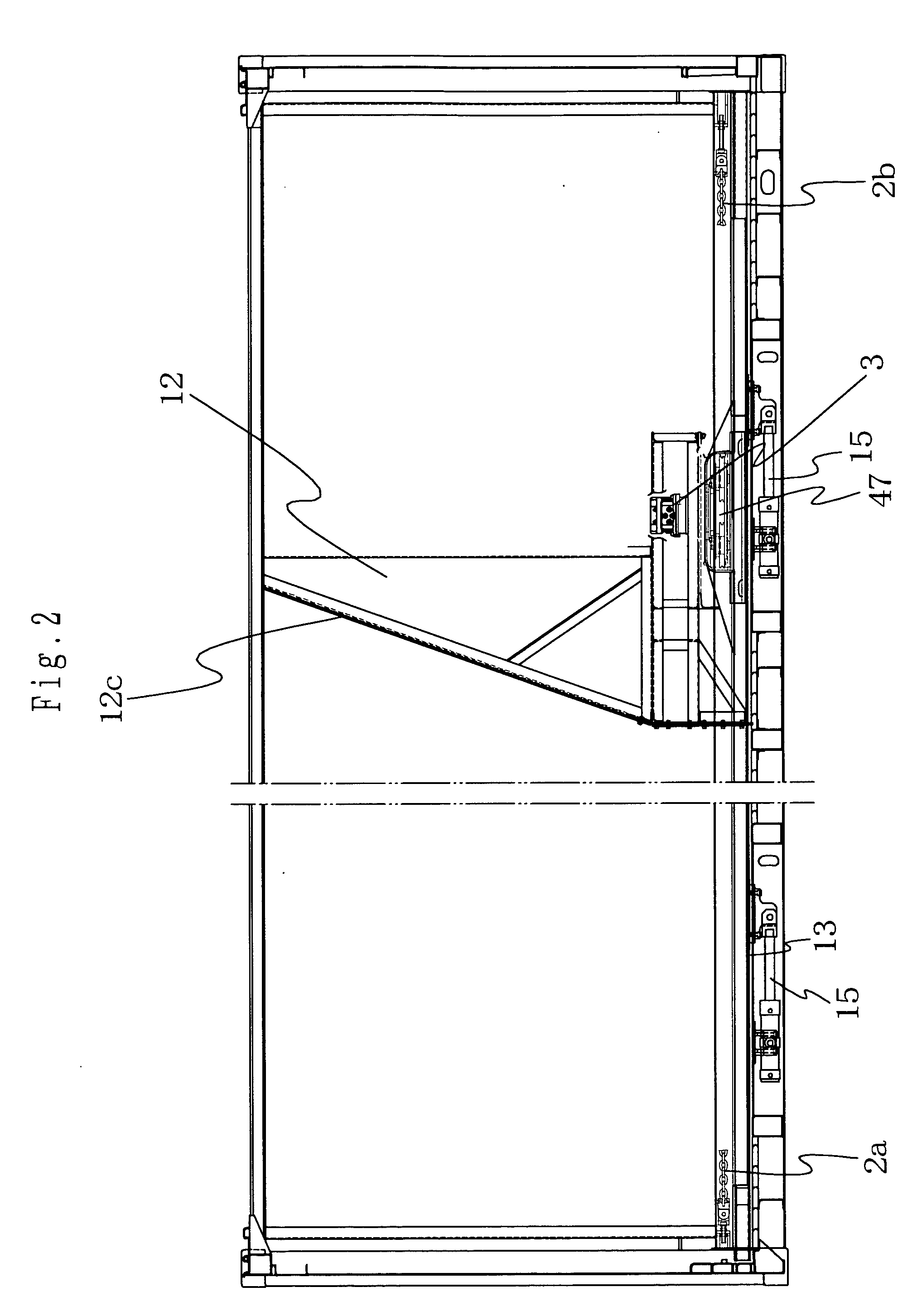

Provided is a cargo transportation box body with a cargo-handling device for cargo unloading or loading, the box body having on its bottom a floor board movable via a cylinder in an antero-posterior direction, and a movable partition wall on the floor board such that, when the movable partition wall is latched, only the floor board is movable, and when allowed to move, the movable partition wall moves in association with the floor board, wherein whether the movable partition wall should be moved synchronously with the floor board or with a divergence relative to the latter is securely selectable, and the movable partition wall maintains a stabilized condition, being safely prevented against lateral swinging fluctuations. A sprocket (3) with projections on its periphery is attached around an axis at the base of the movable partition wall (12) to be rotatable round the axis driven by a reversible motor (47), a first chain (2a) comprising a series of rings has one end fixed to the left (or right) posterior end of the box body (10) and the other end to the right (or left) anterior end of the same body while a second chain (2b) comprising a series of rings has one end fixed to the right (or left) posterior end of the box body (10) and the other side to the left (or right) anterior end of the same body, and the first and second chains (2a), (2b) cross with each other at their mid-portions where resides the sprocket (3) such that the holes of the rings constituting the first and second chains (2a), (2b) engage with the projections of the sprocket (3)

Owner:KOUJI SHOKAI CO LTD +1

Freight Handling Apparatus

InactiveUS20080190917A1Easy to transportLarge containersLoad securingCargo handling gearMechanical engineering

Owner:MAGLINE

Cargo loading and unloading equipment for road transportation

InactiveCN110775896ASave labor costsSimple and fast operationLifting devicesCargo handling gearElectrical battery

Owner:含山县祥瑞运输有限公司

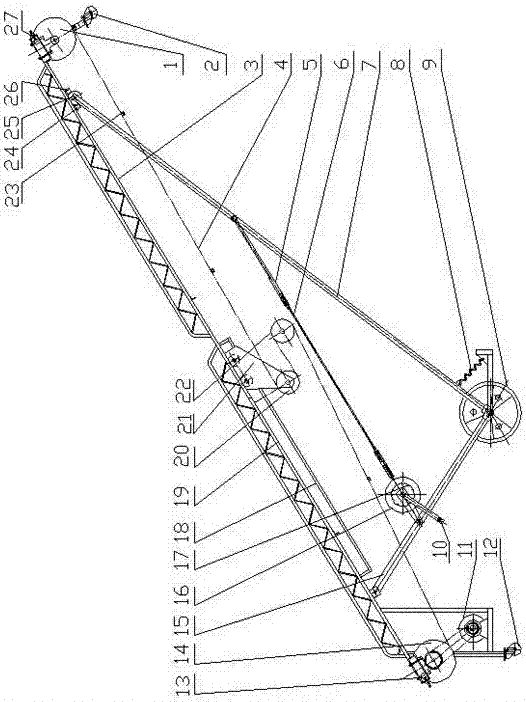

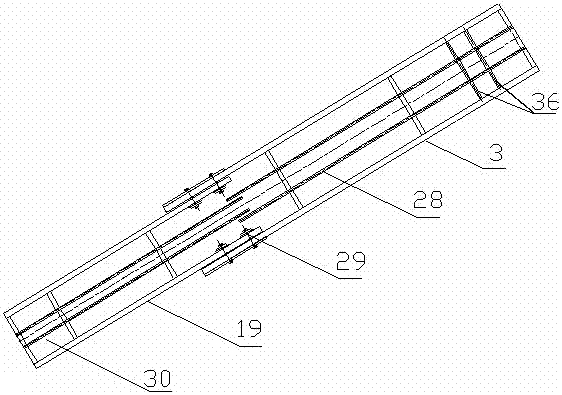

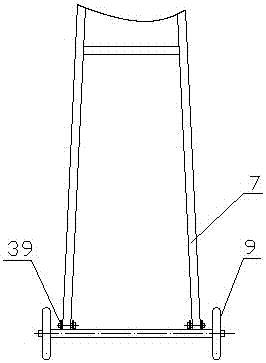

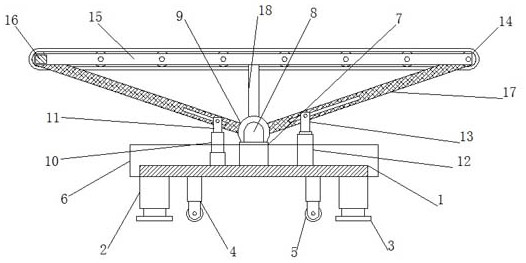

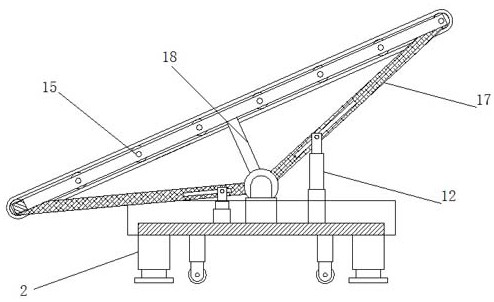

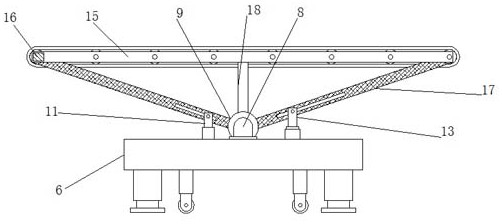

Orchard multifunctional miniature belt conveyor

The invention relates to cargo loading and unloading equipment, in particular to an orchard multifunctional miniature belt conveyor. The orchard multifunctional miniature belt conveyor is characterized by comprising front and back racks, a conveying belt, a machine body stretchable limiting mechanism, a height adjusting mechanism, a conveying length adjusting mechanism, a belt tensioning offset adjustment mechanism, a transmission mechanism, a reset tension spring, a walking mechanism and other components; and the structure is compact, operation is simple, running is stable and reliable, positive and negative running can be carried out, conveying height and length adjustment can be achieved, and the functions of upgoing climbing inclined material conveying, horizontal material conveying and downgoing including material conveying are achieved. The machine type is light and flexible, running is stable, occupied space is small, the common conveying function is achieved, and the orchard multifunctional miniature belt conveyor is particularly suitable for narrow channel and space or multi-layer goods shelf warehouse material loading, unloading and carrying. The orchard multifunctional miniature belt conveyor is cooperatively developed in cooperation with several manufacturing enterprises in Qingyang, Qingyang science and technology institute and Longdong college and is a result of cooperation between schools and enterprises, and the technical advantages of science and technology farming benefiting of scientific research institutions are achieved.

Owner:EASTERN GANSU UNIVERSITY

Device suitable for railway boxcar cargo loading and unloading

InactiveCN112722893AImprove loading and unloading efficiencyEasy to moveLoading/unloadingConveyor partsCargo handling gearElectric machine

The invention discloses a device suitable for railway boxcar cargo loading and unloading, and relates to the technical field of railway boxcar cargo loading and unloading equipment. The device comprises a base, a conveying mechanism, a moving mechanism, a rotating mechanism, a lifting mechanism and a grabbing mechanism, wherein supporting plates are arranged on the two sides of the outer wall of the base, and a top plate is arranged at the top ends of the supporting plates. The device is provided with limiting bases, limiting rolling wheels, a fixed base, a first moving motor, a first gear, moving arms, limiting grooves, a connecting plate, a moving rail, a limiting sliding groove, a second transmission gear block, a transmission arm, a first transmission gear block, a moving base, a second gear, a second moving motor, a connecting base, a first rotating motor, a first rotating arm, a second rotating motor, a second rotating arm, a vertical fixed arm, a lifting arm, a first lifting motor, a second lifting motor, a first bevel gear, a second bevel gear, a lifting sliding groove, a threaded rod and a first lifting sliding block, so that front-and-back, left-and-right and up-and-down movement of the device is achieved.

Owner:CRRC YANGTZE TONGLING CO LTD

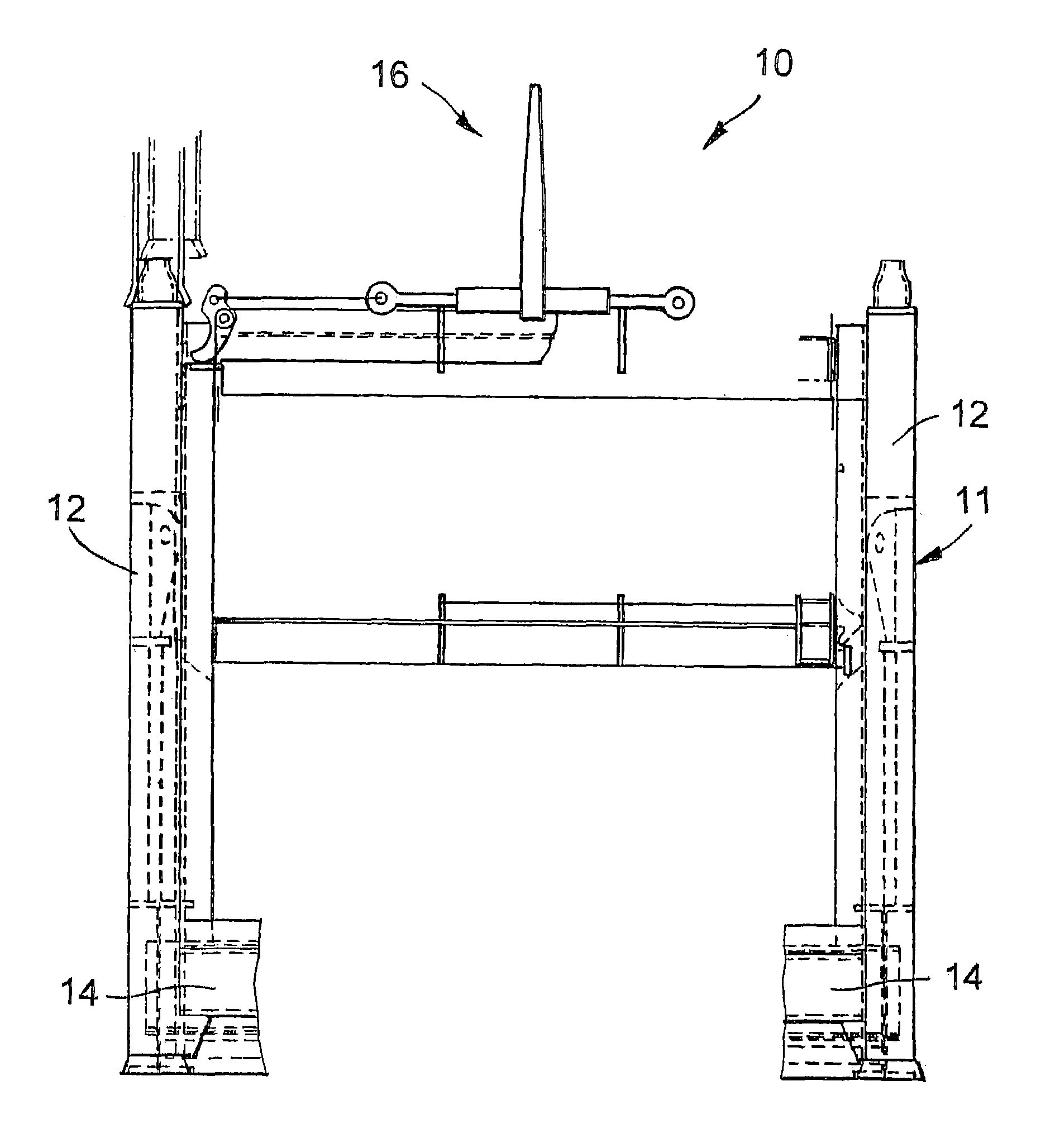

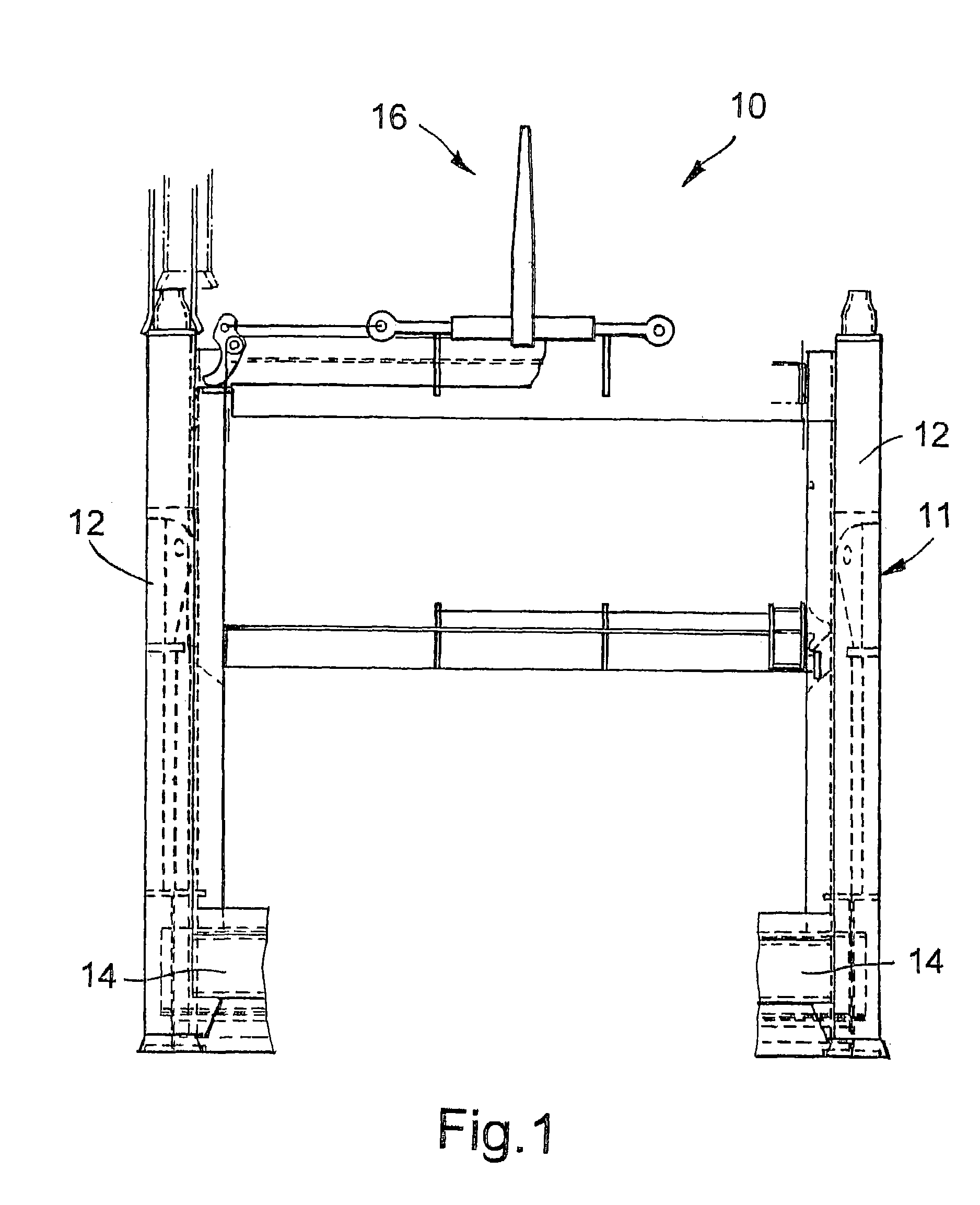

Cargo handling apparatus

A retaining member 16 is provided for use with a frame 10 for packaging elongate members, such as sections of drill pipe. The retaining member 16 comprises a pressure plate 18 on which is mounted a pair of pivoting hooks 20 for engaging with protrusions 36 formed on the frame 10. The hooks 20 are connected to threaded rods 28 received in a sleeve 30. A ratcheted handle 34 allows selective rotation of the sleeve 30 to draw the rods 28 therein, and to pivot the hooks 20 to urge the pressure plate 18 against members received within the frame 10. A quick release mechanism is provided to allow easy release of the hooks 20 and the retaining member 16.

Owner:ROSS RALPH BARCLAY

Intermodal transportation terminal control system and method

An intermodal terminal control system determines characteristics of cargo containers scheduled for receipt into and / or travel out of an intermodal terminal connected with both rail routes and automobile routes, determines characteristics of cargo handling equipment within the intermodal terminal, determines characteristics of rail vehicles scheduled for one or more of entry into or travel out of the intermodal terminal, and determines characteristics of automobile vehicles scheduled for entry into or travel out of the intermodal terminal. The system also determines constraints on cargo handling operations and a plan for the cargo handling equipment to transfer the cargo containers between the different modes of transportation within the intermodal terminal. The plan designates a sequence of operations to be performed in moving the cargo containers with the cargo handling equipment. The plan is based on the characteristics of the cargo containers, the cargo handling equipment, the rail vehicles, and the automobile vehicles.

Owner:GE GLOBAL SOURCING LLC

Cargo transportation box body with cargo handling device

A cargo transporting box body with a cargo-handling device for cargo unloading or loading, the box body having on its bottom a floor board movable, and a movable partition wall on the floor board such that, when the movable partition wall is latched, only the floor board is movable, and when allowed to move, the movable partition wall moves in association with the floor board. A sprocket is attached around an axis at the base of the movable partition wall and driven by a reversible motor. A first chain has one end fixed to the posterior end of the of the box body and the other end to the anterior end; while a second chain has one end fixed to the posterior end of the box body and the other side the anterior end, and the first and second chains cross with each other at their mid-portions and engage with the sprocket.

Owner:KOUJI SHOKAI CO LTD +1

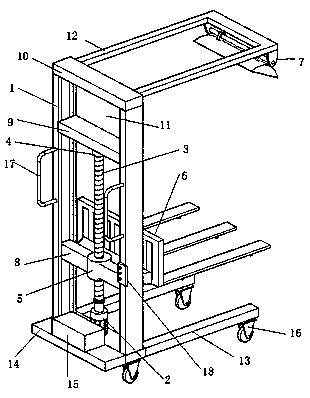

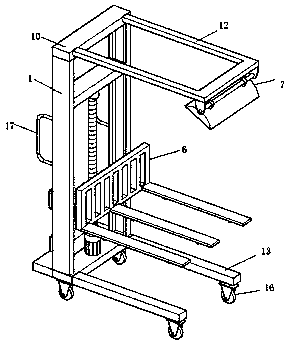

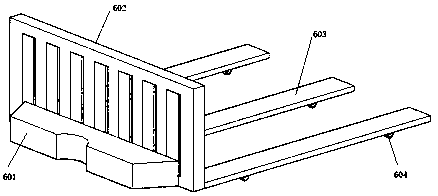

Goods loading and unloading equipment

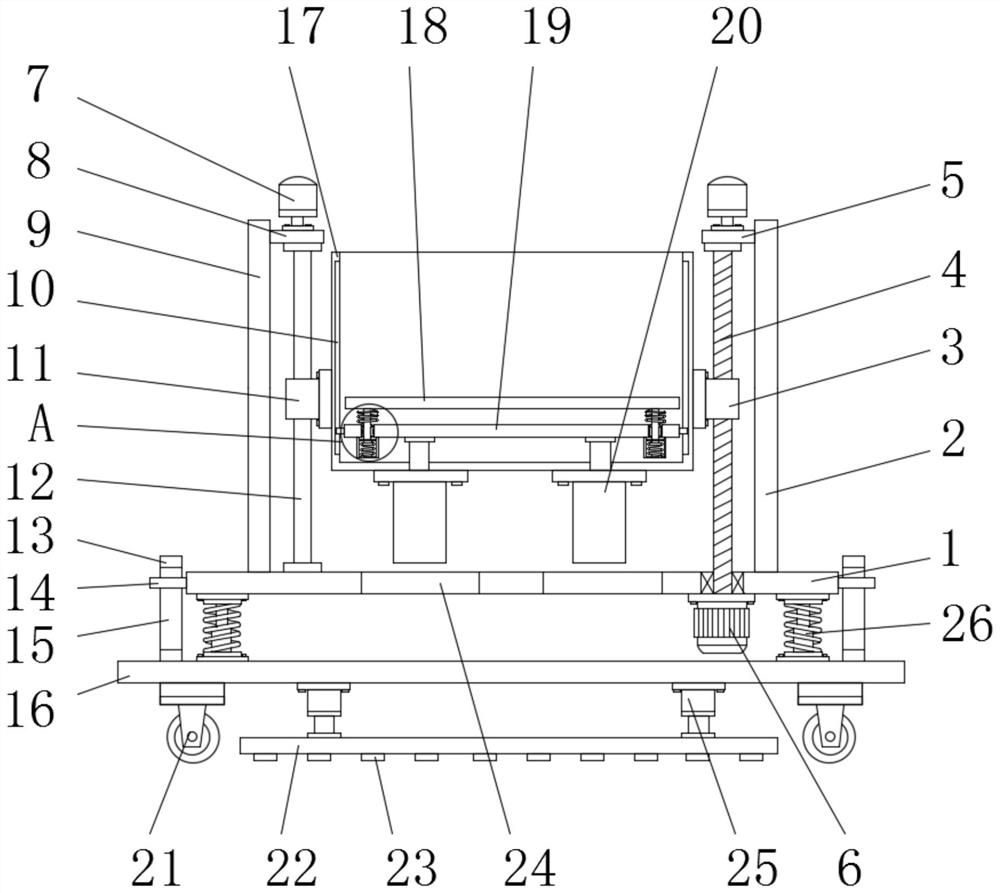

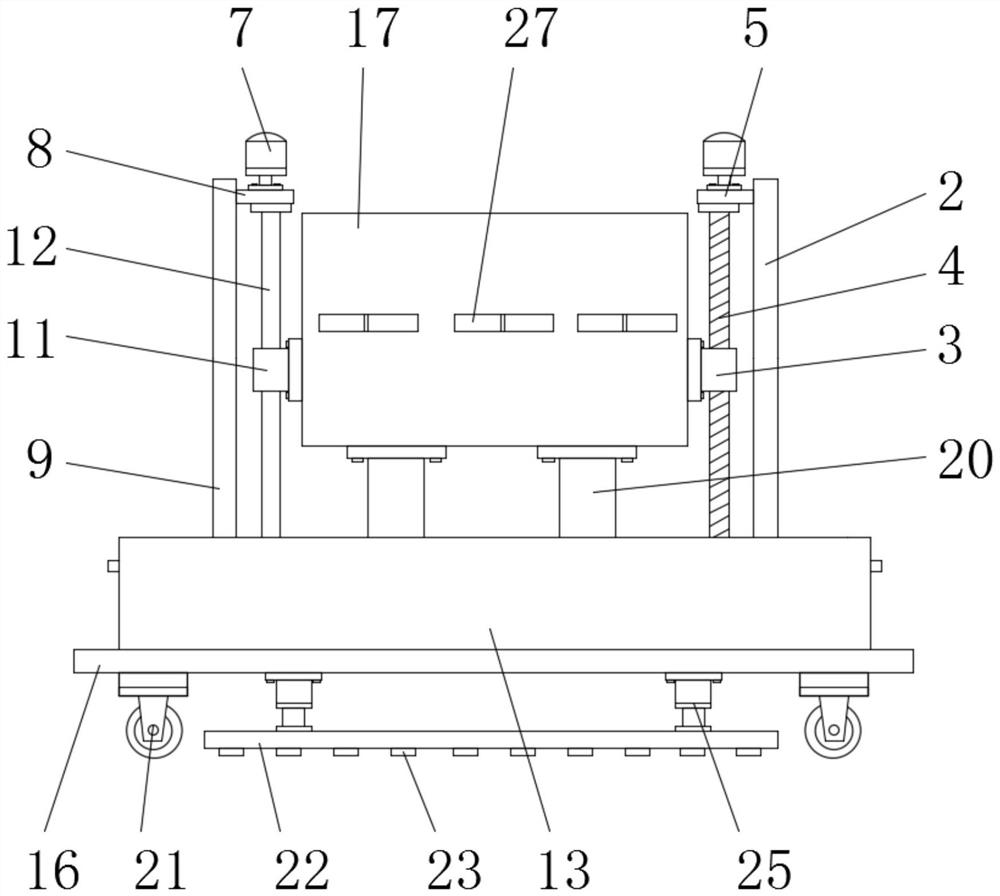

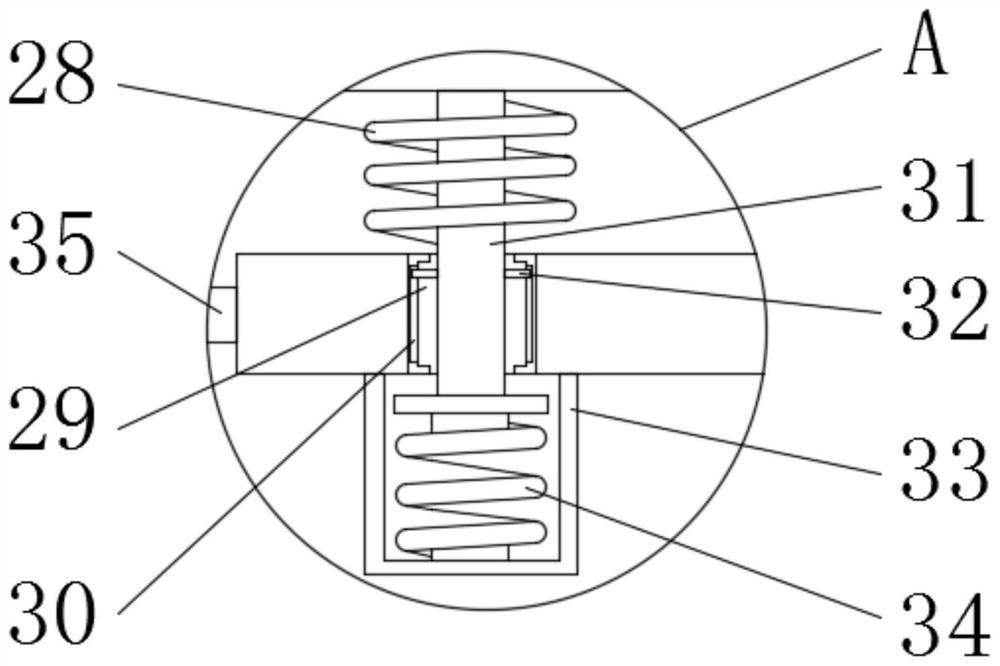

ActiveCN111942915ASimplify the steps of unloading and re-handlingEliminate potential safety hazardsLoading/unloadingCargo handling gearStructural engineering

The invention discloses goods loading and unloading equipment. The structure of the goods loading and unloading equipment comprises base connecting devices that play a bearing and connection role; thebase connecting devices abut against the ground; plate trailer devices used for loading goods are arranged at the two ends of the base connecting devices correspondingly; a lifting and carrying device used for lifting goods is arranged between the base connecting devices; the lifting and carrying device is provided with a conveying and unloading device used for carrying and unloading goods, so that the plate trailers serving as conveying carriers are used as a part of the goods loading and unloading equipment; the step of unloading the goods on the plate trailers and then carrying the goods during traditional loading and unloading work is simplified; and the equipment can be moved with the change of the unloading position, so that the unloading efficiency is improved, the goods are automatically unloaded towards the preset direction and position, and thus the potential safety hazard that workers climb high for unloading goods is eliminated.

Owner:合肥仓小强供应链管理有限公司

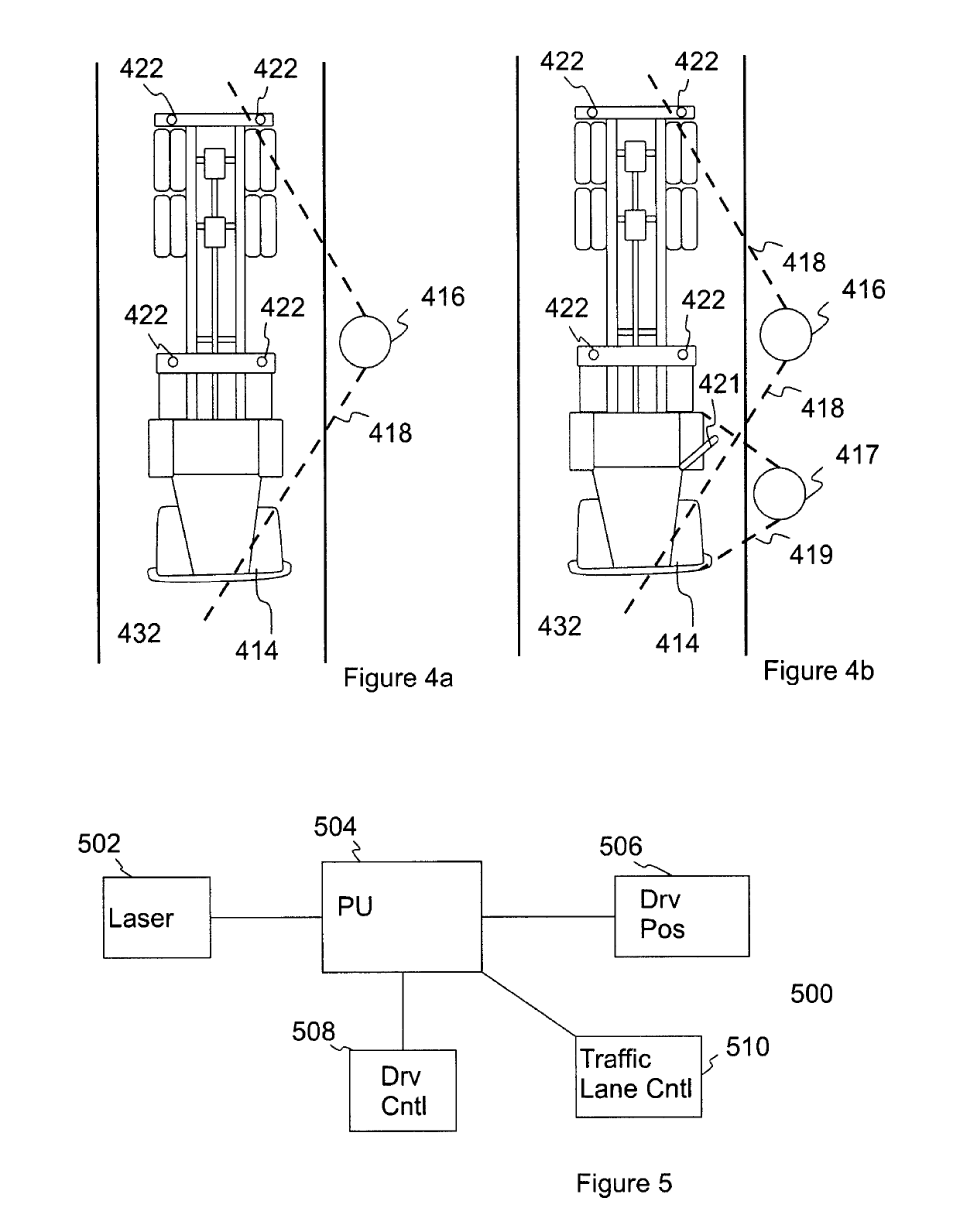

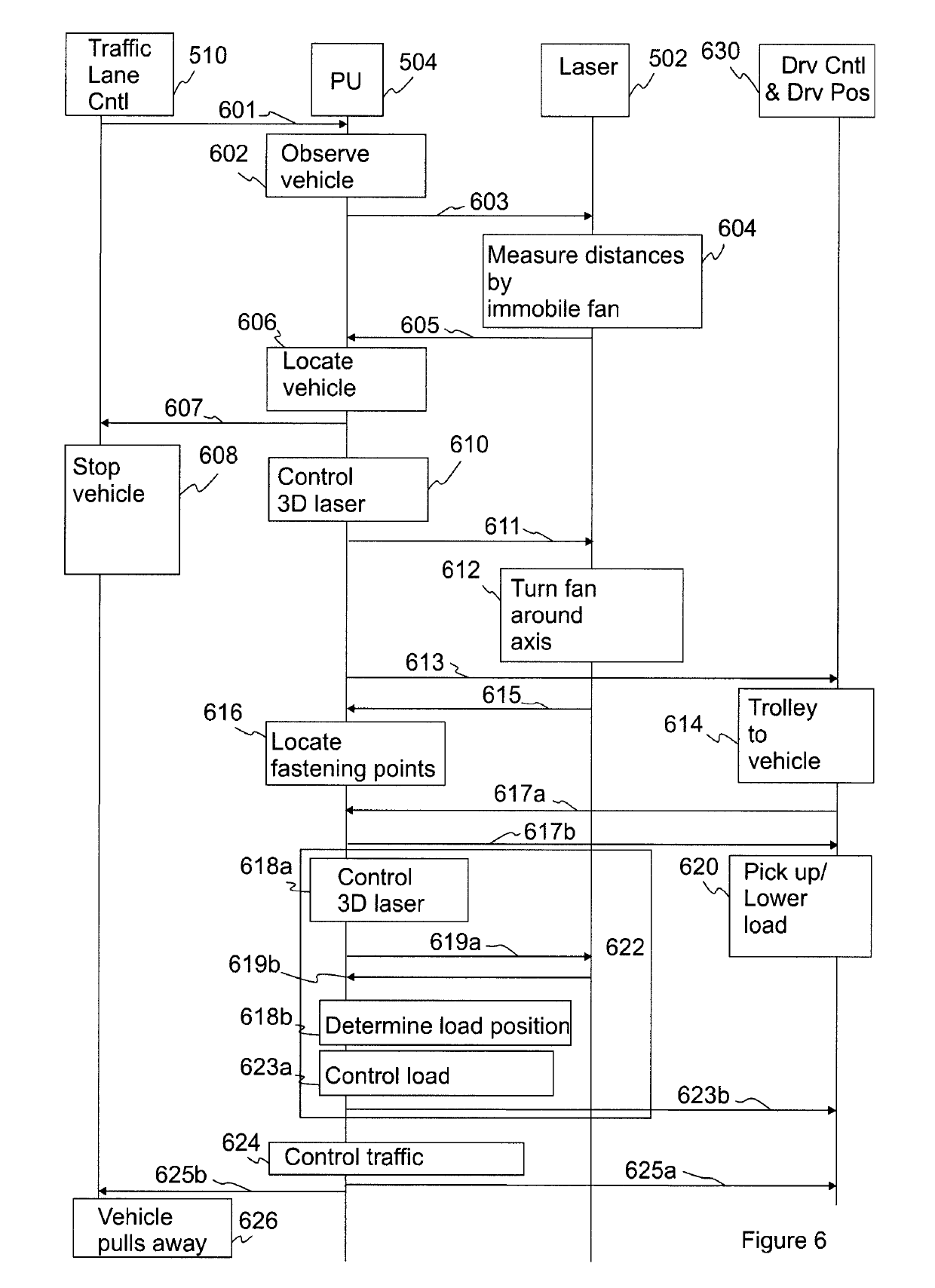

Load transport by means of load handling equipment

ActiveUS10421646B2Reduce in quantityConvenience to workOptical rangefindersTrolley cranesCargo handling gearEngineering

Owner:KONECRANES GLOBAL

Multistage load-reducing quick unloading device

InactiveCN103072889ASimple structureFast load sheddingLoad-engaging elementsCargo handling gearEngineering

Owner:SHANDONG UNIV OF TECH

Cargo loading and unloading equipment for road transportation

InactiveCN112158607AImprove stabilityEasy to moveSupporting framesLoading/unloadingCargo handling gearHydraulic ram

Owner:湖南新正渣土有限公司

Logistics freight classification handling device

InactiveCN111674964APrevent collapseAvoid collapsing and fallingLoading/unloadingCargo handling gearLogistics management

The invention relates to the field of freight handling equipment, in particular to a logistics freight classification handling device. The device comprises a device body. A handling plate is movably installed at the upper end of the device body, a freight stopping device is movably installed at the upper end of the handling plate, a classification device is fixedly installed on the left side of the device body, a sliding groove is formed in the upper end of the handling plate, and the lower end of the handling device is inlaid into the sliding groove. Accordingly, when the handling plate is inserted into a carriage, the freight stopping device can move leftwards and be abut against the freight at the upper end to prevent the freight from collapsing; when the handling plate moves outwards,the freight stopping device can stop the freight at the upper of the interior of the carriage under the action of springs to prevent the freight from moving along with the handling plate, and it is guaranteed that a certain quantity of freight is output through the handling plate at one time; and then because of the arrangement on the outer side of a freight conveying rotating wheel, when the handling plate moves outwards, the freight conveying rotating wheel can make friction with the bottom of the carriage to be driven to rotate anticlockwise so as to drive the freight to move leftwards at the upper end of the handling plate, and the effect that the freight is automatically unloaded outwards is achieved.

Owner:陈珊

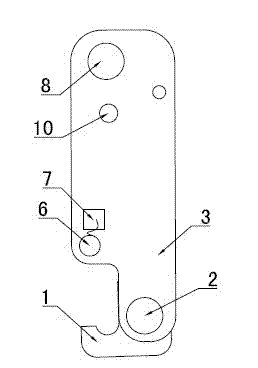

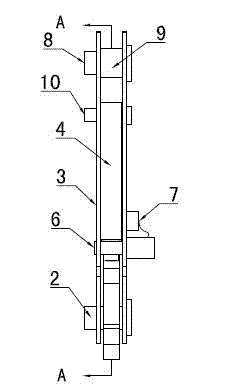

Large-load rapid unloading device based on wireless control

InactiveCN103112778AQuick releaseRelieve pressureLoad-engaging elementsCargo handling gearWireless control

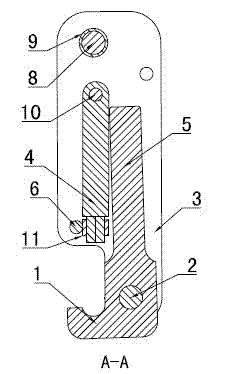

The invention provides a large-load rapid unloading device based on wireless control and belongs to the field of cargo loading / unloading equipment. The large-load rapid unloading device is characterized in that a hook (1) is arranged at one end of a hoisting device and a connecting rod (5) which is integrally connected with the hook (1) is arranged at the other end of the hoisting device; the hoisting device is rotatably mounted in a shell body formed by supporting plates (3) at two sides through a first fixing pin (2); the hook (1) stretches out of the shell body; a gear rod (4) for locking the connecting rod (5) to prevent the hoisting device from rotating is mounted at one side of the hoisting device; a fixed end of the gear rod (4) is fixed in the supporting plates (3) at the two sides through a second fixing pin (10); a movable end of the gear rod (4) is sleeved with a rolling bearing (11); and the outer side of the rolling bearing (11) is provided with an electric push rod device for limiting the rotation of the gear rod (4). The large-load rapid unloading device based on the wireless control, disclosed by the invention, is simple in structure and convenient to operate, and can realize the large-load rapid and safe unloading in any direction.

Owner:SHANDONG UNIV OF TECH

Cargo loading and unloading equipment for automobile freight

ActiveCN113844908AHeight adjustableImprove stabilityLoading/unloadingMechanical conveyorsHydraulic cylinderCargo handling gear

The invention discloses cargo loading and unloading equipment for automobile freight. The cargo loading and unloading equipment comprises a supporting plate, a first vertical plate is arranged on one side of the top surface of the supporting plate, a first top plate is arranged on the surface of one side of the first vertical plate, a bearing seat is arranged on the bottom surface of the first top plate, and a threaded rod is rotationally connected into the bearing seat; and a motor is mounted on one side of the bottom surface of the supporting plate. A motor drives a threaded rod to rotate, a movable sleeve on the threaded rod moves on the threaded rod, a sliding block moves on a sliding rod along with the movable sleeve while the movable sleeve moves on the threaded rod, the height of a protection box between the movable sleeve and the sliding block can be effectively adjusted, and after adjustment is completed, a fixing plate is driven by a hydraulic cylinder to move, and a bearing plate above the fixing plate synchronously moves along with the fixing plate while the fixing plate moves, so that goods are conveniently loaded and unloaded, the limitation during use is reduced, and the application range of the equipment is enlarged.

Owner:萍乡市城南机械有限责任公司

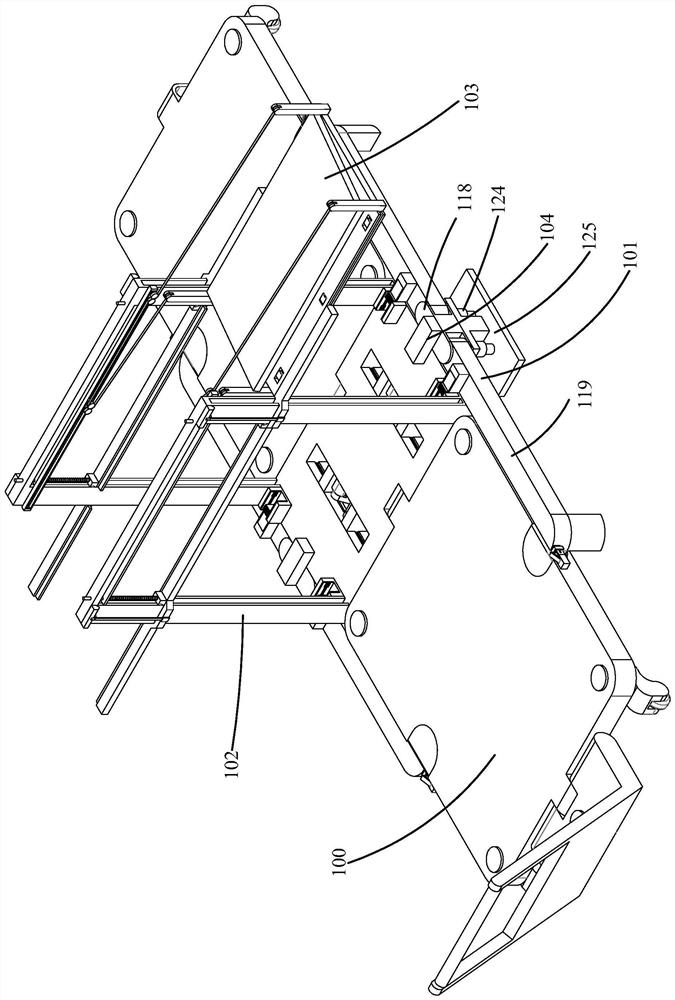

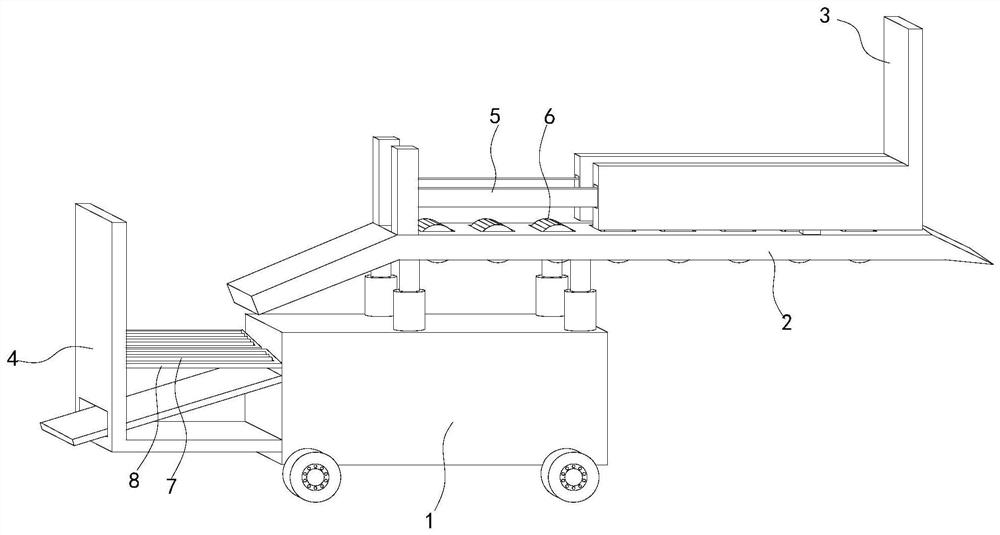

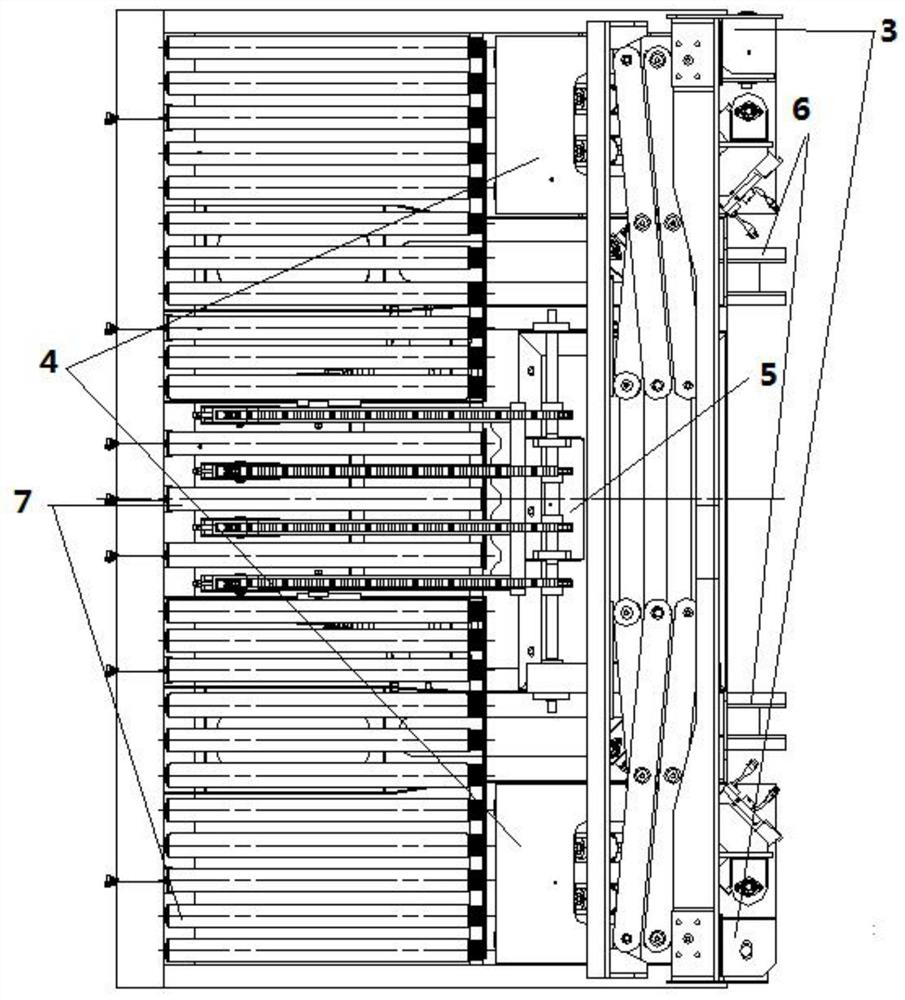

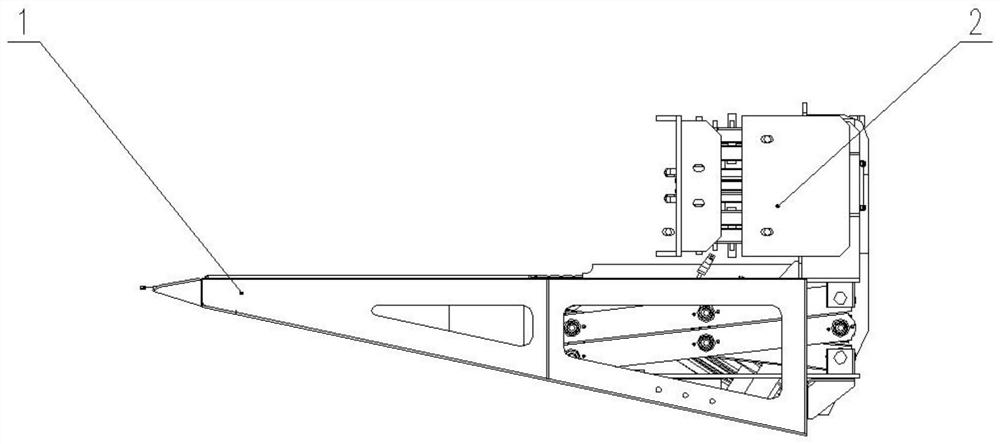

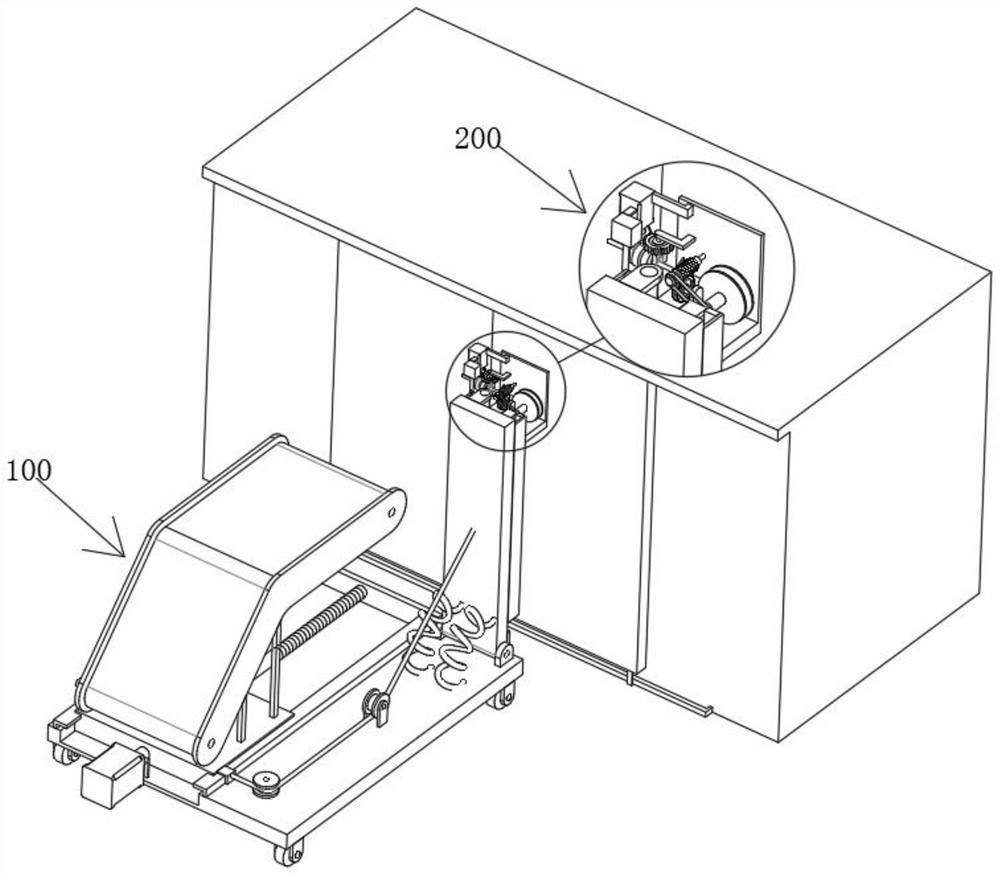

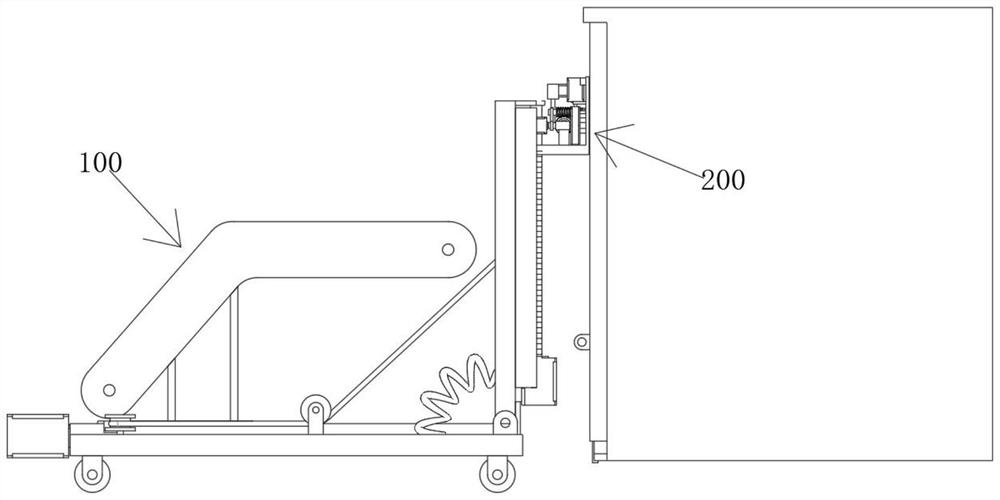

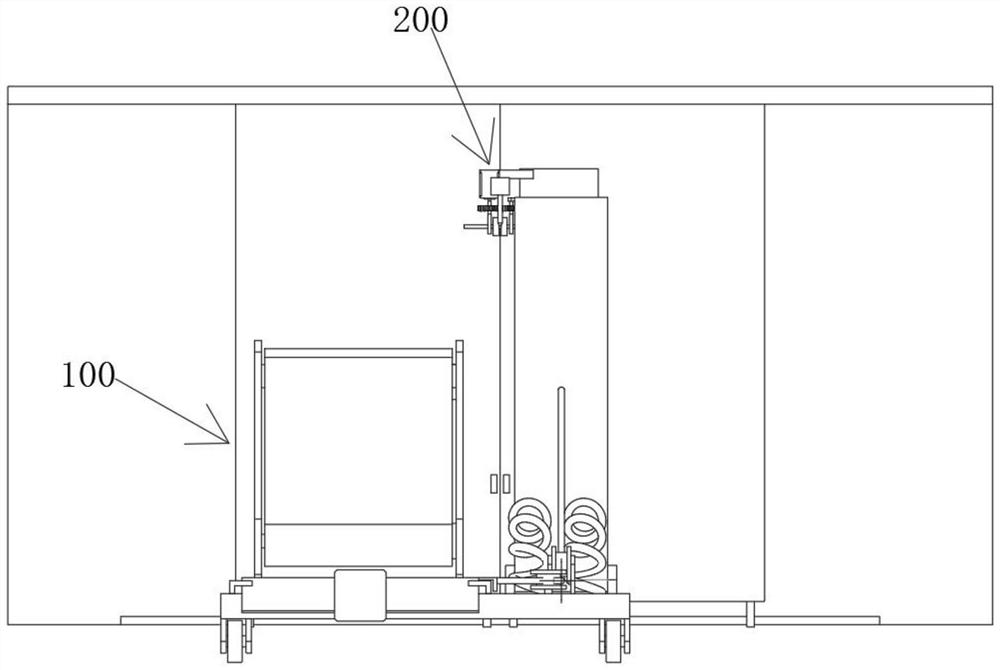

Cargo automatic loading machine

ActiveCN103964222BRealize integrationIntegration and automatic realizationLoading/unloadingMechanical conveyorsCargo handling gearEngineering

The invention provides an automatic cargo loading all-in-one machine, belongs to the field of cargo loading and unloading devices and particularly relates to an all-in-one machine capable of achieving automatic truck loading and stacking. The automatic cargo loading all-in-one machine is characterized in that one side of a longitudinal belt conveying mechanism (1) is provided with a transverse conveying mechanism perpendicular to the longitudinal belt conveying mechanism, the transverse conveying mechanism comprises a transverse support (2) and a transverse conveying belt fixed on the transverse support (2), an adjusting mechanism (4) and a superposing and grouping device (5) are sequentially arranged above the transverse conveying belt, the rear portion of the transverse conveying belt is connected with a positioning mechanism, and a trucking loading and stacking mechanism (7) is connected under the positioning mechanism (6). Manual operation is not needed in the whole truck loading process, truck loading and stacking integration is achieved automatically, the loading efficiency is remarkably improved, an installing space is saved, and the cargo loading conveying demand at any position in a warehouse is achieved though match of the longitudinal conveying mechanism and the transverse conveying mechanism.

Owner:山东长江粮油仓储机械有限公司

cargo handling equipment

ActiveCN111942915BSimplify the steps of unloading and re-handlingEliminate potential safety hazardsLoading/unloadingCargo handling gearArchitectural engineering

The invention discloses a cargo loading and unloading device, the structure of which comprises a base connecting device for bearing and connecting, the base connecting device is abutted against the ground, and two ends of the base connecting device are provided with pallet devices for loading goods, the Between the base connecting devices, a lifting and handling device for lifting and lowering the goods is arranged, and a conveying and unloading device for transporting and unloading the goods is arranged on the lifting and handling device, so that the pallet as a transport carrier is used as a part of the cargo handling equipment. It simplifies the steps of unloading and re-handling the goods on the pallet during traditional loading and unloading work, and can move the equipment with the change of the unloading position to improve the unloading efficiency, and automatically unload the goods to the predetermined direction and position, eliminating the need for staff to climb up. Unloading safety hazards.

Owner:合肥仓小强供应链管理有限公司

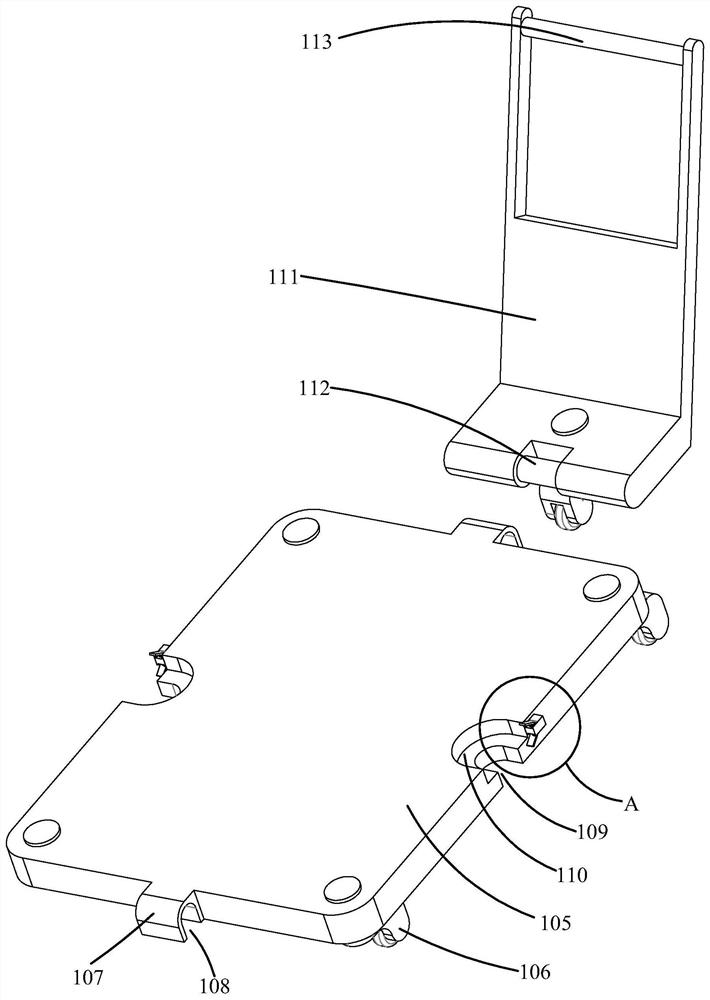

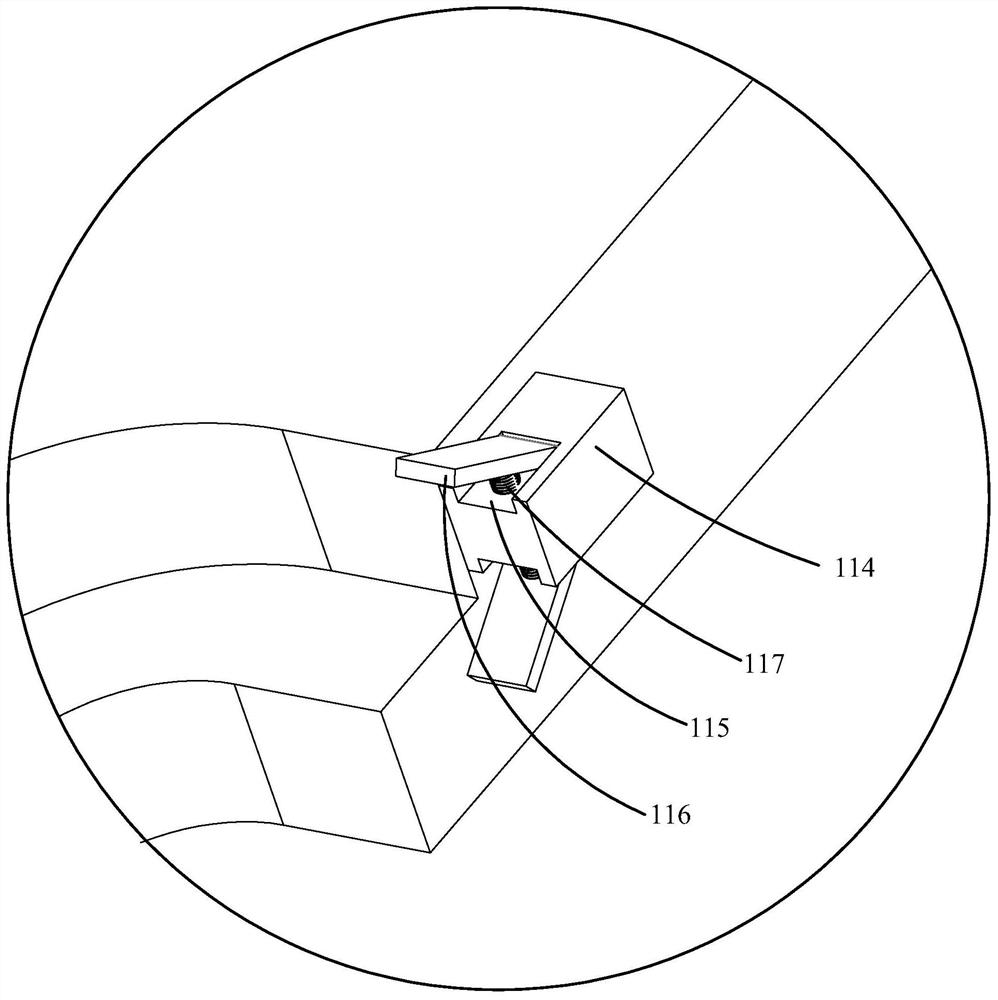

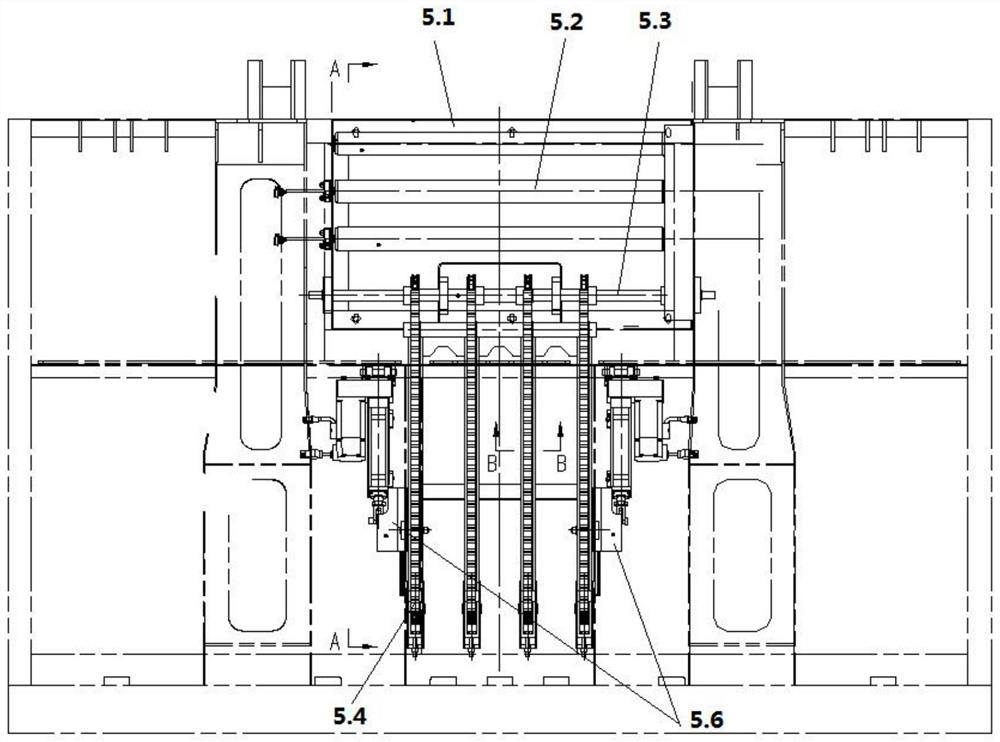

Roller conveyor line

The invention provides a roller conveyor line. The roller conveyor line comprises a steel structure on which an isolation plate is arranged, a chain transfer and lifting device arranged in the middleof the steel structure, lifting shear fork structures arranged on the two sides of a roller area, a telescopic shear fork structure vertically arranged at the upper end of the lifting shear fork structure, and a roller structure comprising an electric roller and a conveying roller. The roller conveyor line is applied to refrigerated container cargo loading and unloading equipment, and power is provided by an electric cylinder; the chain transfer and lifting device is used for reversing and conveying cargoes; the cargoes are drawn onto a roller from a stacking state through the shear fork structure in a whole-layer mode, and the roller conveyor line can adapt to various occasions; and the loading and unloading efficiency is improved.

Owner:CRRC ZHUZHOU ROLLING CO LTD

Cargo loading and unloading equipment for railway vehicle

PendingCN114834920ALoading and unloadingQuickly strengthen and seal the carRailway transportLoading/unloadingCargo handling gearCar door

The invention relates to the technical field of loading and unloading equipment, in particular to cargo loading and unloading equipment for railway vehicles, which comprises a loading and unloading mechanism, and a welding mechanism is fixedly arranged at the top of the loading and unloading mechanism. According to the loading and unloading device for the railway box car, a first servo motor in the loading and unloading mechanism can drive a first screw rod to rotate, so that a moving block can be driven to move on a moving base, a conveying platform can be driven to move, the conveying platform can stretch into the railway box car, and goods can be conveniently loaded, unloaded and transported through the conveying platform; the moving block and the conveying platform are driven to translate back and forth, and the rotating plate can rotate under the extrusion of the two extrusion springs, so that the rotating plate is in an upright state under the limiting of the baffle plate, the rotating plate can be parallel to the car door of the railway box car, and a welding mechanism is conveniently utilized to perform steel wire welding on the door knob on the car door of the railway box car; therefore, loading and unloading equipment can conveniently and quickly reinforce and seal the boxcar door after loading and unloading goods.

Owner:HUNAN VOCATIONAL COLLEGE OF RAILWAY TECH

A mobile robot for automatic loading and unloading of goods

ActiveCN107032141BFunctionalCompact structureWrapping material feeding apparatusWrapping with article rotationCargo handling gearRobot hand

The invention belongs to the field of cargo handling equipment and particularly discloses a mobile robot capable of achieving automatic cargo handling. The mobile robot comprises a mobile platform, a grabbing mechanism, a conveying mechanism, a pallet exchanging mechanism and a film winding mechanism, wherein the grabbing mechanism comprises a front manipulator and a rear manipulator, the conveying mechanism is arranged between the front manipulator and the rear manipulator, and the pallet exchanging mechanism comprises a rotating plate module; the film winding mechanism comprises a film drawing module, a film clamping module and a film cutting module, the film drawing module, the film clamping module and the film cutting module are installed on the mobile platform, the film drawing module carries out up-and-down motion relative to the mobile platform in the film winding process, the film clamping module is a split film clamping mechanism, the film clamping module is fixedly connected with the rotating table module and rotates along with the rotating table module in the film winding process, and the film clamping module is separated from the rotating table module after the film is wound; the film cutting module is used for cutting off the film. The mobile robot can effectively solve the problem that an existing cargo handing robot is difficultly applied to narrow spaces, and has the advantages of being small in overall size, convenient to operate, high in applicability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com