Freight Handling Apparatus

a technology for handling equipment and cargo, applied in the field of cargo systems, can solve the problems of insufficient time and physical effort, insufficient labor intensity, and difficulty in filling orders in this manner, and achieve the effect of facilitating lifting and transporting, and facilitating transportation of the portable floor surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

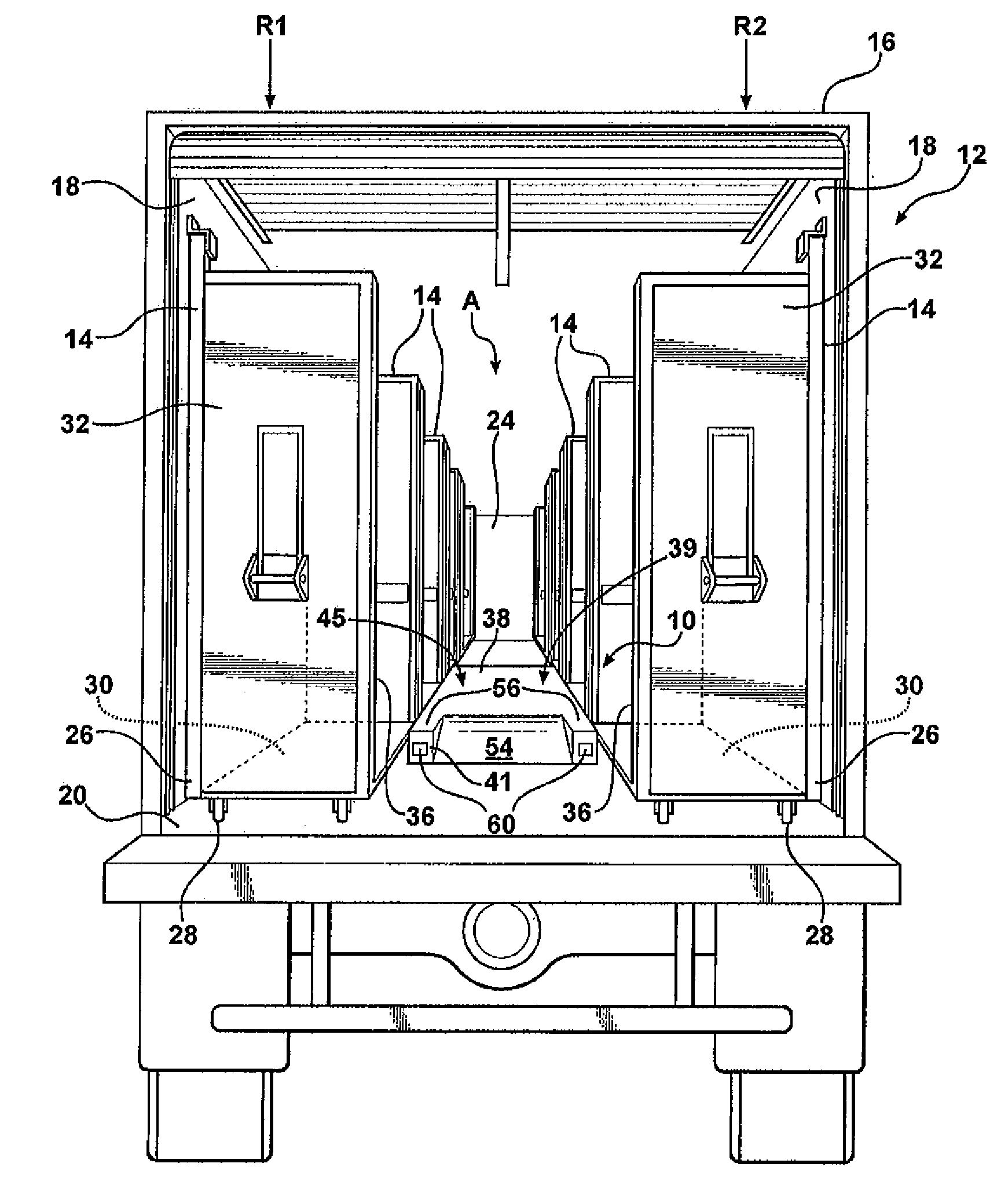

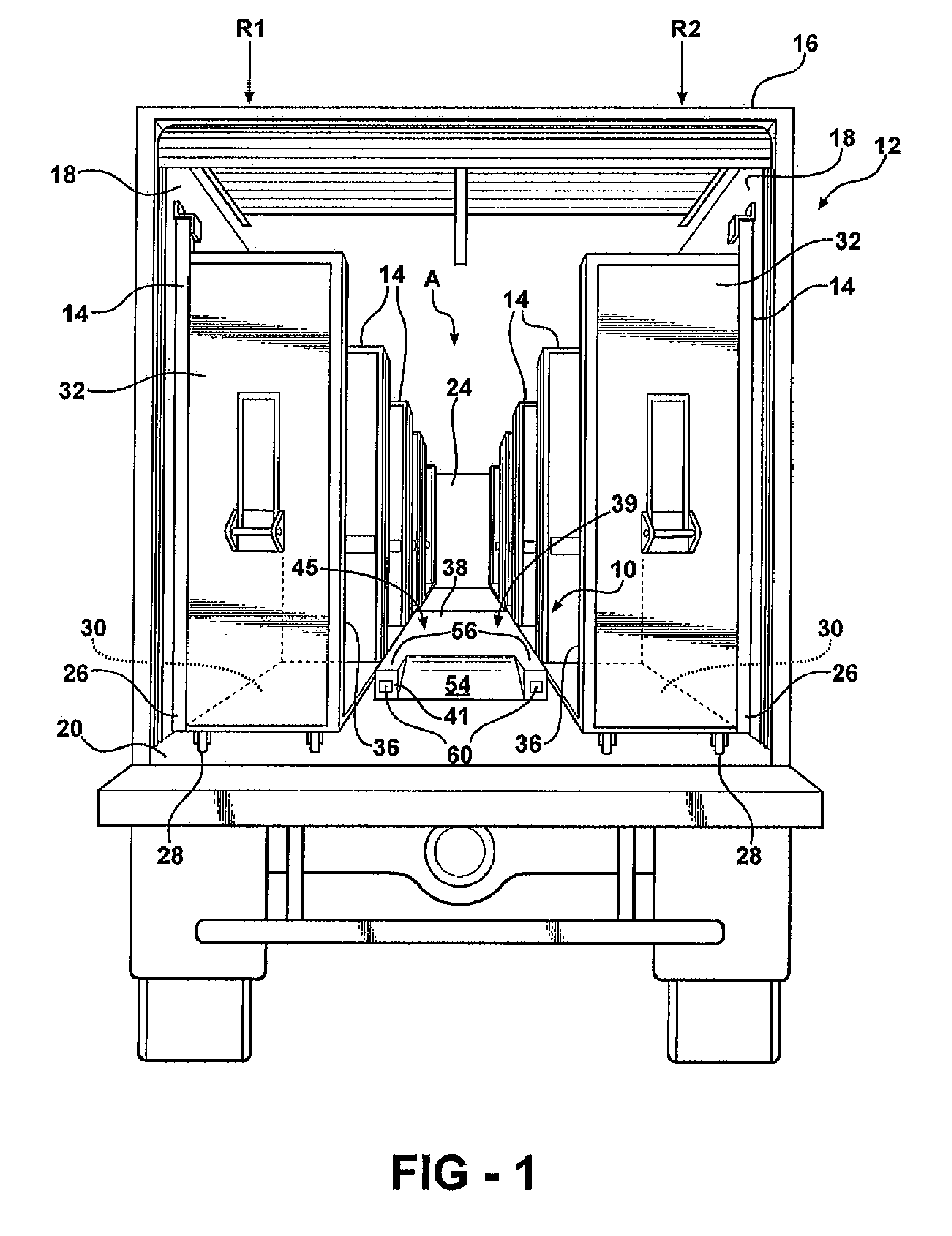

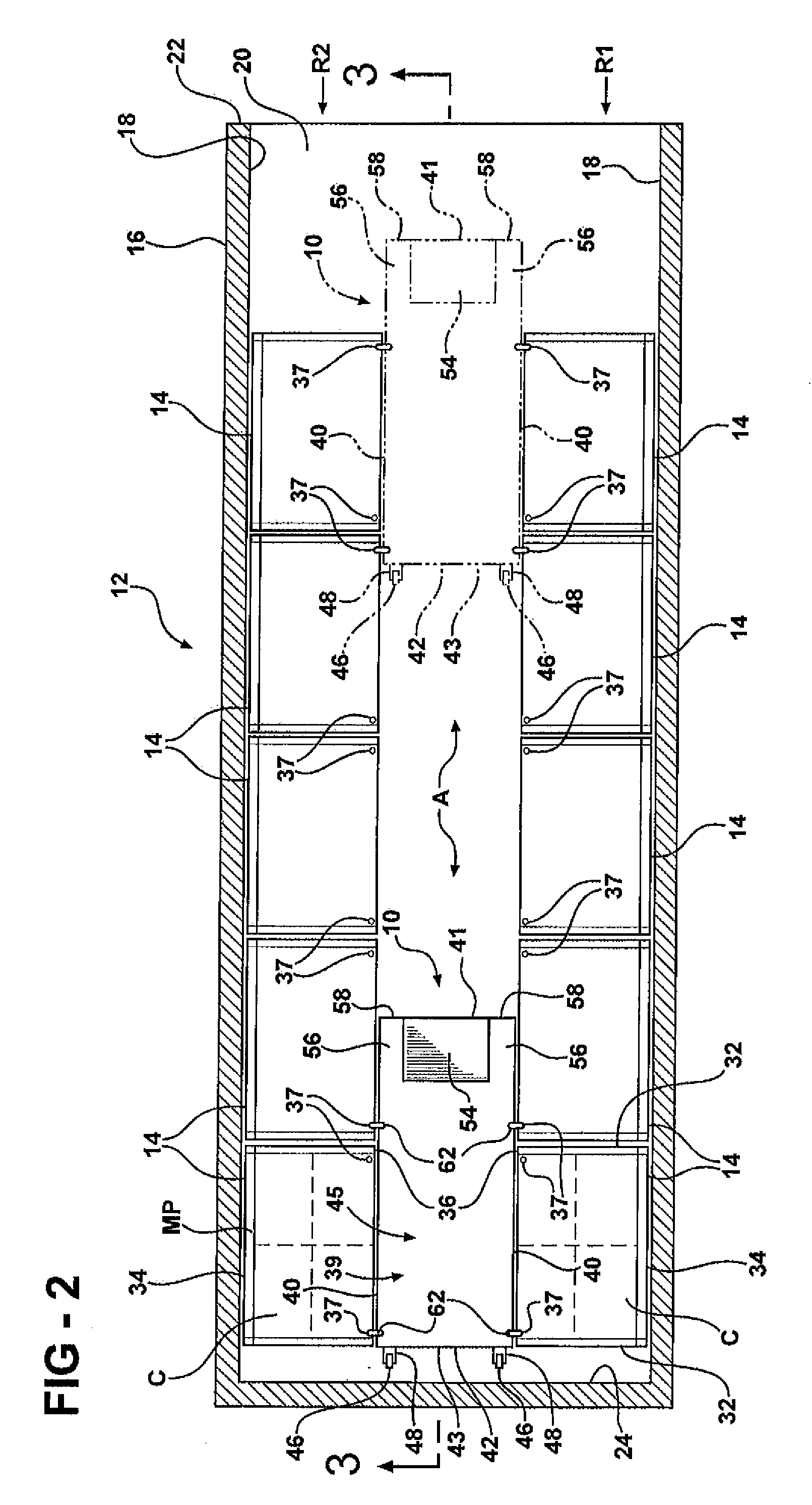

[0021]Referring in more detail to the drawings, FIGS. 1-5 illustrate a transport cart system or freight handling apparatus constructed according to one presently preferred embodiment having a portable floor surface, referred to hereafter as a platform or false floor 10. The false floor 10 is particularly suited for use with a product support and delivery system such as shown generally at 12 in FIGS. 1-4, and 5A, and disclosed in U.S. Pat. No. 6,520,515 to Krawczyk, incorporated herein by reference in its entirety, and which is assigned to Magline, Inc., the assignee of applicants' invention herein. In one aspect, the system 12 includes a plurality of wheeled modules, containers, or carts 14 that can be positioned side-by-side within an interior of a transportation vehicle, such as an enclosed trailer or van 16, for example. The carts 14 are preferably positioned on a floor 20 along opposite sidewalls 18 of the van 16 in longitudinally extending rows R1, R2 (FIGS. 1 and 2). The rows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com