Cargo loading and unloading equipment for road transportation

A technology for cargo handling and equipment, applied in the direction of lifting devices, etc., can solve the problems of easy collision, increased labor costs, and inconvenient observation of obstacles ahead, and achieve the effects of avoiding falling, easy operation, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

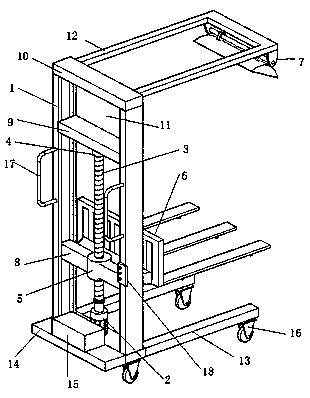

[0034] Such as Figure 1-4 As shown, a cargo handling equipment for road transport includes a vehicle chassis 13, the upper end of the vehicle chassis 13 is welded with a stand 1 and a drive motor 2, and the number of stand 1 is 2, and they are symmetrically distributed on the drive On both sides of the motor 2, the output end of the driving motor 2 is connected with a screw 3 through a coupling, the top of the screw 3 is provided with a bearing seat 4, the outer wall of the screw 3 is threaded with a screw sleeve 5, and the outer wall of the screw sleeve 5 is integrally formed with The connection seat 8, the two ends of the connection seat 8 and the stand 1 are slidingly connected, the front side wall of the connection seat 8 is welded with the loading frame 6; the inside of the stand 1 is also fixed with a beam 9, and the top of the stand 1 is fixed There is a top beam 10, an observation port 11 is formed between the cross beam 9 and the top beam 10, a horizontal frame 12 is...

Embodiment 2

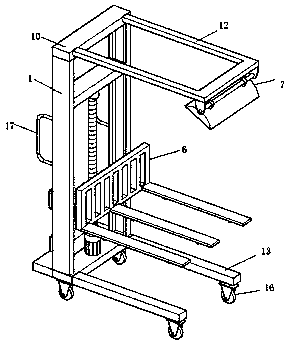

[0037] Such as Figure 1-3 with Figure 5 As shown, a cargo handling equipment for road transport includes a vehicle chassis 13, the upper end of the vehicle chassis 13 is welded with a stand 1 and a drive motor 2, and the number of stand 1 is 2, and they are symmetrically distributed on the drive On both sides of the motor 2, the output end of the driving motor 2 is connected with a screw 3 through a coupling, the top of the screw 3 is provided with a bearing seat 4, the outer wall of the screw 3 is threaded with a screw sleeve 5, and the outer wall of the screw sleeve 5 is integrally formed with The connection seat 8, the two ends of the connection seat 8 and the stand 1 are slidingly connected, the front side wall of the connection seat 8 is welded with the loading frame 6; the inside of the stand 1 is also fixed with a beam 9, and the top of the stand 1 is fixed There is a top beam 10, an observation port 11 is formed between the cross beam 9 and the top beam 10, a horizo...

Embodiment 3

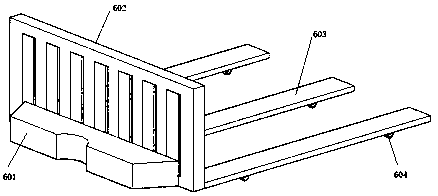

[0040] Such as Figure 6-7 As shown, a cargo handling equipment for road transport includes a vehicle chassis 13, the upper end of the vehicle chassis 13 is welded with a stand 1 and a drive motor 2, and the number of stand 1 is 2, and they are symmetrically distributed on the drive On both sides of the motor 2, the output end of the driving motor 2 is connected with a screw 3 through a coupling, the top of the screw 3 is provided with a bearing seat 4, the outer wall of the screw 3 is threaded with a screw sleeve 5, and the outer wall of the screw sleeve 5 is integrally formed with The connection seat 8, the two ends of the connection seat 8 and the stand 1 are slidingly connected, the front side wall of the connection seat 8 is welded with the loading frame 6; the inside of the stand 1 is also fixed with a beam 9, and the top of the stand 1 is fixed There is a top beam 10, an observation port 11 is formed between the cross beam 9 and the top beam 10, a horizontal frame 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com