Small stepped type natural mating breeding equipment for breeding poultry

A technology of small ladder and bird base, which is applied in the poultry industry, poultry cages or houses, applications, etc., can solve the problems of high environmental requirements, increased heating costs, and increased civil construction or reconstruction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

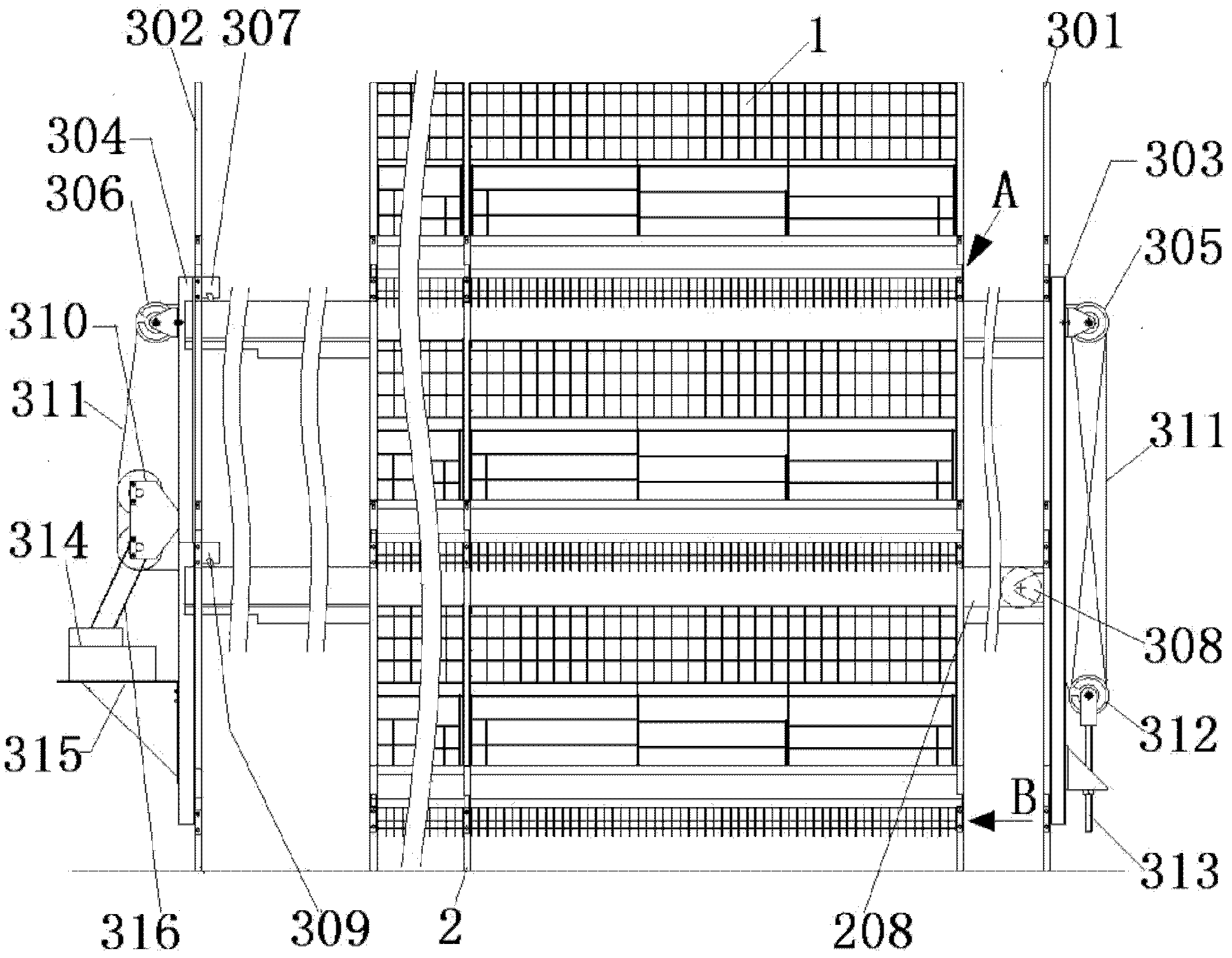

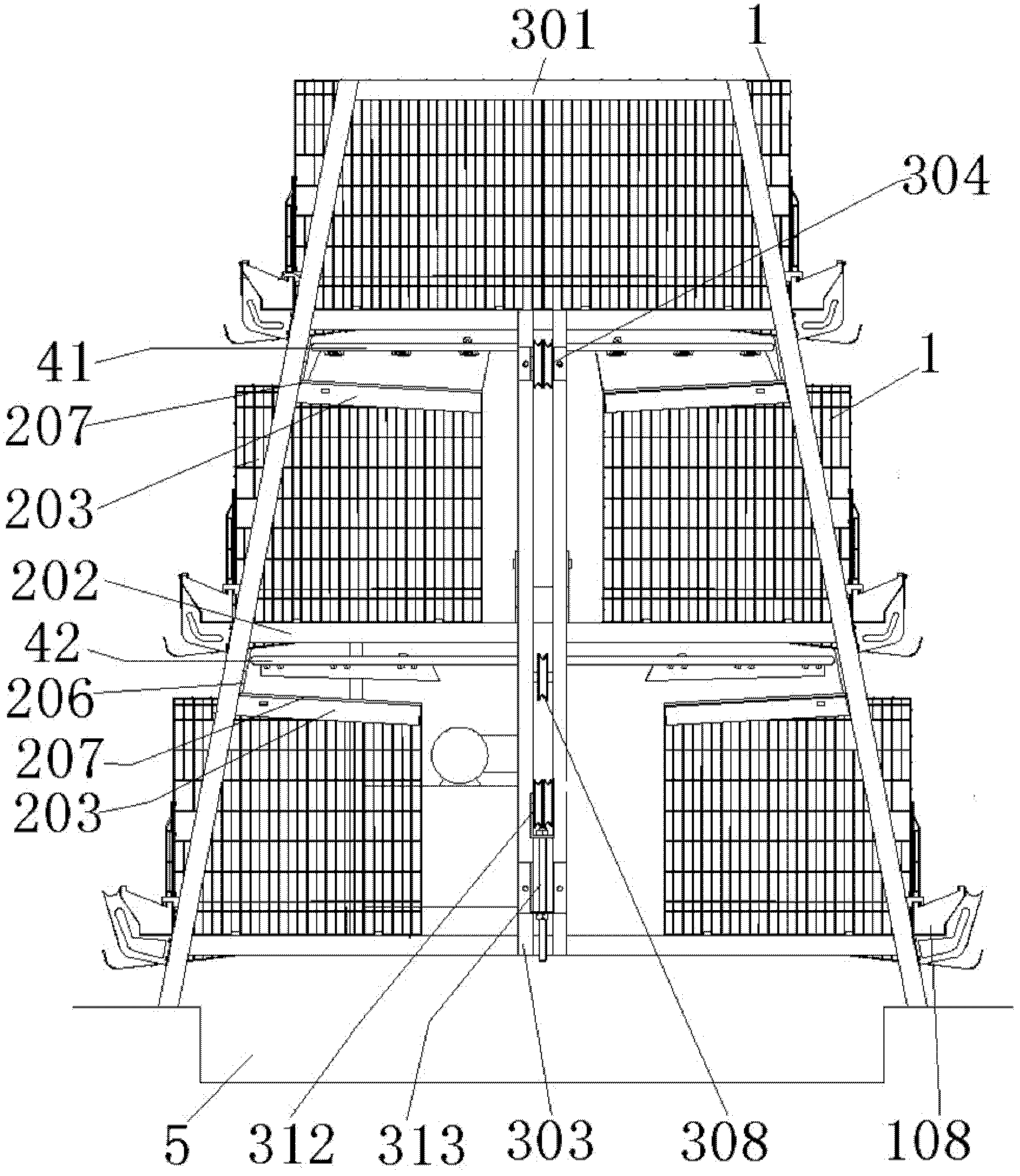

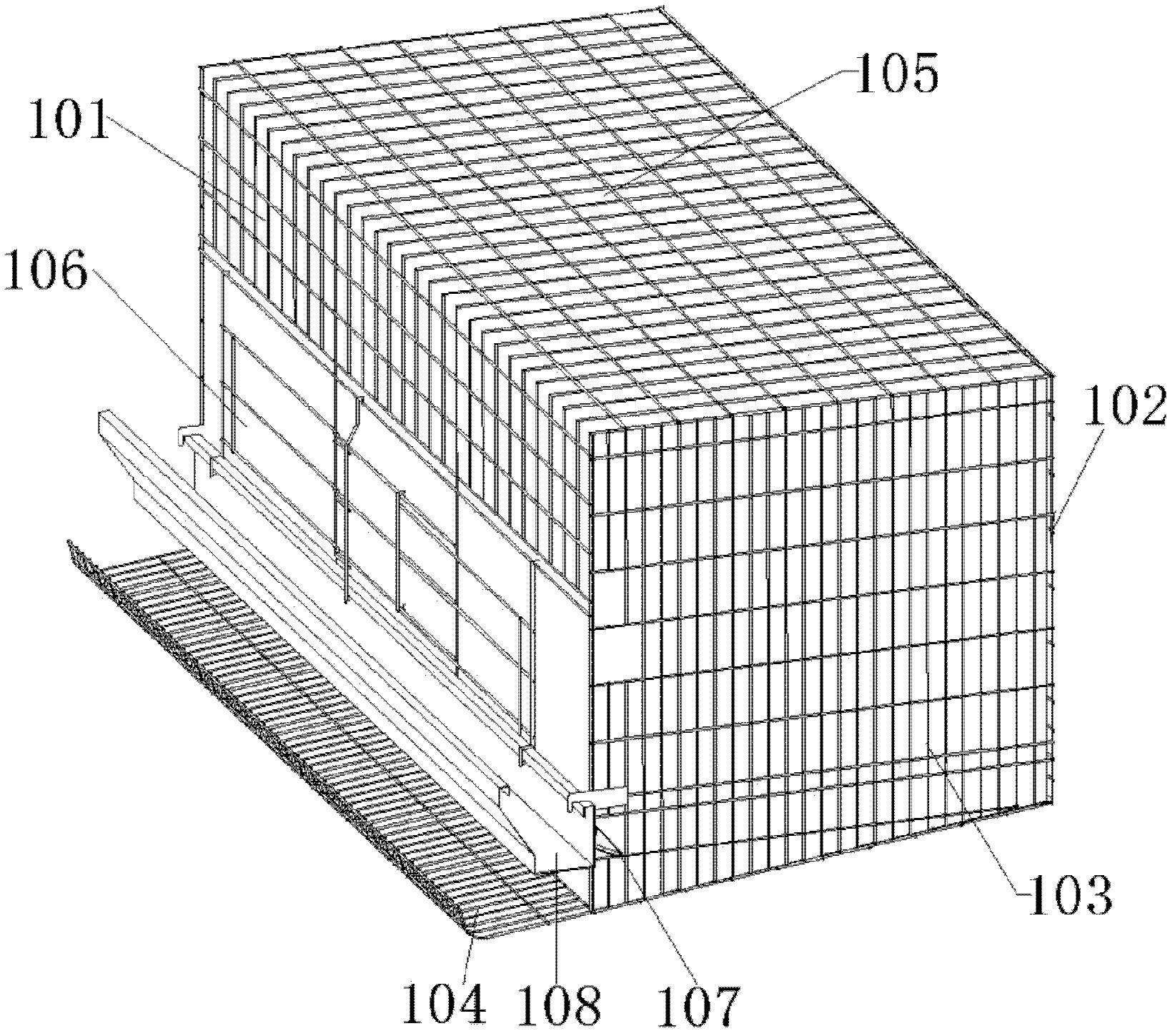

[0044] figure 1 and figure 2 They are the front view schematic diagram and the right view schematic diagram of the embodiment of the small-step breeding poultry breeding equipment, respectively. The small-step breeding poultry breeding equipment includes a small-step breeding cage and a manure cleaning device. The small stepped cage is composed of chicken cage 1 and trapezoidal cage frame 2. The cage frame braces 201 and cage frame beams 202 form a 3-layer trapezoidal cage frame 2, and each layer has 2 chicken cages 1 stuck in 2 trapezoidal cages. Between the same-layer cage beams 202 of the cage frame 2, the horizontal hanging wires at the bottom of the left and right side nets 103 of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com