Method for preventing goaf air leakage during soft rock crack development coal seam mining of coal mine

A goaf and fissure technology, applied in mining equipment, earthwork drilling, filling, etc., can solve problems such as air leakage through air leaks, air leakage through fissures, and poor operation of the whole mine ventilation system, so as to avoid air leakage and ensure normal ventilation.

Inactive Publication Date: 2012-10-10

XUNYI HUHAO HEIGOU COAL IND

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under such geological conditions, the pressure of the mine along the upper and lower sides of the trough is obvious, resulting in coal wall slabs, resulting in loopholes and air leakage, and the large loose circle of surrounding rocks, resulting in serious air leakage from cracks, resulting in poor operation of the ventilation system of the mine.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

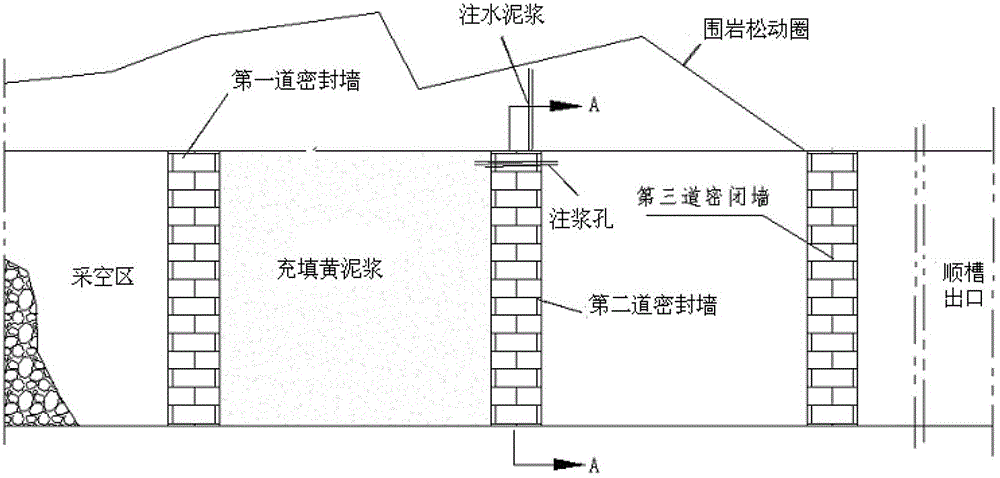

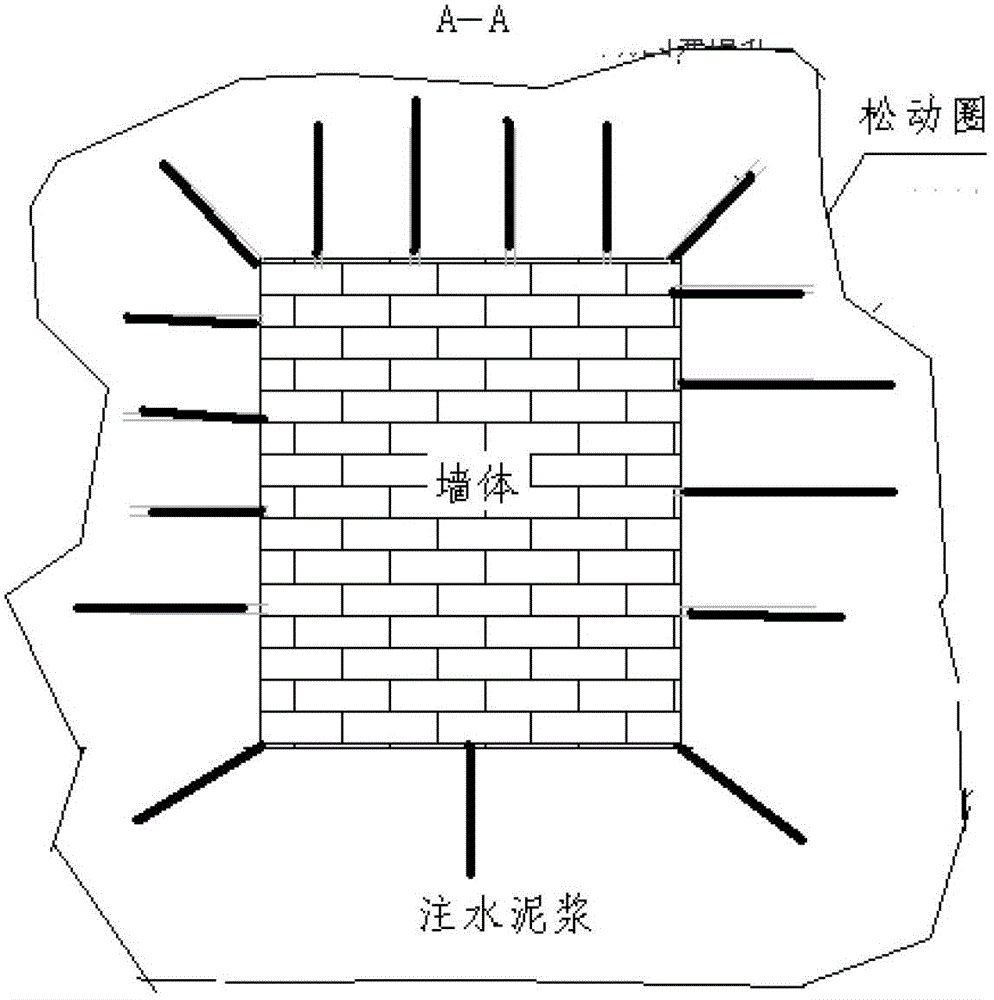

[0013] figure 1 and figure 2 Shows the situation when the present invention is implemented, according to Figure 1-2 The steps described in the technical solutions can be implemented by those skilled in the art, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preventing goaf air leakage during soft rock crack development coal seam mining of a coal mine. The method comprises the steps that firstly, a first sealing wall is built by loess and bricks in a position with the distance being 12m from a crossheading outlet, and then, a second sealing wall is built at a space being 4m; drill holes with the space being 1m are drilled above the second sealing wall, and in addition, the spaces of the first and second sealing walls are fully filled; then, slurry filling holes are dilled in a surrounding rock loosing circle on a cross section with the distance being 3m from the crossheading outlet, surrounding rock comprises a top plate, two sides and a bottom plate, and cement slurry is filled in the surrounding rock loosing circle; and next, a third sealing wall is built on the cross section for filling the surrounding rack crack, so the cross section and a fully filled surrounding rock body are combined into a whole. The method has the advantages that through the technical scheme, the wall caving of coal walls of three soft high-crack development coal layer roadways is avoided, the hole leakage and the air leakage are not generated, and the air leakage is also avoided after the full filling of the crack of the surrounding rock loosing circle, so the normal ventilation of the whole mine is ensured.

Description

Technical field: [0001] The invention relates to coal mining technology. Background technique: [0002] At present, in coal mining, when the mining is over, it is necessary to seal the abandoned upper and lower troughs with walls to prevent air leakage in the goaf and affect the ventilation of the whole mine. However, some coal mines belong to the typical three-soft and highly fractured coal seam, which is mainly characterized by soft floor, soft roof, soft coal seam, and obvious fracture development. Under such geological conditions, the mine pressure in the upper and lower troughs is obvious, causing coal wall slabs, resulting in air leakage through loopholes, and large loose circles in surrounding rocks, resulting in serious air leakage from cracks, resulting in poor operation of the ventilation system of the mine. Contents of the invention [0003] In order to solve the above air leakage problem, the present invention proposes a method for preventing air leakage in go...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F15/00

Inventor 杨志水臧德梁

Owner XUNYI HUHAO HEIGOU COAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com