Patents

Literature

132results about How to "Meet delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

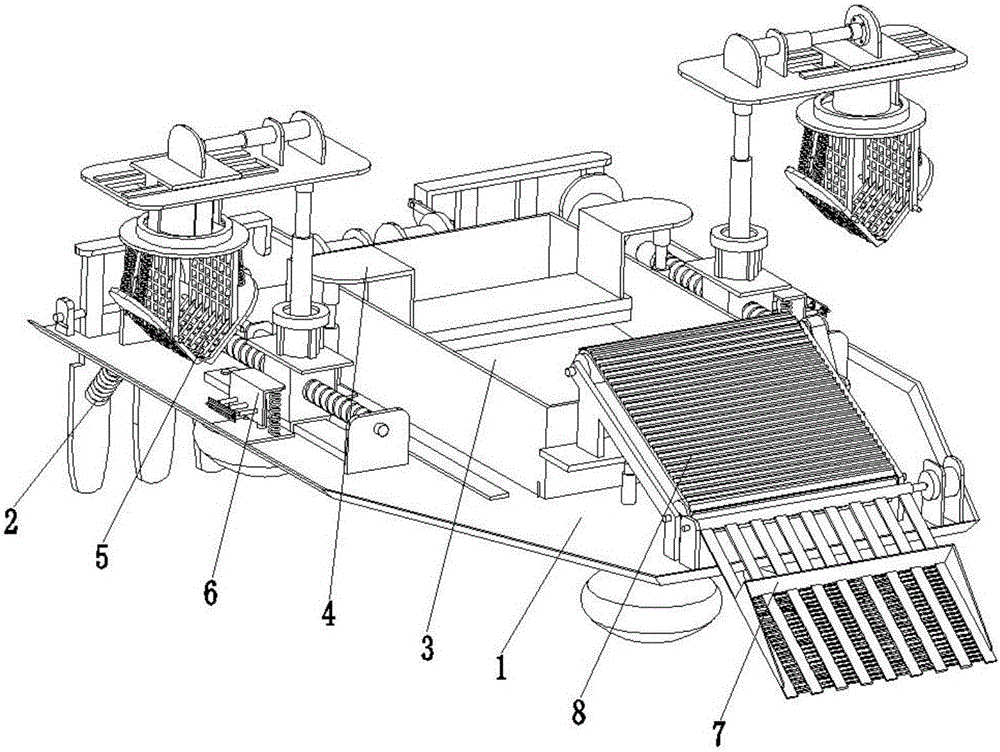

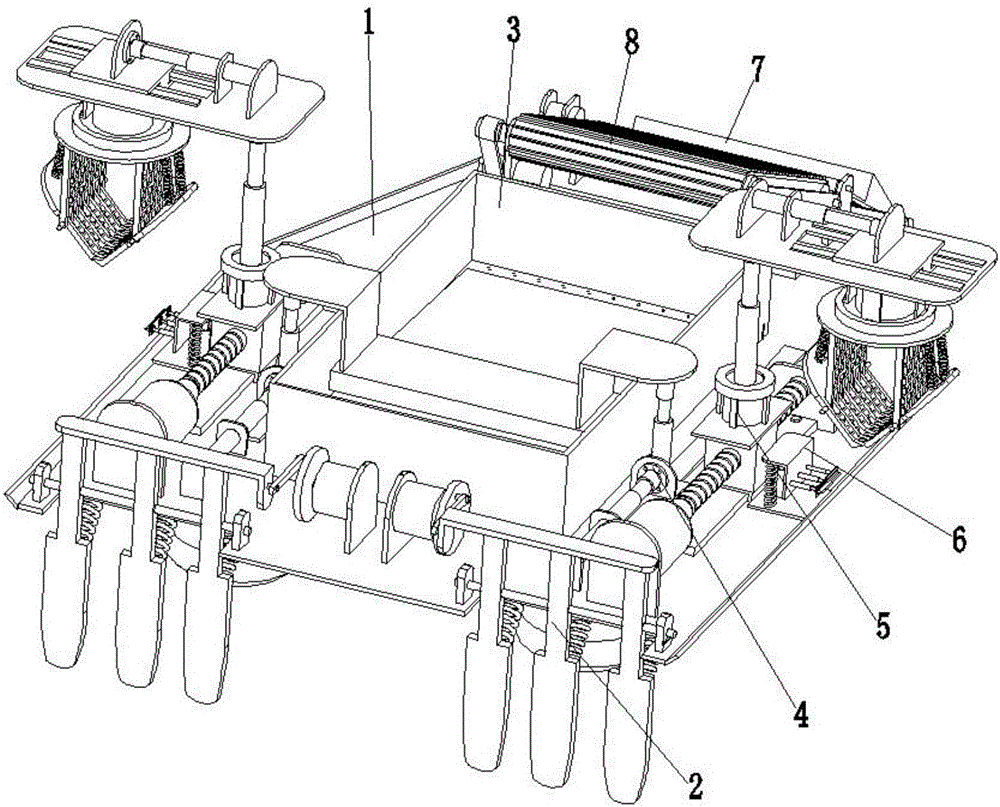

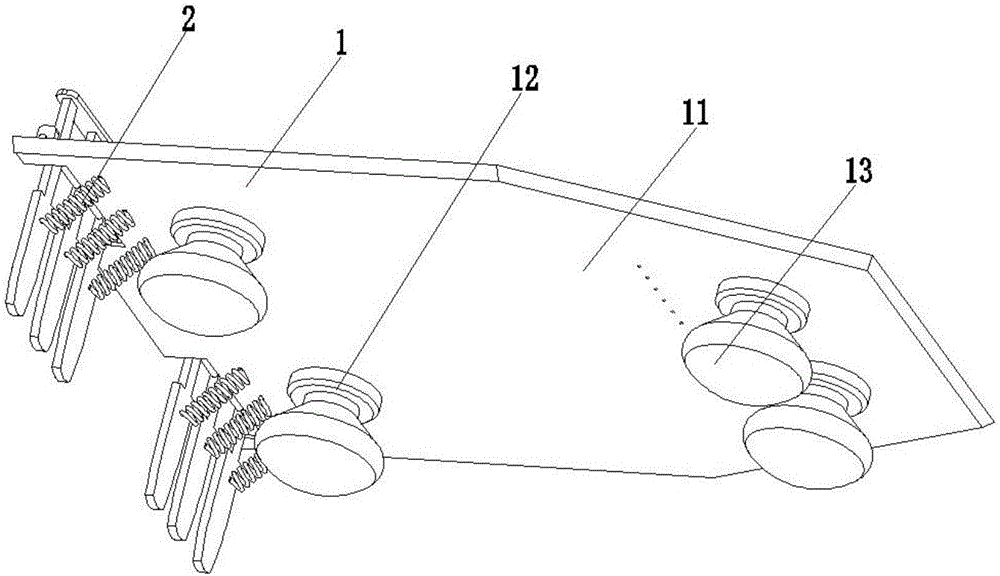

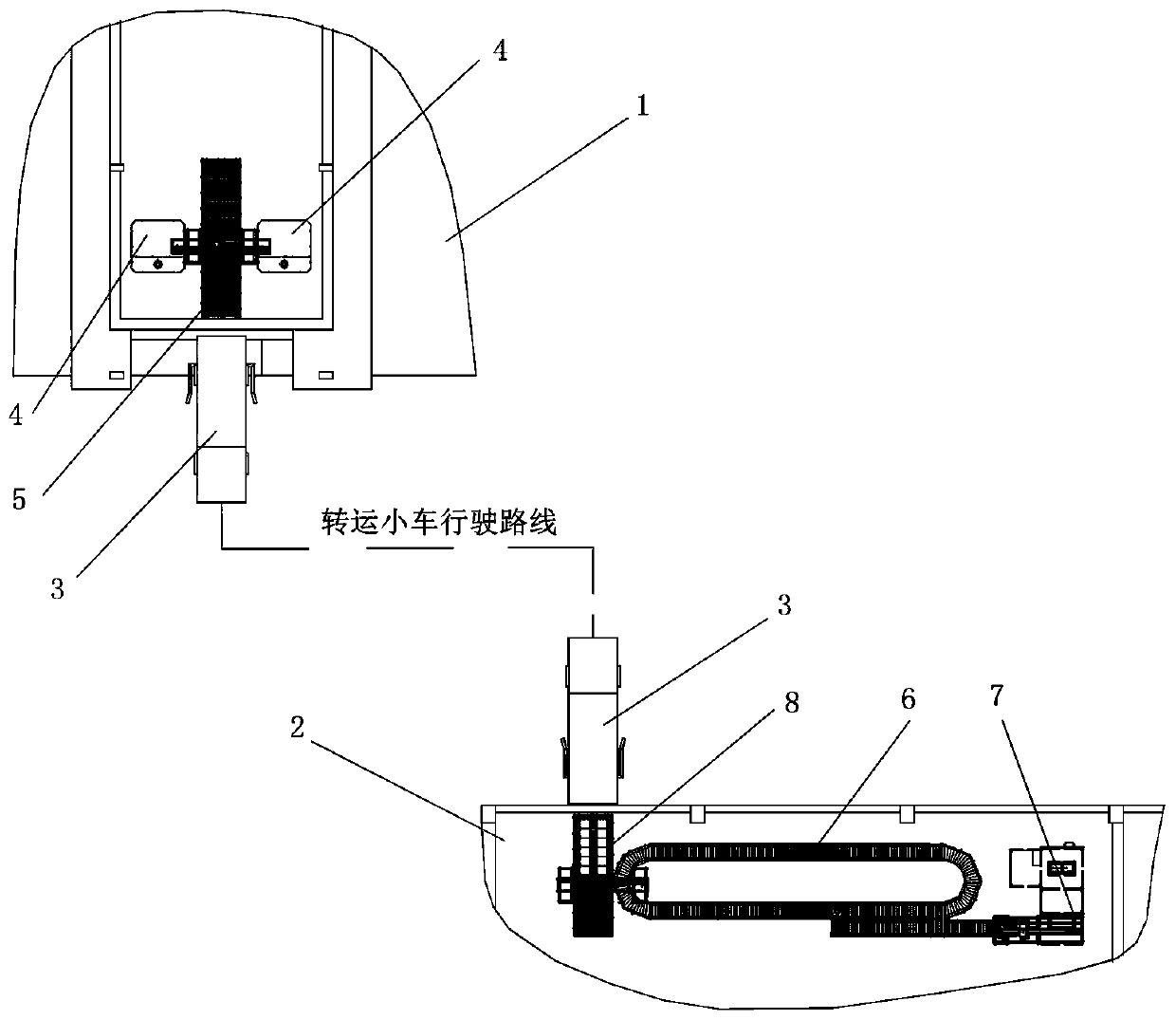

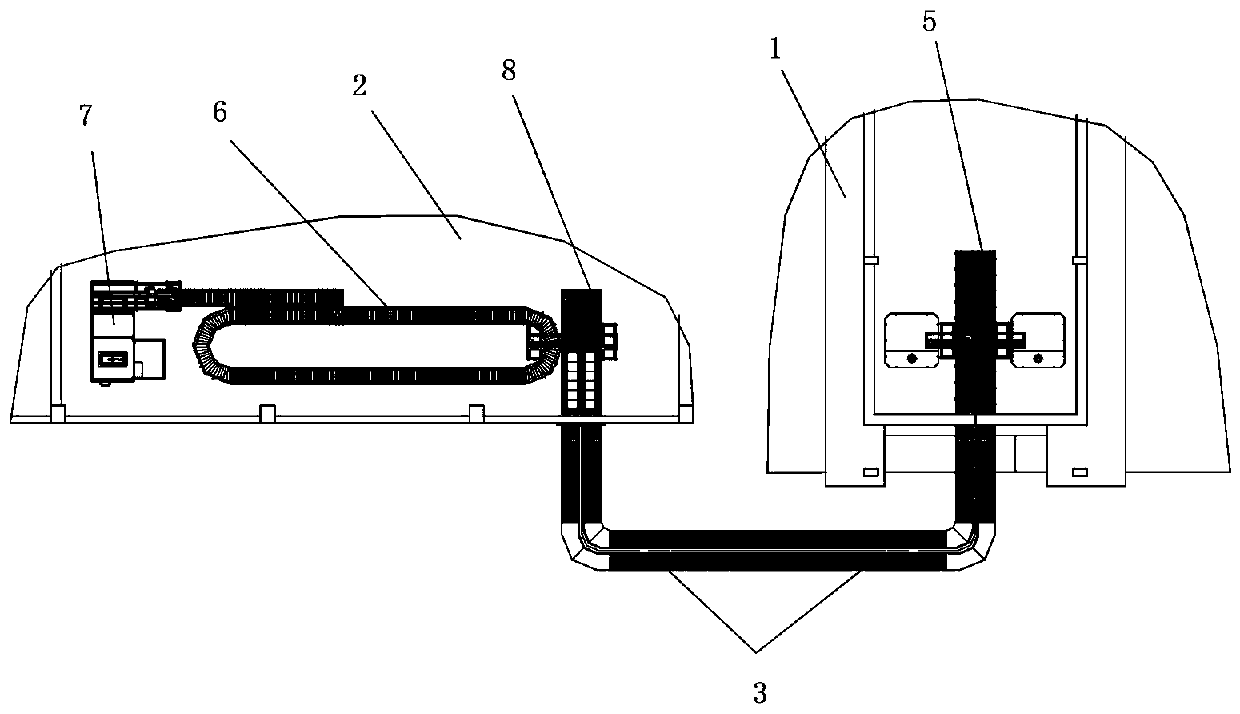

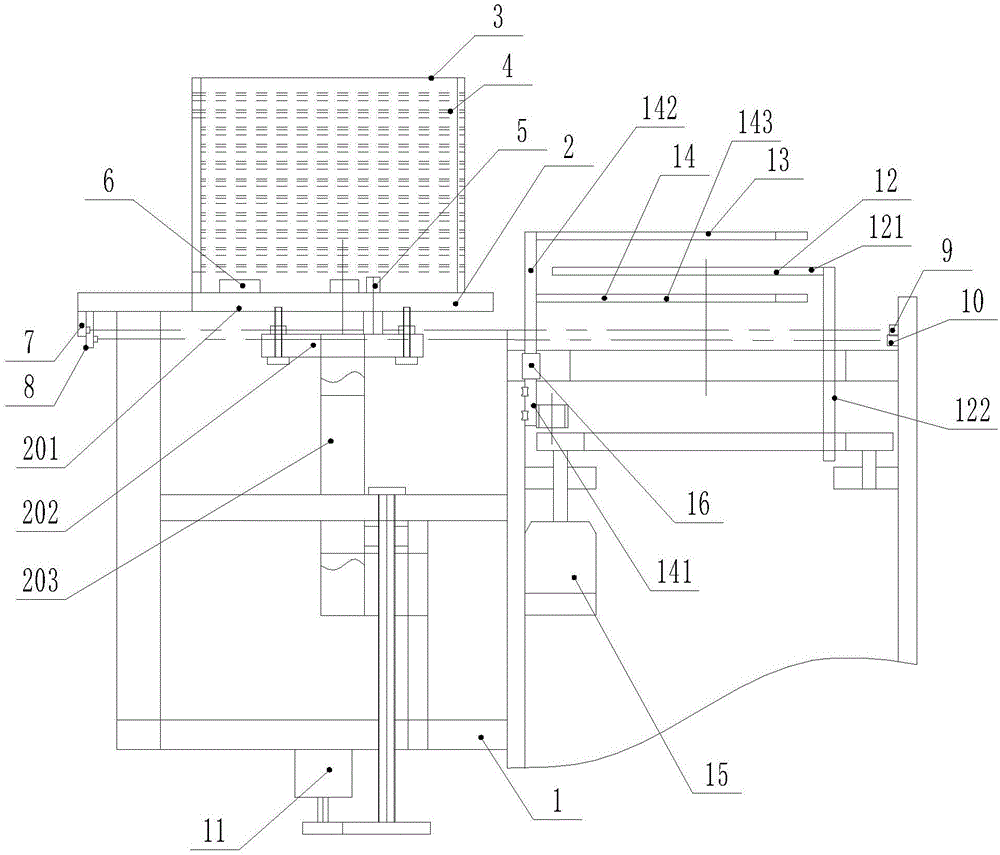

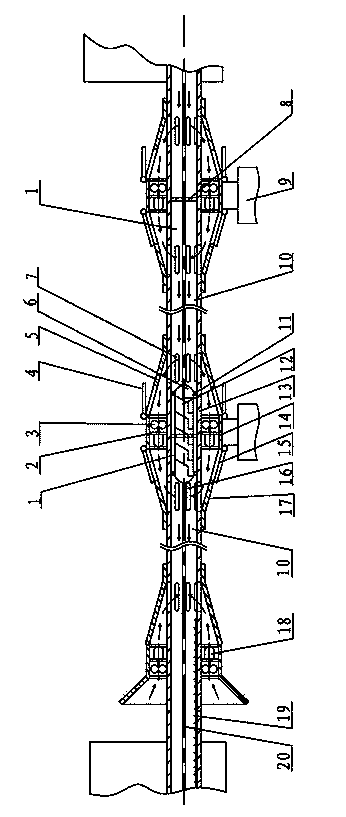

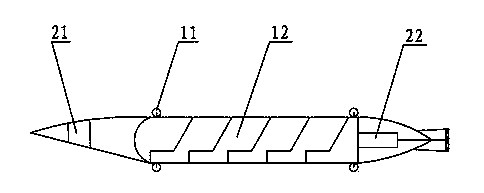

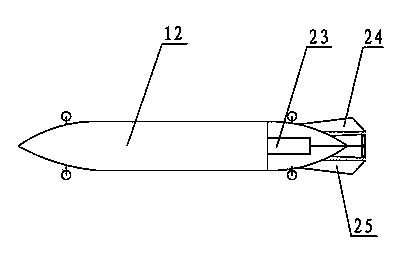

Environment-friendly type river and lake controlling and cleaning equipment

ActiveCN106759196APlay a dredging roleKeep water cleanWater cleaningWaterborne vesselsCompression deviceWater quality

The invention relates to environment-friendly type river and lake controlling and cleaning equipment. The environment-friendly type river and lake controlling and cleaning equipment comprises a boat body, power devices, a storage slot, a compression device, movable gripping devices, cut-off devices, a salvaging device and a conveying device, wherein the power devices are symmetrically mounted at the left side and the right side behind the boat body separately along the longitudinal central axis of the boat body; the compression device is positioned above the storage slot; the movable gripping devices are separately positioned at the left side and the right side of the compression device; the cut-off devices are positioned at the outer sides of the movable gripping devices; the salvaging device is positioned in front of the boat body; and the conveying device is positioned between the salvaging device and the storage slot. The environment-friendly type river and lake controlling and cleaning equipment integrates the functions of floating force adjusting, water-surface travelling, waste compacting, aquatic plant gripping, garbage salvaging, garbage conveying and the like, realizes the functions of eliminating aquatic plants in rivers and lakes as well as floating waste on the water surface, achieves the effect of dredging the rivers and the lakes, keeps water in the rivers and the lakes clean, is high in integral mechanical degree, is complete in function and is high in operating efficiency.

Owner:广东祥实建设有限公司

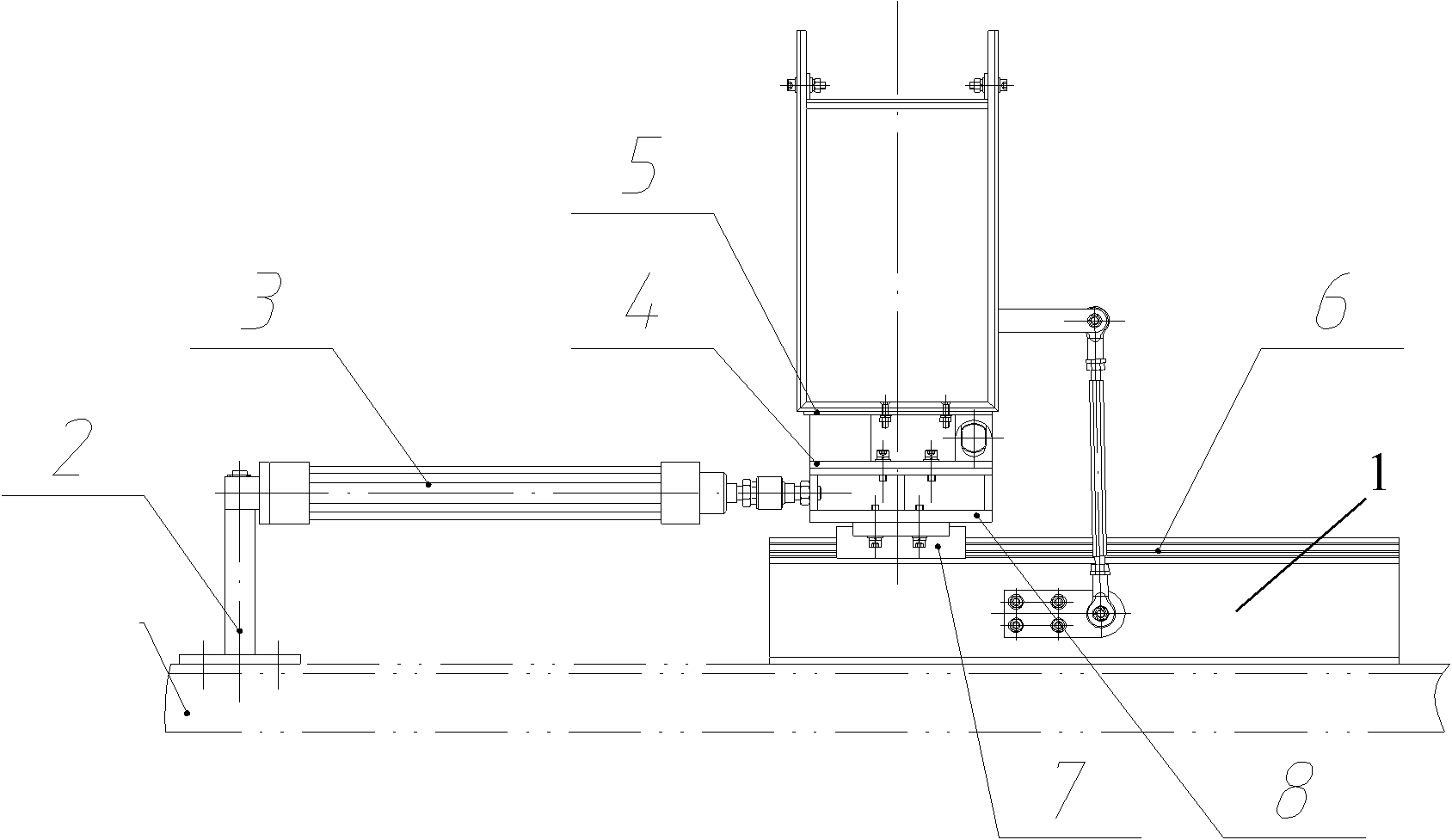

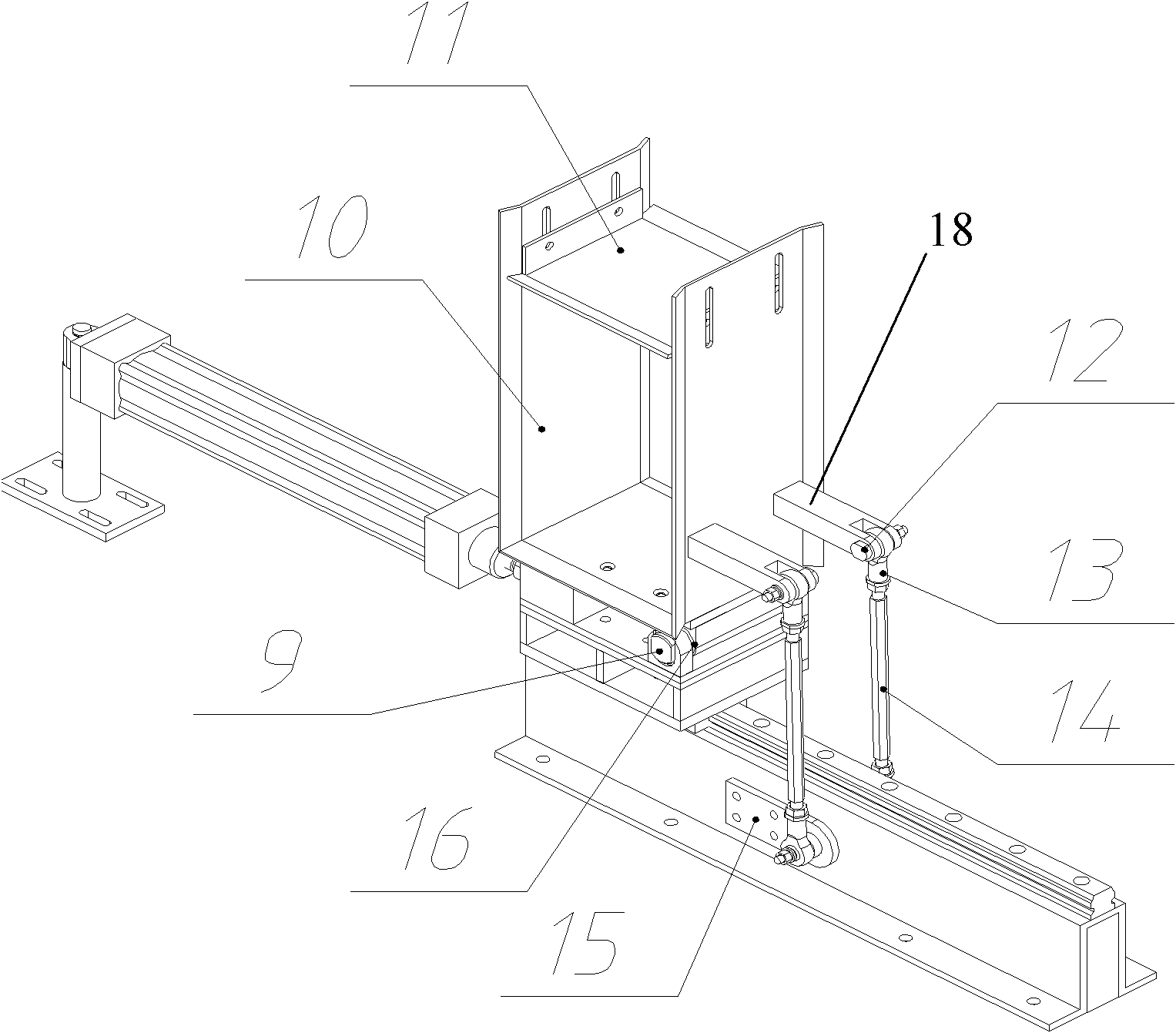

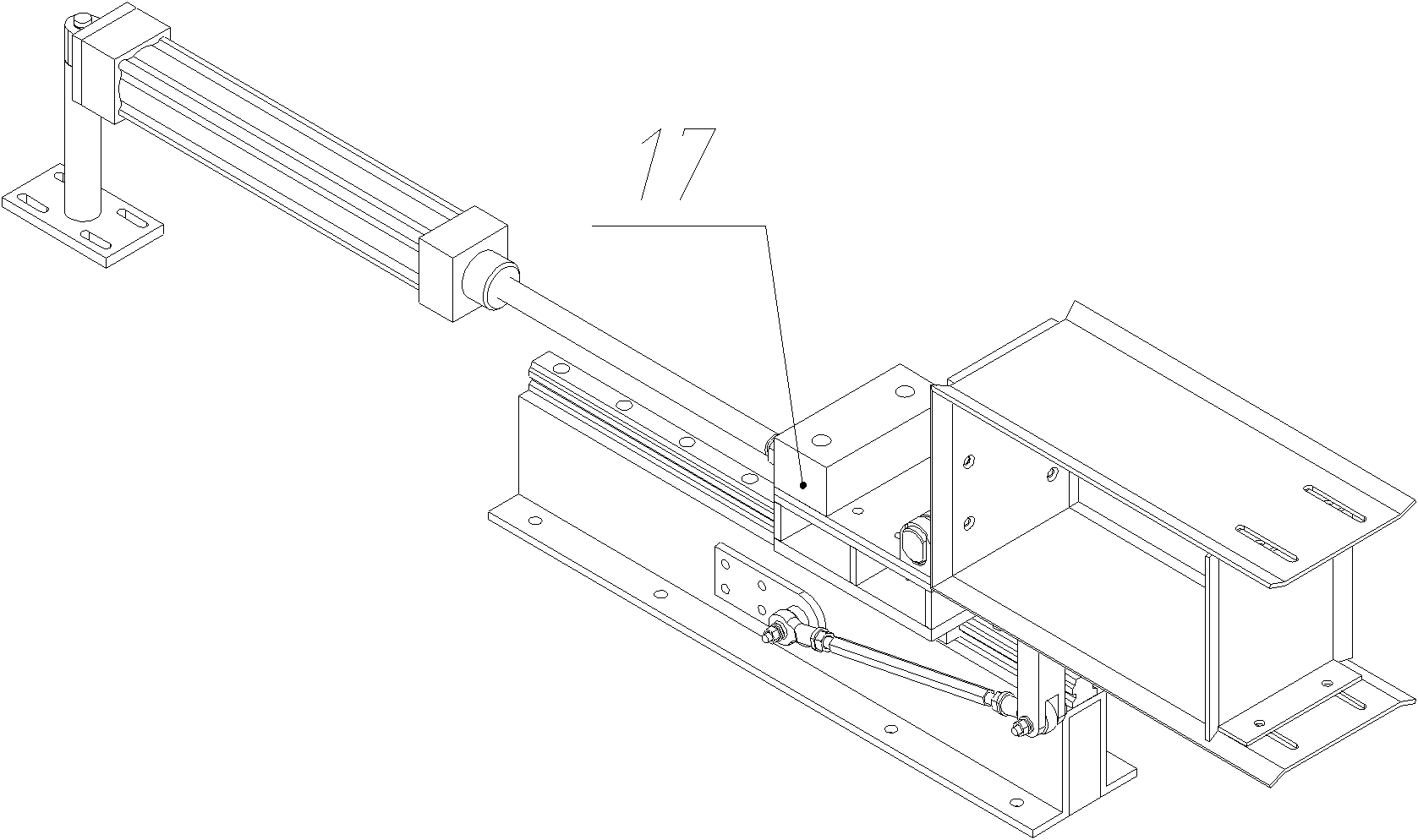

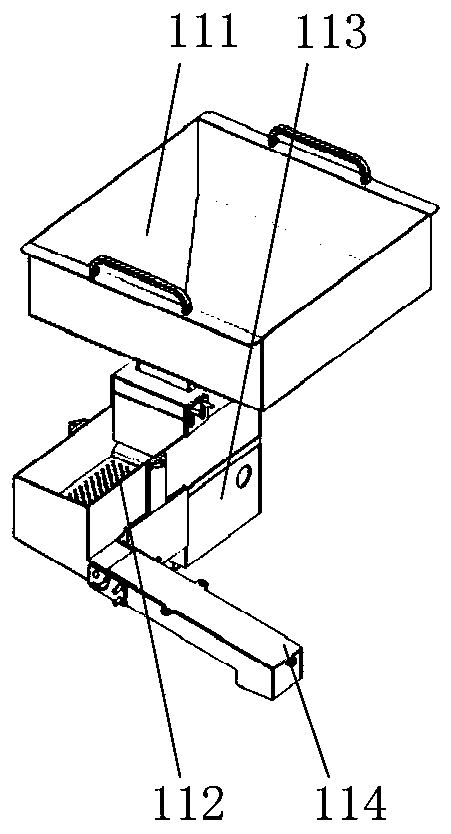

Transferring and turning device

ActiveCN101962121ACompact structureEasy maintenanceConveyor partsChutesTailstockComputer engineering

The invention relates to a transferring and turning device. The device mainly comprises a linear guide support, a tailstock stand, a cylinder, a fixing plate, a turning plate, a linear guide, a guide rail slider, a mobile stand, a rotating shaft, a transfer card, and a link mechanism, wherein the tail end of the cylinder is arranged on the tailstock stand; the head end of the cylinder is arranged on the mobile stand; the fixing plate is arranged on the mobile stand; the transfer card is arranged on the turning plate; the turning plate and the fixing plate are connected with each other through the rotating shaft; a linear guide is arranged on the linear guide support; the guide rail slider is sleeved on the linear guide and can slide in a reciprocating mode; the mobile stand is arranged on the guide rail slider; two connecting rod tailstocks of the link mechanism are symmetrically fixed on two sides of the linear guide support respectively; and the two fixed blocks of the link mechanism are fixed on the transfer card. The transferring and turning device has a compact, small, and simple structure, can be maintained and adjusted conveniently and occupies a small space. The transferring and turning device is driven by only one cylinder to transfer and turn a salt bag in the transfer card.

Owner:WUHAN RENTIAN PACKAGING TECH

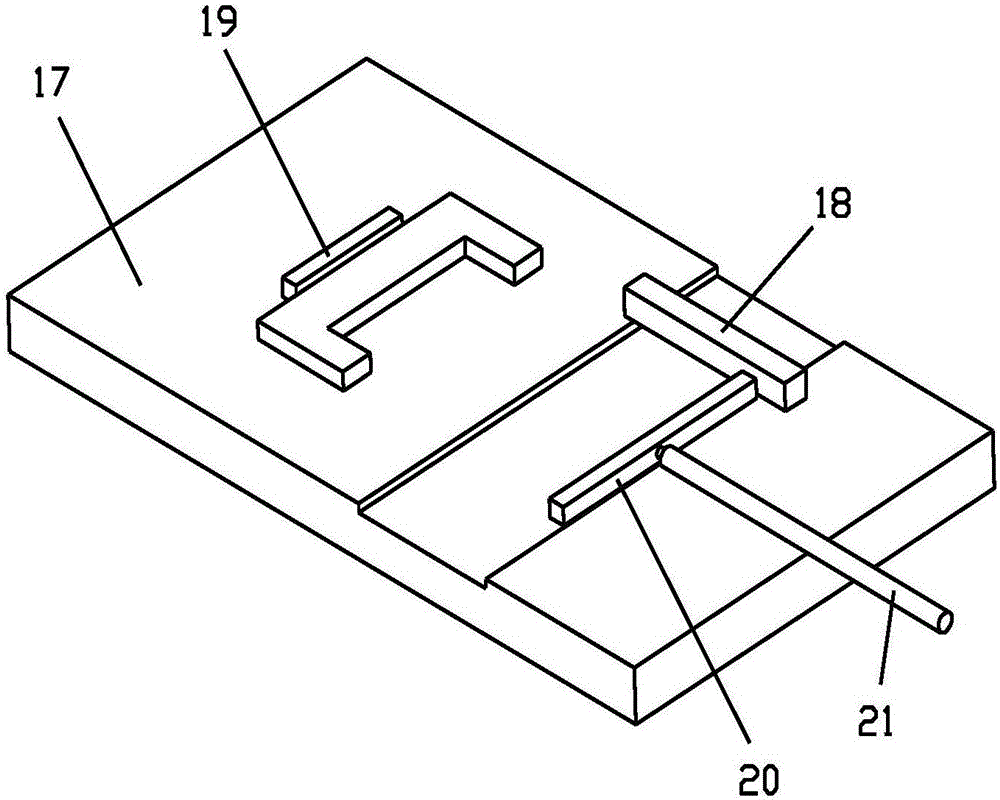

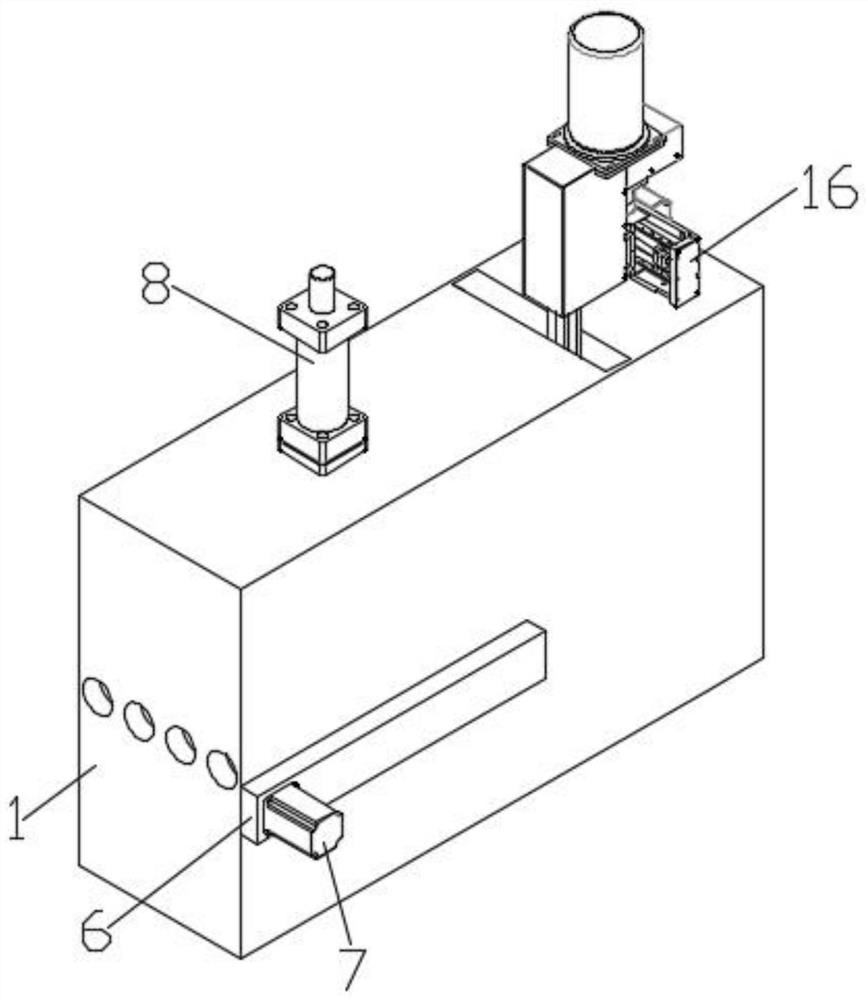

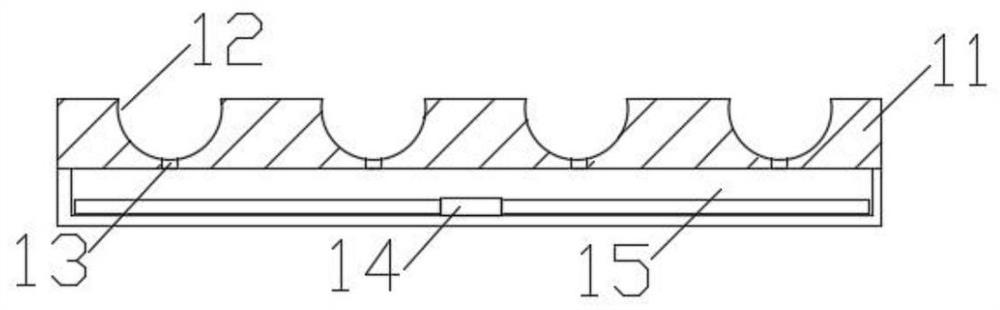

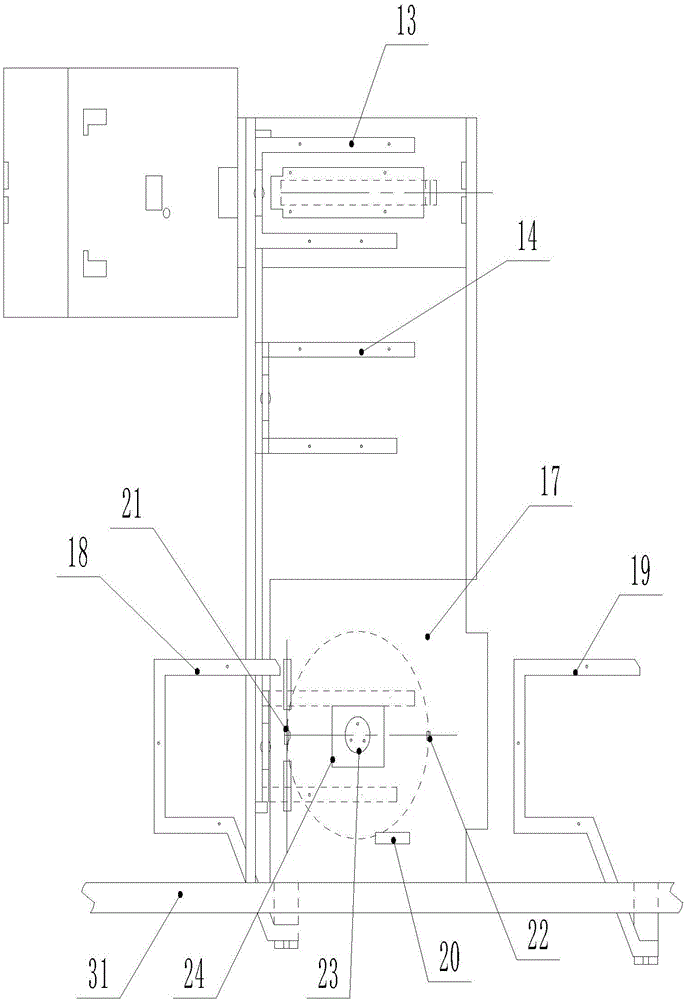

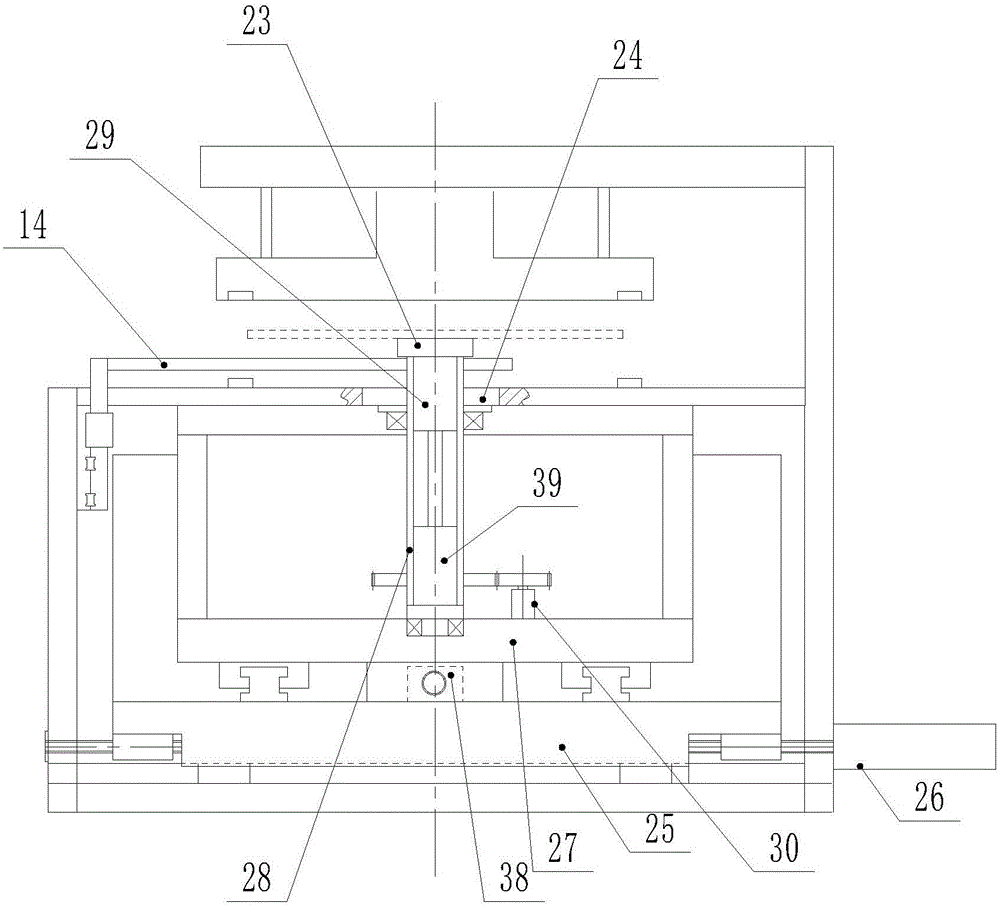

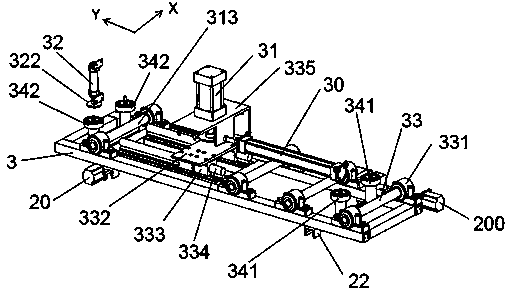

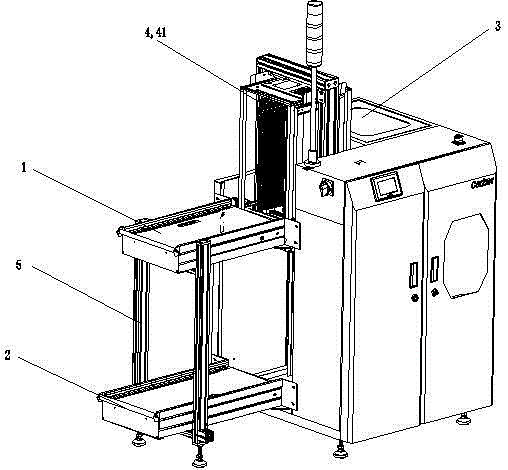

General automatic detection system of connector

ActiveCN106643490ASatisfy positioning and conveyingMeet deliveryUsing optical meansEngineeringPallet

The invention discloses a general automatic detection system of a connector. The system comprises a feeding conveyor belt, a feeding offset device, a visual detector and a blanking conveyor belt; and the visual detector comprises a horizontal detection platform, two linear guide rails, a connector holder pallet, a door-shaped support, a true position detector, a first flatness detector and a second flatness detector, wherein the linear guide rails are arranged on the horizontal detection platform in parallel, the connector holder pallet is arranged on a slide carriage of the linear guide rails, the door-shaped support is positioned in the middle portion of the horizontal detection platform and crosses the upper of the linear guide rails, the first flatness detector is arranged at the left side of the door-shaped support and detects the flatness of the connector, and the second flatness detector is arranged at the right side of the door-shaped support and detects the flatness of the connector. The general automatic detection system can carry out online shooting detection on different models of connectors, the detection accuracy is high, and the versatility is high.

Owner:成都宇航星科技有限公司

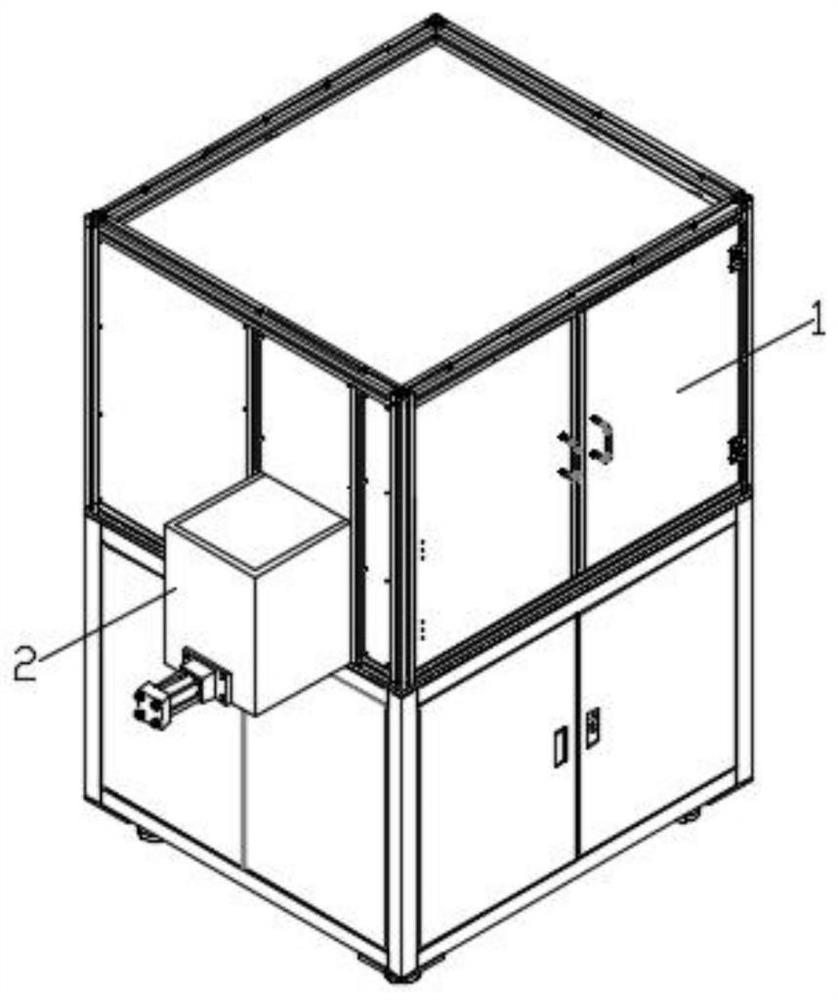

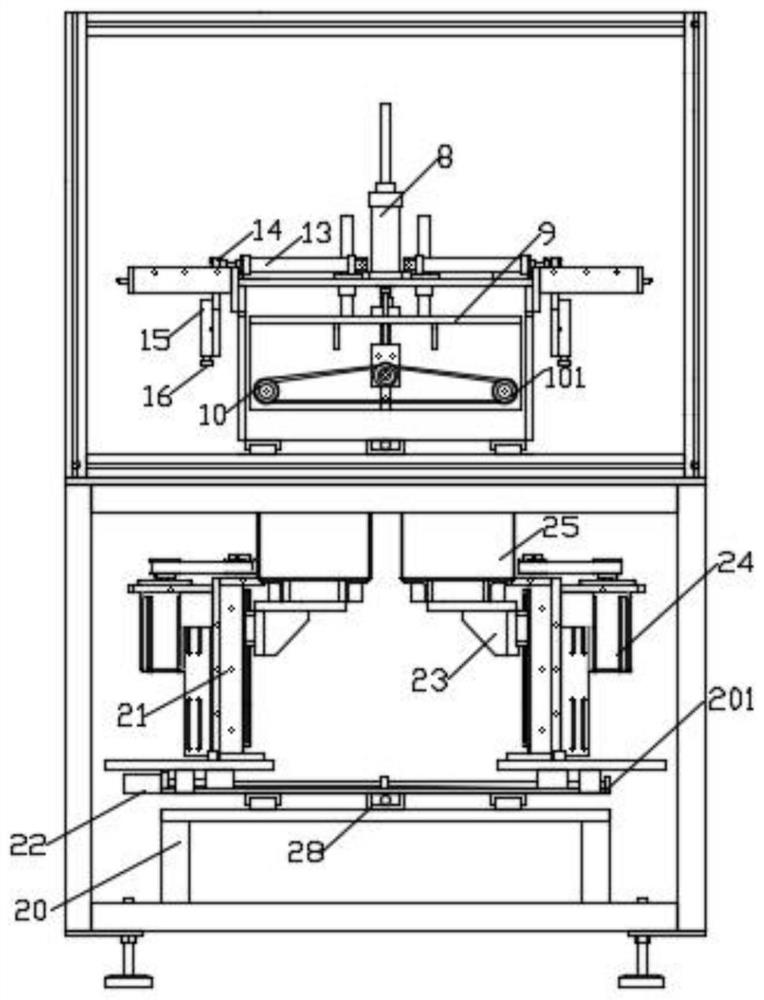

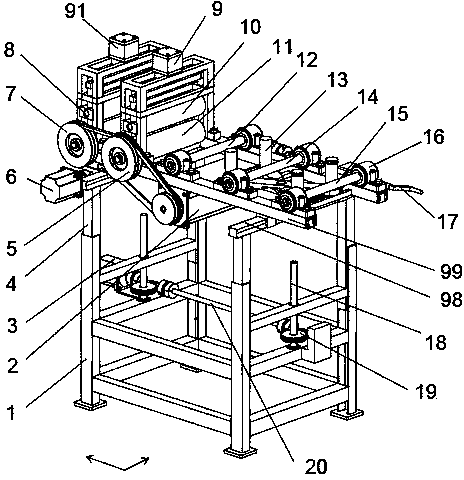

Polishing mechanism for wood board machining and working method thereof

ActiveCN111730472AMeet deliveryImprove convenienceGrinding carriagesGrinding drivesPolishingMachining

The invention discloses a polishing mechanism for wood board machining and a working method thereof. The polishing mechanism comprises a machining cabinet, and the machining cabinet comprises an uppercabinet body and a lower cabinet body; one side of the upper cabinet body is provided with a fixing box, the fixing box is internally provided with an idle cavity, the idle cavity communicates with the top of the fixing box, the side wall of the fixing box is provided with a first air cylinder, and the end of a piston rod of the first air cylinder is provided with a push plate strip; and the bottom of the upper cabinet body is provided with a supporting plate, a polishing frame is slidably installed on the supporting plate in the horizontal direction, and a second air cylinder is installed onthe polishing frame. According to the polishing mechanism, wood boards can be placed in the idle cavity in advance before the wood boards are polished, boards do not need to be charged temporarily when polishing needs to be conducted, and certain convenience is achieved; meanwhile, two adjustable conveying shells are arranged and can convey wood boards different in size, and the practicality is high; and by designing two disc hairbrushes which are adjustable in interval and can be horizontally adjusted in the same direction, and the removing efficiency of wood flour on the surface of the woodboards is greatly improved.

Owner:安徽纬奥特工艺品有限公司

Rolling wheel conveying type punching machine automatic feeding machine

ActiveCN104226838AMeet deliverySolve the laborious and time-consuming problem of manual feedingMetal-working feeding devicesPositioning devicesPunchingDrive motor

The invention provides a rolling wheel conveying type punching machine automatic feeding machine, which comprises a delivery wheel, wherein the delivery wheel is connected with a driving motor through a delivery belt, and is coaxially and fixedly connected with a lower rolling press wheel, the lower rolling press wheel is arranged on a conveying table of a machine frame, an upper rolling press wheel is arranged above the lower rolling press wheel, a plurality of feeding rolling shafts are arranged along the direction vertical to the plate material feeding direction on the conveying table of the machine frame, and at the feeding end of the conveying table, guide wheels are arranged at the two sides of the feeding direction. The distance between the two groups of guide wheels is regulated, boards are placed onto the conveying table and are moved to the punching processing position along the feeding rolling shafts, the upper rolling press wheel tightly presses the boards under the effect of an air cylinder, a punching machine works for punching and cutting the boards, after the punching, the air cylinder is reset, the upper rolling press wheel is upwards lifted, the processed plate materials are taken out, the operation is repeated in such a way, the boards are continuously fed, pressed, punched and cut, and the continuous punching can be realized.

Owner:桂林翔兆科技有限公司

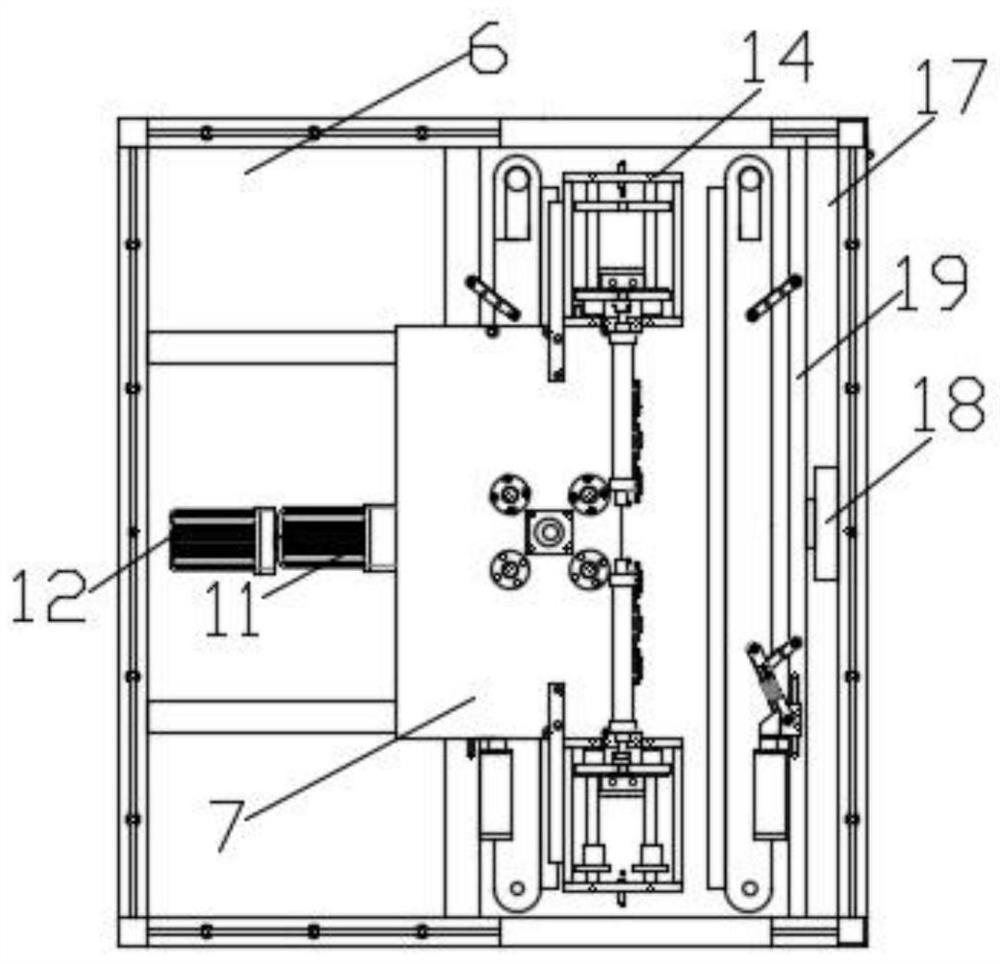

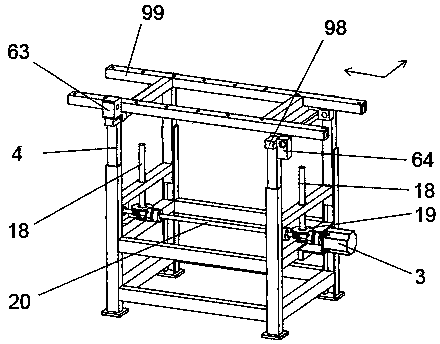

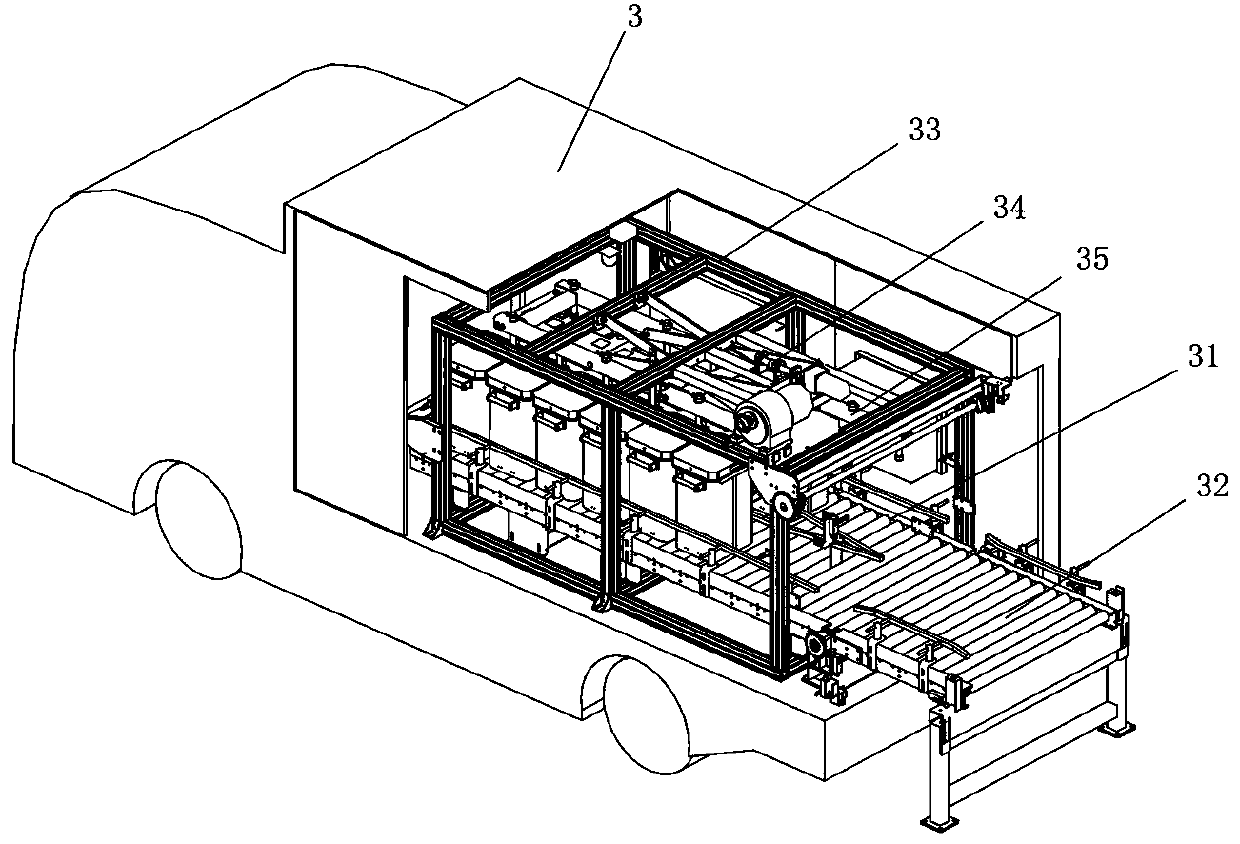

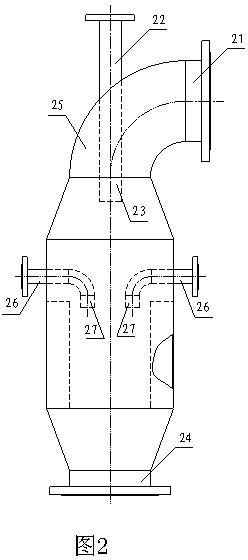

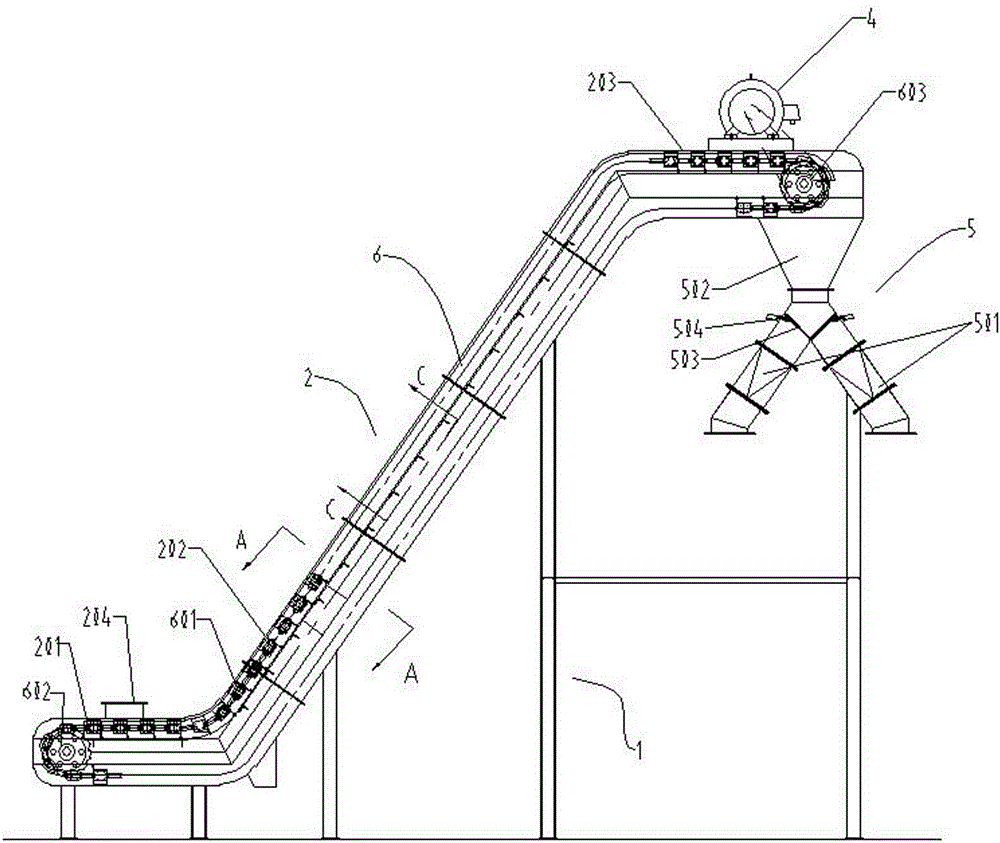

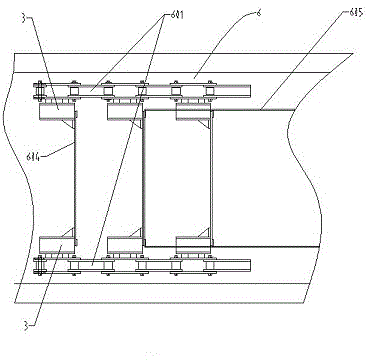

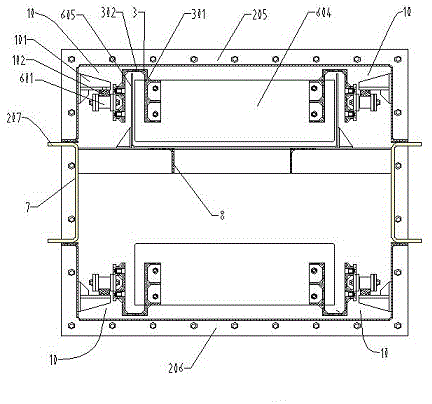

Sampling and sample preparation system used for samples

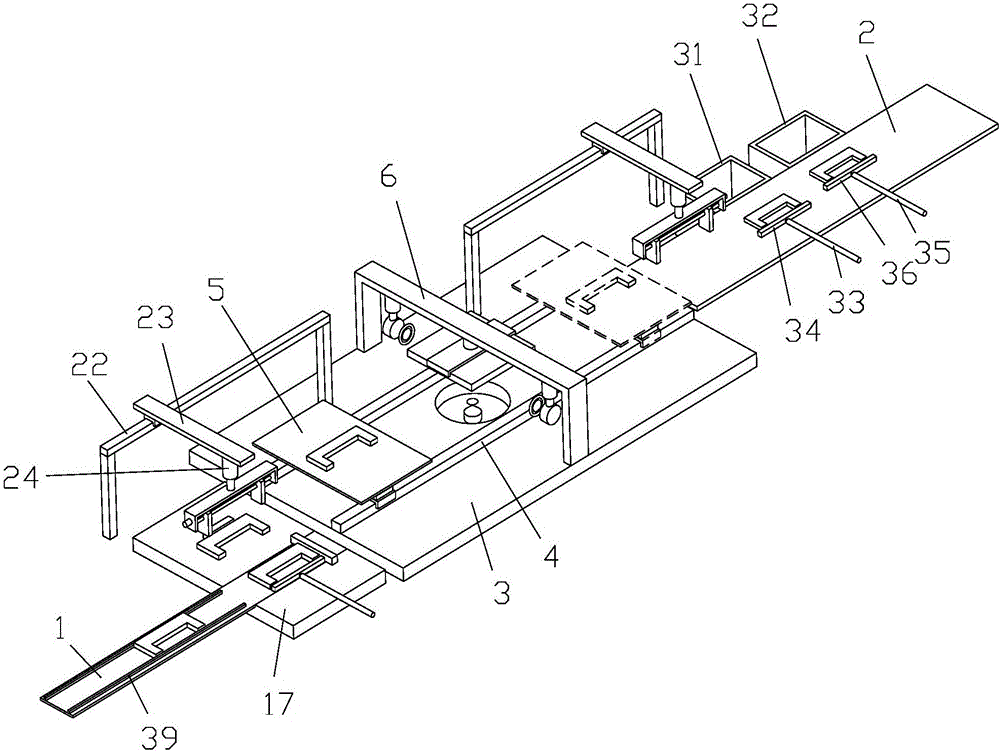

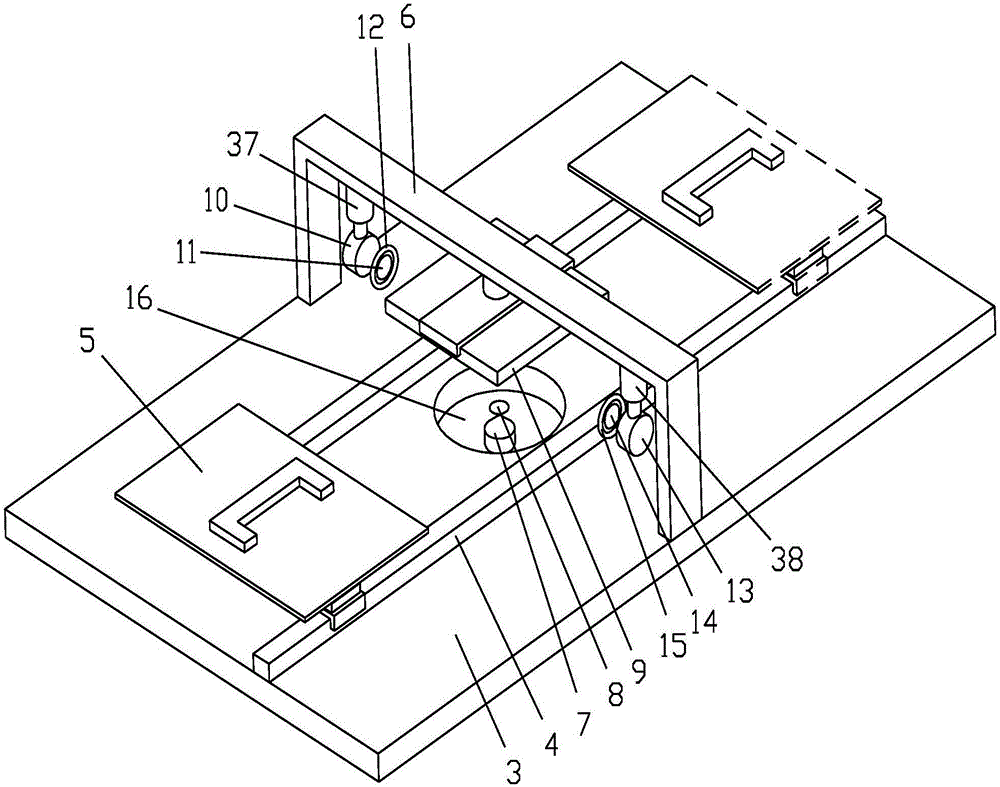

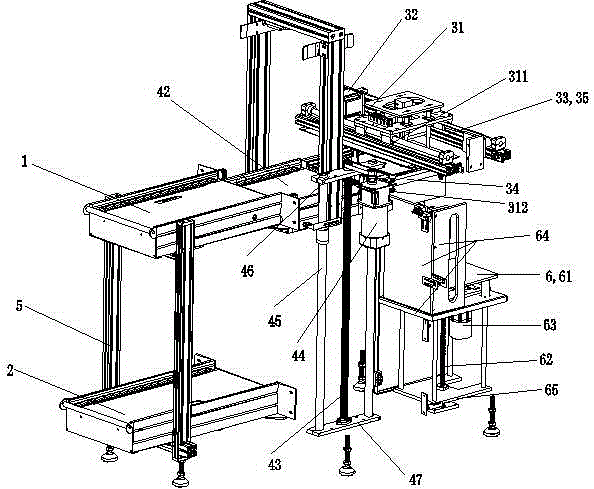

ActiveCN108045935AImprove automationImprove completenessWithdrawing sample devicesPreparing sample for investigationButt jointIn degree

The invention discloses a sampling and sample preparation system used for samples. The sampling and sample preparation system includes a sampling end and a sample preparation end. Butt joint conveyingis conducted between the sampling end and the sample preparation end through a butt joint conveying unit. The butt joint conveying unit is used for conveying a sample shipped sample barrel of the sampling end to the sample preparation end to conduct sample preparation, and conveying an empty sample barrel of the sample preparation end to the sampling end to conduct sample shipping. The sampling end is provided with an intelligent ore separator unit and a sampling end sampling barrel transshipment unit. The sample preparation end is provided with a sample batch unit, an automatic discharging unit, and a sampling end sampling barrel transshipment unit. The sampling and sample preparation system used for the samples has the advantages of being high in degree of automation and intelligence, high in security, capable of reducing manual labor intensity, and capable of keeping working continuity.

Owner:HUNAN SUNDY SCI & TECH DEV

Insulating flame-retardant MPP power cable tube and preparation method thereof

InactiveCN112810098AHigh crystallinityIncreased Vicat softening pointElectrical apparatusMetal working apparatusPower cableEngineering

The invention discloses an insulating flame-retardant MPP power cable tube and a preparation method thereof. According to the insulating flame-retardant MPP power cable tube and the preparation method thereof, isotactic polypropylene is high in crystallinity, and the prepared insulating flame-retardant MPP power cable tube has the characteristics of high vicat softening point, high modulus and low-temperature brittleness by adding the isotactic polypropylene; by adding ultra-high molecular weight polyethylene, the wear resistance of the prepared insulating flame-retardant MPP cable tube is good, and according to GB / T 8802-2001 measurement, the Vicat softening point of the prepared insulating flame-retardant MPP cable tube is 160-168 DEG C; meanwhile, the invention discloses cutting equipment, the cutting equipment can convey multiple strands of cable tubes at the same time; meanwhile, limiting rollers are matched with conveying, then conveying of the cable tubes with different diameters can be met; and meanwhile, the situation that multiple strands of cable tubes are mutually wound during conveying is avoided.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

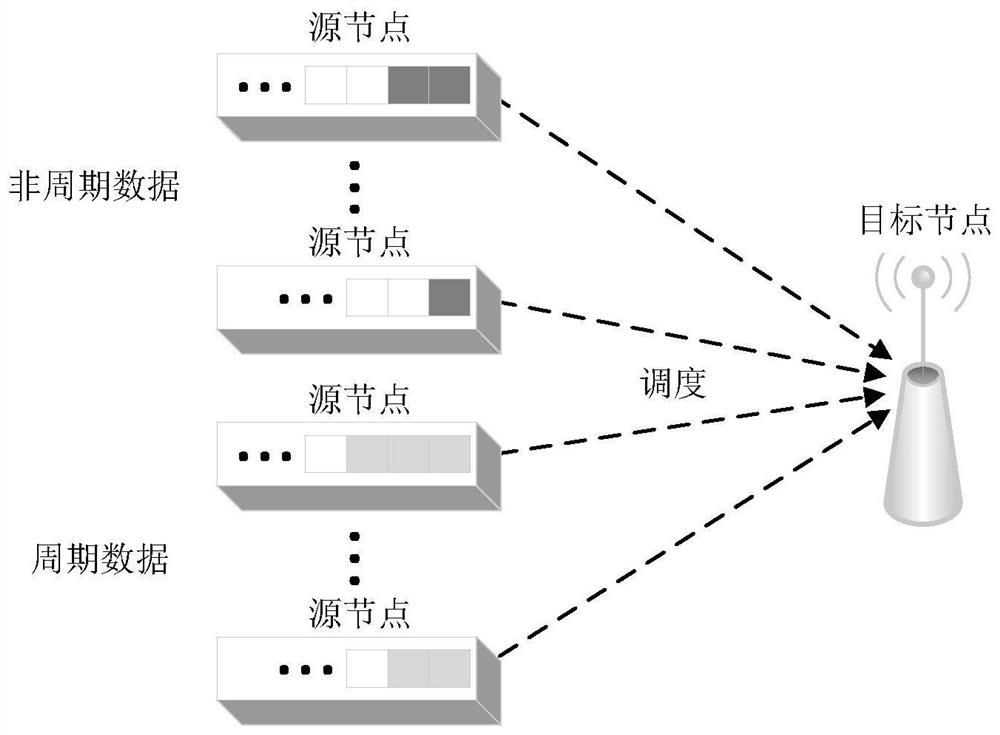

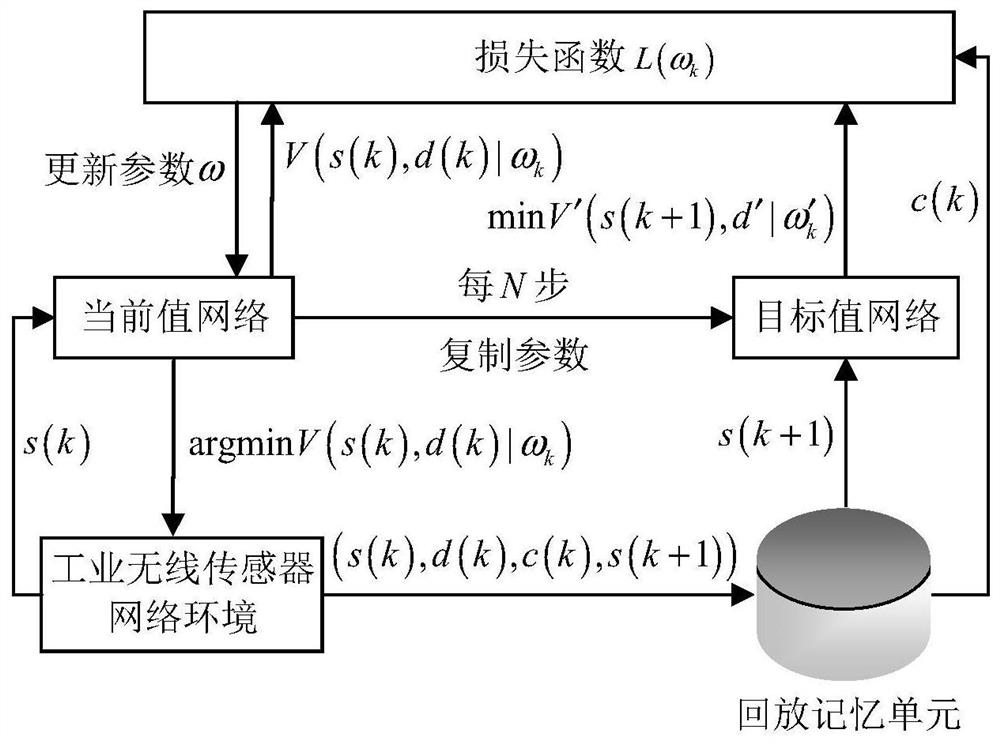

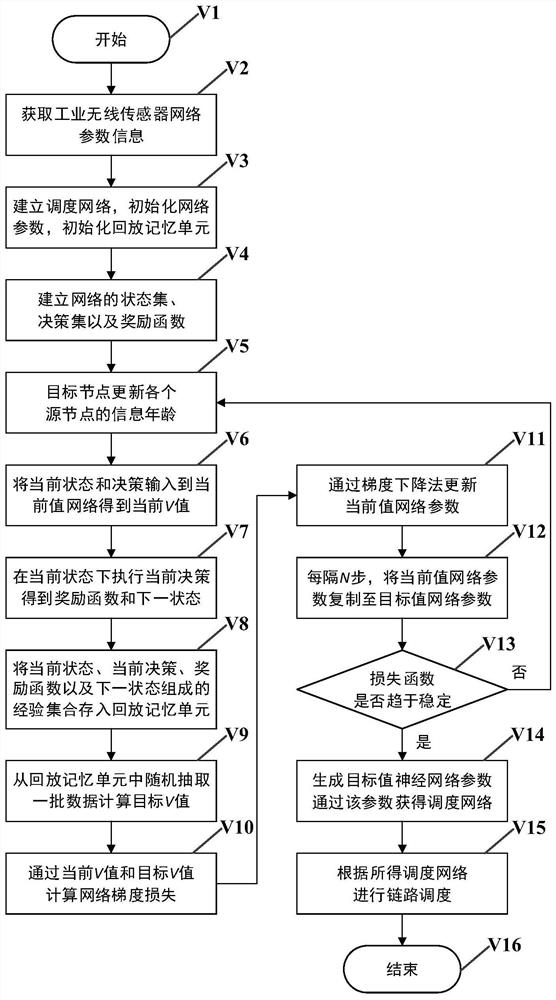

Mixed updating industrial wireless sensor network scheduling method based on information age

ActiveCN113891276ALower average age of informationImprove throughputParticular environment based servicesHigh level techniquesData averagingWireless sensor networking

The invention relates to a hybrid updating industrial wireless sensor network scheduling method based on information age, and belongs to the technical field of industrial wireless sensor networks. According to the method, for an industrial wireless sensor network in which two data updating modes of periodic data and non-periodic data are mixed and coexist, the average information age of data in the network is optimized. Meanwhile, a throughput factor is considered; the link scheduling method comprises the following steps of: performing joint optimization on a link scheduling problem of a minimum information age and throughput weighted sum in a time slot-by-slot scheduling mode, expressing the optimization problem as a finite state Markov decision process, performing approximate representation on a state value function by utilizing a deep Q network, and obtaining the link scheduling method by adopting a deep reinforcement learning mode. According to the joint optimization method provided by the invention, the dimensionality of a system state space is reduced, and the timeliness of data delivery and the throughput of a network are improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

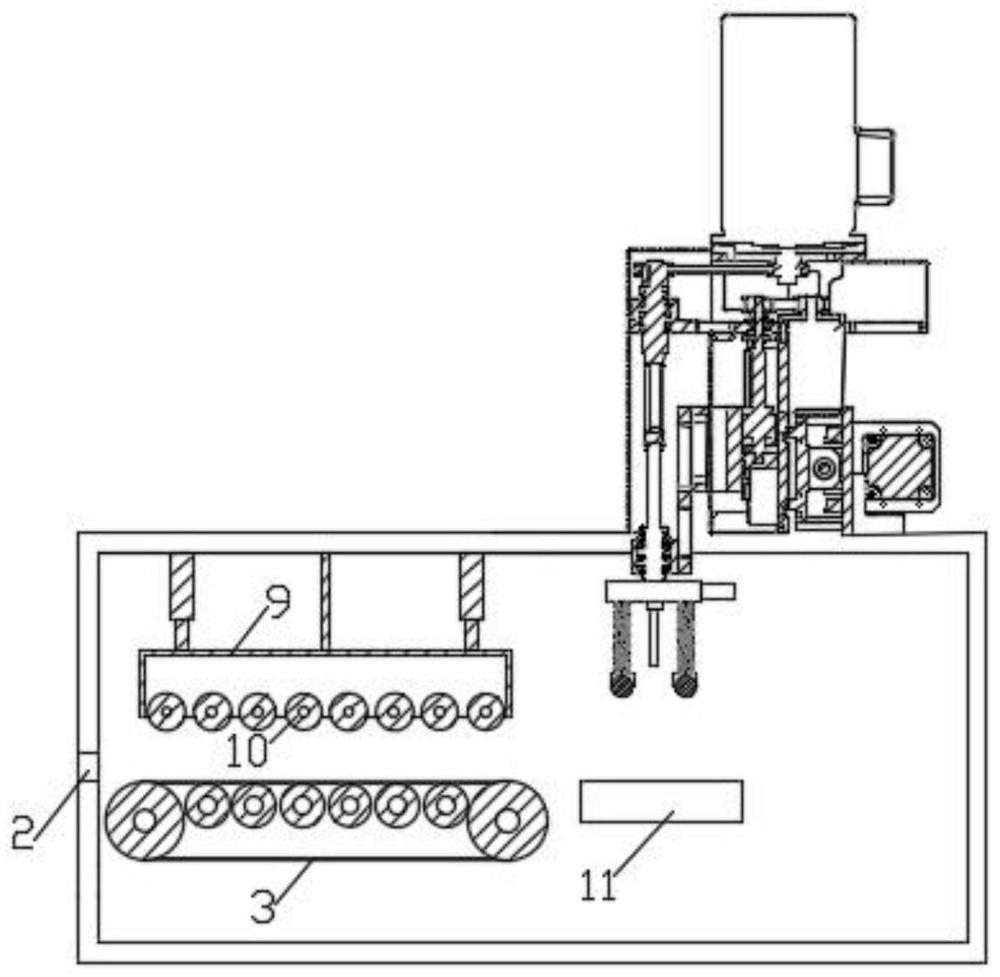

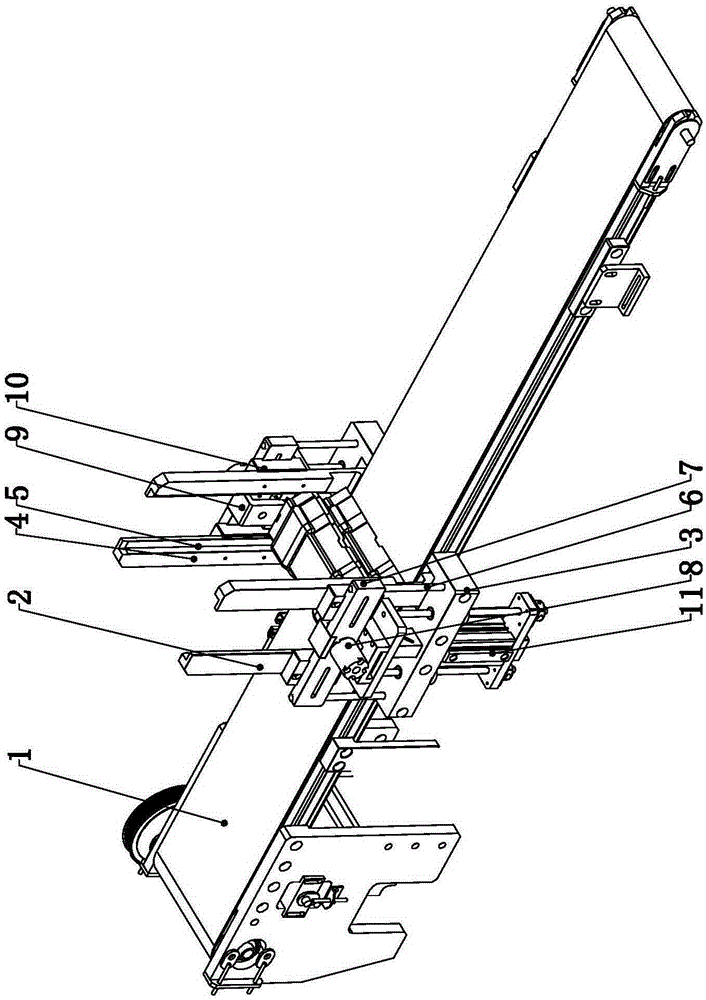

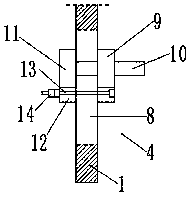

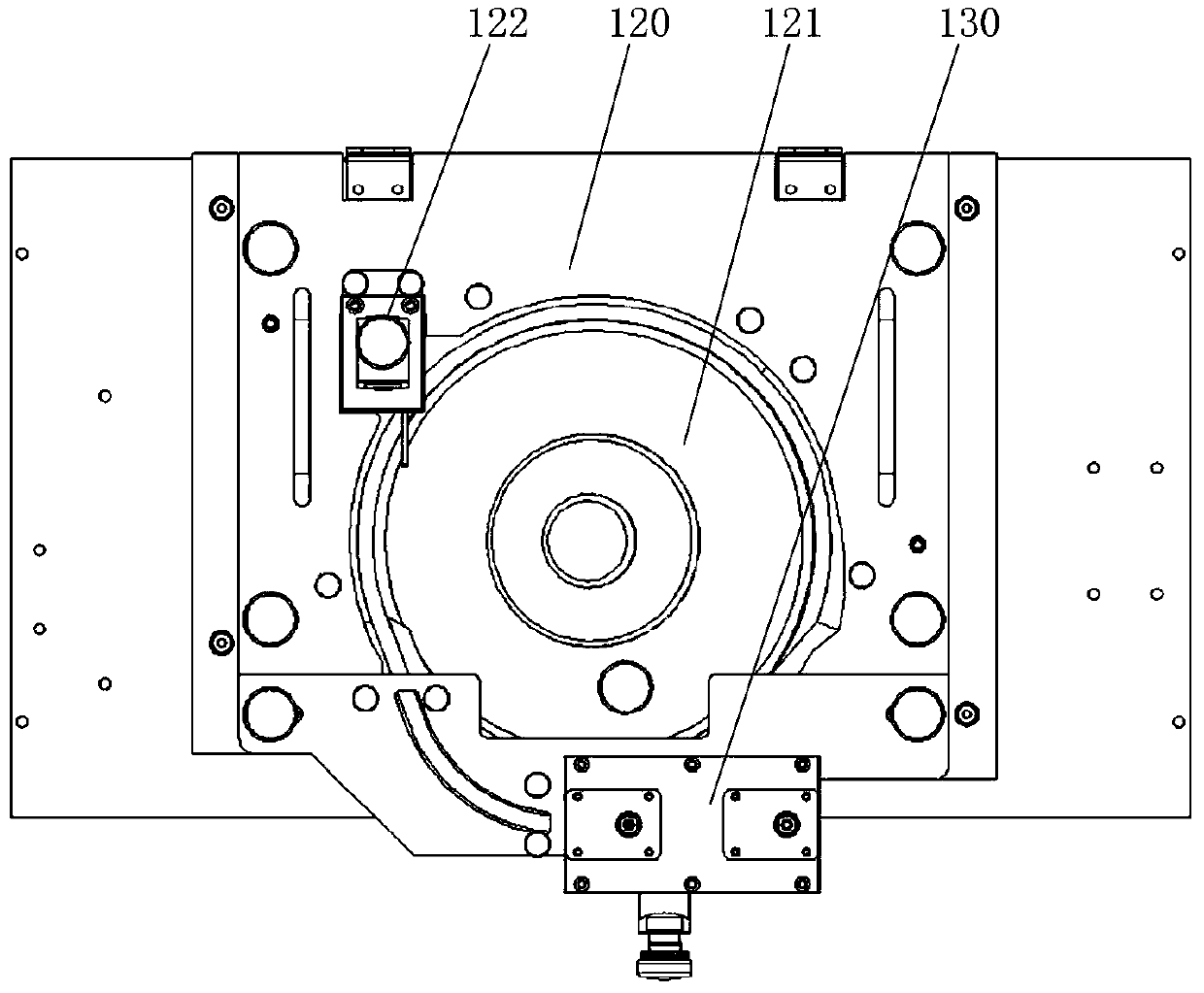

Silicon chip feeding and calibrating device for photoetching machine and silicon chip feeding and calibrating method

ActiveCN106597812AEasy to driveSimple structurePhotomechanical exposure apparatusMicrolithography exposure apparatusSilicon chipPhotolithography

The invention discloses a silicon chip feeding and calibrating device for a photoetching machine and a silicon chip feeding and calibrating method. The silicon chip feeding and calibrating device can take silicon chips out from a silicon chip box one by one and then convey the silicon chips to a calibration station by using a first transmission rack and a second transmission rack alternately; then the silicon chip feeding and calibrating device carries out rapid calibration at the calibration station by using at least three circumference-calibrating through-beam sensors, a rough detection sensor and a fine detection sensor so as to ensure that the circle centers and gaps of the silicon chips are located at assigned positions; and a first transferring rack and a second transferring rack are alternately used for conveying the silicon chips to a photoetching station for photoetching so as to ensure accurate positioning and photoetching of the silicon chips having entered the photoetching station. The silicon chip feeding and calibrating device and the silicon chip feeding and calibrating method save time, improve efficiency and are accurate in calibration and high in calibration precision.

Owner:江苏晋誉达半导体股份有限公司

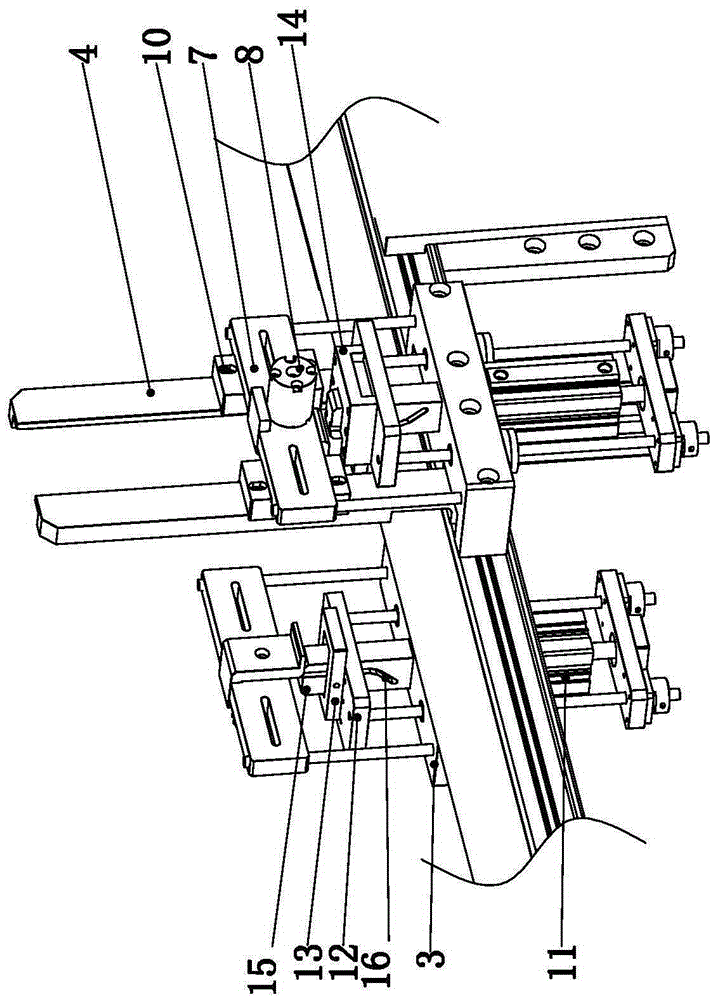

Air cylinder conveying type punching machine automatic feeding machine

ActiveCN104226842AMeet deliverySolve the laborious and time-consuming problem of manual feedingMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to an air cylinder conveying type punching machine automatic feeding machine, which comprises a base and a material conveying platform, wherein the material conveying platform is arranged on the base, a feeding guide rail is arranged at the feeding end of the material conveying platform through a bearing seat, a first guide wheel group, a material conveying module, a second guide wheel group and a second material pressing module are sequentially arranged on the material conveying platform in the feeding direction, plate materials are moved onto a material conveying table of the material conveying module along the feeding guide rail, a first material pressing air cylinder tightly presses the plate materials, a pushing and conveying air cylinder pushes and conveys the plate materials in the feeding direction, after the plate materials reach a specified punching direction, a second material pressing air cylinder is downwards pressed for tightly pressing the plate materials, after the punching of a punching machine on the plate materials is completed, the material pressing air cylinder is reset, the punching and conveying air cylinder returns, and meanwhile, a second material pressing device is driven to return the initial position. Through the reciprocating operation in such a way, the plate materials are continuously fed, and the continuous punching is realized.

Owner:无锡苏惠信息技术服务有限公司

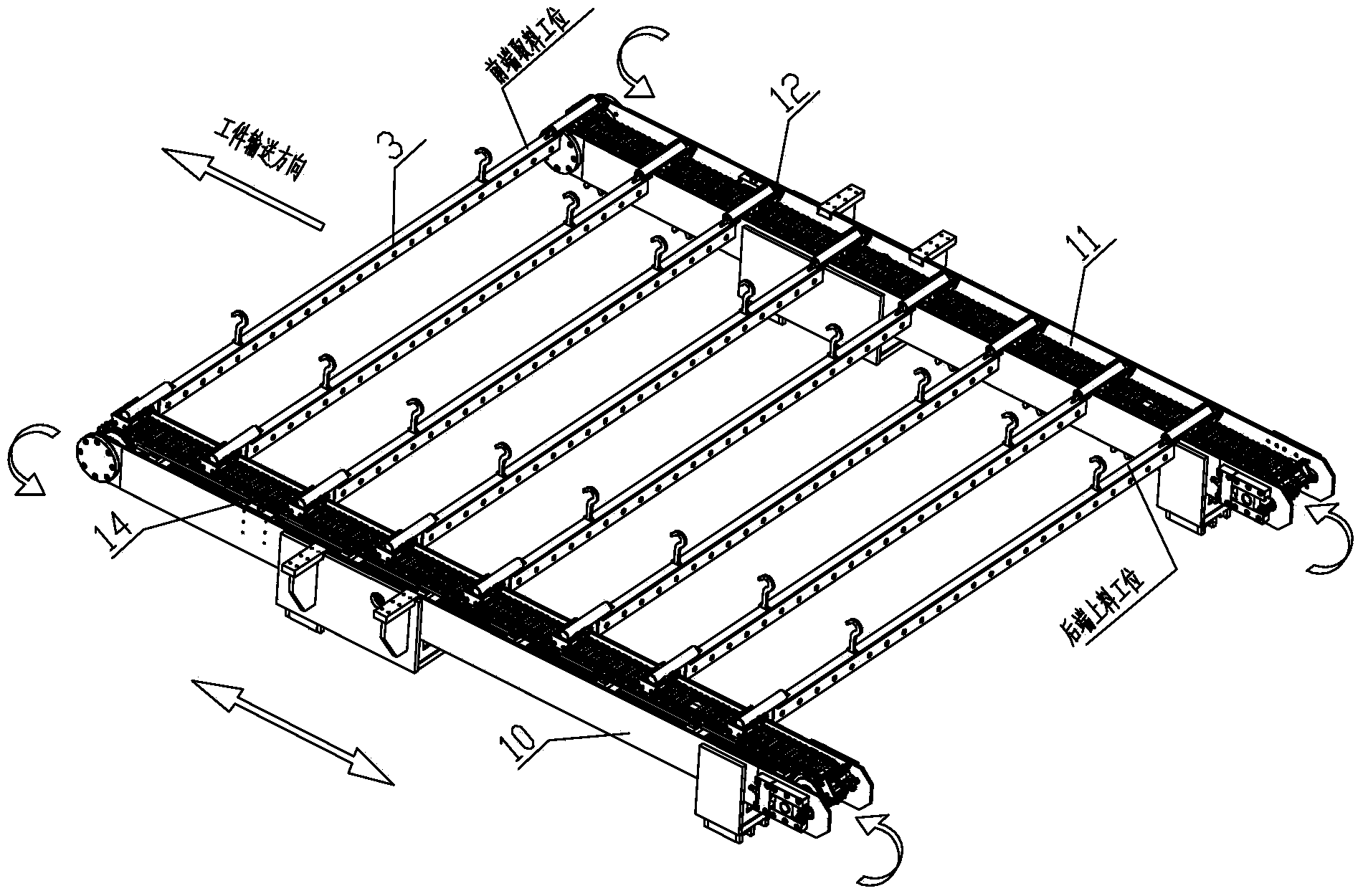

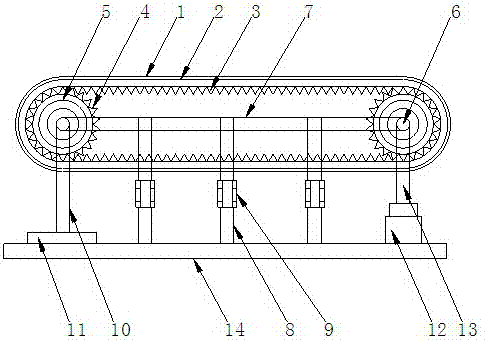

Conveying belt type automatic feeding device

ActiveCN105293011AAccurately control the position and directionMeet deliveryConveyor partsLocking mechanism

The invention relates to a conveying belt, in particular to a conveying belt type automatic feeding device, and belongs to the technical field of conveying equipment. The conveying belt type automatic feeding device comprises a conveying belt and automatic feeding units connected to the two sides of the conveying belt through bolts. Each automatic feeding unit comprises a discharging mechanism, a locking mechanism, a feeding mechanism and a fixing plate, wherein the discharging mechanism, the locking mechanism and the feeding mechanism are sequentially arranged on the fixing plate from top to bottom. The conveying belt type automatic feeding device is simple, compact and reasonable in structure and works stably and reliably. The positions and directions of workpieces placed on the conveying belt can be accurately controlled. Meanwhile, conveying takt time is controlled accurately. Maintenance is convenient, and the cost is low. The requirement for conveying the workpieces of different dimensions can be met, and the application range is broad.

Owner:WUXI MICRO RES PRECISION PRESS PARTS

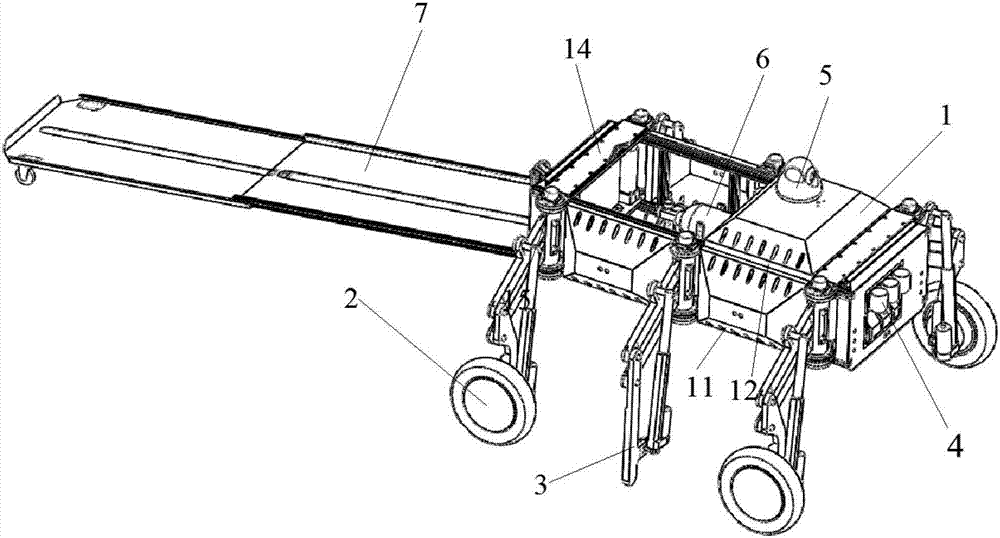

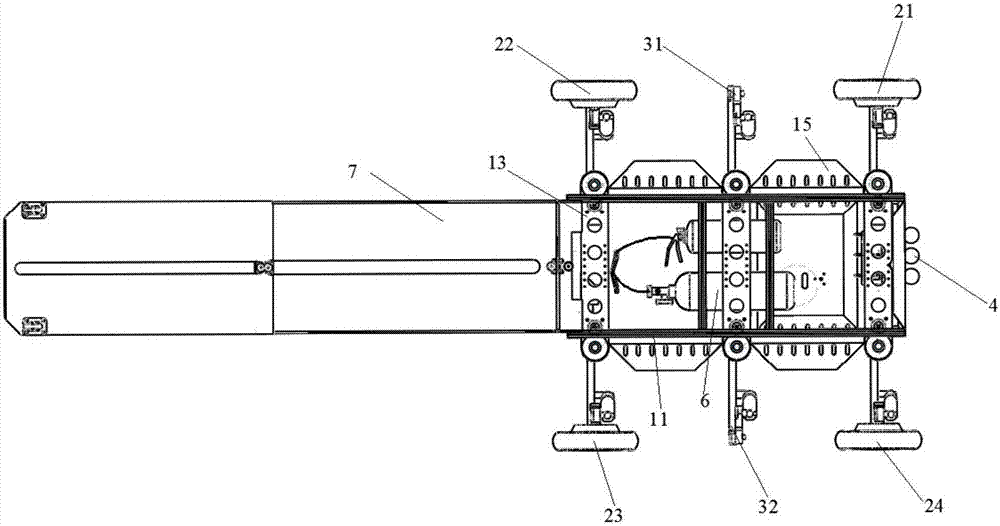

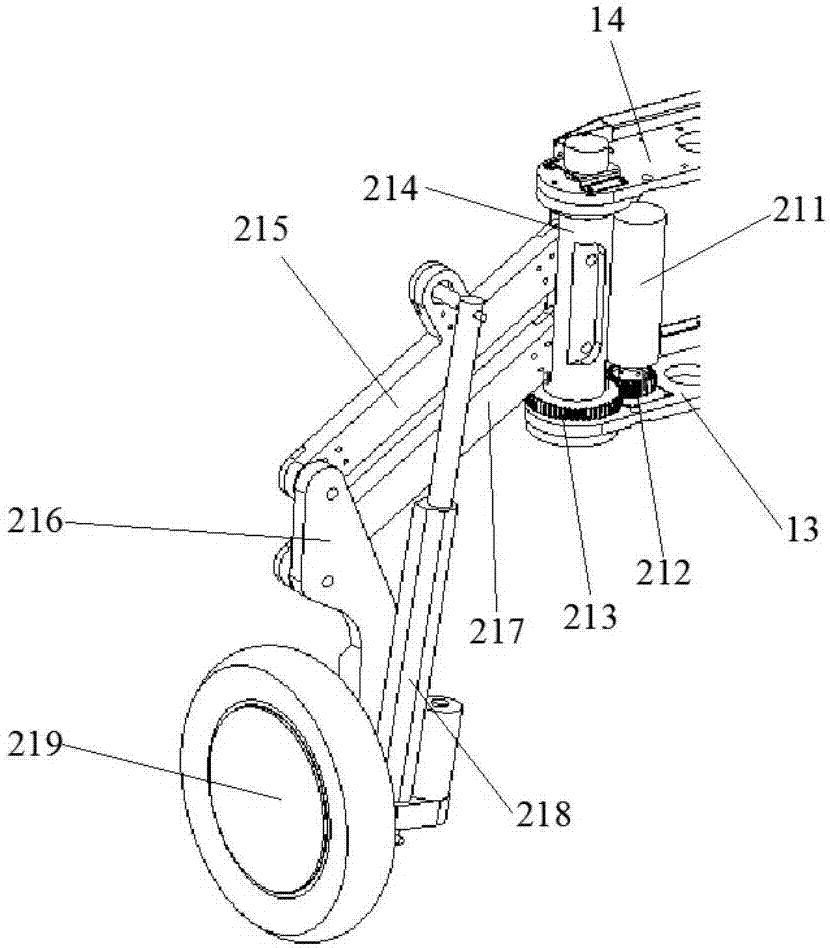

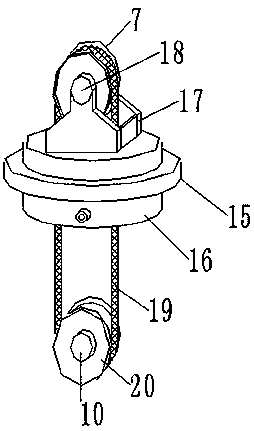

Wheel-legged robot for post-earthquake field rescue

PendingCN107323561ASampling implementationImprove carrying capacityStretcherFire rescueRescue robotLegged robot

The invention discloses a wheel-legged robot for post-earthquake field rescue. The wheel-legged robot for post-earthquake field rescue comprises a trunk framework structure, a wheel-legged structure module, an auxiliary leg structure module, a circumstance sampling structure module, a vision module, an oxygen therapy / fire fighting functional module and a stretcher structure module, wherein the robot can be in various movement states through the wheel-legged structure module; the auxiliary leg structure module can achieve auxiliary supporting when the robot moves in a legged state; the circumstance sampling structure module can sample the substances such as soil and water; the vision module can assist rescue workers in achieving vision monitoring of the post-earthquake circumstance; the oxygen therapy / fire fighting functional module can achieve oxygen therapy to trapped people or emergency extinguishing of a fire; and the stretcher structure module can deliver the wounded or materials. The wheel-legged robot for post-earthquake field rescue has the advantages of high adaptability to complicated circumstances, high loading capacity, complete functions and the like, can be used for searching for and rescuing people and performing circumstance monitoring after an earthquake or a landslide or on other post-earthquake circumstances, and has broad application prospects.

Owner:BEIHANG UNIV

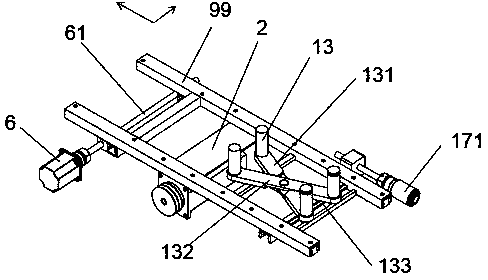

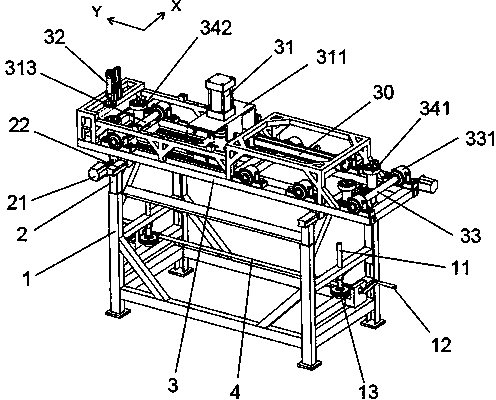

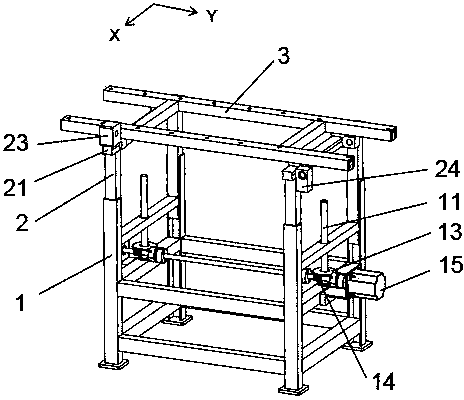

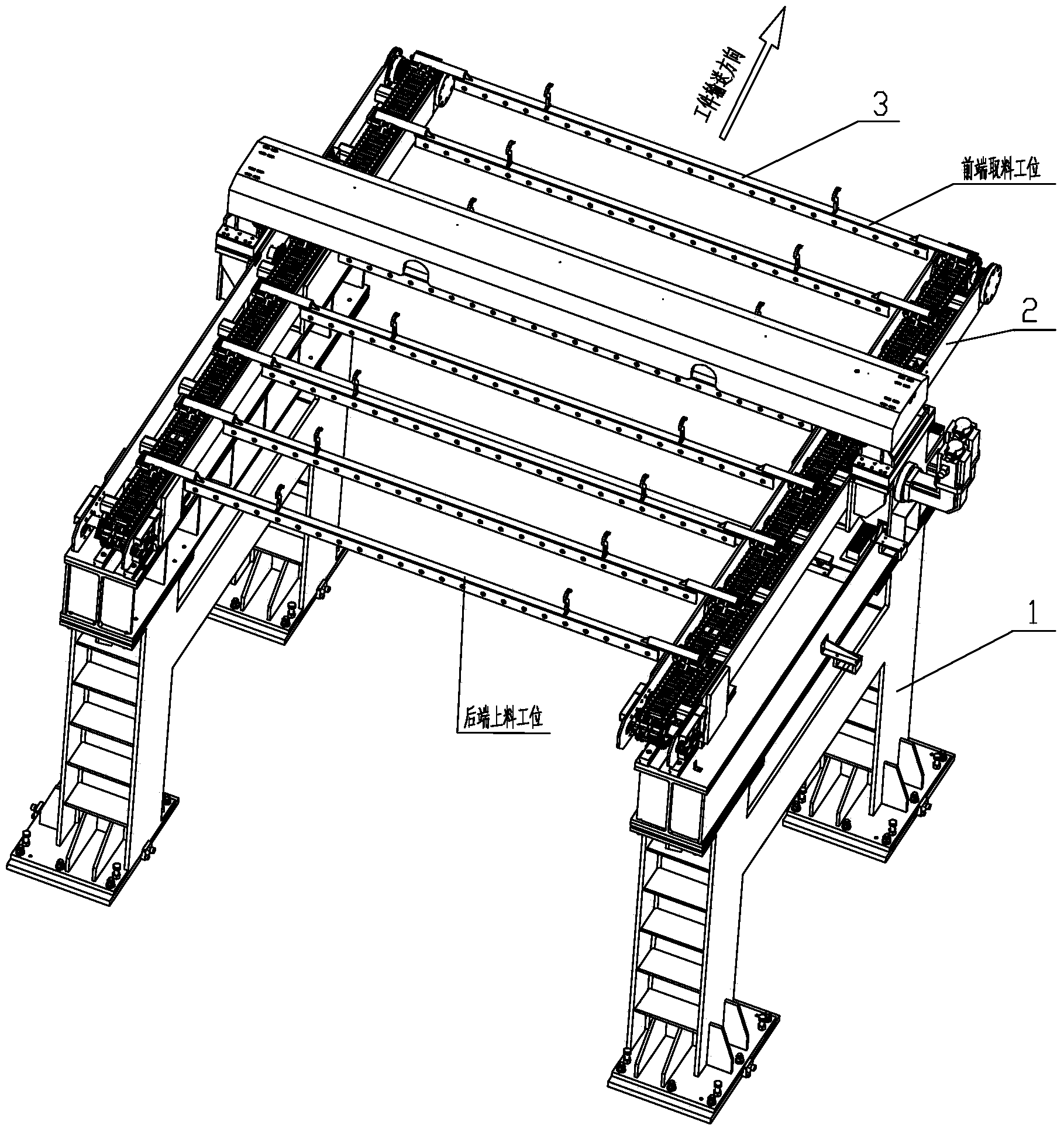

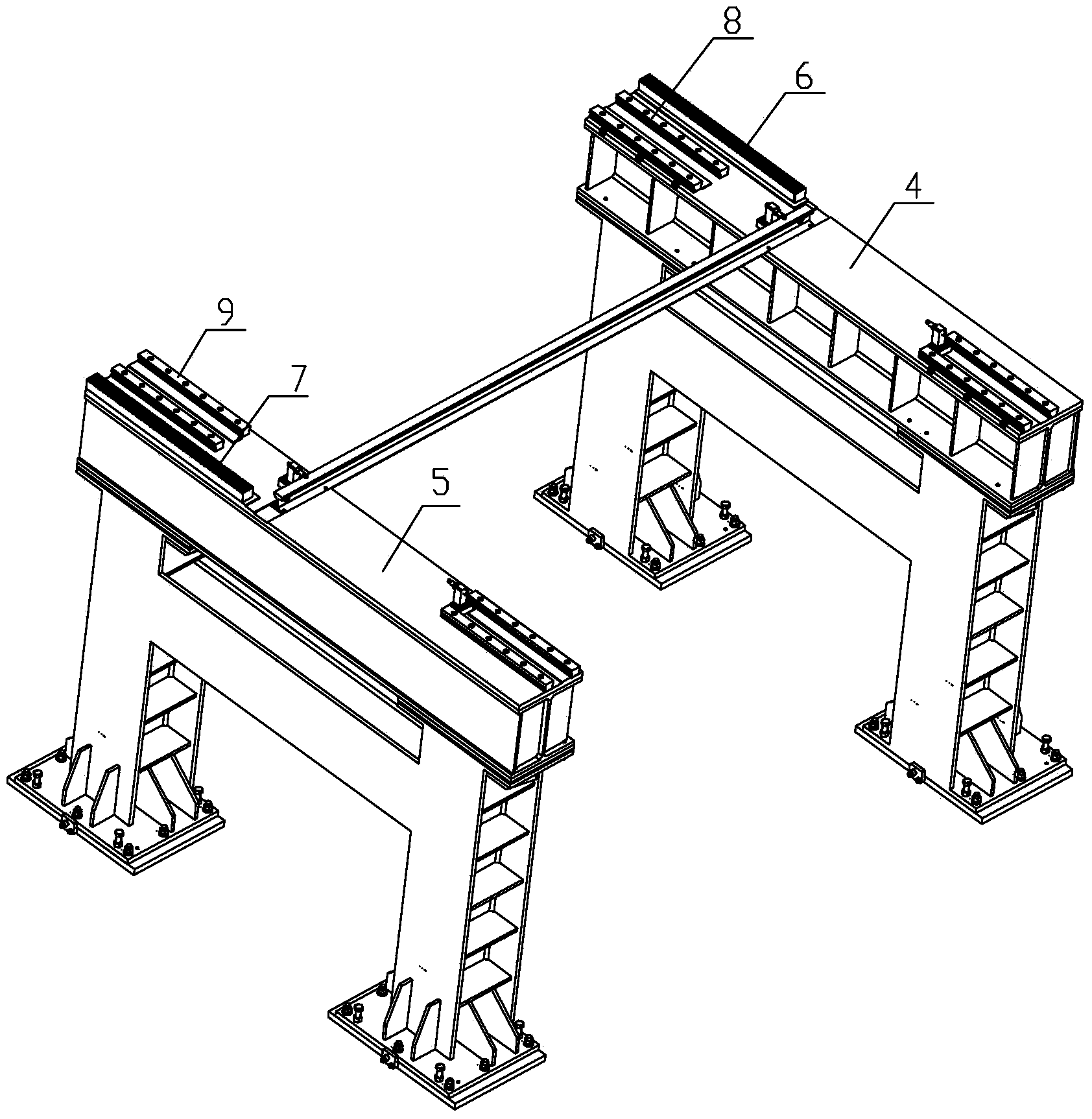

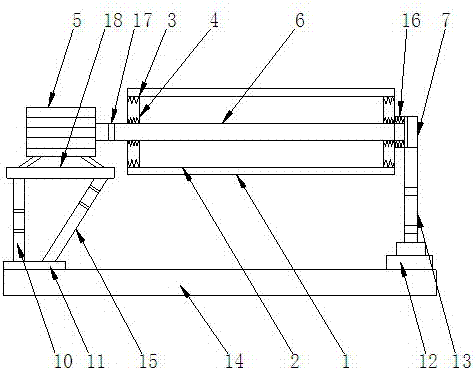

Automatic feeding device

ActiveCN103708177APrecise position controlStable conveying speedConveyorsStructural engineeringMechanical engineering

The invention relates to an automatic feeding device. The automatic feeding device comprises a bottom support part, an upper transmission part and a conveying suspender. The bottom support part comprises a left support and a right support, a left rack is installed on the left support, and a right rack is installed on the right support. Left guide strips are installed at the front end of the left support and the rear end of the left support and right guide strips are installed at the front end of the right support and the rear end of the right support. The upper transmission part comprises a left transmission assembly and a right transmission assembly. Left sliding blocks on the left transmission assembly are matched with the left guide strips, right sliding blocks on the right transmission assembly are matched with the right guide strips, left conveying boat bodies on the left transmission assembly and right conveying boat bodies on the right transmission assembly are equal in number and corresponding in position in a left-and-right mode, and the left end of the conveying suspender and the right end of the conveying suspender are supported by the left conveying boat bodies and the right conveying boat bodies respectively. The automatic feeding device is ingenious in structure, reasonable in design and capable of realizing automatic feeding between a phosphorization line and a powder spraying line, improves the production efficiency and lowers the labor intensity.

Owner:WUXI BEST PRECISION MACHINERY

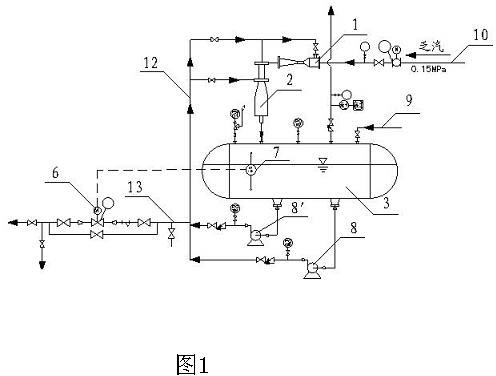

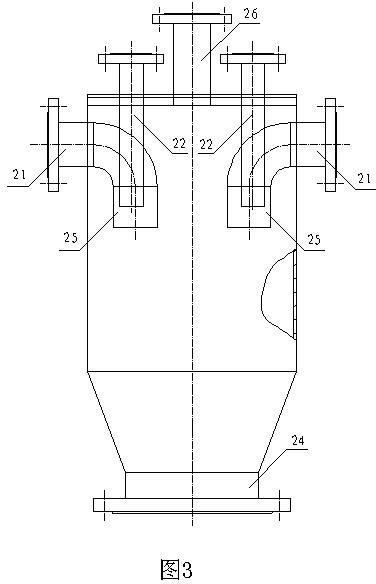

Waste steam heating, pressurizing and recycling system

InactiveCN102146813AIncrease contactIncrease the areaSteam regenerationEngine componentsHigh pressureWaste management

The invention relates to a waste steam heating, pressurizing and recycling system which comprises a recycling tank, a primary jet pump and a secondary jet pump, wherein the recycling tank is a horizontal recycling tank, the top of the recycling tank is provided with a high-pressure steam outlet, the recycling tank is provided with a jet pipeline, a high-pressure draining pump is arranged on the jet pipeline, a jet inlet of the primary jet pump and a jet inlet of the secondary jet pump are connected with the jet pipeline, an outlet of the secondary jet pump is connected with an inlet of the recycling tank, a suction inlet of the secondary jet pump is connected with an outlet of the primary jet pump, a suction inlet of the primary jet pump is connected with an exhaust steam source through a low-pressure exhaust steam pipeline, and the high-pressure steam outlet is connected with a high-pressure steam recycling pipeline. The waste steam heating, pressurizing and recycling system disclosed by the invention is beneficial to solution to the problems of recycling difficulty caused by too low pressure of exhaust steam and pressurizing difficulty in the prior art and has the capability of effectively pressurizing the low-pressure exhaust steam, and the pressurized steam can be suitable for various occasions and especially suitable for occasions with high pressure requirements.

Owner:李树生

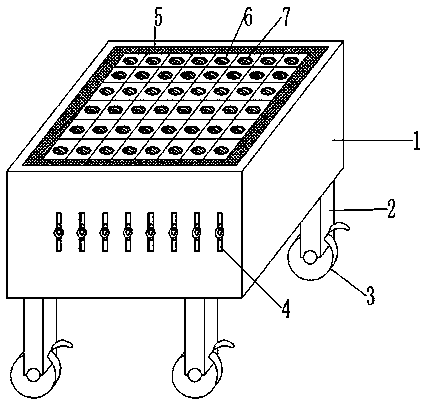

Rolling wheel type sorting machine for logistics

InactiveCN109795836ARealize sortingReduce manufacturing costConveyor partsRoller-waysEngineeringConveyor belt

The invention relates to the field of material conveying, in particular to a rolling wheel type sorting machine for logistics. The rolling wheel type sorting machine for the logistics comprises a fixing outer shell, and four supporting legs are correspondingly welded to the outer walls of the four corners of the bottom of the fixing outer shell; moving wheel with brakes are fixedly installed on the outer walls of the bottoms of the supporting legs; adjusting assemblies symmetrically arranged are correspondingly fixed to the inner walls of the front face and the back face of the fixing outer shell; and the top of the fixing outer shell is of an open structure, an embedded plate is connected to the inner part of an opening of the top of the fixing outer shell in an embedded mode, and installing holes are equidistantly formed in the outer wall of the top of the embedded plate in a matrix distributed mode. The rolling wheel type sorting machine for the logistics has the beneficial effectsthat conveying rolling wheels are adopted to be combined with push rods and push rod motors, so that the conveying rolling wheels can rotate and further can rotate along rotating pillars, the change of conveying direction of conveyor belts is realized, and then logistics goods on one conveyor belt are transferred to another conveyor belt, and the sorting of the logistics goods is realized withoutusing a sorting robot to complete the sorting operation.

Owner:JIN HOUNG FUH (CHUZHOU) CONVEYING EQUIP CO LTD

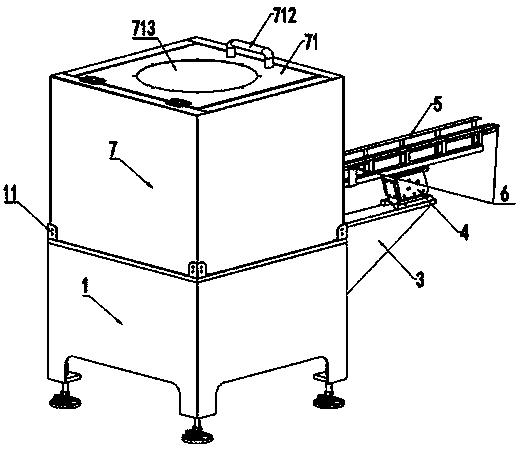

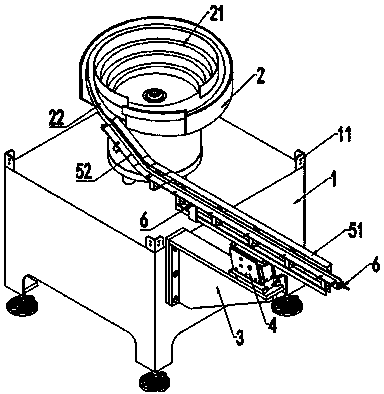

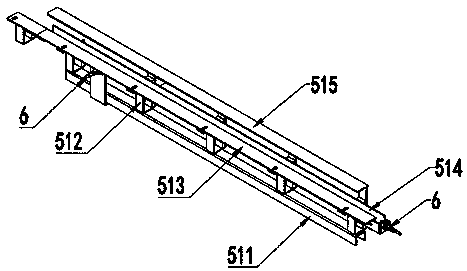

Hole-opening-device delivering device

PendingCN109230381AMeet deliverySimple structureControl devices for conveyorsPackagingElectrical and Electronics engineering

The invention discloses a hole-opening-device delivering device. The hole-opening-device delivering device is characterized in that a delivering rail (5) is composed of a straight rail (51) and a curve rail (52) through connection, and the two ends of the straight rail (51) are each provided with an induction device (6); the straight rail (51) is composed of a fixed base (511), multiple U-shaped connecting plates (512), a left adjusting baffle (513), a right baffle (514) and a top baffle (515); the left adjusting baffle (513), the right baffle (514) and the top baffle (515) are fixedly connected through the multiple U-shaped connecting plates (512) to form the rail, and are connected on a straight vibrator (4) through the fixed base (511); waist-shape holes are formed in the left adjustingbaffle (513), and the width of the rail can be adjusted by adjusting the locking position. The hole-opening-device delivering device is simple in structure and fast and convenient to operate.

Owner:丹阳市宝利锯业机械有限公司

Novel wind tunnel pipeline type rapid-transit transportation tool

ActiveCN103963788AImprove shipping speedImprove securityRailway system combinationsAutomotive engineeringRapid transit

Owner:董根林

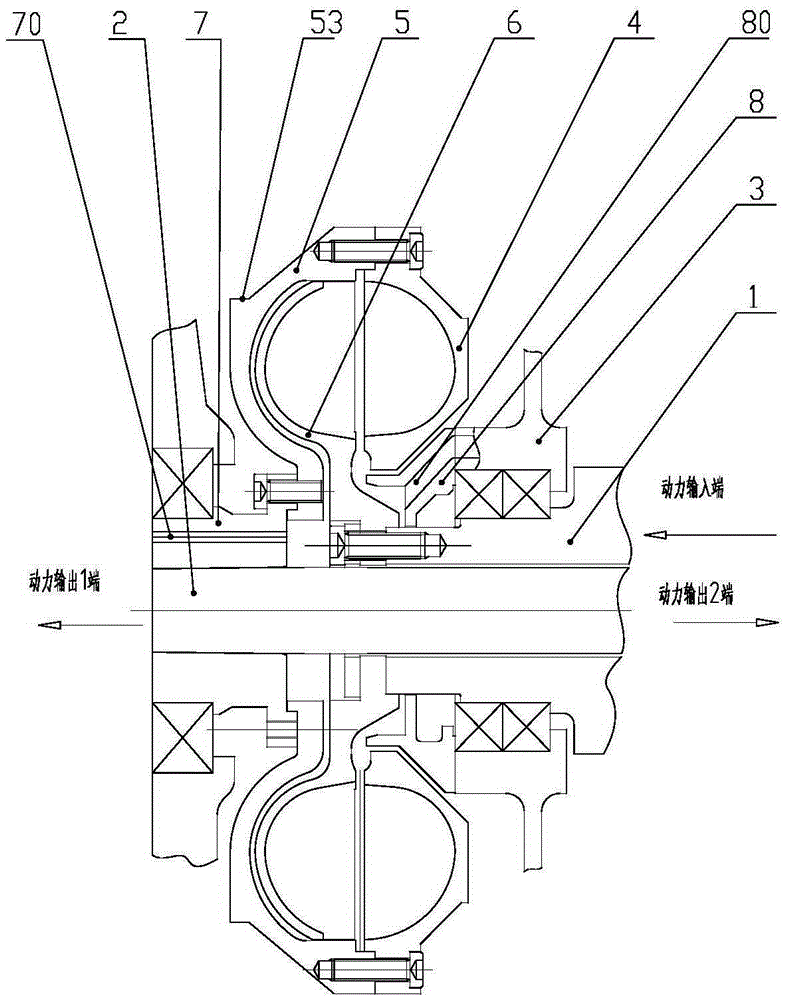

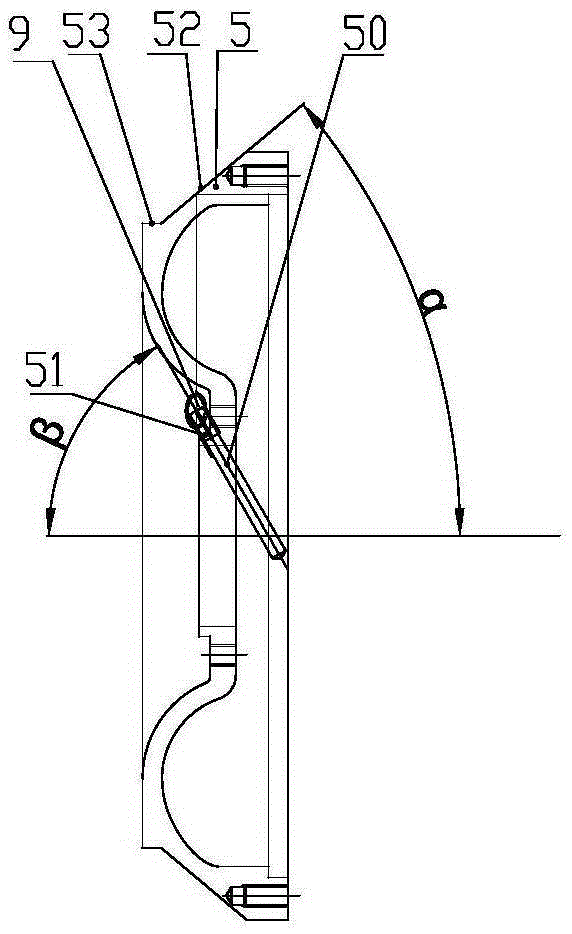

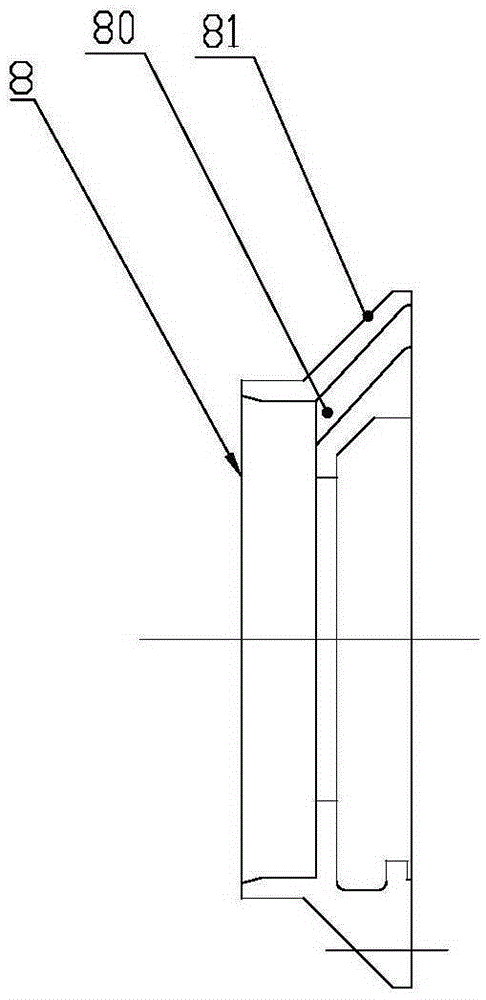

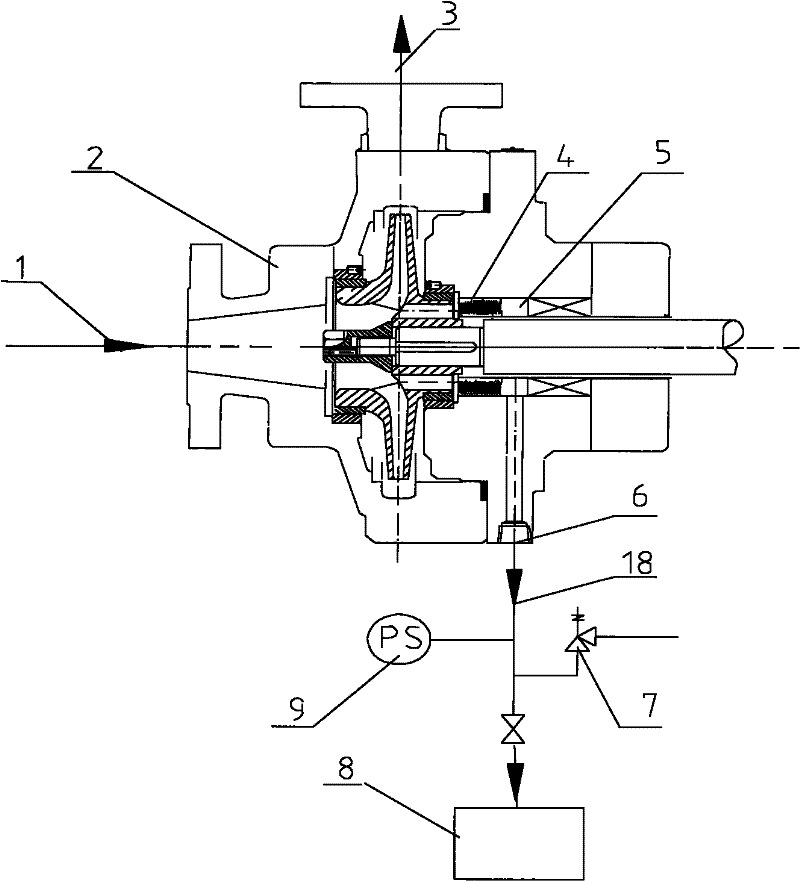

Hydraulic coupler

The invention discloses a hydraulic coupler which is used for connecting an input shaft and an output shaft. A shaft sleeve is arranged on the output shaft. The hydraulic coupler comprises a worm wheel, a volute, a pump impeller and an oil inlet tongue, wherein the pump impeller is mounted in a cavity formed by the worm wheel and the volute and is fixedly connected with the input shaft; the worm wheel and the shaft sleeve are fixedly connected with the volute; the hydraulic coupler is characterized in that an oblique oil outlet is formed in the volute and extends from the external part of the volute to the medial axis of the volute; one end of the oil inlet tongue is fixed in a box, and the other end of the oil inlet tongue is communicated to a gap between the worm wheel and the pump impeller; a first oil inlet is formed in the oil inlet tongue; a second oil inlet capable of extending in the axial direction of the shaft sleeve is formed in the shaft sleeve. The hydraulic coupler can rapidly discharge and feed oil and is high in cooling speed, compact in structure and steady in operation.

Owner:CRRC DALIAN INST CO LTD

Belt conveyor capable of automatically adjusting height

InactiveCN107973080AIncrease frictionSatisfy the supporting roleConveyorsSupporting framesConveyor beltHydraulic cylinder

The invention discloses a belt conveyor capable of automatically adjusting the height. The belt conveyor comprises a conveyor belt, wherein a friction pad is arranged on an outer surface of the conveyer belt; teeth are arranged on an inner wall of the conveyor belt; the conveyor belt is connected with gears through the teeth; the gears are arranged on outer walls of rotary rods; the rotary rods are connected with rotors of motors through couplers; the tail ends of the rotary rods are connected with a bearing; a shaft protection cover is arranged on an outer wall of the bearing; telescopic rodsare welded to the bottom part of the shaft protection cover; telescopic rod protection covers are arranged on outer walls of rod connecting parts of the telescopic rods; a hydraulic rod is arranged on the bottom part of the right end of the shaft protection cover, and is connected with a hydraulic cylinder; and the hydraulic cylinder is arranged on the base. According to the belt conveyor capableof automatically adjusting the height provided by the invention, through arranging the hydraulic rod, the hydraulic cylinder and the telescopic rods, the conveyor belt can freely control a conveyingangle under the drive of the hydraulic rod and the hydraulic cylinder and through the assistance of a telescopic action of the telescopic rods, so that the requirement on conveying materials in various angles is met.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

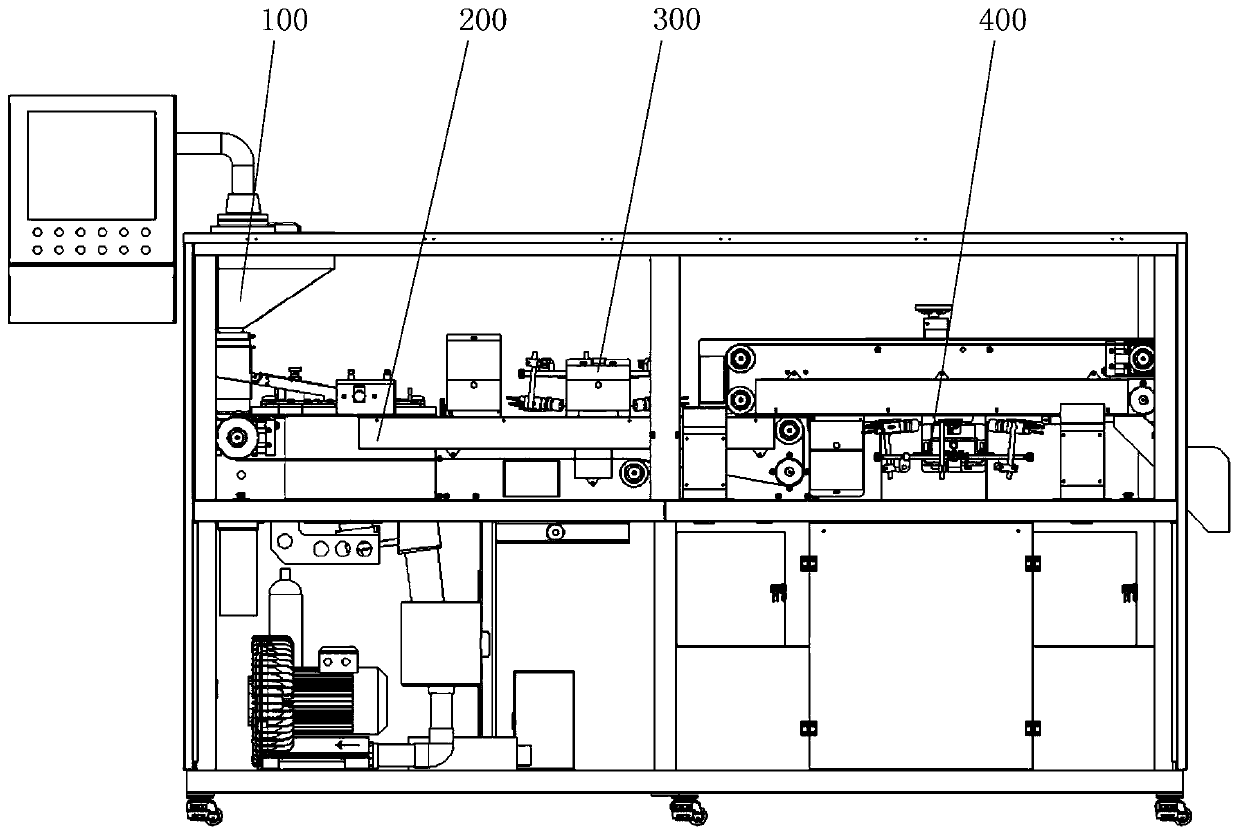

Full-automatic tablet detection equipment

PendingCN111282842AComprehensive image detectionAdjust the gap heightSievingScreeningImage detectionEngineering

The invention provides full-automatic tablet detection equipment. The full-automatic tablet detection equipment comprises a material arranging device, a belt conveying device, a first detection deviceset and a second detection device set, wherein the material arranging device is used for arranging tablets; the belt conveying device comprises a first belt conveying mechanism and a second belt conveying mechanism, the first belt conveying mechanism and the second belt conveying mechanism have the same center line, and the top of the first belt conveying mechanism is adjacent to the bottom of the second belt conveying mechanism; and the first detection device set is arranged at the top of the first belt conveying mechanism and is used for detecting the tablets and removing unqualified tablets, and the second detection device set is arranged at the bottom of the second belt conveying mechanism and used for detecting the tablets and removing the unqualified tablets. According to the full-automatic tablet detection equipment, the upper surfaces and the lower surfaces of the tablets are exposed in the conveying process through the two belt conveying systems, one detection device carriesout image detection on the upper surfaces and the inner side faces of the tablets, and the other detection device carries out image detection on the lower surfaces and the outer side faces of the tablets.

Owner:无锡传奇科技有限公司

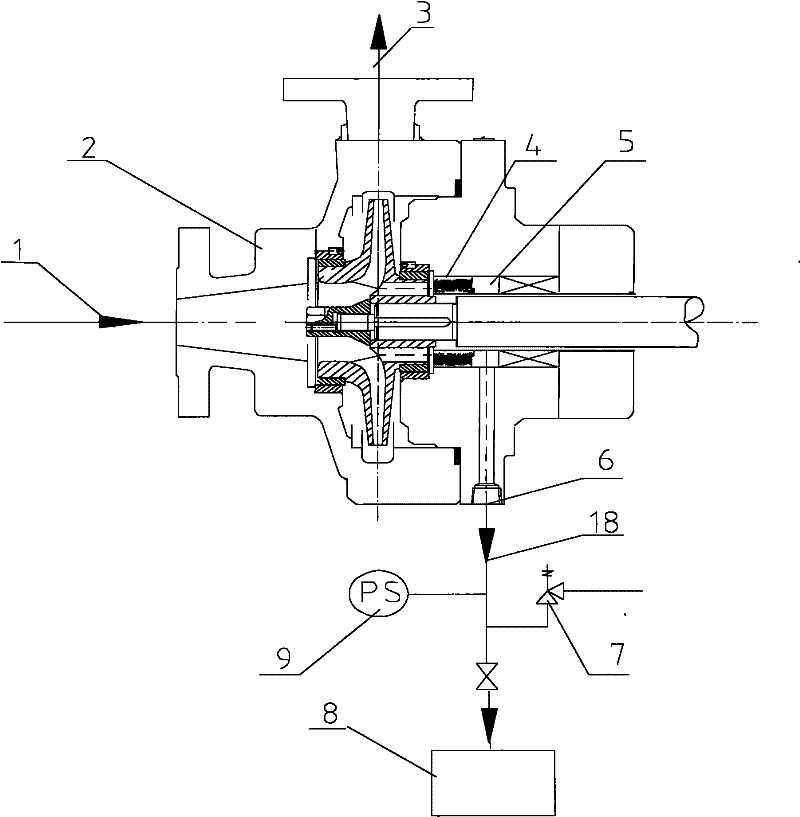

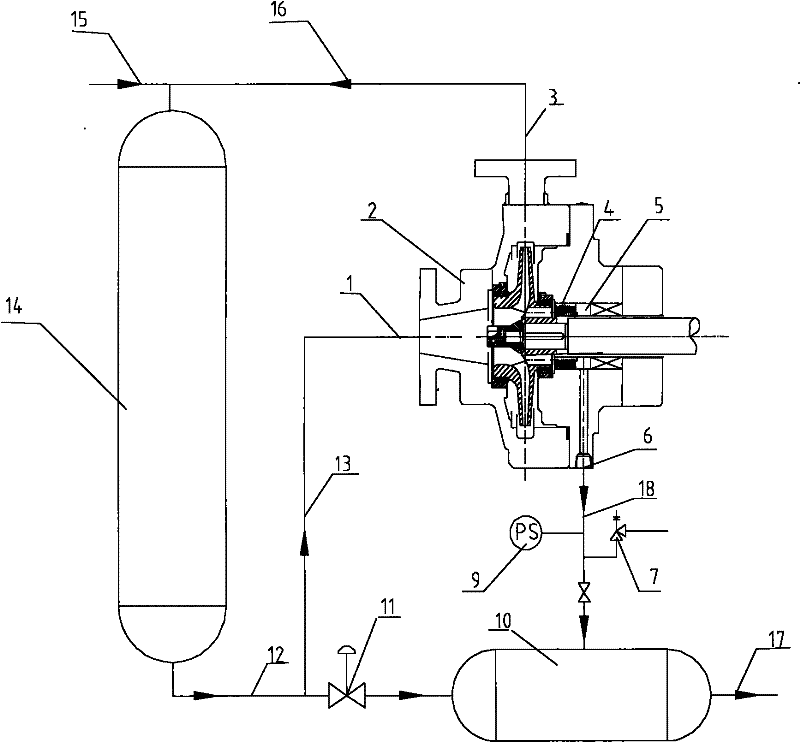

A method for reducing the pressure of pump sealing chamber

ActiveCN102269177ARealize circular conveyingRelieve pressureSpecific fluid pumpsPump componentsHigh pressure chamberHigh pressure

The invention discloses a method for reducing the pressure of a pump sealing cavity, which is characterized in that it comprises the following steps: 1) high-pressure fluid enters the pump body from the inlet of the pump, and is discharged from the pump body after being pressurized by the pump; The liquid discharged from the balance drum or throttling bush is led to the low-pressure container outside the pump body. The invention overcomes the problem that the prior art pump inlet and outlet are both high-pressure sealing chambers with high pressure and difficulty in sealing.

Owner:CHINA PETROCHEMICAL CORP +1

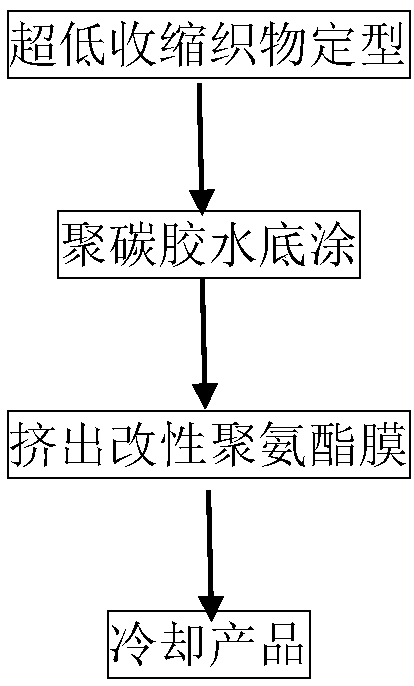

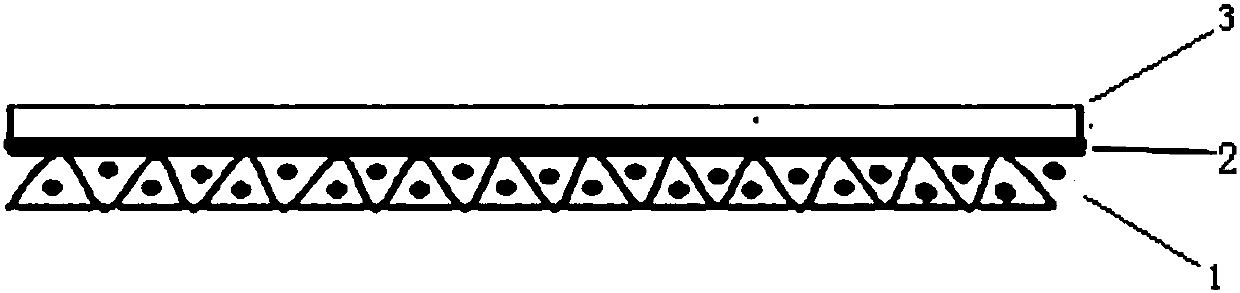

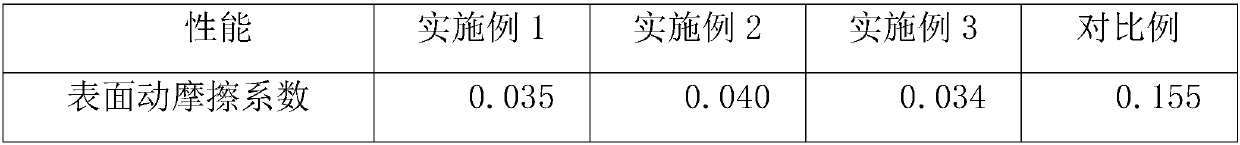

Modified polyurethane film and application thereof

The invention belongs to the technical field of conveying belts in food industry, specifically relates to a modified polyurethane film and application thereof and particularly relates to a low-surfacefriction, temperature-resistant and light conveying belt produced from the modified polyurethane film for the food industry. The modified polyurethane film is produced from low-surface friction temperature-resistant polyurethane through curing, and low-surface friction temperature-resistant polyurethane is prepared from polyurethane, silicone rubber and a compatibilizer in a weight ratio of 100 to (15-25) to (3-5) through blending. The modified polyurethane film is the low-surface friction, temperature-resistant and light conveying belt produced through a covering layer, a polyester fabric with ultra-low shrinkage property is taken as a skeleton of the low-surface friction, temperature-resistant and light conveying belt, and the skeleton is adhered with the covering layer through a poly-carbon glue prime coat. By utilizing silicone rubber modified polyurethane, the temperature resistance is greatly improved, can be increased by 30 DEG C than that of conventional TPU and can meet the front-back conveying requirements of a flour food drying oven; and the modified polyurethane film can be applied to the conveying of foods containing heavy oil, and a phenomenon that the conveying beltturns downwards due to the shrinkage of the fabric is avoided, so that the smooth conveying of the foods is guaranteed.

Owner:SHANGHAI YONGLI BELTING

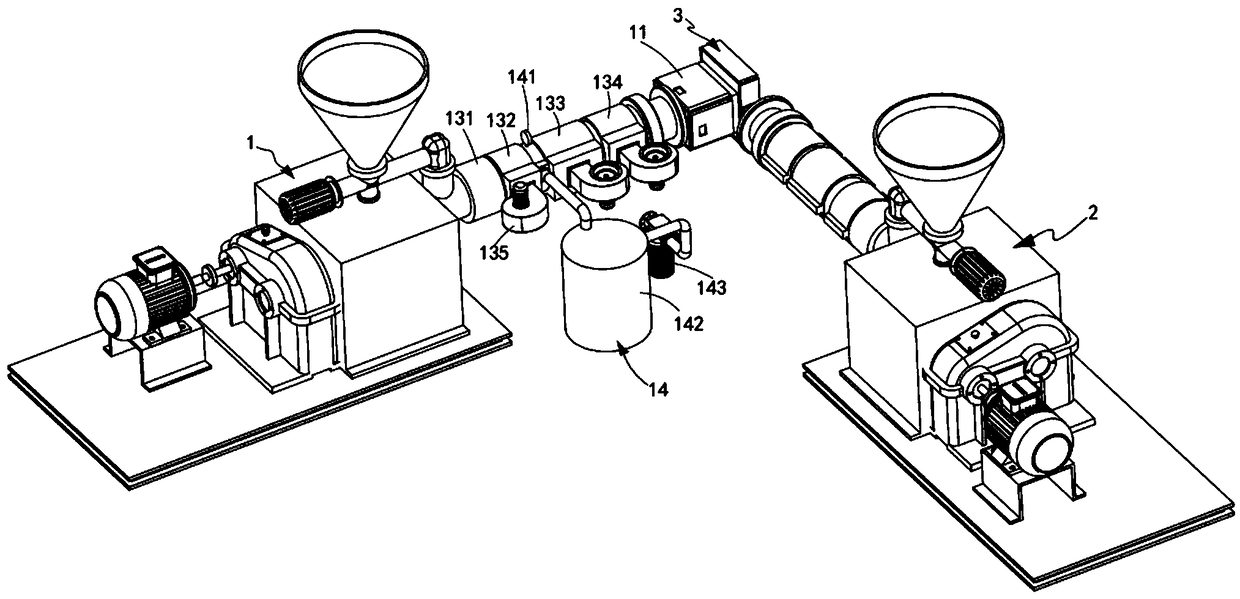

Integrated sucking and conveying machine

ActiveCN105314389AMeet deliveryCompact designConveyor partsMechanical conveyorsEngineeringTransfer mechanism

The invention discloses an integrated sucking and conveying machine which comprises a feeding mechanism and a transferring mechanism, wherein the feeding mechanism comprises a feed-in mechanism and a material box lifting mechanism; the feed-in mechanism comprises an upper dragon tail layer and a lower dragon tail layer which are vertically arranged; the upper dragon tail layer is provided with a pushing mechanism; the material box lifting mechanism comprises a board sending lifting table connected with the feed-in mechanism, a first lifting device, and a material box lifting rail as well; the transferring mechanism comprises a second lifting device and a sucking mechanism; the sucking mechanism comprises a transferring rail and a transportation rail which are vertically arranged, and a board sucking mechanism which slides along the transferring rail; and the material boards of the feeding mechanism and the transferring mechanism are finally sent out through the transportation rail. According to the device provided by the invention, the integral structure is compact in design, the space is saved, the operation is easy, and the production efficiency can be improved.

Owner:SUZHOU CONBER ELECTRONICS EQUIP

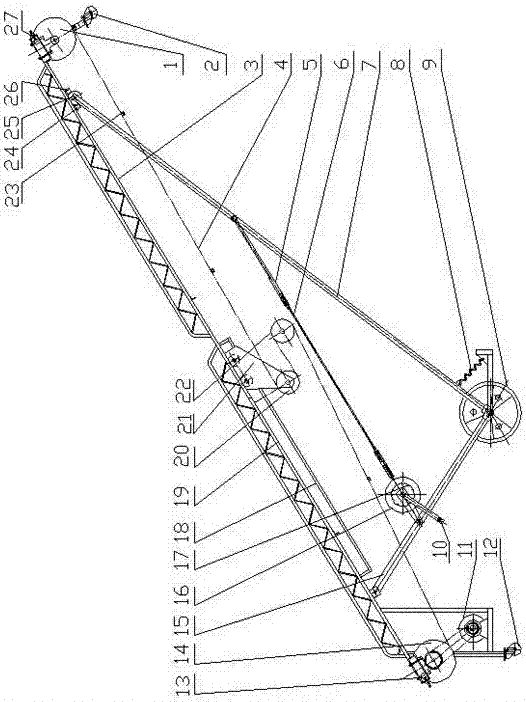

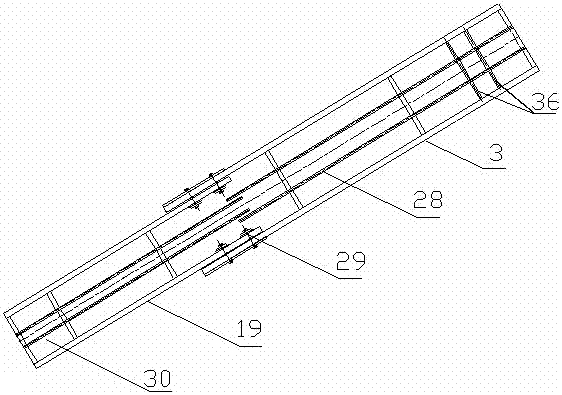

Orchard multifunctional miniature belt conveyor

The invention relates to cargo loading and unloading equipment, in particular to an orchard multifunctional miniature belt conveyor. The orchard multifunctional miniature belt conveyor is characterized by comprising front and back racks, a conveying belt, a machine body stretchable limiting mechanism, a height adjusting mechanism, a conveying length adjusting mechanism, a belt tensioning offset adjustment mechanism, a transmission mechanism, a reset tension spring, a walking mechanism and other components; and the structure is compact, operation is simple, running is stable and reliable, positive and negative running can be carried out, conveying height and length adjustment can be achieved, and the functions of upgoing climbing inclined material conveying, horizontal material conveying and downgoing including material conveying are achieved. The machine type is light and flexible, running is stable, occupied space is small, the common conveying function is achieved, and the orchard multifunctional miniature belt conveyor is particularly suitable for narrow channel and space or multi-layer goods shelf warehouse material loading, unloading and carrying. The orchard multifunctional miniature belt conveyor is cooperatively developed in cooperation with several manufacturing enterprises in Qingyang, Qingyang science and technology institute and Longdong college and is a result of cooperation between schools and enterprises, and the technical advantages of science and technology farming benefiting of scientific research institutions are achieved.

Owner:EASTERN GANSU UNIVERSITY

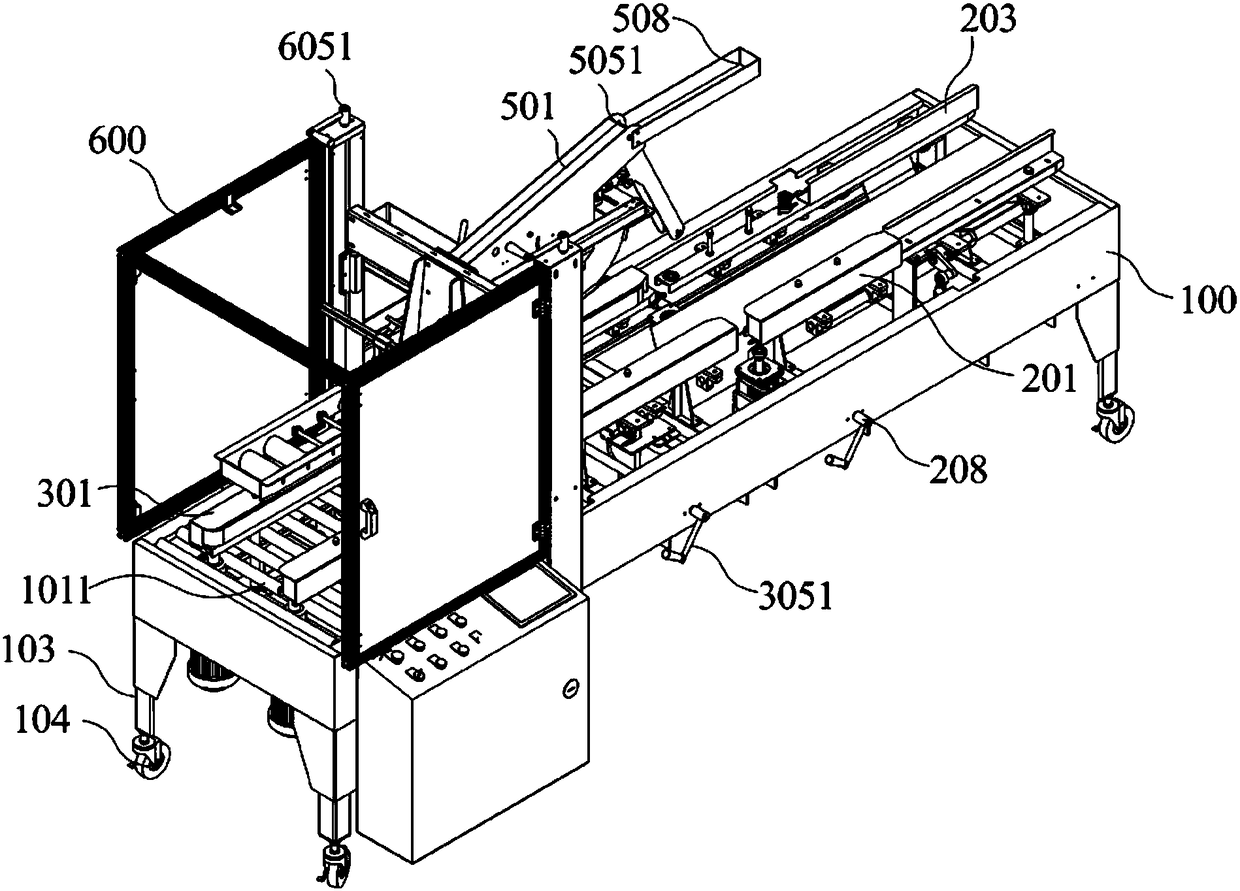

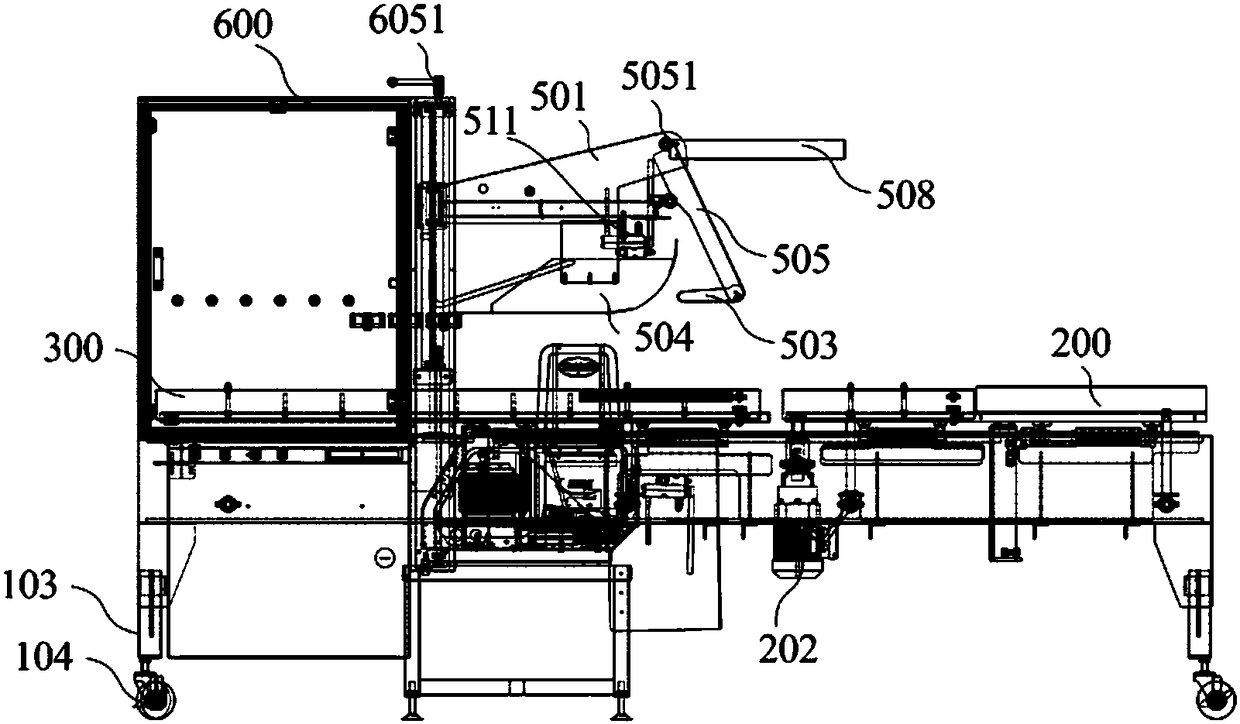

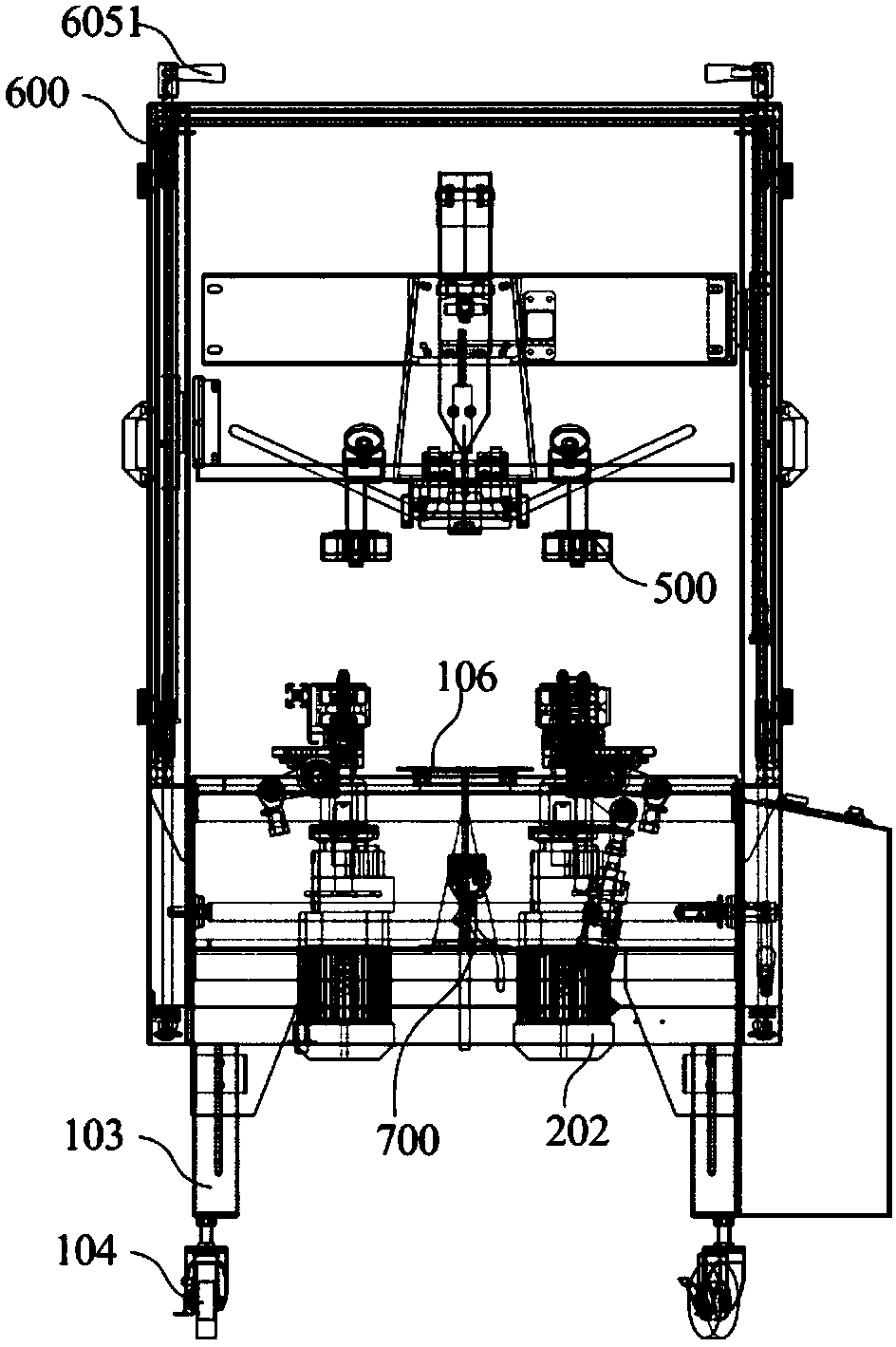

Automatic hot-glue carton sealing machine

PendingCN108438356AHigh positioning accuracyReduce the time required for packingWrapper twisting/gatheringEngineeringCarton

The invention discloses an automatic hot-glue carton sealing machine which comprises conveying devices arranged on a workbench, wherein the conveying devices comprise a first conveying device and a second conveying device; a bottom folding mechanism is arranged below the first conveying device, and used for folding and pressing bottom four-edge sealing covers of a carton; a bottom glue spraying device is arranged below a striking mechanism; the striking mechanism is arranged above the second conveying device, and used for folding and pressing top four-edge sealing covers of the carton; a top glue spraying device is arranged on the striking device; and the carton is inputted by the first conveying device from one side, the bottom sealing cover folding-pressing operation and the glue spraying operation are performed by the bottom folding mechanism and the bottom glue spraying device, the bottom-sealed carton is conveyed to the second conveying device, the top sealing cover folding-pressing operation and the glue spraying operation are performed by the top folding mechanism and the top glue spraying device, and the totally-sealed carton is outputted by the second conveying device after the packaging operation. By adoption of the automatic hot-glue carton sealing machine disclosed by the invention, the accurate positioning effect can be achieved; when cartons of different types need to be exchanged, the adjustment can be completed within a short time without suspending production; and the integration of glue spraying and carton sealing is considered as a better aspect, so thatthe carton loading and production process can be greatly reduced.

Owner:上海宗义自动化设备制造有限公司

Conveying device for paste materials

Owner:ANQIU BOYANG MACHINERY MFR

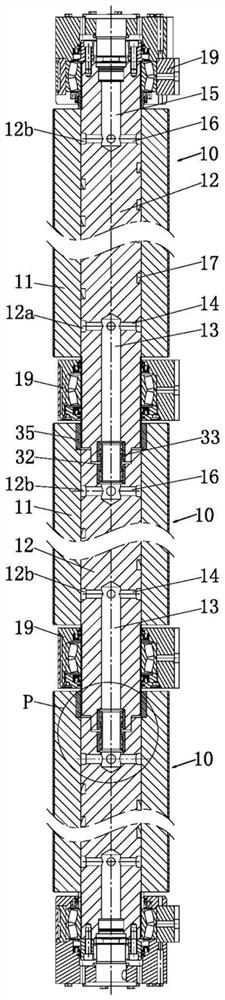

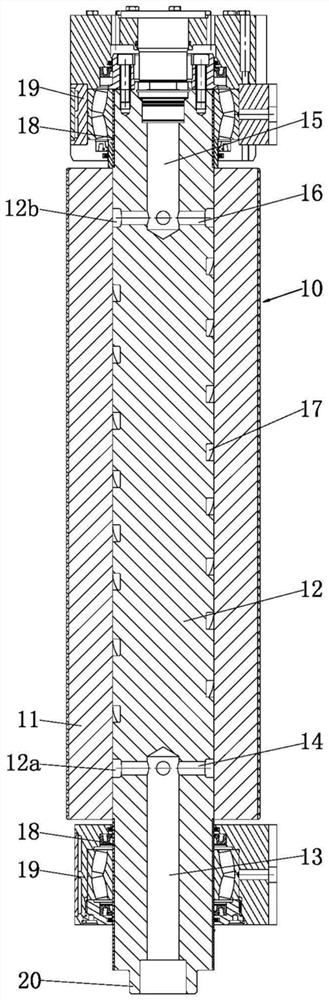

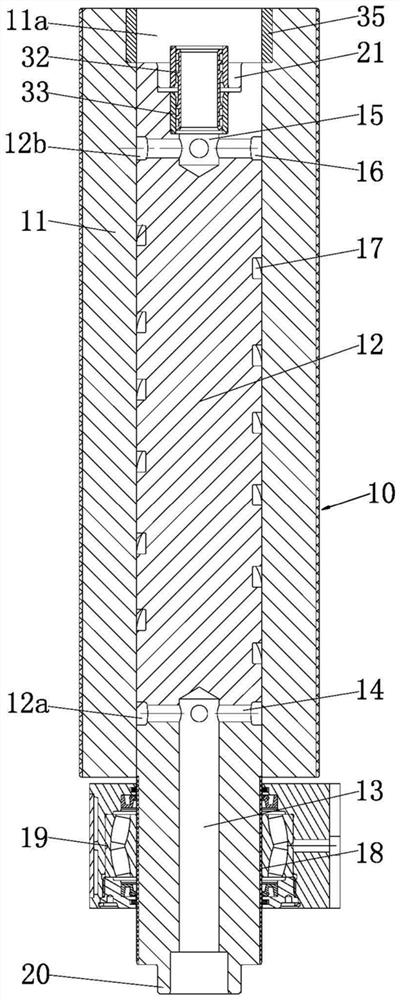

Continuous casting roller and assembling method thereof

The invention relates to a continuous casting roller. The continuous casting roller comprises at least two splicing assemblies, and each splicing assembly comprises a roller sleeve, and a core shaft; after the roller sleeves and the core shafts are in interference fit, a first radial hole, a second radial hole and a cooling medium flowing groove in the same core shaft are covered with the same roller sleeve to form a cooling channel, the part, located between the corresponding roller sleeve and the axial end face of the corresponding core shaft, of the corresponding core shaft forms an installation part, when two adjacent splicing assemblies are spliced, the first axial blind hole in the core shaft of one splicing assembly is matched with a second axial blind hole in the core shaft of the other splicing assembly; and the bearing assemblies are arranged on the installation parts in a sleeving mode and is fixed with the installation parts. The C]continuous casting roller has the advantage of being easy to mount and dismount.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

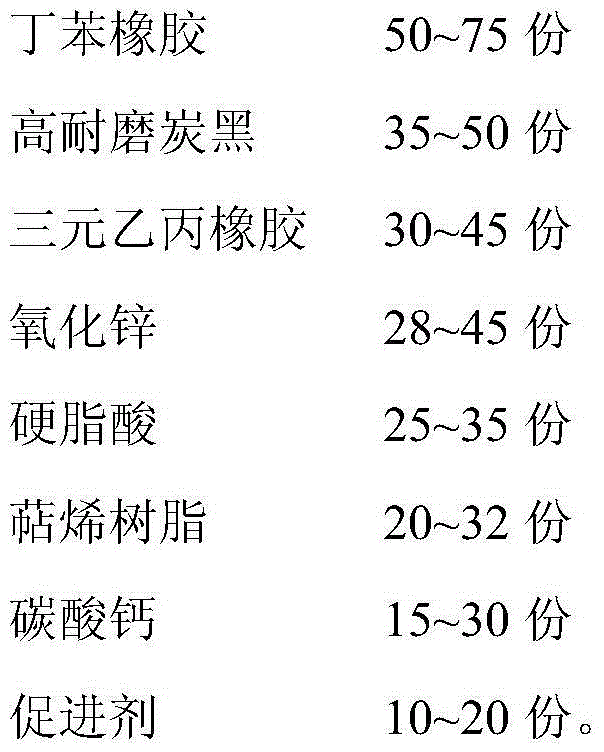

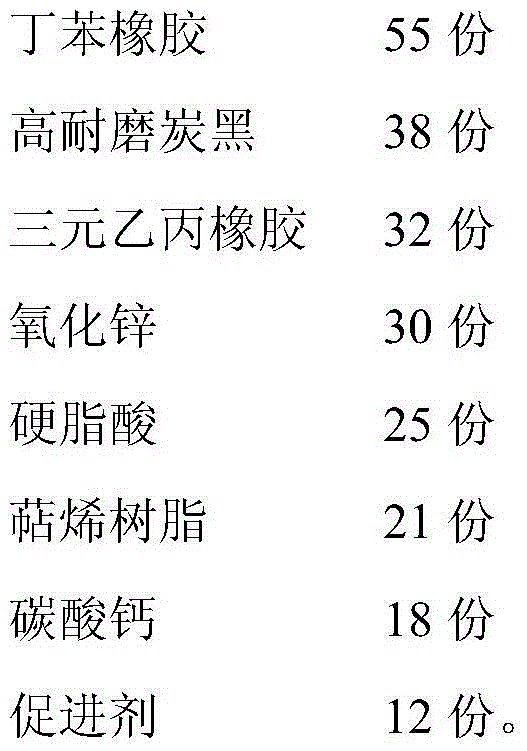

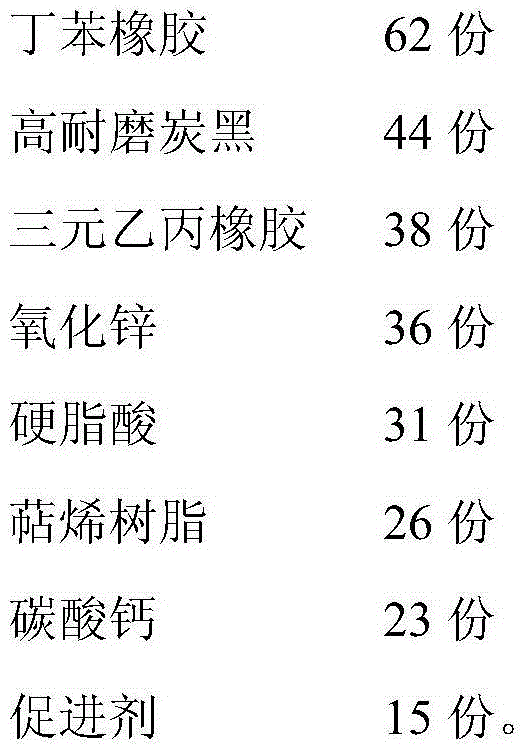

Novel wear-resistant and heat-resistant rubber conveyor belt

InactiveCN104693542AExpand the scope of applicationGood heat resistanceConveyorsChemistryButadiene-styrene rubber

The invention discloses a novel wear-resistant and heat-resistant rubber conveyor belt which comprises a framework, a covering layer and an adhesive layer, and consists of styrene-butadiene rubber, highly wear-resistant carbon block, ethylene propylene diene monomer, zinc oxide, stearic acid, terpene resin, calcium carbonate and an accelerant. A preparation method of the conveyor belt comprises the following steps: adding the styrene-butadiene rubber into an internal mixer, and adding the highly wear-resistant carbon block, the ethylene propylene diene monomer, the stearic acid and the terpene resin to perform internal mixing; adding zinc oxide, calcium carbonate and the accelerant to perform internal mixing, thereby obtaining a rubber compound; performing reprocessing on the rubber compound on a mixing mill; and putting the rubber compound subjected to reprocessing into a calender to perform cloth sticking operation, thereby obtaining a product for the covering layer of the heat-resistant conveyor belt. The novel wear-resistant and heat-resistant rubber conveyor belt disclosed by the invention can meet requirements on oil resistance and heat resistance, can meet conveyance of special materials in special environments, and broadens the application range of the conveyor belt.

Owner:QINGDAO SANHUI RUBBER MACHINERY MFG

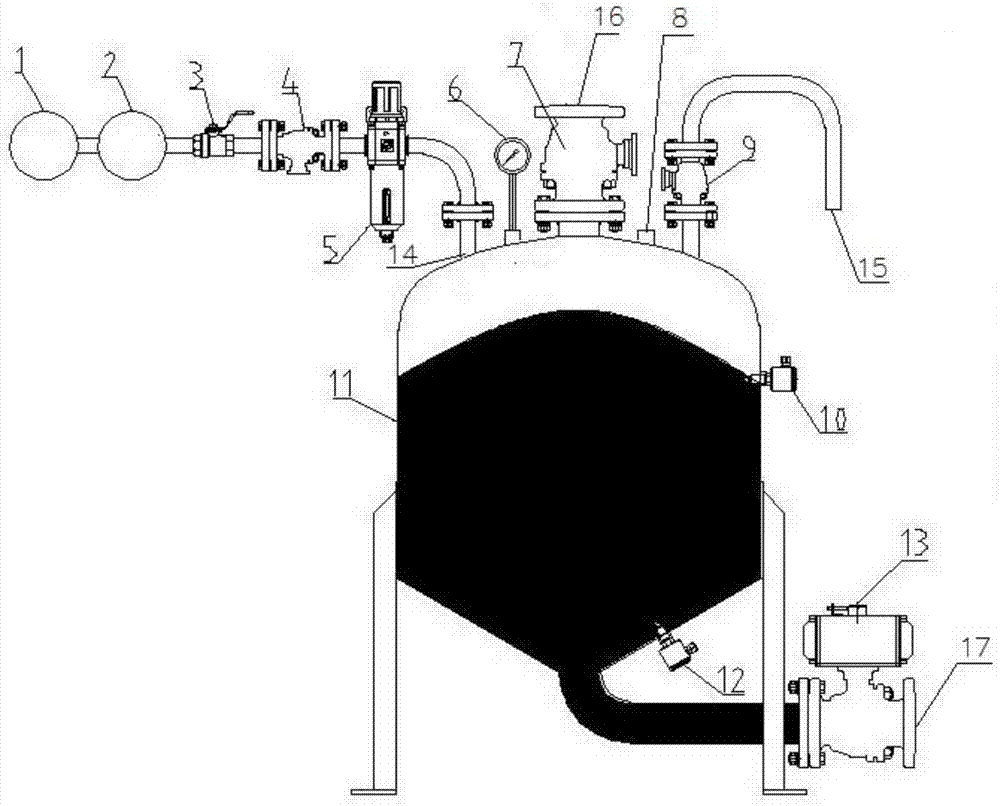

Particle conveying mechanism

The invention relates to the solid-phase material conveying technology, in particular to a particle conveying mechanism. The particle conveying mechanism comprises a storage tank. An air source assembly, a pressure gage, a feed valve, a pressure switch and an exhaust valve are arranged above the storage tank. The air source assembly comprises an air compressor, an air storage tank, a hand valve, an inlet valve and a pressure regulating valve, all of which are connected in sequence. One end of the pressure regulating valve is connected with the storage tank. A first material level induction switch is arranged on the side face of the storage tank. A second material level induction switch and a discharge valve are arranged at the bottom of the storage tank. The particle conveying mechanism is larger in conveying height, the requirement for a special plant structure can be better met, meanwhile, noise discharge is reduced, the impact generated on products is small, and conveying of diverse products can be better achieved; and material conveying can be finished within short time, the conveying amount is large, manual operation is not needed in the whole conveying process, and automation can be completely achieved.

Owner:南京法宁格节能科技股份有限公司

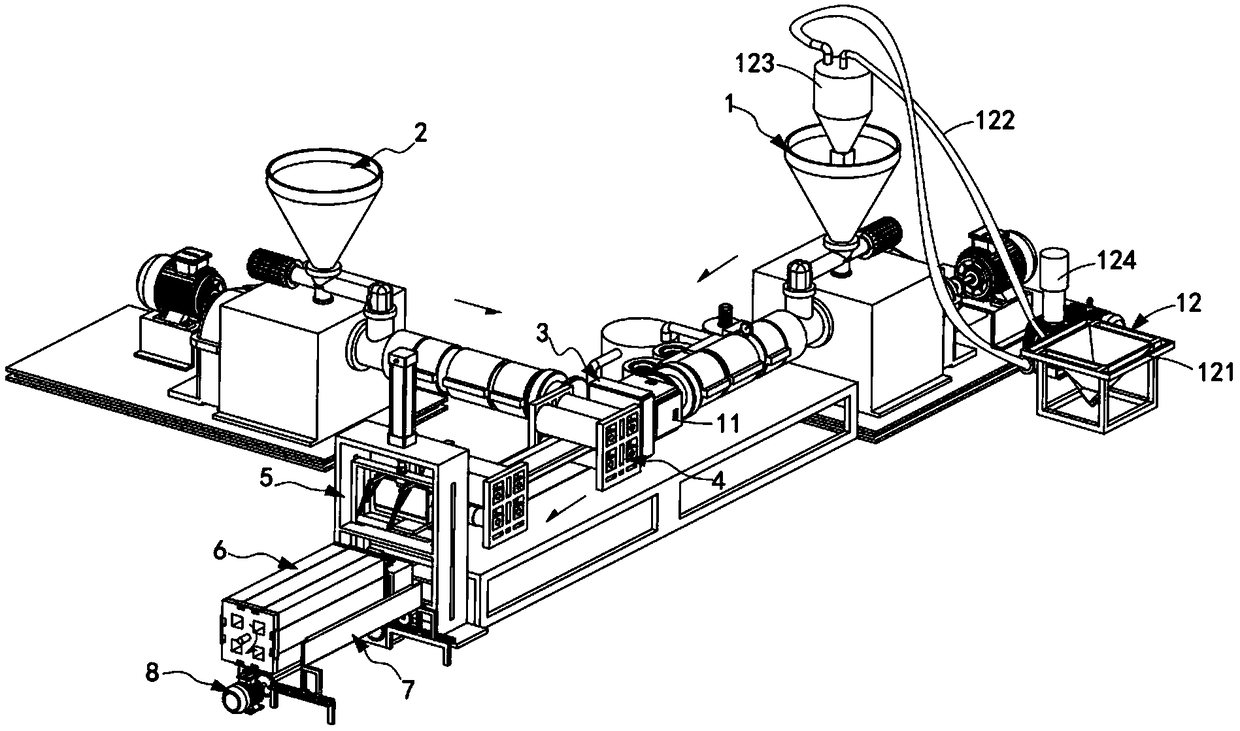

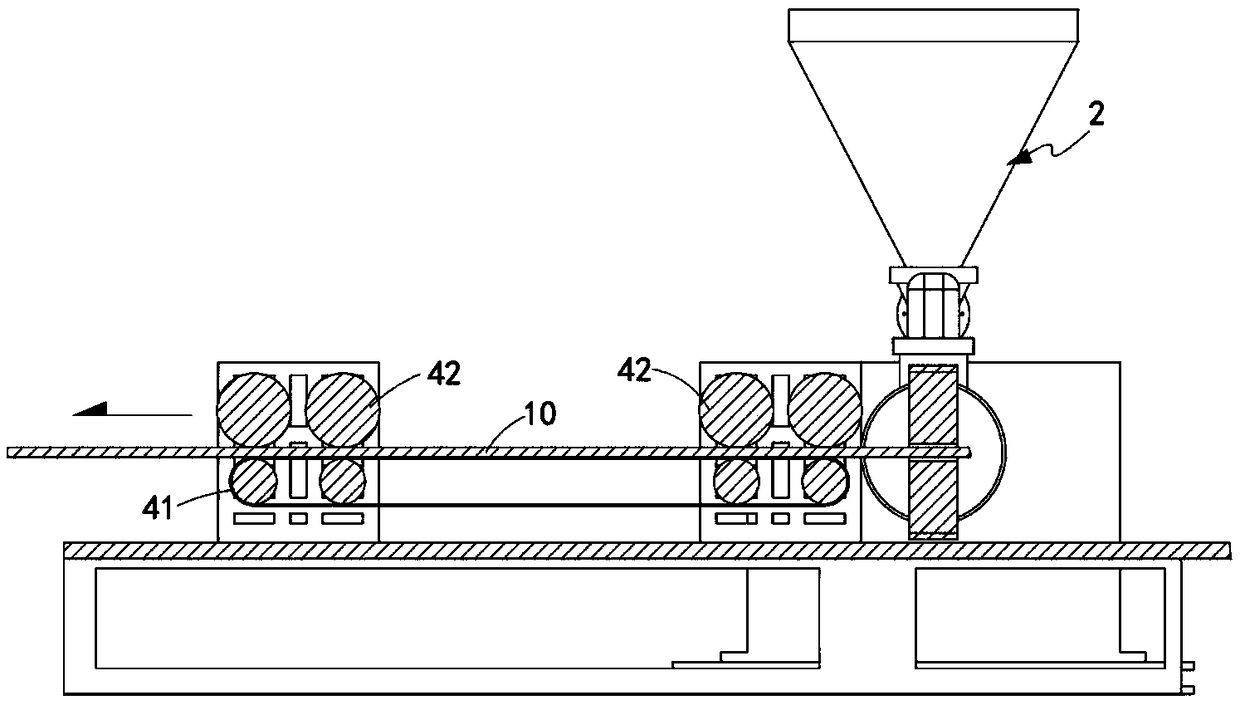

High viscosity and scratch resisting PE wood-plastic plate composite production line and production technology

InactiveCN109176764ASolve the deformationRealize automatic croppingPlywood pressesProfiling/shaping machinesProduction lineEngineering

The invention provides a high viscosity and scratch resisting PE wood-plastic plate composite production line. A working table is rotated synchronously by a push cylinder which drives a cutting tool to cut a wood-plastic plate, and therefore switching among four working stations on the working table of wood-plastic plate products after cutting is automatically achieved. A shaping mechanism is synchronously driven to conduct extrusion shaping on the wood-plastic plate products at the shaping station. The technical problem of deformation of the wood-plastic plate in the production process is solved. The invention provides a high viscosity and scratch resisting PE wood-plastic plate composite production technology. Compared with a traditional wood-plastic plate production technology, three steps of shaping, cutting discharging and waste collecting are added, the driving force in the cutting process is adopted to drive the shaping mechanism synchronously to conduct shaping processing of the wood-plastic plate products. The technical aim of forming the wood-plastic plate products after cutting is achieved. Synchronous conducting of four production steps of cutting, shaping, cutting discharging and waste collecting is achieved.

Owner:ZHEJIANG YUANSENTAI FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com