Novel wear-resistant and heat-resistant rubber conveyor belt

A heat-resistant rubber and conveyor belt technology, applied in the field of conveyor belts, can solve the problems of shortened service life of conveyor belts, cracks, poor heat resistance of conveyor belts, etc. The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

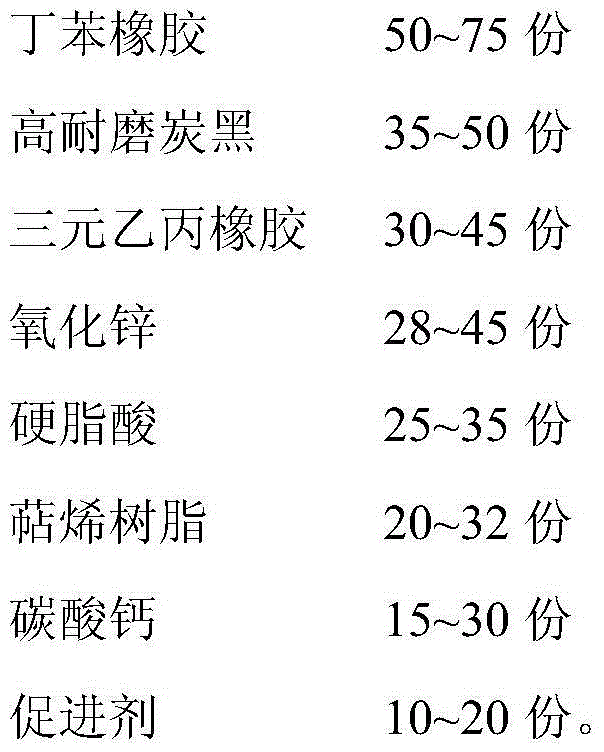

Embodiment 1

[0016]

[0017] Its preparation method is: add styrene-butadiene rubber into the internal mixer, put in high wear-resistant carbon black, EPDM rubber, stearic acid, terpene resin banburying; then add zinc oxide, calcium carbonate, accelerator banburying , to obtain the mixed rubber; take the mixed rubber and carry out re-milling on the open mill; send the re-refined mixed rubber into the calender for patching operation, that is, the product is used for the covering layer of the heat-resistant conveyor belt.

[0018] The invention can meet the requirements of oil resistance and heat resistance, meet the special environment and the transportation of special materials, and broaden the application range of the conveyor belt.

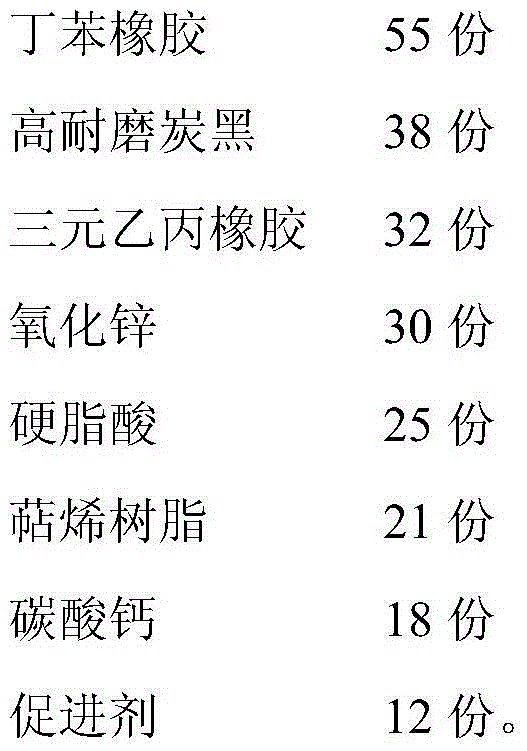

Embodiment 2

[0020]

[0021] The preparation method is the same as above.

[0022] The heat-resistant conveyor belt of the present invention has good heat-resistant performance, can be used at relatively high temperature and is not prone to aging and cracking.

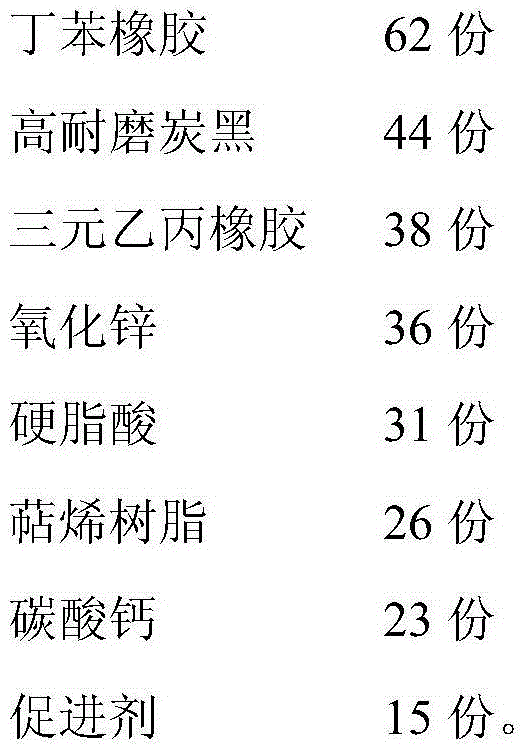

Embodiment 3

[0024]

[0025] The preparation method is the same as above.

[0026] The invention not only maintains the performance of the ordinary heat-resistant conveyor belt adhesive, but also strengthens the heat-oxidative aging resistance of the adhesive itself, and further improves the effect of the adhesive on the skeleton. The affinity of the canvas can better reduce the delamination and cross-cutting of the heat-resistant conveyor belt during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com