Patents

Literature

73results about How to "Improve heat and oxygen aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene composite capable of resisting thermal oxidizing aging

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

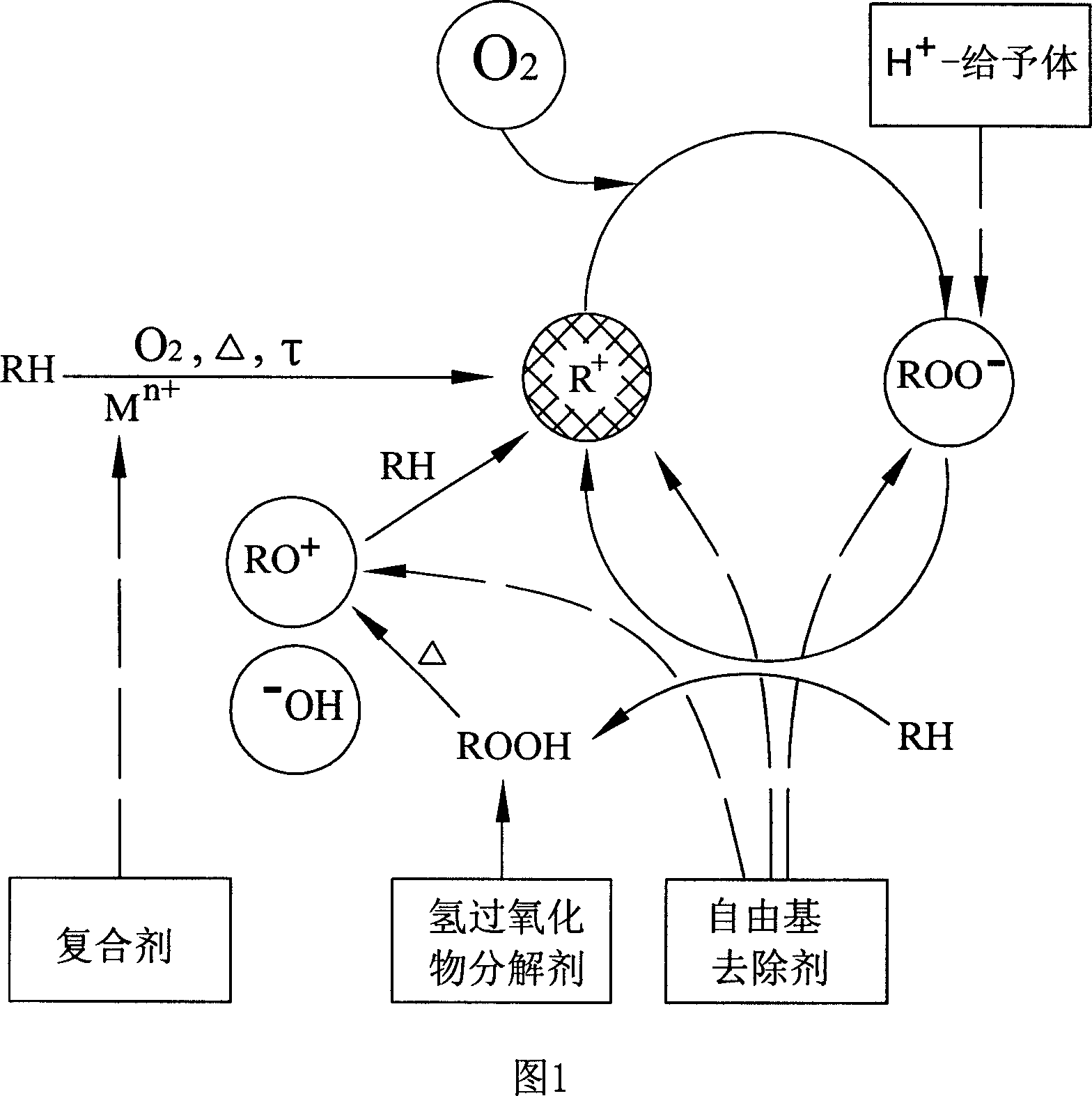

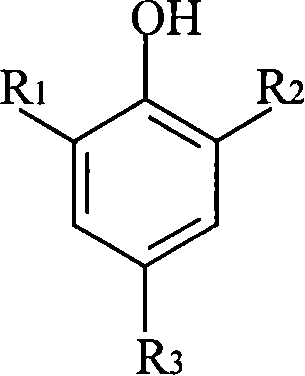

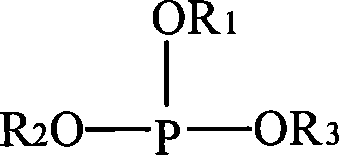

Composite heat resisting antioxidant for polyolefin and its production process and application

InactiveCN101067030AImprove heat aging resistanceEliminate catalytic cleavagePolyolefinPolymer science

The present invention relates to composite heat resisting antioxidant for polyolefin and its production process and application. The composite heat resisting antioxidant consists of hindered phenol antioxidant 20-75 wt%, phosphate antioxidant 20-75 wt%, and chelating metal component containing at least bisamide-metal ion chelating structure 5-50 wt%, and is prepared through physical mixing and airflow crushing. The composite heat resisting antioxidant is applied in polyolefin product and can raise the ageing resisting performance of polyolefin product, especially greenhouse film, greatly.

Owner:广东国望精细化学品有限公司

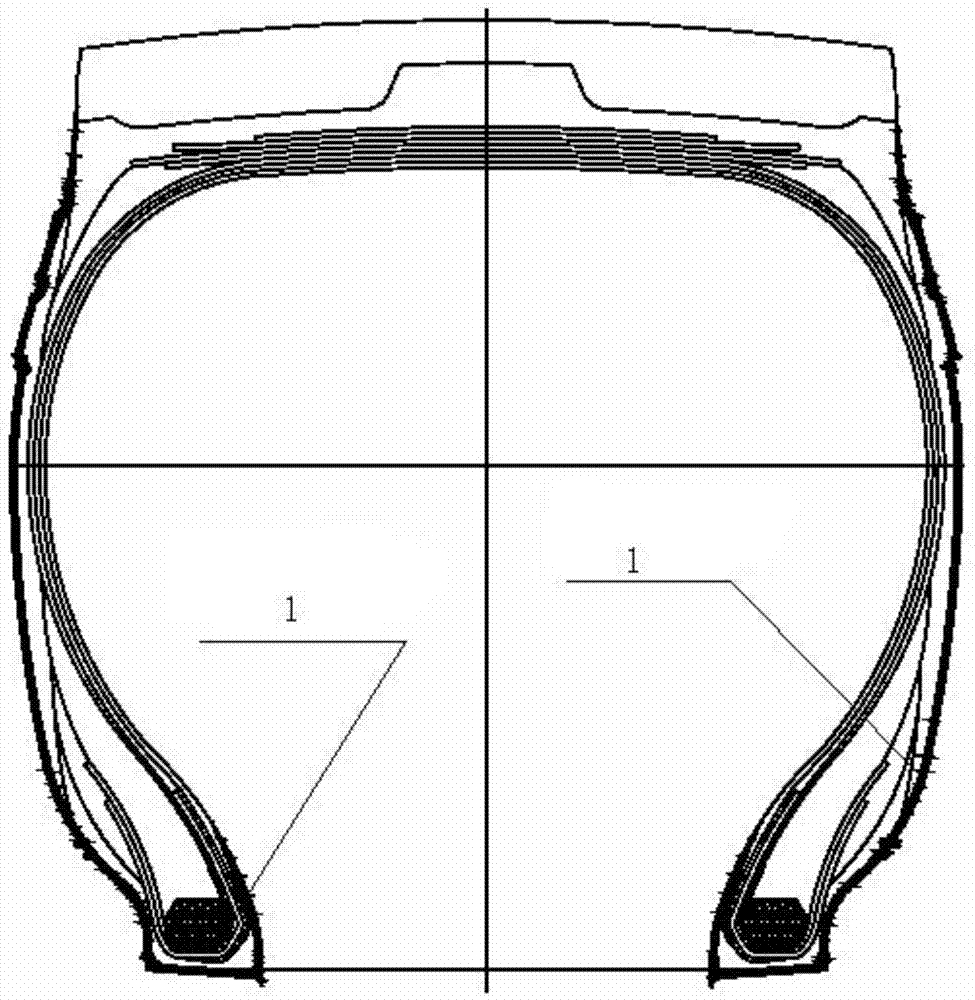

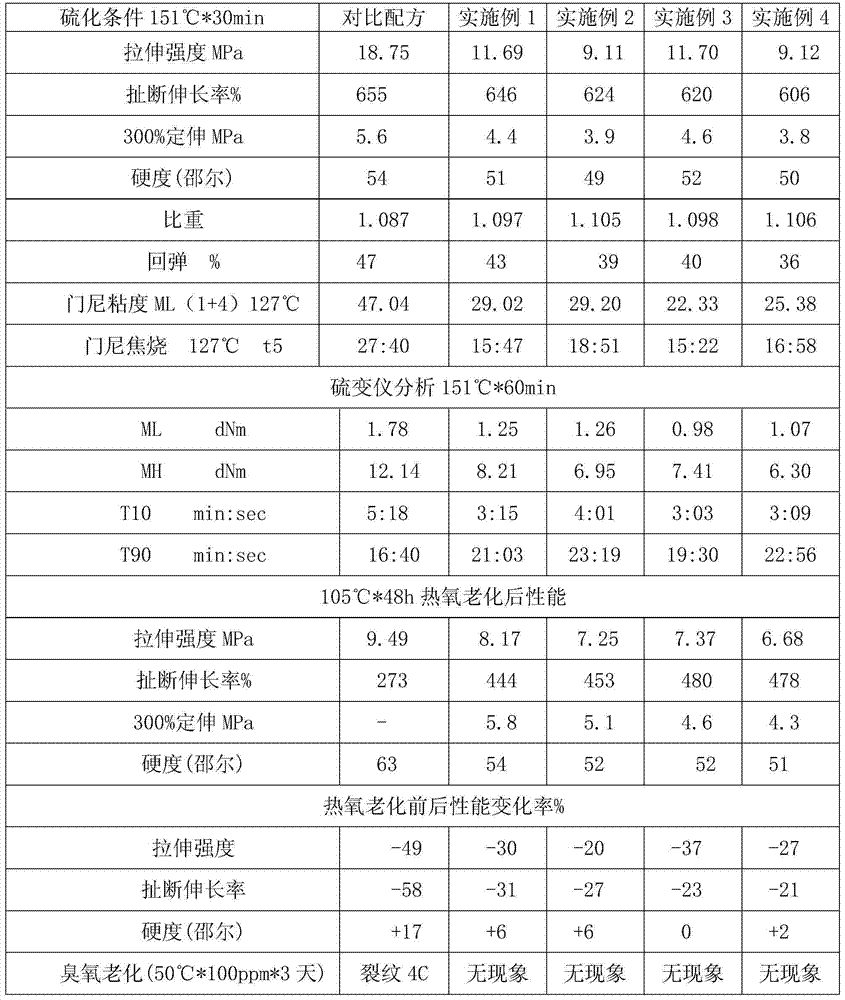

Preparation method for aging resistance protection glue at tire side-wall and seam allowance part and application method thereof

ActiveCN104292511AImprove heat and oxygen aging resistanceImprove ozone aging resistanceSpecial tyresPolymer scienceCopolymer

The invention provides a aging resistance protection glue at tire side-wall and seam allowance part, which comprises components of natural rubber, brominated butyl rubber, high cis-butadiene rubber, ethylene-propylene diene copolymer, butyl reclaimed rubber, carbon black, eleaostearic acid, zinc oxide, octyl-phenolic tackifying resin, a hydrocarbon resin mixture, protection wax, naphthenic oil, sulphur and a promoter; and discloses a preparation method of the above rubber compound and an application method. The method changes a mode that the traditional rubber compound raw rubber system at the side-wall and seam allowance part rubber compound raw rubber system employs a combination mode of natural rubber and high cis-butadiene rubber, brominated butyl rubber with good aging resistance performance and high molecular chain saturation as well as high cis-butadiene rubber are added, a sulfuration system is optimized, thermo-oxidative aging resistance of the rubber compound can be increased, ozone aging resistance is increased; aging and cracking problems generated at the tire side-wall and seam allowance part can be avoided, tire usage security is increased, and refurbishment time of tire is increased.

Owner:SAILUN GRP CO LTD

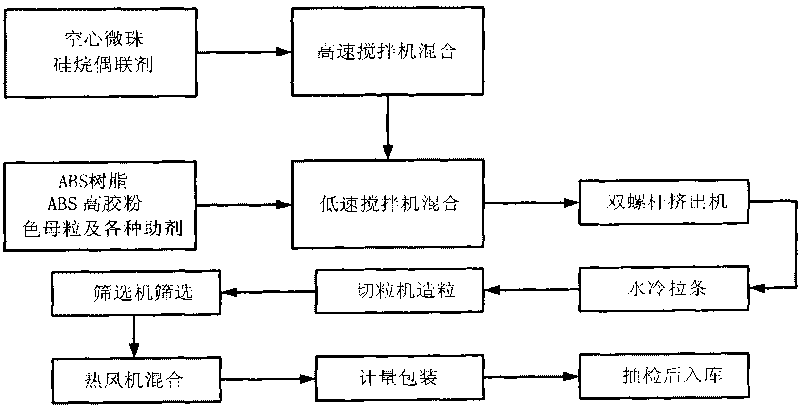

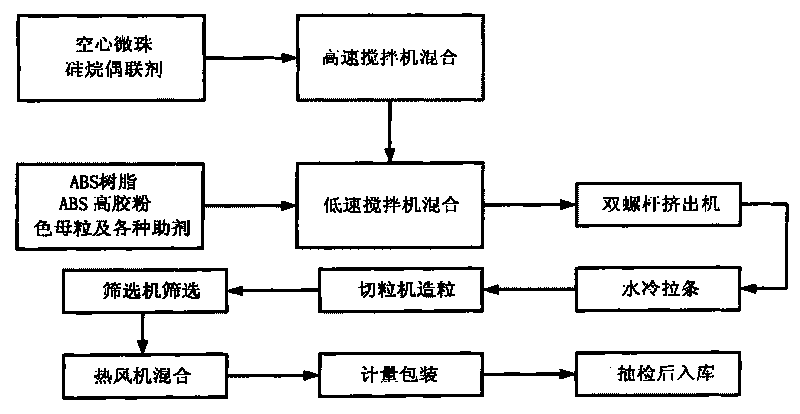

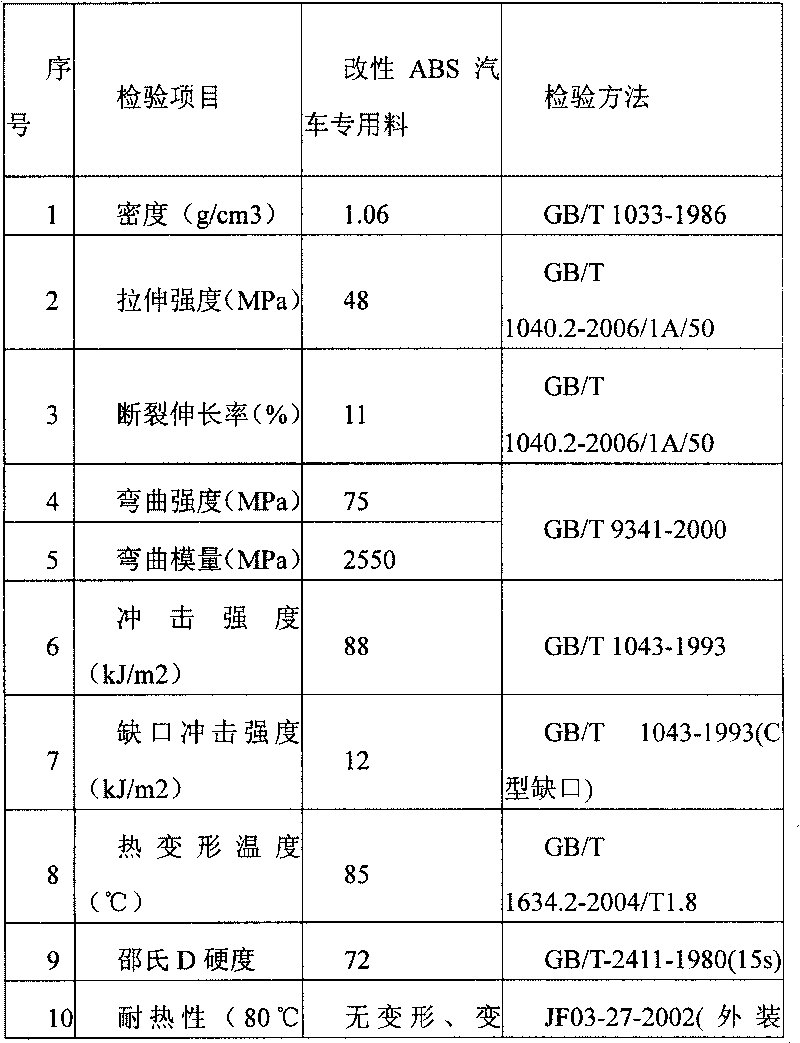

Modified ABS automobile special material and production method thereof

The invention provides a modified ABS automobile special material comprising the following components in the formula in parts by weight: 100 parts of resin matrix ABS, 5-15 parts of active filler hollow microsphere, 4-8 parts of high rubber powder ABS, 0.5-0.8 part of age resister and 2-4 parts of master batch. In the above formula composition, the matrix resin ABS is granular substance; the active filler hollow microsphere is processed by silane coupling agent KH 550; the age resister mainly comprises master antioxidant, slave antioxidant and uvioresistant agent which are all powdery substance; the color of the master batch is determined according to product requirements, and the master batch is granular substance. The invention utilizes the principle that solubility parameters are similar; other polymers and various auxiliary agents, such as age resister, flexibilizer, fillers and the like are added into the ABS material and carry out molten mechanical mixing at certain temperature so as to obtain a new material applied on lorry parts.

Owner:CHINA FIRST AUTOMOBILE

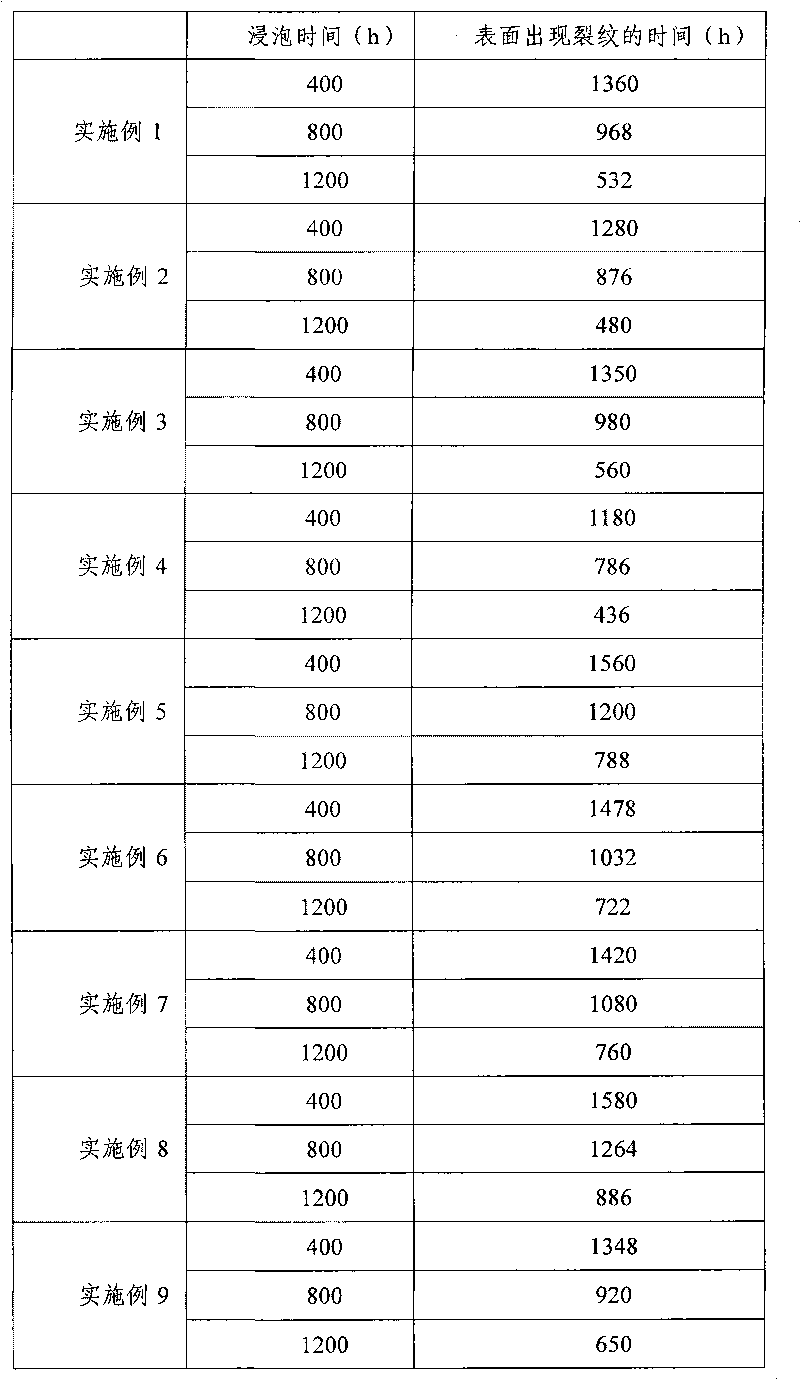

Detergent and hot water solution soakage-resistance polypropylene composite

ActiveCN101759915ASolve the problem of easy agingImprove heat and oxygen aging resistancePolypropylene compositesPolymer science

The invention discloses a detergent and hot water solution soakage-resistance polypropylene composite, which comprises the following components in percentage by weight: polypropylene resin 50-80, flexibilizer 0-15, filler 5-40, composite antioxidant 0.5-1.5 and processing aid 0.2-0.8, wherein the melt index of the polypropylene resin under test conditions of a temperature of 230 DEG C and a mass of 2.16KG is 2 to 40g / 10min; and the composite antioxygen is a composite of a triazine antioxygen, a phosphite ester antioxygen and a thioether antioxygen. Compared with the prior art, the detergent and hot water solution soakage-resistance polypropylene composite has obviously improved heat resistance, aging resistance and oxidization resistance under the condition of the same detergent and hot water solution soakage time and has a service life prolonged by 5 to 12 times. The easy aging problem of the plastic parts, needing to contact detergent directly, of a washing machine, a dish-washing machine and the like in the prior art is solved.

Owner:SHANGHAI KINGFA SCI & TECH +1

Special antifouling corrosion-resistant paint for marine ships

InactiveCN104277635AReduce surface tensionStable structureAntifouling/underwater paintsPaints with biocidesFiberSodium Pyrithione

The invention discloses a special antifouling corrosion-resistant paint for marine ships, which is prepared from the following raw materials in parts by weight: 60-85 parts of organosilicon modified acrylic resin, 15-40 parts of fluorocarbon resin, 20-35 parts of solvent, 3-9 parts of boron carbide, 15-30 parts of kieselguhr, 20-40 parts of nano titanium dioxide, 10-30 parts of capsaicin, 10-25 parts of fiber floss, 3-10 parts of sodium silicate, 3-10 parts of zinc powder, 1.3-3 parts of zinc pyrithione, 2-3.8 parts of sodium hexametaphosphate, 0.3-0.8 part of titanate coupling agent, 2-10 parts of dioctyl dinbutyl phthalate, 0.9-2.6 parts of wetting and dispersing agent, 0.5-1.8 parts of defoaming agent, 0.6-1.9 parts of leveling agent and 0.2-0.6 part of film formation assistant. The special antifouling corrosion-resistant paint for marine ships has the advantages of favorable corrosion resistance, favorable antifouling property and high adhesive force with the substrate.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

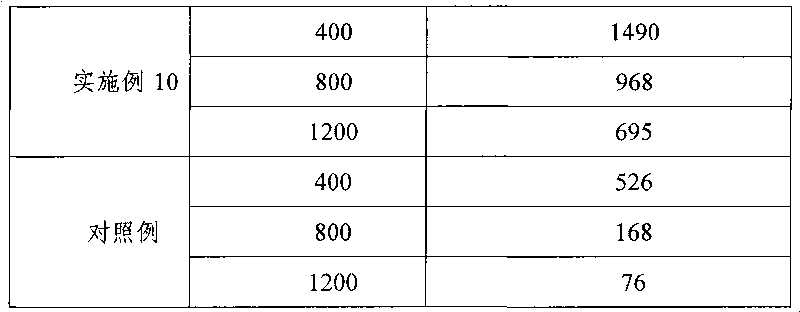

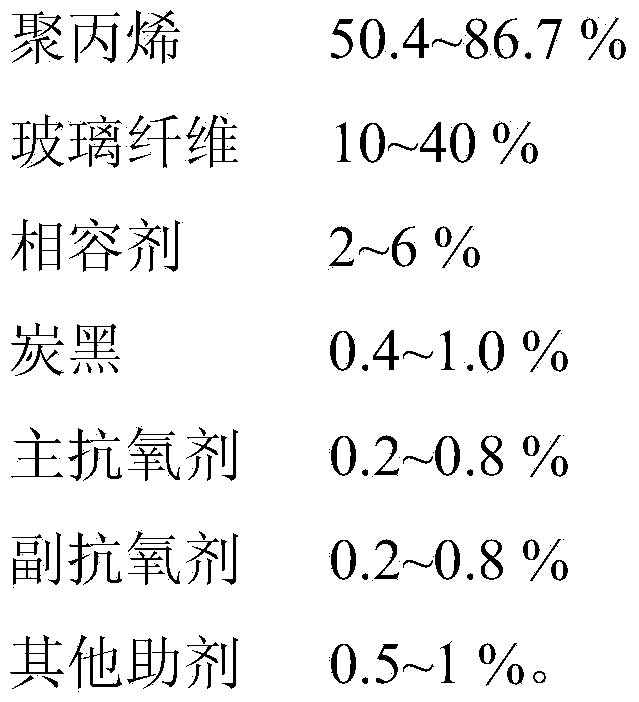

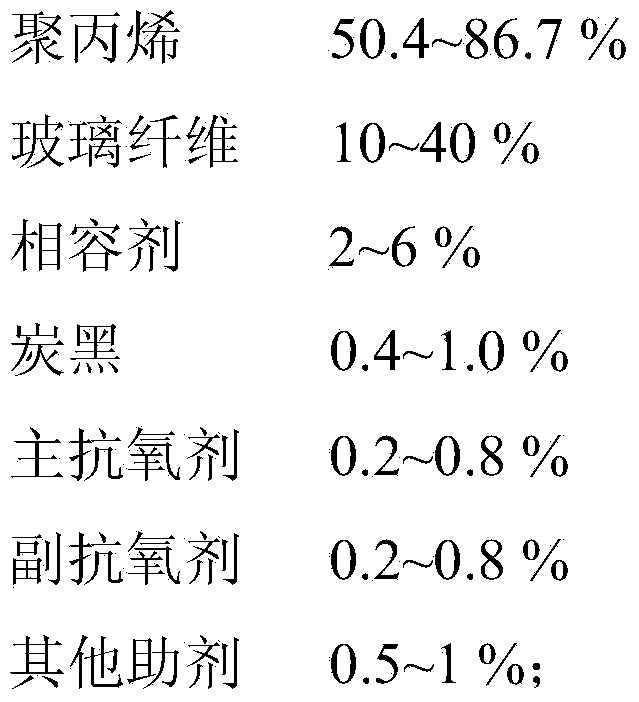

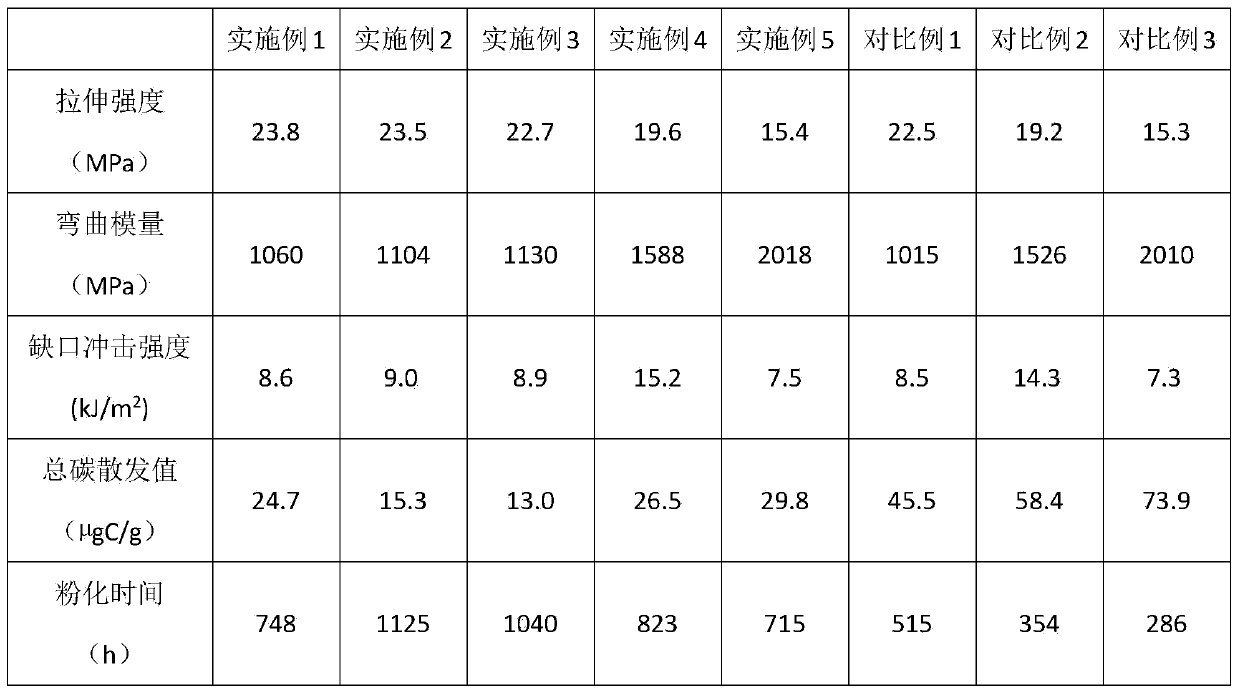

Black glass fiber reinforced polypropylene composite and preparation method and application of same

InactiveCN103467856AReduces adverse effects of thermo-oxidative agingReduced antioxidant contentPolypropylene compositesGlass fiber

The invention belongs to the field of polypropylene composites, and discloses a black glass fiber reinforced polypropylene composite and a preparation method and application of the black glass fiber reinforced polypropylene composite. The black glass fiber reinforced polypropylene composite comprises the flowing components, by mass, 50.4-86.7% of polypropylene, 10-40% of glass fibers, 2-6% of compatilizer, 0.4-1.0% of carbon black, 0.2-0.8% of primary antioxidants, 0.2-0.8% of auxiliary antioxidants and 0.5-1% of other auxiliaries, and the carbon black is furnace carbon black with the 45-145mg / g iodine absorption value. Because the furnace carbon black with the proper iodine absorption value is added to the black glass fiber reinforced polypropylene composite, the adverse effect of the furnace carbon black on the hot oxygen aging resisting performance of the polypropylene composite is reduced, the antioxidant content in the polypropylene composite is reduced and the hot oxygen aging resisting performance of the black glass fiber reinforced polypropylene composite is improved. The black glass fiber reinforced polypropylene composite keeps good dispersity and pigmentation degree and meanwhile reduces the using amount of the antioxidants and product cost.

Owner:TIANJIN KINGFA NEW MATERIAL +1

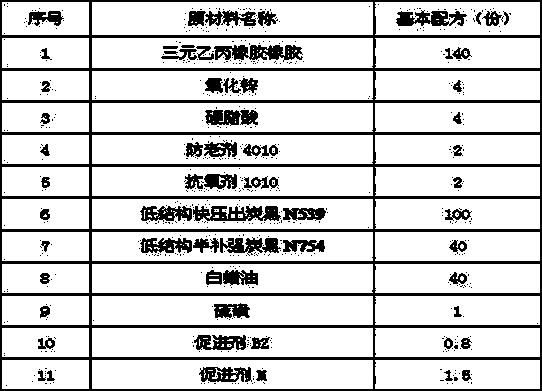

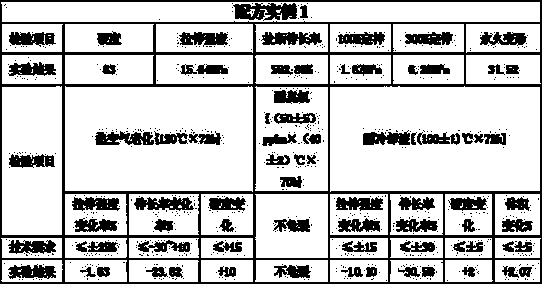

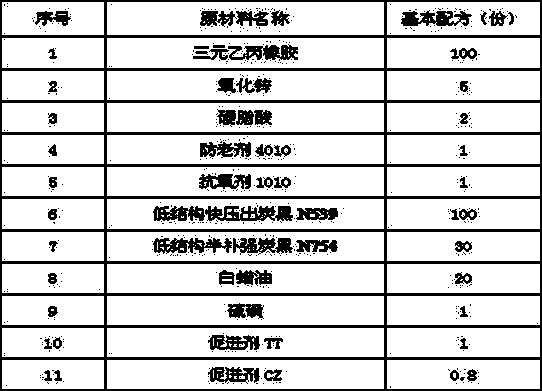

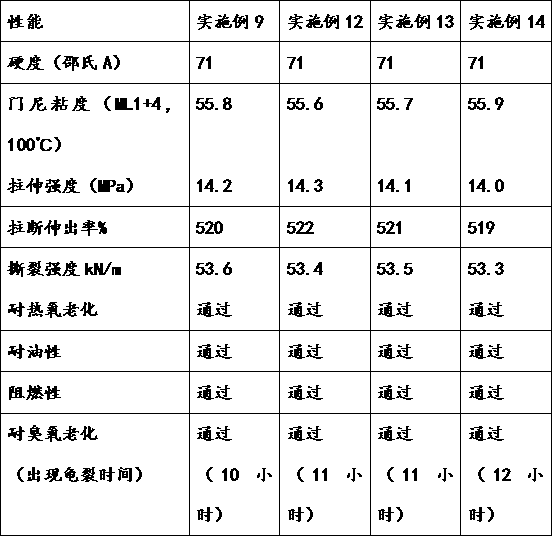

EPDM (Ethylene-Propylene-Diene Monomer) rubber composition and preparation method thereof

InactiveCN103881241AImprove heat and oxygen aging resistanceImprove ozone aging resistancePolymer scienceVulcanization

The invention relates to the technical field of rubber, and particularly relates to an EPDM (Ethylene-Propylene-Diene Monomer) rubber composition and a preparation method thereof. The EPDM rubber composition comprises the following ingredients: EPDM rubber, zinc oxide, stearic acid, antiaging agent, antioxidant, low-structure fast-extruding carbon black N539, low-structure semi-reinforcing carbon black N754, white wax oil, sulfur and accelerant. The preparation method sequentially comprises the steps of: weighing rubber and raw materials; plastifying the rubber; carrying out internal mixing and charging materials; performing one-section open-milling and batching off; stopping and cooling; carrying out two-section open-milling and sulphurating; vulcanizing rubber pieces; cutting patterns according to standard; and carrying out test detection. By use of the EPDM rubber composition, the heat-oxygen aging resistance, ozone aging resistance, weather aging resistance and low temperature resistance of a rubber pipe product can be improved, and the defect that the rubber pipe can resist high temperature, but is hardened and gets fragile under a low-temperature condition can be overcome. Furthermore, the product cost can be greatly saved, and the processing technique is simple and practical.

Owner:柳州日高汽车减振技术有限责任公司

High-glossiness polypropylene composition as well as preparation method and application thereof

The invention discloses a high-glossiness polypropylene composition which comprises the following components in parts by weight: 100 parts of high-isotacticity homo-polypropylene; 2-12 parts of ultrahigh melt index polypropylene; and 10-50 parts of an inorganic filler. By adding a small amount of ultrahigh melt index polypropylene into the polypropylene composition mainly comprising high-isotacticity homo-polypropylene, the technical defect that low shrinkage and high glossiness of the high-isotacticity homo-polypropylene cannot be achieved at the same time is overcome, meanwhile, the heat resistance and aging resistance of the material can be improved, and the polypropylene composition can be widely applied to the fields of household appliances and electronic appliances.

Owner:KINGFA SCI & TECH CO LTD

Environment-friendly polyamide composition with good appearance and hot water stability and preparation method of polyamide composition

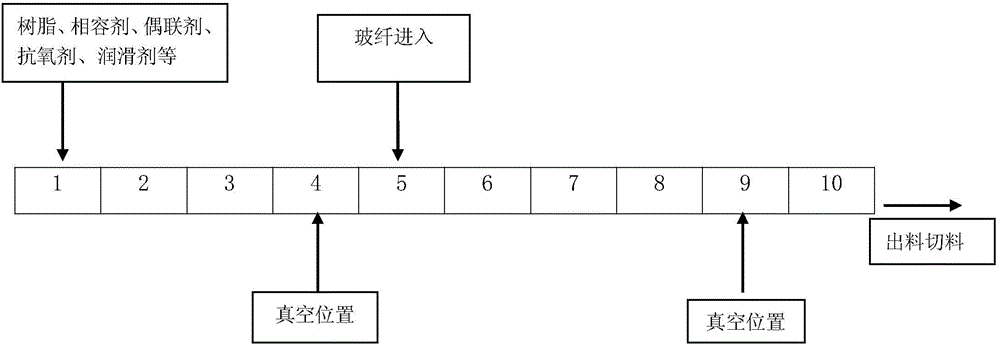

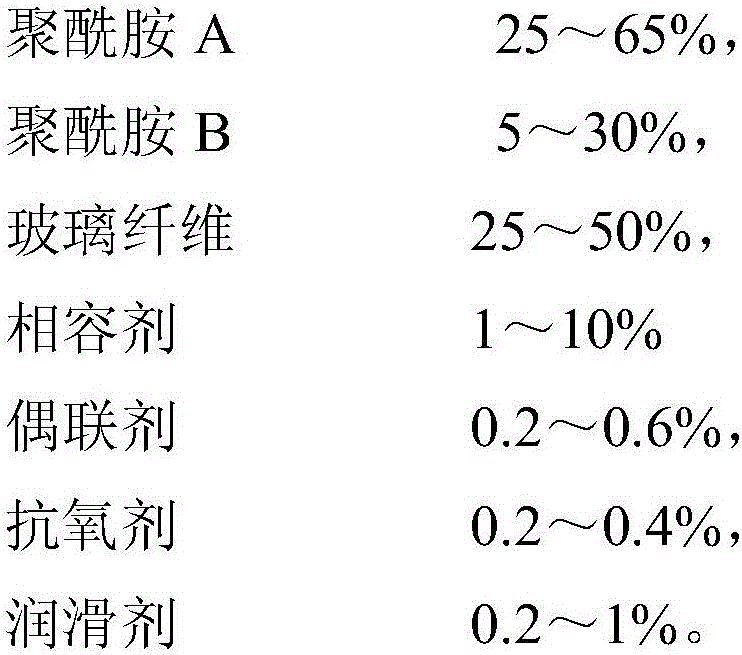

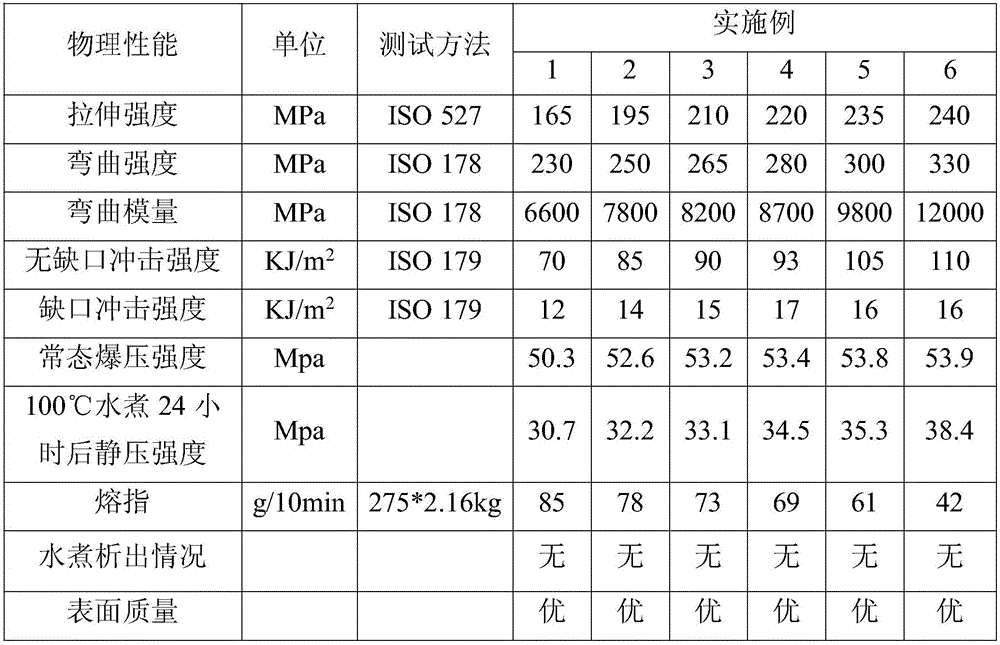

The invention relates to environment-friendly polyamide composition with good appearance and hot water stability and a preparation method of the polyamide composition. The environment-friendly polyamide composition is prepared from components in percentage by weight as follows: 25%-65% of polyamide A, 5%-30% of polyamide B, 25%-50% of glass fibers, 1%-10% of a compatilizer, 0.2%-0.6% of a coupling agent, 0.2%-0.4% of an antioxidant and 0.2%-1% of a lubricant. The invention further provides the preparation method of the composition. The polyamide composition and the preparation method have the advantages as follows: the prepared material has excellent appearance quality and mechanical performance and high hot water resistance retention rate, is environment-friendly and very low in precipitation, meets the requirements of food contact materials and is particularly applicable to the field of high-pressure cleaning and the water contact fields such as daily bathroom equipment accessories and the like.

Owner:上海日之升科技有限公司

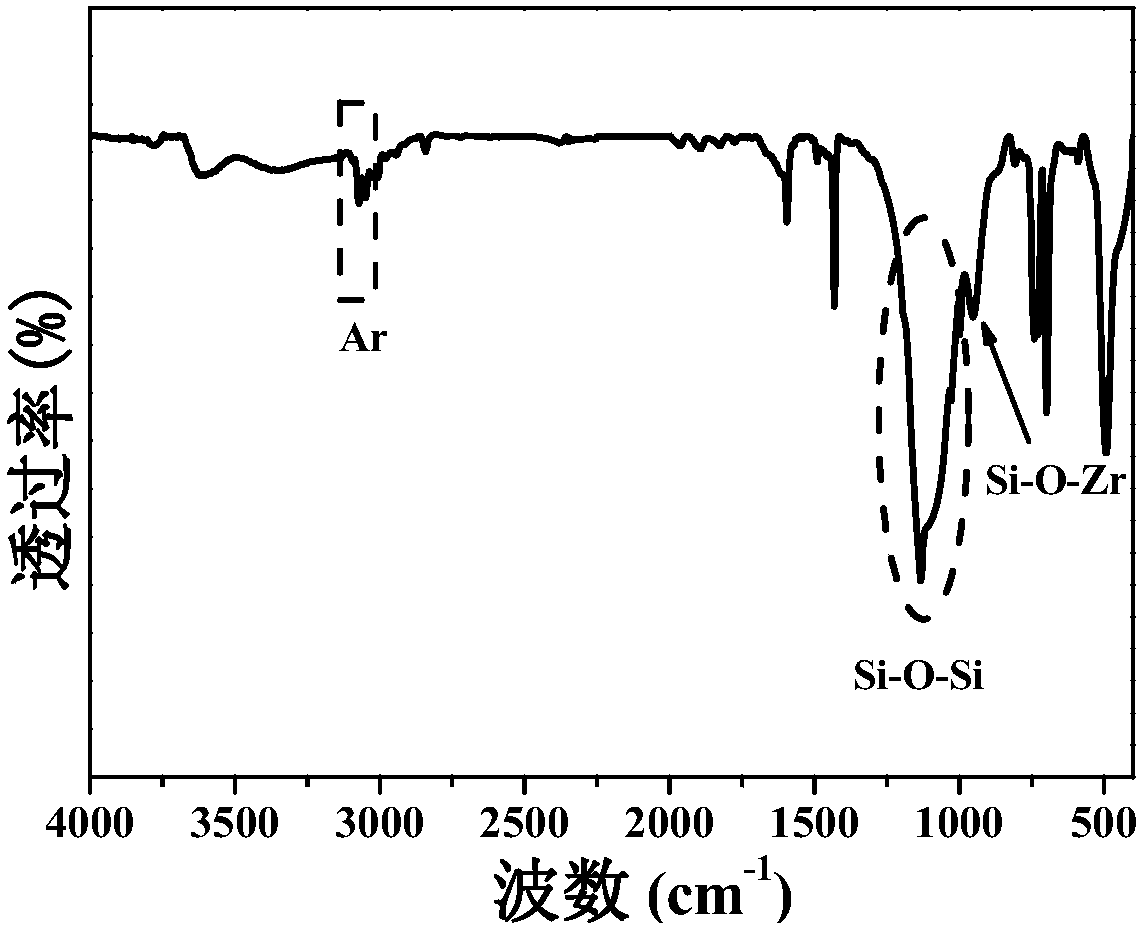

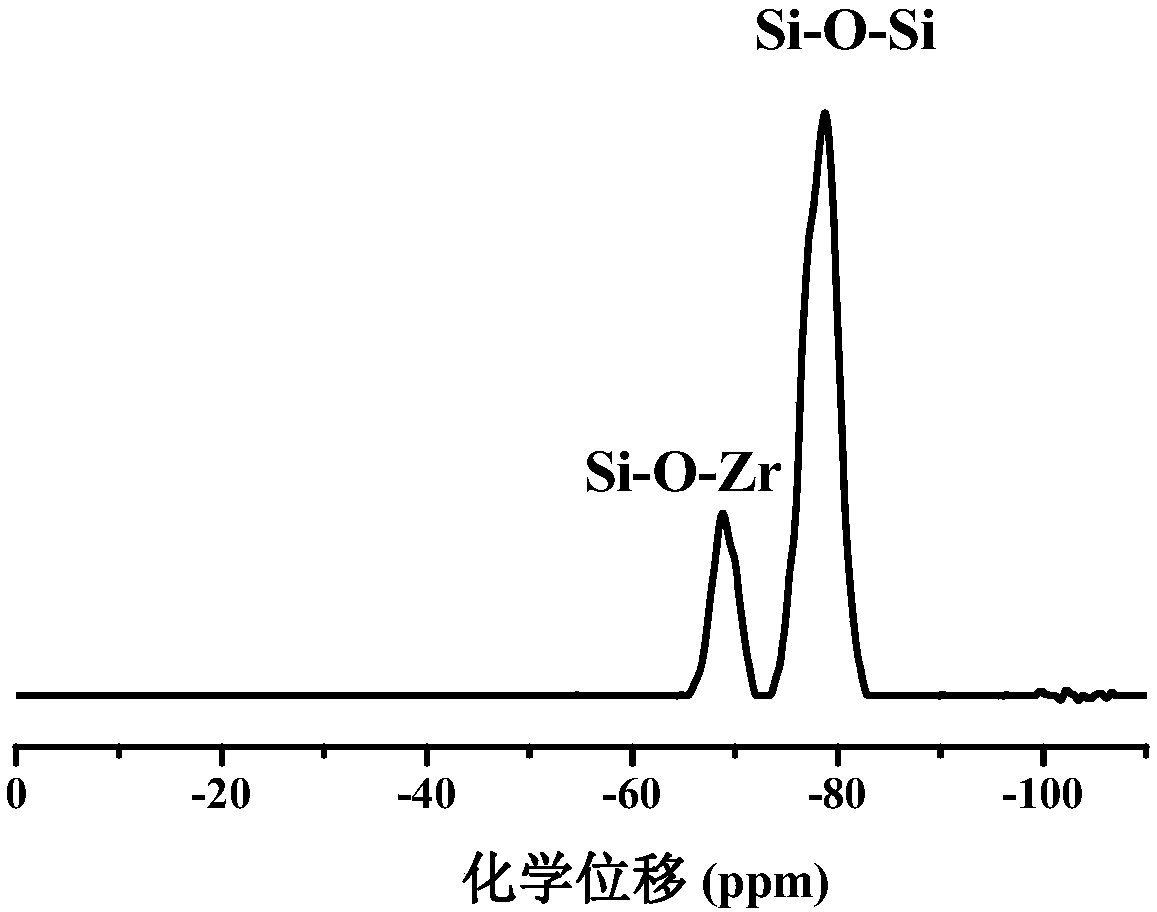

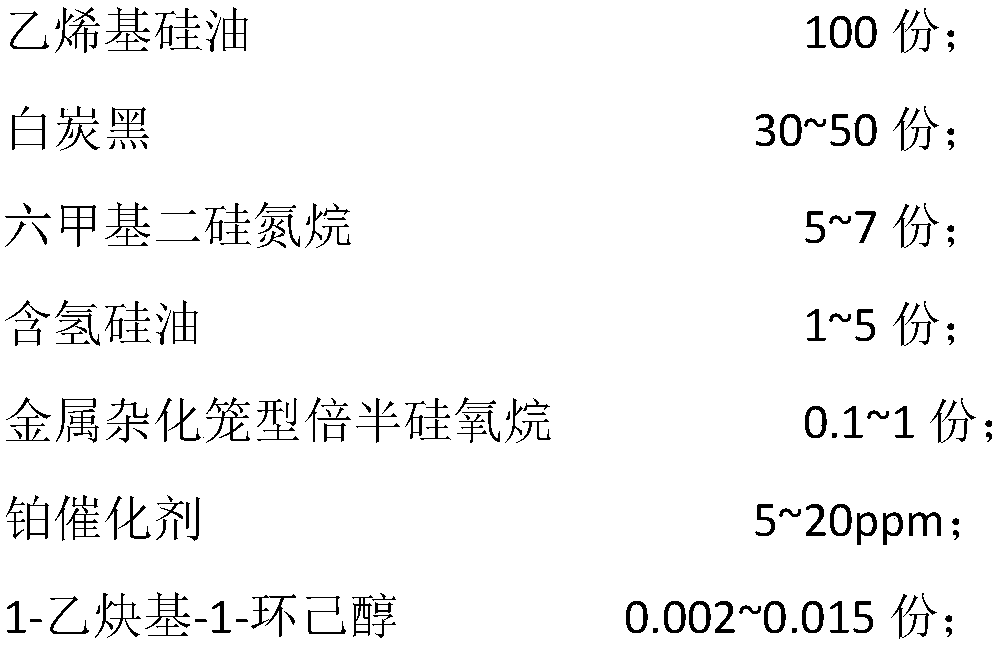

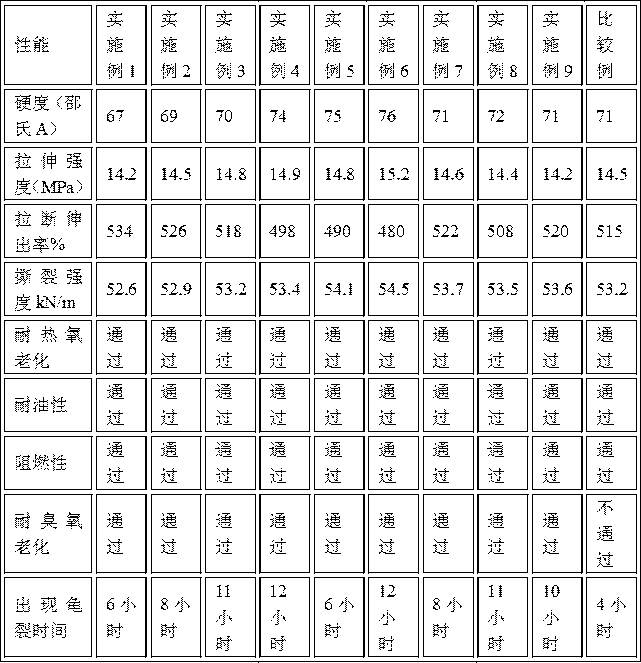

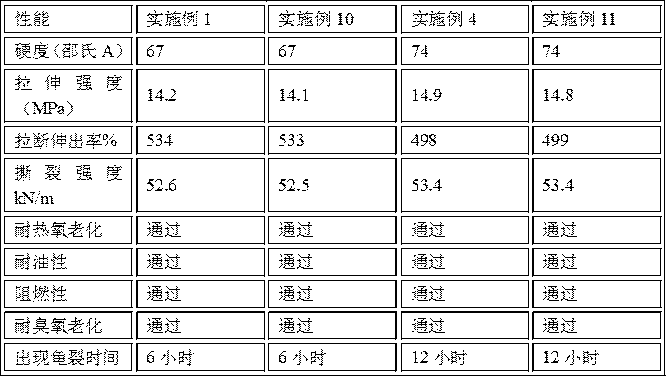

Addition type liquid silicone rubber with high transparency and resistance to thermo-oxidative aging, and preparation method thereof

ActiveCN107936572AOvercome the disadvantage of adding a large amountImprove heat and oxygen aging resistanceAviationVulcanization

The invention discloses an addition type liquid silicone rubber with high transparency and resistance to thermo-oxidative aging, and a preparation method thereof. The addition type liquid silicone rubber comprises the following raw materials by mass: 100 parts of vinyl silicone oil, 30 to 50 parts of white carbon black, 5 to 7 parts of hexamethyldisilazane, 1 to 5 parts of hydrogen-containing silicone oil, 1 to 5 parts of metal hybrid cage silsesquioxane, 5 to 20 ppm of a platinum catalyst and 0.03 to 0.07 part of 1-ethynyl-1-cyclohexanol. The preparation method comprises the following steps:subjecting vinyl silicone oil, white carbon black and hexamethyldisilazane to high-temperature mixing with a vacuum kneader, and then carrying out cooling and grinding with a three-roll grinder so asto obtain masterbatch; and then adding metal hybrid cage silsesquioxane, hydrogen-containing silicone oil, 1-ethynyl-1-cyclohexanol, the platinum catalyst and the like into the masterbatch, and then carrying out mechanical mixing and vulcanization so as to obtain the addition type liquid silicone rubber. The prepared silicon rubber of the invention has excellent resistance to thermo-oxidative aging, high transparency and good mechanical properties, and can be applied to fields such as aerospace and aviation, the nuclear power industry, electronic appliances and medical equipment.

Owner:SOUTH CHINA UNIV OF TECH

Compound rubber and preparation method thereof

The invention relates to the field of rubber materials, and provides compound rubber and a preparation method thereof for the problem of poor ozone-aging resistance. By adoption of the compound rubberand the preparation method, the ozone-aging resistance can be better improved. The invention adopts the following technical scheme that the compound rubber is prepared from the following raw materials in parts by mass: 20-50 parts of polyurethane, 50-80 parts of butadiene-acrylonitrile rubber, 4-8 parts of plasticizer, 20-50 parts of white carbon black, 0.5-3 parts of silane coupling agent, 40-60parts of flame retardant, 1.5-4 parts of crosslinking agent and 6-10 parts of clay. The method for preparing the compound rubber comprises the following steps: (1) mixing of masterbatch; (2) vulcanization of the masterbatch: prolonging the coagulation time of the masterbatch in a stage of no addition of the crosslinking agent. (3) vulcanization. The compound rubber and the preparation method provided by the invention have the beneficial effects that oil resistance is provided by acrylonitrile in the butadiene-acrylonitrile rubber, flame retardance is provided by the flame retardant, and better ozone-aging resistance is provided by the polyurethane; by prolonging of the coagulation time of the masterbatch in the stage of no addition of the crosslinking agent in a mixing machine, the clay can be better dispersed in mixed rubber, so that the ozone-aging resistance of the compound rubber can be improved.

Owner:茂联橡胶制品(深圳)有限公司

Modified coconut shell and natural rubber composite cable sheath material

InactiveCN104194239ALow hydroxyl contentImprove hydrophobicityRubber insulatorsInsulated cablesFiberVulcanization

The invention discloses a modified coconut shell and natural rubber composite cable sheath material which is characterized by comprising the following raw materials in parts by weight: 100 parts of natural rubber, 8-10 parts of maleic anhydride, 30-40 parts of coconut shell fiber, 15-20 parts of kieselguhr, 5-10 parts of nylon PA, 10-15 parts of calcined clay, 30-40 parts of white carbon black, 20-30 parts of carbon black, 20-40 parts of attapulgite, 4-4.5 parts of zinc oxide, 1.5-2 parts of sulfur, 1-2 parts of vulcanization accelerant N-cyclohexyl-2-benzothiazole sulfonamide, 3-4 parts of bi(3-triethoxy silylation propyl) tetrasulfide and 1.5-2 parts of stearic acid, wherein the particle size of the coconut shell fiber is 20-30mm. The modified coconut shell and natural rubber composite cable sheath material is good in physical and mechanical properties and relatively excellent in thermo-oxidative aging resistance, ozone resistance and ultraviolet resistance.

Owner:ANHUI LAND GRP

Rubber vibration reduction device with high anti-aging performance and preparation method thereof

The invention discloses a rubber vibration reduction device with high anti-aging performance. The rubber vibration reduction device is applied to the technical field of anti-aging rubber reduction device preparation. The rubber vibration reduction device is prepared from 80 to 100 parts of natural rubber, 1 to 6 parts of modified chlorosulfonated polyethylene rubber, 0.5 to 3 parts of sulphur, 1 to 2.5 parts of a vulcanizing agent, 6 to 12 parts of an anti-aging agent, 4 to 10 parts of zinc oxide, 1 to 12.5 parts of white carbon black, 10 to 30 parts of carbon black, 12 to 16 parts of a softening agent, 10 to 19 parts of proportioning rubber, 25 to 45 parts of a filling material, 6 to 8 parts of ore fiber, 1 to 5 parts of an aluminum-zirconium coupling agent, 2 to 4 parts of polyoxyethylene glycol monostearate, 0.5 to 1.5 parts of a crosslinking agent, 1 to 2 parts of an antioxidant, 1 to 3 parts of an accelerant and 3 to 7 parts of magnesium oxide. By using the embodiment, the stability of the natural rubber vulcanization crosslinked bond structure under the high-temperature condition can be improved; the high-temperature heat oxidization aging resistance, ozone resistance and weather resistance performance of the rubber vibration reduction device and the anti-vulcanization reversion resistance performance of the natural rubber are improved.

Owner:ANHUI DFSEAL RUBBER SHOCK ABSORBER TECH CO LTD

Preparation method of weather-resistant bamboo-plastic composite material

The invention relates to a preparation method of a weather-resistant bamboo-plastic composite material, and belongs to the technical field of bamboo-plastic materials. The method comprises the steps that ethyl orthosilicate is hydrolyzed to form a sol to coat the surface of a bamboo powder material, so that surface grooves of the bamboo powder material are gradually filled with a coating, shallowgrooves are filled to be leveled, thereby effectively reducing the contact area and contact time between the surface of the bamboo powder material and oxygen., and the sol formed by coating is dried to form a shell due to the loss of moisture of the sol and the volatilization of partial substances in gel, thereby effectively improving the mechanical properties of the material; the modification isachieved through the hydrolysis and coating of the ethyl orthosilicate, the effective load of silica sol on the surface of the bamboo powder material is effectively combined with polyvinyl chloride, amorphous regions of a polyvinyl chloride polymer chain are filled with inorganic silica particles, so that the heat transfer is reduced, the thermal decomposition of the polymer chain is inhibited toa certain extent, thereby effectively improving the heat-resistant oxygen aging property of the bamboo-plastic composite material, and further modifying the weather resistance of the bamboo-plastic composite material.

Owner:翟琳

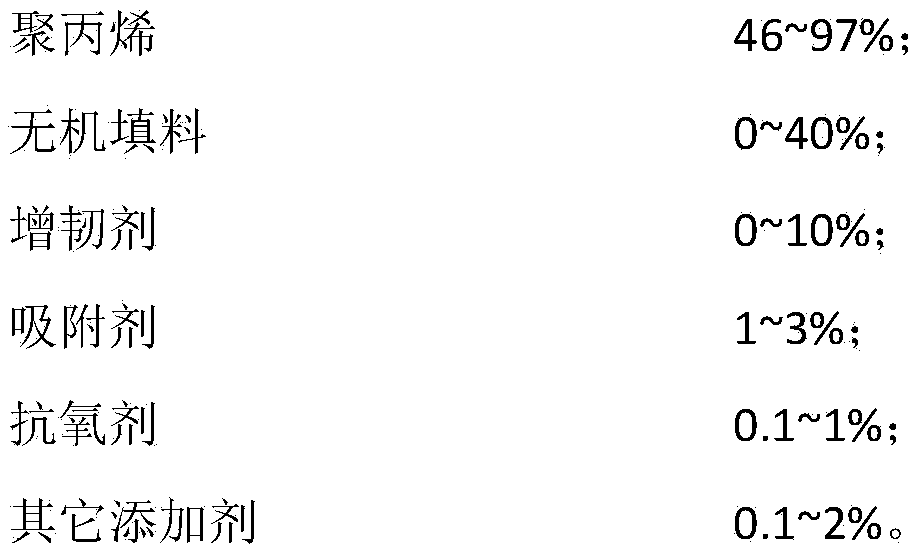

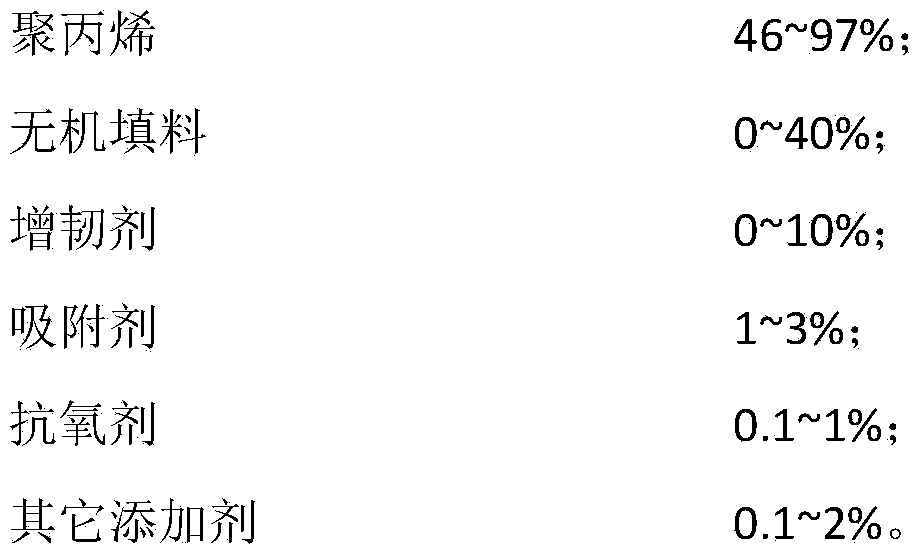

Heat-resisting oxygen aging polypropylene composition with low dispersity and preparation method of heat-resisting oxygen aging polypropylene composition

InactiveCN103724916AReduce sporadicImprove heat and oxygen aging resistanceDispersityPolymer science

The invention discloses a heat-resisting oxygen aging polypropylene composition with low dispersity and a preparation method of the heat-resisting oxygen aging polypropylene composition. The composition is prepared from the following raw materials by weight: 46-97% of polypropylene, 0-40% of inorganic filler, 0-10% of toughening agent, 1-3% of absorbent, 0.1-1% of antioxidant, 0.1-2% of other additives. The preparation method comprises the following steps: weighing the raw materials according to weight percentage, putting the raw materials into a high-speed mixer to dry-blend for 5-15 minutes, adding the mixed raw materials into a double-screw rod extruder, smelting and extruding, subsequently cooling and pelleting so as to prepare the polypropylene composition, wherein a first zone is 190-200 DEG C, a second zone is 200-210 DEG C, a third zone is 210-220 DEG C and a fourth zone is 205-215 DEG C, the retaining time in the whole extrusion process is 1-2 minutes, and the pressure is 12-18Mpa. The heat-resisting oxygen aging polypropylene composition has the advantages that low molecular weight compounds are effectively adsorbed and the dispersity is reduced as the additives are added into the polypropylene composition, acid substances, residual catalyst and the like in the composition are adsorbed and cleaned, so that the heat-resisting oxygen aging property is improved.

Owner:ZHEJIANG PRET NEW MATERIALS +2

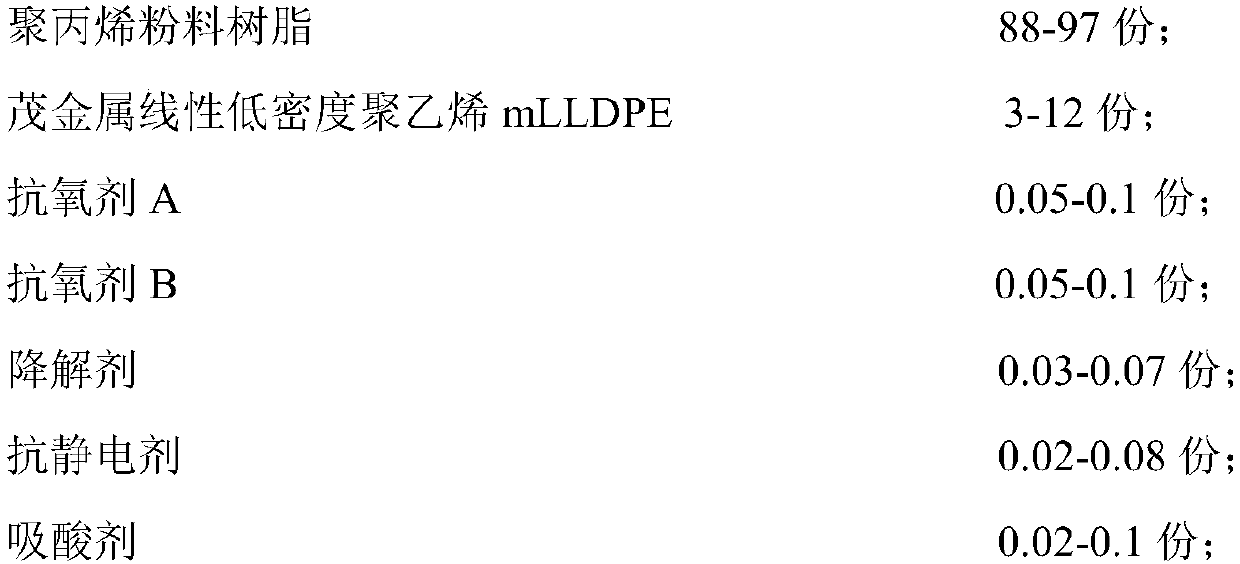

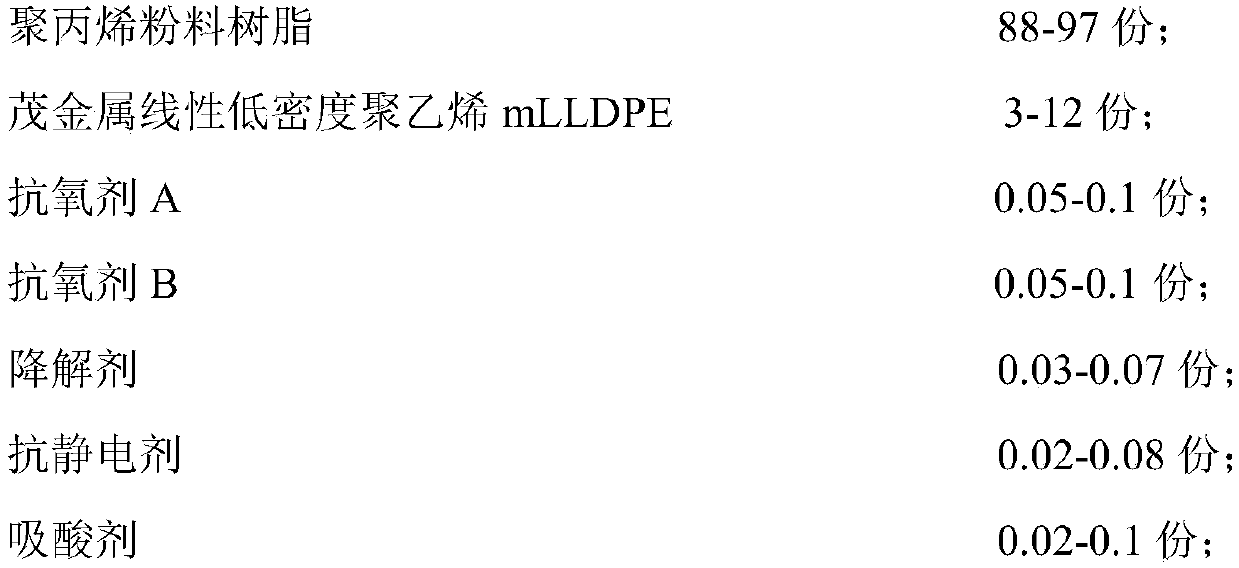

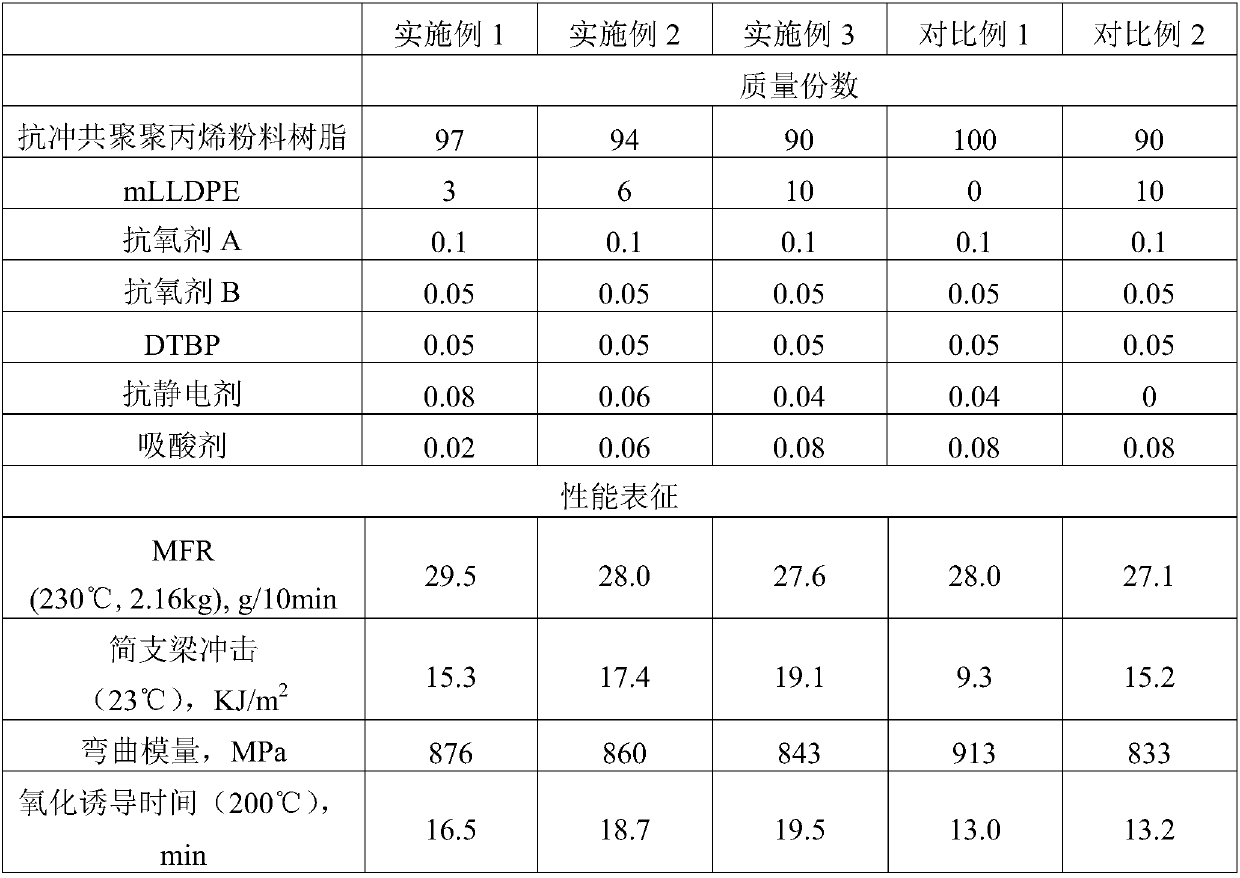

Thermo-oxidative-aging-resistant impact-resistant polypropylene composition and preparation method thereof

InactiveCN110878158AExcellent heat and oxygen aging resistanceImprove liquidityLinear low-density polyethyleneLow-density polyethylene

The invention relates to a polyolefin composition, particularly to a thermo-oxidative-aging-resistant impact-resistant polypropylene composition and a preparation method thereof. The composition comprises the following raw materials: 88 to 97 parts of a polypropylene powder resin, 3 to 12 parts of metallocene linear low density polyethylene mLLDPE, 0.05 to 0.1 part of an antioxidant A, 0.05 to 0.1part of an antioxidant B, 0.03 to 0.07 part of a degradation agent, 0.02 to 0.08 part of an antistatic agent, and 0.02 to 0.1 part of an acid absorption agent, wherein the sum of the polypropylene powder resin and the metallocene linear low density polyethylene mLLDPE is 100 parts, the antioxidant A is mercaptan acrylate and has the number-average molecular weight of 1305, and the antioxidant B is tri(2,4-di-tert-butylphenyl) phosphite, and has the number-average molecular weight of 647. The preparation method comprises the following steps: uniformly mixing the raw materials, and carrying outtwin-screw extrusion granulation to obtain the polypropylene composition with good heat resistance, good impact resistance and good flowability.

Owner:CHINA PETROLEUM & CHEM CORP +1

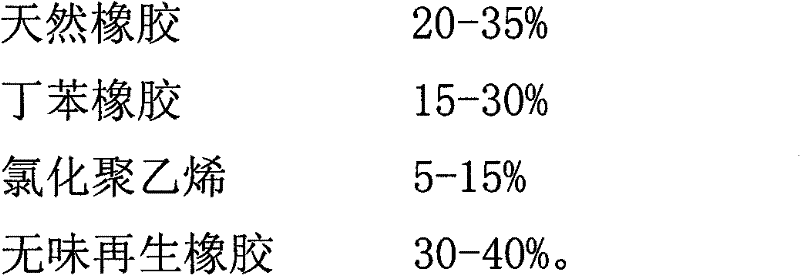

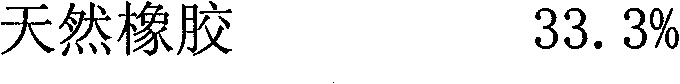

Chlorinated polyethylene rubber formula

InactiveCN102250397AImprove the finishImprove heat and oxygen aging resistancePolymer scienceAging resistance

Relating to the technical field of chemical formulas, the invention provides a chlorinated polyethylene rubber formula, which is characterized by consisting of, by weight: 20-35% of natural rubber, 15-30% of styrene butadiene rubber, 5-15% of chlorinated polyethylene and 30-40% of tasteless reclaimed rubber. Able to increase the product fineness, the formula of the invention also improves the heat oxygen aging resistance, ozone aging resistance, acid and alkali resistance and oil resistance of products, and overcomes the disadvantages of poor elasticity and large deformation. Substantially saving the product cost, the formula of the invention is nontoxic, odorless, novel and environmental friendly.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

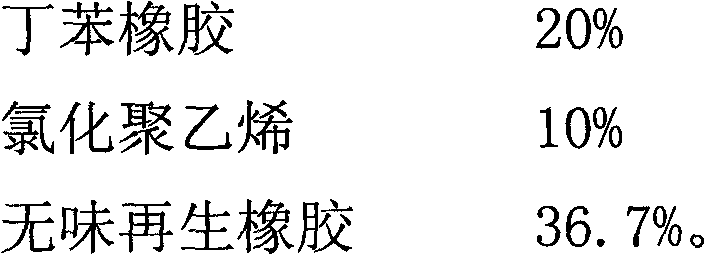

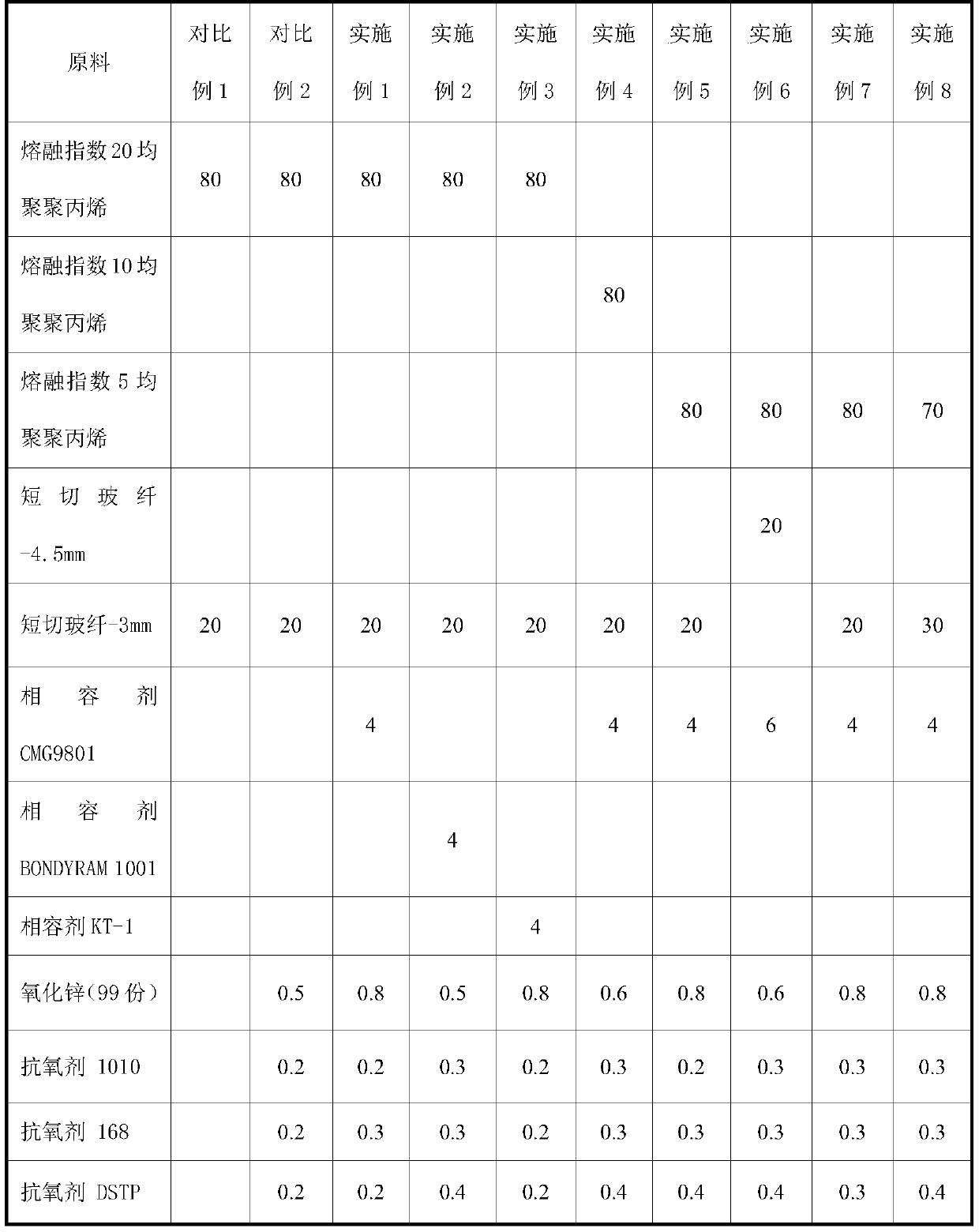

Glass fiber reinforced polypropylene composite material with high thermo-oxidative aging resistance and preparation method of glass fiber reinforced polypropylene composite material

InactiveCN109762247AGood performance retentionImprove heat and oxygen aging resistanceWeather resistanceOxide

The invention discloses a glass fiber reinforced polypropylene composite material with high thermo-oxidative aging resistance and a preparation method of the glass fiber reinforced polypropylene composite material. The glass fiber reinforced polypropylene composite material is prepared from components in parts by weight as follows: 70-80 parts of polypropylene homopolymers, 20-30 parts of glass fiber, 4-6 parts of a compatilizer, 0.5-0.8 parts of zinc oxide and 0.6-1 part of an antioxidant, wherein the compatilizer is one of CMG9801, BONDYRAM 1001 or KT-1. By addition of the compatilizer, zincoxide and the antioxidant to the glass fiber reinforced polypropylene composite material and adoption of a reasonable ratio, weather resistance of the material can be substantially improved, and prepared glass fiber reinforced polypropylene has higher performance retention rate after thermo-oxidative aging and is suitable for certain places with relatively strict requirements for the thermo-oxidative aging.

Owner:合肥卡洛塑业科技有限公司

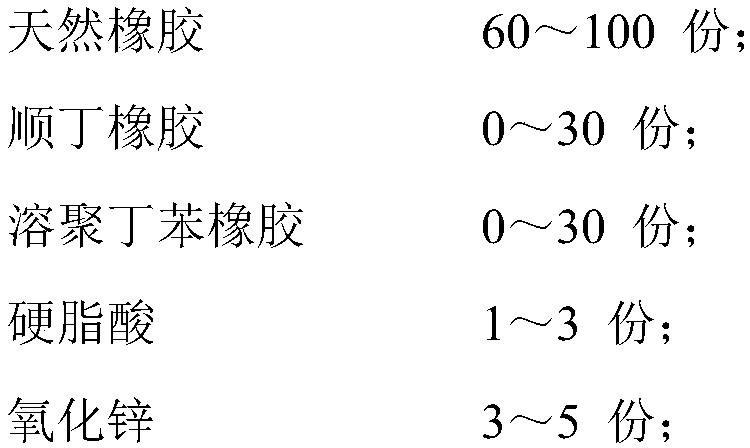

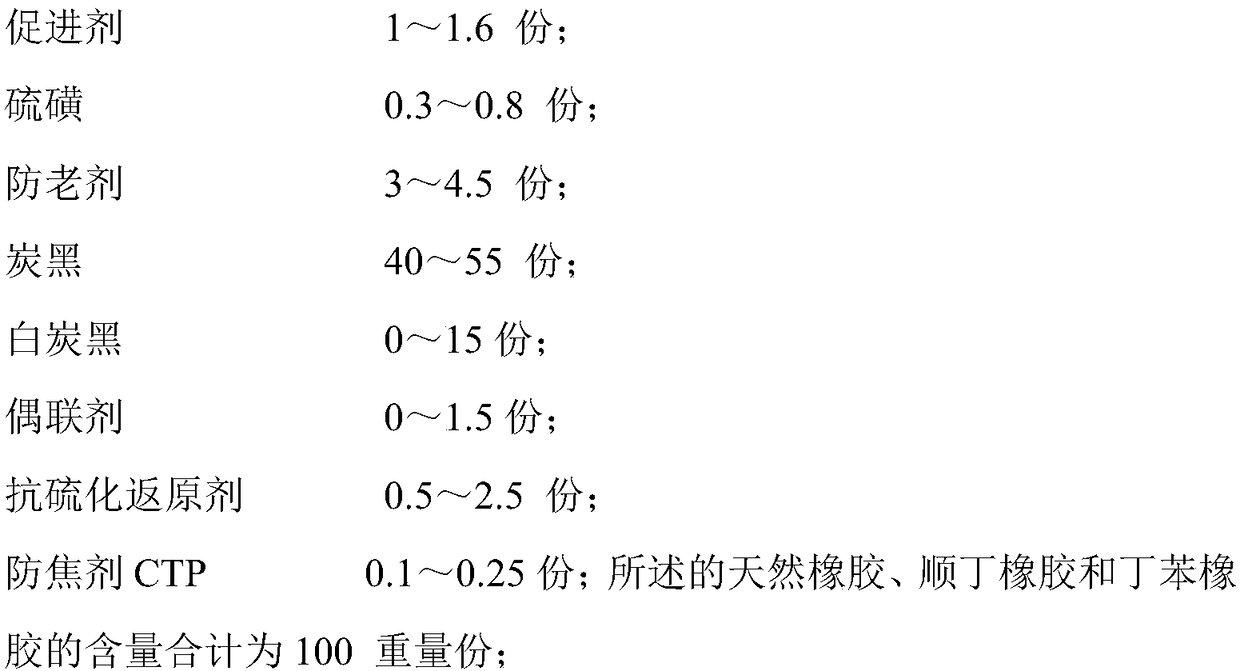

A kind of tread rubber for preparing high-performance tires

Tread rubber for preparing a high performance tire comprises the following raw materials by weight: 60-100 parts of natural rubber, 0-30 parts of butadiene rubber, 0-30 parts of solution polymerized stirene-butadiene rubber, 1-3 parts of stearic acid, 3-5 parts of zinc oxide, 1-1.6 parts of an accelerator, 0.3-0.8 part of sulfur, 3 parts of an antioxidant, 40-55 parts of carbon black, 0-15 parts of white carbon black, 0-1.5 parts of a coupling agent, 0.5-2.5 parts of an anti reversion agent and 0.1-0.25 part of antiscorcher CTP. The invention also provides a method for preparing the tread rubber. The tread rubber uses the anti reversion agent to replace part of sulphur content to form a thermodynamically-stable monosulfide bond, disulfide bond, and mixed crosslinked bond with polysulfide bond flexibility. The tread rubber formula has low heat, good abrasion resistance, good aging resistance, high tear strength and anti reversion and other properties, and can improve the service life of the tire.

Owner:SHANGHAI TIRE & RUBBER TIRE RES INST +1

A kind of anti-aging asphalt and preparation method thereof

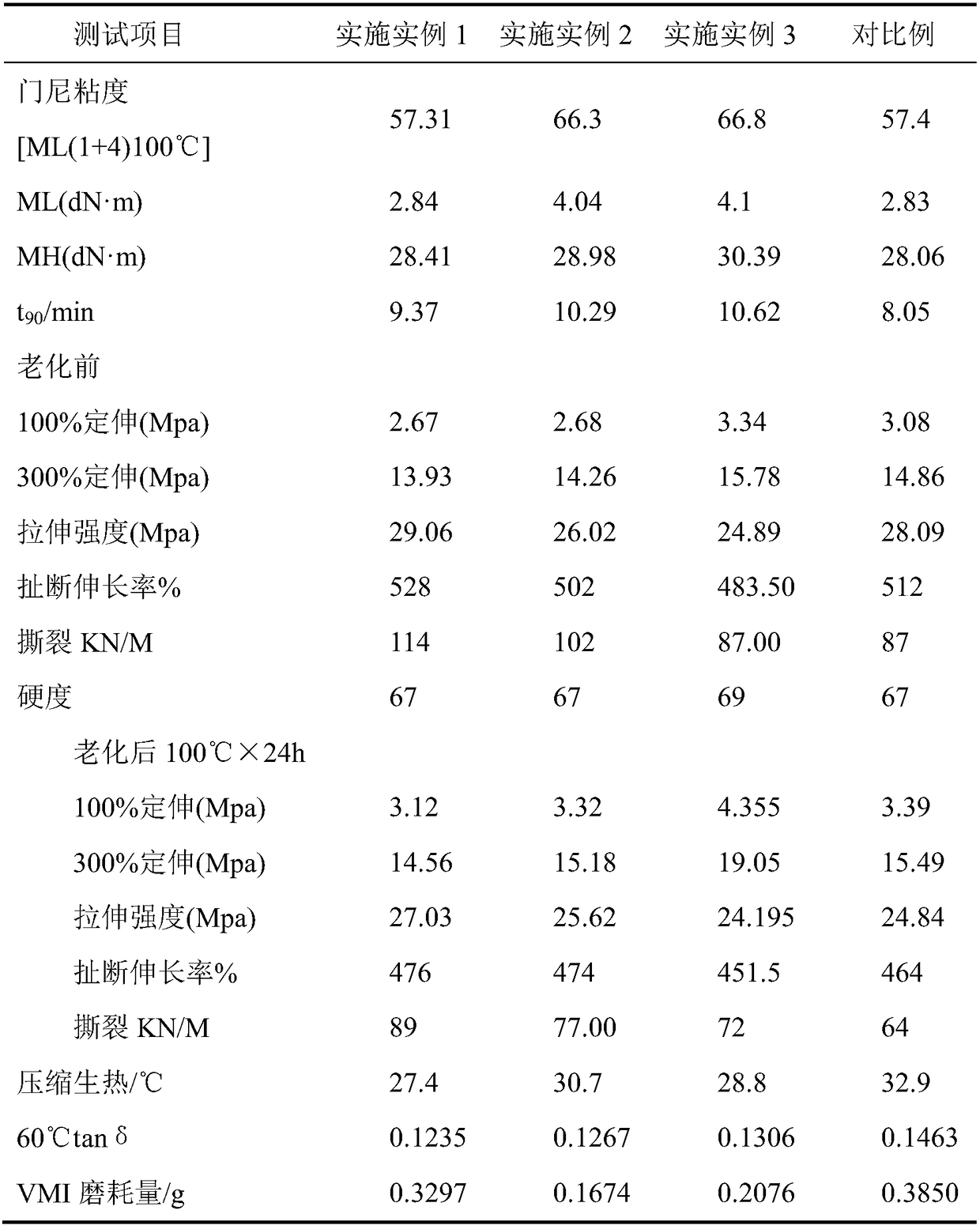

ActiveCN103275502BImprove heat and oxygen aging resistanceEasy accessBuilding insulationsUltraviolet lightsUv absorber

The invention relates to anti-aging asphalt and a preparation method thereof. The anti-aging asphalt is prepared from the following raw materials in percentage by mass: 93 to 98.9 percent of asphalt, 1 to 6 percent of organized vermiculite and 0.1 to 1 percent of ultraviolet light absorber. The preparation method of the anti-aging asphalt disclosed by the invention comprises the following steps: (1) preparing the following raw materials for later use in percentage by weight: 93 to 98.9 percent of asphalt, 1 to 6 percent of organized vermiculite and 0.1 to 1 percent of ultraviolet light absorber; (2) adding the asphalt into a shear mixer, heating the asphalt to a temperature of 130 to 160 DEG C, adding the organized vermiculite, starting the shear mixer, performing high-speed stirring for 1 to 2 hours at a rotating speed of 2,000 to 6,000 rpm and keeping the temperature in the range of 130 to 160 DEG C; and (3) reducing the stirring speed to 500 to 2,000 rpm, adding the ultraviolet light absorber, keeping the temperature in the range of 130 to 160 DEG C and performing stirring reaction for 0.5 to 2 hours to obtain the anti-aging asphalt. The anti-aging asphalt disclosed by the invention has excellent resistance to thermal oxidation and ultraviolet aging, and can prolong the service life of an asphalt pavement.

Owner:HUNAN UNIV

PC/ABS alloy material for household appliances

InactiveCN111621132AImpedance matchingGood absorption coefficientCarbon compoundsMagnetic/electric field screeningAnoxomerFire retardant

The invention discloses a PC / ABS alloy material for household appliances. The composite material comprises the following raw materials in parts by weight: 55-70 parts of PC resin, 18-40 parts of ABS resin, 5-15 parts of a straw biochar material, 6-10 parts of a compatible toughening agent, 0.2-0.8 part of an antioxidant, 0.3-1.0 part of a lubricant, 0.5-1.0 part of modified lignin, 1-5 parts of anantibacterial agent and 5-15 parts of a flame retardant. By adding the modified lignin, the ageing resistance of the PC / ABS alloy material is improved while good electromagnetic shielding performanceis kept.

Owner:宁波保税区君一汽配科技有限公司

Color rubber synchronous belt and preparation method thereof

InactiveCN105440381AGood wear resistance and heat resistanceImprove heat and oxygen aging resistanceBeltsThiolSilanes

The invention relates to a color rubber synchronous belt and a preparation method thereof. The synchronous belt comprises a synchronous belt skeleton and a rubber sheet attached to the outer surface of the synchronous belt in a wrapping manner, wherein the raw material of the rubber sheet comprises the following components in parts by weight: 20 to 40 parts of saturated Buna-N rubber, 30 to 50 parts of thiol chloroprene rubber, 20 to 40 parts of chlorinated butadiene styrene rubber, 4 to 8 parts of methacrylic acyloxy silane, 30 to 50 parts of reinforced resin, 5 to 6 parts of cross-linking agent, 2 to 6 parts of burnishing master batch, 0.5 to 1.5 parts of curing agent, 8 to 12 parts of plasticizer, 1 to 3 parts of anti-aging agent, 3 to 7 parts of telechelic polymer and 5 to 7 parts of homogeneous agent. Through adding various colors of burnishing master batch, the color of the synchronous belt is different from the black color in the past, and is more bright and eye-catching, and better wear-resisting and heat-resisting performances are realized.

Owner:JIANGSU AOFUTE BELT CO LTD

Carboxyl butadiene-acrylonitrile rubber and sodium ethylene acrylate ionic bond polymer blend wear-resisting rubber hose rubber material and preparing method thereof

The invention provides a hose rubber material. The rubber material is prepared from, by mass, 70-95 parts of carboxyl butadiene-acrylonitrile rubber, 5-30 parts of sodium ethylene acrylate ionic bond polymers, 3 parts of stabilizers, 8 parts of magnesium oxide, 4 parts of zinc oxide, 0.6 part of sulfur, 2.4 parts of dicumyl peroxide, 2.5 parts of 1,1-di-tert-butyl peroxy-3,3,5-trimethyl-cyclohexane, 3 parts of stearic acid, 70 parts of fortifier, 15-20 parts of softener, 5 parts of tackifying resin and 1 part of antiager. The sodium ethylene acrylate ionic bond polymers and the carboxyl butadiene-acrylonitrile rubber are adopted for blending, and therefore the rubber material has excellent mechanical performance, wear resistance and ageing resistance.

Owner:LUOHE LETONE RUBBER +1

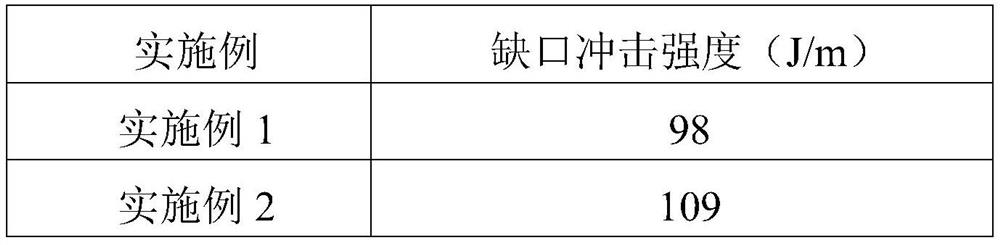

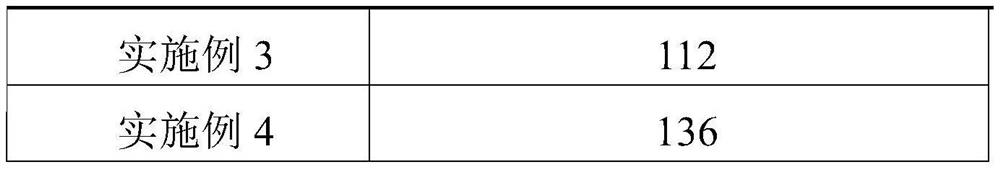

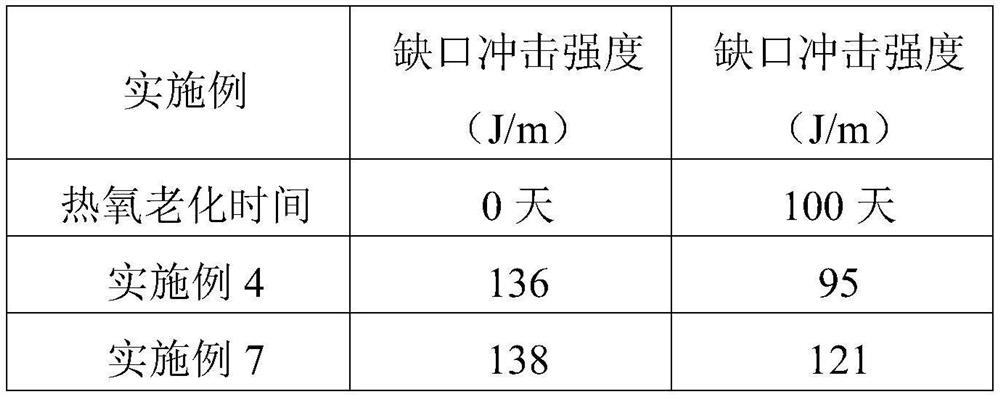

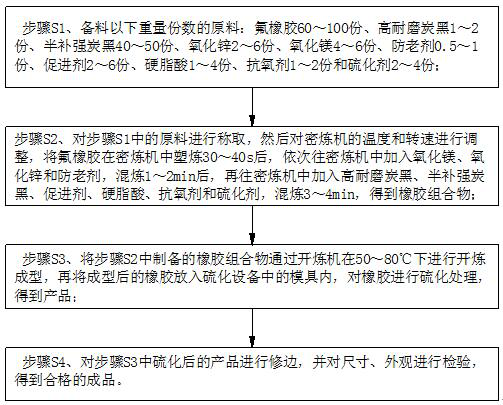

Preparation method of automobile pipeline rubber material

The invention belongs to the technical field of rubber materials, and particularly relates to a preparation method of an automobile pipeline rubber material. The preparation method comprises the steps of S1, preparing the following raw materials in parts by weight: 60-100 parts of fluororubber, 1-2 parts of high wear-resistant carbon black, 40-50 parts of semi-reinforced carbon black, 2-6 parts of zinc oxide, 4-6 parts of magnesium oxide, 0.5-1 part of an anti-aging agent, 2-6 parts of an accelerant, 1-4 parts of stearic acid, 1-2 parts of an antioxidant and 2-4 parts of a vulcanizing agent. Through introduction of fluorine atoms in the fluororubber, the rubber is endowed with excellent heat resistance, oil resistance and corrosion resistance, the wear resistance of the rubber can be enhanced through the high-wear-resistance carbon black, the overall strength of the rubber is guaranteed through the semi-reinforcing carbon black, magnesium oxide and zinc oxide mainly play a role in fluidity and oxidation resistance in the rubber, the tensile strength and the impact resistance of the rubber are improved, the anti-aging agent can improve the thermal oxygen aging resistance of the rubber, and the accelerant can promote the reaction between the rubber and the vulcanizing agent, so that the vulcanization reaction speed is increased.

Owner:扬州尚翔汽车零部件有限公司

Foamed polypropylene composition, foamed polypropylene plate and preparation method thereof

The invention relates to the field of polypropylene foam materials, and discloses a foamed polypropylene composition, a foamed polypropylene plate and a preparation method thereof. The composition isprepared from the following components in parts by weight: 100 parts of high-melt-strength polypropylene, 0.05 to 2 parts of guanidine salt composite antibacterial agent, 0.05 to 5 parts of mildew preventive and 1 to 15 parts of foaming agent, wherein the high-melt-strength polypropylene is prepared from the following components in parts by weight: 100 parts of polypropylene, 0.1 to 0.3 part of antioxidant and 0.25 to 10 parts of mixed butene-maleic anhydride copolymer microspheres, wherein the particle size of the copolymer microspheres is 0.1-10 [mu] m. The foamed polypropylene which is compact in foam hole, uniform in pore size distribution, smooth in surface, high in thermo-oxidative aging resistance and capable of being recycled in a non-crosslinking mode can be prepared in an extrusion molding mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-static polyformaldehyde and preparation method thereof

InactiveCN105295294AImprove heat and oxygen aging resistanceHigh tensile strengthAntioxidantDecomposition

The invention discloses anti-static polyformaldehyde, which comprises the following raw materials in parts by weight: 100 parts of polyformaldehyde, 5-12 parts of oleic acid polyglycol ester, 3-8 parts of dimethyl hydroxyethyl stearamide-ethyl quaternary ammonium nitrate, 3-8 parts of polyethylene glycol terephthalate, 4-10 parts of copolymer nylon, 5-12 parts of magnesium oxide, 3-10 parts of copper powder, 2-6 parts of an antioxidant, 1-4 parts of a light stabilizer and 1-10 parts of a lubricating agent. An antistatic component and the polyformaldehyde have appropriate compatibility; the condition that a proper amount of antistatic component migrates to the surface from the inside of the polyformaldehyde is ensured to reach certain surface concentration; when the antistatic component on the surface is washed by a solvent or removed by friction in use, the antistatic component in the polyformaldehyde can further migrate outwards to restore the antistatic effect; the antistatic property is good, lasting and stable; and the problem of intense decomposition of POM in the molding and processing processes can be effectively solved, so that the thermal-oxidative-ageing property of the polyformaldehyde is improved; and the tensile strength and the breaking elongation are improved.

Owner:YUNNAN YUNTIANHUA

Special automobile exterior material prepared from TPO skin reclaimed material and preparation method thereof

PendingCN112048114AGood solvent resistanceAccelerated corrosionSuperstructure subunitsFenderAntioxidant

The invention discloses an automobile exterior trimming special material prepared from a TPO skin reclaimed material and a preparation method thereof. Raw materials comprise: a TPO skin reclaimed material, copolymerized PP, a molecular weight regulator, a flexibilizer, a compatilizer, a weather-resistant agent, a filler, an antioxidant and a colorant. The preparation method comprises the followingsteps: mixing and stirring the TPO skin reclaimed material and the molecular weight regulator, adding the copolymerized PP, the flexibilizer, the weather-resistant agent, the compatilizer, the antioxidant, the filler and the colorant, mixing and stirring the components; and feeding the mixture into a double-screw extruder for perfomring extrusion, cooling, drying and granulation. The TPO skin regenerated material is creatively applied to production of special materials for automobile exterior decorations such as automobile fenders and wheel covers, so that the product can completely meet theworking condition performance requirements of the automobile exterior decorations such as the automobile fenders and the wheel covers, so that high-impact-resistance PP or PE materials are replaced, the problems of resource waste, environmental pollution and the like can be relieved, the production cost can be effectively reduced, and economic benefit is increased.

Owner:广西鑫深科技有限公司

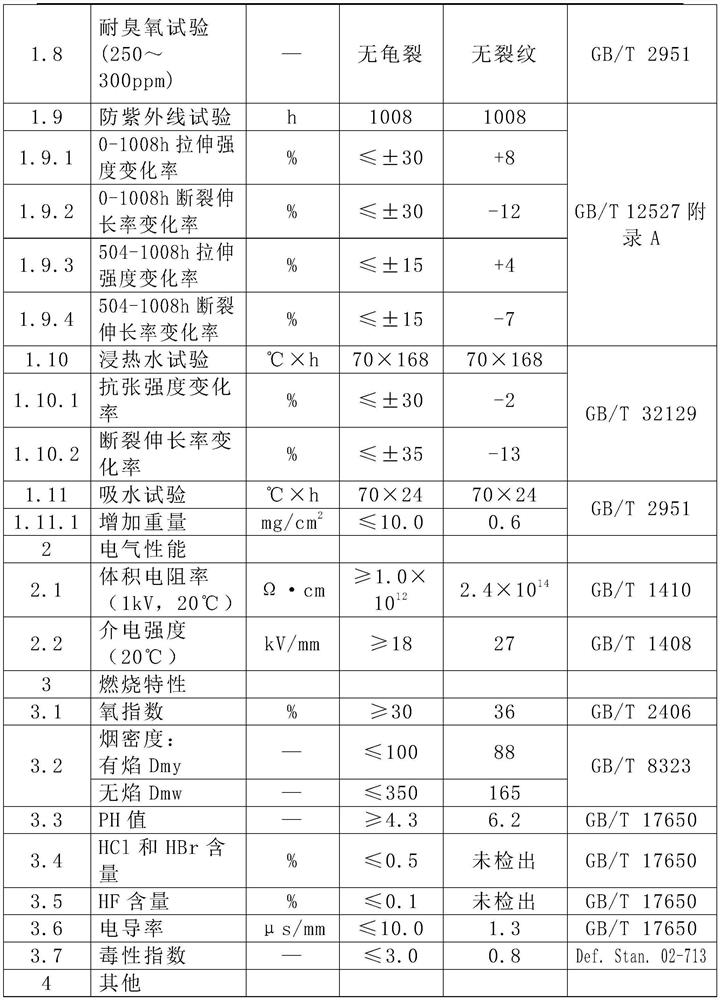

Thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheathing material for nuclear power plant cables

ActiveCN110724324BAchieve uniformityWith uniformityPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention relates to a thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheath material for nuclear power plant cables, belonging to the technical field of novel cable materials. In order to solve the material performance requirements when the existing sheathing materials cannot meet the large size, a thermoplastic radiation-resistant halogen-free low-smoke flame-retardant sheathing material for nuclear power plant cables is provided, which includes the following parts by weight: 100% of the base material, and the base material is at least Contains high temperature resistant polyolefin elastomer; high temperature resistant radiation resistant modified masterbatch: 30~40, at least contains condensed polycyclic polynuclear aromatic hydrocarbon resin and high temperature and radiation resistant resin; flame retardant: 100~200, at least contains aluminum hydroxide ; Antioxidant: 4.0-12, at least containing asymmetric hindered phenolic calixarene as main antioxidant; Anti-radiation agent: 1.0-12. The invention can form a synergistic effect, can meet the requirements of thermal life and radiation resistance performance of 90°C / 60 years, and its sheath has uniformity, which is suitable for cable materials with large diameter and thick sheath layer, and has high flame retardant performance.

Owner:临海市亚东特种电缆料厂

High-strength anti-ageing skid-proof conveying belt

InactiveCN104672518AImprove appearance qualityImprove heat and oxygen aging resistanceNatural rubber adhesivesConveyorsPolyvinyl chlorideStearic acid

The invention discloses a high-strength anti-ageing skid-proof conveying belt. The high-strength anti-ageing skid-proof conveying belt is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of natural rubber, 15-20 parts of nitrile rubber, 2-3 parts of nanometer-grade active argil, 8-15 parts of polyvinyl chloride resin, 2-3 parts of a VP adhesive, 1.5-2 parts of a plasticizer, 2-4 parts of calcium carbonate, 2-4 parts of stearic acid, 6-10 parts of carbon black N754, 6-8 parts of white carbon black, 1-2 parts of coumarone, 4-5 parts of aromatic hydrocarbon oil, 1-1.2 parts of engine oil, 4-5 parts of sulfur and 1-2 parts of an anti-ageing agent. The high-strength anti-ageing skid-proof conveying belt disclosed by the invention is improved in appearance quality, and a damaged part is flatly replenished with the adhesive, so that the adhesion between frame canvases of the conveying belt maintains the properties of an original common heat-resisting conveying belt adhesive, the thermal oxidization and ageing resistance of the adhesive is enhanced; the performances such as tensile strength, layer-layer adhesion strength, heat resistance and wear resistance are all improved; the high-strength anti-ageing skid-proof conveying belt can be applied to large machineries for coal mines, stone materials and the like.

Owner:QINGDAO ALLPOLY CONVEYOR BELT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com