Patents

Literature

109results about How to "Excellent heat and oxygen aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

Weatherproof and wear-resisting cable sheath material

InactiveCN104231600AImprove wear resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsEpoxyCopper oxide

The invention discloses a weatherproof and wear-resisting cable sheath material which comprises the following raw materials in parts by weight: 40-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of chloroprene rubber, 20-30 parts of chlorinated polyethylene, 30-45 parts of nano-titanium dioxide / graphene oxide, 10-15 parts of modified nano talcum powder, 20-35 parts of coupling-agent-modified attapulgite, 3-5 parts of activated zinc oxide, 4-9 parts of stearic acid, 10-18 parts of expansible graphite, 3-7 parts of copper oxide, 5-12 parts of ferric oxide, 5-9 parts of coupling-agent-modified ammonium polyphosphate, 3-6 parts of sulfur, 2-3.5 parts of tricresyl phosphate, 0.5-2 parts of oxidic polyethylene, 3.5-4.5 parts of an accelerant TMDT, 2-5 parts of an anti-aging agent, 1-2.8 parts of epoxy flaxseed oil and 1-1.8 parts of triethyl O-acetylcitrate. The weatherproof and wear-resisting cable sheath pipe has the advantages of good weather resistance, high wear resistance, good mechanical property and long service life.

Owner:无为县华祥电缆材料有限公司

Polypropylene composite capable of resisting thermal oxidizing aging

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

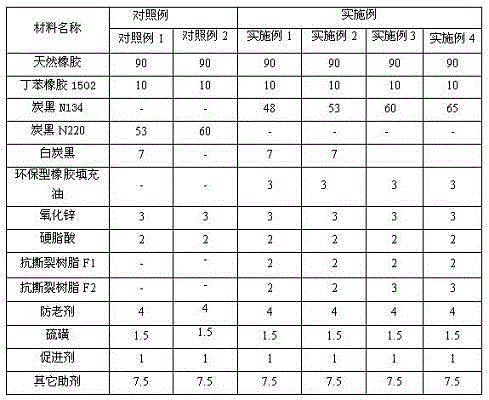

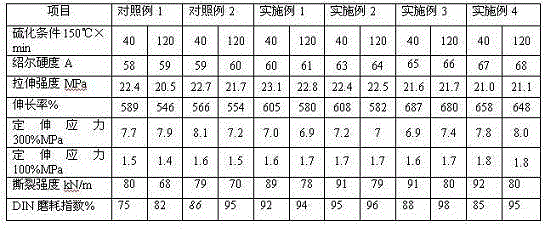

Articulated truck tire tread rubber composition and preparation method thereof

InactiveCN104356442AImprove wear resistanceImprove cut resistanceSpecial tyresSulfenamideStearic acid

The invention relates to an articulated truck tire tread rubber composition and a preparation method thereof, belonging to the field of tire production. The articulated truck tire tread rubber composition is composed of the following components in parts by weight: 75-100 parts of natural rubber, 0-25 parts of styrene-butadiene rubber, 50-70 parts of small-particle-size highly-structure-reinforced carbon black, 0-15 parts of silica white, 0-10 parts of tear-resistant resin, 0-3 parts of protective wax, 0-4 parts of N-(1,3-dimethyl butyl)-N'-phenyl-p-phenylenediamine, 0-1 part of acetone-diphenylamine high-temperature condensate, 0-3 parts of stearic acid, 0-10 parts of environment-friendly oil, 0-5 parts of phenol formaldehyde resin tackifier, 0-5 parts of zinc oxide, 0-1 part of anti-reversion agent WK-901, 0-5 parts of dispersing agent, 0-2.5 parts of sulfur and 0.5-2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide. The articulated truck tire tread rubber composition has the advantages of excellent wear resistance, excellent cutting resistance and excellent thermo-oxidative aging resistance, and can adapt to the operating requirements of high wear resistance, high cutting resistance and excellent thermo-oxidative aging resistance for the articulated truck tire tread rubber.

Owner:TRIANGLE TIRE

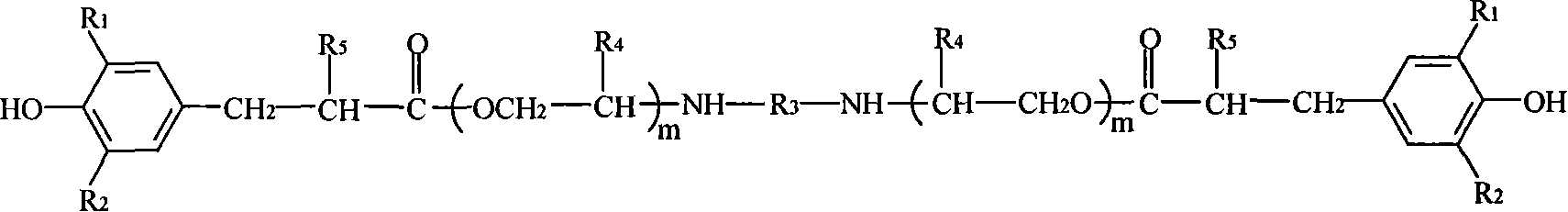

Composite heat resisting antioxidant for polyolefin and its production process and application

InactiveCN101067030AImprove heat aging resistanceEliminate catalytic cleavagePolyolefinPolymer science

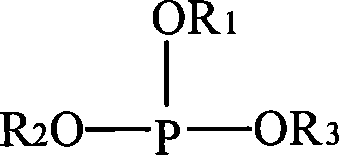

The present invention relates to composite heat resisting antioxidant for polyolefin and its production process and application. The composite heat resisting antioxidant consists of hindered phenol antioxidant 20-75 wt%, phosphate antioxidant 20-75 wt%, and chelating metal component containing at least bisamide-metal ion chelating structure 5-50 wt%, and is prepared through physical mixing and airflow crushing. The composite heat resisting antioxidant is applied in polyolefin product and can raise the ageing resisting performance of polyolefin product, especially greenhouse film, greatly.

Owner:广东国望精细化学品有限公司

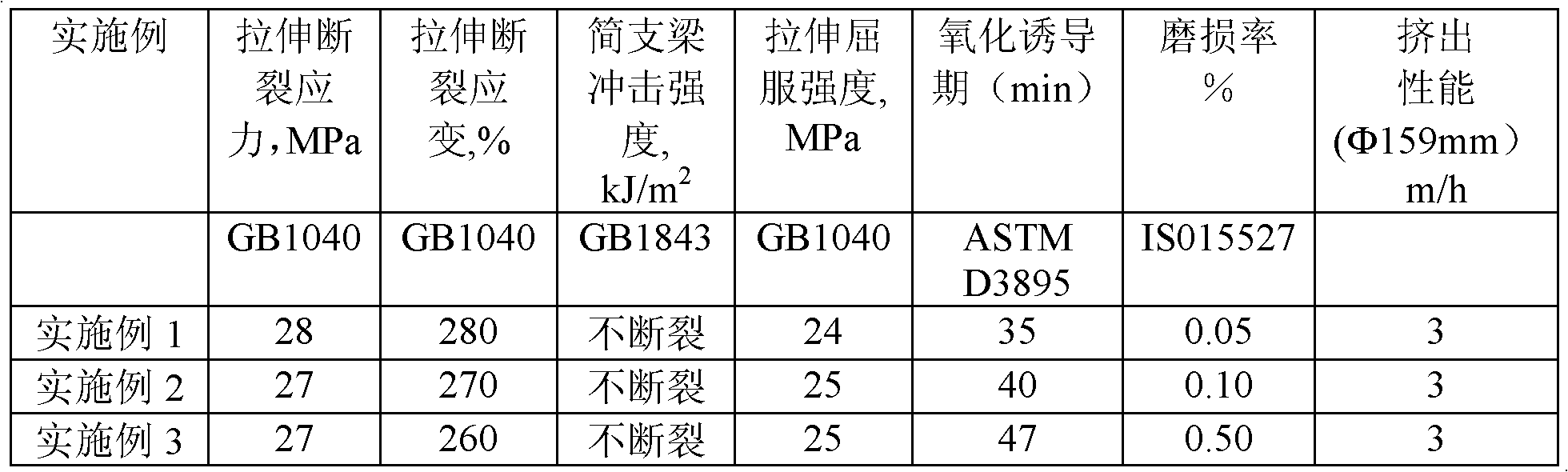

Composition for preparing polyethylene pipe with superhigh molecular weight and preparation method thereof

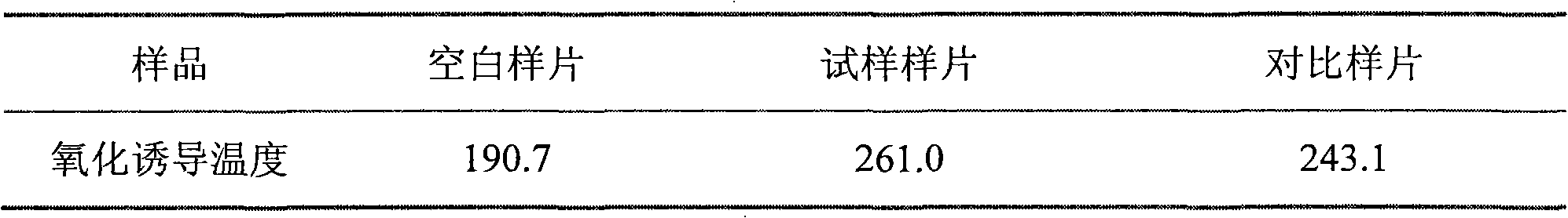

ActiveCN102382344AExcellent heat and oxygen aging resistanceImprove mechanical propertiesPolymer scienceProcedure Agents

A composition for preparing polyethylene pipe with superhigh molecular weight and a preparation method thereof are disclosed. The composition is prepared by the following raw materials by weight percentage: polyethylene with superhigh molecular weight: fluoropolymer processing agent: polyethylene wax: calcium stearate / zinc stearate compound: complex antioxidant: carbon black is equal to 100 parts: 0.01-0.1: 1-8:0.1-1.0:0.1-0.5:0.5-3. The preparation method comprises the steps of: putting the polyethylene resin with superhigh molecular weight, starting a mixer, putting the calcium stearate / zinc stearate compound into the mixer to mix for 1-2 hours, then adding the complex antioxidant, polyethylene wax, fluoropolymer processing agent and carbon black to mix for 2-3 hours; and detecting the bulk density according to GB / T1636 and sealing and packaging. The polyethylene pipe composition with superhigh molecular weight prepared by the method has excellent heat-resisting and anti-aging performance with oxidation induction time at 200 DEGC longer than 30 minutes. The polyethylene pipe composition with superhigh molecular weight further has excellent mechanical, wear-resisting, corrosion resisting, heat-resisting and anti-aging properties and extrusion process performance.

Owner:CHINA PETROLEUM & CHEM CORP

Cushion for engine suspension system and preparation method thereof

InactiveCN103772758AGood durabilityExcellent thermal and oxygen aging resistanceSilane couplingActive agent

The invention provides a cushion for an engine suspension system and a preparation method thereof. The cushion comprises the following rubber materials in parts by weight: 60-80 parts of natural rubber, 20-40 parts of cis-polybutadiene, 5-8 parts of inorganic active agent, 1-3 parts of organic active agent, 1-3 parts of paraffin, 2-3 parts of age resister A, 1-1.5 parts of age resister B, 1-2 parts of heat stabilizer, 1-3 parts of antifatigue, 1-2 parts of silane coupling agent, 5-10 parts of white reinforced material, 10-30 parts of fast compression reinforced material, 30-40 parts of semi reinforced material, 5-10 parts of softener, 1.5-2.0 parts of vulcanizing agent and 1-2 parts of vulcanizing aid. The cushion for an engine suspension system has excellent endurance quality and outstanding heat / oxygen aging resistance and also has remarkable anti-fatigue performance under a dynamic condition.

Owner:柳州日高汽车减振技术有限责任公司

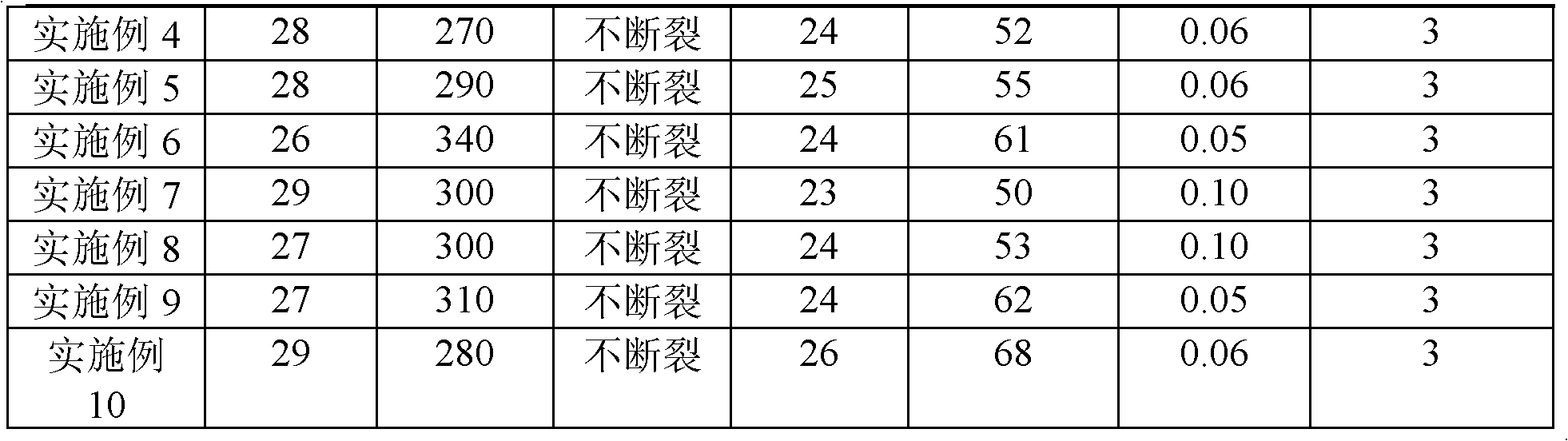

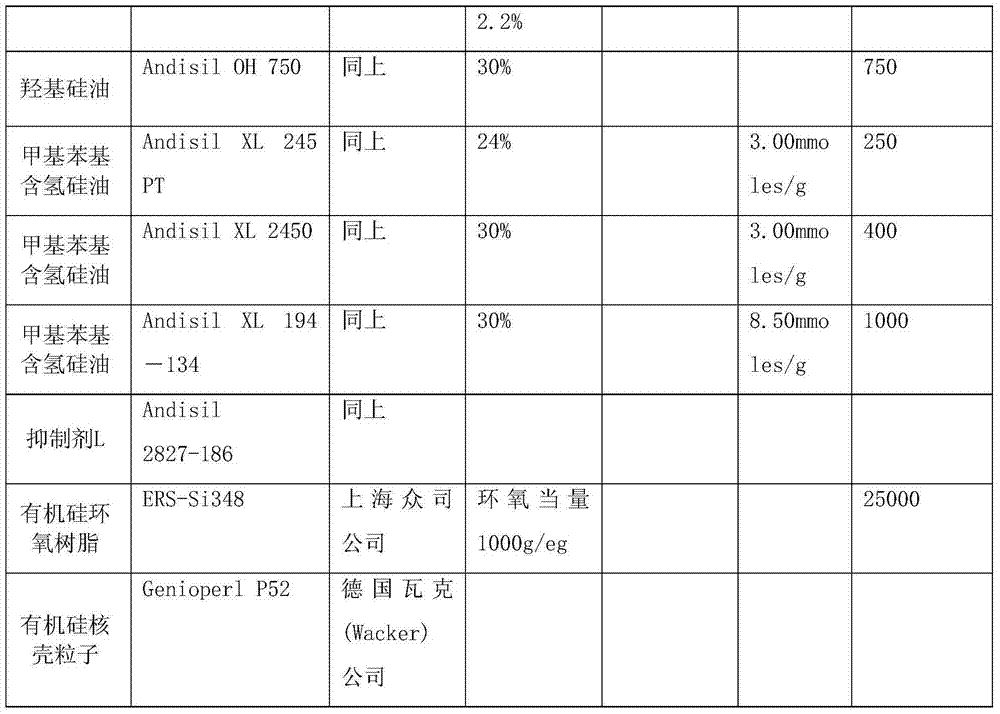

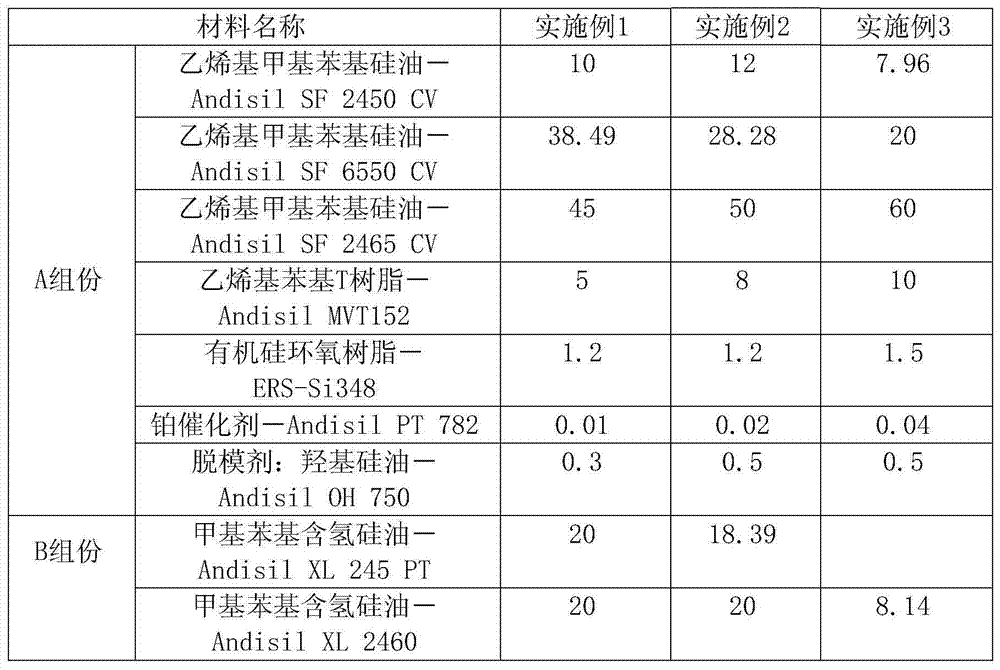

Organic silicon gel composition for high-power LED (light-emitting diode) packaging

The invention discloses an organic silicon gel composition for high-power LED (light-emitting diode) packaging, belonging to the field of gel for electronic products. The composition is composed of a component A and a component B, wherein the mass ratio of the component A to the component B is 1:1 when the two components are used and mixed; the component A comprises the raw materials in percentage by weight: 83-94% of vinyl methylphenyl silicone oil, 5-10% of vinylphenyl T resin, 0.5-5% of organic silicon epoxy resin, 0.2-2% of releasing agent and 50-500ppm of platinum catalyst; and the component B comprises the raw materials in percentage by weight: 96-99% of methylphenyl hydrogen-containing silicone oil, 0.1-1% of antioxidant, 0.1-2% of silane coupling agent, 0.001-0.1% of inhibitor and 0.1-1% of rheology modifier. In use, the component A and the component B are mixed at 25-50 DEG C and need to be used up within 6 hours. The composition is used for packaging of high-power LEDs for illumination, and is suitable for preparation of fluorescent powder in white light LED packaging.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

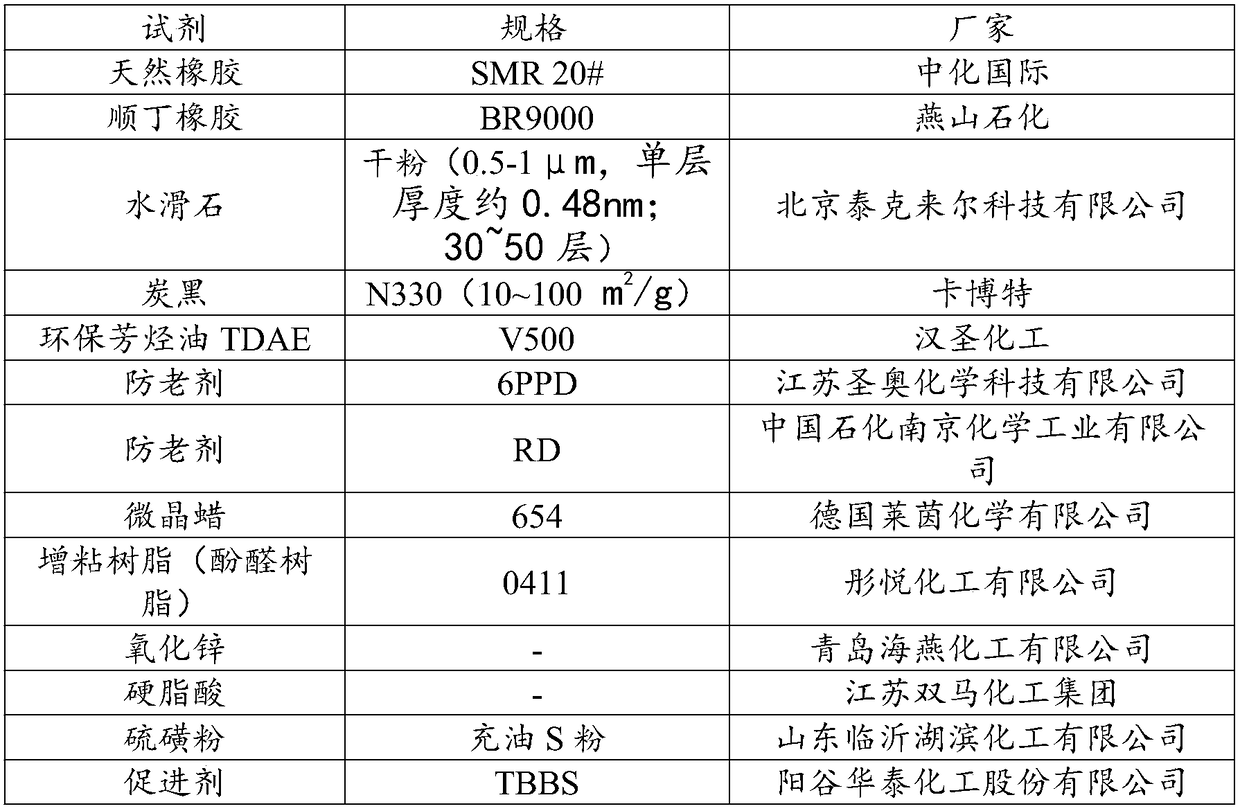

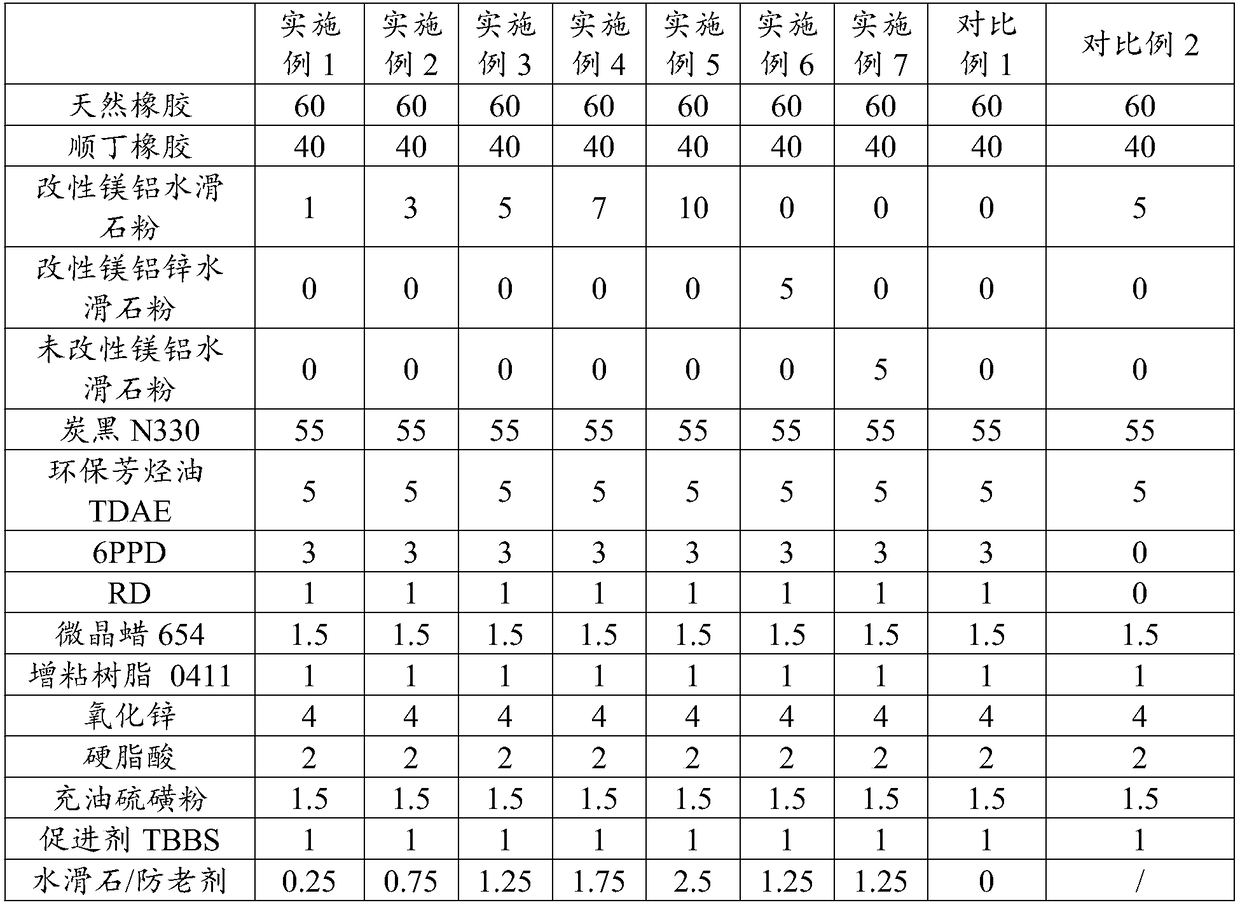

Tire sidewall rubber composite material and preparation method thereof

ActiveCN108239306AWarranty requirementsExcellent heat and oxygen aging resistanceSpecial tyresStearic acidOxygen

The invention relates to a composite material for tires, and in particular relates to a tire sidewall rubber composite material. The material comprises 100 parts by weight of rubber, by weight of rubber, 1-10 parts by weight of hydrotalcite, 40-70 parts by weight of carbon black, 4.0-8.0 parts by weight of environment-friendly aromatic hydrocarbon oil, 3.0-9.0 parts by weight of an anti-aging agent, 1.0-4.0 parts by weight of wax, 0.5-3.0 parts by weight of tackifying resin, 1.5-5.0 parts by weight of zinc oxide, 1.0-3.5 parts by weight of stearic acid, 1.0-3.0 parts by weight of sulfur powderand 0.5-2.0 parts by weight of an accelerant. A preparation method of the composite material comprises the following steps: plasticating rubber in an internal mixer, adding other components except the sulfur powder and the accelerator for mixing, lifting a top bolt at the temperature of 120-125 DEG C, performing dumping at 150-160 DEG C to obtain the mixed rubber, mixing the mixed rubber, the sulfur powder and the accelerator in an open mill, rolling for 4-5 times, and conducting thin-pass for 5-8 times to obtain a product. The composite material disclosed by the invention not only meets thebasic mechanical property requirements of the sidewall rubber, but also obviously improves the heat oxygen aging resistance and the ultraviolet aging resistance of the sidewall rubber and the servicelife of the tire can be effectively prolonged.

Owner:SHANDONG LINGLONG TIRE

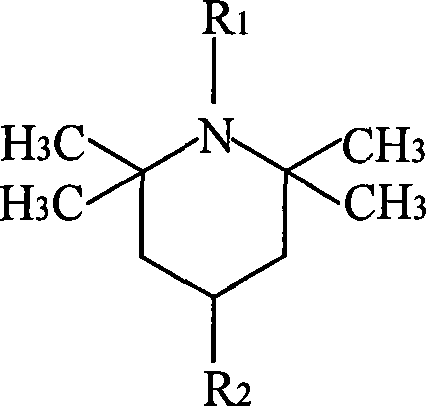

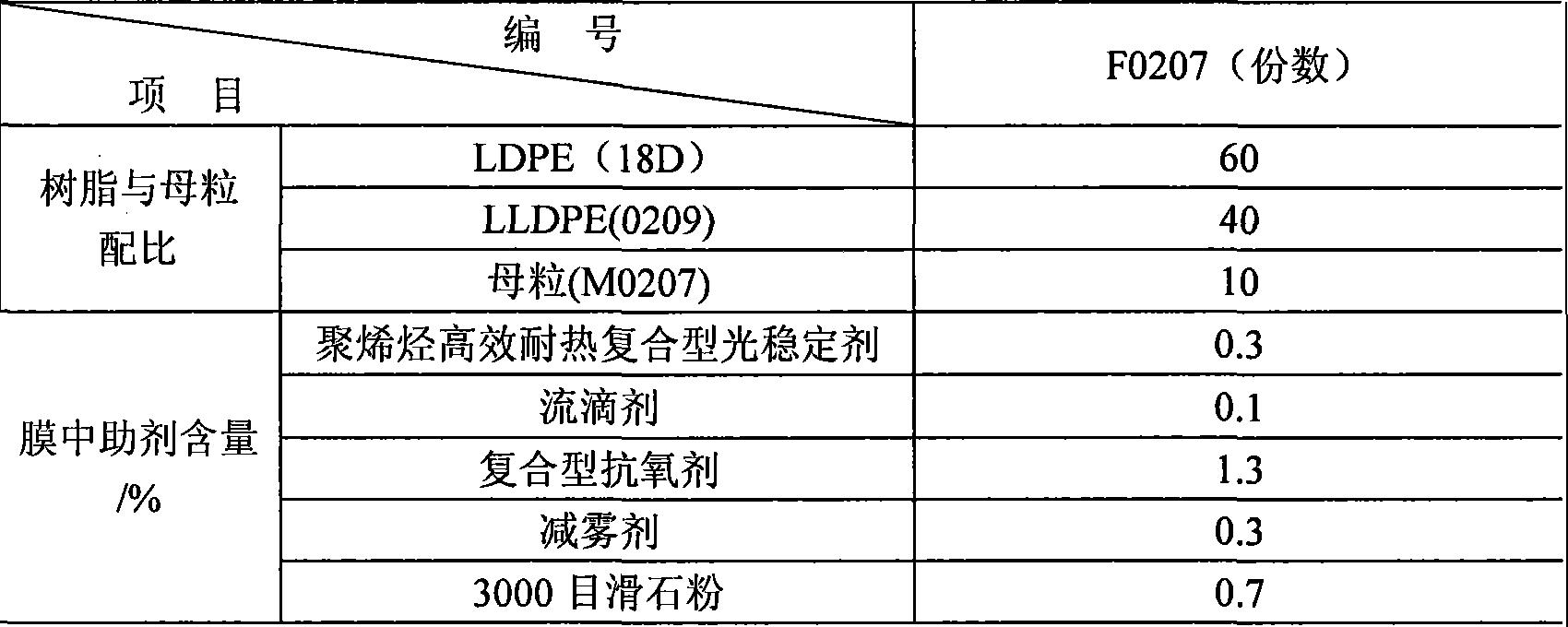

Efficient heat-resisting polyolefine composite light stabilizer, its production and use

ActiveCN101029149AEliminate catalytic cleavageAddressing Accelerated AgingPolyolefinHindered amine light stabilizers

An efficient composite heat-resisting polyolefine light stabilizer, its production and use are disclosed. The light stabilizer consists of two or above polymerized hindered amine light stabilizer mixed components 60-95wt% and metal-ion chelate component 5-40wt%, which has hindered phenol anti-oxidant structure and bis-amide metal ion chelating structure and / or oxalamide semi-hindered amine structure. It has excellent heat and ageing resistances and can be used for PE and EVA agricultural long-life thin film or functional greenhouse thin film.

Owner:广东华南精细化工研究院有限公司 +1

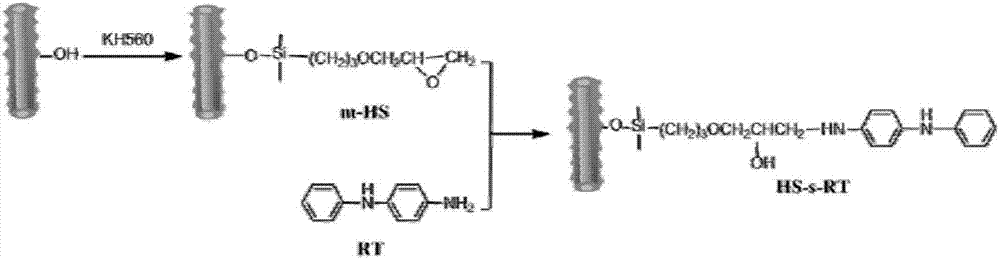

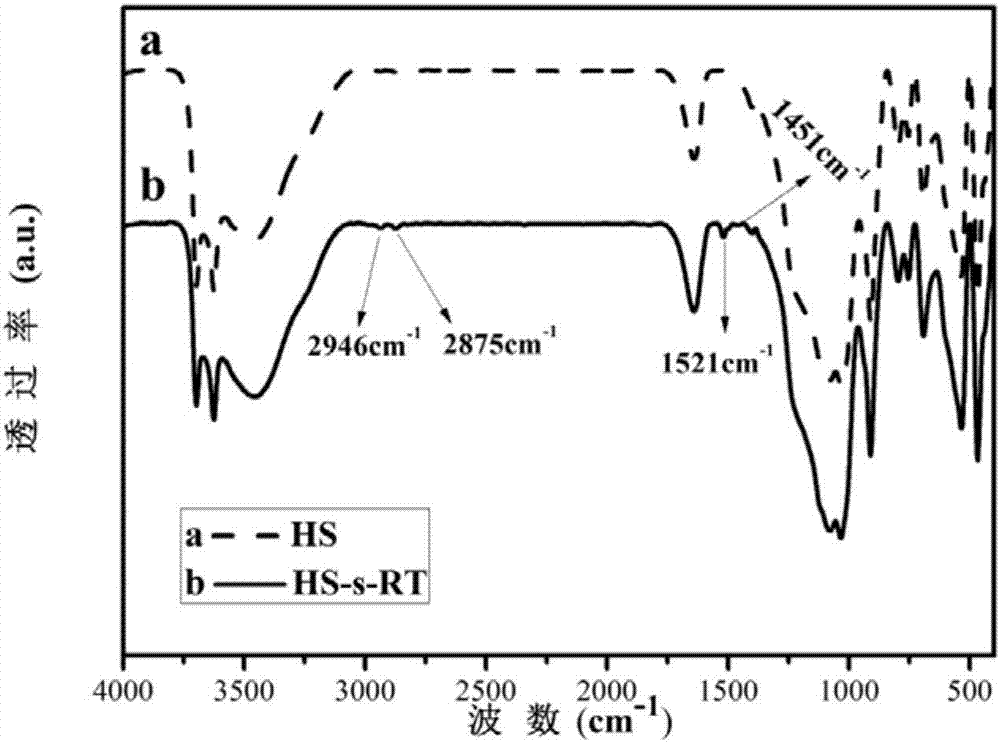

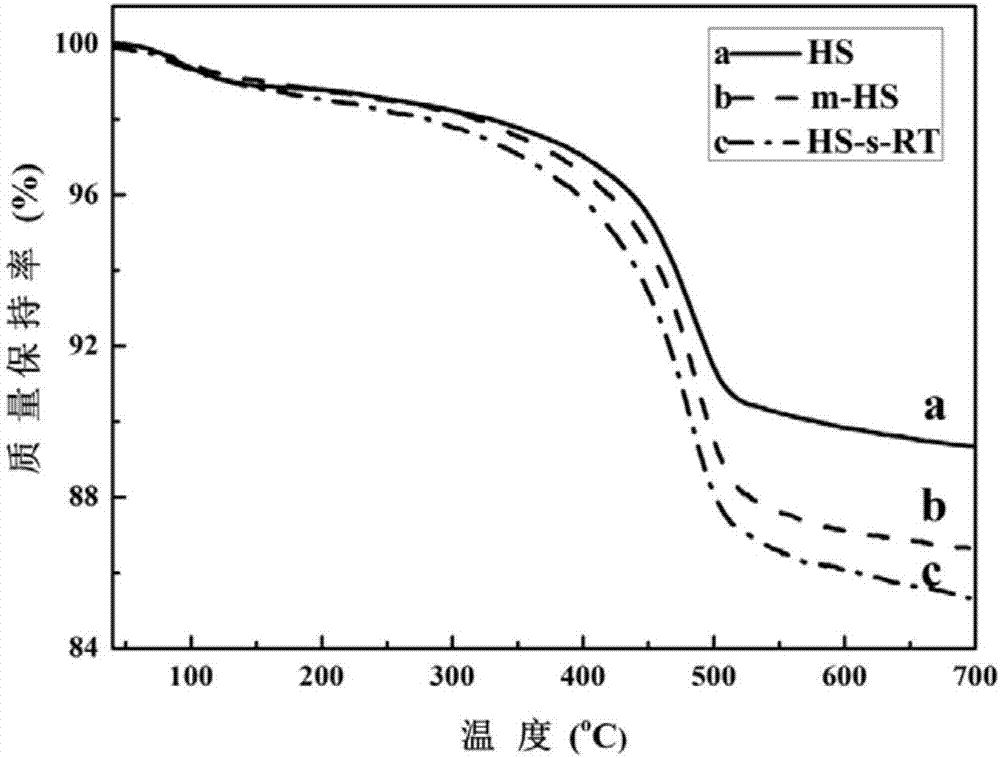

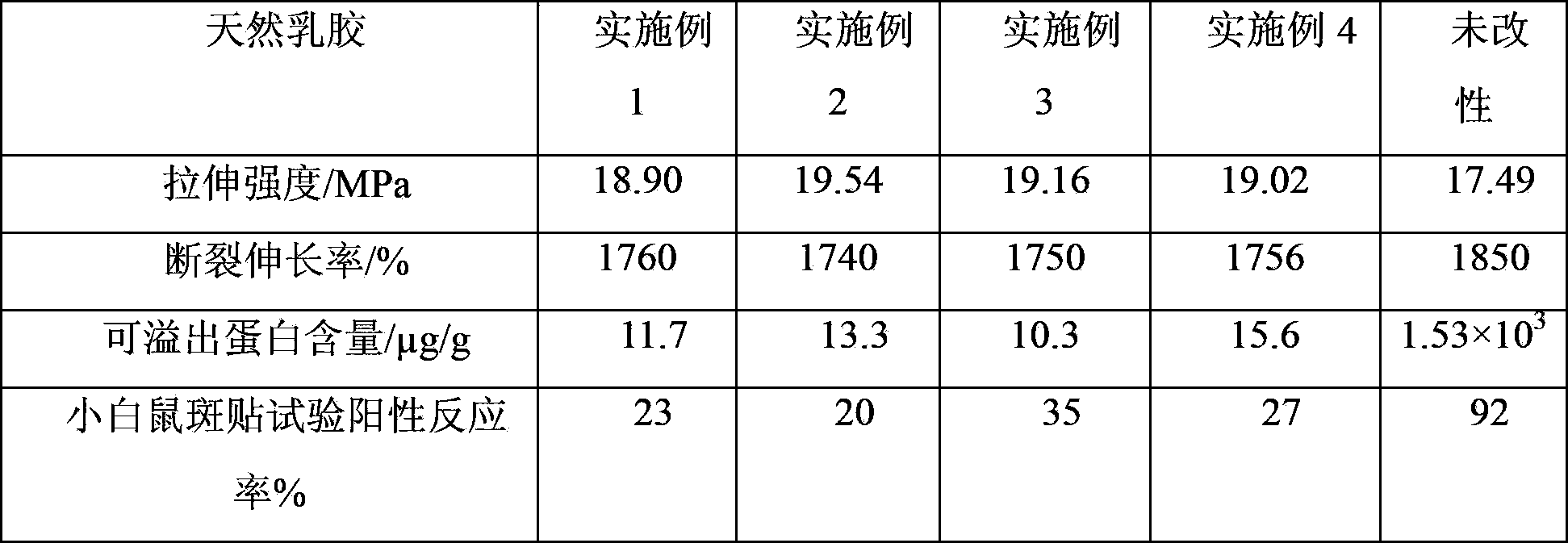

Hybrid filler load type anti-aging agent, and preparation method and application thereof

The invention discloses a hybrid filler load type anti-aging agent, and a preparation method and application thereof. The method comprises the following steps that (1) hybrid fillers and a silane coupling agent are mixed; stirring reaction is performed for 10 to 24h at 70 to 90 DEG C; after drying, an intermediate product is obtained; (2) the intermediate product in the step (1) and N-phenyl p-phenylenediamine (RT) are mixed; stirring reaction is performed for 8 to 12h at 50 to 70 DEG C; after drying, the hybrid filler load type anti-aging agent is obtained. The hybrid filler load type anti-aging agent can obviously reduce the volatile migration phenomenon of micromolecule anti-aging agents in a rubber base body, has a better anti-aging effect than that of an ordinary ammonia anti-aging agent 4010NA, and has wide application prospects in the field of rubber.

Owner:SOUTH CHINA UNIV OF TECH

High-strength and high-toughness composite material

The invention discloses a high-strength and high-toughness composite material, the raw material of which comprises the following components: polyvinyl chloride, polyurethane elastomer, chlorinated polyethylene, EPDM rubber, silicone-acrylate copolymer, α-methyl Styrene Acrylonitrile, Tetraacicular Zinc Oxide Whiskers, Plant Fiber, Basalt Fiber, Nano Calcium Carbonate, Diatomaceous Earth, Organically Modified Montmorillonite, Zinc Hydroxide Stannate, Calcium Stearate, Zinc Stearate , molybdenum trioxide, acetyl tributyl citrate, soybean oil, polyepichlorohydrin, coupling agent, dioctyl sebacate, oxidized polyethylene wax, hydroxypropyl methylcellulose, triethanolamine. The high-strength and high-toughness composite material of the invention has high strength, good toughness, good heat resistance and strong aging resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Modified nature latex, preparation method and use thereof

The invention belongs to the technical field of rubber chemical modification, and relates to a preparation method and a use of a modified nature latex. The modified nature latex is prepared from the following components by weight: 100 parts of nature latex, and 10-30 parts of sericin grafted aqueous polyurethane emulsion. According to the present invention, the modified rubber has advantages of surface functionalization, good biocompatibility and the like; the mechanical property and the allergy of the nature latex gloves are improved; and the traditional method that the protein removing method is adopted to solve the allergy of the latex product is changed, the allergy problem is solved without reduction of the protein content, and the physical and mechanical properties of the latex product are ensured.

Owner:HEFEI GENIUS NEW MATERIALS

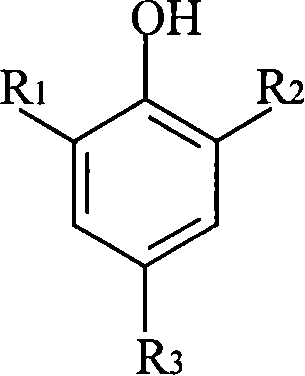

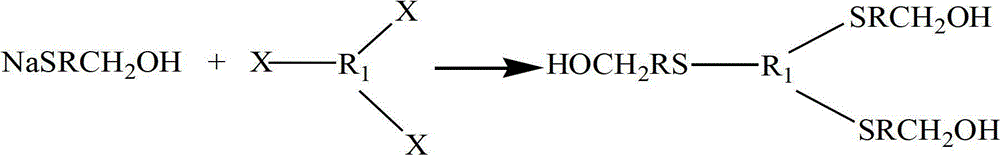

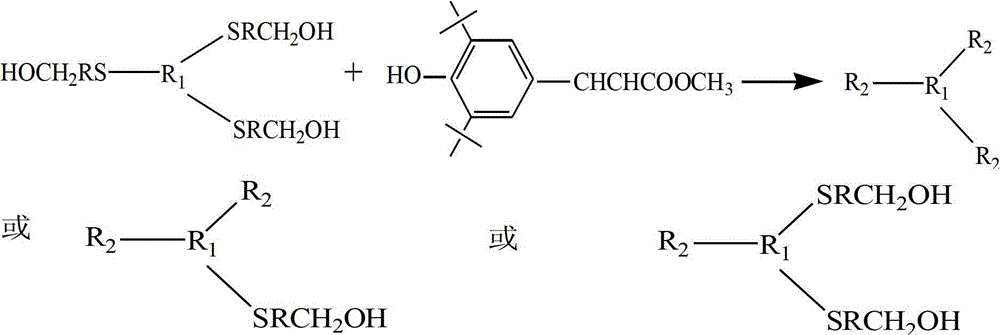

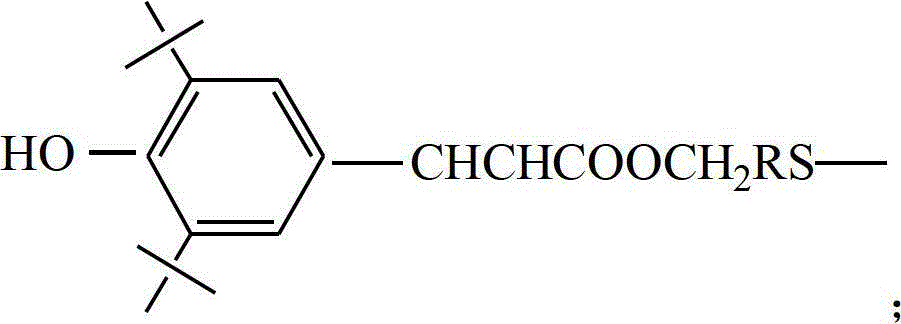

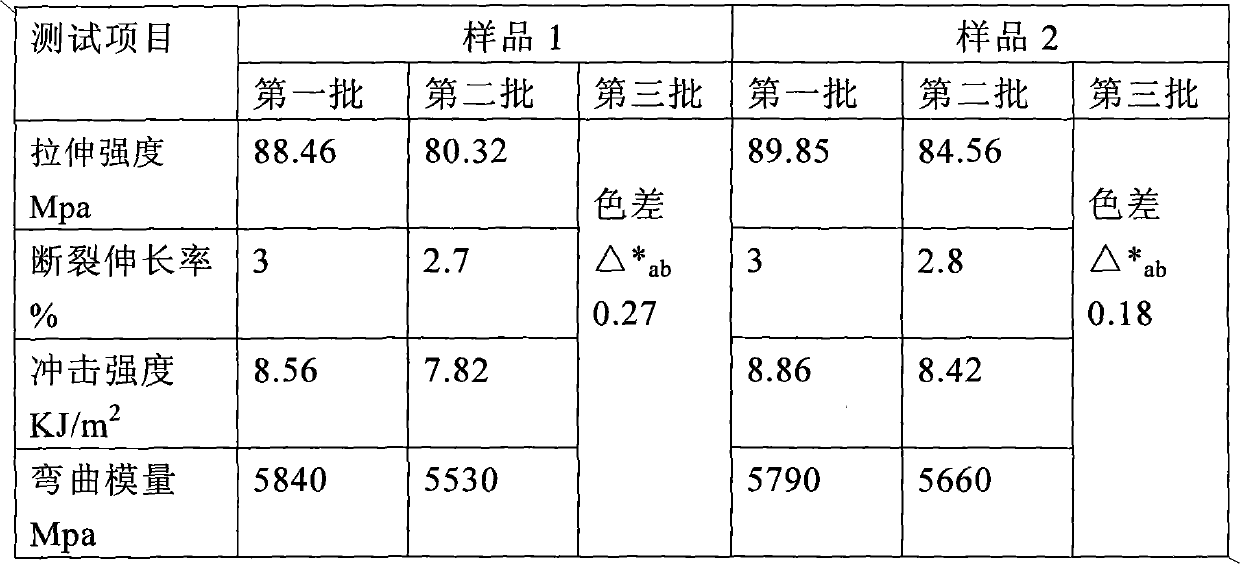

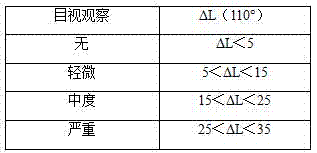

Preparation method of heat-resistant oxygen-resistant polyester film

ActiveCN102875980AImprove thermal oxygen resistanceImprove temperature resistanceFlat articlesSulfide preparationOxygenPhenol

The invention discloses a preparation method of a heat-resistant oxygen-resistant polyester film. The preparation method is characterized by including the steps of preparation of hydroxy thiophenol containing compounds, preparation of sulfur-containing hindered phenol antioxidants, polyester synthesis and film processing. The preparation method includes: using 4-hydroxy benzyl thiophenol sodium, 1, 3, 5-trichlorobenzene, 1, 3, 5-tribromobenzene and 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine to synthesize the hydroxy thiophenol containing compounds, namely, 1, 3, 5-tri(4-hydroxy benzyl thiophenyl) benzene and 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine in N, N-dimethyl formamide solvent; synthesizing the 1, 3, 5-tri(4-hydroxy benzyl thiophenyl) benzene, the 2, 4, 6-tri(4-hydroxy benzyl thiophenyl)-1, 3, 5-triazine and 3, 5-di-tert-butyl-4-hydroxy phenylacrylic acid methyl ester to prepare the type A reactive sulfur-containing hindered phenol antioxidant and the type B reactive sulfur-containing hindered phenol antioxidant; and synthesizing the type A reactive sulfur-containing hindered phenol antioxidant, the type B reactive sulfur-containing hindered phenol antioxidant, terephthalic acid and ethylene glycol to prepare heat-resistant oxygen-resistant polyester resin, so that the heat-resistant oxygen-resistant polyester film good in performance is prepared.

Owner:四川东方绝缘材料股份有限公司

Composite material capable of resisting ageing for long time and preparation method of composite material

InactiveCN102558685AImprove mechanical propertiesExcellent heat and oxygen aging resistanceGlass fiberAging resistance

The invention relates to a composite material capable of resisting ageing for a long time and a preparation method of the composite material. The composite material comprises the following components in percent by weight: 45-75 percent of polypropylene, 10-40 percent of glass fiber, 3-10 percent of compatilizer, 10-20 percent of antioxygen and 0.1-0.5 percent of lubricating agent. The preparation method comprises the steps of: placing raw material in a high speed mixer and then placing the raw materials in a double-screw extruder for granulating, controlling the rotating speed of the double-screw extruder to be 300-700 turns / min and the temperature to be 190-220 DEG C, melting and then extruding and granulating to obtain the composite material. Compared with the prior art, the PP / GF (polypropylene / glass fiber) composite material capable of resisting the ageing for a long time, prepared in the invention has excellent mechanical property, heat and oxygen ageing resistance and ultraviolet ageing resistance. The composite material can be used for manufacturing a member with higher ageing performance, and can be widely applied to the fields such as electric products and automobile parts.

Owner:SHANGHAI SUNNY

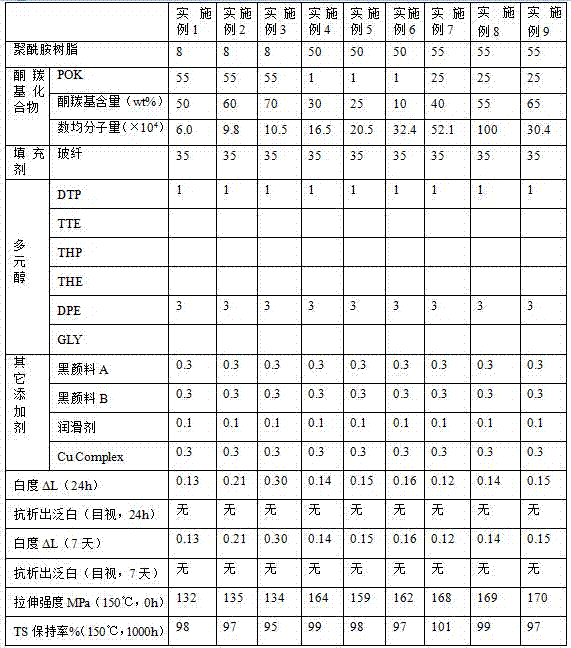

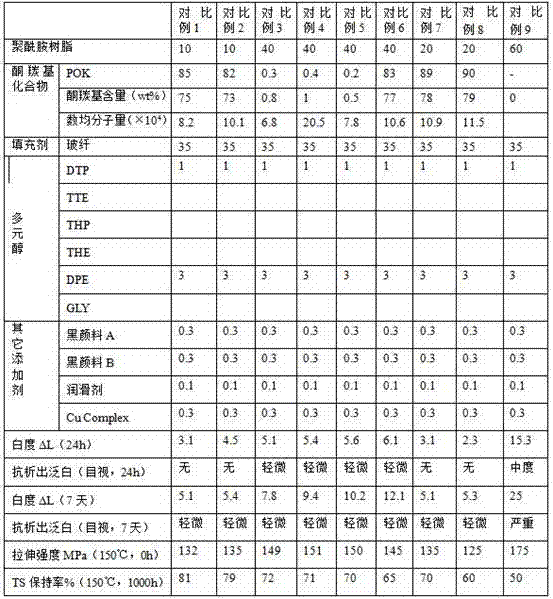

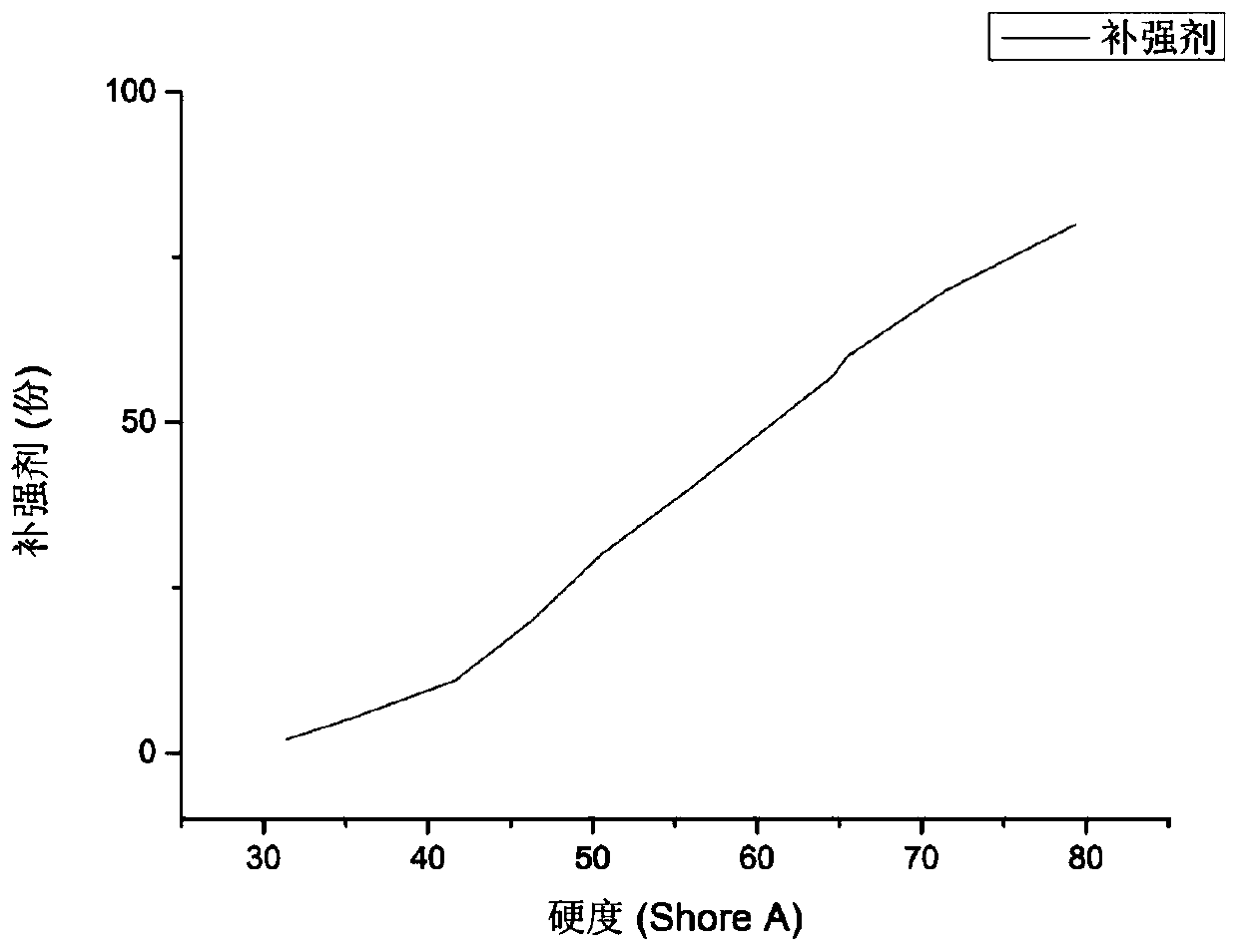

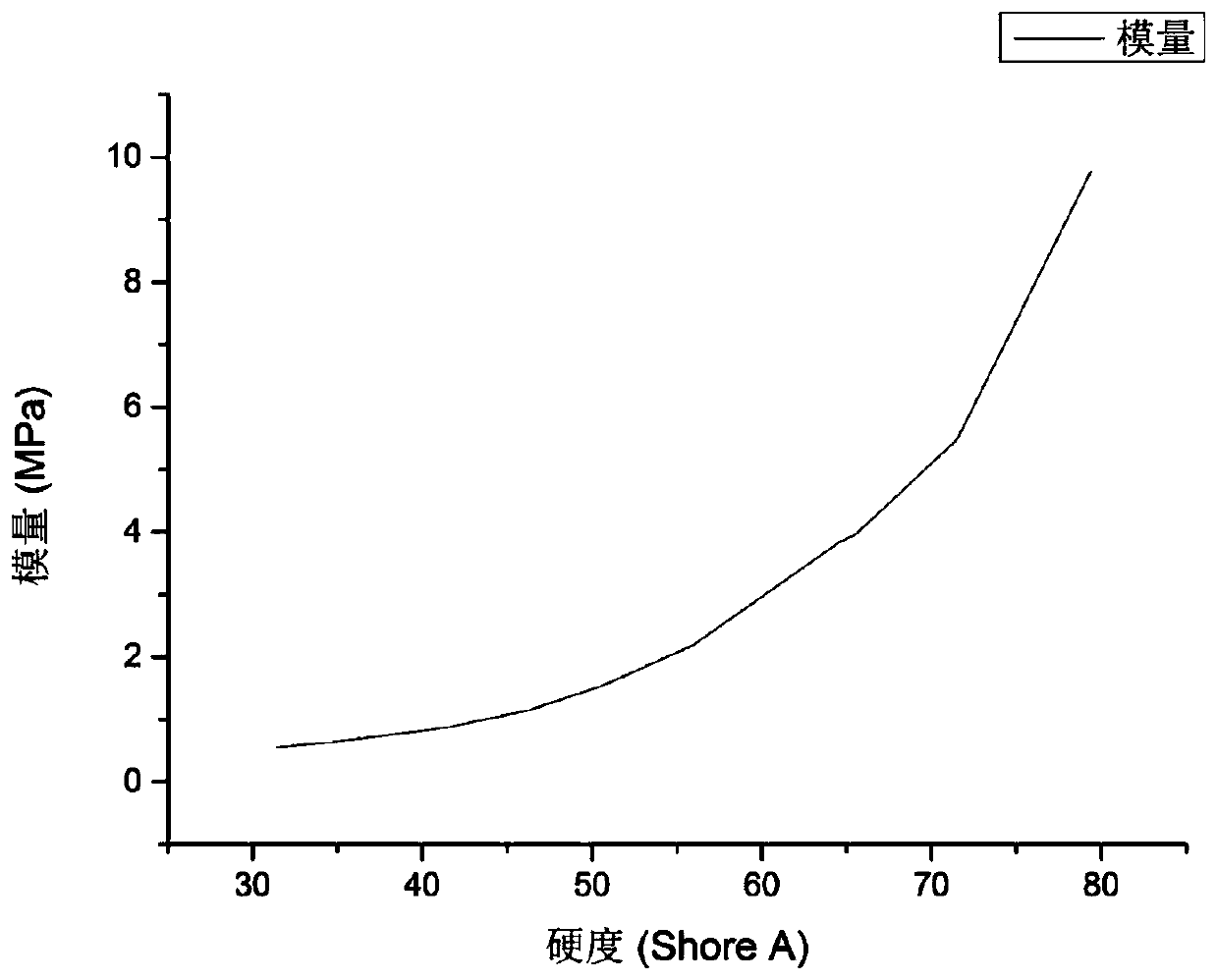

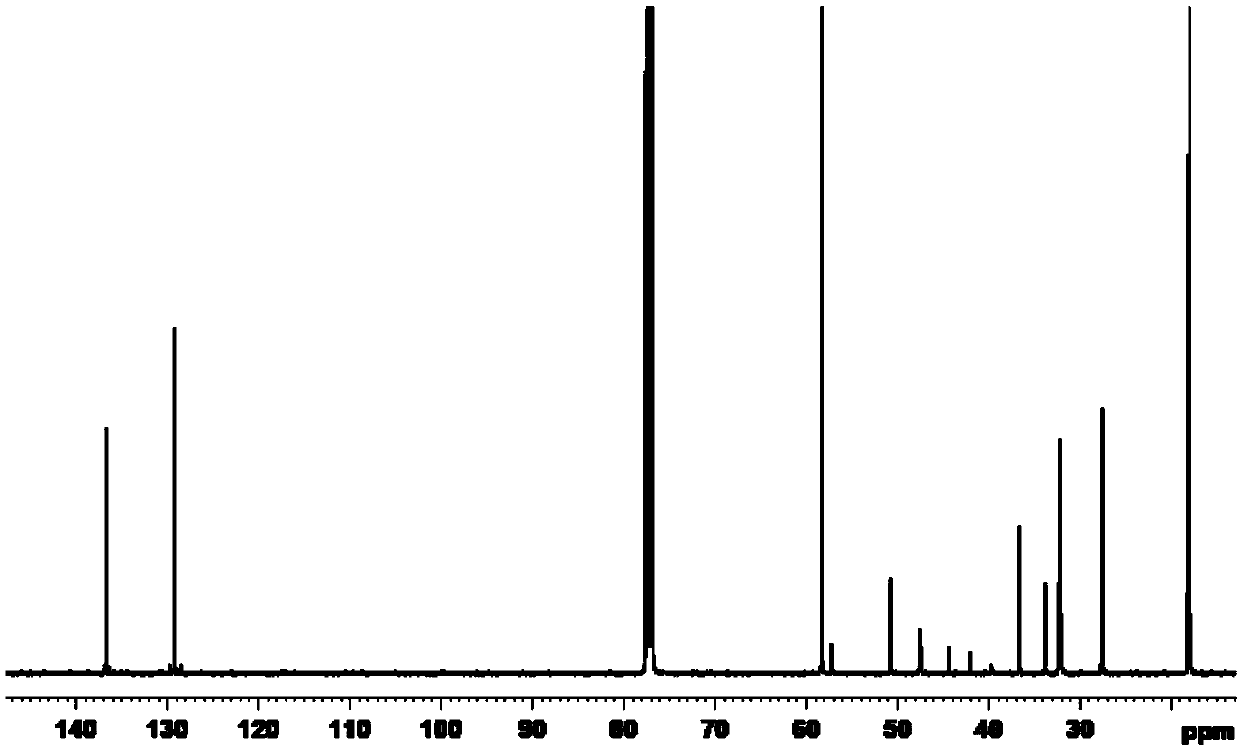

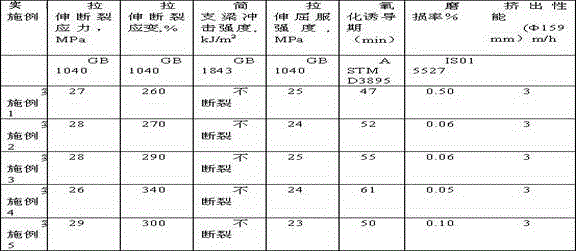

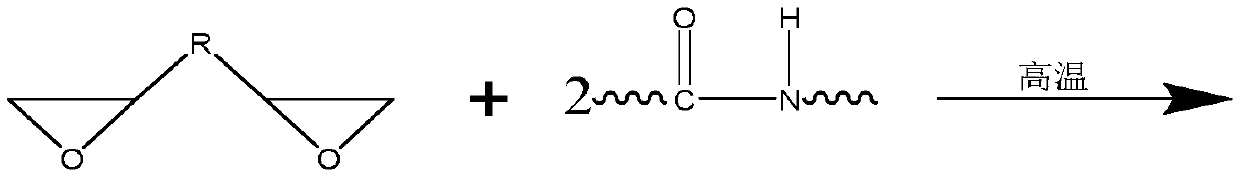

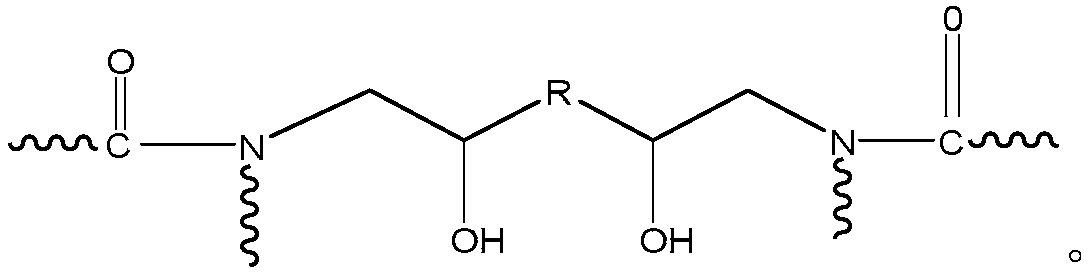

Thermoplastic resin composition, preparation method and applications thereof

The invention discloses a thermoplastic resin composition, which comprises the following components in parts by weight: 5 to 60 parts of polyamide resin, 1 to 10 parts of polyol, and 0.5 to 79 parts of compound containing carbonyl group; on the basis of the total weight of the compound containing carbonyl group, according to the GB / T6324.5-2008 or element analysis method, the measured carbonyl group content is in a range of 10 to 70 wt%, the preferable content is 25 to 60 wt%, and the more preferable content is 30 to 50 wt%. According to the provided preparation method, a compound with a certain ratio of carbonyl group is added to prepare the thermoplastic resin composition; compared with the conventional thermoplastic resin composition, which only contains a specific amount of polyol, the prepared thermoplastic resin composition has an excellent performance on resisting thermo-oxidative aging, wherein the performance is represented by the tensile strength retention rate after thermo-oxidative aging; the provided thermoplastic resin composition is exposed in an environment cabinet with a humidity of 85% and a temperature of 85 DEG C for seven days, the phenomenon of precipitation and whitening does not appear; while conventional thermoplastic resin composition that does not contain the compound containing carbonyl group easily transfers to the surface of mould parts namely precipitation and whitening, and the provided thermoplastic resin composition avoids the phenomenon mentioned above.

Owner:TIANJIN KINGFA NEW MATERIAL +2

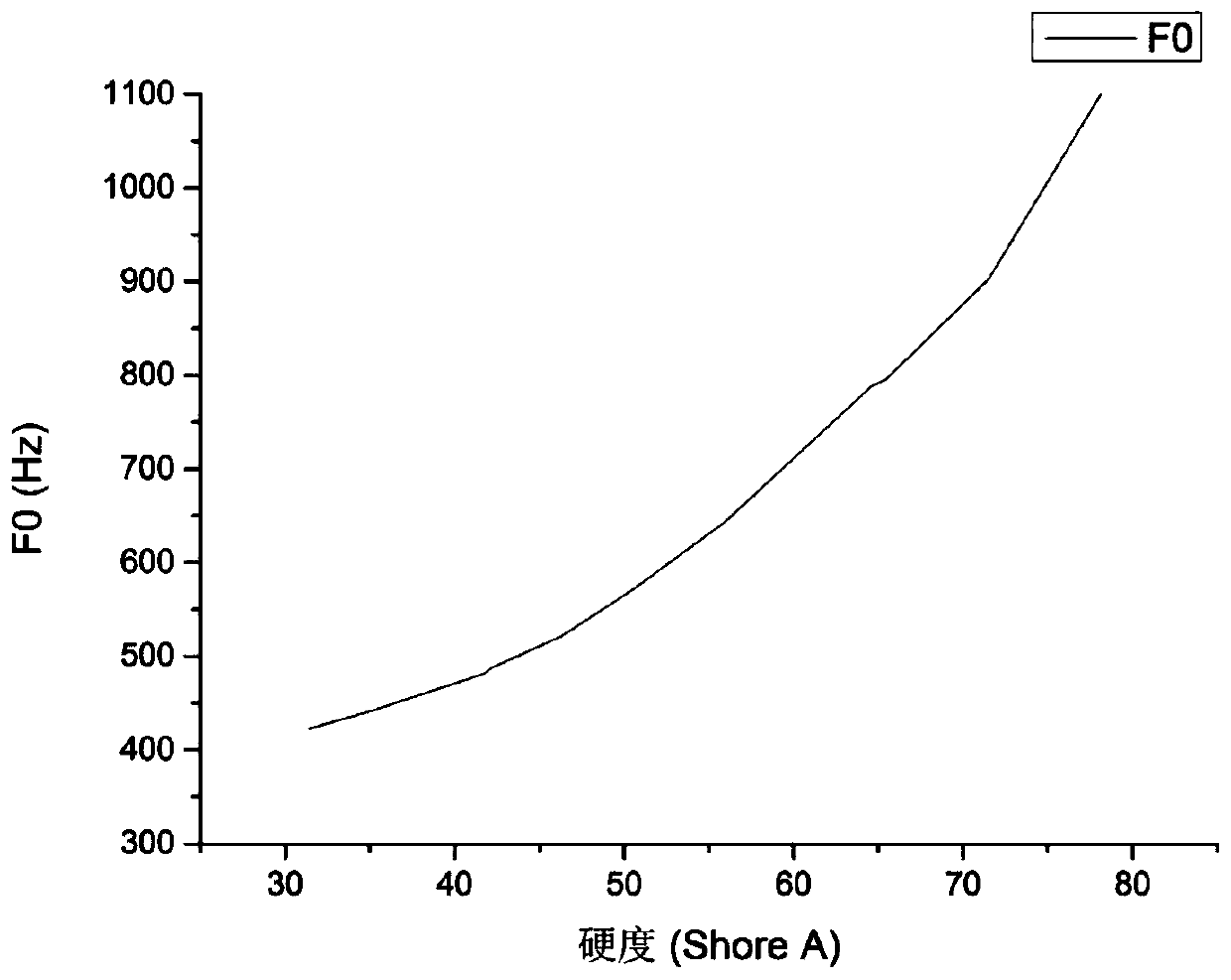

Diaphragm of sounding device and sounding device

PendingCN110283389AImprove high temperature resistanceExcellent heat and oxygen aging resistancePolymeric diaphragmsSynthetic resin layered productsElastomerPolymer science

The invention discloses a diaphragm of a sounding device and the sounding device. The diaphragm comprises at least one layer of an elastomer layer; the elastomer layer is made of a EPDM rubber; the EPDM rubber is formed by polymerization of three monomers, wherein the three monomers include an ethylene monomer, a propylene monomer and a non-conjugated diene monomer, the mass ratio of the ethylene monomer to the propylene monomer ranges from 0.25 to 4, and the content of the non-conjugated diene monomer is 1%-15% of the total content of the ethylene monomer and the propylene monomer. The EPDM rubber has good high temperature resistance and thermo-oxidative aging resistance; after the EPDM rubber is made into the diaphragm, the diaphragm can work in a high temperature environment for a long time, not only can maintain excellent elasticity, but also has excellent fatigue resistance, and thus has excellent reliability.

Owner:GOERTEK INC

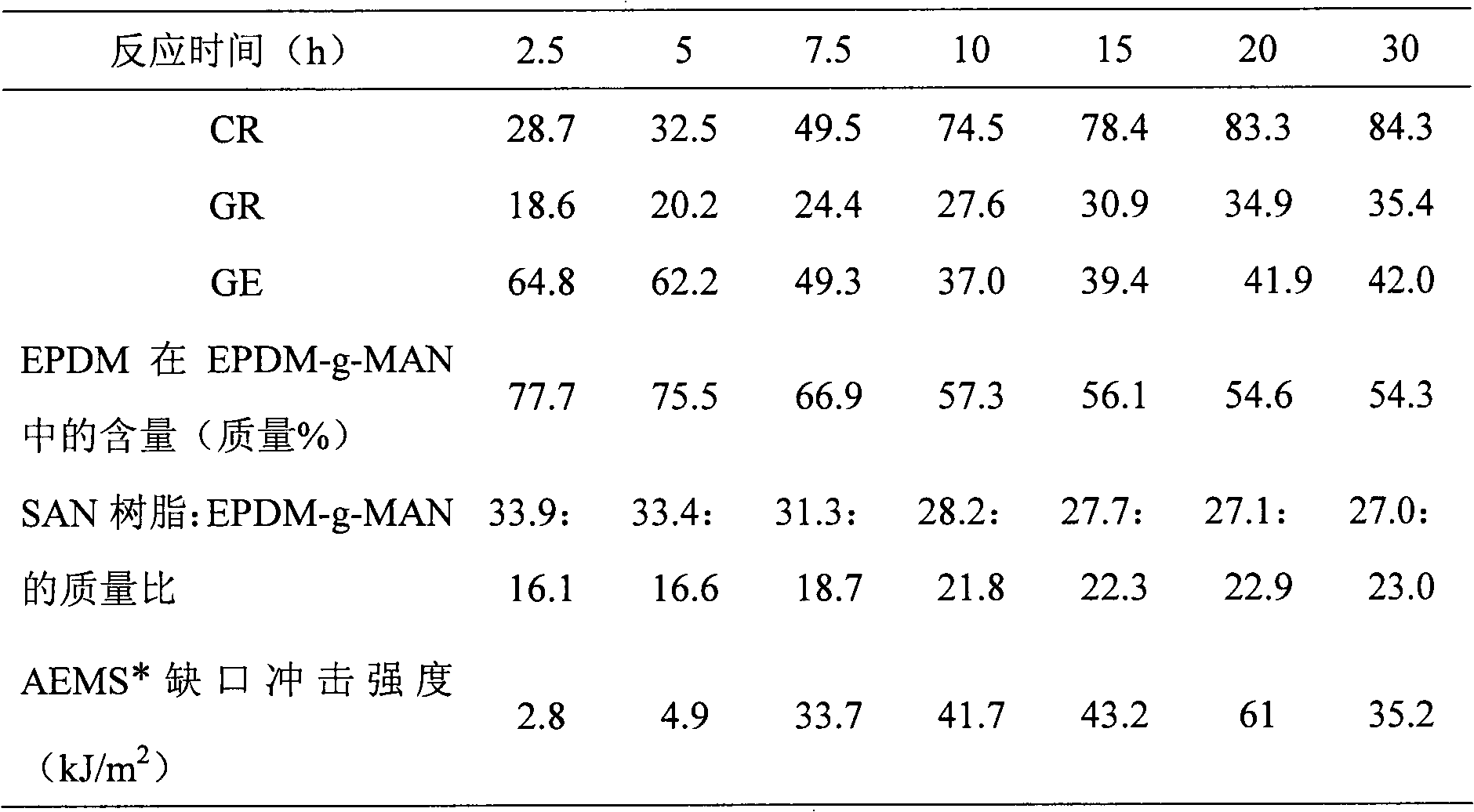

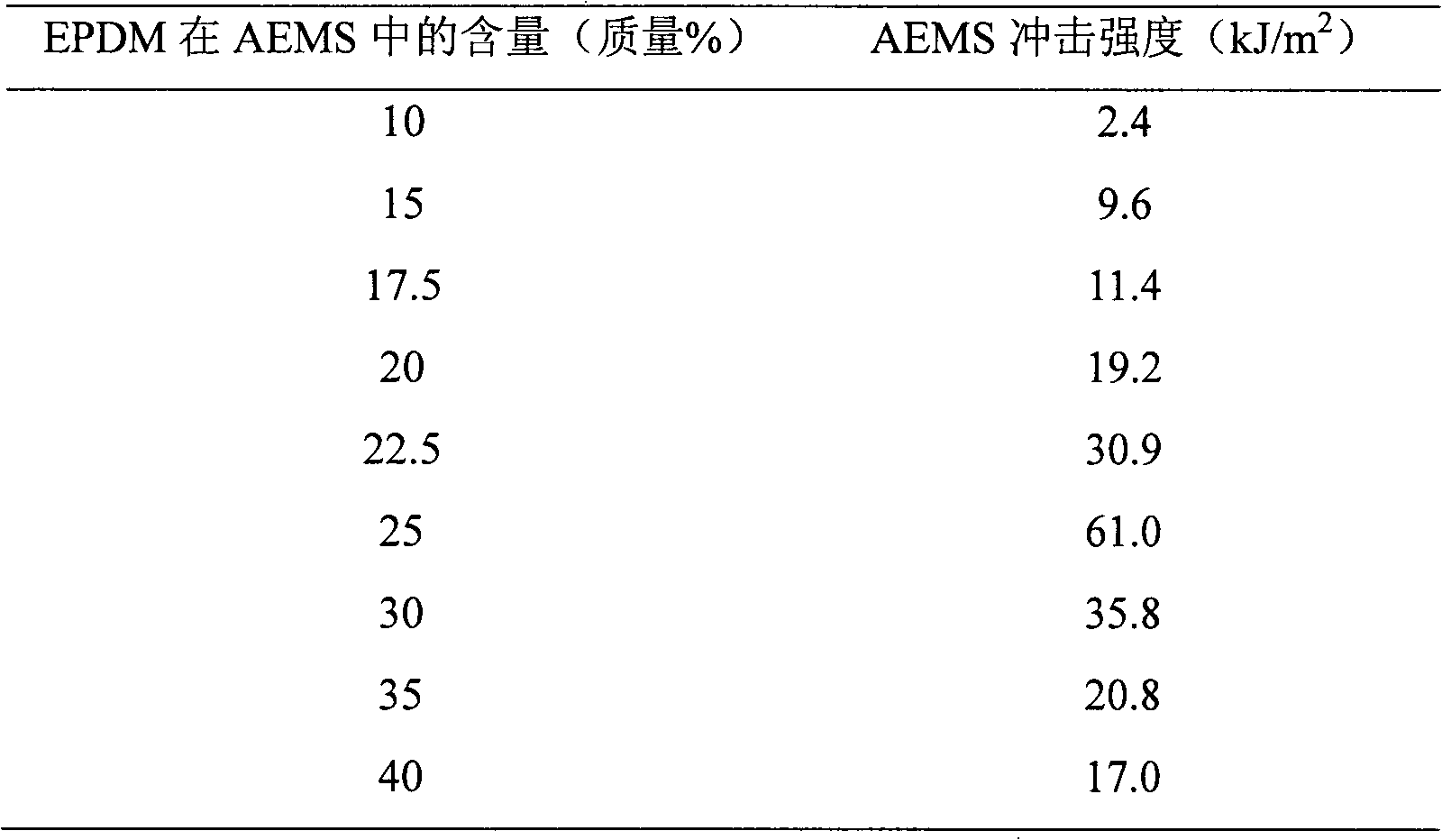

Method of preparing ethylene propylene diene monomer graft polymer through solution grafting copolymerization and application thereof

The invention discloses a method of preparing ethylene propylene diene monomer (EPDM) graft polymer through solution grafting copolymerization and an application thereof in the preparation of engineering plastics. The method optimizes and improves the preparation method on the basis of the solution grafting copolymerization preparation of EPDM-g-SAN, introduces polar monomer MMA, synthesizes EPDM-g-MAN or EPDM-g-MAS which has less content of AN unit of the graft chain, on the condition of low AN dosage; in addition, the highest monomer conversion rate of the method can reach 70-95% by adjusting the monomer proportioning so as to increase the grafting rate and grafting efficiency of the grafting copolymerization system and significantly improve the compatibility between EPDM graft polymer and SAN resin and the toughening efficiency of EPDM graft polymer to SAN resin. By mixing the EPDM graft polymer prepared in the invention and SAN resin, impact resistance engineering plastics with excellent weather resistance, aging resistance and yellowing resistance and high glossiness can be prepared.

Owner:KINGFA SCI & TECH CO LTD +1

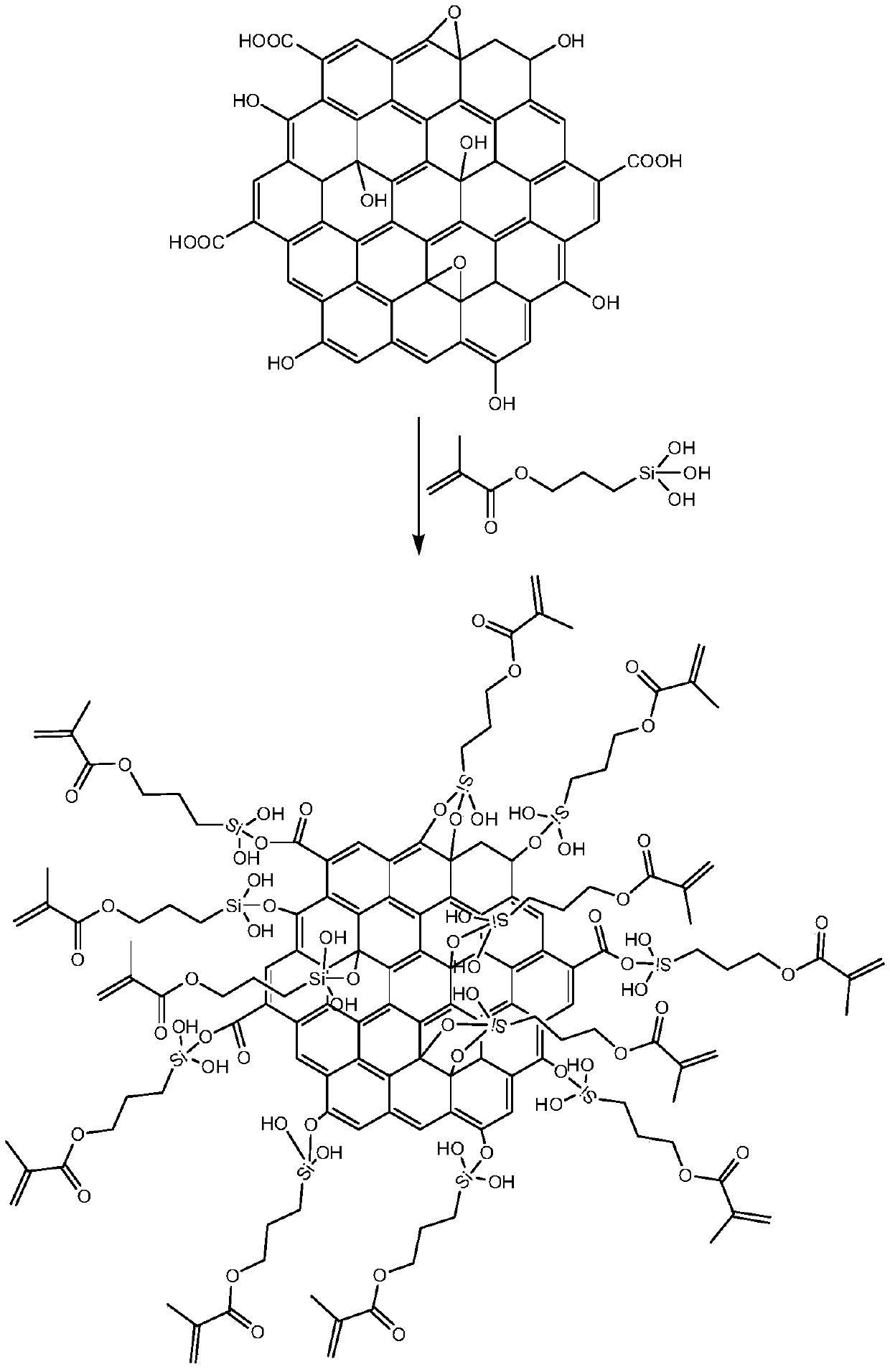

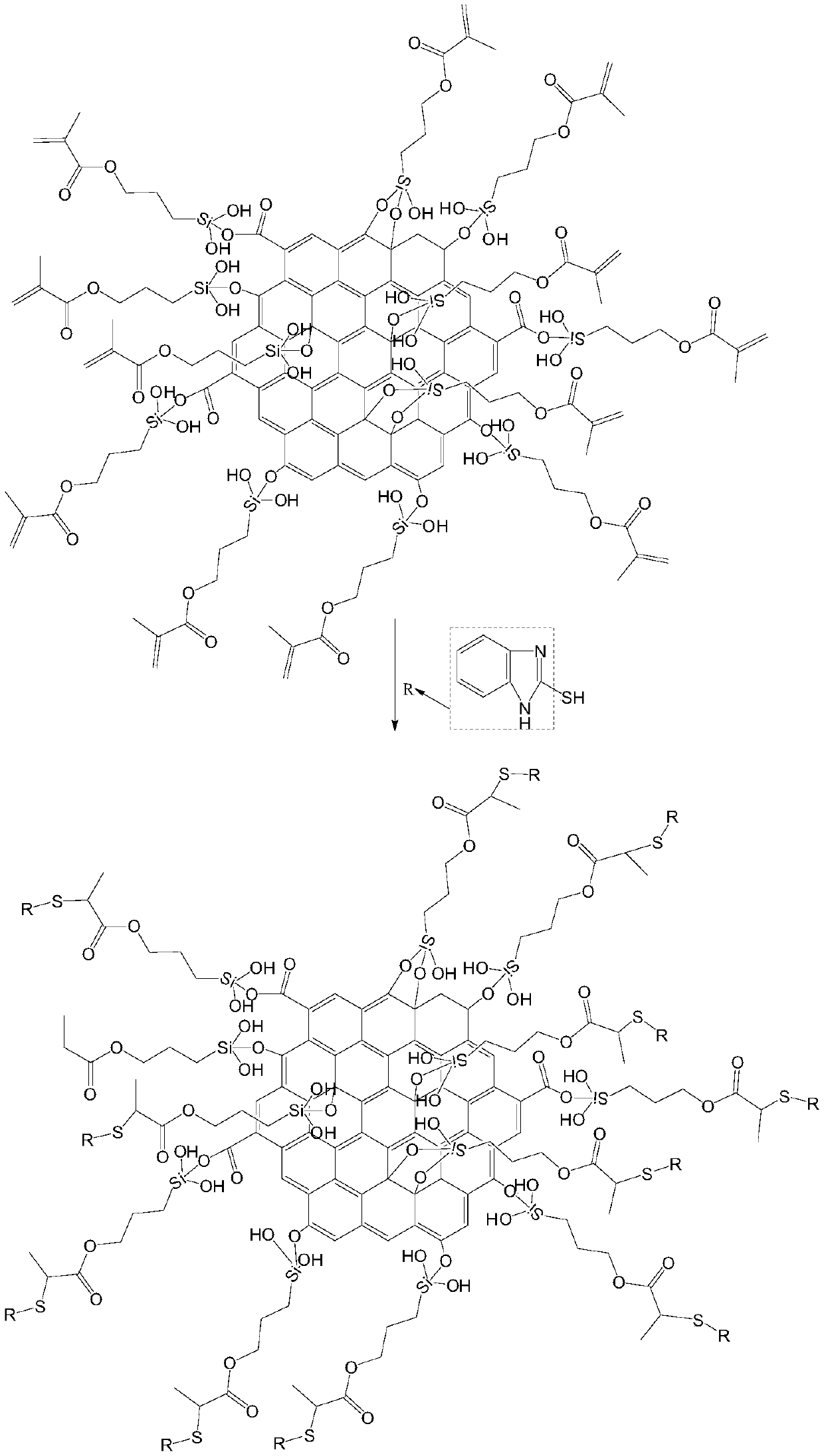

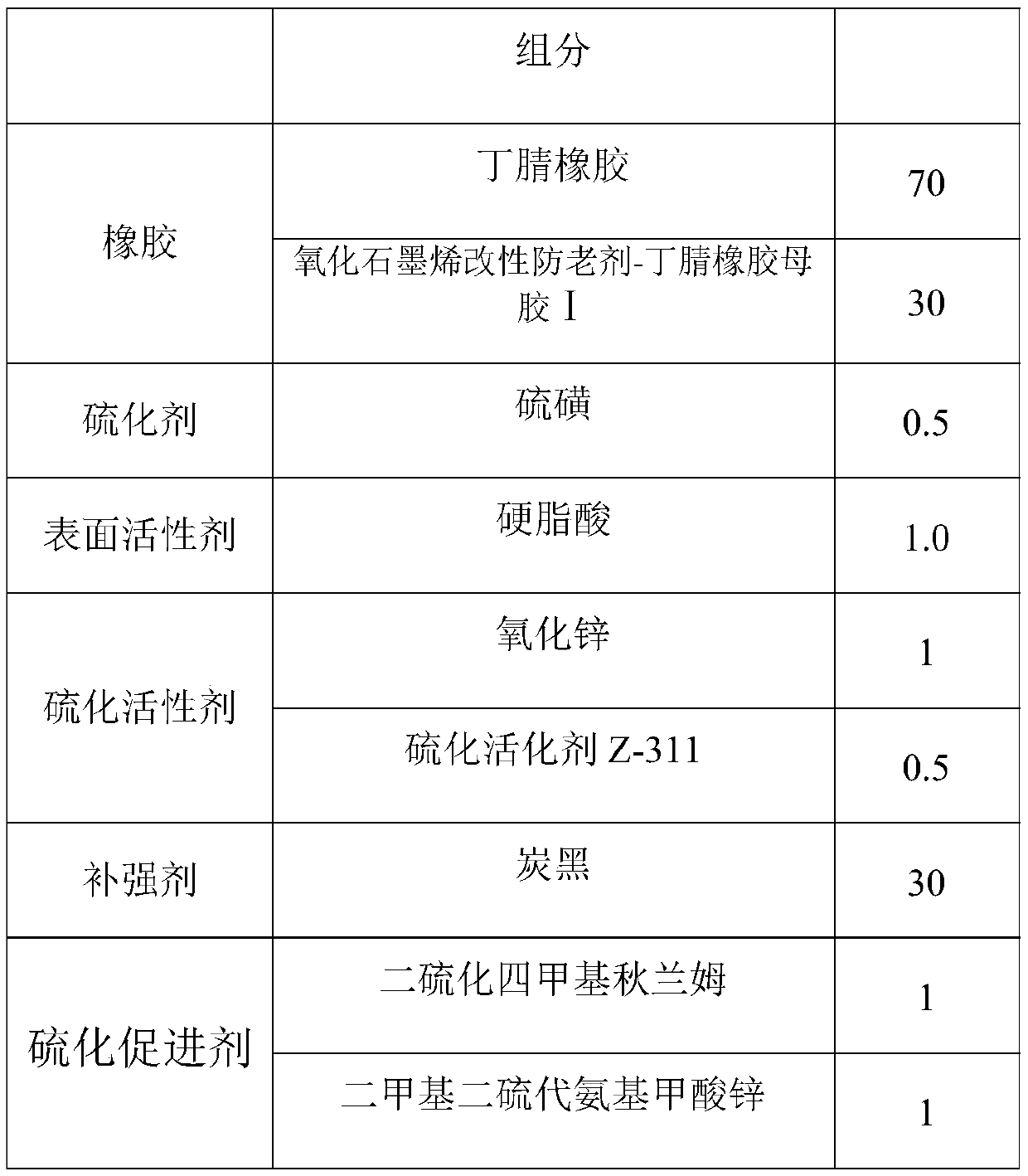

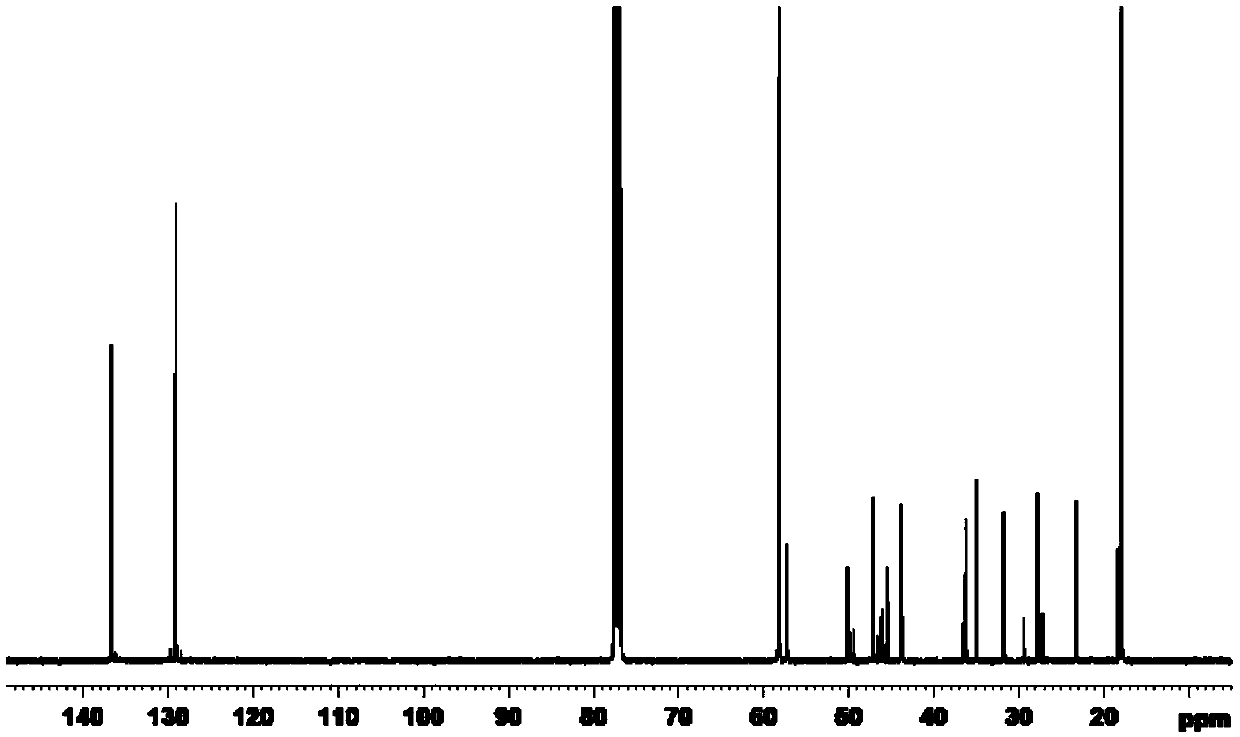

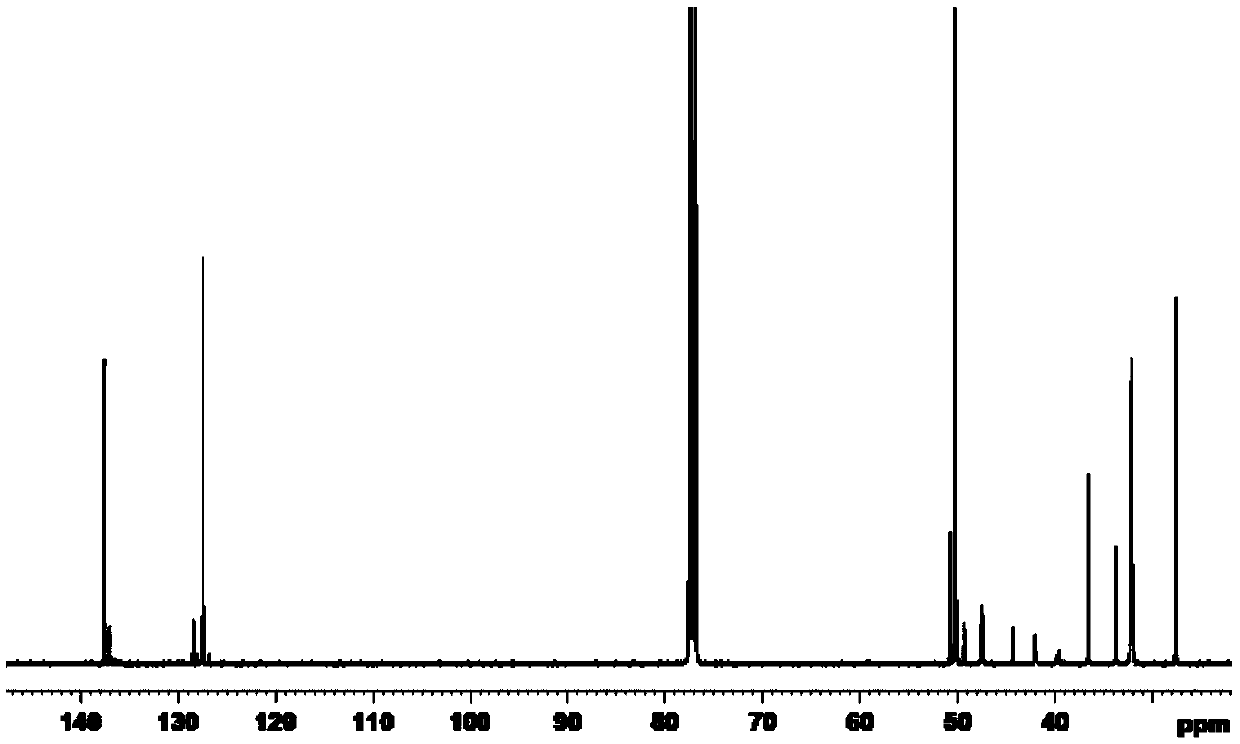

Graphene oxide modified anti-ageing agent, anti-thermo-oxidative-aging rubber containing graphene oxide modified anti-ageing agent and preparation method

ActiveCN110117390AExcellent heat and oxygen aging resistanceInhibit migrationAging resistanceDouble bond

The invention relates to the technical field of graphene rubber composite materials, in particular to a graphene oxide modified anti-ageing agent, anti-thermo-oxidative-aging rubber containing the graphene oxide modified anti-ageing agent and a preparation method. Organosilane containing carbon-carbon double bonds and graphene oxide are subjected to a dehydration condensation reaction to obtain anintermediate product, and the intermediate product and an anti-ageing agent containing mercapto groups are subjected to a click reaction to prepare the graphene oxide modified anti-ageing agent. Thegraphene oxide modified anti-ageing agent, can effectively reduce the using amount of the anti-ageing agent and is difficult to draw out, and the anti-thermo-oxidative-aging rubber prepared from the graphene oxide modified anti-ageing agent is high in mechanical strength and high in thermo-oxidative aging resistance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Bis-secondary amine containing siloxane groups and preparation method and application of bis-secondary amine

ActiveCN110760047AExcellent heat and oxygen aging resistanceSlow curingGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses bis-secondary amine containing siloxane groups and a preparation method and application of the bis-secondary amine. The bis-secondary amine containing the siloxane groups is obtained by Michael addition reaction of one or more bis-primary amines and siloxane containing unsaturated double bonds. A B component of spray polyurea is prepared by mixing the bis-secondary amine and an auxiliary agent, an isocyanate prepolymer generated by reaction of polyether polyol and isocyanate is taken as a component A, and the component A and the component B are mixed and sprayed according to the volume ratio of the components A and B of 1 : 1 to obtain a polyurea material. Two active hydrogens of the bis-secondary amine can react with the isocyanate to generate linear polyurea, andthe siloxane groups can be hydrolyzed to generate Si-O-Si cross-linking points, so that the cross-linking speed of the amine and the isocyanate is reduced and the mechanical properties of the polyureamaterial are improved.

Owner:WANHUA CHEM GRP CO LTD

Composition for preparing ultrahigh molecular weight polyethylene pipe material

InactiveCN106750724AExcellent heat and oxygen aging resistanceImprove mechanical propertiesPolymer scienceOxygen

The invention relates to a composition for preparing an ultrahigh molecular weight polyethylene pipe material. The composition is prepared from the following raw materials: ultrahigh molecular weight polyethylene, a fluorine-containing polymer processing aid, polyethylene wax, a calcium stearate / zinc stearate compound, a compound antioxidant and carbon black according to the corresponding mass ratio of 100:0.01-0.05:2-6:0.1-1.0:0.2-0.4:1-3; wherein the viscosity average molecular weight of the ultrahigh molecular weight polyethylene is 200*10<4>-300*10<4>; the fluorine-containing polymer processing aid is a fluorinated copolymer of vinylidene fluoride; the mass ratio of the calcium stearate to zinc stearate is 1-3:1; the compound antioxidant is a mixture of (A) a hindered phenol antioxidant and (B) a phosphite ester antioxidant according to the mass ratio of A:B = 1:1-3. According to the formula, the ultrahigh molecular weight polyethylene pipe composition has excellent thermal oxidative aging resistance, is higher than 4530 min in oxidizing induction time at 200 DEG C, and has excellent mechanical performance, wear-resisting property, corrosion resistance, thermal oxidative aging resistance and extrusive processability.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Modified coconut shell and natural rubber composite cable sheath material

InactiveCN104194239ALow hydroxyl contentImprove hydrophobicityRubber insulatorsInsulated cablesFiberVulcanization

The invention discloses a modified coconut shell and natural rubber composite cable sheath material which is characterized by comprising the following raw materials in parts by weight: 100 parts of natural rubber, 8-10 parts of maleic anhydride, 30-40 parts of coconut shell fiber, 15-20 parts of kieselguhr, 5-10 parts of nylon PA, 10-15 parts of calcined clay, 30-40 parts of white carbon black, 20-30 parts of carbon black, 20-40 parts of attapulgite, 4-4.5 parts of zinc oxide, 1.5-2 parts of sulfur, 1-2 parts of vulcanization accelerant N-cyclohexyl-2-benzothiazole sulfonamide, 3-4 parts of bi(3-triethoxy silylation propyl) tetrasulfide and 1.5-2 parts of stearic acid, wherein the particle size of the coconut shell fiber is 20-30mm. The modified coconut shell and natural rubber composite cable sheath material is good in physical and mechanical properties and relatively excellent in thermo-oxidative aging resistance, ozone resistance and ultraviolet resistance.

Owner:ANHUI LAND GRP

Glass fiber reinforced nylon material for engine intake manifold and preparation method thereof

The invention discloses a glass fiber reinforced nylon material for an engine intake manifold and a preparation method thereof. The glass fiber reinforced nylon material comprises the following raw materials: 20-40 parts of nylon resin No. 1, 20-40 parts of nylon resin No. 2, 30-35 parts of glass fibers, 0.5-1 part of a coupling agent, 0.2-0.5 part of a main antioxidant, 0.2-0.5 part of an auxiliary antioxidant, 0.2-0.5 part of a heat stabilizer, 3-5 parts of metal microbeads, 0.1-0.3 part of a nucleating agent, 0.3-0.8 part of a lubricant, 1.0-1.5 parts of a hydrolysis-resistant agent, 0.5-2.5 parts of epoxy resin and 1-2 parts of black masterbatch. The invention also discloses the preparation method for the above-mentioned nylon material. According to the invention, the epoxy resin is adopted for coating pretreatment of the metal microbeads, and the metal microbeads flow onto the surface of the material during the subsequent processing of the nylon material, thereby improving the gloss of the obtained product and reducing the phenomenon of emergence of glass fibers on the surface. Thus, the prepared intake manifold has a smooth surface and good use performance.

Owner:QINGDAO GON TECHNOLOGY CO LTD

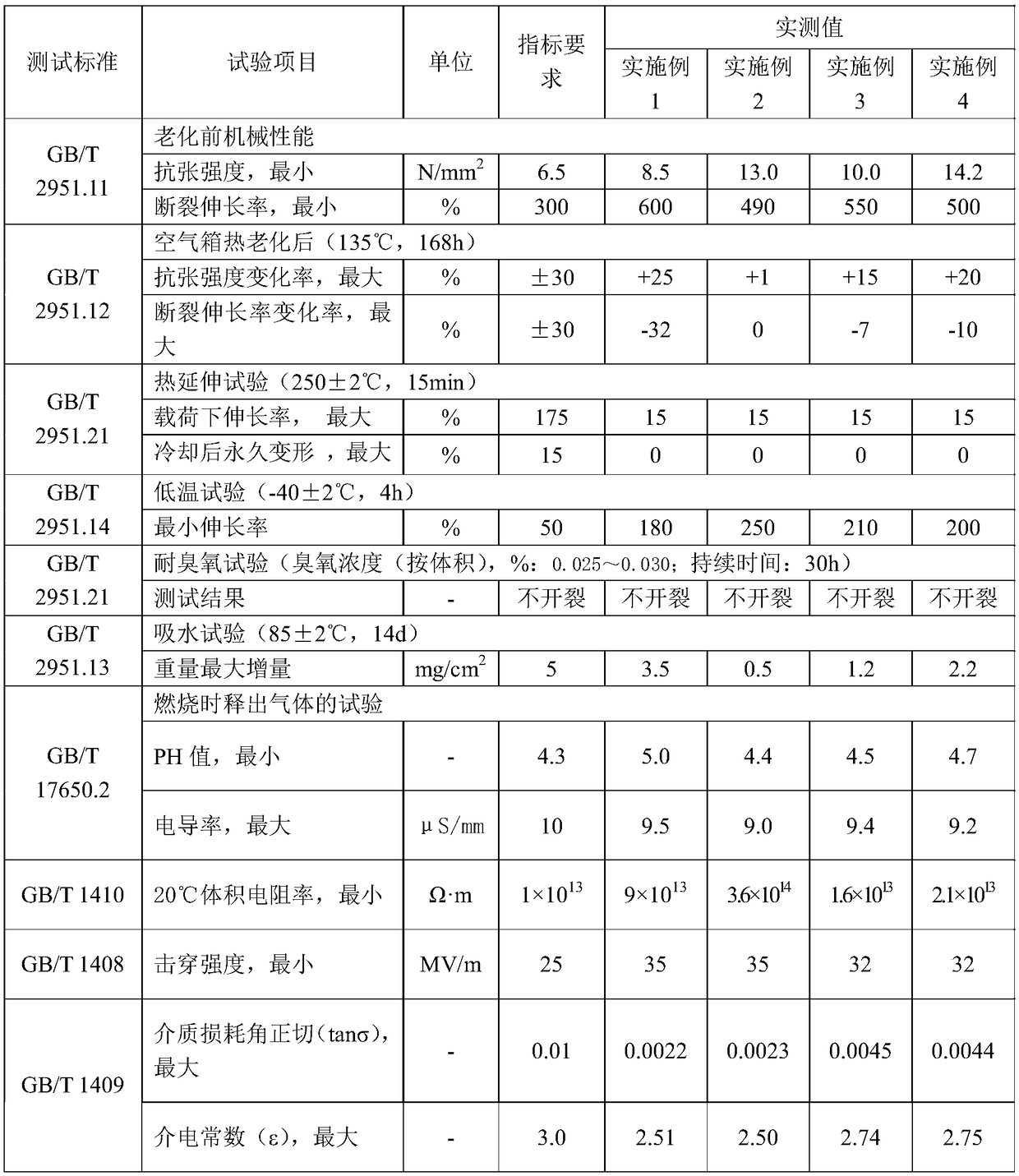

35kV environmentally-friendly intermediate-pressure ethylene-propylene insulation material and preparation method thereof

InactiveCN108841089AExcellent heat and oxygen aging resistanceImprove mechanical propertiesRubber insulatorsLow-density polyethyleneVulcanization

The invention discloses a 35kV environmentally-friendly intermediate-pressure ethylene-propylene insulation material and a preparation method thereof. The 35kV environmentally-friendly intermediate-pressure ethylene-propylene insulation material comprises the following raw materials and components in parts by mass: 80-100 parts of ethylene-propylene-diene monomer, 0-20 parts of low-density polyethylene, 2-5 parts of vulcanizing agent, 0-2 parts of co-curing agent, 5-10 parts of vulcanization accelerator, 60-100 parts of filler, 1-3 parts of antioxidant, and 4-20 parts of softening agent. According to the 35kV environmentally-friendly intermediate-pressure ethylene-propylene insulation material, all raw materials and components coordinately promote, so that the heat aging resistant property, the mechanical performance, the electric performance and the like of the material are outstanding; the material is applicable to environments such as a humid environment; the material does not influence any harmful substances such as lead, so that the environment is protected, and the safety is ensured; the material is simple to prepare; the operation is easy; and the cost is low.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

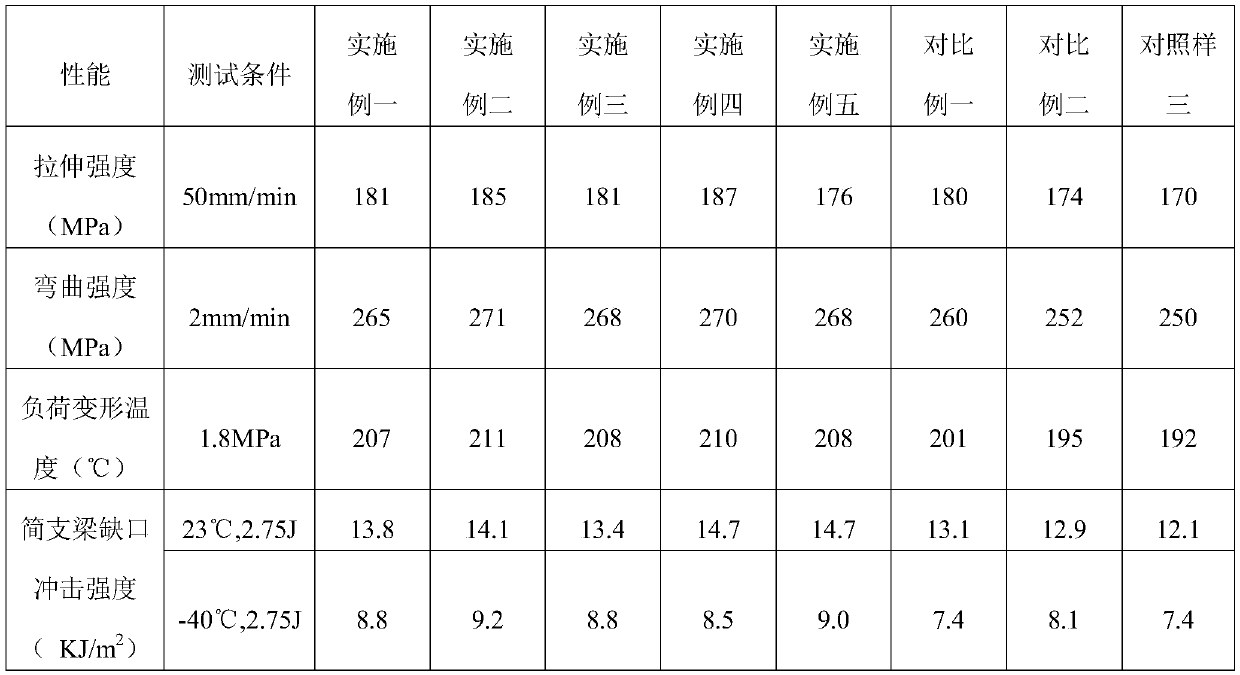

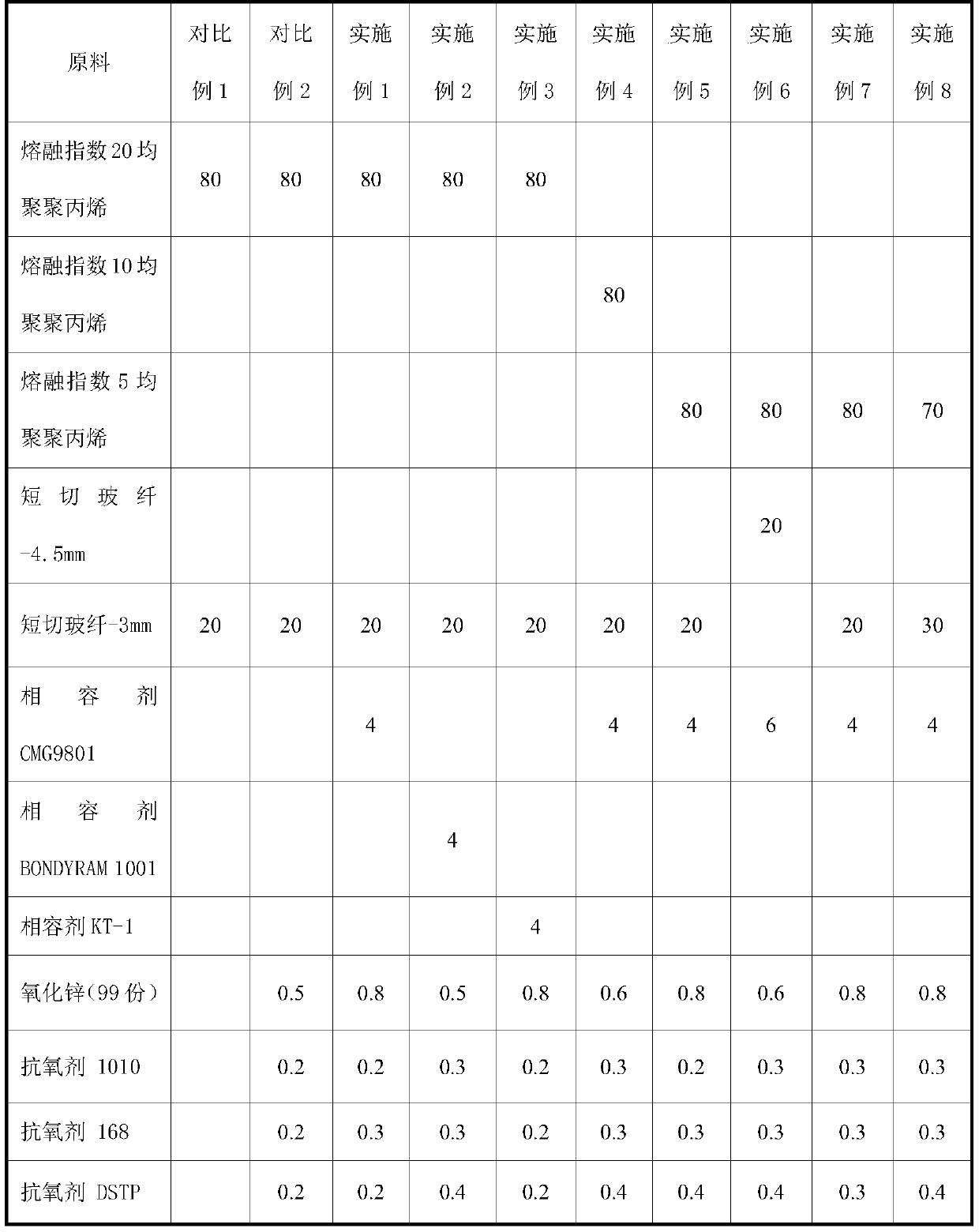

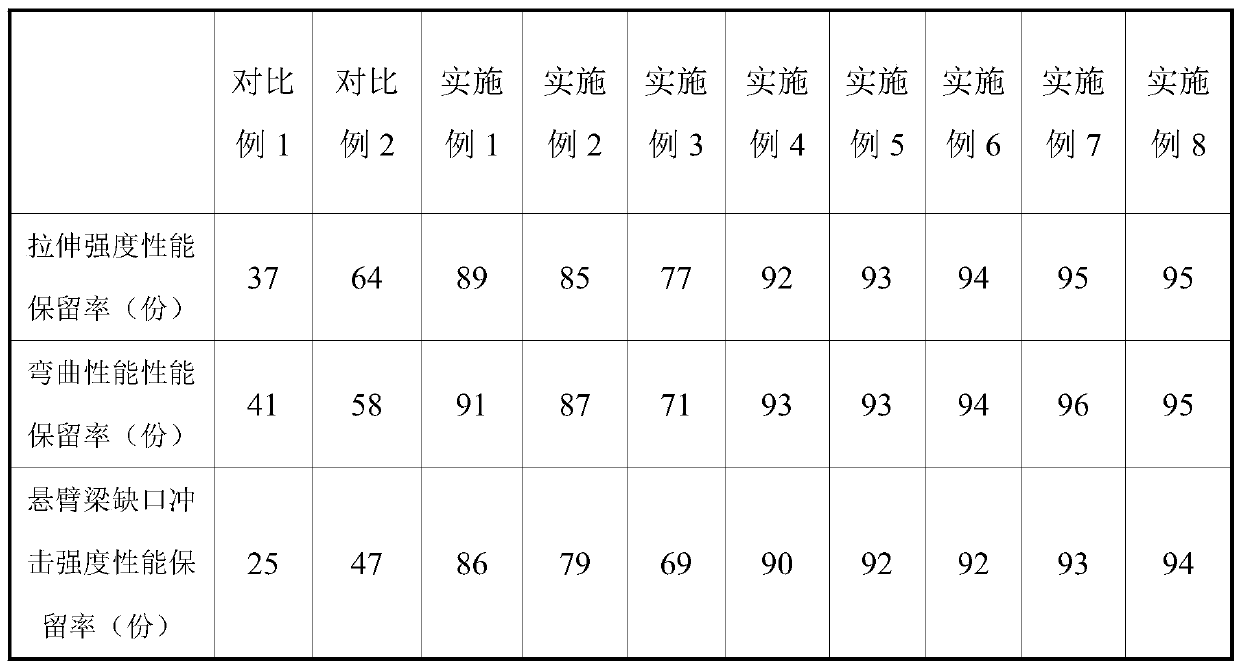

Glass fiber reinforced polypropylene composite material with high thermo-oxidative aging resistance and preparation method of glass fiber reinforced polypropylene composite material

InactiveCN109762247AGood performance retentionImprove heat and oxygen aging resistanceWeather resistanceOxide

The invention discloses a glass fiber reinforced polypropylene composite material with high thermo-oxidative aging resistance and a preparation method of the glass fiber reinforced polypropylene composite material. The glass fiber reinforced polypropylene composite material is prepared from components in parts by weight as follows: 70-80 parts of polypropylene homopolymers, 20-30 parts of glass fiber, 4-6 parts of a compatilizer, 0.5-0.8 parts of zinc oxide and 0.6-1 part of an antioxidant, wherein the compatilizer is one of CMG9801, BONDYRAM 1001 or KT-1. By addition of the compatilizer, zincoxide and the antioxidant to the glass fiber reinforced polypropylene composite material and adoption of a reasonable ratio, weather resistance of the material can be substantially improved, and prepared glass fiber reinforced polypropylene has higher performance retention rate after thermo-oxidative aging and is suitable for certain places with relatively strict requirements for the thermo-oxidative aging.

Owner:合肥卡洛塑业科技有限公司

Highly flame-retardant aging-resistant fluorine rubber cable sheath material

ActiveCN109370117AImproves compression set performanceFast vulcanizationRubber insulatorsGroup 5/15 element organic compoundsPolymer sciencePhosphate

The invention discloses a highly flame-retardant aging-resistant fluorine rubber cable sheath material which contains the following raw materials: fluorine rubber, acrylic rubber, ethylene-propylene-diene monomer, stearic acid, magnesium oxide, dicumyl peroxide, triallyl isocyanurate, bisphenol AF, benzyl triphenyl phosphorous chloride, cerium oxide, white carbon black, fibrous sepiolite, basic magnesium sulfate whisker, zinc sulfate, desulfurized fly ash, barium sulfate, ferric oxide, a composite flame retardant and an anti-aging agent. The composite flame retardant is a mixture of caged pentaerythritol phosphate, expansible graphite, zinc borate, tea saponin and a phosphorus nitrogen flame retardant. The highly flame-retardant aging-resistant fluorine rubber cable sheath material provided by the invention is excellent in flame-retardant property, good in heat resistance and aging resistance, and small in permanent deformation.

Owner:ANHUI ZHONGHONG CABLE

Rubber diaphragm synthetic material for pressure-bearing gas pressure regulator, and preparation method of rubber diaphragm synthetic material

ActiveCN102660058AOvercome the shortcomings of high-pressure gas pressure regulatorsImprove performanceEqualizing valvesSafety valvesSolubilityVulcanization

The invention relates to a rubber diaphragm synthetic material for a pressure-bearing gas pressure regulator, and a preparation method of the rubber diaphragm synthetic material. The rubber diaphragm synthetic material for the pressure-bearing gas pressure regulator comprises the following components in part by weight: 70-90 parts of nitrile rubber, 30-10 parts of chlorinated polyethylene, 10-30 parts of plasticizer, 30-50 parts of silica, 6-10 parts of vulcanizing agent and vulcanization accelerator and the balance of being other processing aids. According to the preparation method, the nitrile rubber and the chlorinated polyethylene are used as a main body, and simultaneously, an acid-filler material and a mineral oil type softener are avoided being used; in vulcanization system, low sulfur and high accelerator, peroxides and other series are adopted, so that the solubility resistance is ensured on the basis of ensuring certain elasticity; according to the rubber membrane obtained from the components by the method provided by the invention, the energy consumption is low in the rubber mixing process, the dimensional stability of an extrudate is good, the rubber surface quality is good, and under the premise of ensuring the processing performance, the performance of the rubber membrane is improved, an the service life of the rubber membrane is prolonged.

Owner:BEIJING GAS GRP +1

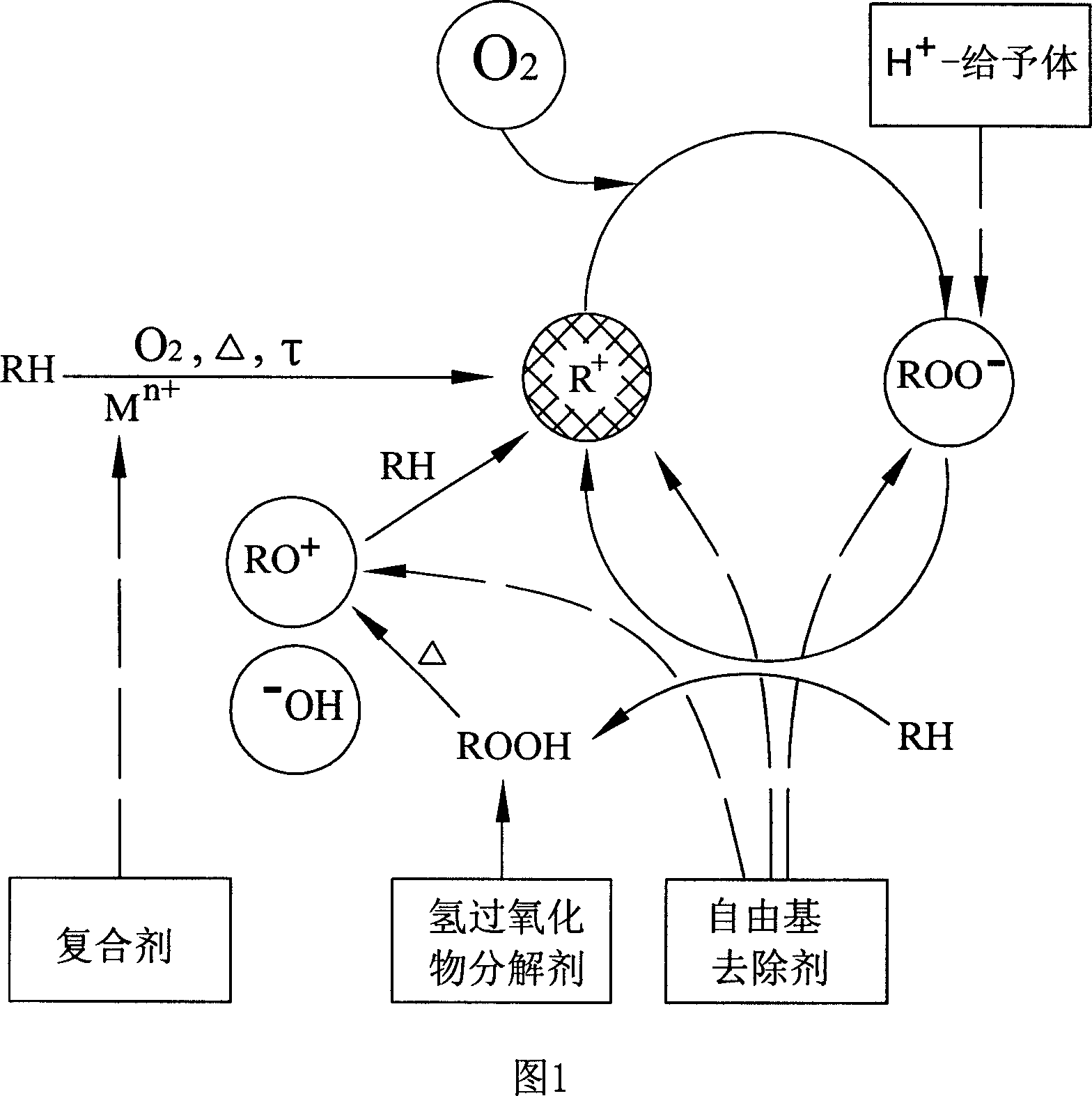

Heat oxygen aging resistance high polymer material and preparation method and application thereof

InactiveCN101633789AHigh antioxidant efficiencyImprove thermal stabilityGallic acid esterPolymer science

The invention discloses a heat oxygen aging resistance high polymer material and a preparation method and an application thereof; the high polymer material adopts gallic acid and / or gallic acid ester as antioxidant and the dosages are 0.005%-10.00% of high polymer material. Gallic acid and gallic acid ester belong to polyhydrophenol compound and have high antioxidation rate in polymer, non-toxic and environmentally friend; the gallic acid and gallic acid ester have good thermal stability, can satisfy the processing conditions of various high polymer materials and have obvious antioxidant effect on high polymer.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Functionalized unimodal radial block copolymer and its preparation method

InactiveCN1569912AImprove high temperature resistanceExcellent heat and oxygen aging resistanceAromatic hydrocarbonOrganic chemistry

The invention provides a functionalized unimodal radial block copolymer and its preparation method whose structure is illustrated by formula AYB#-[3]-(B#-[2]-S#-[3])B#-[1] / S#-[2]-S#-[1]}#-[3]}#-[n], wherein S is styrene single vinyl aromatic hydrocarbons, B is butadiene conjugated diolefin, Y=Si, Sn, n=1, 2, A is hydrocarbon radical with hydroxy, imino, benzene imino, mercapto functional group or polymer chain P.

Owner:PETROCHINA CO LTD

Modified natural rubber composite material for cable insulation layer

InactiveCN105111656AGood resistance to heat and oxygenGood aging resistanceMaleic anhydrideCarbon black

The invention discloses a modified natural rubber composite material for a cable insulation layer. The material is prepared from the following raw materials in parts by weight: 30 to 40 parts of natural rubber, 40 to 60 parts of methyl methacrylate natural rubber, 50 to 60 parts of ethylene propylene diene monomer, 50 to 55 parts of nanosilicon dioxide, 16 to 20 parts of diatomite, 7 to 12 parts of nylon PA-66, 12 to 16 parts of calcined clay, 33 to 37 parts of white carbon black, 15 to 25 parts of carbon black, 30 to 45 parts of attapulgite, 2 to 3 parts of zinc oxide, 1.8 to 2.5 parts of sulphur, 2 to 4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1 to 2 parts of bis(3-triethoxysilicyl propyl)-tetrasulfide, 2.5 to 3 parts of magnesium stearate, 5 to 10 parts of maleic anhydride and 2 to 5 parts of liquid carboxylated nitrile rubber. According to the modified natural rubber composite material for the cable insulation layer, provided by the invention, the cable insulation layer adopts the modified natural rubber composite material, the oxidation and heat resistant properties are good, the ageing-resistant performance is excellent, the mechanical property is good and the service life is long.

Owner:ZIBO KUAKE MEDICINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com