Efficient heat-resisting polyolefine composite light stabilizer, its production and use

A light stabilizer and production process technology, which is applied in the fields of fine chemicals and polymer materials, can solve the problems of light stabilization efficiency decline, reduce the activity of nitrogen and oxygen free radicals, etc., and achieve the effect of eliminating catalytic cracking and excellent light and heat stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The composite light stabilizer of the present invention should be selected and compounded according to different use areas and local climate conditions. The formula with the best effect is based on the compound use of different high molecular weight hindered amine light stabilizers. A sufficient amount of metal ion chelating components with appropriate functional structure. Because the anti-aging additives are greatly affected by climate factors, and other factors such as the resin matrix used and the use environment, agricultural planting methods, and the weather conditions of the year are more complicated, there are mainly region-based formulas and resin-based formulas Wait. For example, the following formula (the content of the components is calculated in weight percentage).

[0045] Polyolefin high-efficiency heat-resistant composite light stabilizer formula 1:

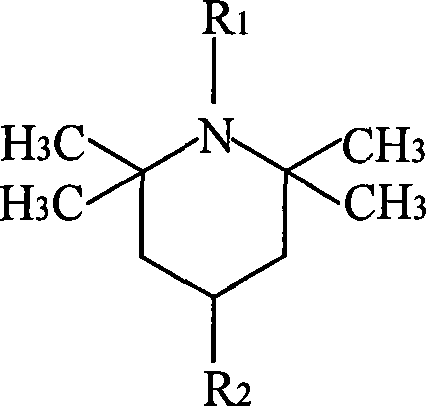

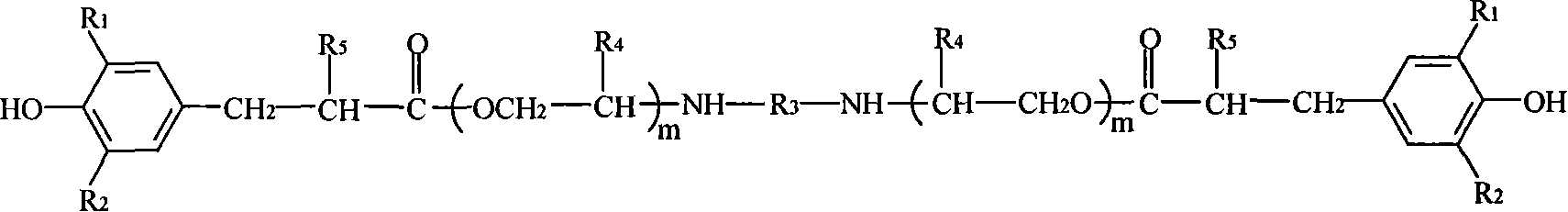

[0046] The polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidineethanol 40%;

[004...

Embodiment 2

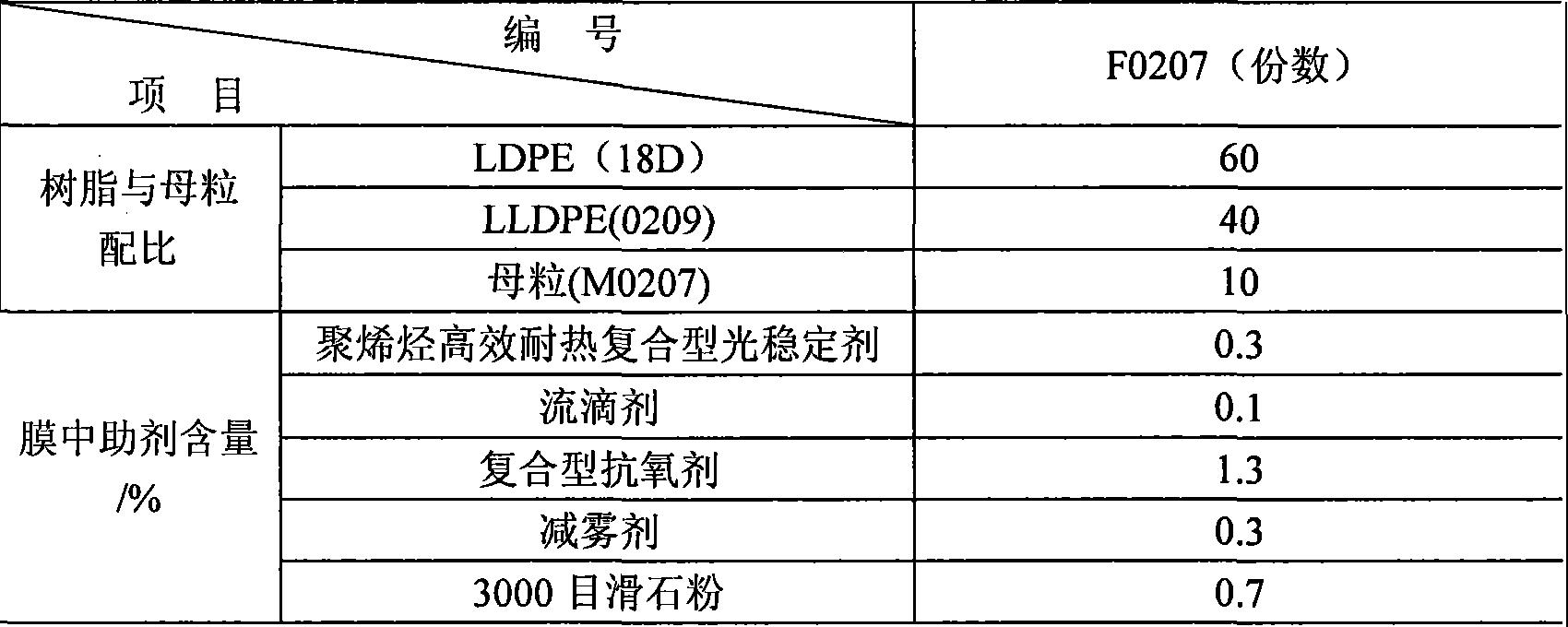

[0066] Embodiment 2 (application in LDPE / LLDPE multifunctional shed film)

[0067] According to the formula in Table 3, the masterbatch of polyolefin high-efficiency heat-resistant composite light stabilizer was manufactured. The masterbatch manufacturing process is to first mix polyolefin high-efficiency heat-resistant composite light stabilizer and polyolefin resin in a high-speed mixer at a temperature of 70°C, and then add it to a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature was controlled at 200°C. The granulation method can choose air-cooled hot cutting or water-cooled strand granulation.

[0068] Then blow the PE multifunctional shed film according to the formula in Table 4. The main technical parameters of the film blowing unit are: the diameter of the extruder screw (screw of the corrugated belt mixing head) is 90mm, and the length-diameter ratio (L / D)=30:1. The diameter of the die is 500mm, and the die gap is 1.8mm. The main techni...

Embodiment 3

[0076] Example 3 (application in mLLDPE shed film)

[0077] The thin mLLDPE shed film was blown with the blended resin of mLLDPE (350D60) and LDPE (18D), and the composite light stabilizer / composite antioxidant aging resistance system was used for the test. Pre-made anti-aging masterbatch, and then mix the resin and masterbatch evenly, use a film blowing unit to blow a shed film with a folded diameter of 4000mm and a thickness of 0.06mm (number 2104) according to the technical conditions in Table 9, and its initial mechanical properties are tested. The results are listed in Table 8.

[0078] shed film

[0079] Film blowing unit model

[0080] The number 2104mLLDPE greenhouse film was covered on the solar greenhouse and the arched steel pipe frame greenhouse for application test. Covering the greenhouse for 6, 10, 15, and 21 months, samples were taken to test the mechanical properties and optical properties of the greenhouse film. The results are listed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com