Wind driven generator blade deicing device capable of realizing automatic temperature control

A wind turbine, self-controlled temperature technology, applied in wind turbines, wind power generation, engines, etc., can solve the problems of accelerated aging, low practicability, blade damage, etc., to avoid local overheating, low installation cost, and high cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

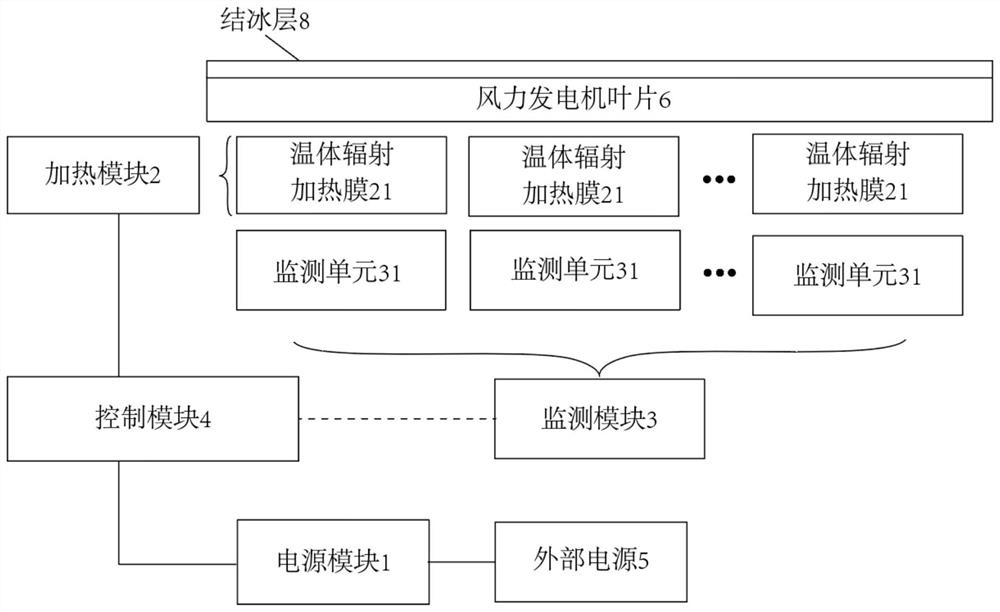

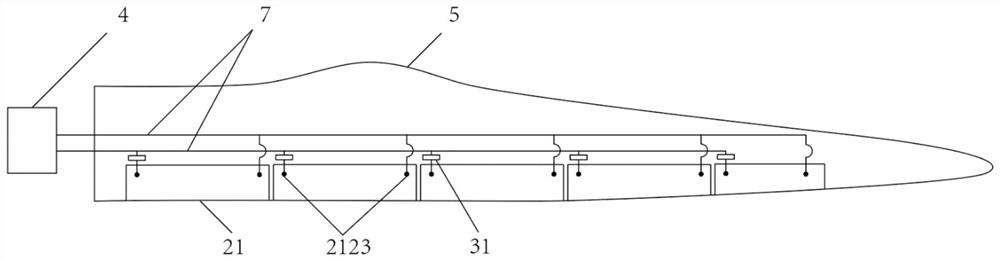

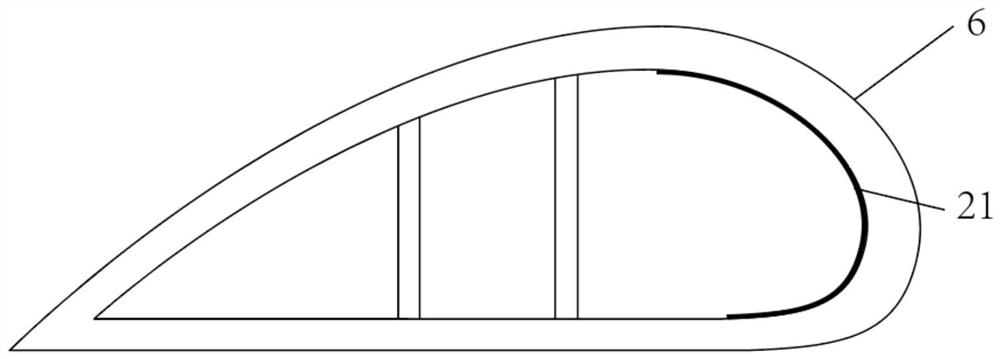

[0050] Reference attached figure 1 -Attached Figure 4 As shown, in the deicing device of this embodiment, the control module is connected to the external power supply through the power supply module. During deicing work, the control module 4 turns on the heating module 2, and the warm body radiation heating film 21 in the heating module 2 can be adjusted according to the blade 5 The temperature of the inner surface automatically adjusts the output power of the radiant heating element 213 to stabilize the temperature near the preset target temperature without regulation by the control module 4 , thereby avoiding damage and aging caused by local overheating of the blade 5 .

[0051] First, the power supply module 1 provides power for the device, and the voltage range of the power supply module 1 is 220V-690V to supply the control module 4 with a suitable working voltage of 690V, which is adapted to the voltage of the wind turbine. The heating module 2 and the control module 4 ...

Embodiment 2

[0055] At the same position on the inner surface of the blade 5, a warm body radiation heating film 21 with multiple layers of non-reflection layers 214 can be laid, and then the multi-layer warm body radiation heating films are connected in parallel, and then the reflective layer 214 is uniformly installed and connected to the control module 4 to enhance the warm body radiation. Radiant heating effect of the thermal film 21 .

[0056] It can be seen from the implementation that the present invention can be used to realize automatic temperature control of any local position in the process of heating and deicing wind turbine blades, avoid blade damage and aging caused by local overheating, improve the energy efficiency of deicing, and reduce the cost of the device. complexity, reducing installation costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com