Efficient heat-resisting polyolefine composite light stabilizer, its production and use

A light stabilizer and production process technology, which is applied in the fields of fine chemicals and polymer materials, can solve the problems of light stabilization efficiency decline, reduce the activity of nitrogen and oxygen free radicals, etc., and achieve the effect of eliminating catalytic cracking and excellent light and heat stabilization effect

Active Publication Date: 2010-08-18

广东华南精细化工研究院有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

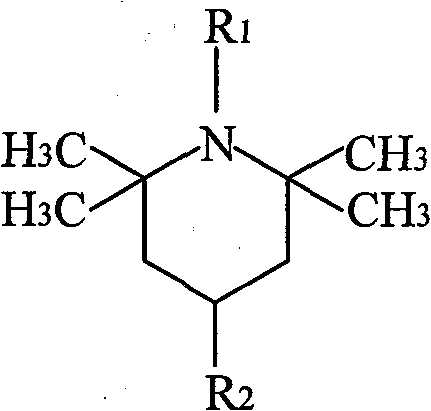

To improve the resistance of light stabilizers to acidic substances, we should start with reducing the alkalinity (reactivity) of hindered amine light stabilizers to prevent acidic agricultural chemicals from reacting with hindered amines to form amine salts, reduce the activity of nitrogen oxide free radicals, and cause light stability. Efficiency drops

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

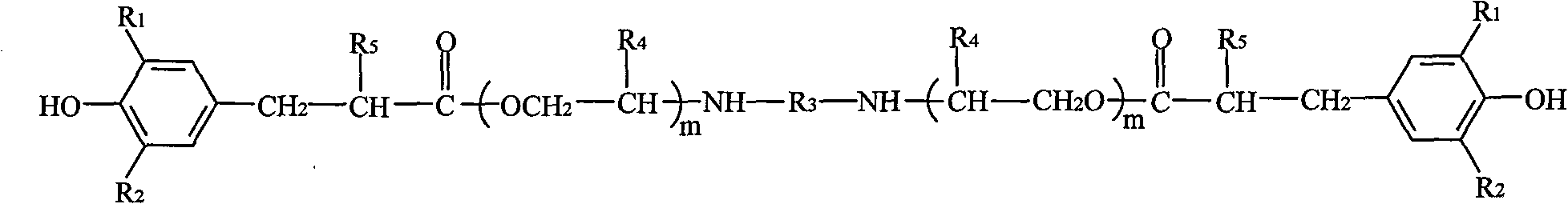

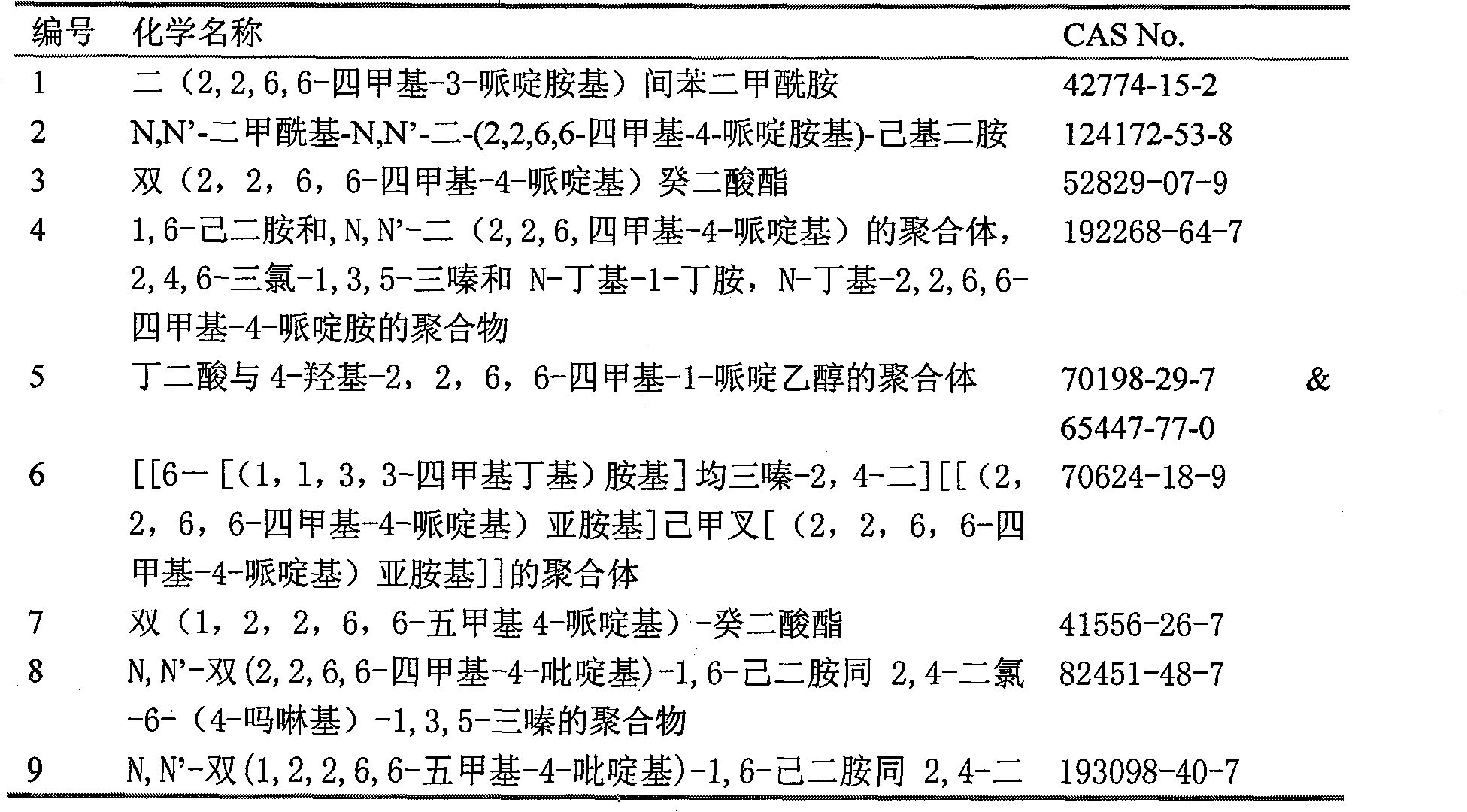

An efficient composite heat-resisting polyolefine light stabilizer, its production and use are disclosed. The light stabilizer consists of two or above polymerized hindered amine light stabilizer mixed components 60-95wt% and metal-ion chelate component 5-40wt%, which has hindered phenol anti-oxidant structure and bis-amide metal ion chelating structure and / or oxalamide semi-hindered amine structure. It has excellent heat and ageing resistances and can be used for PE and EVA agricultural long-life thin film or functional greenhouse thin film.

Description

technical field The invention relates to the fields of fine chemicals and polymer materials, in particular to a composite light stabilizer. Background technique The aging of polymer materials can be caused by many reasons, such as heat, ultraviolet light, mechanical stress, high-energy radiation, electric field, etc., which can be caused by a single factor or a combination of multiple factors. As a result, the molecular structure of the polymer material changes and the relative molecular weight decreases or cross-linking occurs, so that the performance of the material deteriorates, so that it cannot be used. The most common aging factors are heat and ultraviolet light, because the most exposed environment of plastics from production, storage, processing to product use is heat and sunlight (ultraviolet light). Sunlight includes ultraviolet light, visible light and infrared light. Although ultraviolet light only accounts for 6% of the energy of sunlight reaching the earth's...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08K5/3435C08L23/00B29C47/00B29C47/92B29B9/12B29C48/92

Inventor 陈宇王朝晖

Owner 广东华南精细化工研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com