Composition for preparing ultrahigh molecular weight polyethylene pipe material

A technology of ultra-high molecular weight and polyethylene, applied in the field of polymer materials, can solve the problems of high cost, high energy consumption, and no mention of heat and oxygen aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

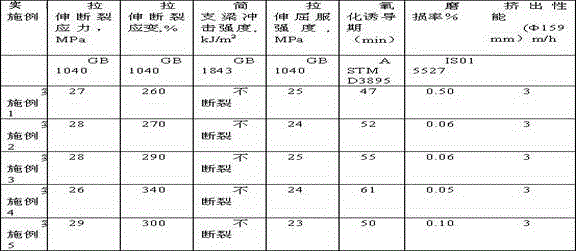

Examples

Embodiment 1

[0033] Ultra-high molecular weight polyethylene (viscosity average molecular weight 202×10 4 ) 100

[0034] Polyethylene wax 4

[0035] Calcium stearate 0.2

[0036] Zinc stearate 0.5

[0037] Compound antioxidant 0.3

[0038] Fluoropolymer processing aid FX-5920 0.05

[0039] Carbon black 1.2

Embodiment 2

[0041] Ultra-high molecular weight polyethylene (viscosity average molecular weight 237×10 4 ) 100

[0042] Polyethylene wax 5

[0043] Calcium stearate 0.5

[0044] Zinc stearate 0.1

[0045] Compound antioxidant 0.3

[0046] Fluoropolymer processing aid FX-5920 0.02

[0047] carbon black 1

Embodiment 3

[0049] Ultra-high molecular weight polyethylene (viscosity average molecular weight 256×10 4 ) 100

[0050] Polyethylene wax 6

[0051] Calcium stearate 0.2

[0052] Zinc stearate 0.1

[0053] Compound antioxidant 0.3

[0054] Fluoropolymer processing aid FX-5920 0.01

[0055] Carbon black 1.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com