Functionalized unimodal radial block copolymer and its preparation method

A block copolymer and radial technology, which is applied in the field of functionalized monomorphic radial block copolymer and its preparation, can solve problems such as unfavorable industrial production, prolonged butadiene feeding time, discontinuity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

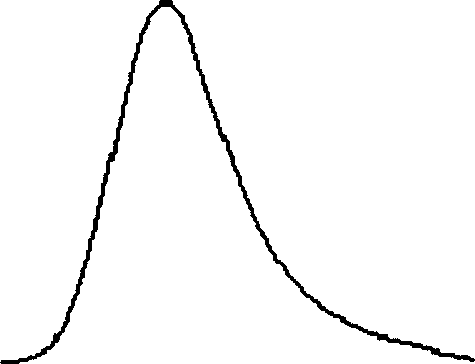

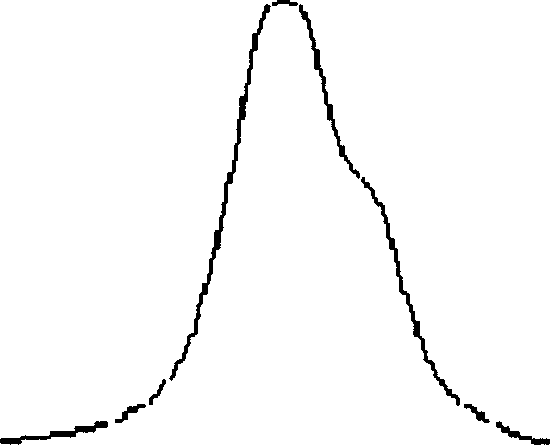

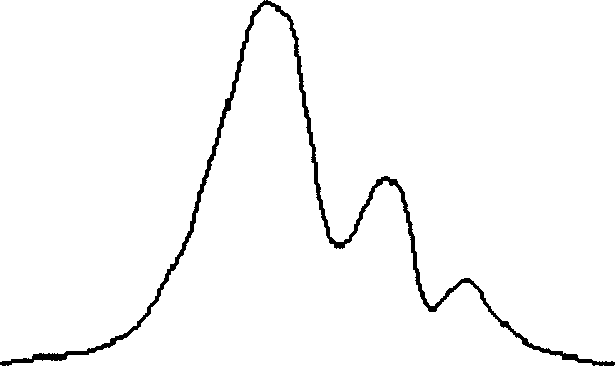

Image

Examples

Embodiment 1~10

[0044] In a jacketed 14L stainless steel reactor, the polymerization was carried out in a hydrocarbon solvent under the protection of argon. Continuous stirring of the reaction mixture is required during polymerization and coupling. Adding steps are as follows:

[0045] (1) monovinylarene monomer and initiator;

[0046] (2) A mixture of monovinylarene monomers and conjugated diene monomers (70% to 85% of the total weight of the mixture);

[0047](3) A mixture of monovinylarene monomers and conjugated diene monomers (the remaining 15% to 30% mixture);

[0048] (4) conjugated diene monomer;

[0049] (5) Coupling agent.

[0050] After the coupling reaction is complete, water and CO 2 The coupled reaction mixture is treated and antioxidants are added prior to obtaining the polymer xylk of the invention. Table 1 shows the types of raw materials and additives used in Examples 1-10, and Table 2 shows the formulations and process conditions for preparing the copolymers of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com