Patents

Literature

37results about How to "Improves compression set performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual polyhydroxy polymer embolism microsphere and preparation method thereof

ActiveCN107050501AReduce surgical riskGood flexibilitySurgical adhesivesPharmaceutical non-active ingredientsChemistryBiocompatibility Testing

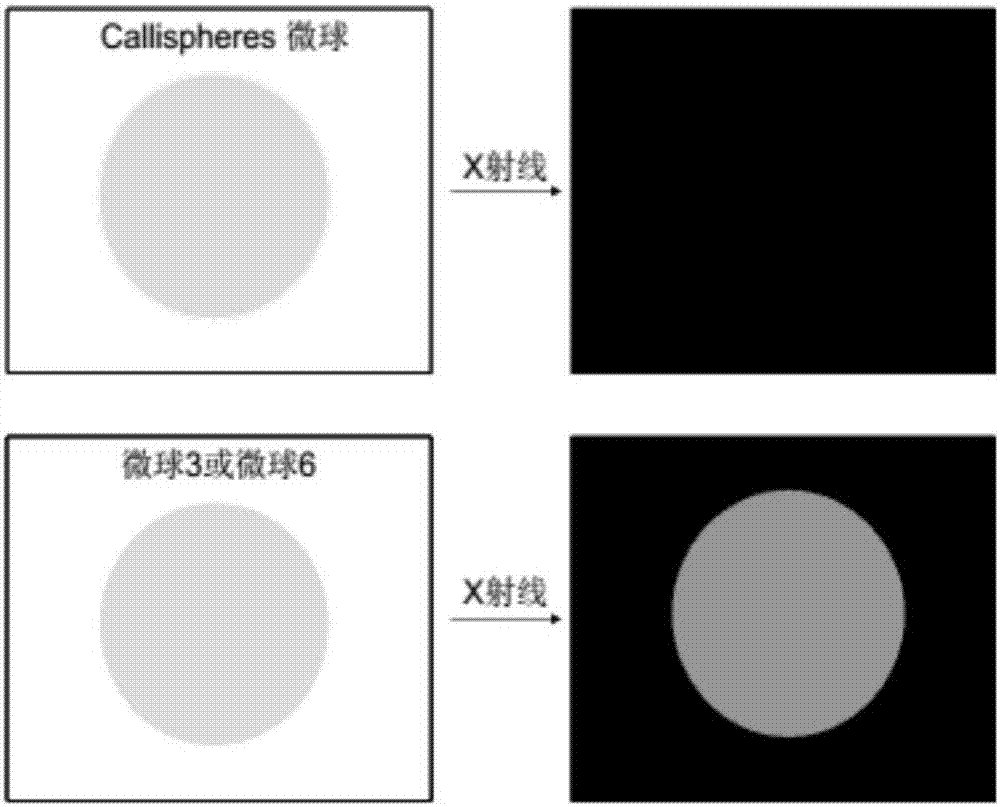

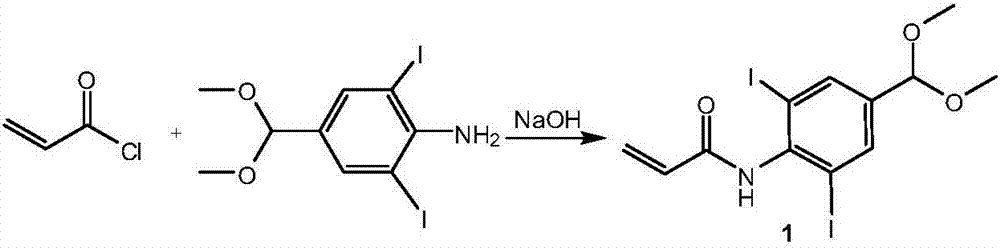

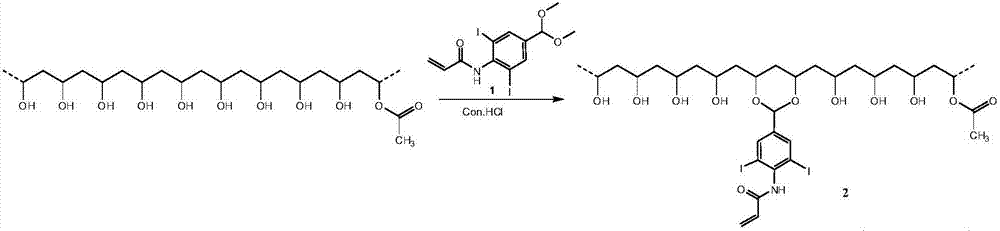

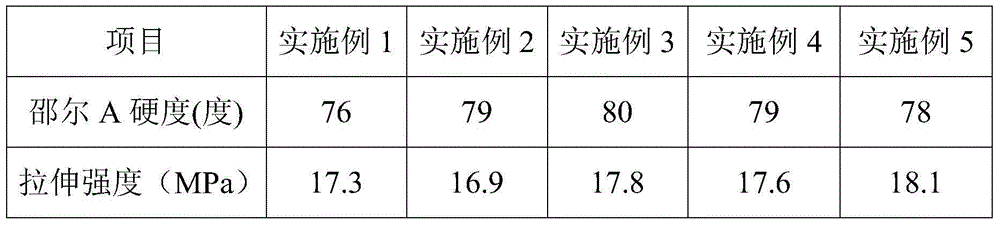

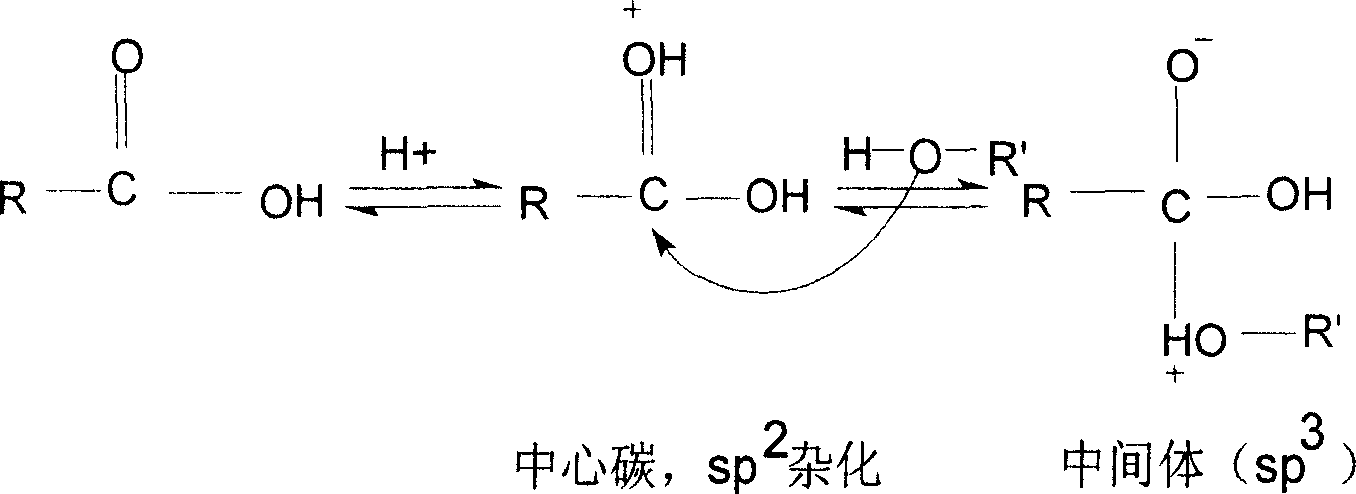

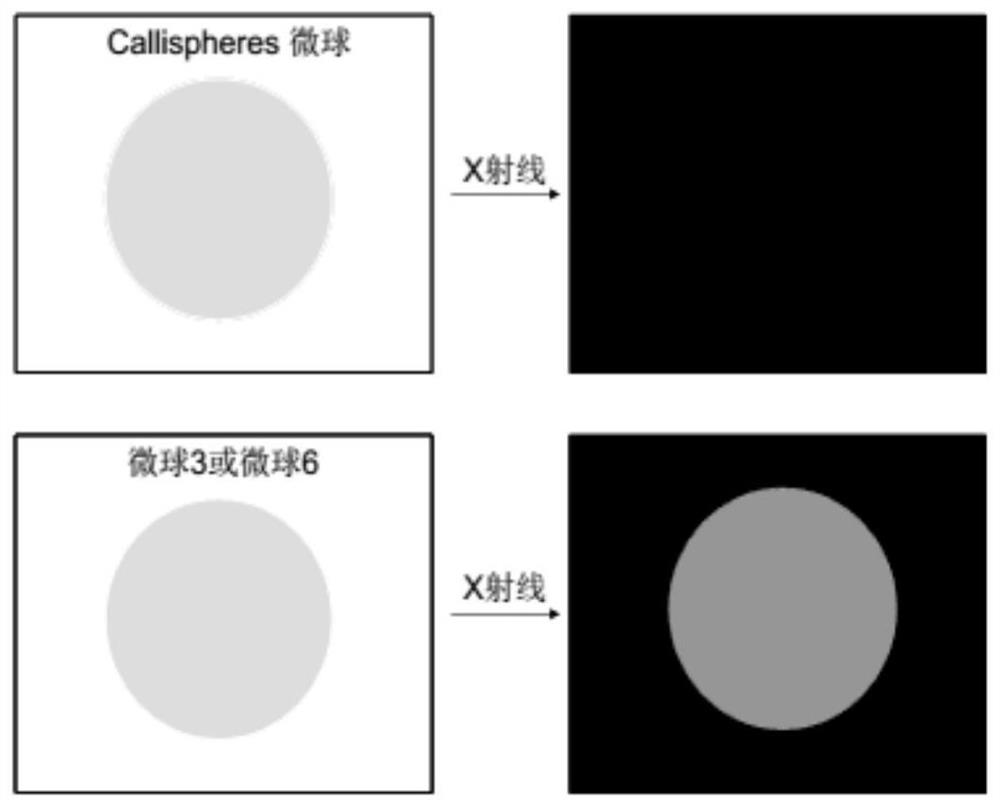

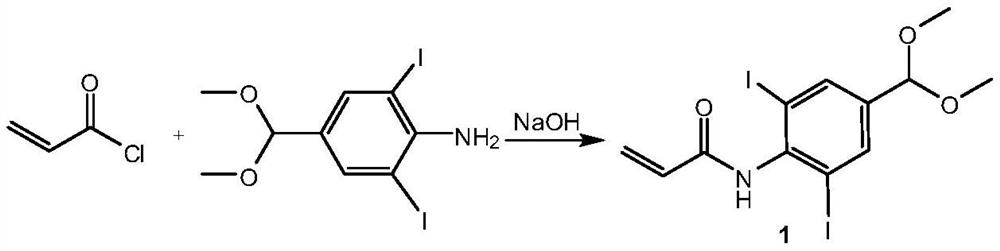

The invention relates to a visual polyhydroxy polymer embolism microsphere and a preparation method thereof, belonging to the technical field of medical treatment materials. The visual embolism microsphere is prepared from functional macromolecules with biocompatibility and a cross-linking agent, namely an iodobenzene compound through cross-linking polymerization and is capable of reflecting or weakening X rays. The invention relates to a novel visual embolism microsphere in the technical field of medical materials and a preparation process of the novel visual embolism microsphere. According to the process, the defect that a contrast agent is added into a traditional surgical embolism process for developing is changed, the surgical risk is reduced, and convenience is provided for treating tumor diseases by virtue of a minimally invasive interventional therapy; the visual microsphere prepared by virtue of the preparation process is capable of reflecting or weakening the X rays and has good flexibility, elasticity and compression deformation property; and meanwhile, a traditional embolism microsphere needs to be dyed so as to guarantee that a doctor can conveniently observe in a surgical process, but the embolism microsphere prepared by virtue of the process is yellow and does not need to be dyed, so that the operation is simple and feasible.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

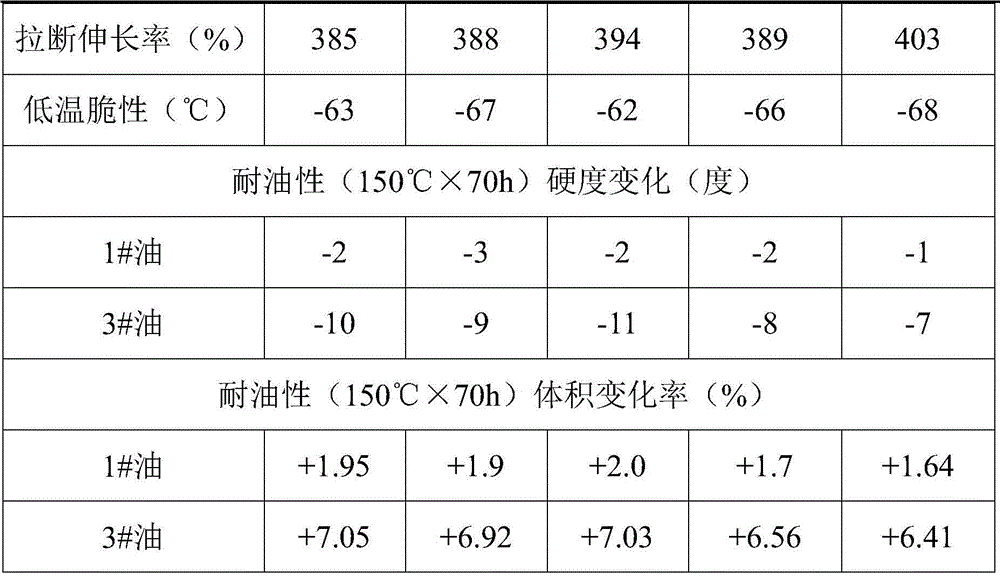

Cold-resisting oil-resisting modified fluorine rubber cable sheath material

The invention discloses a cold-resisting oil-resisting modified fluorine rubber cable sheath material which comprises the following components in parts by weight: 50-70 parts of fluorine rubber, 15-30 parts of silica rubber, 15-20 parts of fluorine silica rubber, 10-25 parts of pre-swelled organic clay, 15-25 parts of white carbon black, 5-13 parts of ternary nylon, 1-2.5 parts of stearic acid, 3-10 parts of active magnesium oxide, 3-9 parts of rare earth complex, 5-12 parts of calcium hydroxide, 0.5-1.8 parts of polyethylene glycol, 1-5 parts of epoxy octyl stearate, 1-2.5 parts of epoxy triglyceride fatty acid, 4-8 parts of a bisphenol vulcanizing agent, 1-3 parts of an accelerant, 0.5-2 parts of an anti-aging agent MB and 0.8-1.5 parts of an anti-aging agent 4010NA. The cold-resisting oil-resisting modified fluorine rubber cable sheath material disclosed by the invention is excellent in cold resistance and oil resistance and is good in comprehensive property and long in service life when used for manufacturing a cable sheath.

Owner:安徽华峰电缆集团有限公司

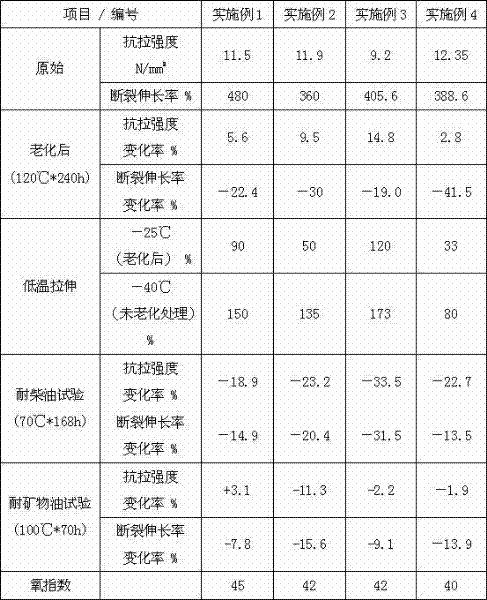

Cable sheath rubber

InactiveCN102250426AGood compression set properties and toughnessGood processing performanceInsulated cablesInsulated conductorsFlame resistanceMineral oil

The invention provides cable sheath rubber, which is characterized in that the raw material comprises 100 weight parts of chlorinated polyethylene, 2 to 6 weight parts of organic peroxide vulcanizing agent, 3 to 6 weight parts of sulfurization assisting agent, 0.5 to 1.5 weight parts of antiaging agent, 10 to 30 weight parts of fire retardant and 20 to 40 weight parts of reinforcing agent. The product has high fuel oil resistance, high mineral oil resistance, high resistance to low temperature after aging; the cable sheath rubber can be filled with more filler and has high compression deformation performance and toughness; and the smooth appearance of the rubber has high processing technical performance and high flame retarding performance.

Owner:上海南洋电缆有限公司

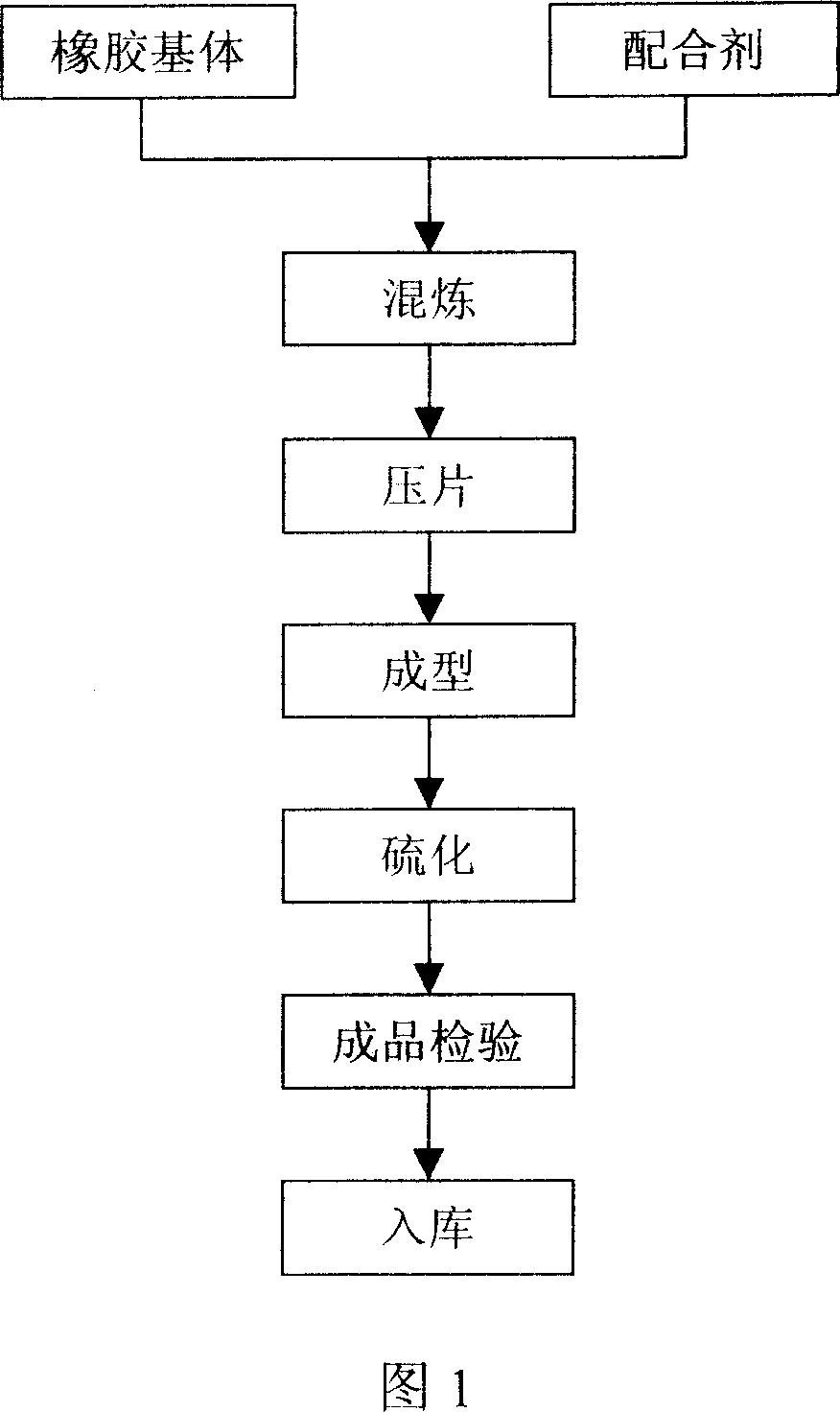

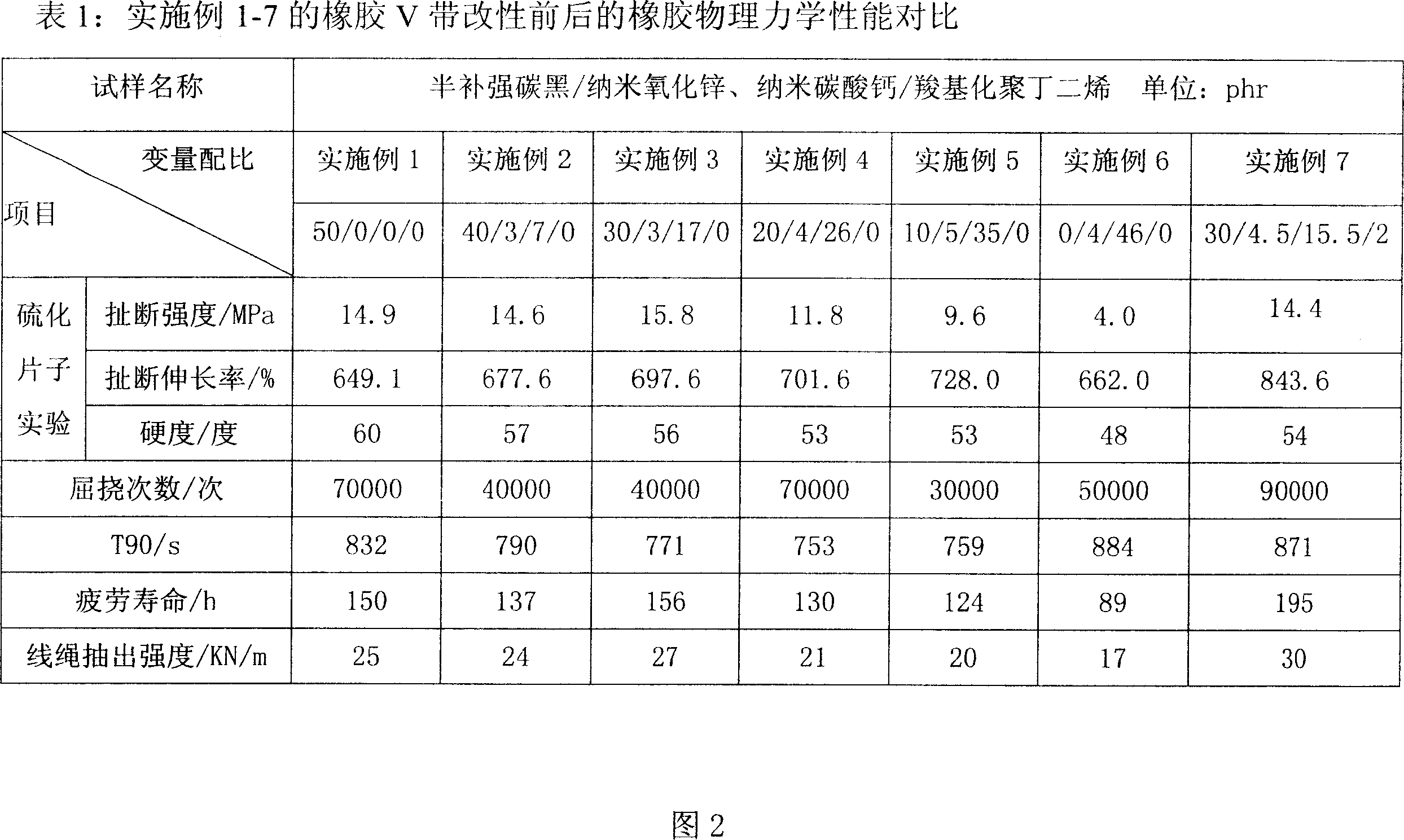

Nano material modified rubber V strip

The invention provides a modified rubber V belt made of nano-material, which comprises rubber matrix, vulcanizing agent, accelerators, stearic acid, antioxidant, softener and carbon black, and comprises further nano-zinc oxide and nano-calcium carbonate. The product is made with 2.5 to 10 portions of the nano-zinc oxide and 5 to 50 portions of nano-calcium carbonate on the basis of 100 portions of rubber matrix. Mechanical property, wear resistance, compression set and tearing property of the rubber can be improved obviously and the performance of the finished product is improved with indirect zinc oxide being replaced by the nano-zinc oxide, soft semi reinforcing carbon black being replaced by the nano-calcium carbonate.

Owner:SANLUX

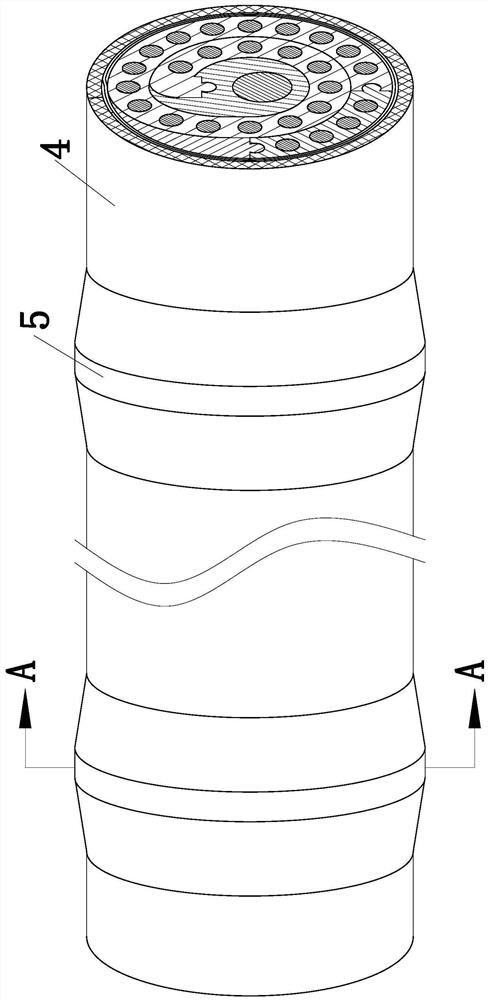

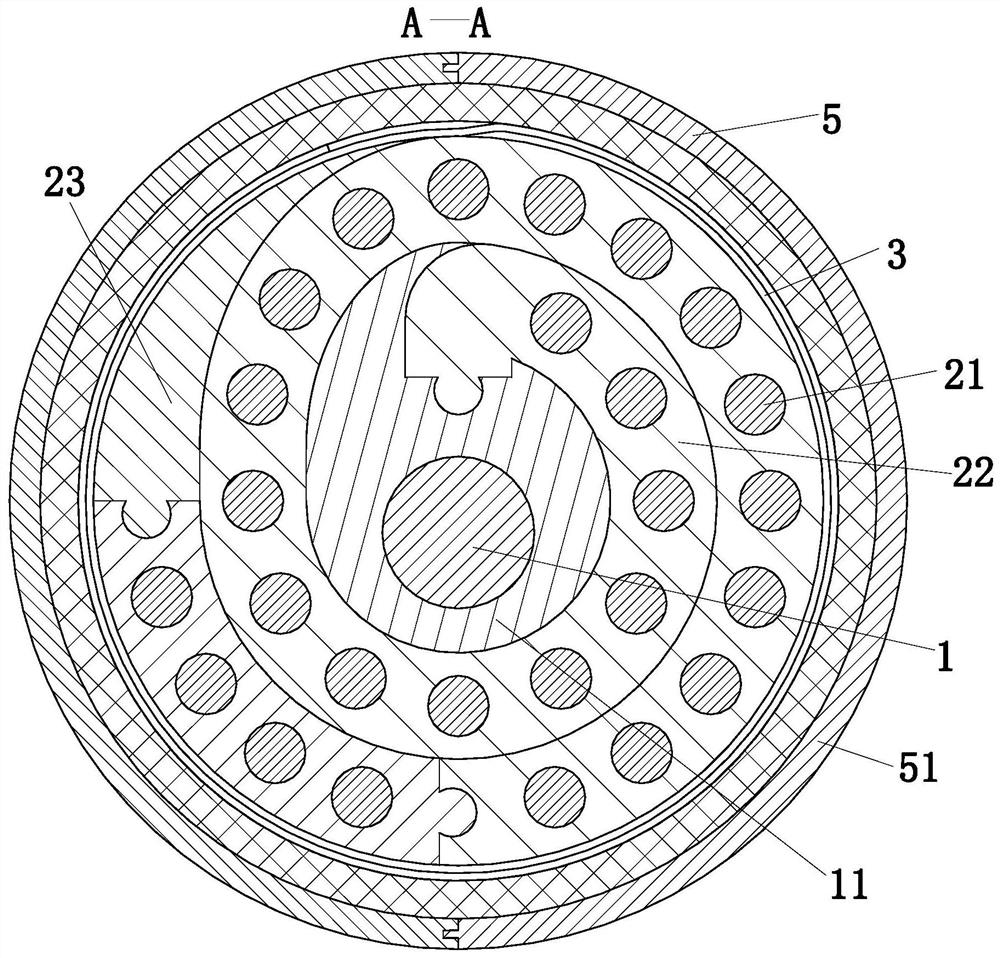

Nano material modified rubber bearing

InactiveCN1598155AImproves compression set performanceImprove aging resistanceBridge structural detailsStearic acidAccelerant

The invention relates to a nanometer material modified rubber support bass. It is made up of nanometer material modified rubber support and steel plate equipped in it. Its weight copies ratio constituent is that caoutchouc (100 portion); nanometer zinc oxide (2-3); stearic acid (1.5-2.5); accelerant CZ (1-1.5); sulfur (1.5-2); anti-aging agent granule (1-2); anti-aging agent4010NA (1-2); carbon blackN220 (30-35); nanometer calcium carbonate (25-30). The invention improves the compression deformation capability and ageing resistance of the sizing material, prolongs the useful life; it can improve dynamic performance of the production, and avails to improve the service performance.

Owner:李树奎

High-strength wear-resistant tear-resistant rubber material

ActiveCN104086839AGood anti-scorch performanceImprove securityRubber materialEnvironmental resistance

The invention discloses a high-strength wear-resistant tear-resistant rubber material which is prepared from the following raw materials in parts by weight: 40-50 parts of carboxy nitrile rubber, 20-30 parts of chloroprene rubber, 10-18 parts of natural rubber, 12-20 parts of ethylene-octylene copolymer, 5-13 parts of silane coupling agent, 1.5-2 parts of sulfur, 2-4 parts of magnesium oxide, 2-5 parts of zinc oxide, 2.5-4 parts of environment-friendly flame retardant FR-T801, 1-2 parts of antimony trioxide, 20-30 parts of carbon microsphere, 5-15 parts of nano carbon black, 20-30 parts of modified kaolin, 1-2 parts of CPE special-type stabilizer, 1.5-3 parts of stearic acid, 5-7 parts of trioctyl trimellitate and 0.5-1.5 parts of paraffin. The rubber material has the advantages of excellent wear resistance, excellent tear resistance, high strength and high toughness.

Owner:宁国日格美橡塑股份有限公司

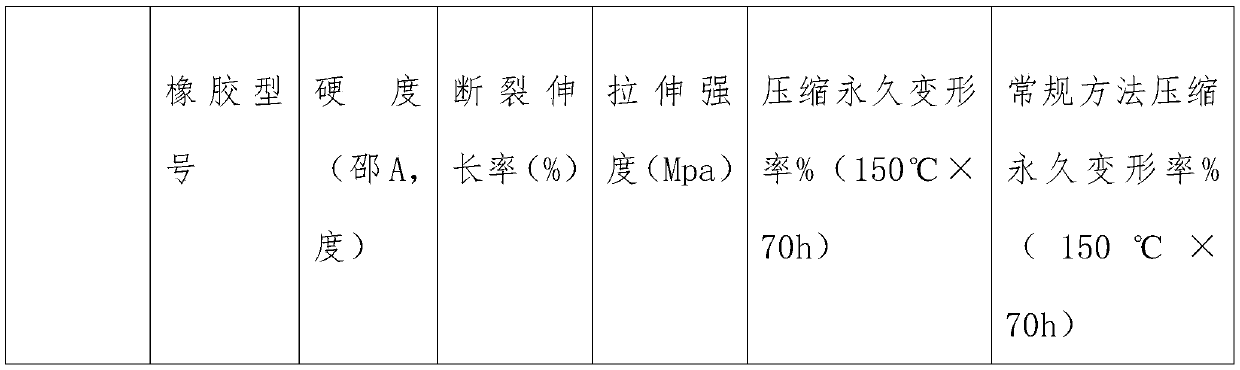

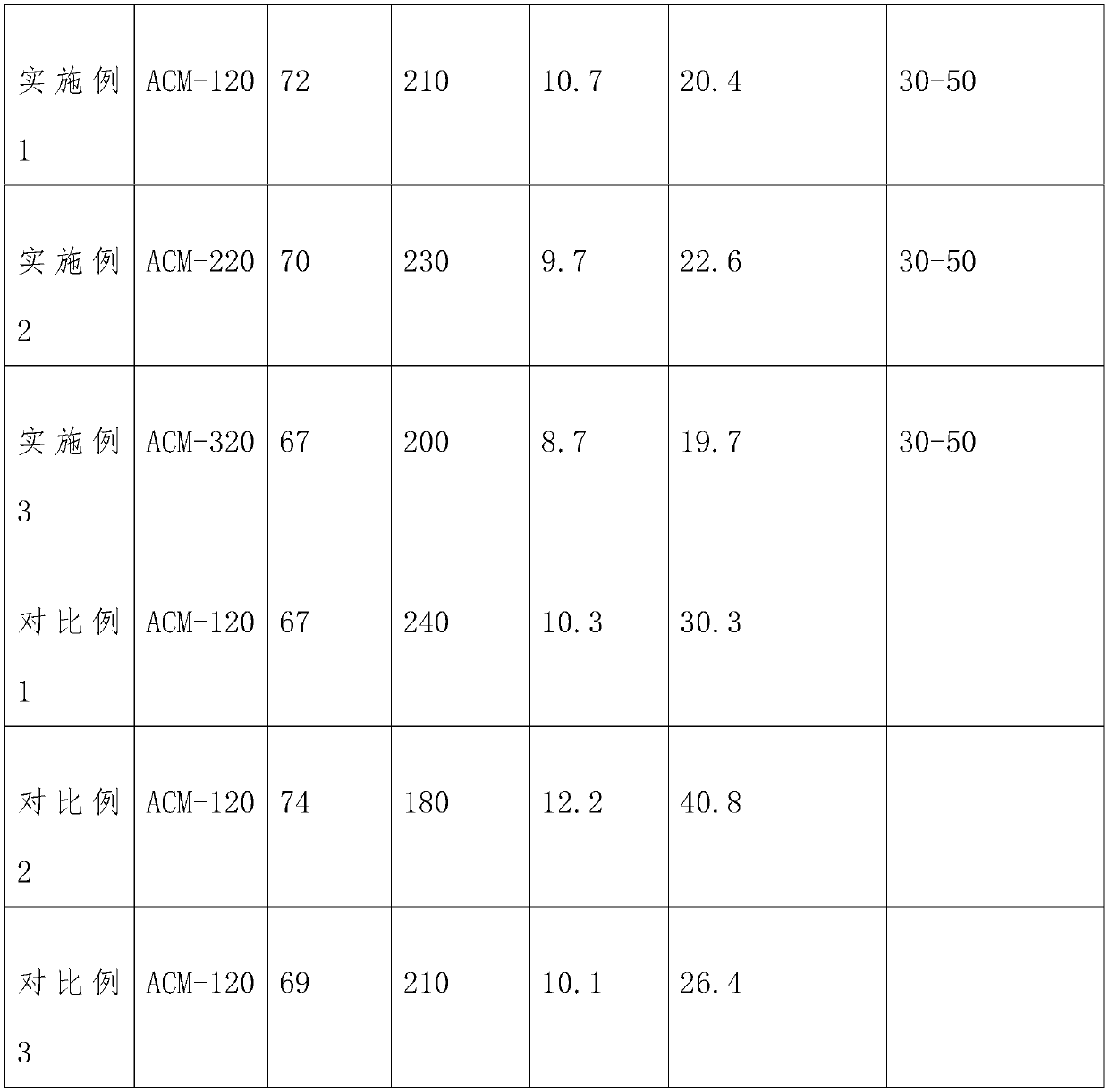

Low-compression permanent-deformation carboxylic acid type acrylate rubber, and preparation method thereof

ActiveCN110330750AImprove heat aging performanceImproved compression setPolymer scienceCarboxylic acid

Owner:四川青龙丙烯酸酯橡胶有限公司

Heat-resistant anti-aging cable sheath material and preparation method thereof

ActiveCN103897231AImprove tear resistanceImproves compression set performanceElectromagnets with armaturesCarbon blackMagnesium

The invention discloses a heat-resistant anti-aging cable sheath material, comprising the following raw materials in parts by weight: 30-40 parts of poly-stabilizer-nitrile butadiene rubber, 20-30 parts of hydrogenated butadiene-acrylonitrile rubber, 5-8 parts of magnesium oxide, 8-13 parts of calcined clay, 8-10 parts of calcium carbonate, 2-5 parts of chlorinated paraffin, 0.2-0.3 part of phthalocyanine blue, 14-17 parts of white carbon black, 13-18 parts of organic montmorillonite, 1.5-3 parts of DOP (Dioctyl-Phthalate) softener, 0.7-1.3 parts of accelerant DM, 0.5-1.2 parts of accelerant TMTD and 0.5-0.9 part of sulphur. The heat-resistant anti-aging cable sheath material disclosed by the invention is excellent in heat resistance, abrasive resistance, oil resistance, tear resistance and compression deformation performance, and can be applied to a relatively harsh environment, and the service life is obviously prolonged.

Owner:威海高新园区运营管理有限公司

Highly flame-retardant aging-resistant fluorine rubber cable sheath material

ActiveCN109370117AImproves compression set performanceFast vulcanizationRubber insulatorsGroup 5/15 element organic compoundsPolymer sciencePhosphate

The invention discloses a highly flame-retardant aging-resistant fluorine rubber cable sheath material which contains the following raw materials: fluorine rubber, acrylic rubber, ethylene-propylene-diene monomer, stearic acid, magnesium oxide, dicumyl peroxide, triallyl isocyanurate, bisphenol AF, benzyl triphenyl phosphorous chloride, cerium oxide, white carbon black, fibrous sepiolite, basic magnesium sulfate whisker, zinc sulfate, desulfurized fly ash, barium sulfate, ferric oxide, a composite flame retardant and an anti-aging agent. The composite flame retardant is a mixture of caged pentaerythritol phosphate, expansible graphite, zinc borate, tea saponin and a phosphorus nitrogen flame retardant. The highly flame-retardant aging-resistant fluorine rubber cable sheath material provided by the invention is excellent in flame-retardant property, good in heat resistance and aging resistance, and small in permanent deformation.

Owner:ANHUI ZHONGHONG CABLE

Cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell and preparation method of cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell

InactiveCN106280130ANo pollution in the processCold resistance noInsulated cablesInsulated conductorsPlasticizerPolyvinyl chloride

The invention discloses a cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell. The cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell comprises, by mass, 20-25 parts of resin powder, 15-20 parts of plasticizer, 5-10 parts of lubricant, 10-15 parts of carbon black, 8-13 parts of stabilizer, 9-14 parts of polyethylene glycol, 17-22 parts of flame retardant, 7-12 parts of Elvaloy and 16-21 parts of nitrile butadiene rubber powder. The cold-resistant oil-resistant flame-retardant polyvinyl chloride cable material without pungent smell and a preparation method have the advantages that since polyethylene glycol is added into a preparation process, the intrinsic pungent smell of the materials can be eliminated; the plasticizer, the Elvaloy and the nitrile butadiene rubber powder are added into the preparation process, so that the prepared material is resistant to cold and oil; the nitrile butadiene rubber powder is capable of assisting the Elvaloy in preventing the plasticizer from separating out, and the Elvaloy is a non-migrating terpolymer and endows a PVC (polyvinyl chloride) polymer with high durability and high heat stability.

Owner:JIANGSU LINRY NEW MSTAR TECH

Waterproof oilproof temperature-resistant anti-aging cable material and preparation method thereof

InactiveCN106750675AWide variety of sourcesSimple preparation processRubber insulatorsLinear low-density polyethyleneButadiene-styrene rubber

The invention discloses a waterproof oilproof temperature-resistant anti-aging cable material which is prepared from, by weight, butadiene styrene rubber, fluororubber, linear low-density polyethylene, fluorocarbon resin, hydrogen-containing silicon oil, modified kaolin, carbon black, ammonium polyphosphate, glass fiber, vermiculite, triethanolamine, nickel, chromium, calcium carbonate, nano silicon dioxide, ethylene glycol, oxide powder, sulfur, stabilizer, plasticizer, flame retardant and fish oil. The invention further discloses a preparation method of the cable material. The cable material is extensive in raw material source, simple in preparation process, low in production cost and suitable for large-scale industrial production. The butadiene styrene rubber, the fluororubber and the fluorocarbon resin are matched in use and are high in compatibility; sulfur is adopted as a vulcanizing agent to be matched with modified kaolin, the fish oil, the stabilizer, the plasticizer and the flame retardant, so that the prepared cable material has excellent heat resistance, wear resistance, oil resistance, tear resistance and compressive deformation resistance, long service life and wide application range.

Owner:ZHENGZHOU BEIDOU COMM TECH

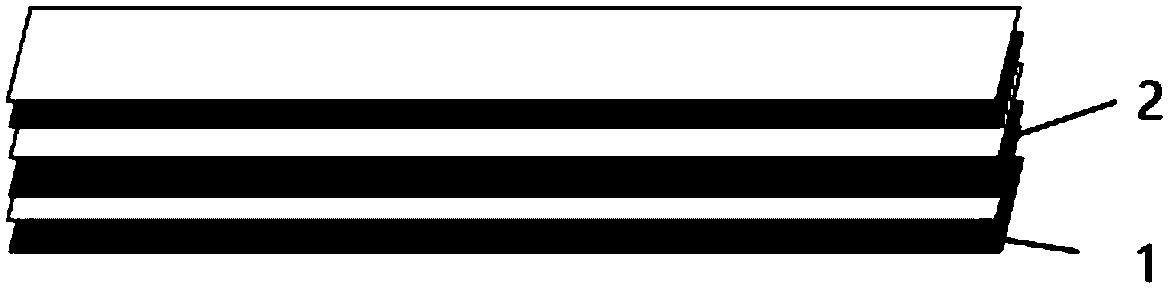

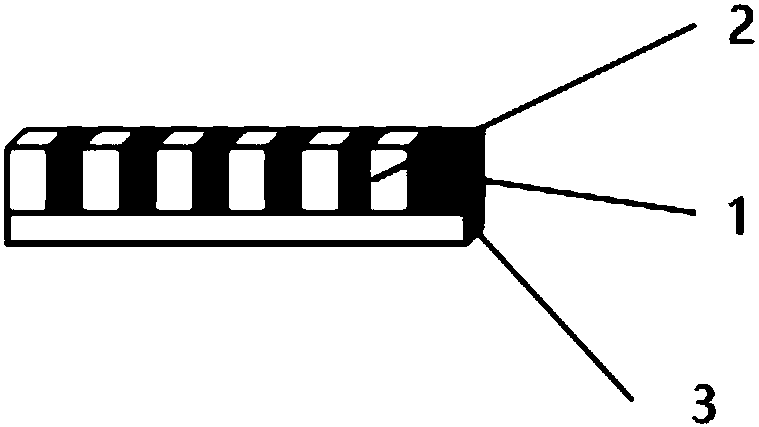

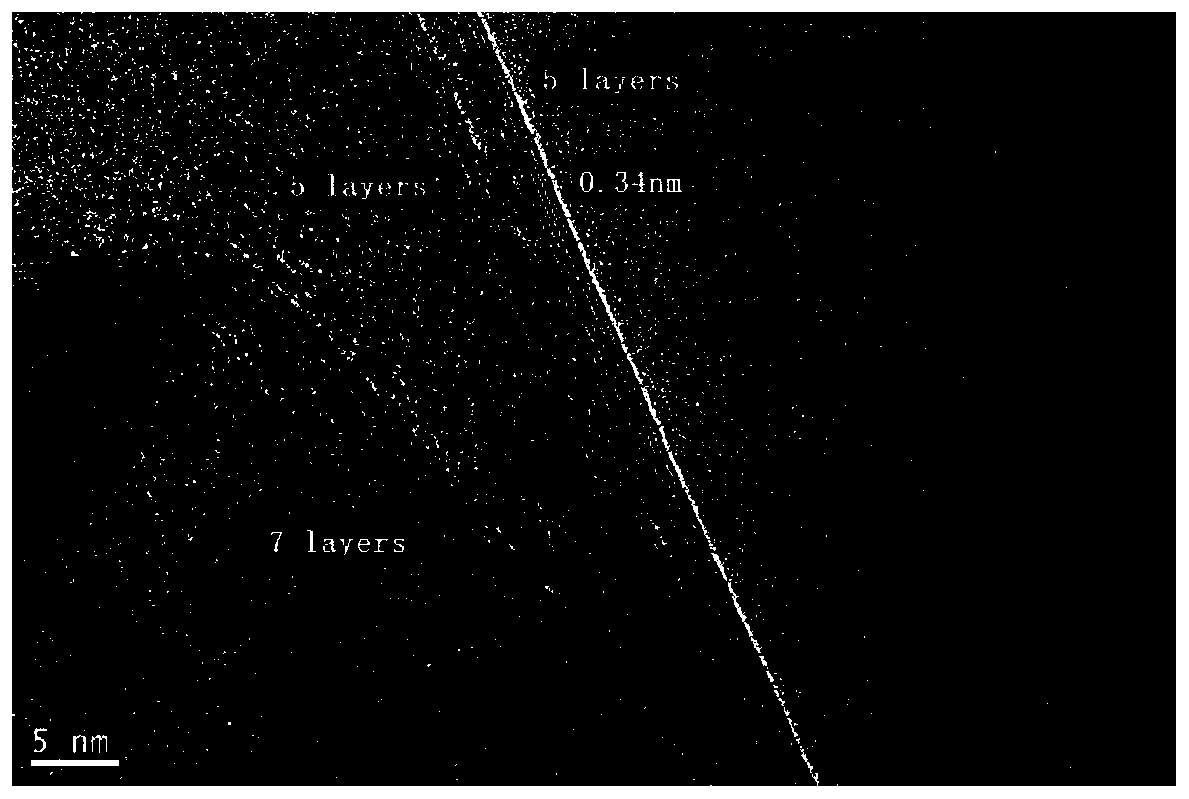

Graphene-carbon nanometer tube film-based heat-conducting gasket and preparation method thereof

PendingCN108189515AImprove thermal conductivityEasy to stretchLayered productsFlat articlesFilm baseHeat conducting

The invention provides a graphene-carbon nanometer tube film-based heat-conducting gasket and a preparation method thereof. The heat-conducting gasket comprises a substrate and a composite graphene-carbon nanometer tube film arranged on the substrate, wherein the composite graphene-carbon nanometer tube film is obtained by overlapping at least two layers of single-layer graphene-carbon nanometer tube films; a heat-conducting glue layer is arranged between every two single-layer graphene-carbon nanometer tube films. The heat-conducting gasket has the characteristics that the heat conduction effect is good; the stretch and compression deformation is great; the weight is light.

Owner:广东光钛领先新材料有限公司

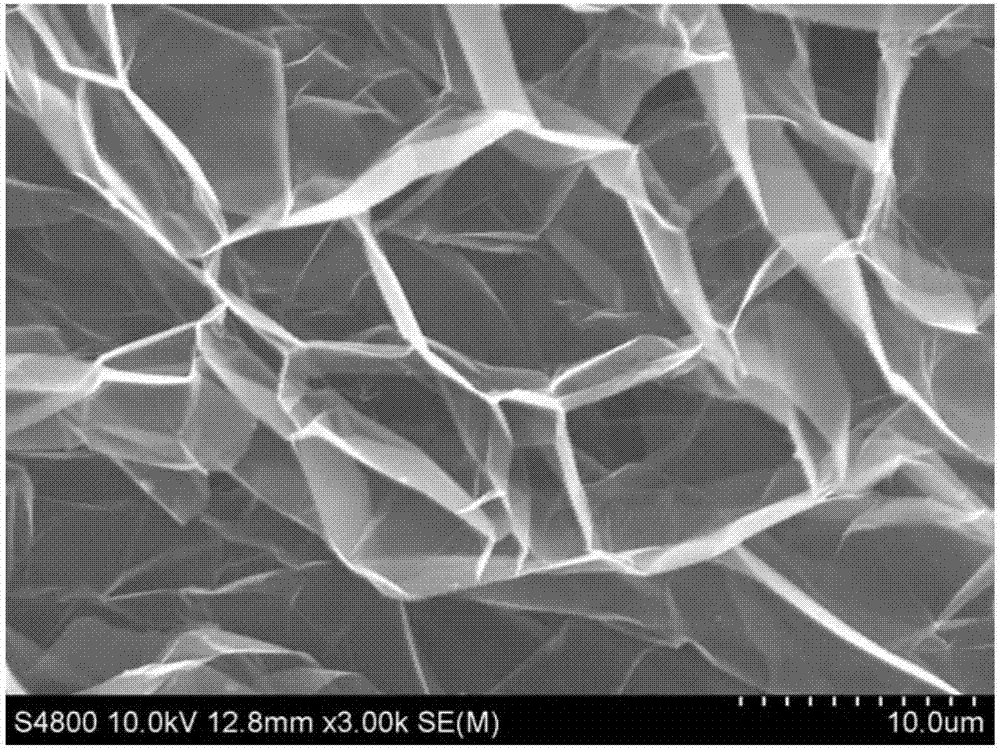

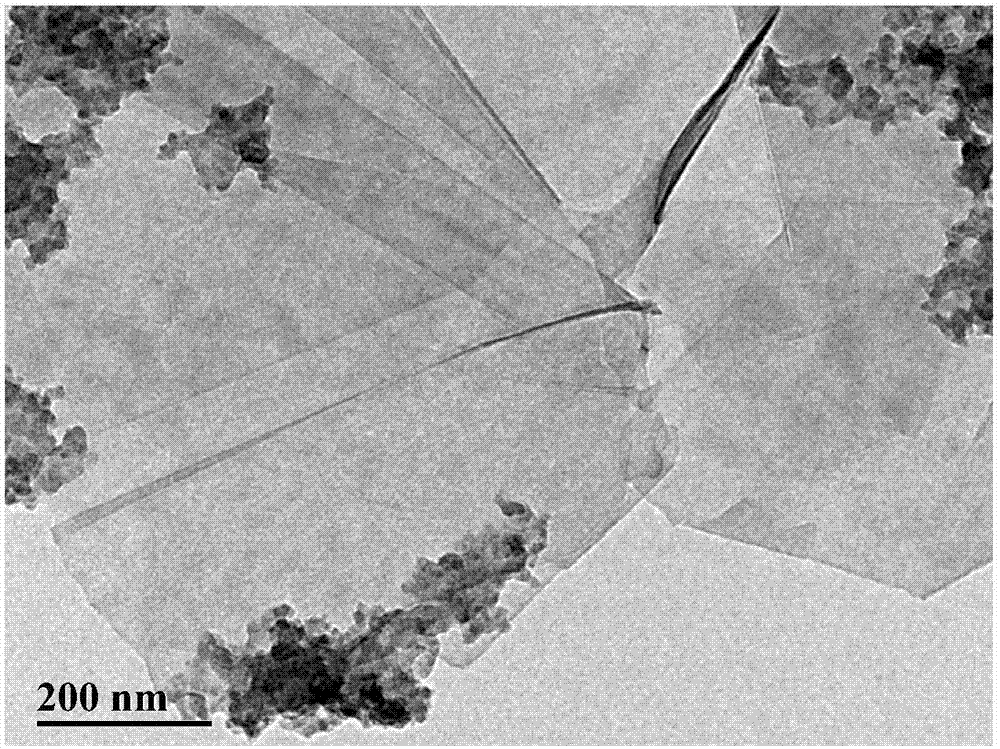

Multiscale carbon material/silicone rubber thermal interface material and preparation method

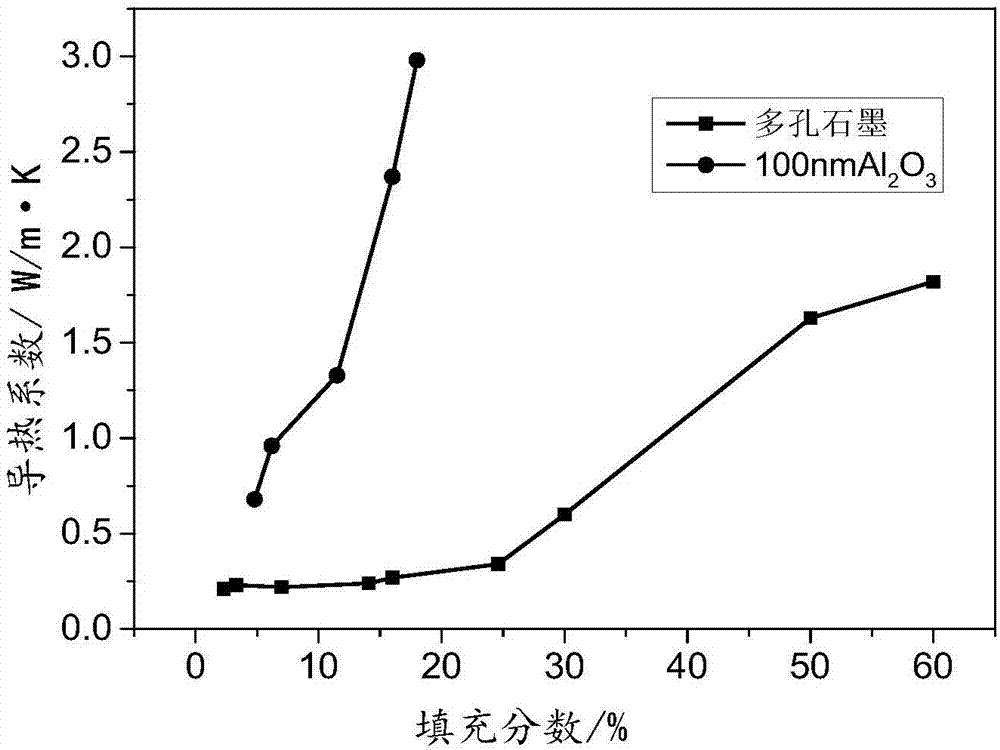

InactiveCN107022194ALarge specific surface areaHigh probability of overlapping/contacting each otherHeat-exchange elementsHeat conductingGraphite

The invention discloses a preparation method of a multiscale carbon material / silicone rubber composite material. The method takes expanded graphite as a heat-conducting main body, graphene as a heat-conducting reinforcement and organic silicon rubber as a flexible substrate, and a thermal interface material with better performance can be obtained through performing mixing kneading, degassing, molding and curing on the materials. The heat conductivity of the composite material is 0.68 to 2.98W / m.K, and the modulus of compression of the composite material is less than 1.2MPa (specified compression set Epsilon is equal to 30 percent). The preparation method of the multiscale carbon material / silicone rubber composite material has the advantages that the raw materials are cheap and easy to obtain, the process is simple and the performance is stable, so that the method is adapted to large-scale production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Synthetic rubber

InactiveCN105153482AEnhancement and effectImproves compression set performancePhenolPolymer chemistry

The present invention provides a synthetic rubber, and relates to the field of rubbers. The synthetic rubber comprises, by weight, 15-25 parts of natural rubber, 10-17 parts of an ethylene propylene diene monomer, 3-7 parts of a phenol resin, 5-10 parts of a titanate coupling agent, 15-25 parts of mineral oil, 5-11 parts of calcium oxide, 3-7 parts of magnesium hydroxide, 2-6 parts of carbon black, 1-4 parts of an anti-aging agent, and 1-3 parts of a vulcanizing agent. According to the present invention, the synthetic rubber has characteristics of good compression deformation performance, good wear resistance, and high practicality.

Owner:四川珍福堂商贸有限公司

Polyvinyl chloride cable material resistant to heat and shock

InactiveCN106117895AHigh tensile strengthHigh tear strengthPlastic/resin/waxes insulatorsPolyvinyl chlorideShock resistance

The invention discloses a polyvinyl chloride cable material resistant to heat and shock. The polyvinyl chloride cable material resistant to heat and shock is prepared from polyvinyl chloride, polyurethane, bisphenol-A polycarbonate, poly (tetramethylene succinate), di (2-ethylbutanoic acid) triuret gylcol ester, 2-ethylhexyl epoxystearate, montmorillonite, ammonium heptamolybdate, kaolin, aluminum hydroxide, magnesium hydroxide whisker, antioxidant, 1-azyl-4-methyl piperazine, tri methylol propane tri methacrylate, bisferrocene-base acetylene and a heat stabilizer. The heat stabilizer is prepared through mixing of rhenium complex, cerous carbonate, tribasic lead sulfate, bisphenol A diglycidyl ether, epoxy butyl stearate, lanthanum stearate, glyzinc, aceticacid,2,2',2''-[(octylstannylidyne)tris(thio)]tris-,triisooctylester, mannitol and 2,5-diphenyl-1,3,4-oxadiazole. The polyvinyl chloride cable material has high strength, heat resistance and shock resistance, is resistant to bending and torsion, and has a long service life.

Owner:ANHUI ELECTRIC GRP SHARES

Sealing pad for engine of automobile and method for preparing sealing pad

The invention provides a sealing pad for an engine of an automobile and a method for preparing the sealing pad. The sealing pad for the engine comprises, by weight, 45-58 parts of acrylonitrile-butadiene rubber, 18-22 parts of isoprene rubber, 17-20 parts of styrene butadiene rubber, 2-4 parts of hollow glass micro-beads, 3-5 parts of modified nanometer montmorillonite, 1-3 parts of vulcanizing agents, 0.4-0.7 part of silane coupling agents and 0.3-0.6 part of tert-phenol-formaldehyde resin. The sealing pad for the engine of the automobile and the method have the advantages that the sealing pad is excellent in hardness, permanent compression deformation and aging resistance in oxygen-containing fuel environments; the method is easy to implement, and industrial production can be facilitated.

Owner:李英

Formula of ethylene-propylene-diene-terpolymer rubber three-layer pad of air-conditioner compressor

The invention discloses a formula of an ethylene-propylene-diene-terpolymer rubber three-layer pad of an air-conditioner compressor. The formula comprises 120 parts of ethylene-propylene-diene-terpolymer rubber, 50 parts of N550 carbon black, 30 parts of N990 carbon black, 20 parts of kieselguhr, 30 parts of environmental-friendly paroline, 3 parts of environmental-friendly zinc oxide, 1 part of stearic acid, 0.5 part of sulfur, 2 parts of an accelerant TP / S, 0.7 part of an accelerant ZBEC (Zinc Dibenzyldithio Carbamate), 0.8 part of an accelerant MBT, 1 part of an RN75 antistatic agent, 1 part of a foaming agent, 2 parts of an anti-aging agent RD, and the total parts are 262. The formula adopts environmental-friendly systems, is free of toxic or side effects and can replace silica gel pads of high price; due to use of the N990 carbon black, the elasticity and the damping effect of a product can be improved; due to use of the kieselguhr, the problem that heat can be generated in the use process of the three-layer pad can be solved; the cross-linking degree of a rubber material can be increased due to addition of the accelerant TP / S and the accelerant ZBEC; the thermal resistance can be improved; and the permanent compression deformation property of the product can be improved.

Owner:WUHU JITUO RUBBER TECH

High heat-resistant anti-aging cable material and preparation method thereof

InactiveCN106750643AWide variety of sourcesReduce manufacturing costLinear low-density polyethylenePolymer science

The invention discloses a high heat-resistant anti-aging cable material. The high heat-resistant anti-aging cable material is prepared from the following raw materials in parts by weight: Buna-N rubber, ethylene propylene rubber, linear low density polyethylene, fluorocarbon resin, hydroxyl silicone oil, modified attapulgite, graphene, ammonium polyphosphate, glass fibre, vermiculite, sodium silicate, nickel, chromium, calcium carbonate, nano-silicon dioxide, ethylene glycol, nano-silicon nitride, sulphur, a stabilizer, a plasticizer, a fire retardant and silicone oil. The invention further discloses a preparation method for the cable material. The cable material is wide in raw material source, simple in preparation process, low in production cost, and suitable for large-scale industrial production; according to the cable material, the Buna-N rubber, the ethylene propylene rubber and the fluorocarbon resin are matched for use, so that the compatibility is high; moreover, the sulphur is adopted to serve as a vulcanizing agent and is matched with the modified attapulgite, the silicone oil, the stabilizer, the plasticizer and the fire retardant, so that the heat resistance, the wear resistance, the oil resistance, the tear resistance and the compressive deformation property of the prepared cable material are excellent; the service life is long; the application range is wide.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

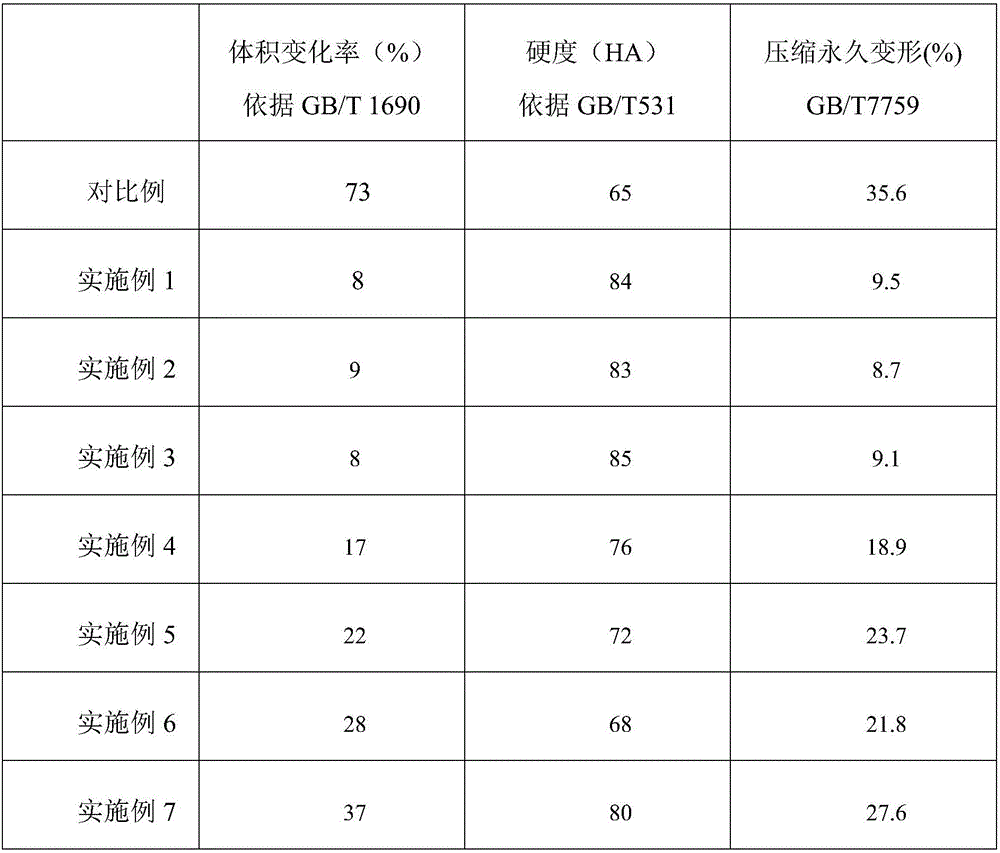

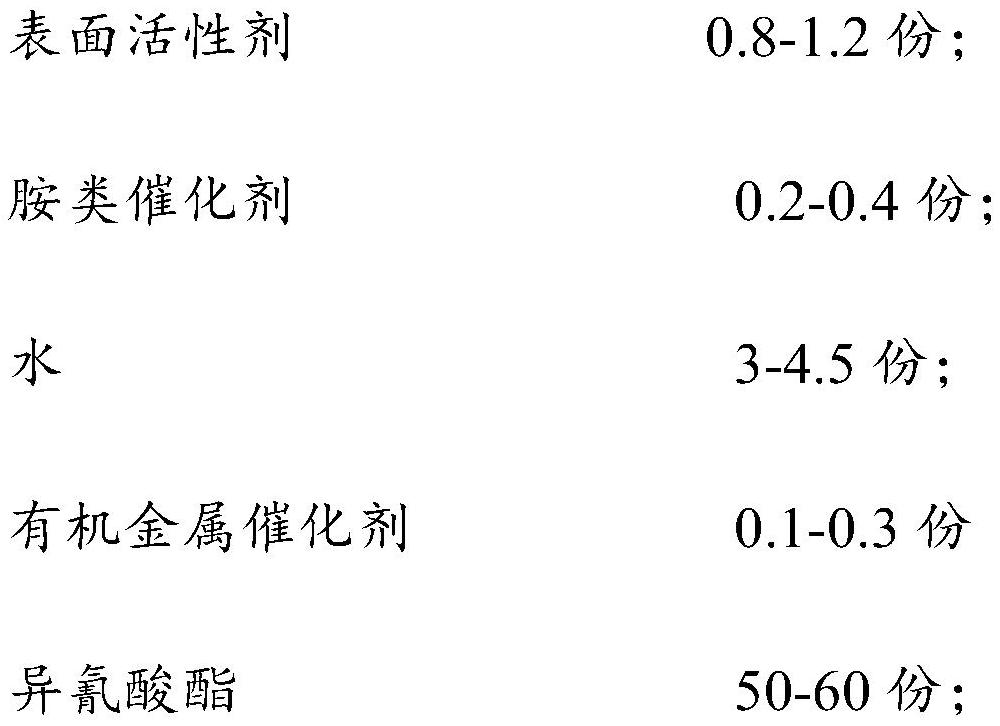

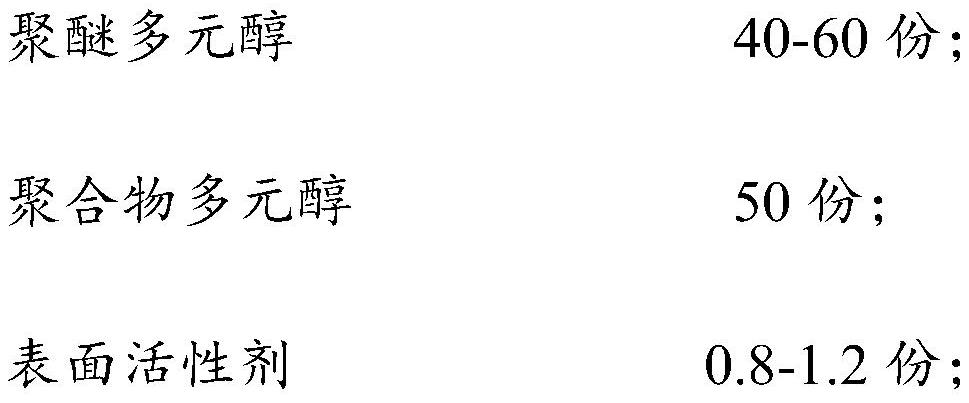

Common polyurethane flexible foam and preparation method thereof

The invention provides common polyurethane flexible foam. The common polyurethane flexible foam is prepared from the following raw materials: polyether polyol for assisting in improving the tearing and compression permanent deformation performance of polyurethane; the preparation method of the polyether polyol for assisting in improving the tearing and compression permanent deformation performance of the polyurethane comprises the following steps: taking micromolecular polyol with the functionality of 3-4 as an initiator, taking ethylene oxide and epoxypropane as composite monomers, and reacting under the action of a catalyst to prepare the polyether polyol. The polyether polyol has high reaction activity and relatively high ethylene oxide content, and when the polymer polyol is added into other raw materials of common polyurethane flexible foam, not only can the air permeability of sponge be directly improved, but also the use amount of a catalyst in a polymerization reaction process is reduced to the greatest extent, the production cost can be reduced, the obtained polyurethane foam has remarkably improved air permeability, excellent rebound resilience and higher comfort, and the problem that the existing medium-low density polyurethane common soft foam is easy to be stiff in hand feeling is solved.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

A kind of low compression set carboxylic acid type acrylate rubber and preparation method thereof

ActiveCN110330750BImprove heat aging performanceImproved compression setPolymer scienceCarboxylic acid

The invention provides a low compression set carboxylic acid type acrylate rubber and a preparation method thereof, belonging to the technical field of compounding and processing of synthetic rubber. A kind of low compression set carboxylic acid type acrylate rubber, its raw material comprises by weight parts: 100 parts of carboxylic acid type acrylate rubber, 10-50 parts of fast extrusion carbon black, 10-50 parts of precipitated white carbon black, 1-5 parts of silane coupling agent, 1-3 parts of No. 1 vulcanizing agent, 1-4 parts of accelerator, 1-3 parts of processing aid and 2-5 parts of anti-aging agent, quick extrusion of carbon black and precipitated silica The mass ratio is 1:1. Not only has good low compression set performance, but also has good thermal stability, high hardness and high tensile strength. A method for preparing carboxylic acid acrylate rubber with low compression set. The silane coupling agent is added when the temperature of the rubber mixture is 50-70°C. The method is simple, and the prepared carboxylic acid acrylate rubber has good properties .

Owner:四川青龙丙烯酸酯橡胶有限公司

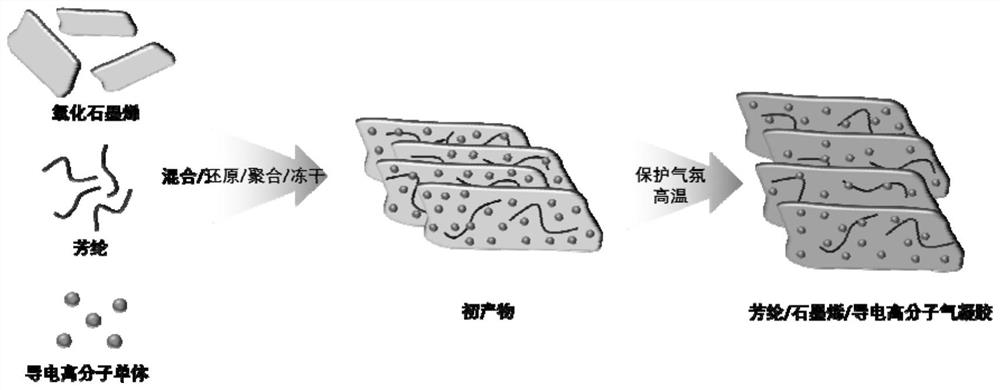

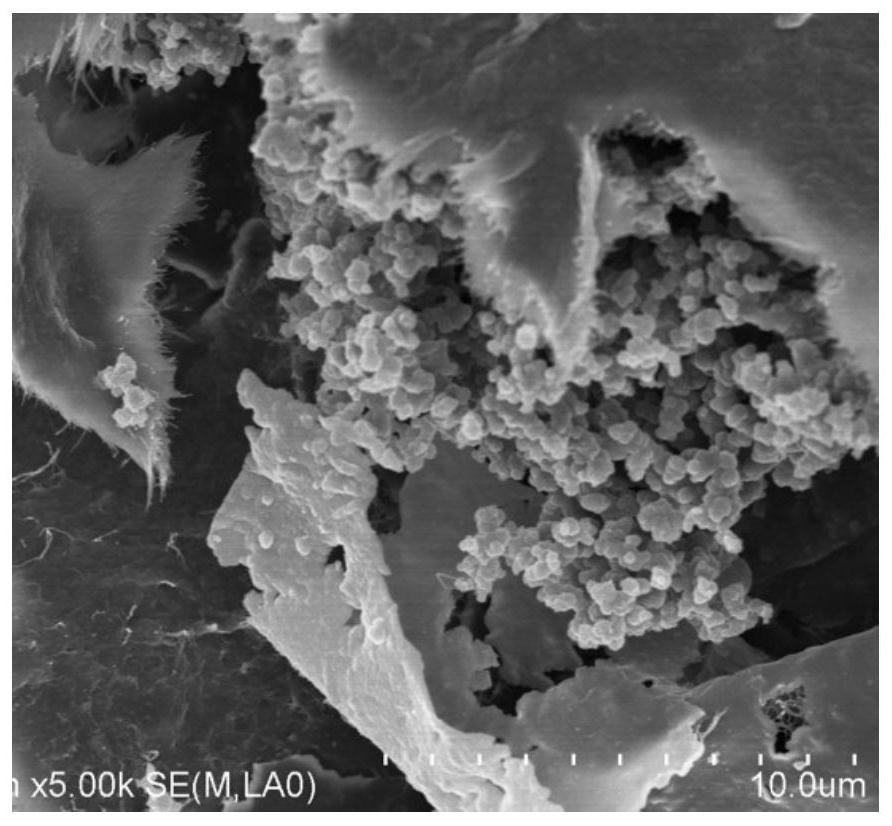

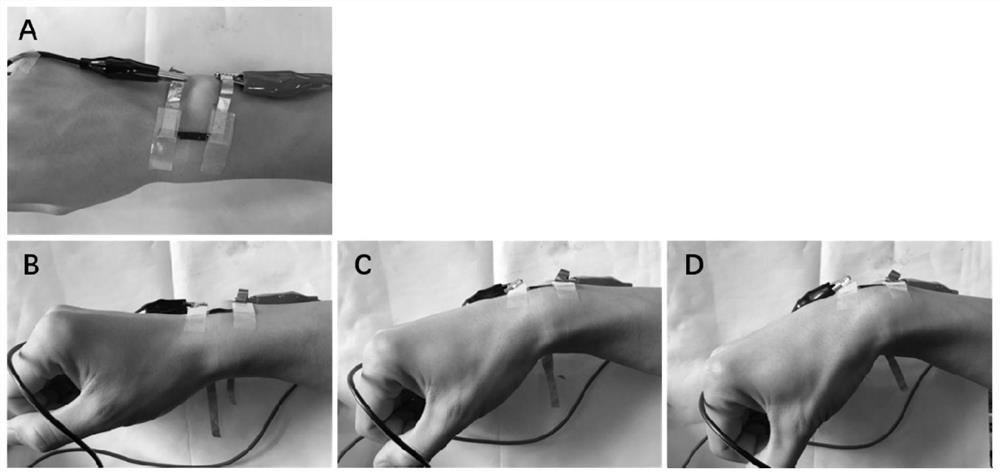

Preparation method of aramid fiber/graphene/conductive polymer aerogel composite pressure sensing material

PendingCN113201168AImprove conductivityGood flexibilityCarbon preparation/purificationConductive polymerGraphene

The invention discloses a preparation method of an aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material. The preparation method comprises the following steps of (1) preparing an aramid fiber solution, (2) preparing an aramid fiber / graphene / conductive polymer monomer solution, (3) preparing aramid fiber / graphene / conductive polymer hydrogel, (4) preparing an aramid fiber / graphene / conductive polymer aerogel initial product, and (5) preparing the aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material. The aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material prepared by the invention is high in conductivity and good in flexibility, and also has high compressive deformation performance and high fatigue resistance.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

A kind of visible polyhydroxy polymer embolization microsphere and preparation method thereof

ActiveCN107050501BImprove flexibilityIncrease elasticitySurgical adhesivesPharmaceutical non-active ingredientsMicrosphereX-ray

The invention relates to a visual polyhydroxy polymer embolism microsphere and a preparation method thereof, belonging to the technical field of medical treatment materials. The visual embolism microsphere is prepared from functional macromolecules with biocompatibility and a cross-linking agent, namely an iodobenzene compound through cross-linking polymerization and is capable of reflecting or weakening X rays. The invention relates to a novel visual embolism microsphere in the technical field of medical materials and a preparation process of the novel visual embolism microsphere. According to the process, the defect that a contrast agent is added into a traditional surgical embolism process for developing is changed, the surgical risk is reduced, and convenience is provided for treating tumor diseases by virtue of a minimally invasive interventional therapy; the visual microsphere prepared by virtue of the preparation process is capable of reflecting or weakening the X rays and has good flexibility, elasticity and compression deformation property; and meanwhile, a traditional embolism microsphere needs to be dyed so as to guarantee that a doctor can conveniently observe in a surgical process, but the embolism microsphere prepared by virtue of the process is yellow and does not need to be dyed, so that the operation is simple and feasible.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

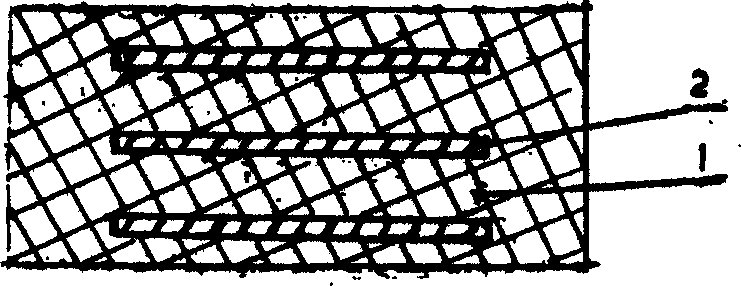

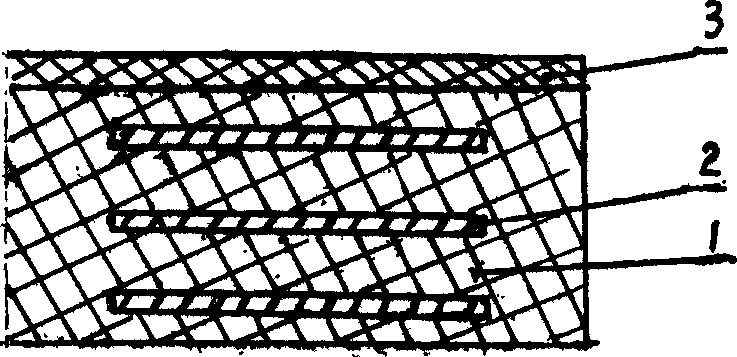

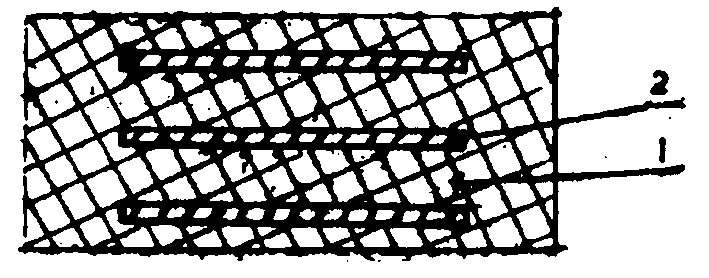

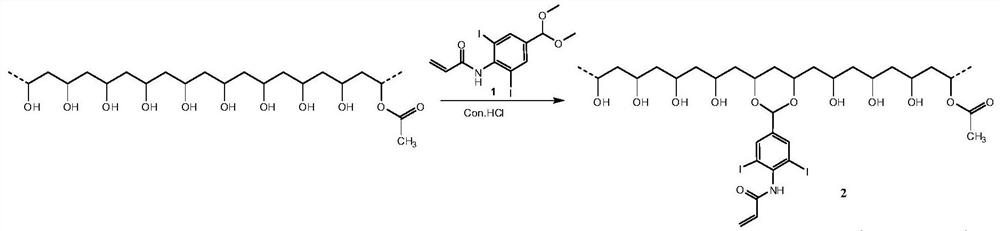

Side filling material of road retained for next sublevel

ActiveCN100494112CRealize long-distance pumpingImproves compression set performanceSolid waste managementFilling materialsWater reducer

Filling material for sides of a roadway driven along goaf is characterized by having cement, fly ash, stone, sand, water and compound addictive, wherein the compound addictive consists of water reducing agent, water retaining agent, air-entraining agent and hardening accelerator. The material described in the present invention is obtained through mixing and preparaten at a prescribed rate and satisfies long-distance delivery and construction; the material has good load bearing and deformation performance following hardening and the formed filling structure can control a delamination of direct roof and cut off the connection between direct roof and lower basic roof in a timely manner, which allows the an establishment of relatively compact filling in the goaf and minimizing bending and settlement of the basic roof, thereby reducing loads applied on the roadway support and deformation of enclosure with a view to the roadway stability; also the goaf can be sealed timely to avoid ventilation leakage and coal self-ignition and prevent hazardous gases entering into the working room from the goaf.

Owner:HUAINAN MINING IND GRP +2

A kind of low compression set active chlorine type acrylate rubber and preparation method thereof

The invention provides a low compression set active chlorine type acrylate rubber and a preparation method thereof, belonging to the technical field of synthetic rubber. A low compression set active chlorine type acrylate rubber, its raw materials include by weight fraction: 100 parts of active chlorine type acrylate rubber, 20-100 parts of reinforcing agent, 1-5 parts of silane coupling agent, vulcanizing agent 1 ‑3 parts, 1‑5 parts of processing aid and 2‑5 parts of anti-aging agent, the reinforcing agent includes fast extruded carbon black and precipitated silica, the mass ratio of fast extruded carbon black and precipitated silica is 1:1 . The active chlorine-type acrylate rubber not only has good low compression set performance, but also has good thermal stability, high hardness and high tensile strength. A method for preparing low compression set active chlorine-type acrylate rubber. The silane coupling agent is added when the temperature of the rubber mixture is 50-70°C. The method is simple, and the prepared active chlorine-type acrylate rubber has better properties .

Owner:四川青龙丙烯酸酯橡胶有限公司

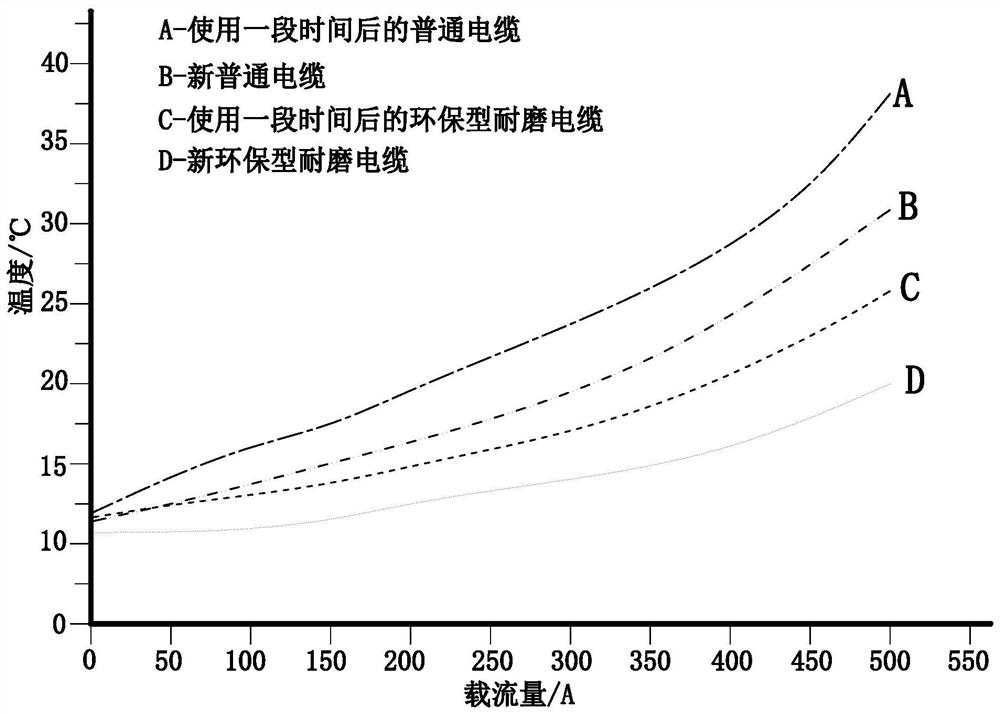

An environment-friendly wear-resistant cable

ActiveCN110591190BWith wear resistanceStable structureInsulated cablesCoatingsElectrical conductorStructural engineering

The invention belongs to the technical field of electric cables, and is specifically an environment-friendly wear-resistant cable, which includes a main conductor whose surface is wrapped with a No. 1 insulating layer, and a secondary conductor whose surface is wrapped with a No. 2 insulating layer. Arranged and connected through the second insulating layer to form a flat wire group; one edge of the first insulating layer is provided with a concave part, and the concave part is located inside the first insulating layer; the outer side of the second insulating layer on one side of the wire group is set There is a convex part, and the convex part is suitable for the concave part of the No. 1 insulating layer; the wire group is wrapped around the outside of the main conductor and solidified by gluing; the outer side of the solid wire group is wrapped with multi-layer wear-resistant waterproof cloth and It is solidified by gluing; the waterproof cloth is wrapped with a wear-resistant rubber layer; the present invention can produce cables with wear resistance and tear resistance through the production method of environmentally friendly wear-resistant cables. The problem of indistinguishability when the number of conductors is large.

Owner:阳谷鑫辉电缆有限公司

Production process of high-heat-conductivity flexible graphene film gasket

InactiveCN110589810AEasy to stretchImproves compression set performancePositive displacement pump componentsGraphenePorous grapheneSlurry

The invention discloses a production process of a high-heat-conductivity flexible graphene film gasket. The heat conduction gasket comprises a few-layer porous graphene film and a film-based heat conduction net, wherein the film-based heat conduction net is vertically arranged on the few-layer porous graphene film substrate. The process is characterized by comprising the following process steps: performing mesh sieve screening on graphene; rolling the mesh-screened graphene by using a rolling machine so as to obtain a graphene film; preparing spraying slurry, and spraying the spraying slurry to the few-layer porous graphene film by using a spraying machine; performing rolling molding and drying on the few-layer porous graphene film coated by the spraying slurry so as to form a film heat conduction net which is formed in a longitudinal and transverse interwoven manner and is perpendicular to the few-layer porous graphene film, and performing combination, so as to obtain the high-heat-conductivity flexible graphene film gasket. With the combination of the slurry heat conduction nets with excellent heat conduction performance, heat conduction channels of the film can be effectively increased, the heat conduction performance of the film in an X direction and a Z direction can be improved, the interlayer strength of the few-layer porous graphene films in overlapping can be improved,and the composite material heat conduction gasket has excellent heat conduction performance.

Owner:曾功昶

A high-strength wear-resistant and tear-resistant rubber material

Owner:宁国日格美橡塑股份有限公司

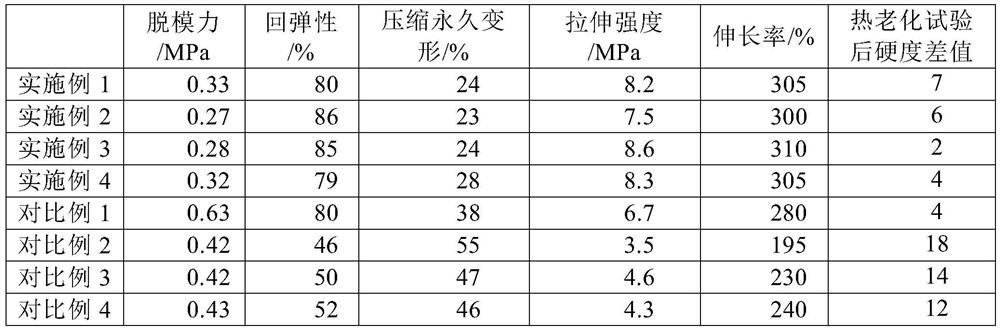

Silicone rubber and product thereof

The invention provides silicone rubber which comprises 100 parts of methyl vinyl silicone rubber, 20-60 parts of fumed silica, 20-40 parts of cerium oxide, 30-50 parts of spinel powder, 30-50 parts of titanium dioxide, 2-10 parts of a structure control agent, 1-5 parts of a release agent and 0.2-5 parts of a vulcanizing agent. The silicone rubber which is easy to demould and excellent in sealing performance is obtained through formula design. In the formula design, the cerium oxide, the spinel powder and the titanium dioxide in a proper ratio are added at the same time, so that the compression permanent deformation of the silicone rubber can be synergistically enhanced, and the problem that a product is easy to harden is effectively solved. The silicone rubber disclosed by the invention is particularly suitable for application fields with relatively high requirements on sealing performance, and a product of the silicone rubber can be a sealing ring, or a sealing gasket, or a sealing strip, or a sealant.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

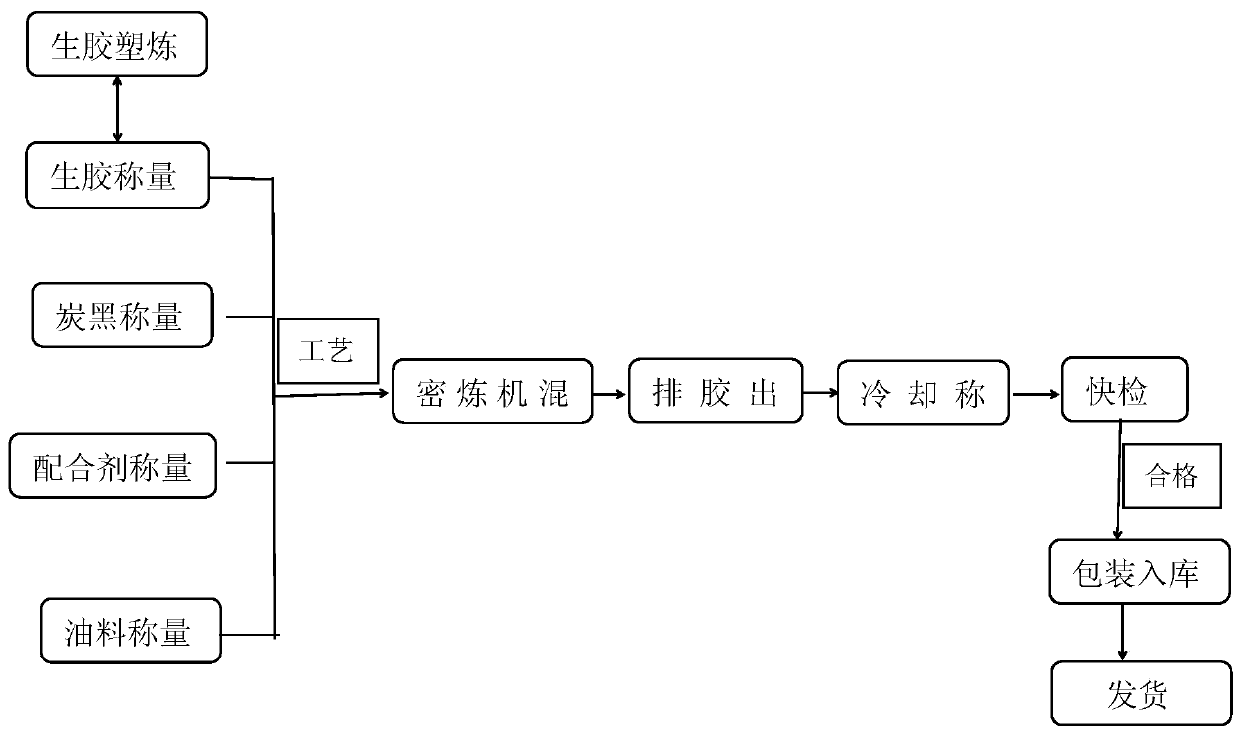

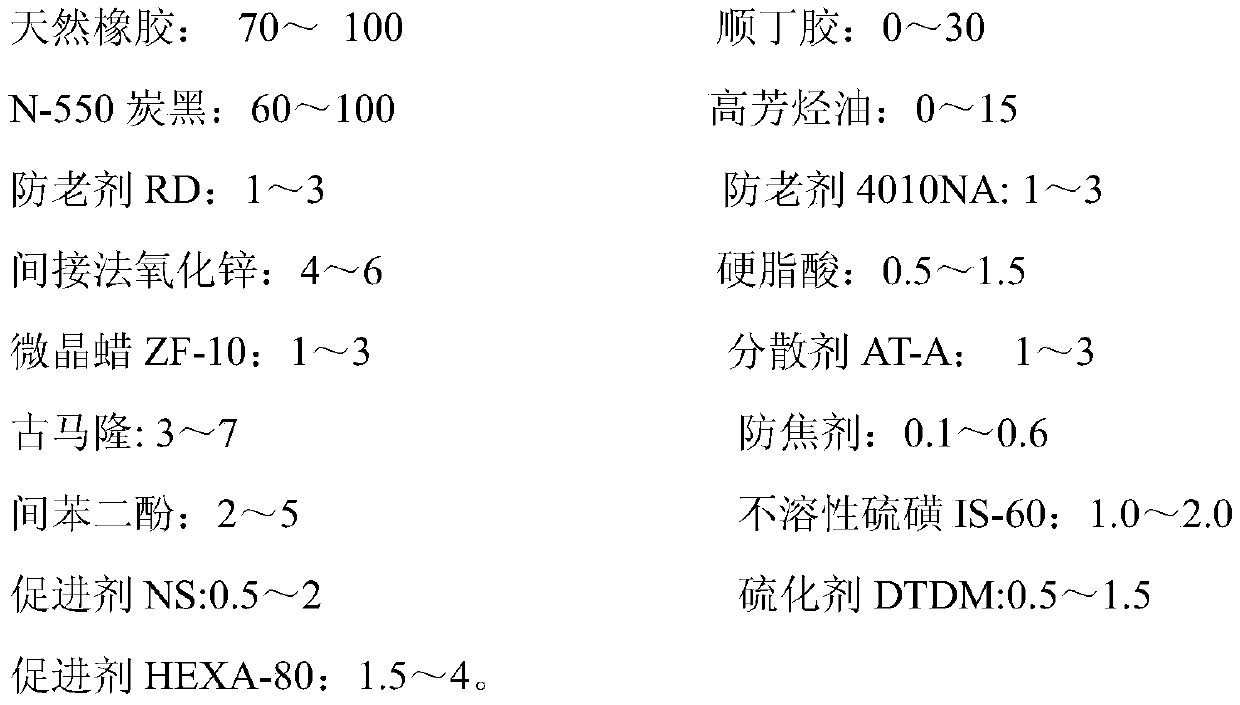

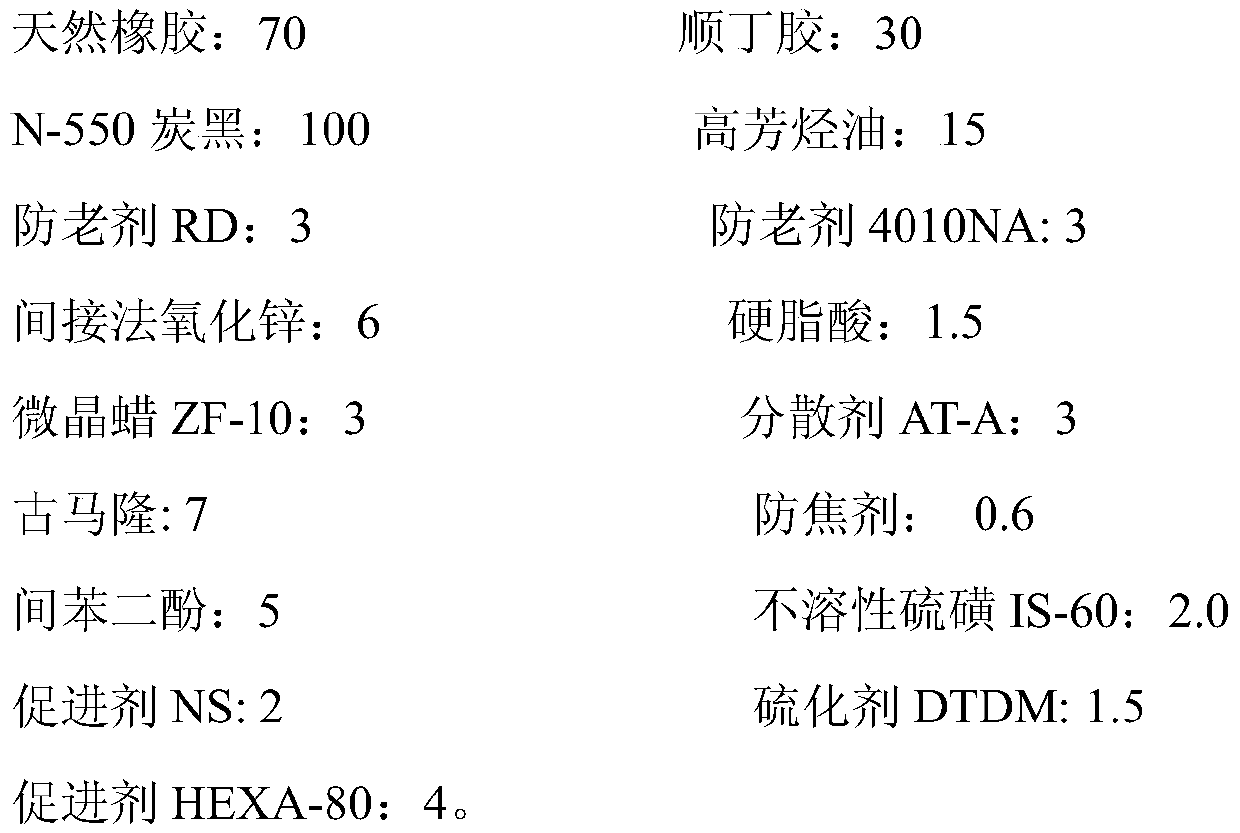

Elevator roller rubber compound for vertical elevator and preparation technology

The invention discloses an elevator roller rubber compound for a vertical elevator. The rubber compound comprises, by weight, 70-100 parts of natural rubber, 0-30 parts of butadiene rubber, 60-100 parts of N-550 carbon black, 0-15 parts of high aromatic oil, 1-3 parts of an anti-aging agent RD, 1-3 parts of an anti-aging 4010 NA, 4-6 parts of indirect method zinc oxide, 0.5-1.5 parts of stearic acid, 1-3 parts of microcrystalline wax ZF-10, 1-3 parts of a dispersing agent AT-A, 3-7 parts of coumarone, 0.1-0.6 part of a scorch retarder, 2-5 parts of resorcinol, 1.0-2.0 parts of insoluble sulfurIS-60, 0.5-2 parts of an accelerant NS, 0.5-1.5 parts of a vulcanizing agent DTDM and 1.5-4 parts of an accelerant HEXA-80. The rubber compound is small in compression permanent deformation and longin fatigue life, and therefore the use requirements under long-time harsh conditions are met.

Owner:安徽鼎连高分子材料科技有限公司

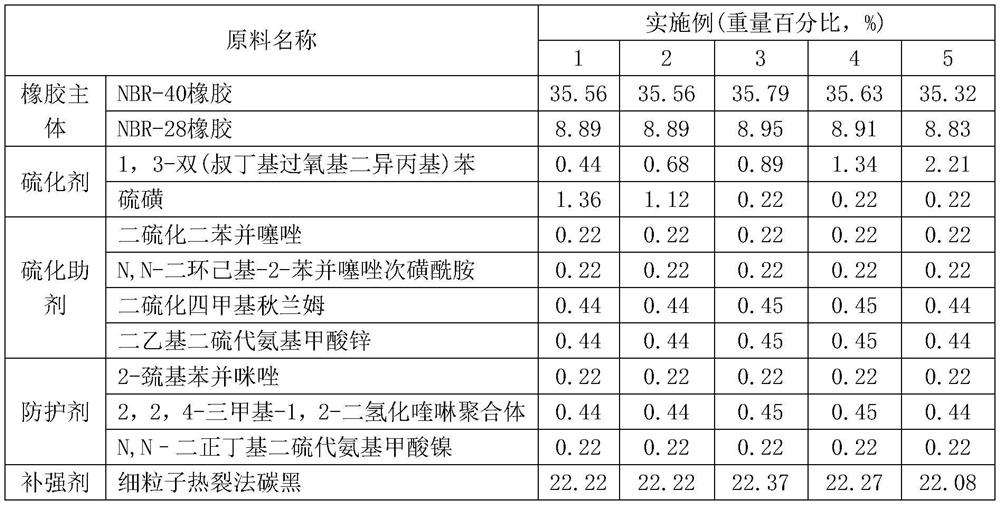

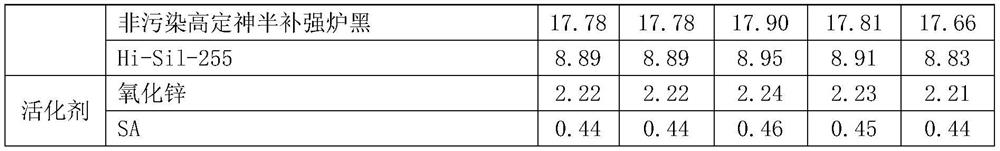

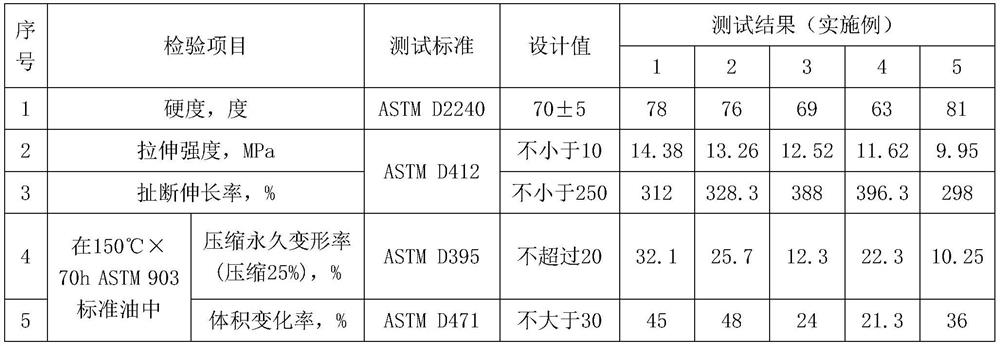

NBRrubbermaterial with low compression set and preparation process thereof

ActiveCN113881118AGood oil resistanceImprove wear resistanceRolling resistance optimizationRubber materialVulcanization

The invention discloses an NBR rubber material with low compression set and a preparation process thereof, belonging to the technical field of rubber sealing elements. The NBR rubber material is prepared from the following raw materials by mass: 44.15-44.75% of a main rubber body, 1.11-2.43% of a vulcanizing agent, 1.32-1.34% of a vulcanizing aid, 0.88-0.89% of a protective agent, 48.57-49.22% of a reinforcing agent, and 2.65-2.70% of an activator. According to the invention, NBR rubber and various assistants are reasonably selected, so the compression set performance of the rubber material is improved, and the prepared product meets environmental protection requirements; product quality cost is controlled to be within a reasonable range; and through adjustment, the tensile strength of the NBR rubber material is not less than 10 Mpa, a compression set test shows that a compression set rate does not exceed 20% under the conditions of compression of 25% and 150 DEG C * 70 h in ASTM 903, and comprehensive performance is good.

Owner:南阳天一密封股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com