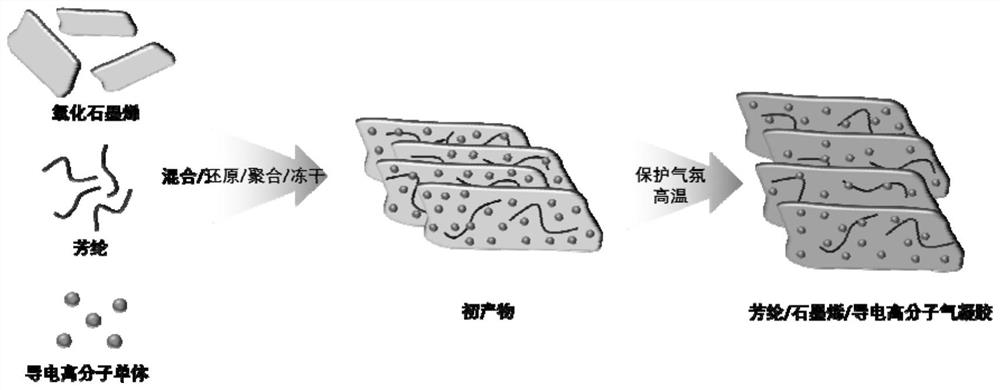

Preparation method of aramid fiber/graphene/conductive polymer aerogel composite pressure sensing material

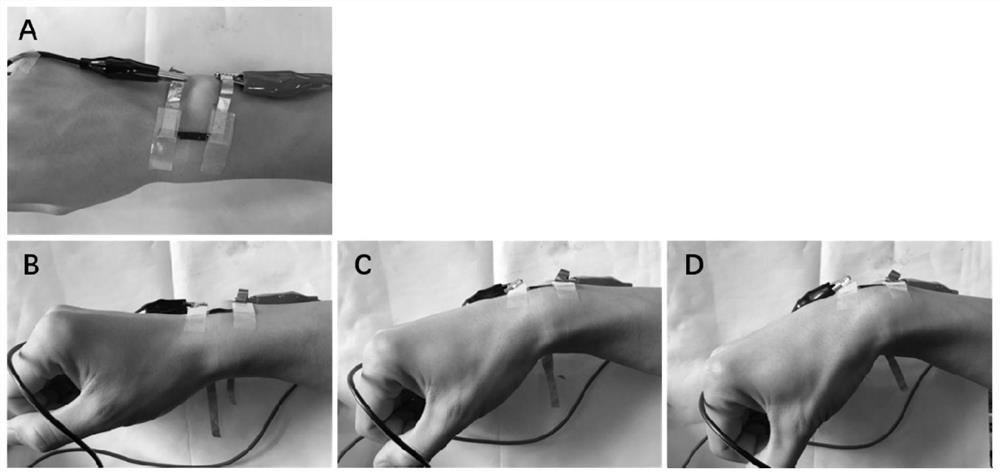

A technology of conductive polymers and sensing materials, applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of phase separation of materials with weak binding force, affecting sensor sensitivity and cycle stability, etc., to achieve The effect of low requirements for experimental equipment, enhanced electrostatic bonding force, and high compression deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

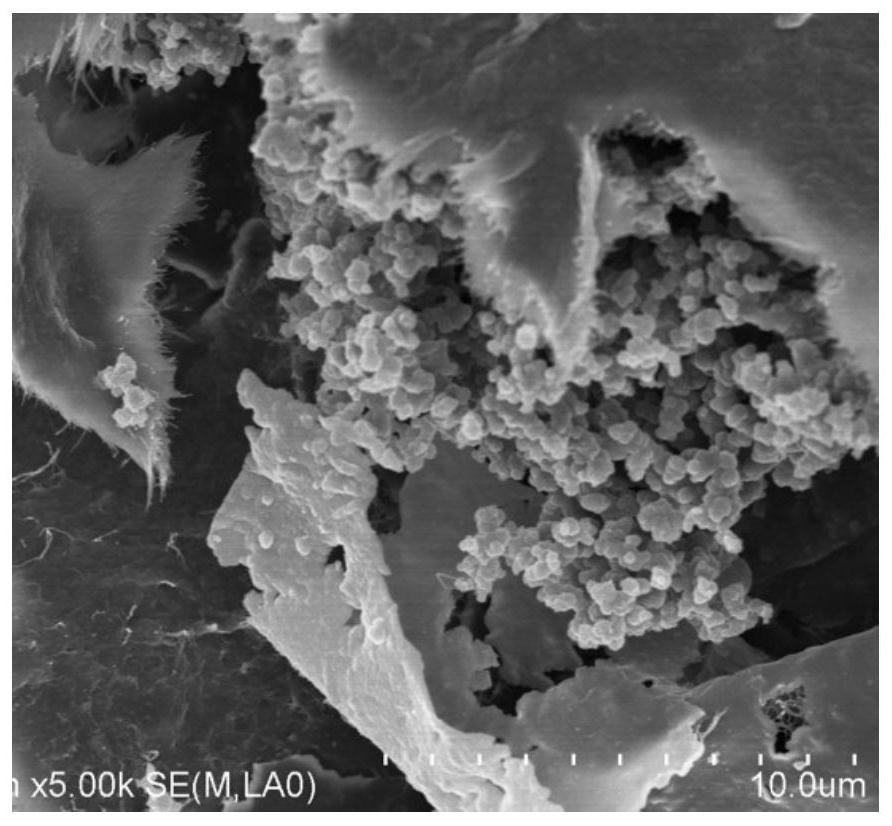

Image

Examples

Embodiment 1

[0034] A preparation method of aramid fiber / graphene / conductive polymer airgel composite pressure sensing material, comprising the following steps:

[0035] (1) Measure and mix 100mL dimethyl sulfoxide with 1mL water to prepare a dimethyl sulfoxide / water mixed solution with a volume ratio of 100:1, weigh 505mg sodium hydroxide and add it to prepare a mass concentration of 5mg / mL dimethyl sulfoxide / water / strong alkali solution; add 110mg of aramid fiber (Kevlar 49 produced by DuPont China Co., Ltd.) to the above 101mL dimethyl sulfoxide / water / strong alkali system, and stir at 20r / min for 60h to complete Peel off, wash 6 times with water, store in 101mL deionized water for later use.

[0036] (2) Weigh 120 mg of amino-modified graphene oxide and 1.5 mg of pyrrole, add them to the aramid solution prepared in step (1), and stir at 20 r / min for 10 min to obtain aramid / graphene / conductive polymer monomer solution.

[0037] (3) Add 0.015 mg of ammonium persulfate, 12 mg of hydrazin...

Embodiment 2

[0041] A preparation method of aramid fiber / graphene / conductive polymer airgel composite pressure sensing material, comprising the following steps:

[0042] (1) Measure and mix 100mL dimethyl sulfoxide with 0.1mL water to prepare a dimethyl sulfoxide / water mixed solution with a volume ratio of 100:0.1, weigh 100.1mg sodium hydroxide and add it to prepare a mass concentration of 1mg / mL of dimethyl sulfoxide / water / strong alkali solution; add 11mg of aramid fiber (Kevlar 49 produced by DuPont China Co., Ltd.) to the above 100.1mL dimethyl sulfoxide / water / strong alkali system, at 600r / min Stir for 2 hours to complete the peeling, wash twice with water, and store in 100.1 mL deionized water for later use.

[0043] (2) Weigh 2g of amino-modified graphene oxide and 10g of aniline, add it to the aramid solution prepared in step (1), and stir at 300r / min for 1min to prepare aramid / graphene / conductive polymer monomer solution .

[0044] (3) Add 10 g of sodium persulfate, 2 g of ascor...

Embodiment 3

[0049] A preparation method of aramid fiber / graphene / conductive polymer airgel composite pressure sensing material, comprising the following steps:

[0050] (1) Measure 100mL of dimethyl sulfoxide and mix it with 10mL of water to prepare a dimethyl sulfoxide / water mixed solution with a volume ratio of 100:10. Weigh 1.1g of sodium hydroxide and add it to prepare a mass concentration of 10mg / mL of dimethyl sulfoxide / water / strong alkali solution; add 1.1g of aramid fiber (Kevlar 49 produced by DuPont China Co., Ltd.) to the above 110mL dimethyl sulfoxide / water / strong alkali system, and stir at 150r / min After 40 hours, the stripping was completed, washed with water four times, and stored in 110 mL of deionized water for later use.

[0051] (2) Weigh 1.1g of amino-modified graphene oxide and 1.1g of phenylacetylene, add them to the aramid solution prepared in step (1), and stir at 150r / min for 5min to prepare aramid / graphene / conductive polymer monomer solution.

[0052] (3) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com