Silicone rubber and product thereof

A silicone rubber and rubber technology, applied in the field of silicone rubber and its products, can solve the problems of products such as easy hardening, achieve the effect of enhancing compression set and solving easy hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation of internal release agent: Put ester wax and simethicone in a kneader at a mass ratio of 100:50, add 14 parts by mass of talcum powder, 12 parts by mass of mica powder, and 4 parts by mass of stearin Zinc acid and 10 parts by mass of surfactant (such as polyether modified silicone oil, viscosity is 1800mPa·s, side chain contains 3 (CH 2 ) 3 O(C 2 h 4 O) 12 H), discharge after mixing evenly.

[0020] Preparation of rubber: Add 3 to 6 parts of hydroxyl silicone oil to 100 parts of methyl vinyl silicone rubber raw rubber (the molar fraction of vinyl chains is 0.15%, and the average degree of polymerization is about 7000), and the specific surface area of 40 parts is 200m 2 / g of fumed silica, mixed uniformly in a kneader. Then treat it at 170°C for 2 hours to make a compound compound. Add 1-3 parts of internal release agent and 0.3-1.5 parts of vulcanizing agent to every 100 parts of compound rubber, knead evenly, put it into a metal mold, and hot-press...

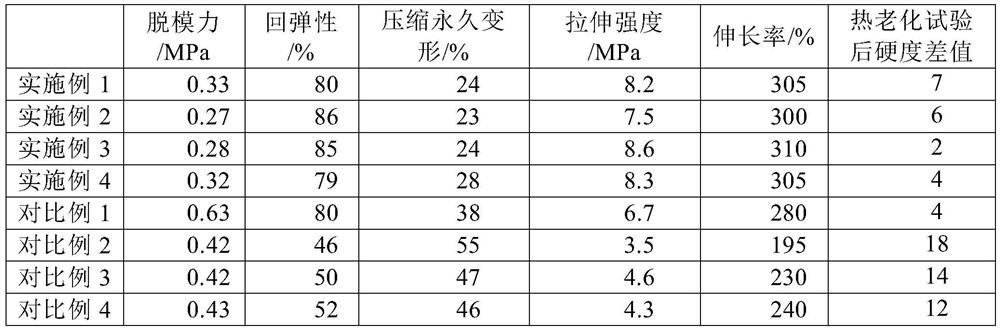

Embodiment 1-4 and comparative example 1-4

[0023] Preparation of rubber products: Add 1 part of hydroxy silicone oil with a polymerization degree of 10 to 100 parts of methyl vinyl silicone rubber raw rubber (the molar fraction of vinyl chain segments is 0.15%, and the average degree of polymerization is about 7000), and 3 parts of 15 hydroxy silicone oil, 40 parts BET method specific surface area is 200m 2 / g of fumed silica, mixed evenly in a kneader, and made into a compound compound. Then treat it at 170°C for 2 hours, add 2 parts of self-made internal release agent, 1 part of vulcanizing agent, 20 parts of cerium oxide, 30 parts of spinel powder, and 30 parts of titanium dioxide to 100 parts of the mixed rubber material to mix evenly, and then Place the uniformly mixed rubber material in a mold, and heat-press vulcanize it at 170°C for 10 minutes to form a disc-shaped (diameter 25mm x thickness 1.2mm) silicone rubber product.

Embodiment 2

[0025] Preparation of rubber products: Add 1 part of hydroxy silicone oil with a polymerization degree of 10 to 100 parts of methyl vinyl silicone rubber raw rubber (the molar fraction of vinyl chain segments is 0.15%, and the average degree of polymerization is about 7000), and 3 parts of 15 hydroxy silicone oil, 40 parts specific surface area is 200m 2 / g of fumed silica, mixed evenly in a kneader, and made into a compound compound. Then treat it at 170°C for 2 hours, add 2 parts of internal release agent, 1 part of vulcanizing agent, 40 parts of cerium oxide, 50 parts of spinel powder, and 50 parts of titanium dioxide to 100 parts of the mixed rubber material to mix evenly, and then mix The uniformly mixed rubber material is placed in a mold, and hot-pressed and vulcanized at 170°C for 10 minutes to form a disc-shaped (diameter 25mm x thickness 1.2mm) silicone rubber product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com