Patents

Literature

76results about How to "Easy to harden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for titanium dioxide serving as catalyst carrier

InactiveCN102583522AImprove performanceEasy to processCatalyst carriersTitanium dioxidePtru catalystMaterials science

The invention discloses a preparation method for titanium dioxide serving as a catalyst carrier. The preparation method comprises the following steps of: dispersing metatitanic acid serving as a raw material by pulping, and adjusting until the concentration of the slurry is 12 to 26 mass percent based on titanium dioxide (TiO2); adding ammonia water into the slurry, and adjusting the pH value to be between 6.0 and 9.0; filtering and dehydrating to obtain a blocky filter cake; mechanically crushing the blocky filter cake; drying and calcining the crushed filter cake at 200 to 560 DEG C for 6 hours; and grinding the calcined material in a kiln to obtain a titanium dioxide product which serves as a denitration catalyst carrier. By the preparation method, the manufacturing cost is low, the process is simple, the prepared product has the advantages of large specific area, high surface chemical activity and high processability, and the prepared final product is high in catalytic efficiency.

Owner:四川华铁钒钛科技股份有限公司

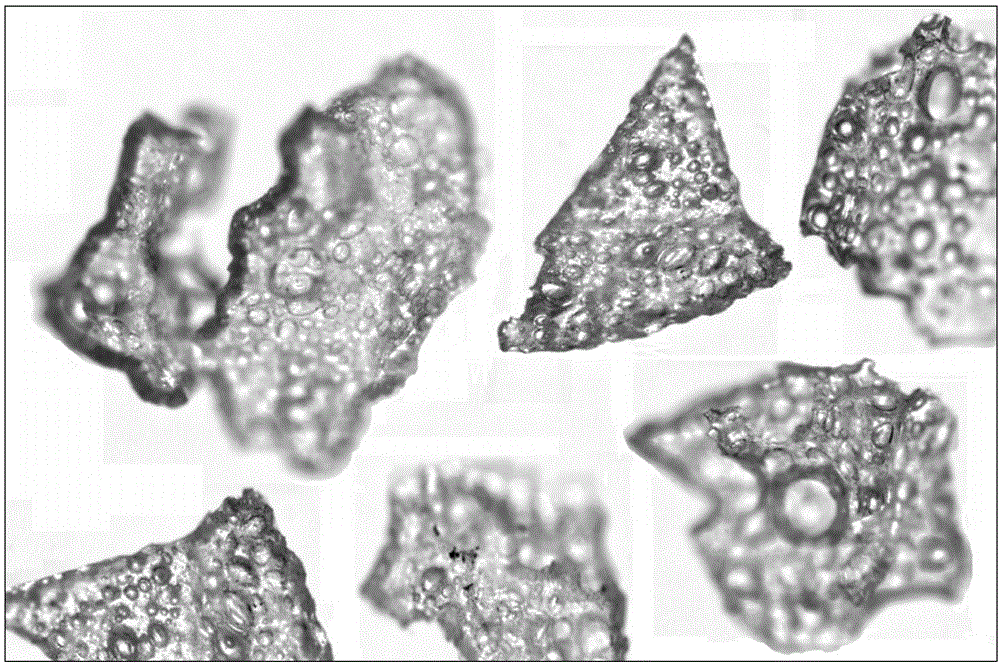

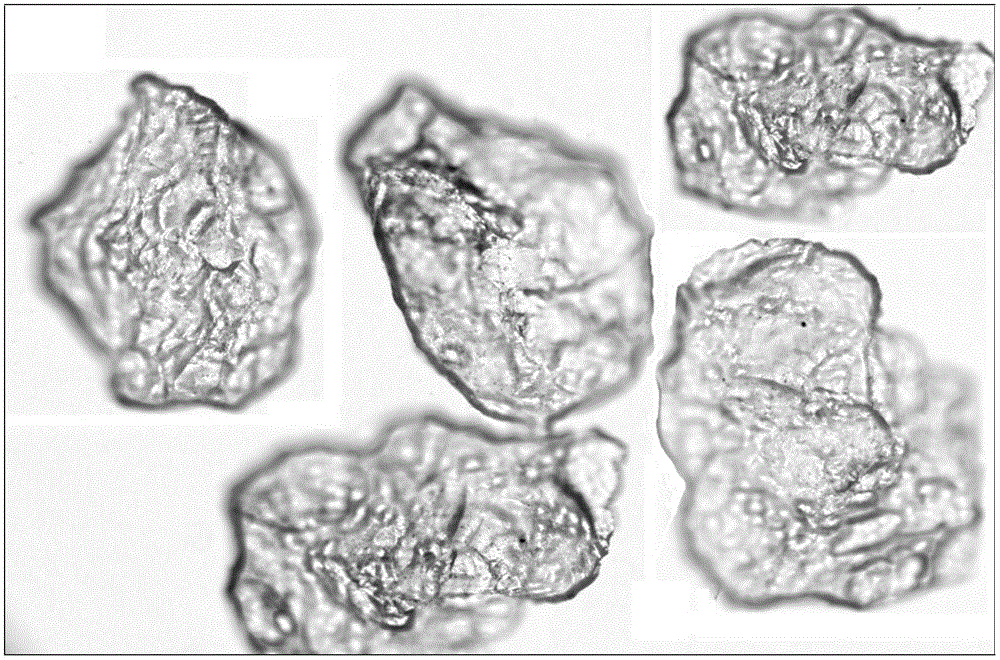

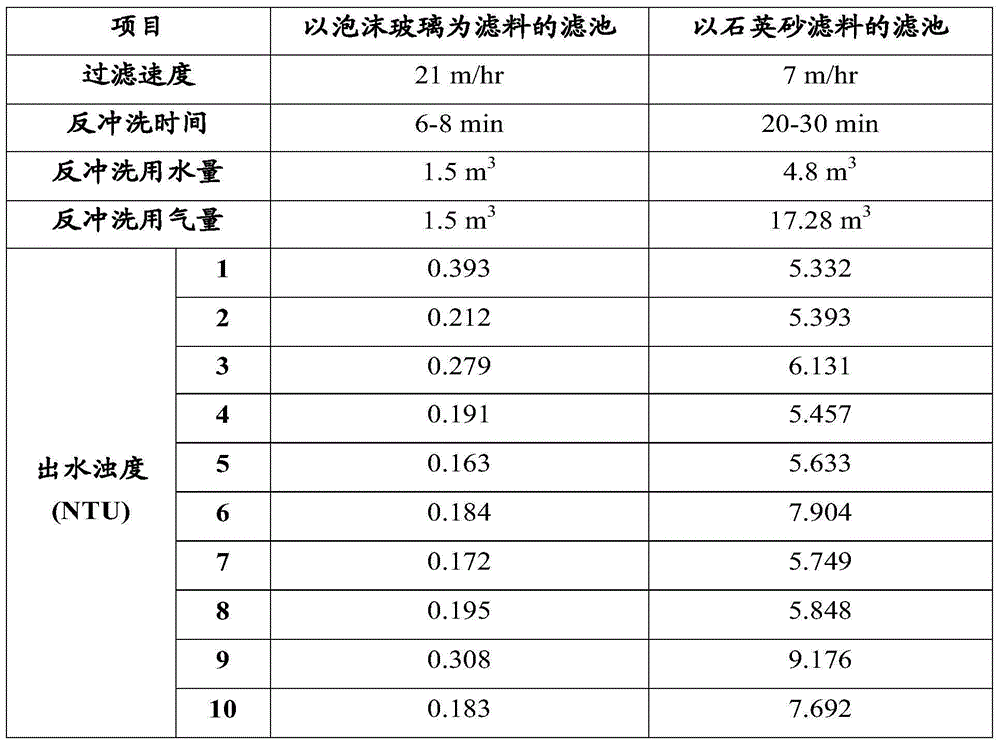

Light filtration medium for water treatment and preparation method and application thereof

The invention provides a light filtration medium for water treatment and a preparation method and application thereof, and belongs to the field of water treatment. The light filtration medium for water treatment adopts granular foam glass. The preparation method of the light filtration medium includes the following steps: adding a foaming agent, a foaming agent promoter and a modifier into the fine glass powder, and mixing uniformly to obtain a mixed raw material; smelting and foaming the mixed raw material, and then sequentially cooling and smashing again, so as to obtain the foam glass which can be used as the light filtration medium for water treatment. The foam glass has the characteristics of being high in voidage, large in specific surface area, porous and light; during the using process, the filtering speed is high, the effluent quality is excellent, and the material filtering layer is quite easy to expand (with a highest expansion ratio of 200%) during back washing, which facilitates the back washing in a fast and effective manner and provides guarantee for performing microflocculation rapid filtration; in addition, the surface of the foam glass filtration medium is uneven with multiple corner angles, high in voidage and large in specific surface area, and has excellent suspended solids retention property.

Owner:北京魔砂科技有限公司

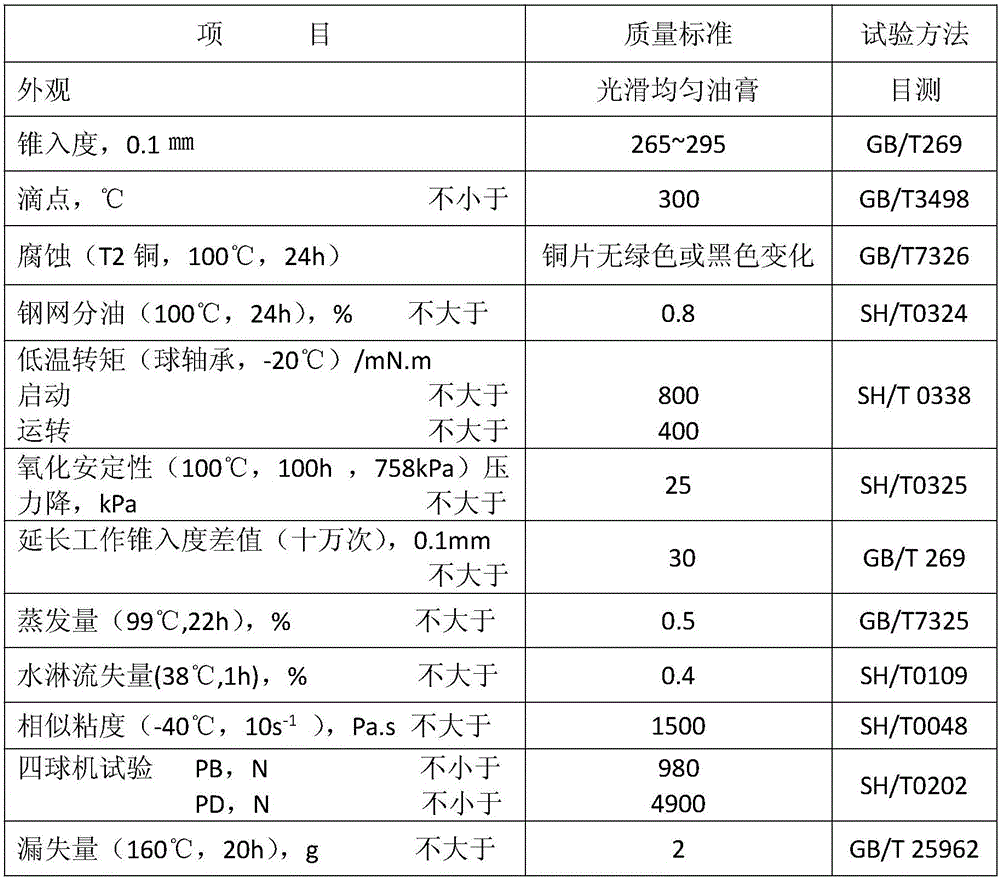

Long-life high-temperature bearing grease and preparation method thereof

InactiveCN106118832AEasy to hardenSolve the poor shear stability of urea-based thickenerLubricant compositionLubricationChemistry

The invention discloses long-life high-temperature bearing grease which comprises the following raw materials in parts by weight: 12 parts of octadecylamine, 4 parts of cyclohexane, 9 parts of MDI, 10 parts of petroleum calcium sulfonate, 1 part of petroleum ether, 100 parts of base oil A, 70 parts of base oil B, 1.5 parts of an antioxidant A, 0.3 part of an antioxidant B, 1.5 parts of an anti-wear reagent A at extreme pressure, 3 parts of an anti-wear reagent B at extreme pressure, 4 parts of an oiliness agent, 5 parts of a stabilizer, 1 part of a tackifier and 1.5 parts of anti-rust agent. During preparation, the various raw materials are subjected to stirring reaction under the required order according to different temperature and time parameters and treated according to related process requirements. The grease has excellent high temperature resistance, lubricating property, adhesion, water resistance and extreme pressure anti-wear property, excellent shearing resistance, thermal stability and sealing property, as well as excellent oxidation resistance, chemical corrosion resistance and rustproof property and can realize long-life lubrication of each equipment bearing. Moreover, the preparation method is simple, easy to operate, wide in product purposes and good in effect.

Owner:安徽中天石化股份有限公司

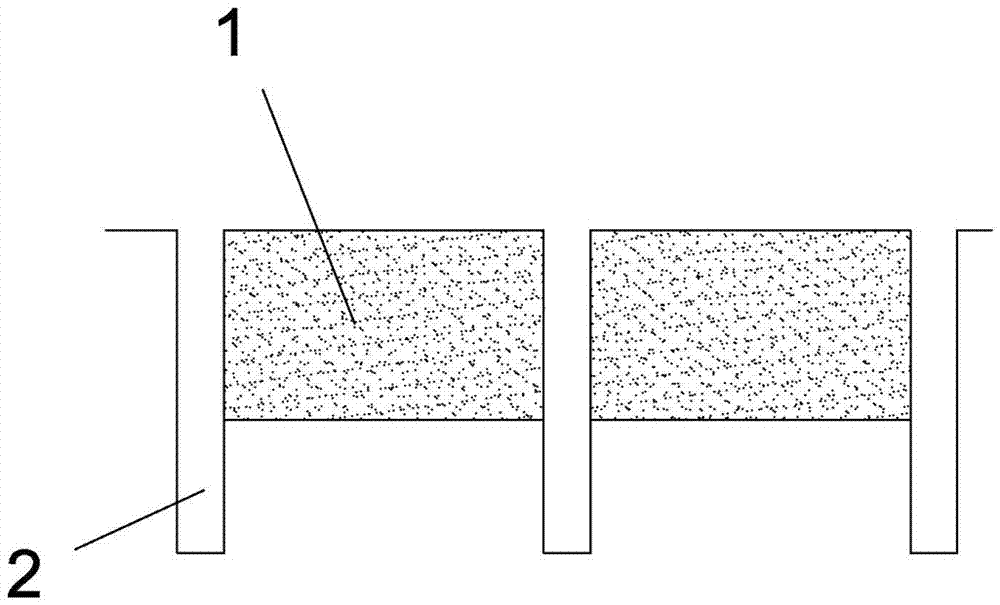

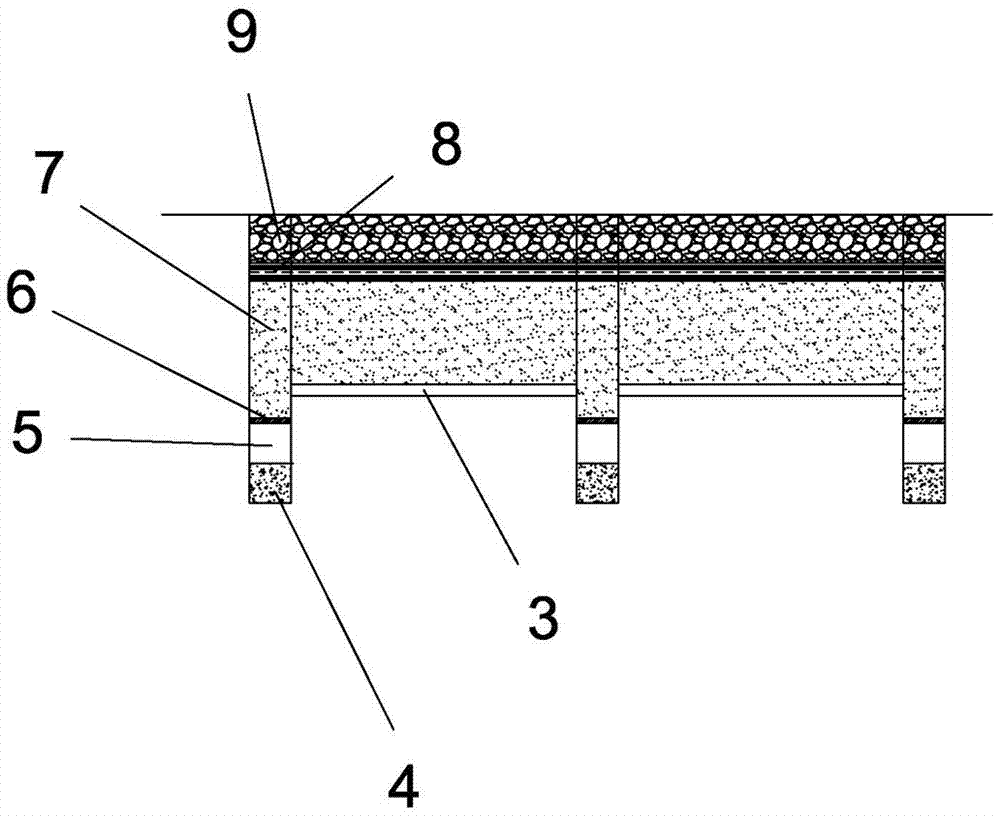

Coastal saline-alkali soil improving method

The invention relates to a coastal saline-alkali soil improving method and belongs to the technical field of saline-alkali soil improvement. The method comprises the following steps that 1, a drainage ditch is built; 2, soil tillage is conducted; 3, drip washing and salt elimination are conducted; 4, the third step is repeated until the salinity and alkalinity are lowered to the specialized range; 5, resin is poured into saline-alkali soil to form a salt prevention layer; 6, the bottom of the drainage ditch is filled with filling materials; 7, soil conditioner and organic fertilizer are applied to the soil. According to the coastal saline-alkali soil improving method, firstly a drainage system is built, soil tillage is conducted, then the tilled soil is subjected to drip washing, after drip washing is conducted repeatedly, the salinity and alkalinity of the soil are lowered quickly, and the method accords with the growth of general plants; due to the fact that fertilizer in the soil is also taken away at the same time of drip washing, the soil is poorer and easier to harden, and therefore, complex fertilizer operation such as application of biological fertilizer is also conducted after drip washing on the soil, so that the fertility of the soil is improved quickly, and the method is suitable for the growth of plants.

Owner:德润建安工程集团有限公司

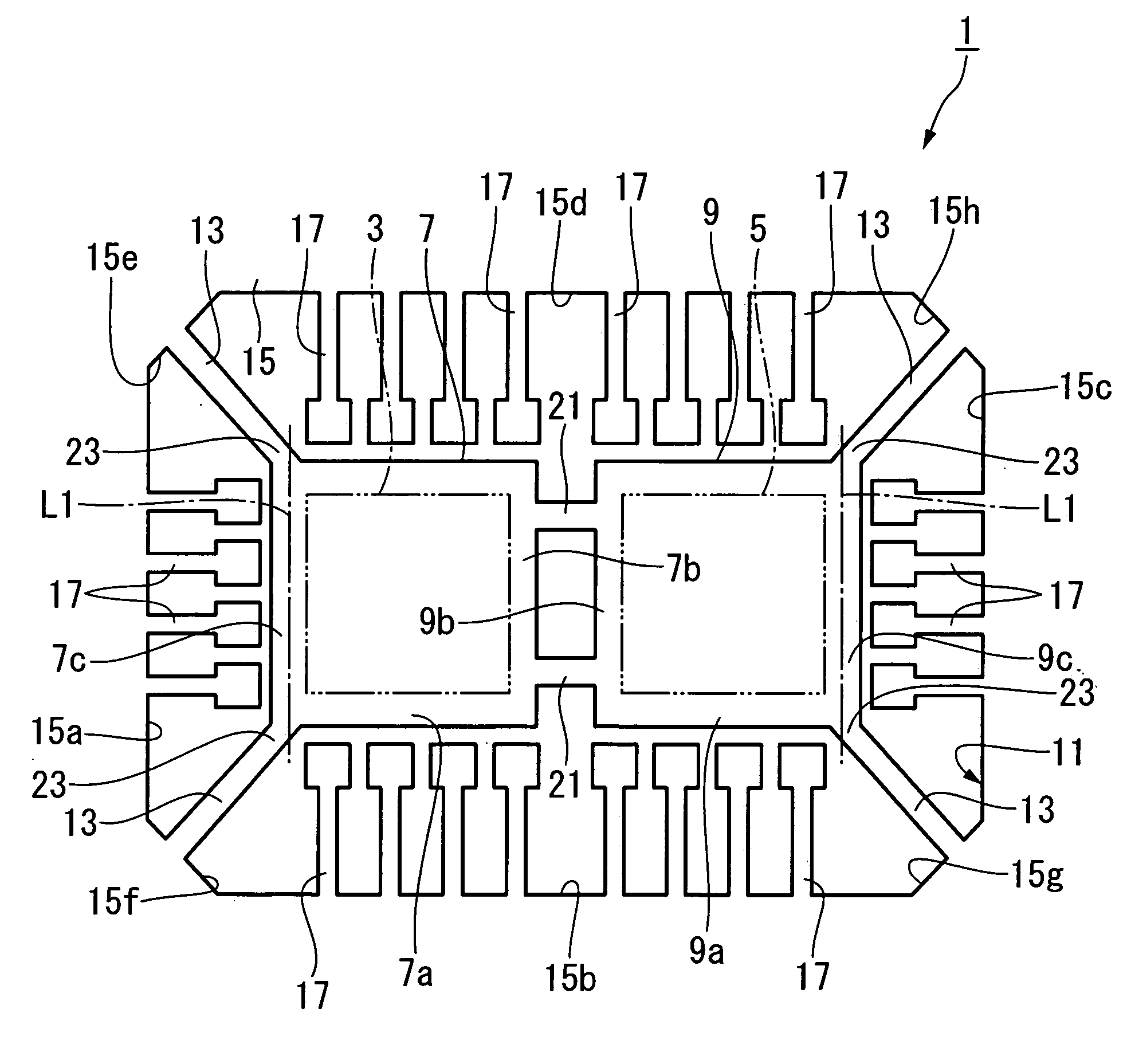

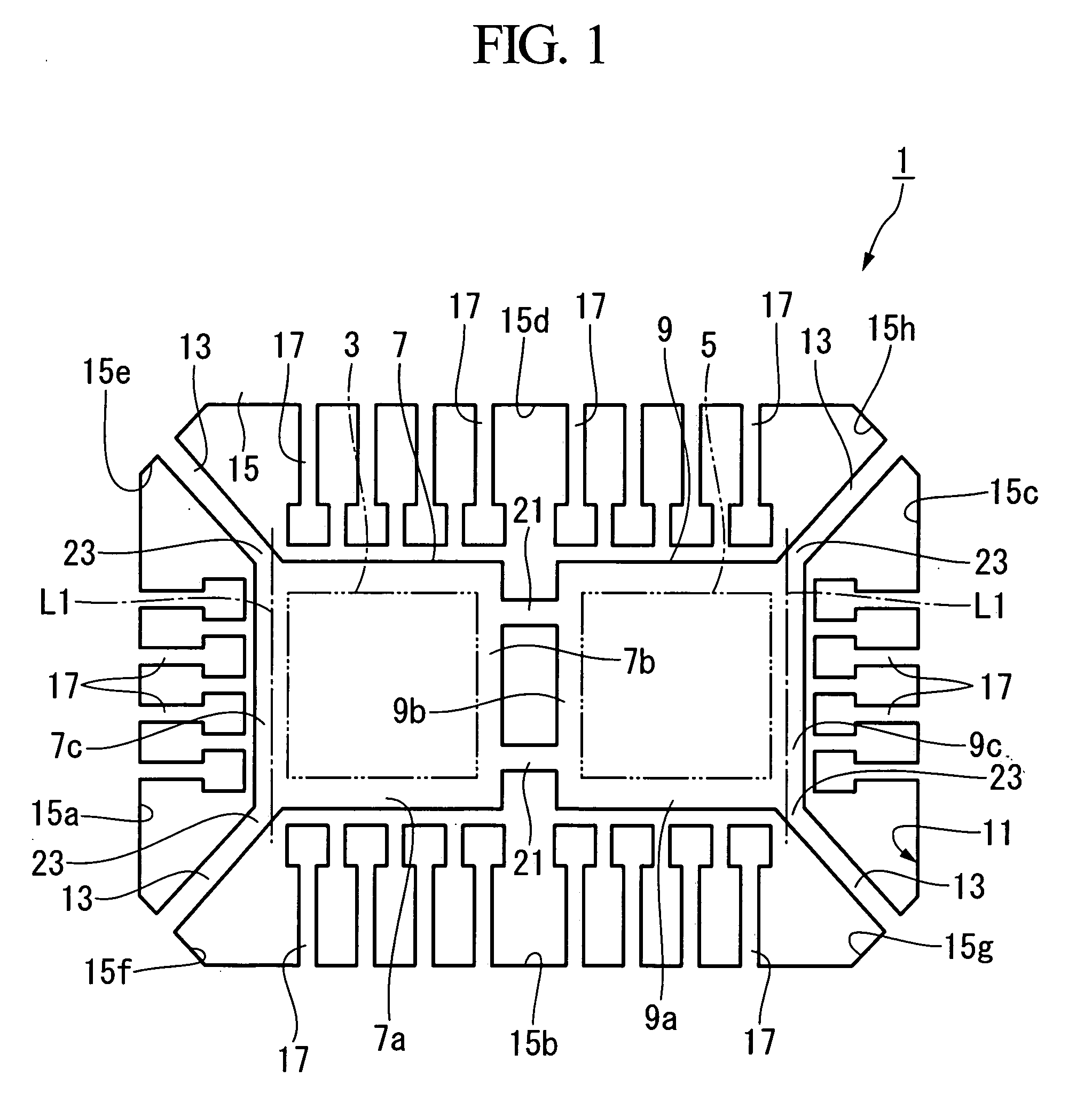

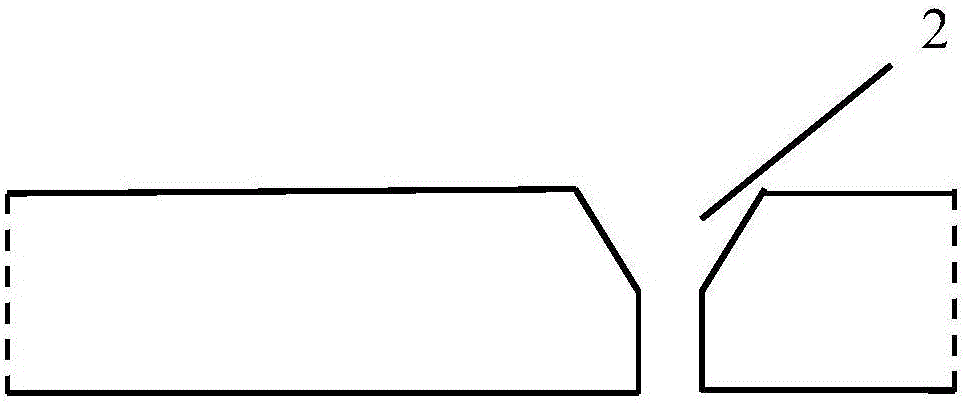

Manufacturing method for physical quantity sensor using lead frame and bonding device therefor

InactiveUS20060211176A1Easy to manufactureEasy to assembleSemiconductor/solid-state device detailsSolid-state devicesShape-memory alloyAlloy

A physical quantity sensor is produced using a lead frame having at least one stage for mounting a physical quantity sensor chip and a frame having leads, wherein the physical quantity sensor chip is inclined with respect to the frame. A bonding device performs wire bonding so as to electrically connect the physical quantity sensor chip and leads, which are respectively located perpendicular to a capillary for discharging wires. The bonding device includes a wedge tool having a first planar surface for holding one ends of wires with leads and a second planar surface for holding the other ends of wires with the physical quantity sensor chip. The lead frame includes interconnection leads, having shape memory alloys, for interconnecting the stage and frame together. The physical quantity sensor chip can be mounted on the stage via an inclination member having a wedge shape.

Owner:YAMAHA CORP

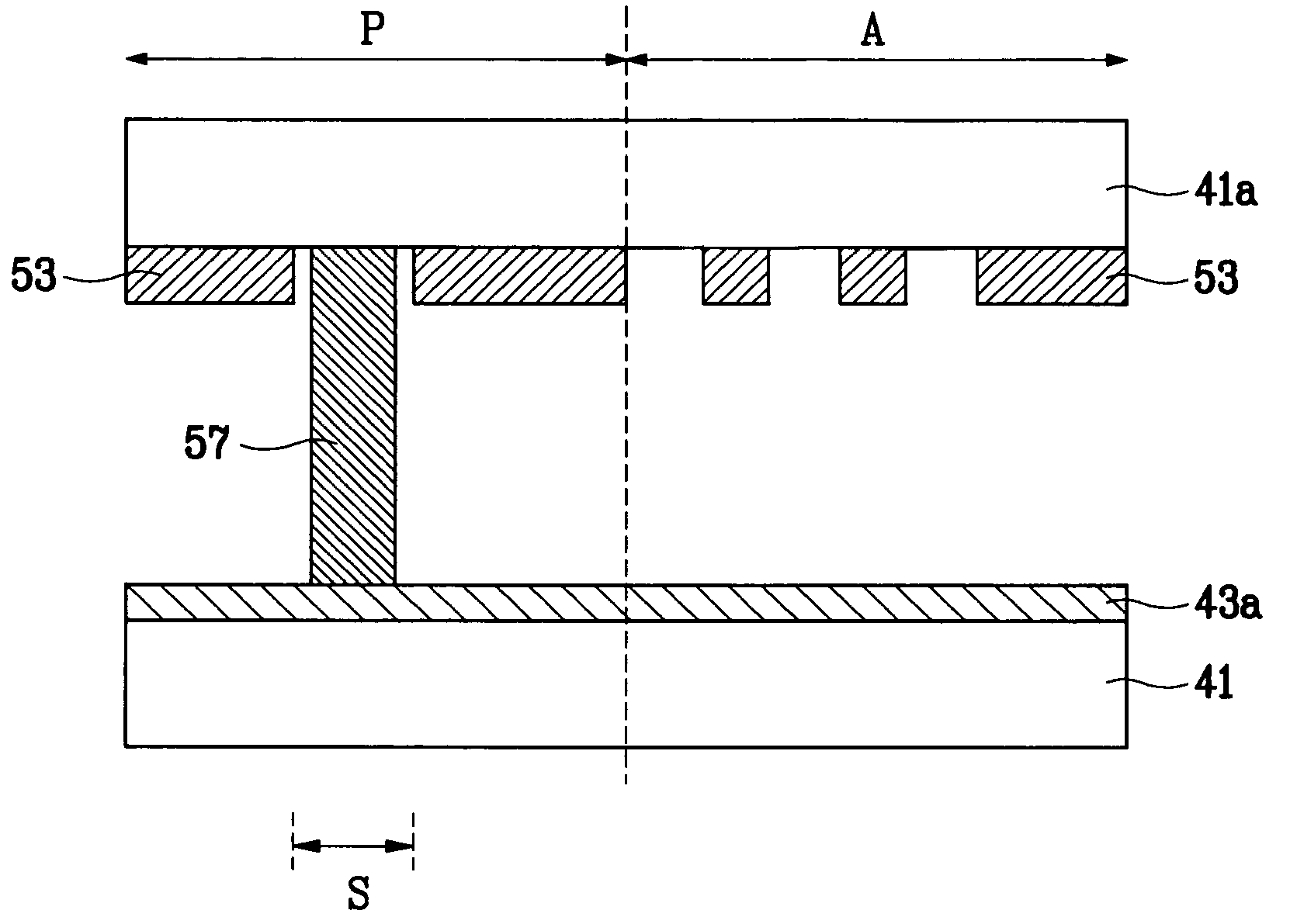

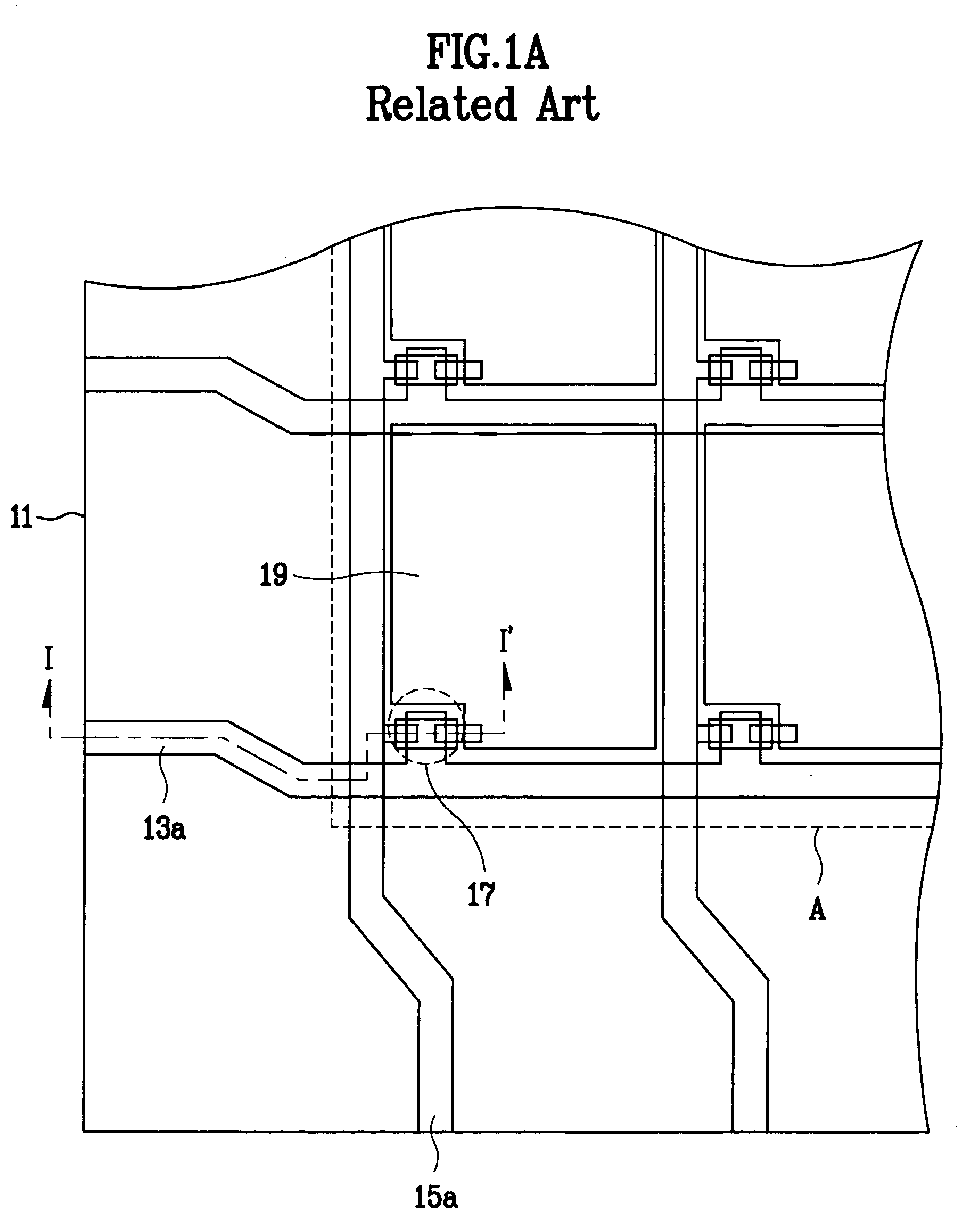

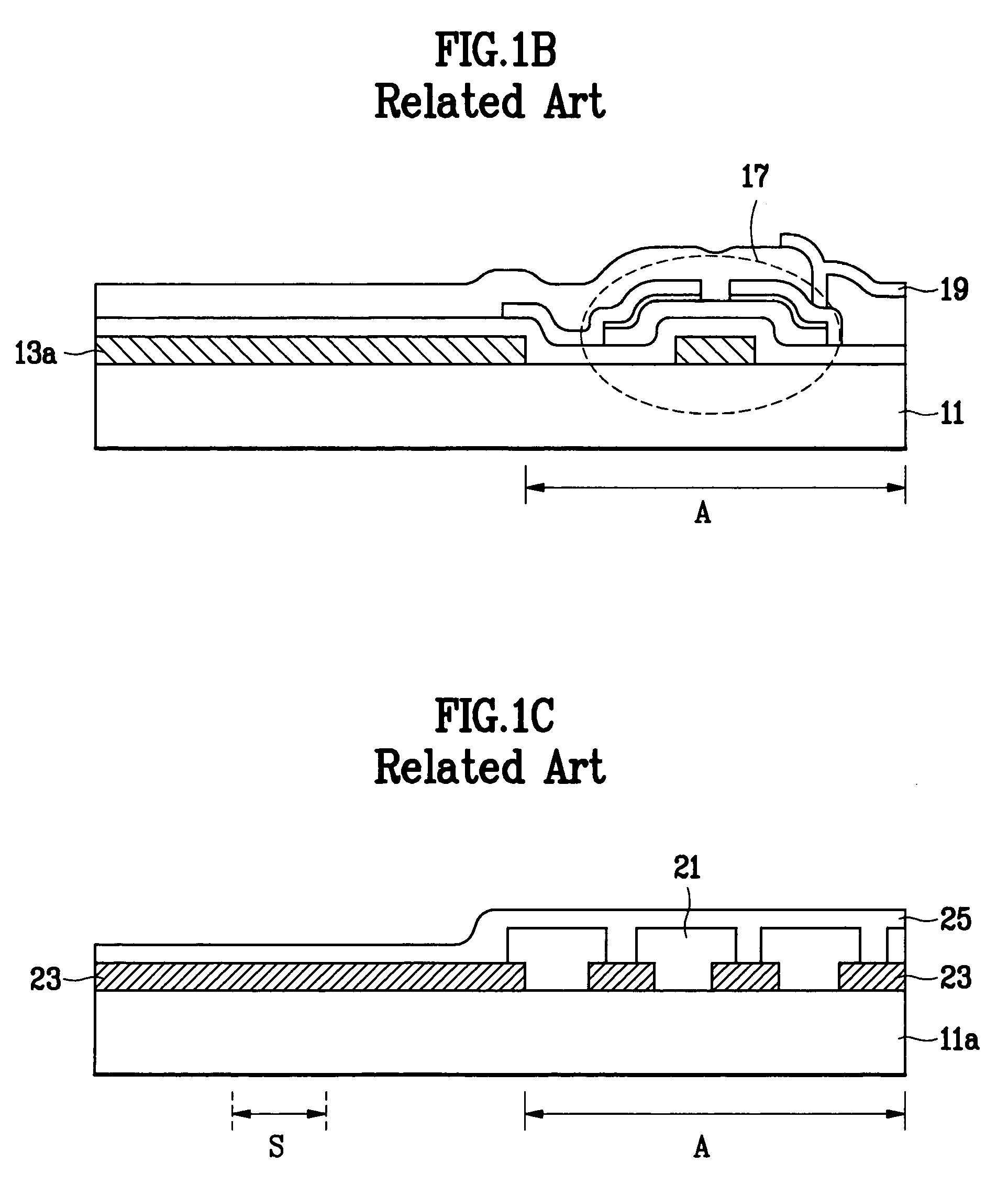

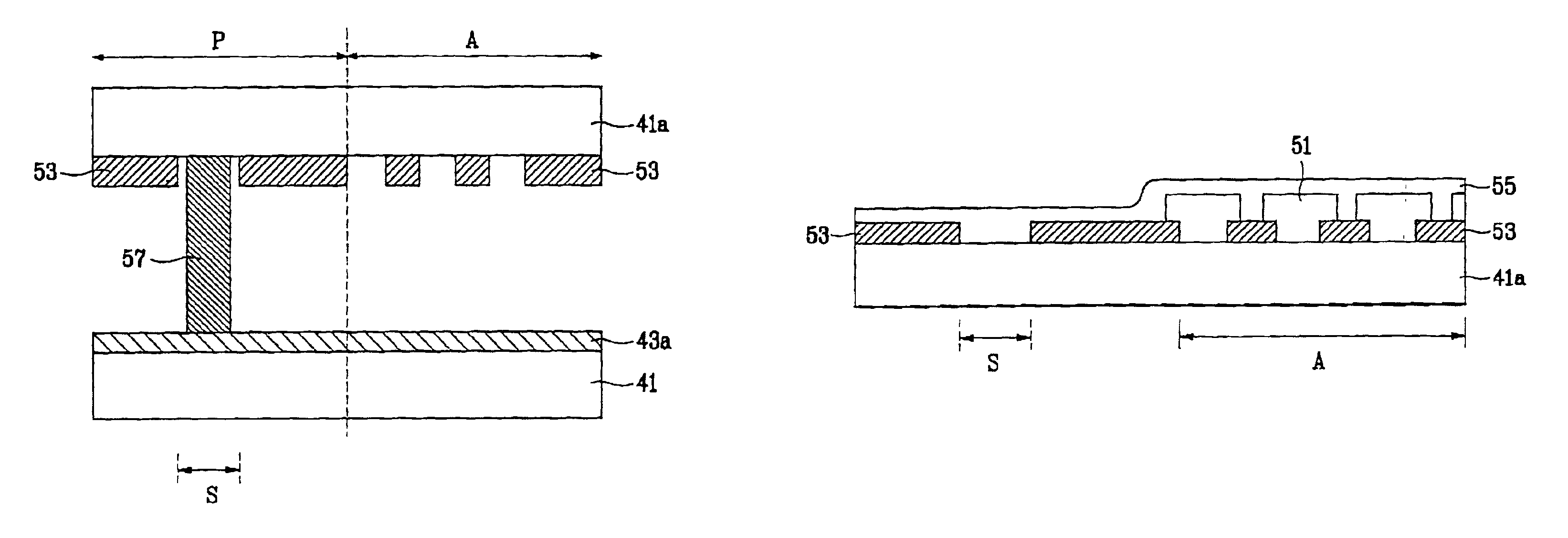

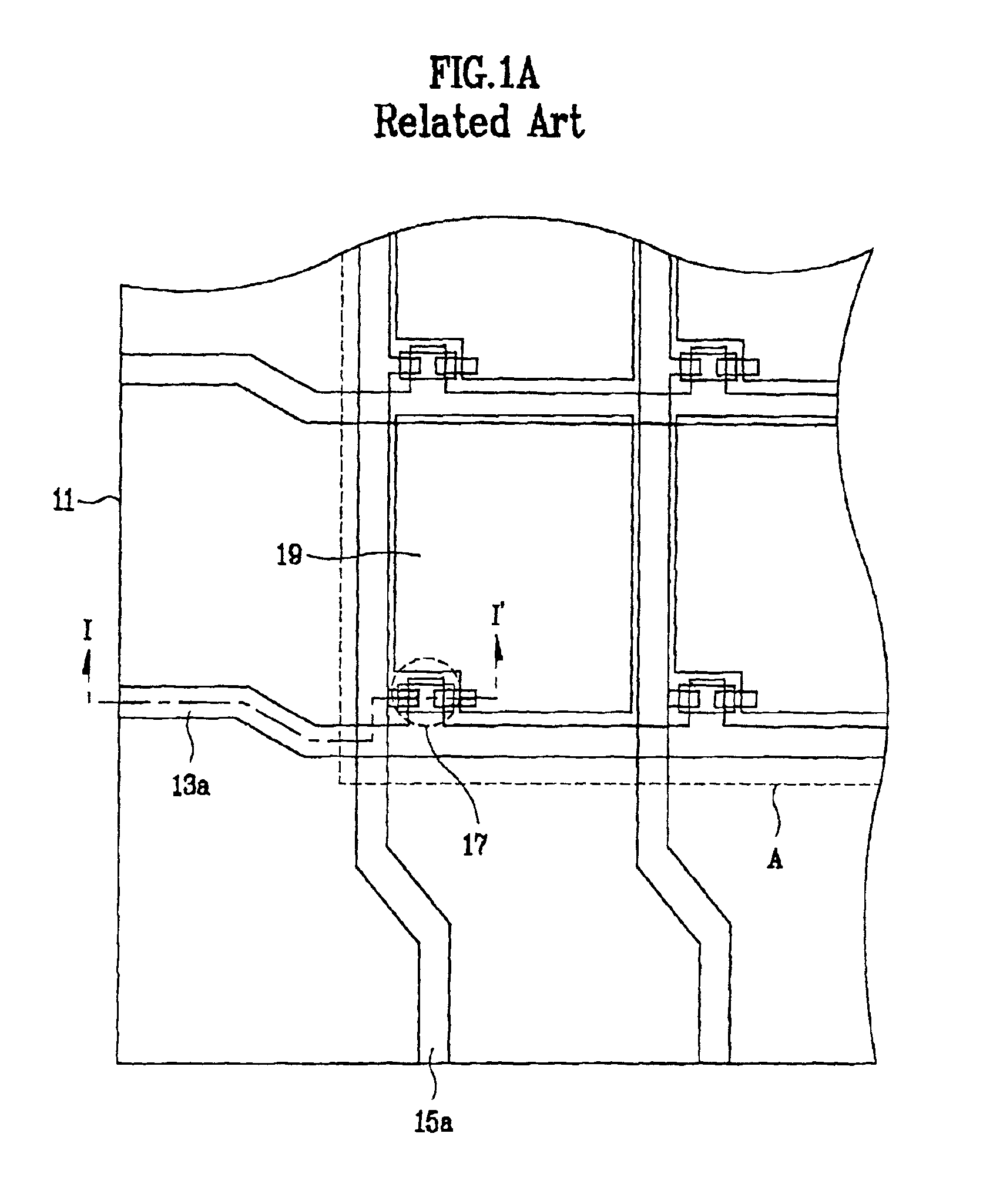

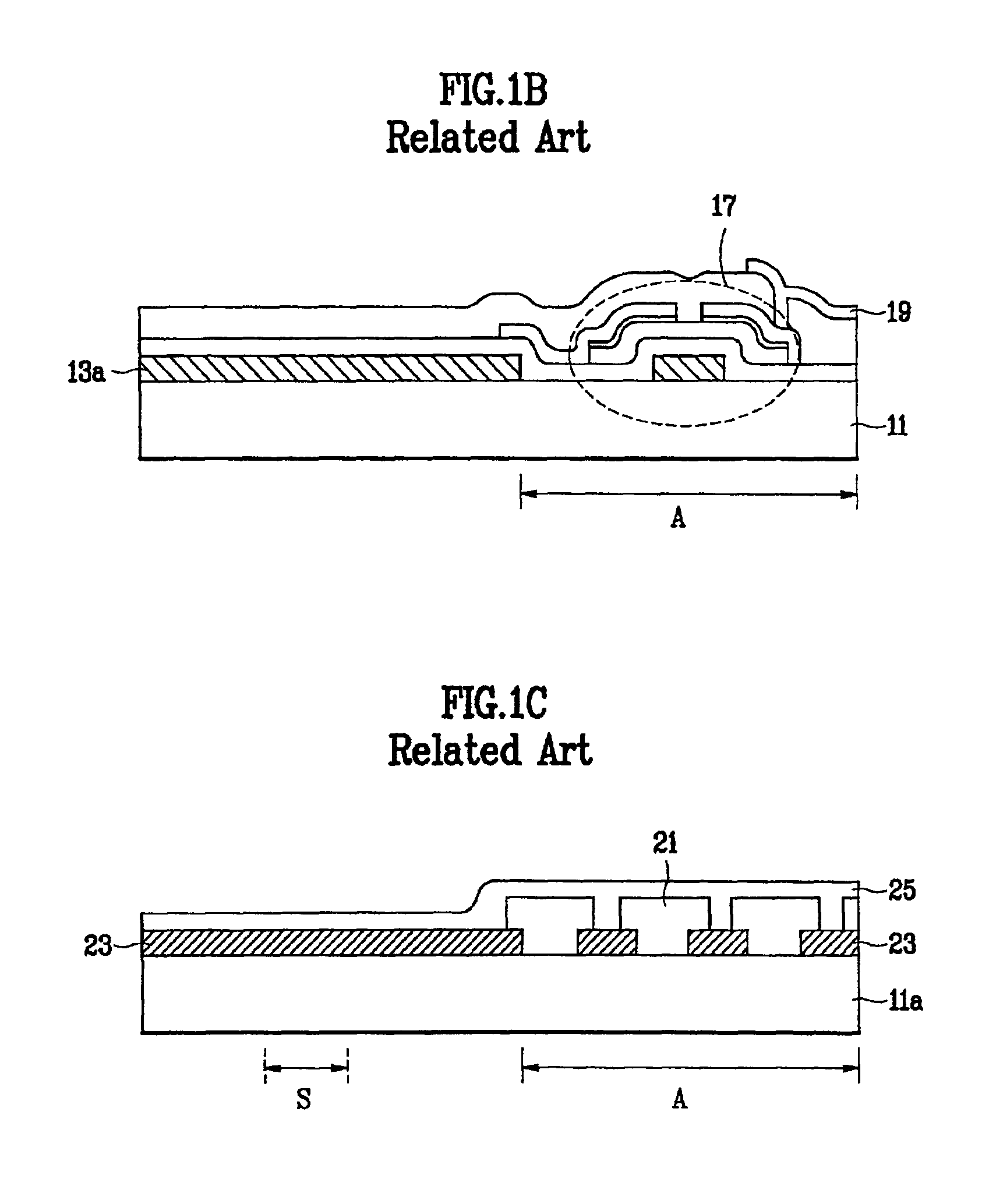

Liquid crystal display panel and method for manufacturing the same

InactiveUS20060028608A1Easy to hardenReliable formingNon-linear opticsLiquid-crystal displayUltraviolet

An LCD panel and a method for manufacturing the same facilitate more efficient hardening a UV-type hardening sealant suitable for a large size panel. The LCD panel includes first and second substrates, an active region defined on the first substrate and provided with a plurality of TFT's and pixel electrodes, a sealing region defined along a periphery of the active region, a light-shielding region defined on the second substrate other than on the sealing region, and a liquid crystal region between the first and second substrates. The method for manufacturing an LCD panel includes the steps of preparing first and second substrates, forming a plurality of patterns in an active region on the first substrate, forming a UV hardening type sealant along a periphery of the active region, forming a light-shielding layer on the second substrate so as not to shield the sealant, attaching the first and second substrates to each other, and irradiating the sealant with UV-rays to harden the sealant.

Owner:LG DISPLAY CO LTD

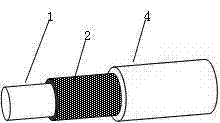

High temperature (150 DEG C) resistant tightly packaged fiber and preparation process thereof

InactiveCN102520477AHigh strengthResistant to bendingOptical fibre with multilayer core/claddingFibre mechanical structuresFiberTetrafluoroethylene

The invention discloses a high temperature (150 DEG C) resistant tightly packaged fiber and a preparation process thereof. The fiber is characterized in that: the periphery of a fiber core is provided with a coating layer which is coated by ultraviolet curing acrylate; and the periphery of the coating layer is provided with a tightly packaged outer layer made of an ethylene-tetrafluoroethylene (ETFE) copolymer. According to the preparation process, the fiber core of the fiber is divided into a single mode fiber core and a multimode fiber core, a single mode structure has 9 / 125 mu m and a multimode structure has 50 / 125 mu m or 62.5 / 125 mu m; the coating layer is coated with the ultraviolet curing acrylate, and has the outer diameter of 250 mu m; and the tightly packaged layer is prepared by extruding the high-temperature ETFE copolymer through a single-layer or double-layer thin wall of a high-temperature extruding machine. The invention has the advantages that: the fiber resists high and low temperature ranging from 65 DEG C below zero to 150 DEG C, and a tightly packaged inner layer and the tightly packaged outer layer resist high temperature of 150 DEG C; and the fiber has the characteristics of high strength, bending resistance, impact resistance, ageing resistance, long service life, corrosion resistance, flame retardancy and the like, can provide high-reliability service in a severe environment, and is suitable for high-speed signal transmission under aerospace, electronic and onboard special environmental conditions.

Owner:NANJING QUANXIN CABLE TECH

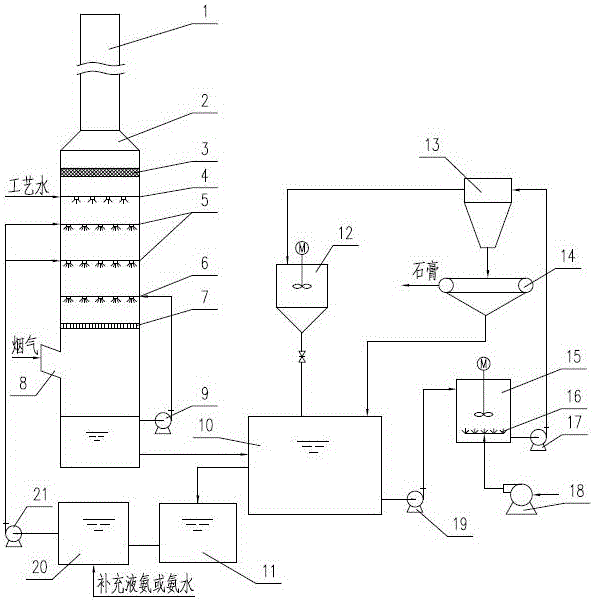

Desulphurization device and method capable of realizing cyclic utilization of ammonia water

InactiveCN106178896ALow priceImprove performanceGas treatmentDispersed particle separationFlue gasProduct gas

The invention discloses a desulphurization device and method capable of realizing cyclic utilization of ammonia water. The desulphurization device comprises a desulphurization tower with a flue gas inlet and a chimney. A defogging layer, a washing layer, an absorbing and spraying layer and a gas distributor are arranged inside the desulphurization tower in sequence from top to bottom. An ammonia gas regeneration system is arranged outside the desulphurization tower, and comprises a regeneration tank connected with the bottom of the desulphurization tower. An oxidation tank is connected with the bottom of the regeneration tank through a thick slurry pipeline. A vortex concentrator is connected with the bottom of the oxidation tank. A digestion tank is connected with the upper part of the vortex concentrator through an overflow pipe, and is led into the regeneration tank. A drying machine is connected with the bottom of the vortex concentrator. A liquid filtering hole in the bottom of the drying machine is connected with the regeneration tank. A sedimentation tank is connected onto the regeneration tank, and is connected with a recirculating tank through a pipeline. The recirculating tank is led into the absorbing and spraying layer. The desulphurization device and method can realize cyclic utilization of ammonia water as an absorbent, so that the operation cost of ammonia desulfurization is reduced greatly.

Owner:JIANGSU SUNPOWER TECH

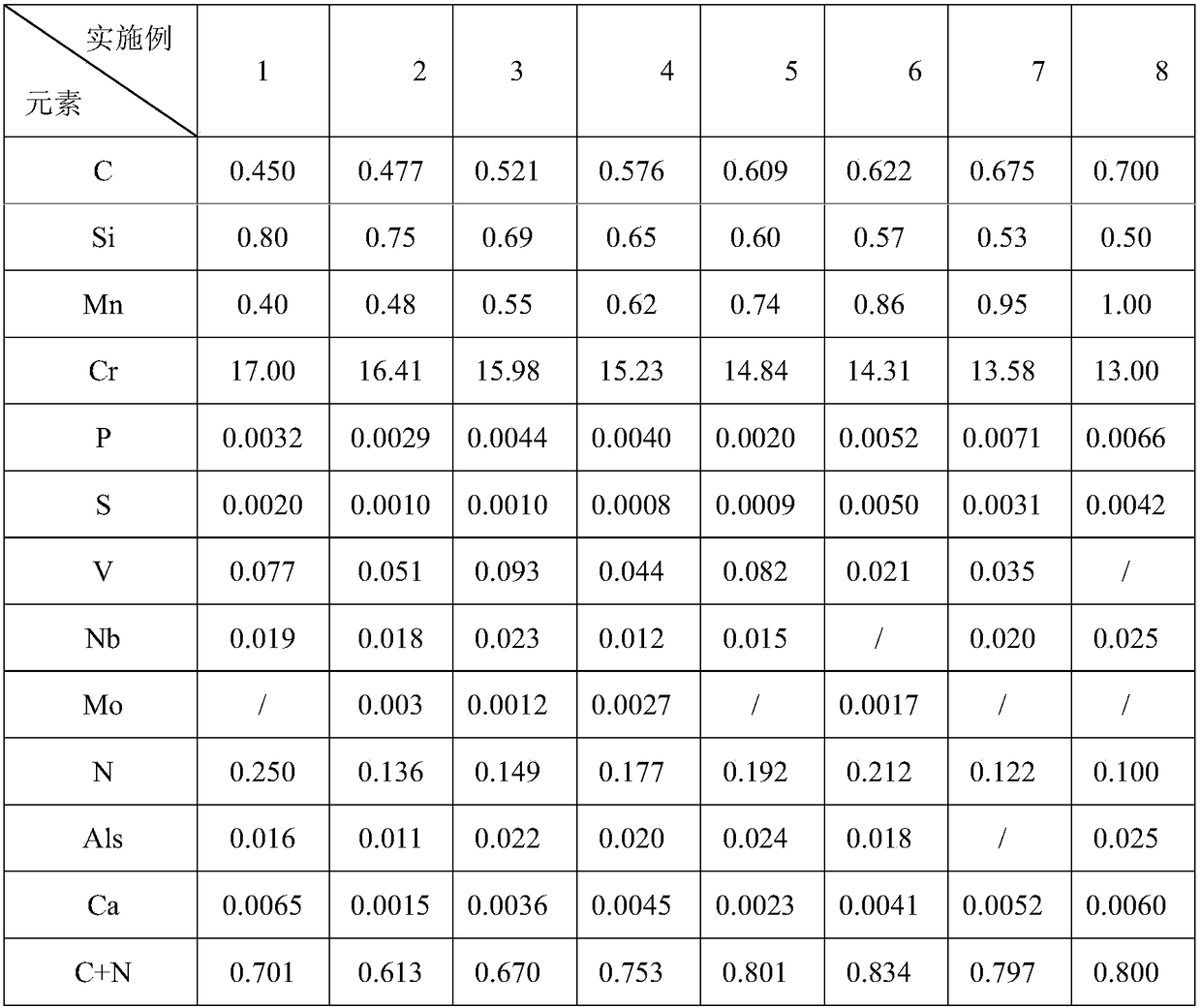

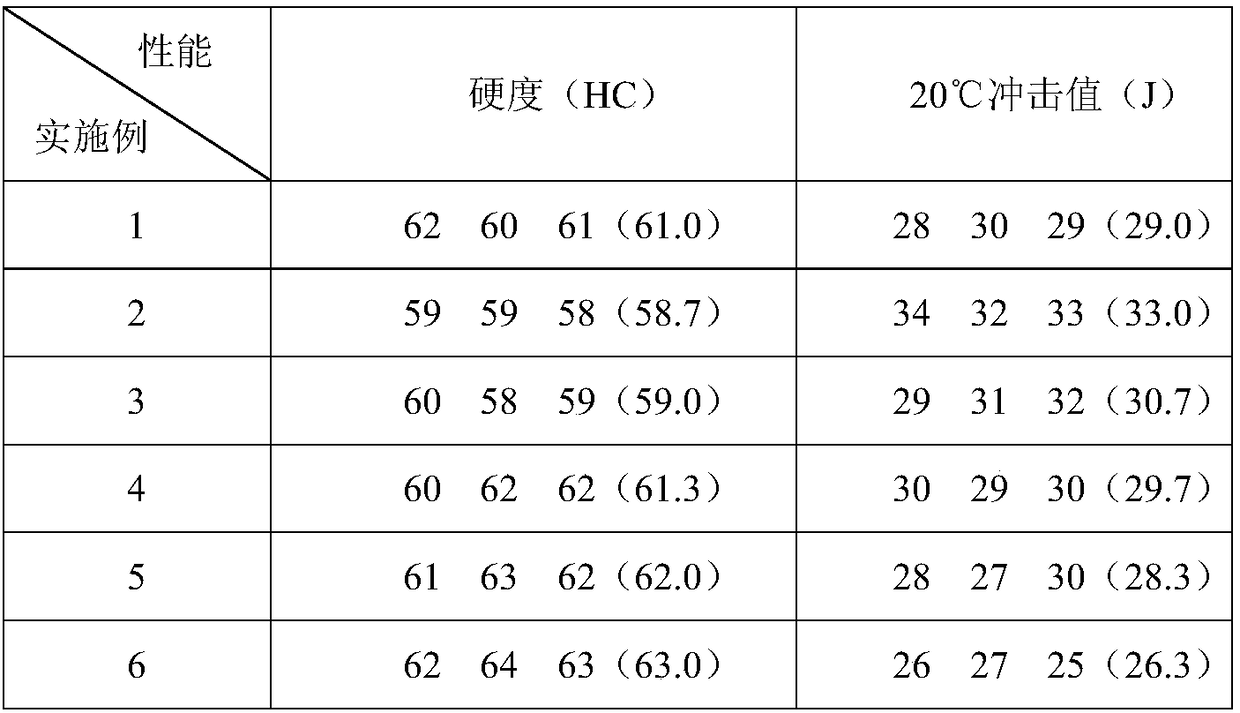

Nitrogen containing martensitic stainless steel for cutting tool and manufacturing method of nitrogen containing martensitic stainless steel

InactiveCN108277432AImprove corrosion resistanceImprove plasticityMartensitic stainless steelNitrogen

The invention relates to nitrogen containing martensitic stainless steel for a cutting tool and a manufacturing method of the nitrogen containing martensitic stainless steel. According to the technical scheme, chemical components of the nitrogen containing martensitic stainless steel for the cutting tool comprise 0.45wt%-0.70wt% of C, 13.0 wt%-17.0wt% of Cr, 0.10wt%-0.25wt% of N, 0.50wt%-0.80wt% of Si, 0.40wt%-1.0wt% of Mn, 0.0015wt%-0.0065wt% of Ca, not larger than 0.20wt% of V, not larger than 0.025wt% of Nb, not larger than 0.025wt% of Als, not larger than 0.03wt% of Mo, not larger than 0.008wt% of P, not larger than 0.005wt% of S and the balance Fe and inevitable elements. Meanwhile, the above chemical components meet the condition that C+N is 0.60-0.85wt%. The manufacturing method ofthe nitrogen containing martensitic stainless steel for the cutting tool comprises the steps of vacuum induction smelting, normal-pressure nitrogen increasing, casting, casting blank heating, rolling,quenching and tempering. The nitrogen containing martensitic stainless steel has the advantages that the alloy components are simple, the process is simple and convenient, the production cost is low,and large-scale production is easy. The manufactured nitrogen containing martensitic stainless steel for the cutting tool is high in hardness and good in toughness.

Owner:WUHAN UNIV OF SCI & TECH

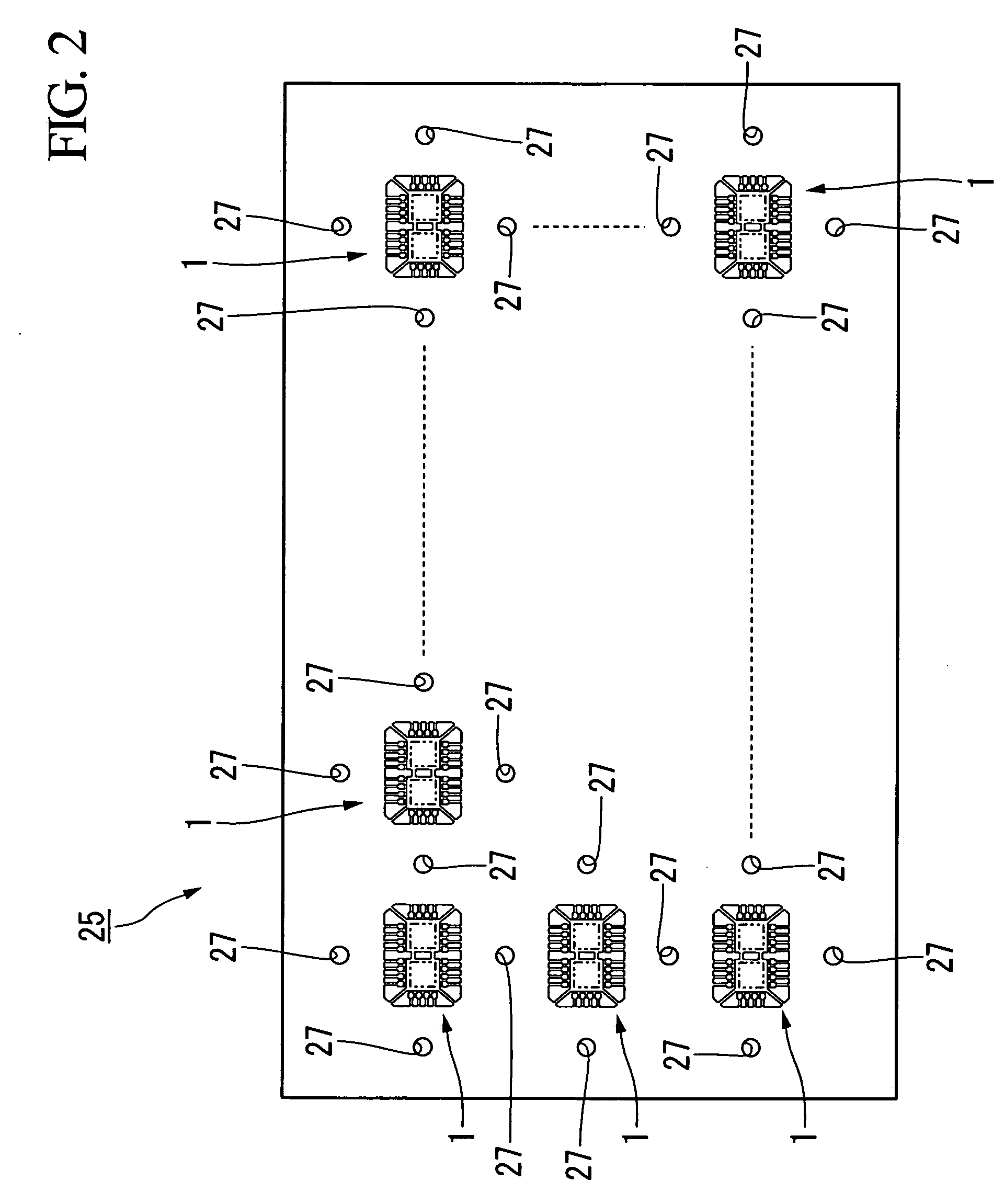

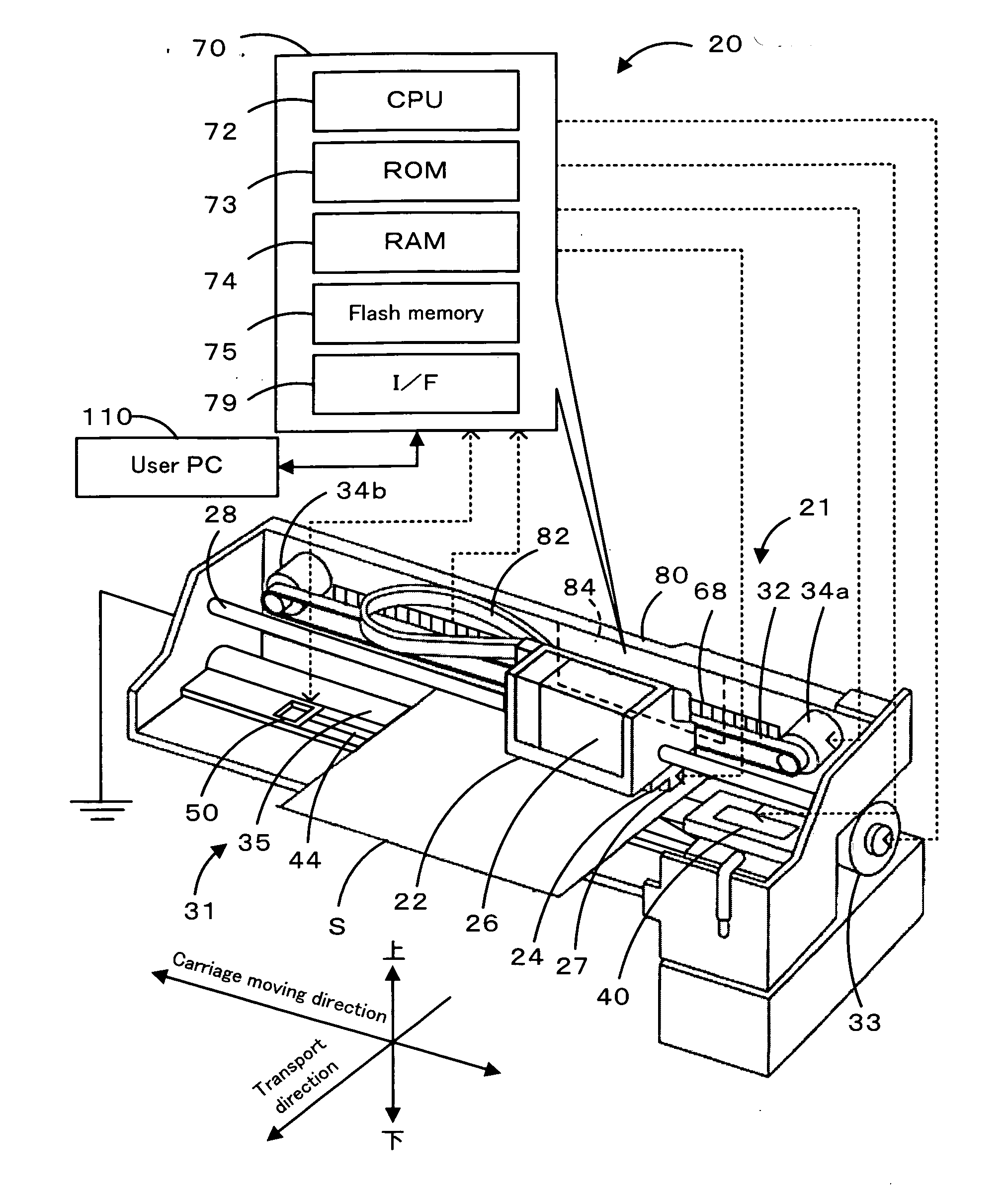

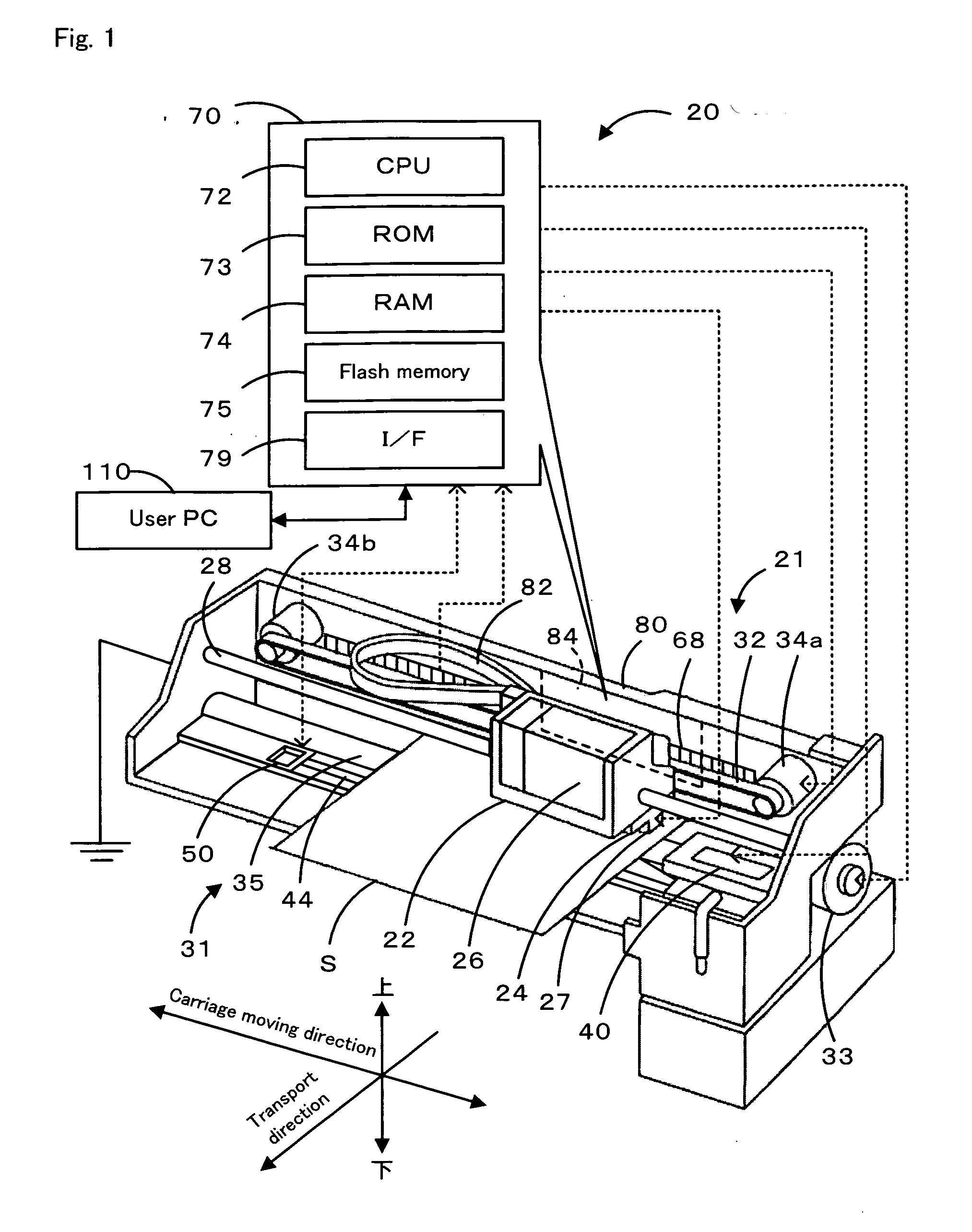

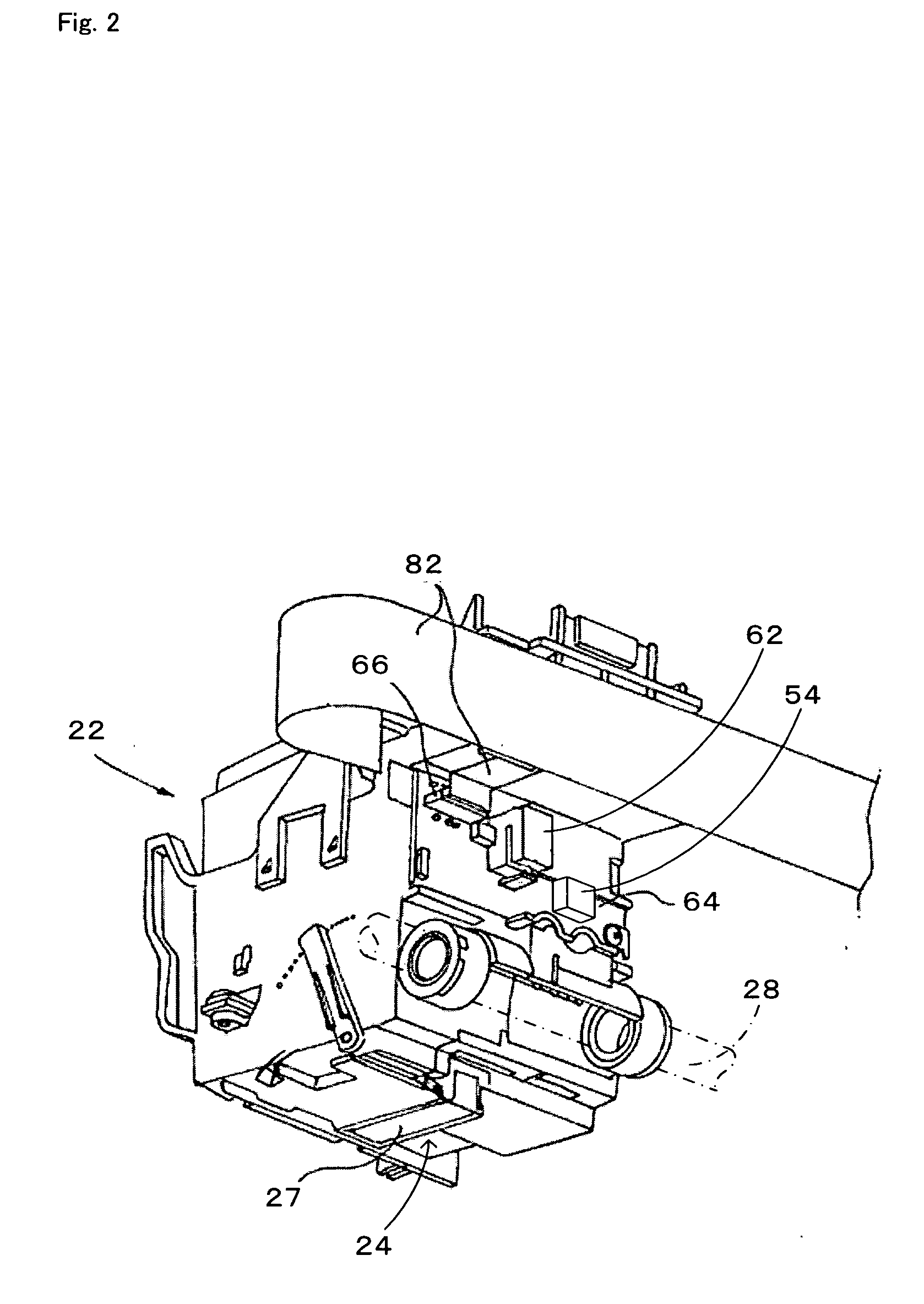

Ink jet recording apparatus, nozzle inspection method and program thereof

InactiveUS20070076029A1Reduce distanceLess susceptible to noiseOther printing apparatusPotential differenceInk printer

In this ink jet printer, on the basis of voltage of a nozzle plate 27 at the time that a print head 24 is driven and in a state in which a predetermined potential difference has been generated between the nozzle plate 27 and the inspection area 52, a nozzle inspection is performed so as to confirm whether or not ink is in practice being ejected from each nozzle 23, so that ink can be sequentially ejected to an inspection area 52 from each nozzle. According to the nozzle inspection voltage change is detected in the nozzle plate 27 by a voltage detection circuit 54 provided on an encoder board 64 on a carriage 22. Since both the nozzle plate 27 and the voltage detection circuit 54 are installed on the carriage 22, and the distance between the two of them is shorter, they are less likely be affected by noise. In addition, there is no need to prepare a new board on which the voltage detection circuit 54 needs to be mounted.

Owner:SEIKO EPSON CORP

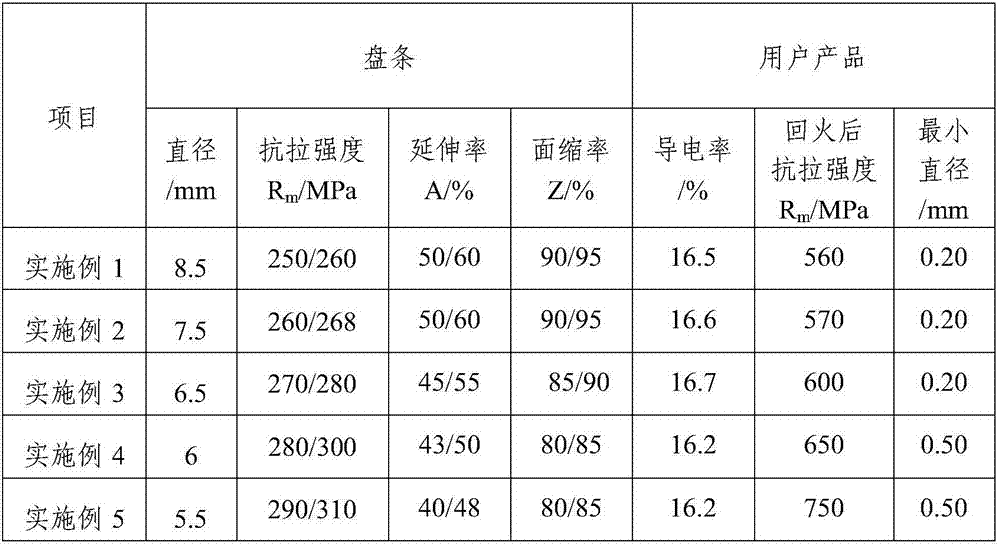

Semi-hard type cable steel and production method thereof

The invention belongs to the technical field of steel for cables and particularly provides semi-hard type cable steel and a production method thereof. The semi-hard type cable steel is prepared from the following chemical components in percentage by mass: smaller than or equal to 0.02 percent of C, smaller than or equal to 0.02 percent of Si, 0.05-0.1 percent of Mn, smaller than or equal to 0.020 percent of P, smaller than or equal to 0.015 percent of S, 0.005-0.01 percent of Als and the balance of Fe and inevitable impurities, wherein the elements satisfy the relationship that Cu+Ni+Cr+Mo is smaller than or equal to 0.030 percent, and Mn / S is larger than or equal to 10. The production method of the semi-hard type cable steel comprises the following steps: molten iron desulphurization, converter smelting, argon blowing, RH furnace treatment, continuous casting, billet heating, high-speed wire rolling and Stelmor controlled cooling. A product prepared by the steel has the tensile strength reaching 560-750Mpa, the electrical conductivity being 16.2 percent or above and good drawing property; and by adopting the production method, through mechanical descaling, pollution of pickling to environment is avoided, operation is simple, and the production requirements are met.

Owner:武汉钢铁有限公司

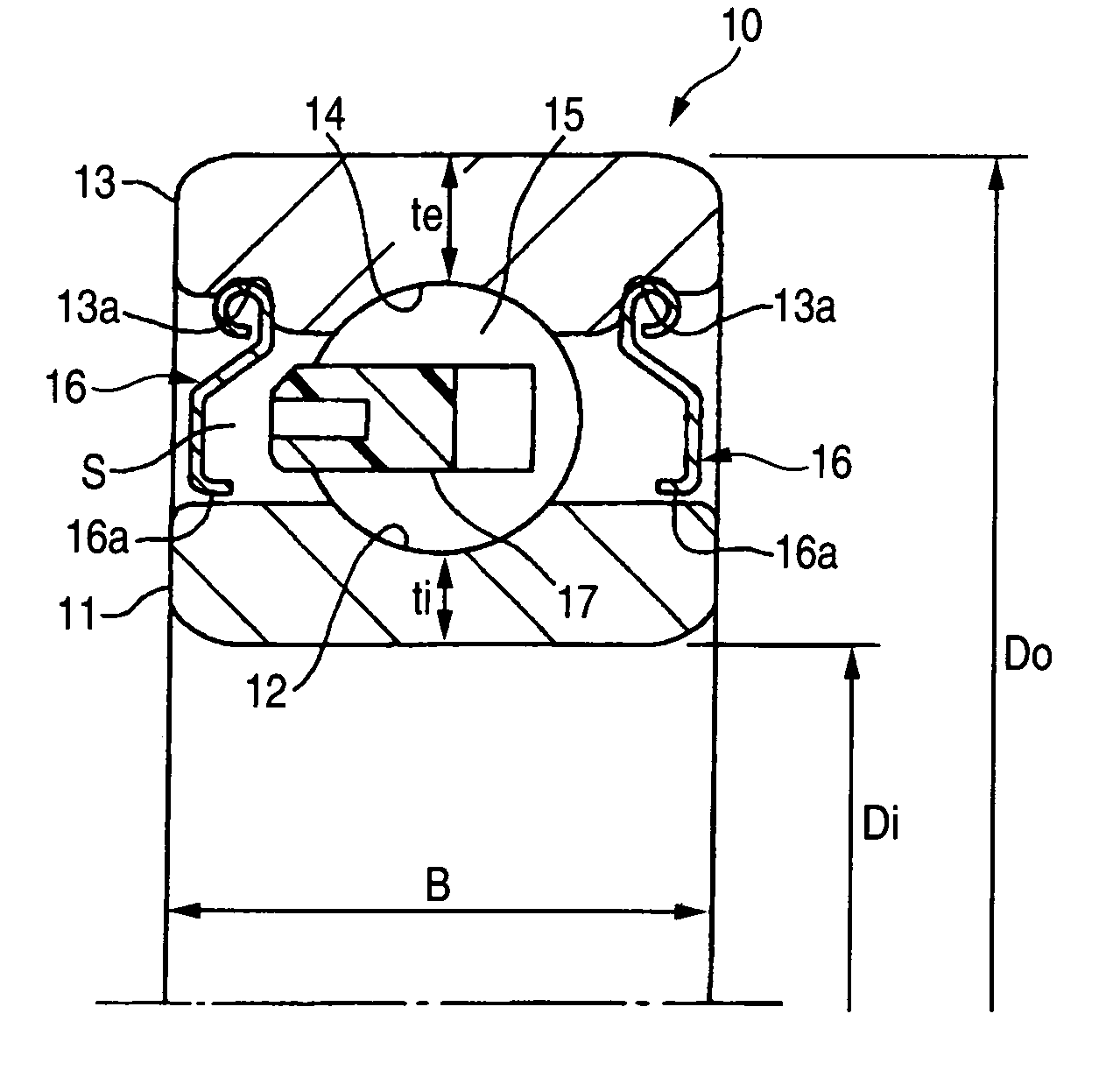

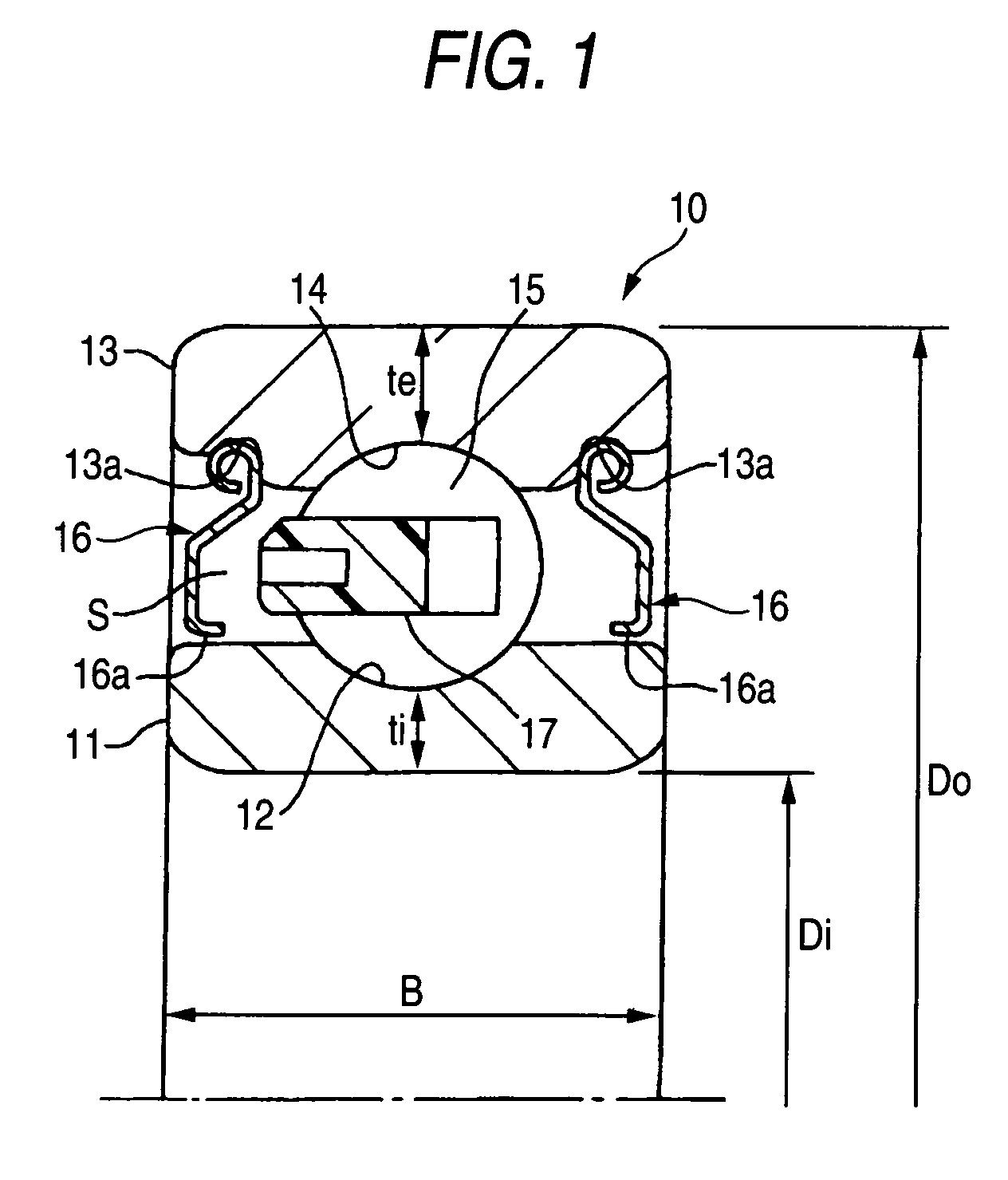

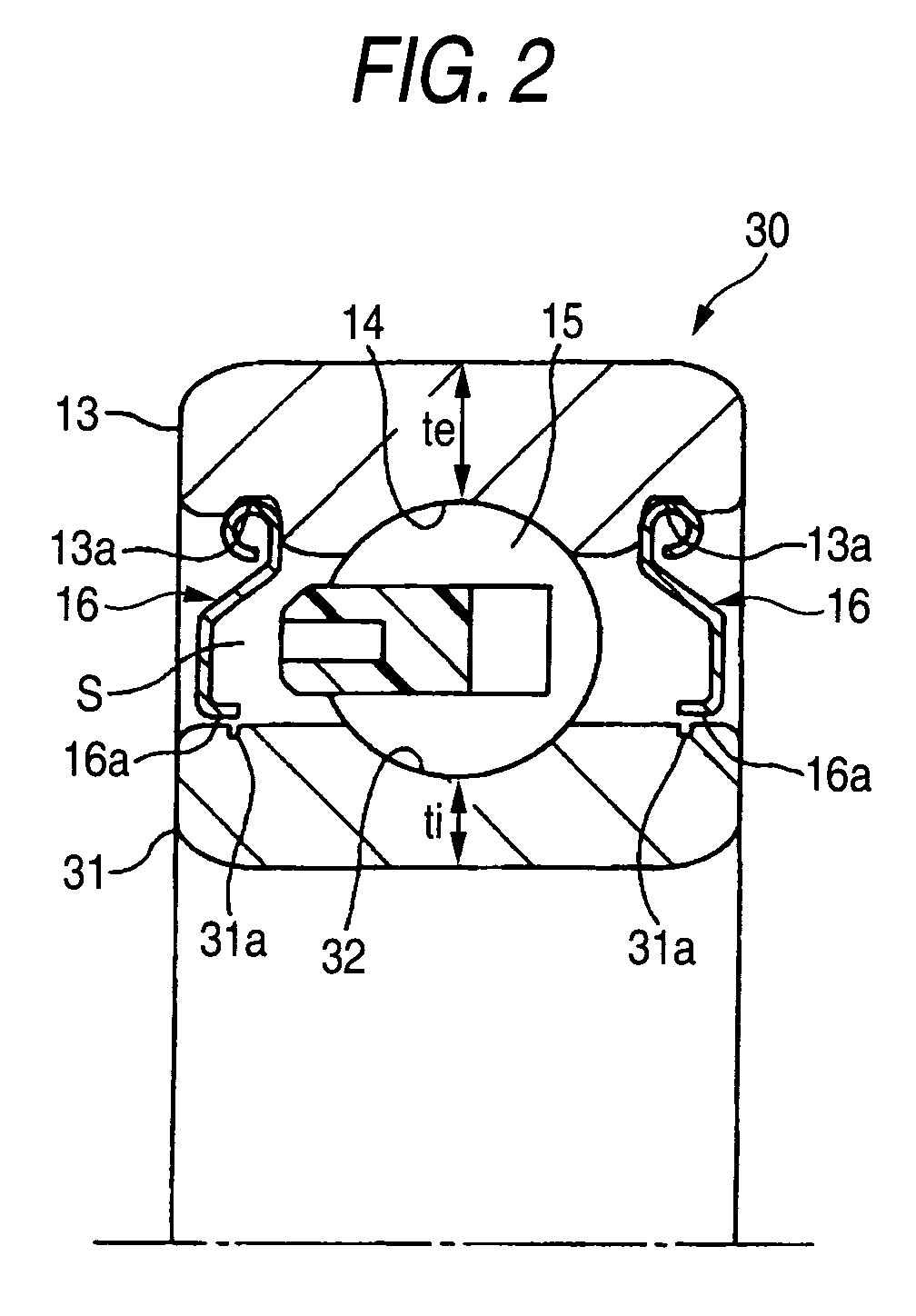

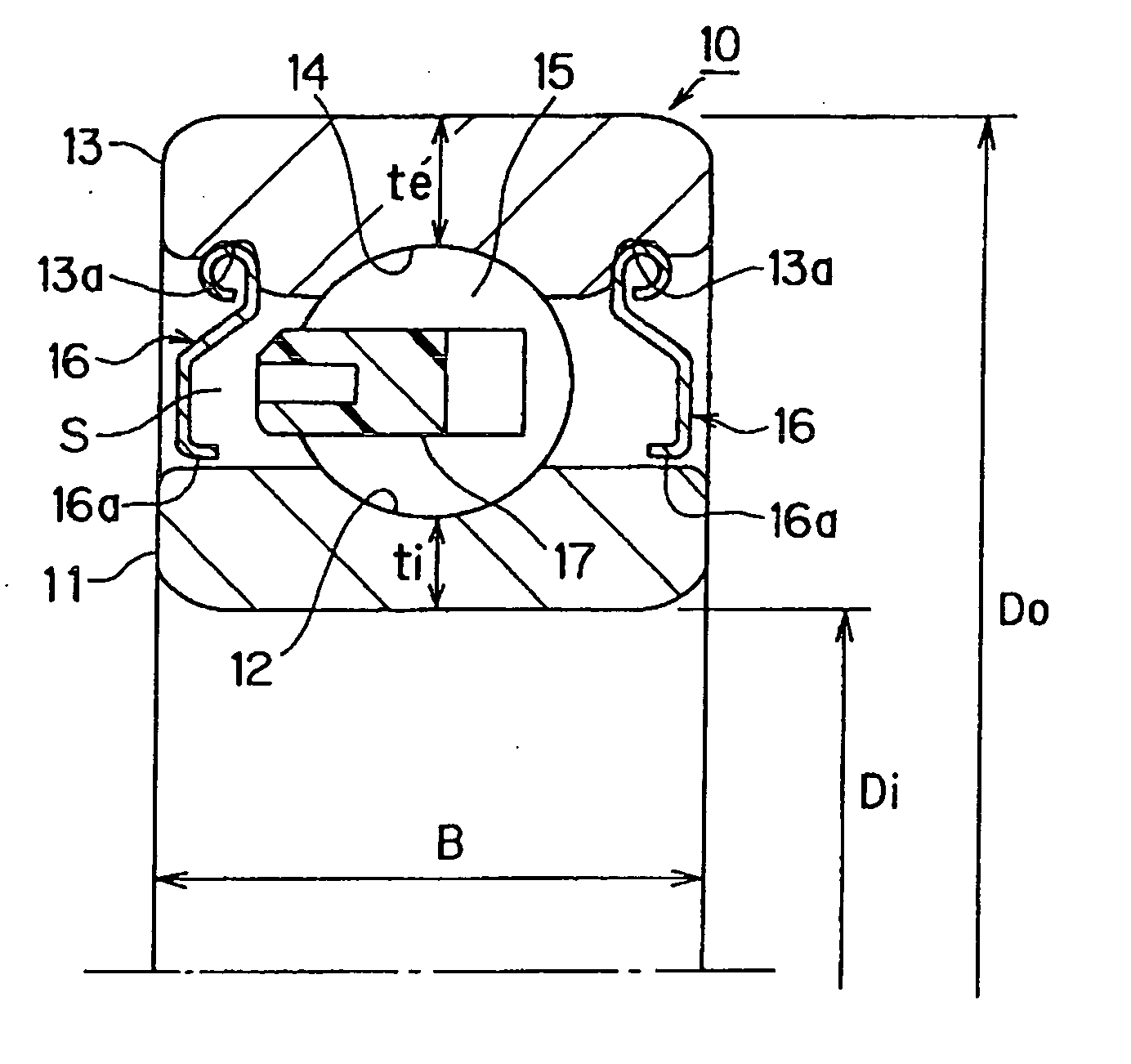

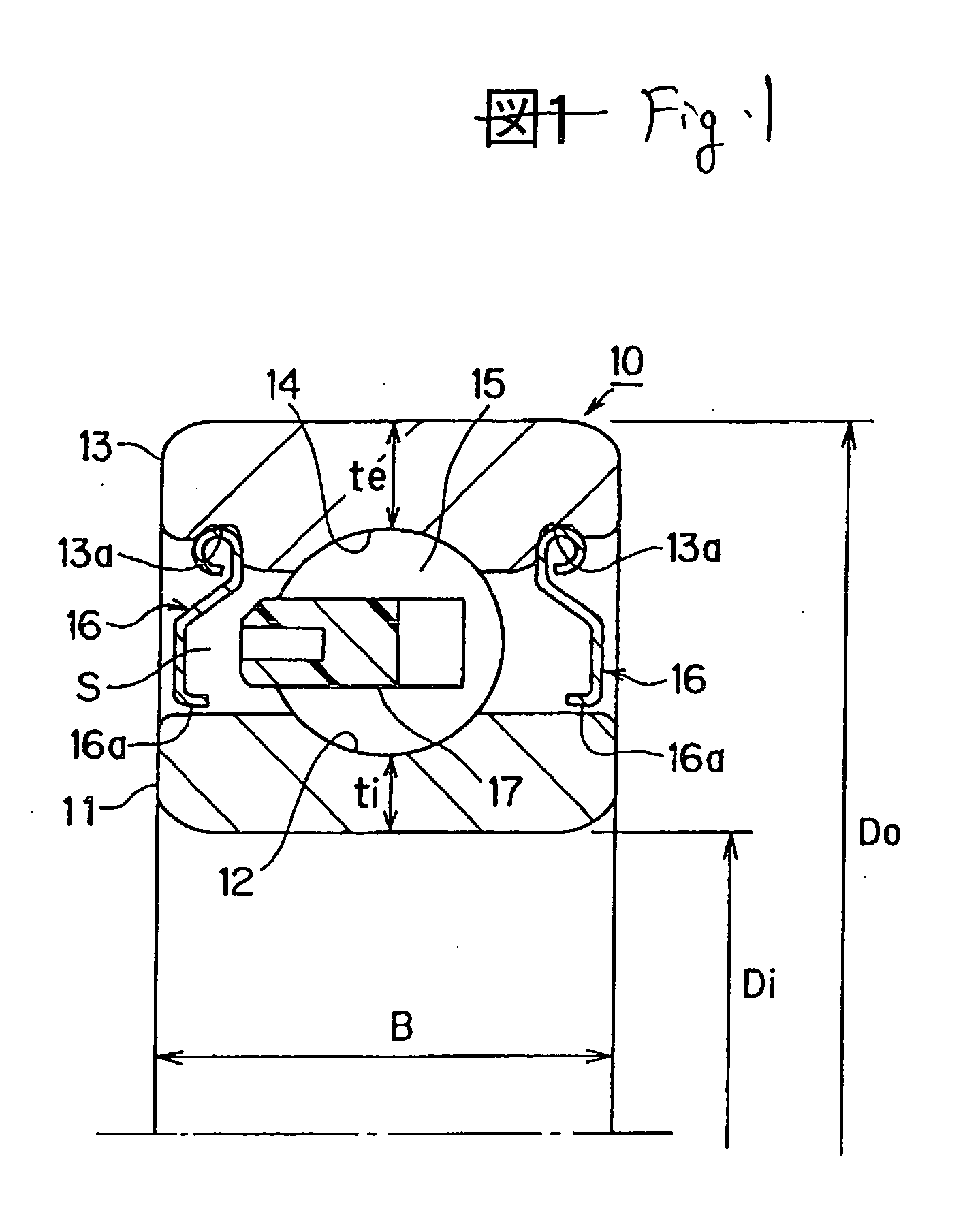

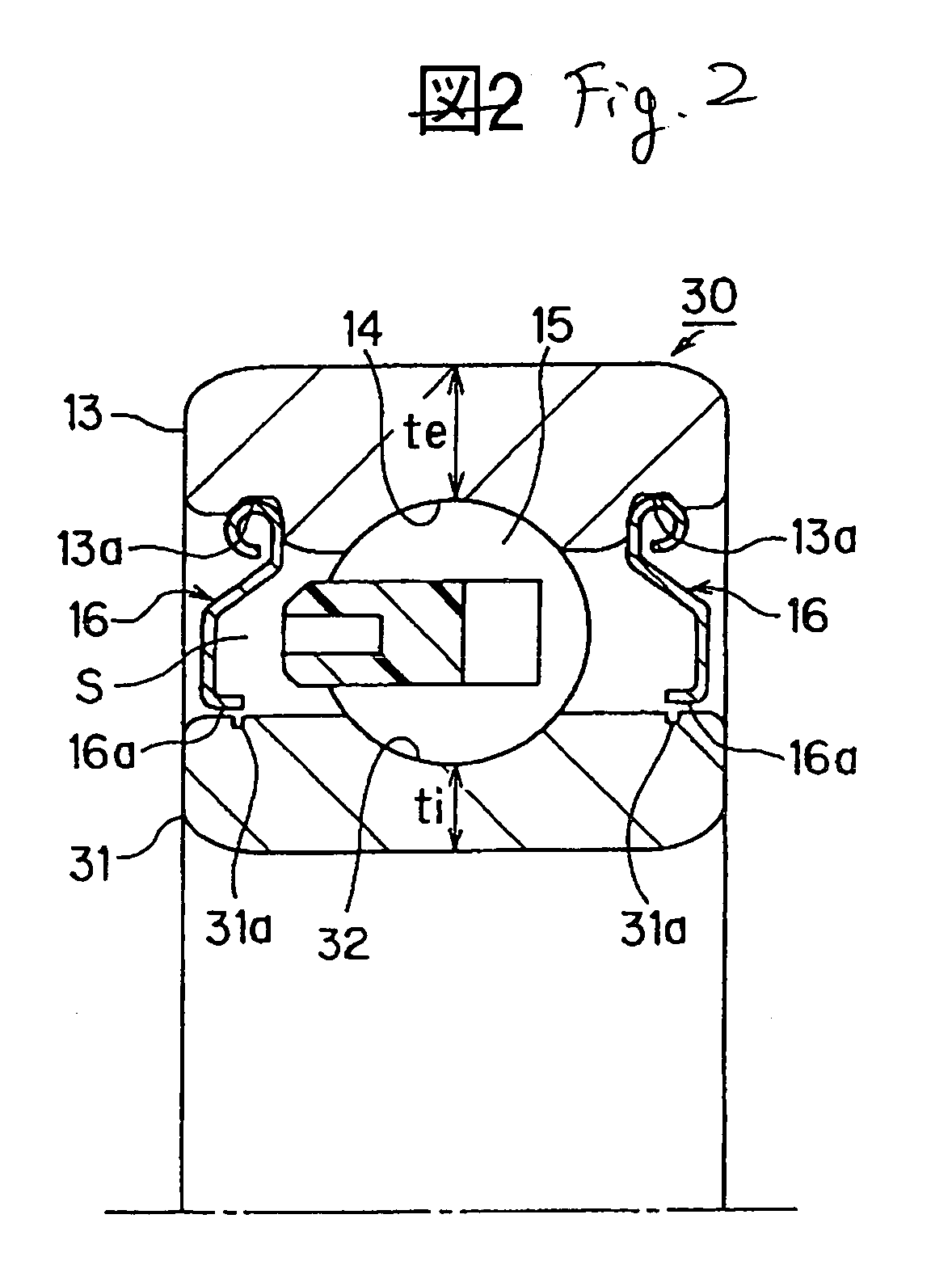

Rolling element bearing and motor

InactiveUS7186029B2Avoid it happening againDeterioration of roundnessShaftsBall bearingsRolling-element bearingEngineering

A rolling bearing for supporting a shaft on which a fan is provided, has an inner ring having an inner ring race on an outer surface thereof, an outer ring having an outer ring race on an inner surface thereof, balls provided between the inner ring race and the outer ring race and a retainer which keeps the balls apart each other in a circumferential direction, wherein an inner diameter of the bearing is set to be 3 mm or more and 17 mm or less, an outer diameter of the bearing is set to be 8 mm or more and 40 mm or less, when a thickness ti and a thickness te satisfies a relationship te≧1.24 ti, and a residual austenite content in the inner ring is 7 wt % or less.

Owner:NSK LTD

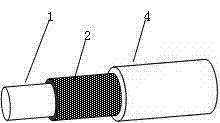

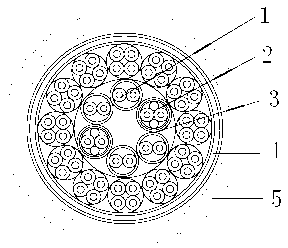

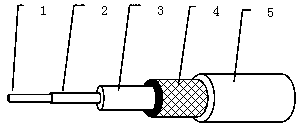

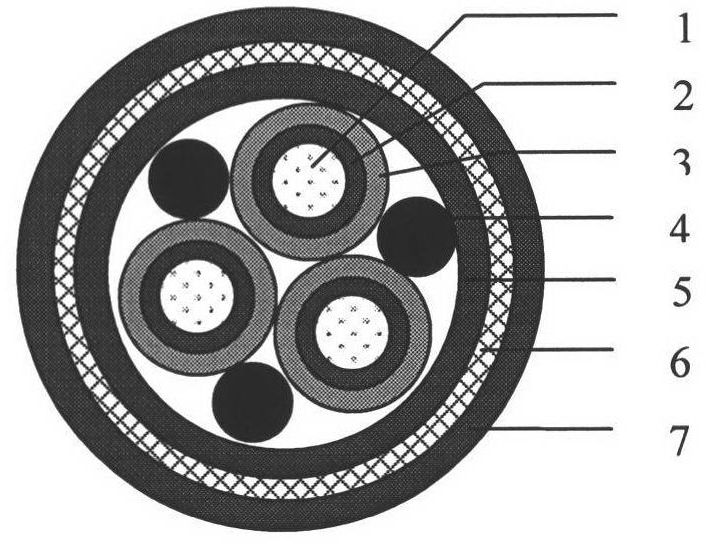

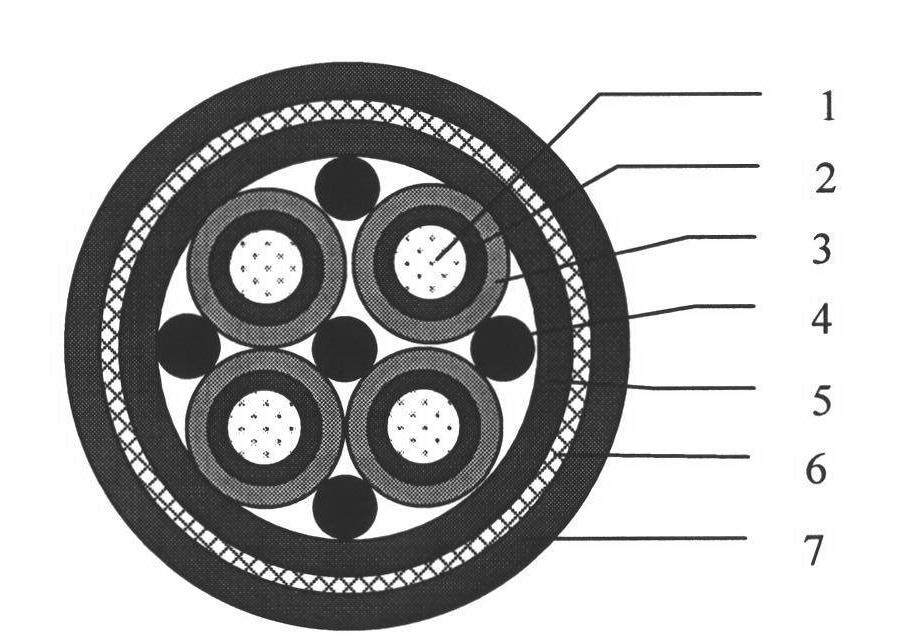

Nuclear electromagnetic pulse resisting cable and manufacturing process thereof

ActiveCN103345969AEasy to hardenSolve problems such as brittle cracksFlexible cablesCable/conductor manufactureElastomerElectrical conductor

The invention relates to a nuclear electromagnetic pulse resisting cable which structurally comprises a conductor, an insulator, a separated shield part, a combined shield part and a protection sleeve. The high-temperature-resisting fluoroplastic insulator extruded by high-temperature extruding equipment is arranged at the periphery of the conductor using a tin-plated round copper stranded wire or a sliver-plate round copper stranded wire, the separated shield part woven by high-weaving tin-plated round copper wires is arranged at the periphery of the high-temperature fluoroplastic insulator, the combined shield part formed by a control line and a data line which are stranded by a cabling machine is positioned at the periphery of the separated shield part, and the low-temperature-resisting elastic protection sleeve extruded by a normal-temperature extruding machine is positioned outs of the combined shield part. Manufacturing process uses a combined method of lapped shield and braided shield and primarily uses 300T conductive cloth lapping materials to substitute metal lapping materials. The nuclear electromagnetic pulse resisting cable has the advantages of resisting to nuclear electromagnetic pulse, being soft, being high in abrasion resistance, preventing mould, resisting to moist, resisting to acid-base corrosion, being capable of keep good data transmission performance in complex electromagnetic environment, being applied to a hydraulic information control system and having the information transmission function in special portions of the hydraulic information control system.

Owner:NANJING QUANXIN CABLE TECH

Liquid crystal display panel and method for manufacturing the same

An LCD panel and a method for manufacturing the same facilitate more efficient hardening a UV-type hardening sealant suitable for a large size panel. The LCD panel includes first and second substrates, an active region defined on the first substrate and provided with a plurality of TFT's and pixel electrodes, a sealing region defined along a periphery of the active region, a light-shielding region defined on the second substrate other than on the sealing region, and a liquid crystal region between the first and second substrates. The method for manufacturing an LCD panel includes the steps of preparing first and second substrates, forming a plurality of patterns in an active region on the first substrate, forming a UV hardening type sealant along a periphery of the active region, forming a light-shielding layer on the second substrate so as not to shield the sealant, attaching the first and second substrates to each other, and irradiating the sealant with UV-rays to harden the sealant.

Owner:LG DISPLAY CO LTD

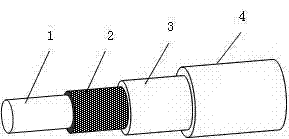

High temperature resistance multimode special optical fiber for aviation and manufacturing method thereof

InactiveCN104049330AHigh strengthWith high and low temperature resistanceFibre mechanical structuresAviationUltraviolet

The invention provides a high temperature resistance multimode special optical fiber for aviation and a manufacturing process of the optical fiber. The optical fiber structurally comprises a fiber core, an ultraviolet curing acrylic ester coating layer, an ethylene tetrafluoroethylene copolymer tight cladding, an aromatic polyamide fiber reinforcing layer and an ethylene tetrafluoroethylene copolymer restrictive coating. According to the manufacturing process, the fiber core of the optical fiber is a multimode, the coating layer is coated through the special ultraviolet curing acrylic ester, and the temperature of which the coating layer can withstand ranges from -55 DEG C to +125 DEG C. The outer diameter of the coating layer is 245 micron. According to the tight cladding, a high temperature extrusion molding machine is adopted to extrude out the high temperature ethylene tetrafluoroethylene copolymer in a double-layered mode. The reinforcing layer is knitted through the aromatic polyamide fiber having high tension resistance performance. According to the restrictive coating, the high temperature extrusion molding machine is adopted to extrude out the ethylene tetrafluoroethylene copolymer. The optical fiber has the advantages that the high-low temperature of which the coating layer can withstand ranges from -55 DEG C to +125 DEG C, and the optical fiber is high in intensity, resistant to bending, impact and aging, long in service life, resistant to mucedine, high in flame retardant, capable of providing highly reliable services in the severe environment and suitable for high-speed signal transmission under special environmental conditions such as the aerospace or electron or airborne environment.

Owner:NANJING QUANXIN CABLE TECH

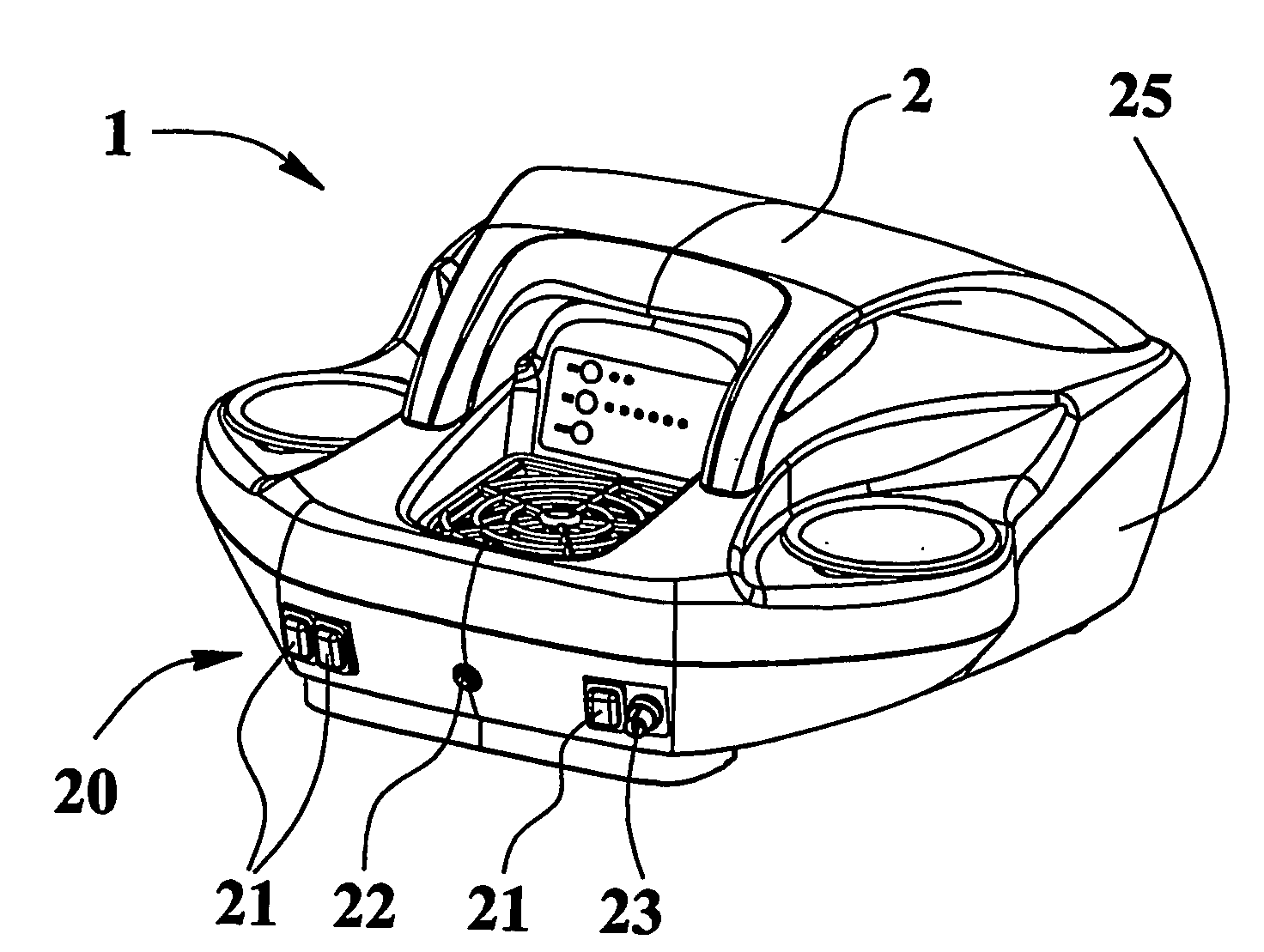

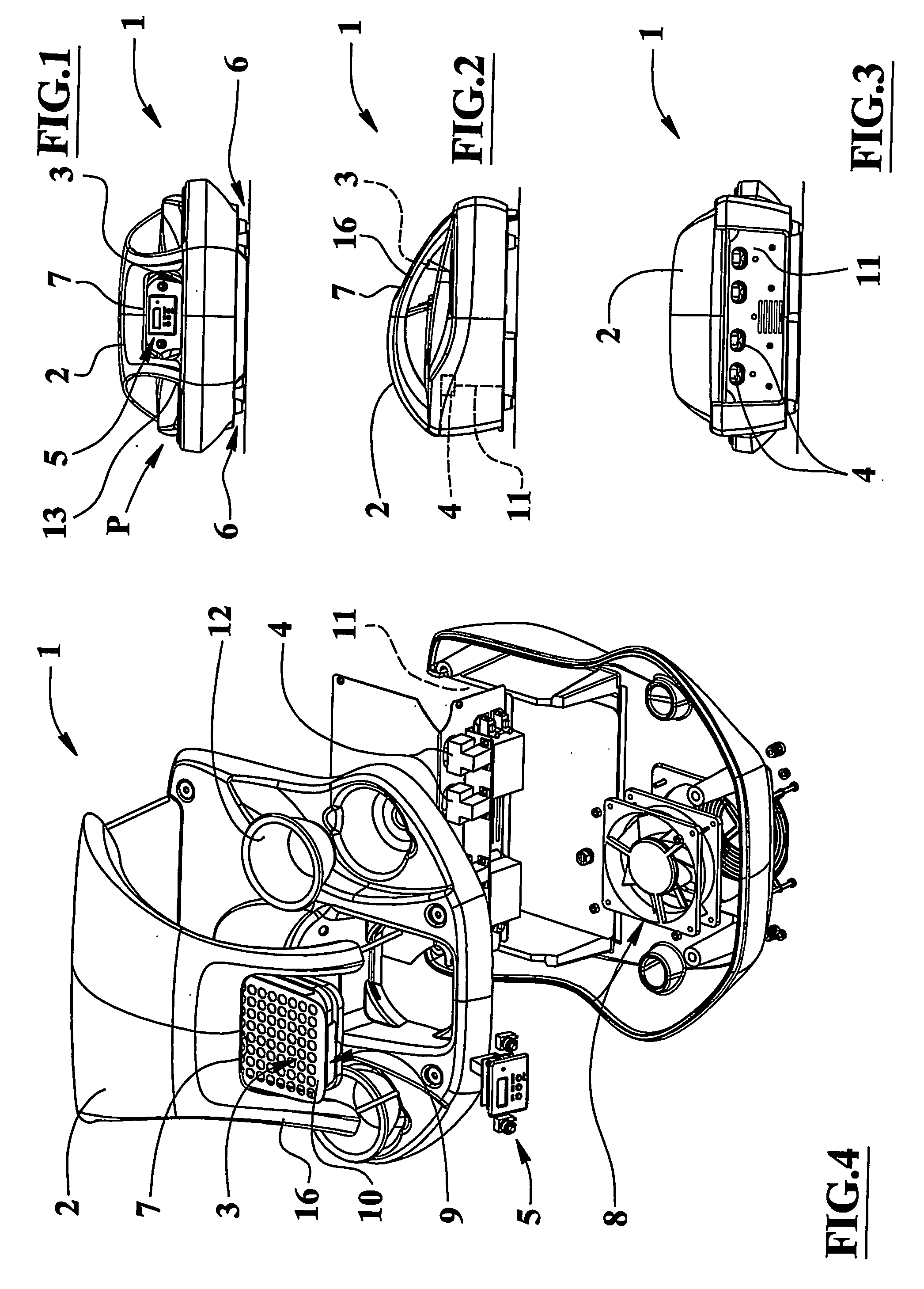

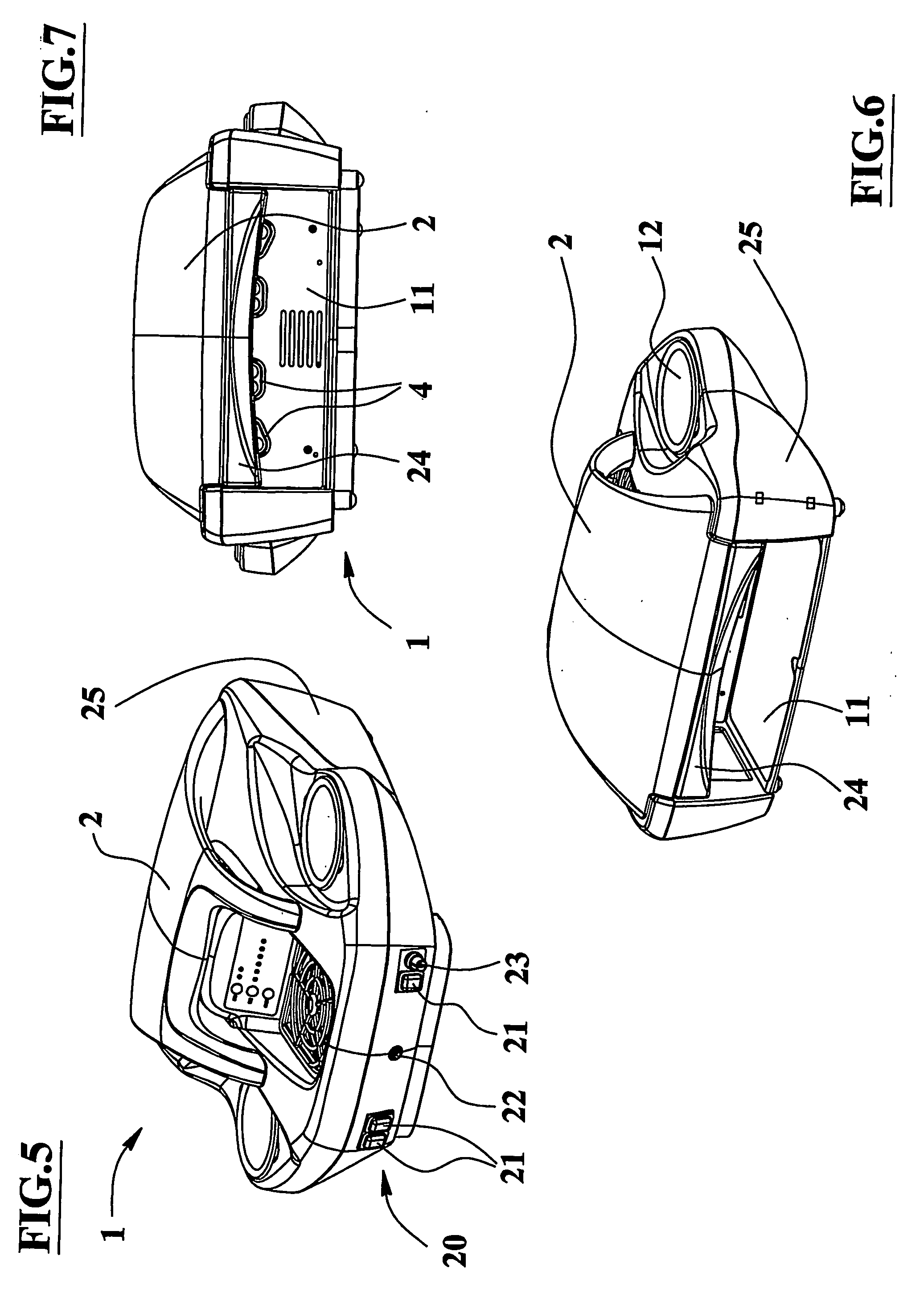

Device for beauty treatment of limbs

A device for beauty treatment of limbs includes at least: a first support (2) for at least one limb portion fit for allowing an operator to operate on said portion by using tools, products and material; aspirator means (3) fit to suck air with powders and / or vapors of products used for the beauty treatment of limbs and fit to reintroduce the purified air in the environment; a set of lamps (4) for the treatment of the limb portion or for working on products applied to the limb.

Owner:C M L SRL

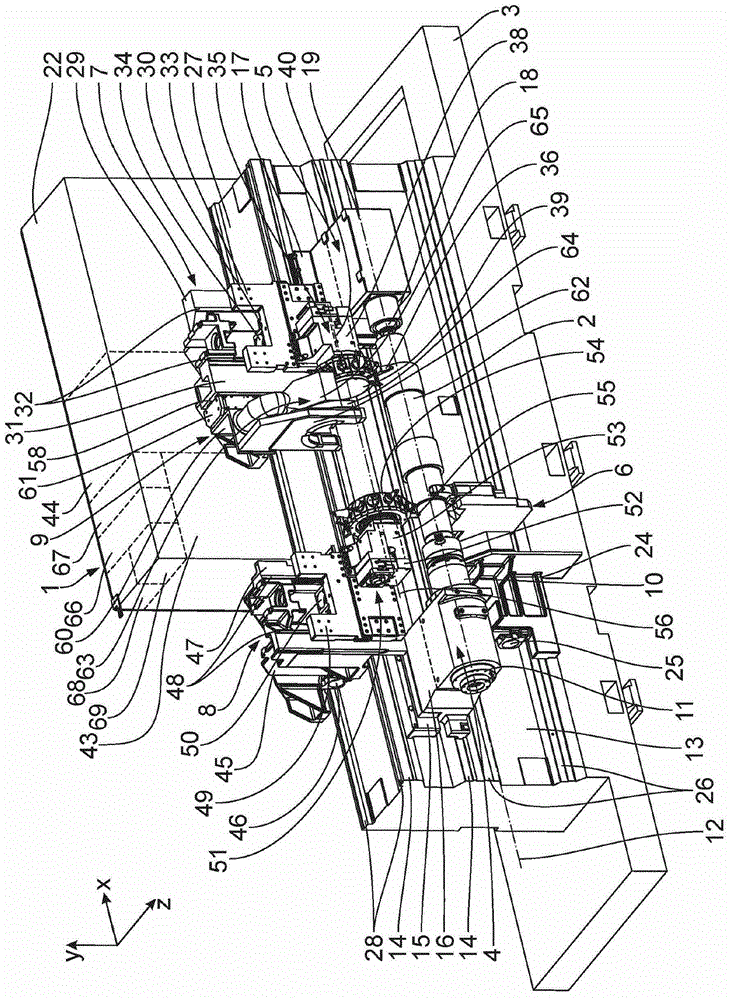

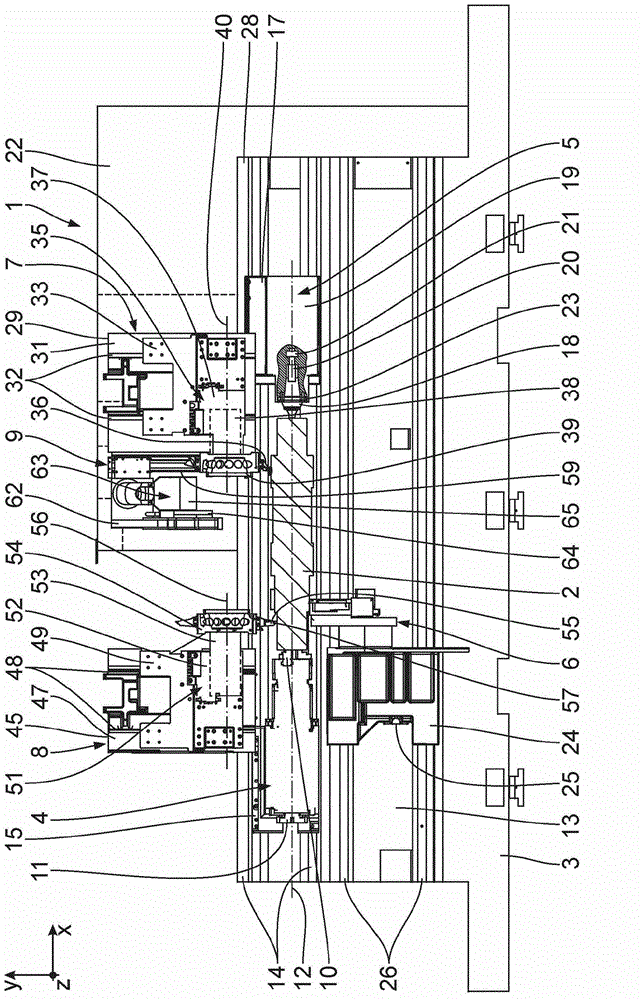

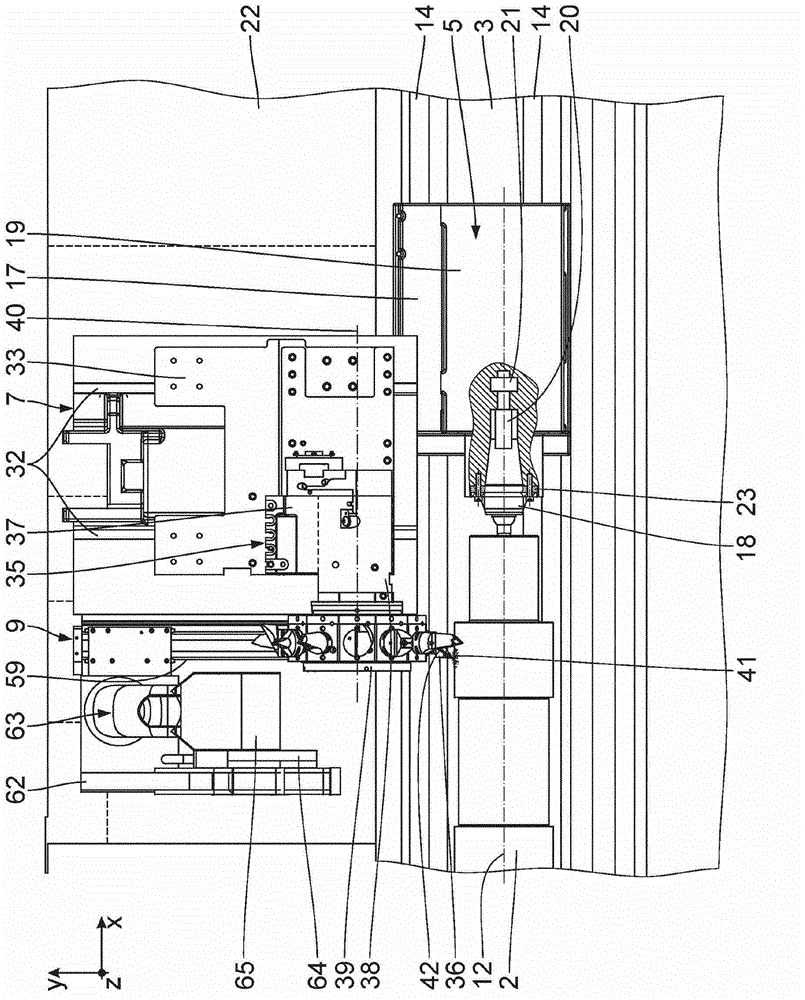

Method and machine tool for machining and hardening metallic workpieces

InactiveCN103338897ARapid quenchingReduce distortionMeasurement/indication equipmentsFurnace typesCycle timeMachine tool

The invention relates to a method and a machine tool (1) for machining and hardening metallic workpieces (2). The workpiece (2), clamped in workpiece holders (4 to 6), is first machined by means of a machining device (7, 8) and subsequently hardened by means of a hardening device (9). The machined workpiece (2) is, for hardening purposes, first heated by means of a heating unit (62) and subsequently quenched by means of a quenching unit (63). The quenching takes place using a cryogenic coolant, such as, for example, liquid or gaseous nitrogen. High machining quality and low machining and cycle times are achieved by machining and hardening the workpiece (2) in a clamp and rapidly quenching the heated workpiece (2).

Owner:5ME IP

Quenching test method of austenite grain size of high-strength ship plate steel

ActiveCN103454188APrevent surface oxidationEasy to hardenPreparing sample for investigationParticle size analysisSteel platesGrinding

The invention provides a quenching test method of austenite grain size of high-strength ship plate steel. The method comprises the following steps: grinding and polishing a ship plate metallographic specimen, placing the metallographic specimen on a steel plate with the test surface being upwards, and uniformly paving and scattering carbon powder on the test surface; placing the steel plate and the metallographic specimen in a 930-940 DEG C heat treatment furnace, heating up to 900-930 DEG C, maintaining the temperature for 1-1.5 hours, and quenching the steel plate and the metallographic specimen into water; grinding and polishing the carbon powder covering surfaces after the steel plate and the metallographic specimen are completely cooled, eroding the steel plate and the metallographic specimen into a 20% picric acid aqueous solution for 1-2 minutes, washing with water and drying the steel plate and the metallographic specimen, observing the austenite grain morphology under a metallographic microscope, and grading the grain size. According to the quenching test method provided by the invention, the steel matrix surface is prevented from being oxidized, the formation of a hardening layer on the steel sample surface is promoted, so that the austenite grain morphology of the steel is easily and completely shown so as to provide good microstructure morphology for accurately evaluating the grade of the austenite grain size of the steel, the energy consumption can be reduced, the corrosive material is saved, the test period is shortened and the inspection efficiency is improved.

Owner:ANGANG STEEL CO LTD

Efficient environment-friendly water flush fertilizer

InactiveCN104557237APromote growthImprove drought resistanceUrea compound fertilisersFertilizer mixturesBoraxNutrient

The invention discloses an efficient environment-friendly water flush fertilizer which is characterized in that the water flush fertilizer comprises components in percentage by weight as follows: 3%-5% of plant protein powder, 3%-5% of compound bacteria, 3%-5% of compound enzyme, 10%-20% of alkaline process and ammonium sulfite process mixed concentrated black liquor, 15%-25% of soluble phosphate fertilizer, 10%-20% of soluble potash fertilizer, 20%-30% of urea, 10%-20% of sodium humate, 8%-10% of an amino acid solution, 6%-9% of a compound nutrition conditioning agent, 3%-5% of borax, 5%-10% of microelement fertilizer, 5%-10% of medical stone powder and 0.2%-0.3% of a synergist. The synergist increases the absorption capability of water and fertilizer, crop growth is promoted, and the drought resisting capability of crops is improved; after compound sodium nitrophenolate and plant are contacted, the nutrition element absorption capability and the disease-resistant effect of plants can be improved; two types of straw pulp black liquor are comprehensively treated, acid is not added, and the cost is reduced; the efficient environment-friendly water flush fertilizer has comprehensive nutrition elements, has high fertilizer efficiency and facilitates yield increase of the crops, and nutrients are easy to assimilate.

Owner:SHANDONG ENBAO BIOTECH

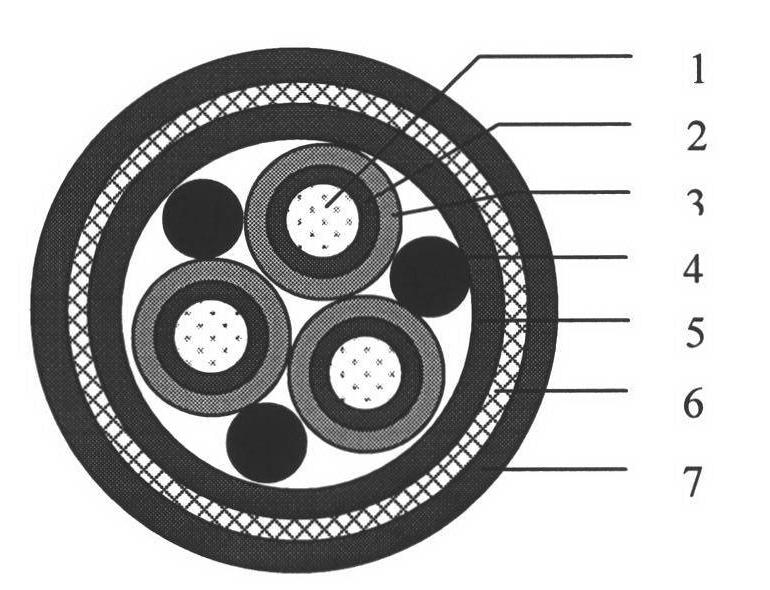

Walking power cable and preparation method thereof

ActiveCN102097177AGood flexibilityHigh tensile strengthBraided wire conductorsPower cables with screens/conductive layersFiberElectrical conductor

The invention provides a walking power cable and a preparation method thereof. The cable is characterized in that an insulating layer is arranged on the outer layer of each combined conductor and is formed by stranding a plurality of insulated cores; filling cores are arranged between two insulating layers and an inner sheath; a tensile layer is arranged on the outer layer of the inner sheath; and an outer sheath is arranged on the outer layer of the tensile layer. The preparation method is characterized in that tinned copper wires and special fibers are stranded by a wire and cable stranding machine to serve as inner conductors; the tinned copper wires are braided by a braiding machine to serve as outer conductors; inner insulating layers are manufactured by extruder equipment and are processed by an electron accelerator through radiation crosslinking, and outer insulating layers are manufactured by the extruder equipment; the filling cores are stranded by a cabling machine; the tensile layer is formed by a braiding machine through braiding; and the inner and outer sheathes are manufactured by the extruder equipment. The cable has the advantages of softness, low temperature and aging resistance, tear resistance, high flame retardance and high strength, has softness characteristic under low temperature, improves the tensile strength, is suitable for the special environment such as reciprocation and has excellent mechanical property and electrical property.

Owner:NANJING QUANXIN CABLE TECH

High-temperature 260 DEG C resistant tightly-packaged fiber and preparation process thereof

InactiveCN102520476AHigh strengthResistant to bendingOptical fibre with multilayer core/claddingFiberAging resistance

The invention discloses a high-temperature 260 DEG C resistant tightly-packaged fiber and a preparation process thereof. The high-temperature 260 DEG C resistant tightly-packaged fiber is characterized in that a coating layer is arranged on the periphery of a fiber core, and a tightly-wrapping layer is arranged on the periphery of the coating layer. According to the preparation process, a fiber core comprises a single-mode fiber core and a multi-mode fiber core, wherein the single-mode structure has a thickness of 9 / 125mu m and the multi-mode structure has a thickness of 50 / 125mu m or 62.5 / 125mu m; polyimide is coated on the coating layer by using a coating device, a tightly-wrapping fiber is normally laid and installed at a temperature of -65 DEG C by the coating layer, wherein the polyimide resists the temperature grade of -65 DEG C- +260 DEG C, the outer diameter of the coating layer is 155mu m; and soluble polytetrafluoroethylene (FPA) thin-wall-extruded by adopting a high-temperature extruding machine in the tightly-wrapping layer, and the tightly-wrapping layer resists a high temperature of 260 DEG C. The high-temperature 260 DEG C resistant tightly-packaged fiber has the characteristics of high temperature 260 DEG C and low temperature -65 DEG C resistance, high strength, bending resistance, impact resistance, ageing resistance, long service life, corrosion resistance, inflaming retarding and the like, and is suitable for high-speed signal transmission under aerospace, electrons and onboard special environment conditions.

Owner:NANJING QUANXIN CABLE TECH

Production process for preparing novel carburant from carbon solid waste material

ActiveCN111302753AWeakened water retentionEasy to hardenSolid waste managementProcess engineeringEnvironmental engineering

The invention discloses a production process for preparing a novel carburant from a carbon solid waste material. A binder which is low in cost, high in viscosity, non-toxic, odorless, green and environment-friendly is selected to replace coal pitch. Carbon solid waste is subjected to a series of procedures of crushing, screening, purifying, stirring, mixing, kneading, profiling, drying, cooling and packaging, and through the step of water locking, the carbon solid waste is convenient to form, good in toughness and high in strength.

Owner:江苏嘉明碳素新材料有限公司

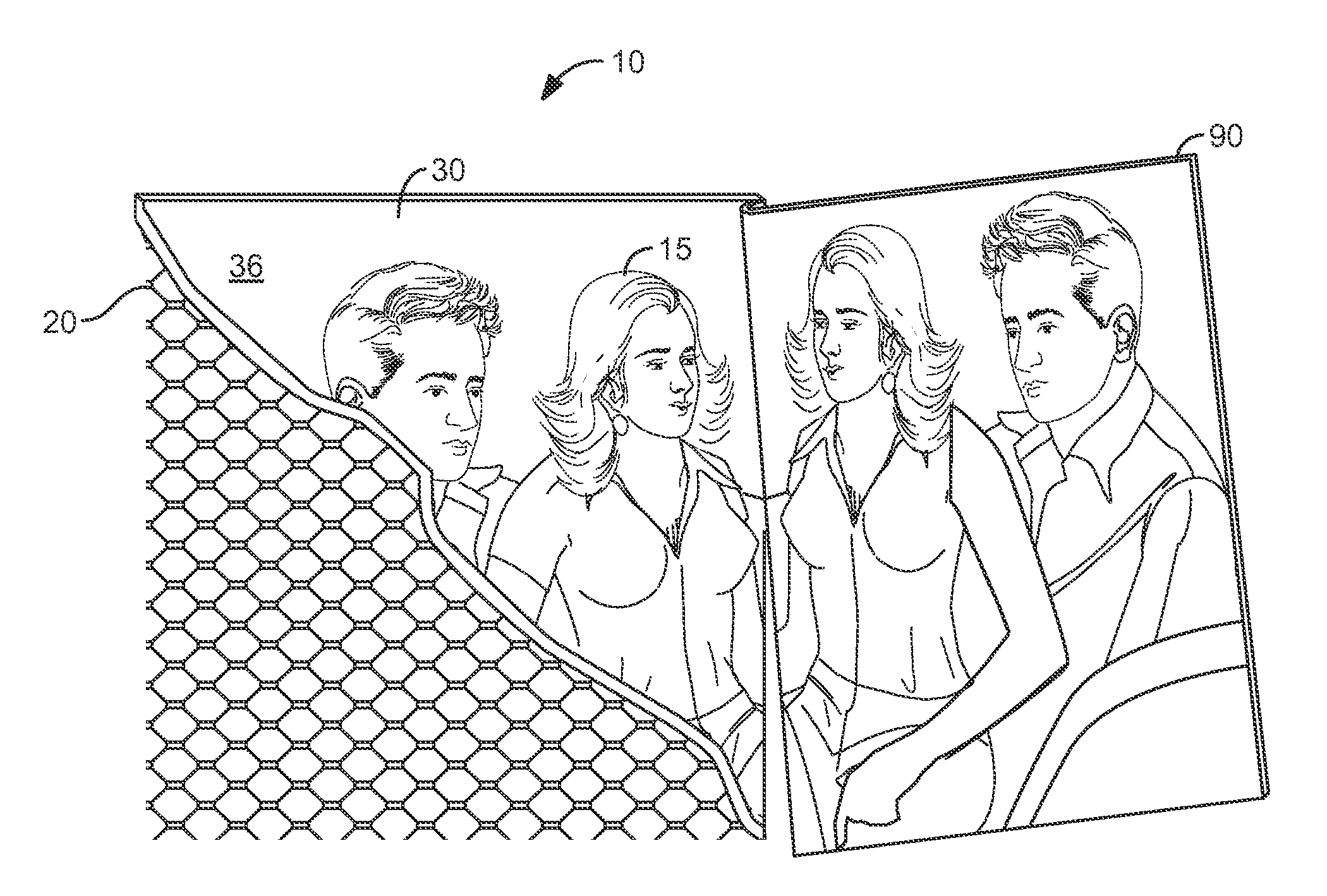

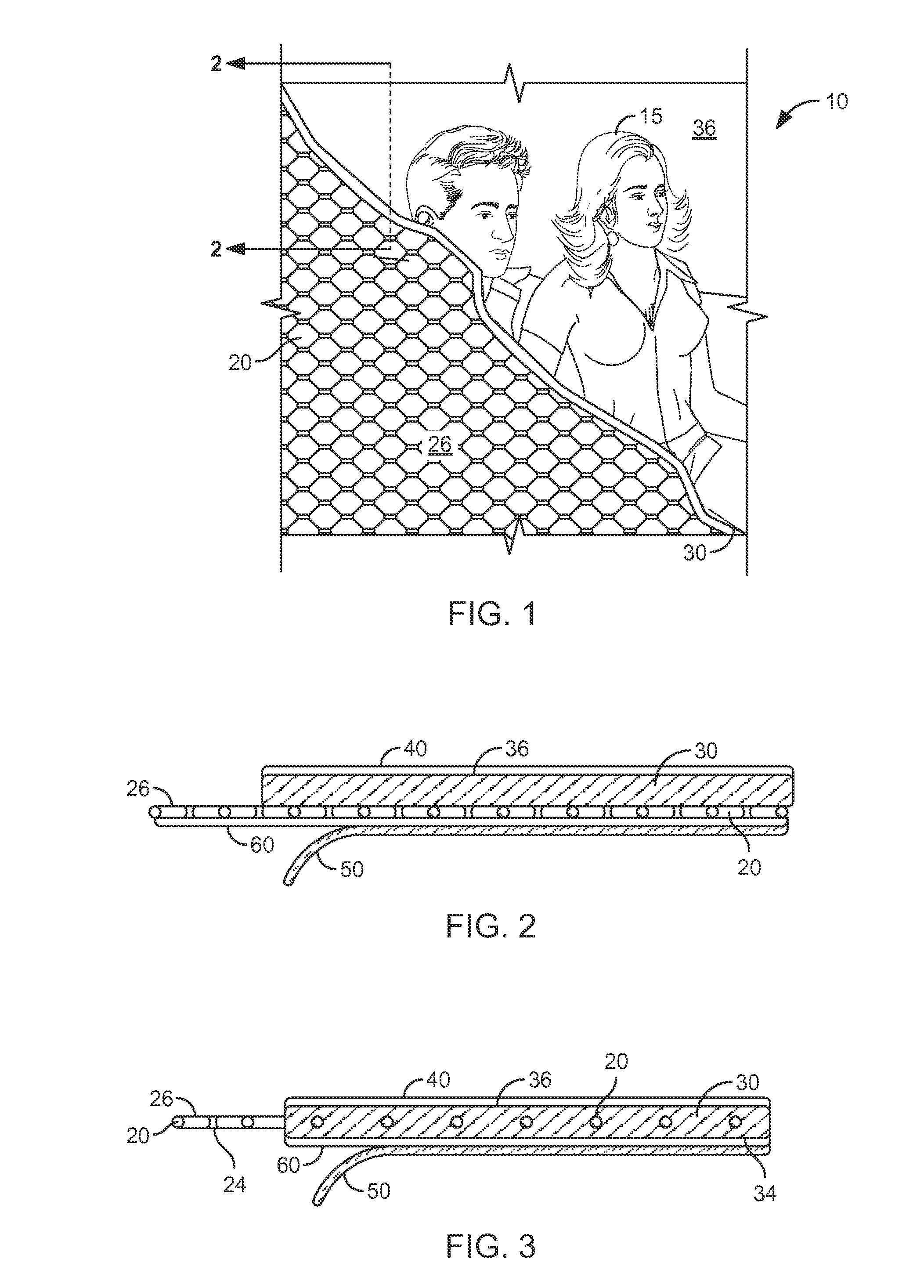

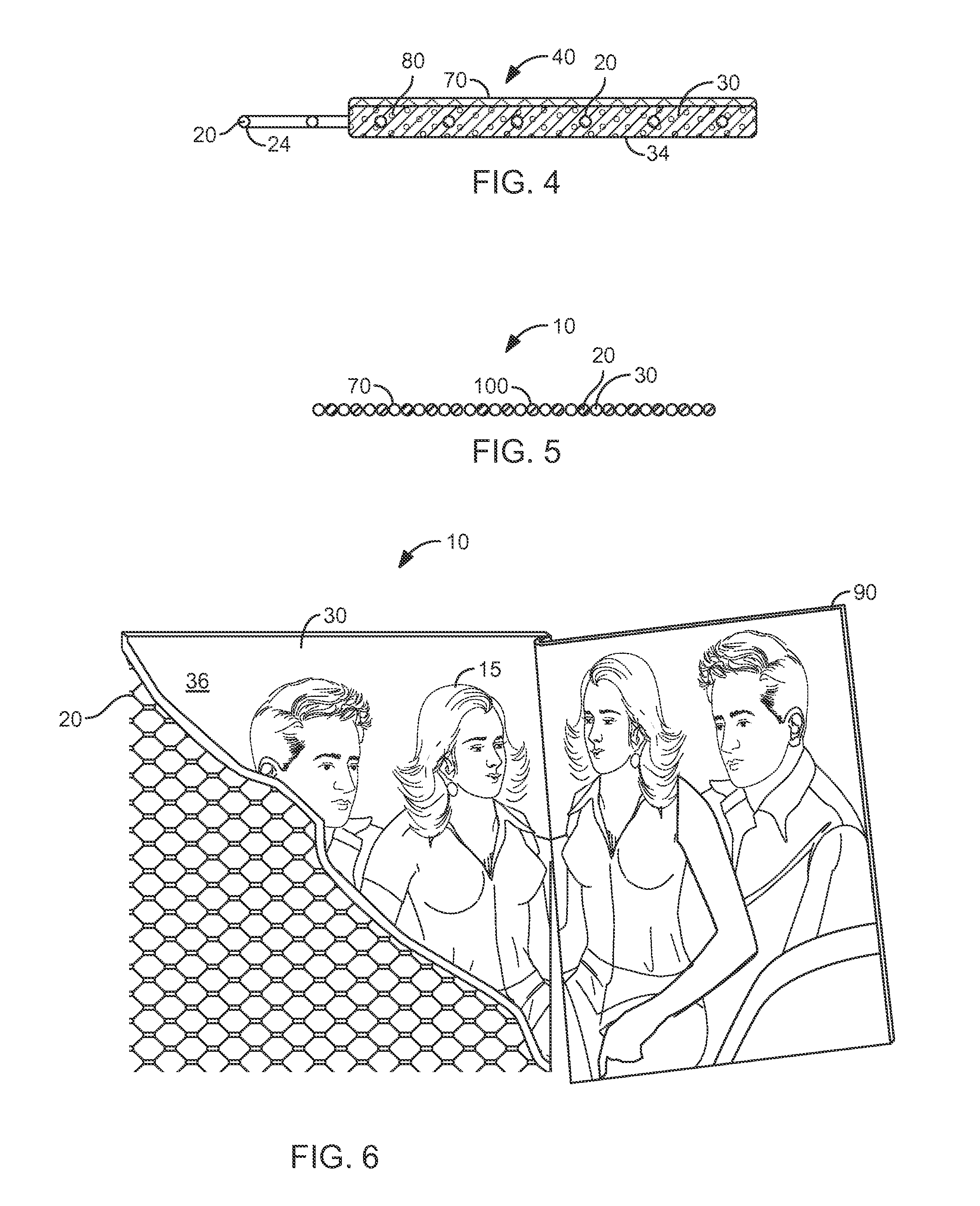

Ductile Printed Media and methods of use therefore

InactiveUS20090061123A1Easy to hardenDecorative surface effectsOrnamental structuresAdhesiveWater-reactive

A ductile media for receiving an image thereon is disclosed and comprises a ductile mesh and an elastomeric membrane fixed to at least a top side of the mesh. The ductile mesh is preferably an expanded metal material. The elastomeric membrane has a substantially flat top surface that is adapted to receive the image thereon. A printable coating may be further applied to the top surface of the membrane. In one embodiment of the invention, a selectively removable liner is temporarily fixed with adhesive to a bottom surface of the mesh or to a bottom surface of the elastomeric membrane to prevent printer feeding rollers of a printing device, for example, from deforming or stretching the media as the media advances through the printing process. Alternately the image may be applied to the ductile media through a heat transfer or dye-sublimation process. Once the image is printed on the media, the user may form the media into a desired shape by applying pressure thereto. Additionally, the elastomeric membrane may be impregnated with a water-reactive hardening agent, such that once the media is formed into a desired shape, water may be introduced to the elastomeric membrane to activate the hardening agent and cause the media to become substantially rigid.

Owner:MAHONEY TRAVIS

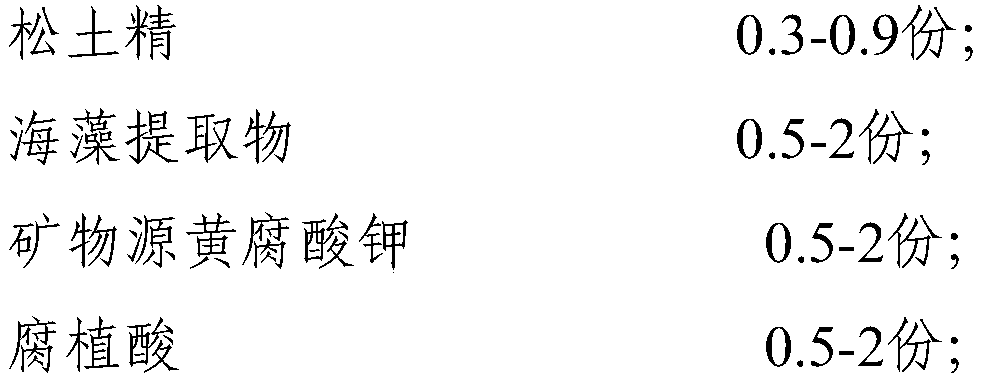

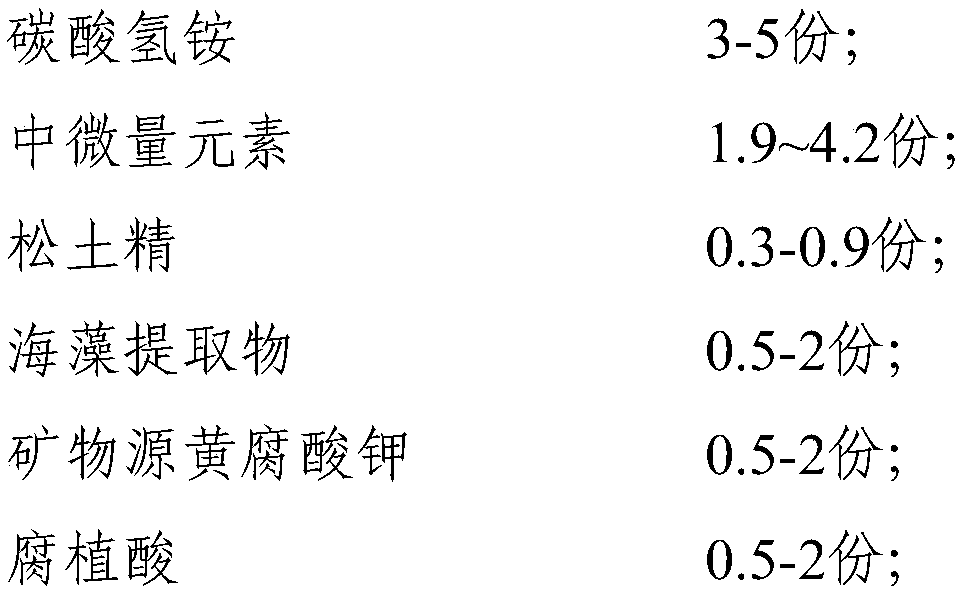

Special multifunctional soil conditioning type protected area commercial crop fertilizer as well as preparation method and application thereof

InactiveCN109438121AImprove soil structure and qualityStrong stabilityMagnesium fertilisersAlkali orthophosphate fertiliserNutrientBiology

The invention relates to a special multifunctional soil conditioning type protected area commercial crop fertilizer as well as a preparation method and application thereof. The protected area commercial crop fertilizer provided by the invention comprises a basic fertilizer, medium / trace elements and a soil conditioning agent, wherein the soil conditioning agent comprises a mixture of grondverbeteraar, an alga extract and humic acid and one of fulvic acid and a fulvic acid salt; the weight ratio of the grondverbeteraar to the alga extract ranges from (1:4) to (9:5). According to the special fertilizer provided by the invention, the soil porosity of protected area planting can be remarkably increased, the soil bulk density can be reduced, and soil structures can be improved; in addition, theyield of vegetables is increased, the contents of nutrient substances in the vegetables can be increased, and the quality of a vegetable product can be improved.

Owner:STANLEY AGRI GRP CO LTD

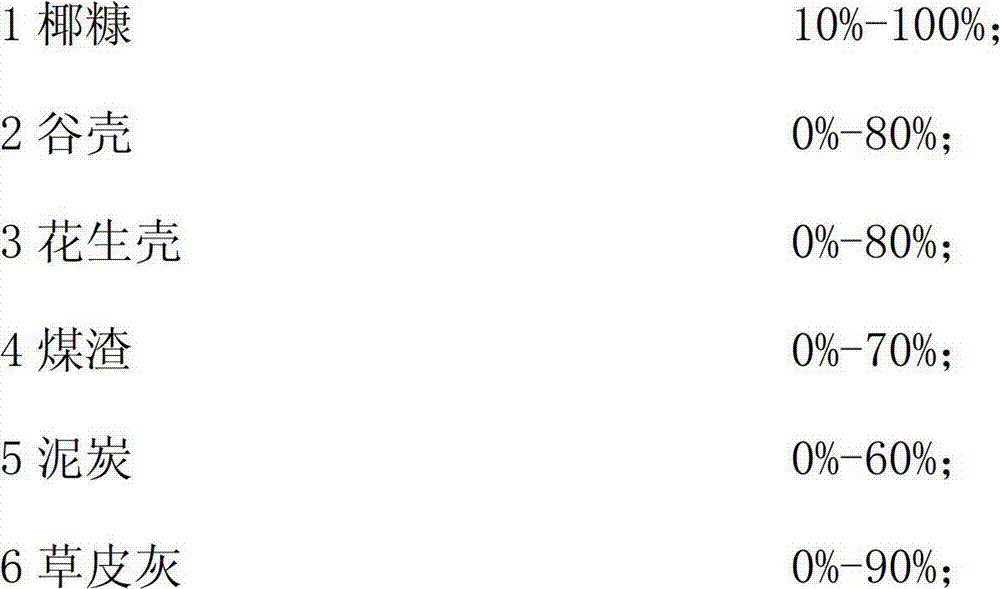

Method for cultivating clumping bamboo shoots or tillered bagged seedlings by lightweight coco coir medium

The invention discloses a method for cultivating clumping bamboo shoots or tillered bagged seedlings by lightweight coco coir medium. The method includes: proportionally mixing coco coir, peat, rice hull, peanut shell, cinder and turf ash to obtain nutrient bagged-seedling medium, and clumping bamboo shoots or new shoots are tillered and directly loaded in nutrition bags for cultivating bamboo clone bagged seedlings. The method has the advantages that bamboo seedlings grow roots fast (for about 15-20 days at normal temperature) by using the lightweight medium both high in absorbency and permeability to cultivate the bamboo seedlings, the roots are strong and developed, bag-penetrating roots can appear in 30-50 days, the light medium is rich in organic matters, bamboo leaves can be kept green in 3-5 months, survival rate of the bamboo seedlings is increased to more than 85%, the lightweight medium for dead plants can be recycled, and accordingly cost in seedling raising is economically low.

Owner:广西华劲竹林发展有限公司

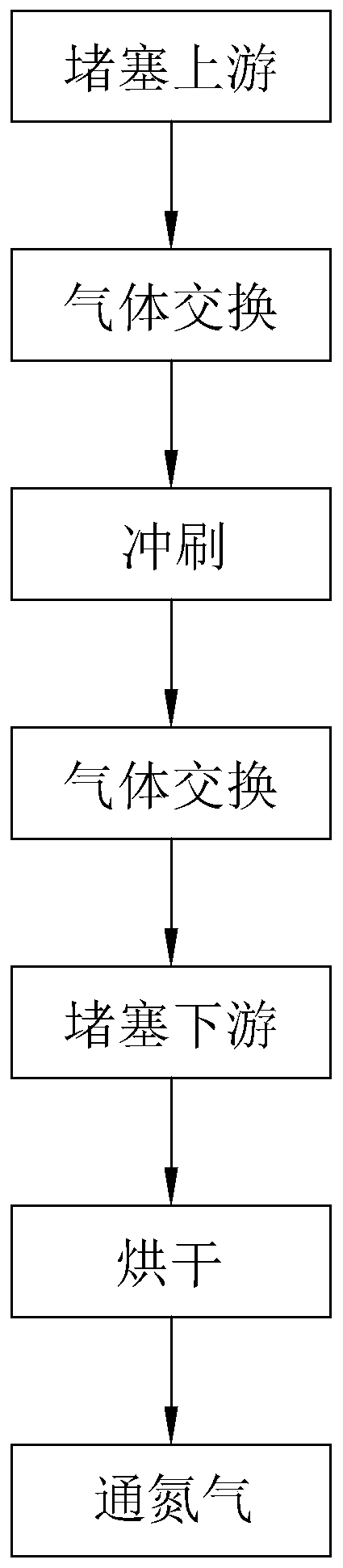

Method for clearing sewage pipeline

The invention discloses a method for clearing a sewage pipeline, and relates to the technical field of pipeline clearing. The method comprises the following steps: S1, the upstream is blocked; S2, flushing is conducted, specifically, a high-pressure water gun is used for flushing sludge on the inner wall of the to-be-repaired pipeline, and a pumping pump is used for actively pumping sewage away tothe downstream while flushing is conducted; S3, the downstream is blocked; and S4, drying is conducted, specifically, warm air is continuously introduced into the to-be-repaired pipeline till the inner wall of the to-be-repaired pipeline is dry. According to the method, firstly, the upstream of the to-be-repaired pipeline is blocked; then the inner wall of the to-be-repaired pipeline is flushed through the high-pressure water gun, thus the sludge on the inner wall of the to-be-repaired pipeline is diluted and then pumped away by the pumping pump, clearing is more convenient, and evacuation isquicker; then after the inner wall of the to-be-repaired pipeline is flushed to be clean, the downstream is blocked through the same method; finally, the inner wall of the to-be-repaired pipeline isventilated and dried; and it is guaranteed that no water drop and the sludge adhere to the inner wall of the to-be-repaired pipeline, dryness and cleanliness are kept, and hardening and tight attachment of a liner pipe in the later period are convenient.

Owner:上海信立生态环境工程有限公司

Rolling element bearing and motor

InactiveUS20050254740A1Reduce noiseReduce vibrationShaftsBall bearingsRolling-element bearingEngineering

A rolling bearing for supporting a shaft on which a fan is provided, has an inner ring having an inner ring race on an outer surface thereof, an outer ring having an outer ring race on an inner surface thereof, balls provided between the inner ring race and the outer ring race and a retainer which keeps the balls apart each other in a circumferential direction, wherein an inner diameter of the bearing is set to be 3 mm or more and 17 mm or less, an outer diameter of the bearing is set to be 8 mm or more and 40 mm or less, when a thickness ti and a thickness te satisfies a relationship te≧1.24 ti, and a residual austenite content in the inner ring is 7 wt % or less.

Owner:NSK LTD

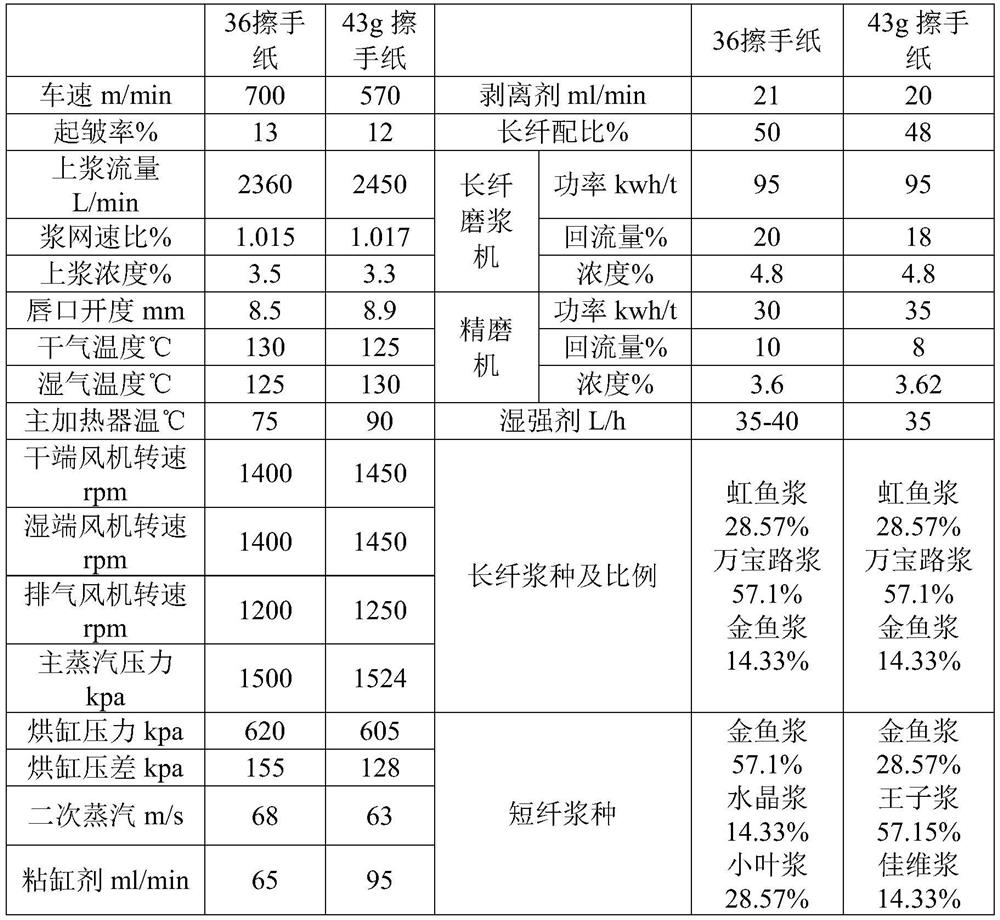

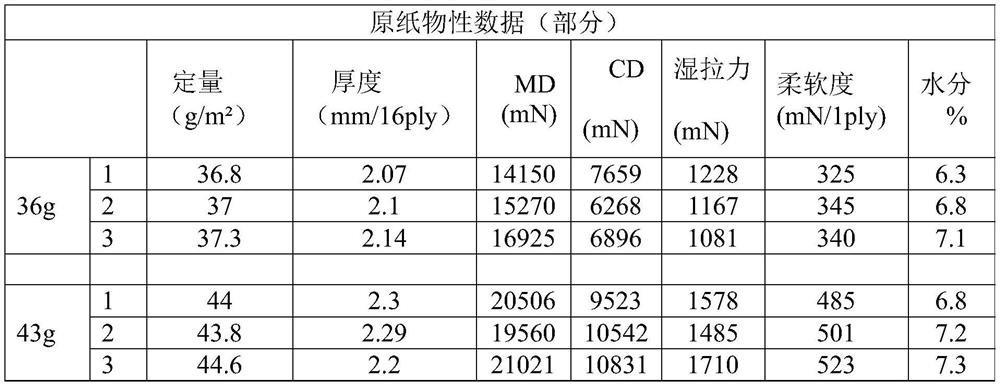

A kind of production process of environment-friendly high grammage paper towel

ActiveCN108570875BLow costGuaranteed stiffnessDryer sectionPulp beating/refining methodsFiberPaper towel

The invention relates to an environment-friendly high-gram weight paper towel production process. The high-gram weight paper towel is prepared through two steps of a pulp preparation process and a papermaking process. The pulp preparation process includes pulping and refining long-fiber pulp. Treatment, adding broke paper to the long-fiber pulp obtained after refining treatment, and preparing the pulp; the papermaking process includes transporting the pulp stored in the pulping tank to the headbox through the pulping pump, and the pulp enters between the screen blankets After dehydration, a wet paper web is formed, passed through the felt, enters the press section for pressing and dehydration, and the paper web exiting the press section is transferred to the drying cylinder and air hood system for drying, and the dried paper web enters the coiling section for coiling, forming Paper rolls are produced to obtain environmentally friendly high-gram weight paper towels. Compared with the prior art, the present invention has the advantages of stable pulp quality, higher operation efficiency, lower wrinkle rate of finished products, and the like.

Owner:上海东冠纸业有限公司

Method for preparing titanium dioxide product for high-specific surface area denitrating catalyst

InactiveCN101318697BImprove performanceWill not polluteCatalyst carriersDispersed particle separationFiltrationHigh surface

The invention relates to a method for preparing titania raw materials with high specific surface area used by denitration catalyst, which relates to the chemical product preparation technical field. The method comprises the following steps that: a metatitanic acid produced by adoption of the sulfuric acid method is processed by an organic surfactant and then modified so as to reduce the viscosityof the metatitanic acid; and loose titania products with high specific surface area and high surface chemical activity used by the denitration catalyst are prepared through filtration and calcinationof the processed metatitanic acid. The method has a simple technique for processing the metatitanic acid and has low cost; and added organic substances are fully decomposed during the calcining stage, thereby impurities can not be brought into the final products and the environmental pollution can not be caused.

Owner:四川华铁钒钛科技股份有限公司

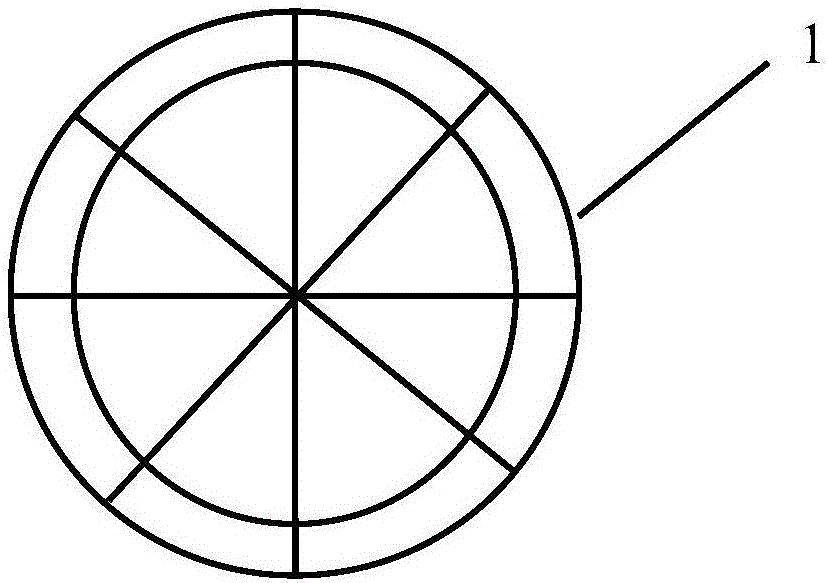

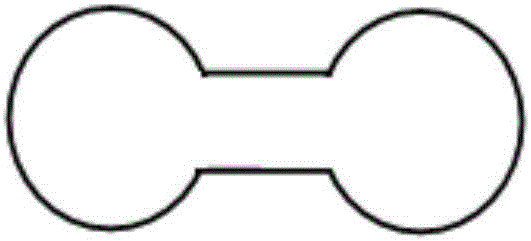

Acrylic fibers with peanut-shaped cross section and production method thereof

InactiveCN106435802AEasy to hardenImprove shrinkageArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceFiber bundle

The invention discloses acrylic fibers with a peanut-shaped cross section. The acrylic fibers with the peanut-shaped cross section are mainly prepared from the following components in percentage by mass: 91 percent to 94 percent of acrylonitrile and 6 percent to 9 percent of vinyl acetate. The acrylic fibers with the peanut-shaped cross section are obtained by extruding through a spinneret plate and the length-width ratio of the section is (3 to 5) to 2. The invention further discloses a production method of the acrylic fibers with the peanut-shaped cross section; the production method comprises the following steps: carrying out a copolymerization reaction on the acrylonitrile and the vinyl acetate and then forming a raw spinning solution in a solvent; heating the raw spinning solution to 82 DEG C to 90 DEG C and extruding from the spinneret plate; forming as-spun fibers in a condensation bath; carrying out water washing and drafting on the as-spun fibers to form a fiber bundle; and carrying out oil application, drying and sizing on the fiber bundle to obtain the acrylic fibers with the peanut-shaped cross section. According to the acrylic fibers with the peanut-shaped cross section, the content of the acrylonitrile and the vinyl acetate in a copolymer and the molecular weight of the copolymer are adjusted, the spinneret plate is reasonably designed and a production process is adjusted, so that the prepared acrylic fibers have excellent performances.

Owner:NINGBO ZHONGXIN ACRYLIC FIBERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com