Patents

Literature

46results about How to "Improve surface chemical activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral honeycomb denitration catalyst for novel WO3 addition technology and preparation method of catalyst

InactiveCN102773090ALow costSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAdhesive

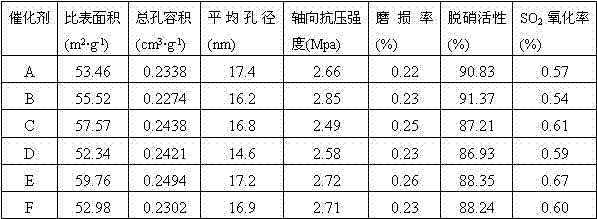

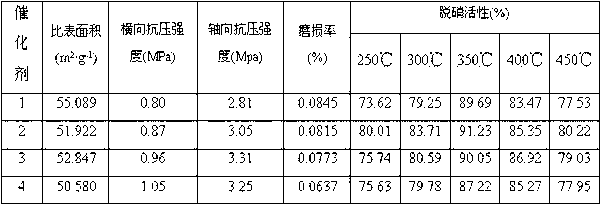

The invention discloses an integral honeycomb denitration catalyst for a novel WO3 addition technology. The integral honeycomb denitration catalyst comprises, by weight, 4%-8% of WO3, 1%-1.5% of V2O5, 80.5%-90% of TiO2 and 5%-10% of adhesives, wherein the WO3 is added into precursor solution in a catalyst mixing procedure. The honeycomb denitration catalyst is prepared by extruding, drying and calcining materials, has fine chemical stability, heat stability and SO2 oxidization resistance, represents high NH3-SCR (selective catalytic reduction) catalytic activity and a wide active temperature window, has a large specific surface area, high chemical surface activity and fine catalytic effects, and can meet the requirement of flue gas denitration. Compared with the method of leading in WO3 by directly mixing TiO2-WO3 composite powder serving as a raw material, the preparation technology is simpler without relying on imported TiO2-WO3 composite powder, nationally rich titanium resources are made full use of, the cost of the catalyst is reduced, Chinese industrialization progress of the denitration catalyst can be promoted, and popularization of the flue gas denitration technology in China is promoted.

Owner:CHONGQING UNIV +1

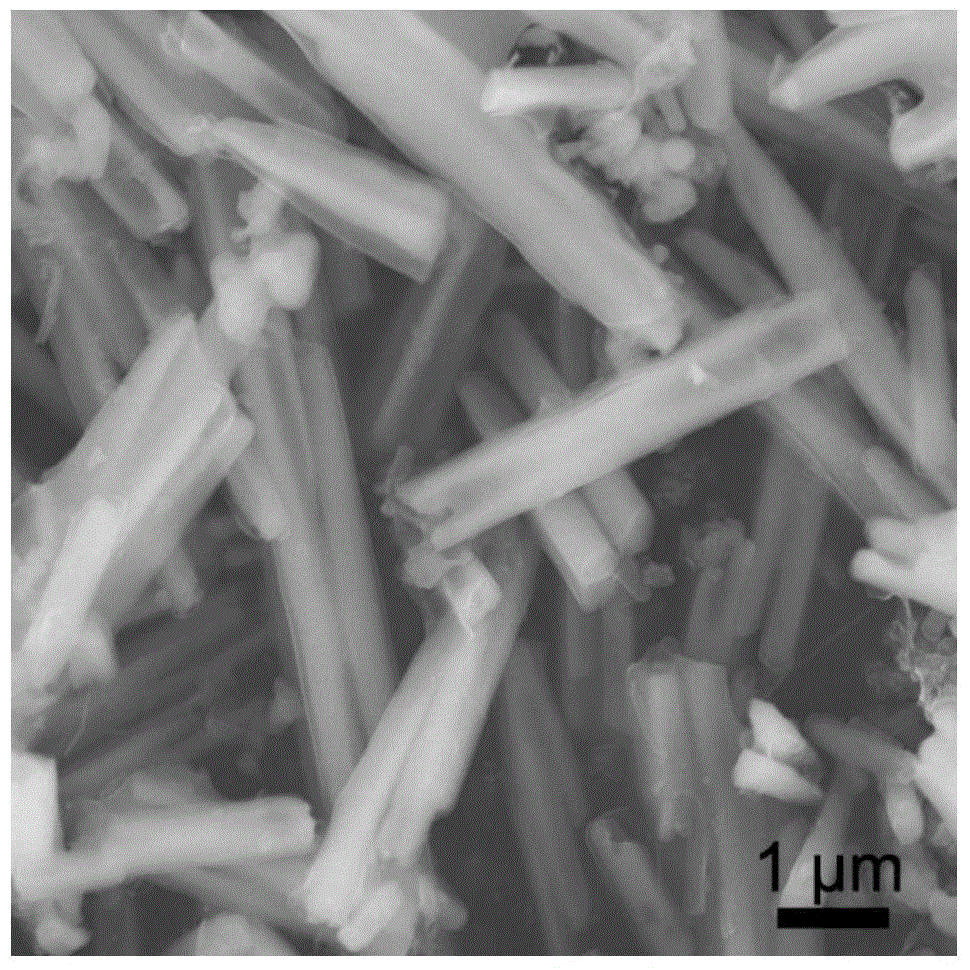

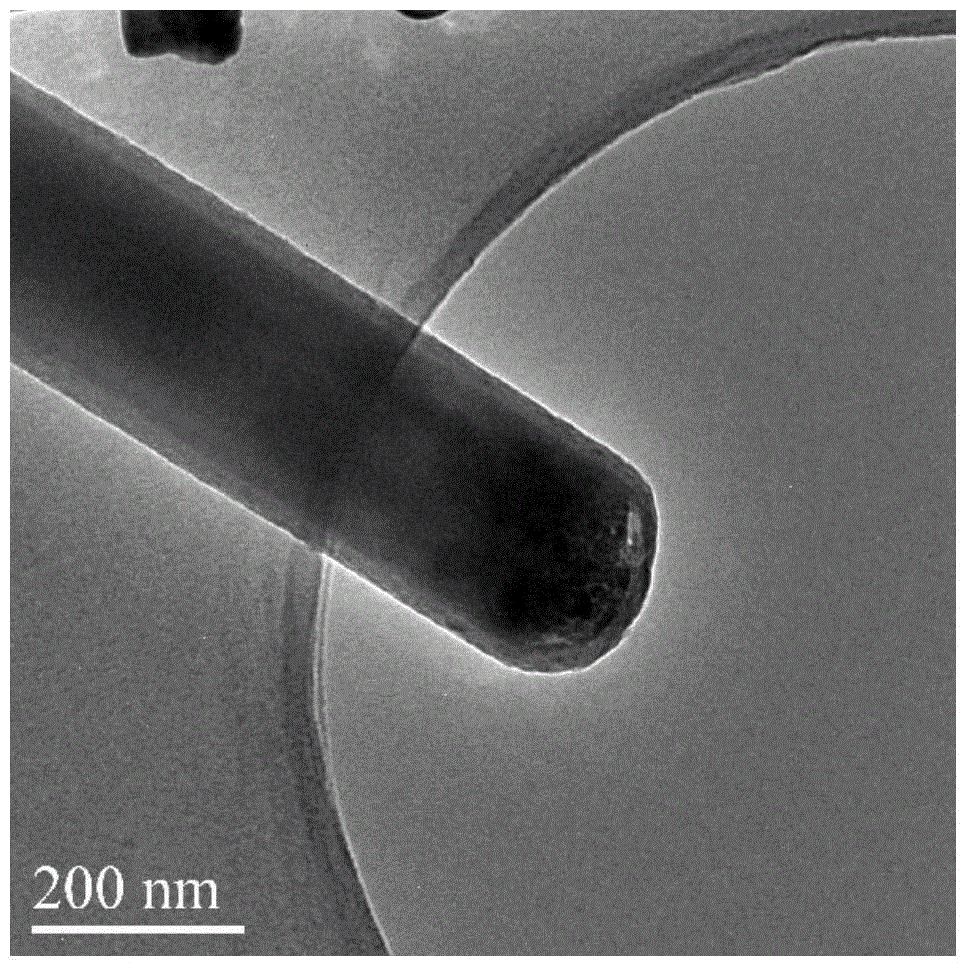

Charcoal-coated metal fluoride nano material with core-shell structure, preparation method and application of nano material as lithium battery positive electrode material

InactiveCN104091949ALower transfer resistanceReduce erosionMaterial nanotechnologyCell electrodesSolventLithium-ion battery

The invention discloses a charcoal-coated metal fluoride nano material with a core-shell structure, a preparation method and application of the nano material in the field of lithium ion battery positive electrodes. The nano material is of a core-shell structure; the shell layer is charcoal; the core layer is metal fluoride; the nano material has high specific capacity and good cyclic stability by being taken as the positive electrode material of a lithium ion battery. The nano material with the core-shell structure can be prepared through the processes of mixing, pyrolysis and solvent washing of a raw material metal compound and a fluorine-containing compound, has the characteristics of abundant source of raw material, simple process, low material preparation cost, high purity, wide metal choice range and the like, and facilitates large-scale production.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

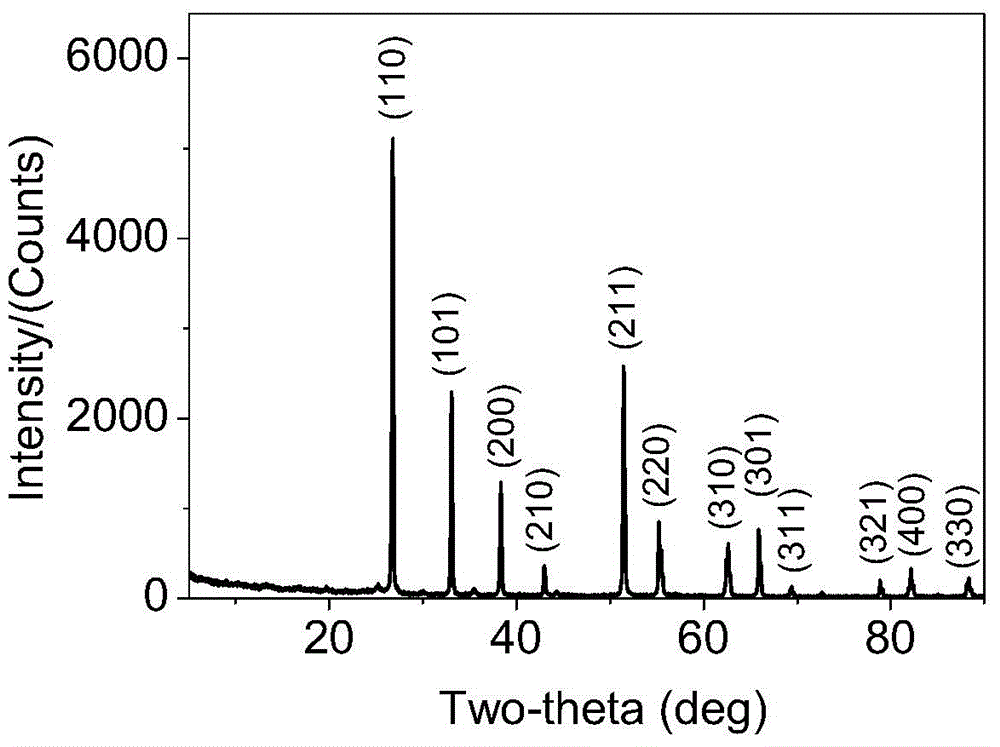

Preparation method for titanium dioxide serving as catalyst carrier

InactiveCN102583522AImprove performanceEasy to processCatalyst carriersTitanium dioxidePtru catalystMaterials science

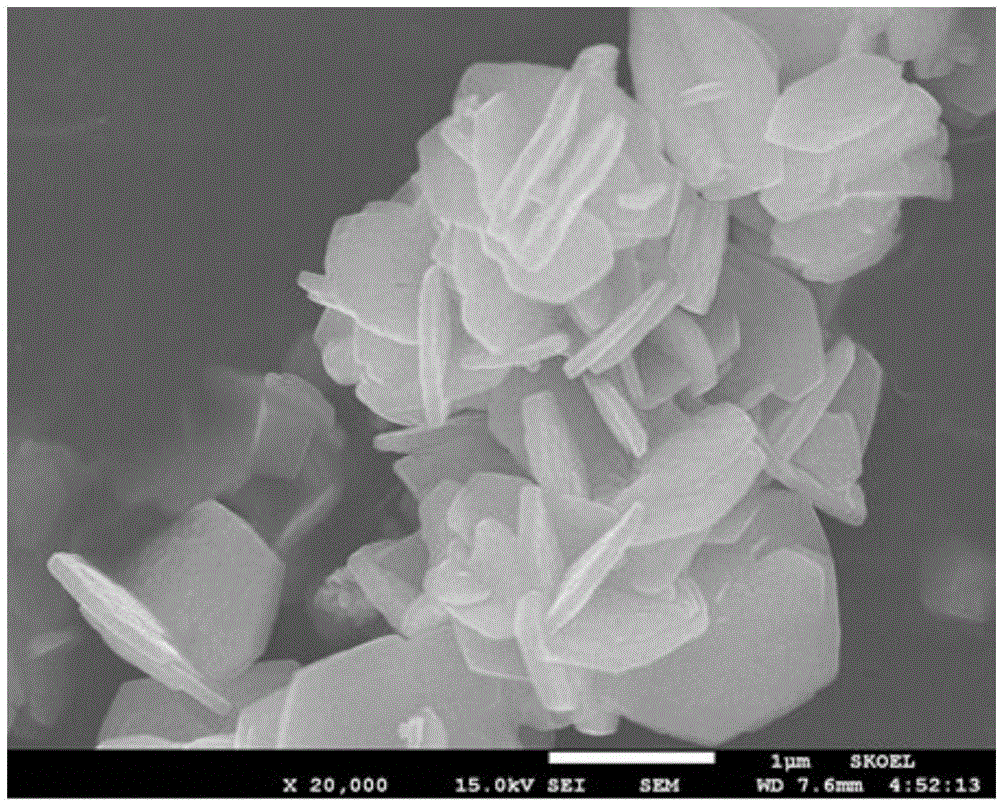

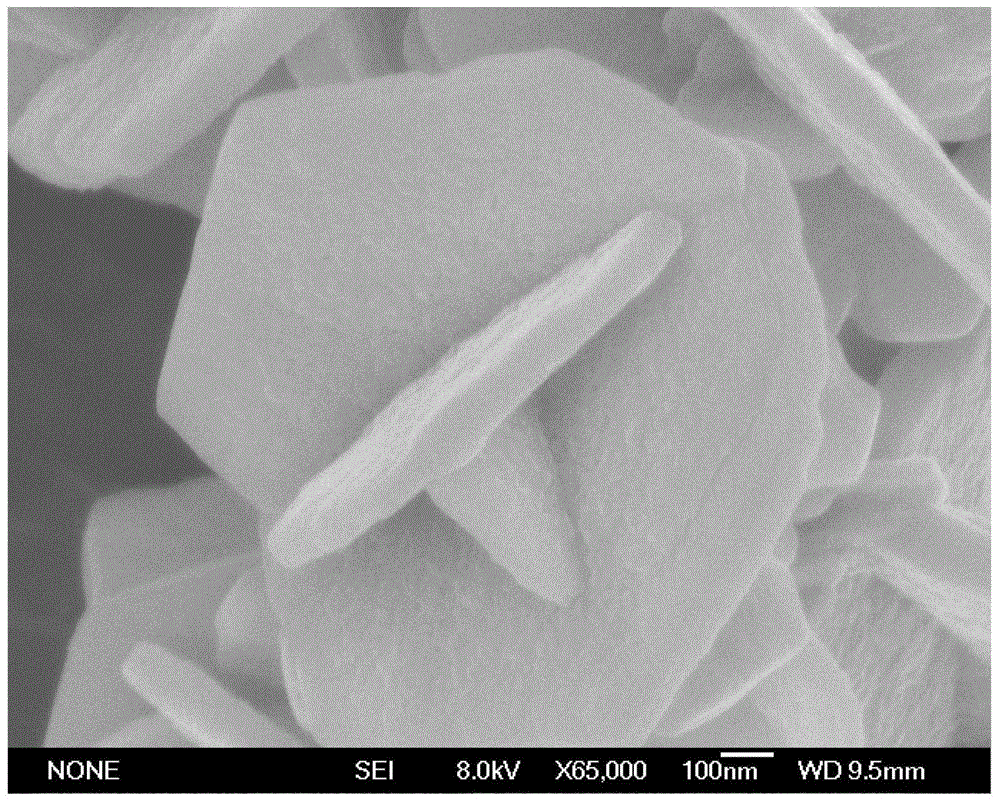

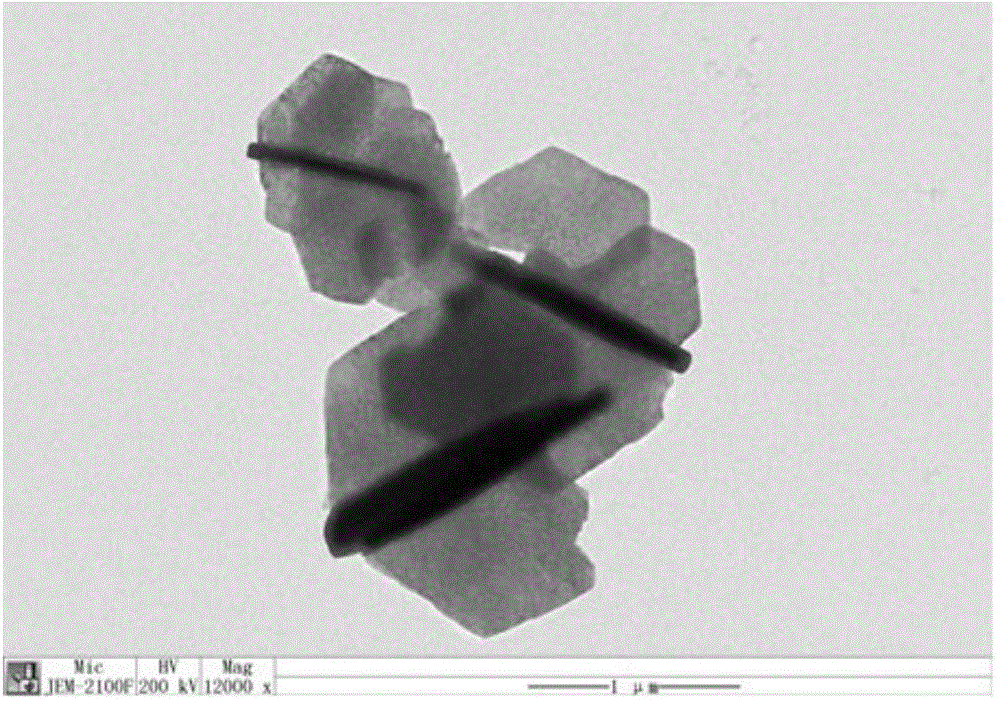

The invention discloses a preparation method for titanium dioxide serving as a catalyst carrier. The preparation method comprises the following steps of: dispersing metatitanic acid serving as a raw material by pulping, and adjusting until the concentration of the slurry is 12 to 26 mass percent based on titanium dioxide (TiO2); adding ammonia water into the slurry, and adjusting the pH value to be between 6.0 and 9.0; filtering and dehydrating to obtain a blocky filter cake; mechanically crushing the blocky filter cake; drying and calcining the crushed filter cake at 200 to 560 DEG C for 6 hours; and grinding the calcined material in a kiln to obtain a titanium dioxide product which serves as a denitration catalyst carrier. By the preparation method, the manufacturing cost is low, the process is simple, the prepared product has the advantages of large specific area, high surface chemical activity and high processability, and the prepared final product is high in catalytic efficiency.

Owner:四川华铁钒钛科技股份有限公司

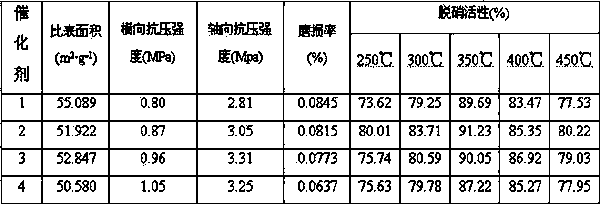

Novel composite-carrier honeycomb monolithic denitration catalyst and preparing method thereof

InactiveCN102773091AImprove removal effectLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberPolyvinyl alcohol

The invention discloses novel composite-carrier honeycomb monolithic denitration catalyst, in particular to honeycomb monolithic SCR (selective catalytic reduction) denitration catalyst with modified cordierite and titanium dioxide as a composite carrier and a preparing method of the honeycomb monolithic SCR denitration catalyst. The novel composite-carrier honeycomb monolithic denitration catalyst includes the following components, 10-25wt% of modified cordierite powder, 65-85wt% of titanium tungsten powder (containing 3-10wt% of WO3), 1-2wt% of V2O5, and the balance additive which is glass fiber or polyvinyl alcohol. The novel composite-carrier honeycomb monolithic denitration catalyst is prepared from following steps of mixing, mud refining, extrusion forming, drying and roasting, has the advantages of chemical stability, thermostability and wear-resisting property, and expresses higher catalytic activity of NH3-SCR and wider active temperature window. Cordierite power at low cost is utilized to substitute part of imported titanium tungsten powder and serve as the carrier for the SCR denitration catalyst which is simple to prepare, degree of dependence on imported titanium tungsten powder is reduced, and the defects that the carrier for existing SCR denitration catalyst is unstable in mechanical performance and high in price are overcome.

Owner:CHONGQING UNIV +2

Tin dioxide nanoflower with hollow structure and preparation method of tin dioxide nanoflower

InactiveCN104891557AImprove gas sensing performanceGood dispersionMaterial nanotechnologyTin oxidesTin dioxideNanoparticle

The invention discloses a tin dioxide nanoflower with a hollow structure and a preparation method of the tin dioxide nanoflower, belonging to the technical field of nanomaterials and solving the technical problems that a preparation method of tin dioxide nanoparticles is complex in operation and high in cost and tin dioxide nanoparticles with complex appearances cannot be prepared in the prior art. The nanoflower is composed of more than one subunit, wherein all the subunits share the same geometric central point; each subunit is composed of a hollow tin dioxide sheet layer and a solid tin dioxide sheet layer which are respectively of a regular hexagonal structure; the hollow tin dioxide sheet layer is composed of a shell and an inner cavity; the solid tin dioxide sheet layer is parallel to the hollow tin dioxide sheet layer and shares the same geometric central point with the hollow tin dioxide sheet layer; and the solid tin dioxide sheet layer is arranged in the hollow tin dioxide sheet layer to divide the inner cavity into two regions. The nanoflower is of a hollow hierarchical structure and is good in monodispersity and crystallinity, large in specific surface area and favorable in gas sensibility.

Owner:JILIN UNIV

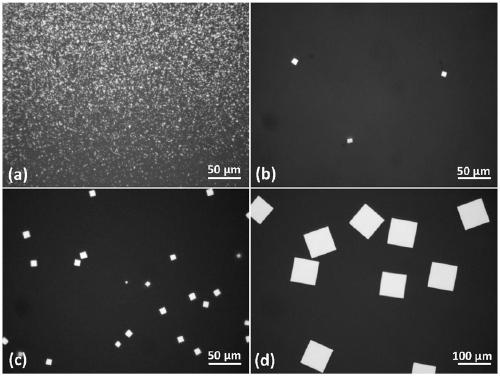

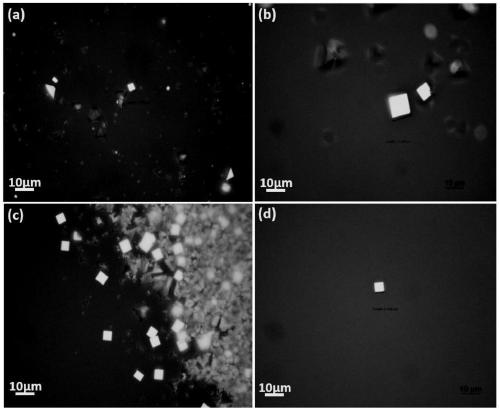

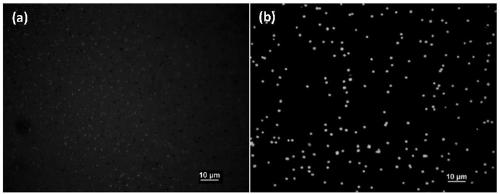

Preparation method and application of two-dimensional lead telluride nano sheet and nano material

ActiveCN109650354AIncrease the areaReduce surface roughnessNanotechnologyPhotovoltaic energy generationPhotovoltaic detectorsDecomposition

The invention relates to the technical field of nano materials, in particular to a preparation method and application of a two-dimensional lead telluride nano sheet and a nano material. The method comprises the steps that a reaction raw material which is used for the growing of the lead telluride nano sheet is weighed; a sheet-like material with a surface with an atomic level smoothness is taken as a growing substrate; the reaction raw material is thermostatically heated to perform vapor deposition in a protective gas flow after programmed temperature increasing; the substrate is allowed to bequenched after the decomposition process is completed, and the two-dimensional lead telluride nano sheet is obtained on the substrate. The thickness of the nano sheet is 5 nm-200 nm, the width or length is 0.1-70 microns, and the nano sheet is provided with a monocrystalline structure. The nano sheet is of a face-centered cubic crystal, and the exposed crystal face of the nano sheet belongs to {100} crystal face family and is provided with a sheet-like rectangular morphology; the ultra-thin two-dimensional lead telluride nano sheet with large area, uniform orientation and morphology and crystallinity can be obtained through a Van der waals epitaxy technology, and the two-dimensional lead telluride nano sheet can be applied to the fields of infrared ray photoelectric detectors and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

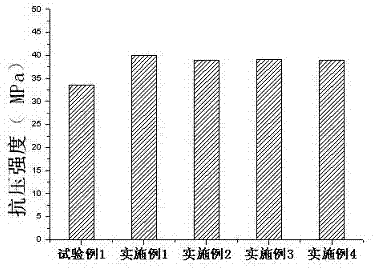

Modified basalt fiber reinforced scoria lightweight aggregate concrete and preparation method thereof

Owner:JILIN JIANZHU UNIVERSITY

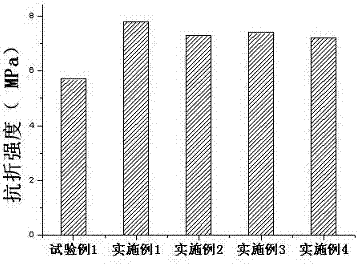

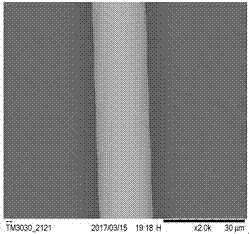

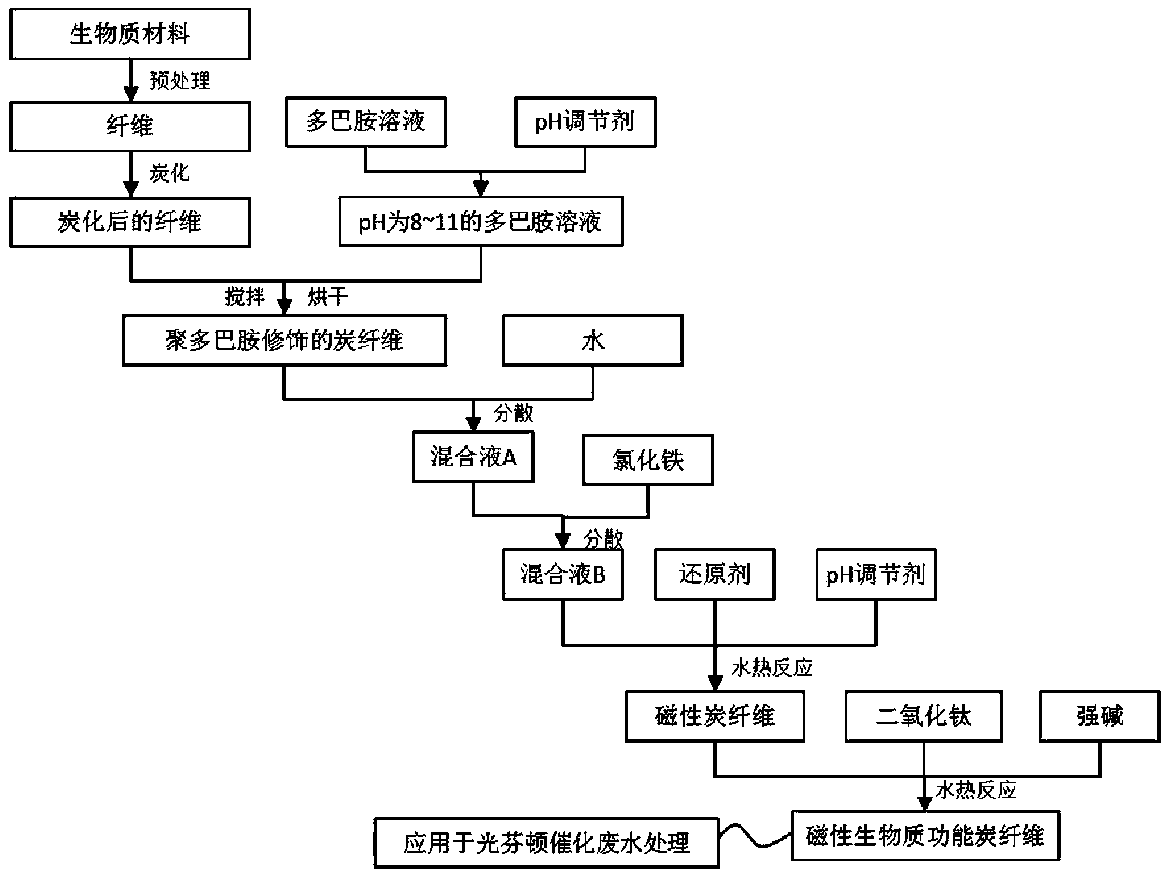

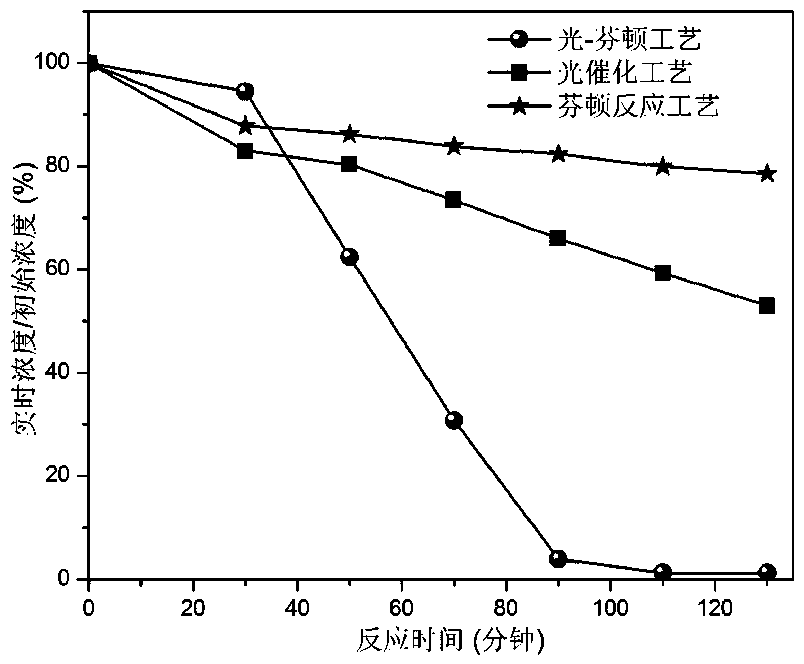

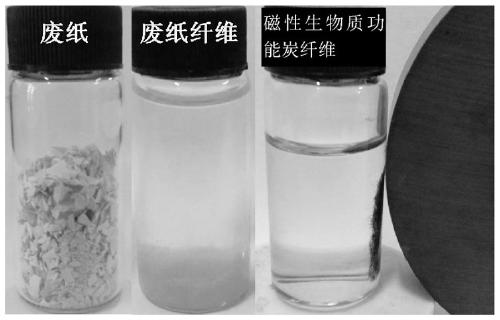

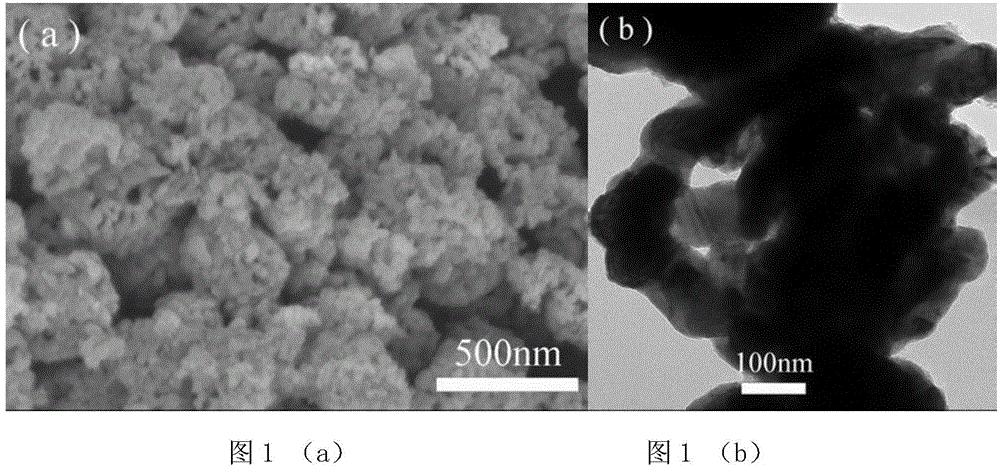

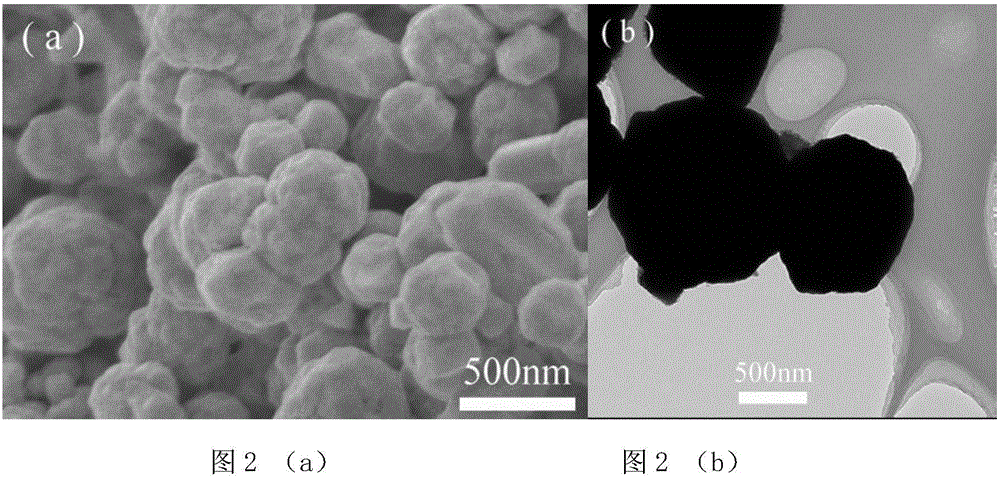

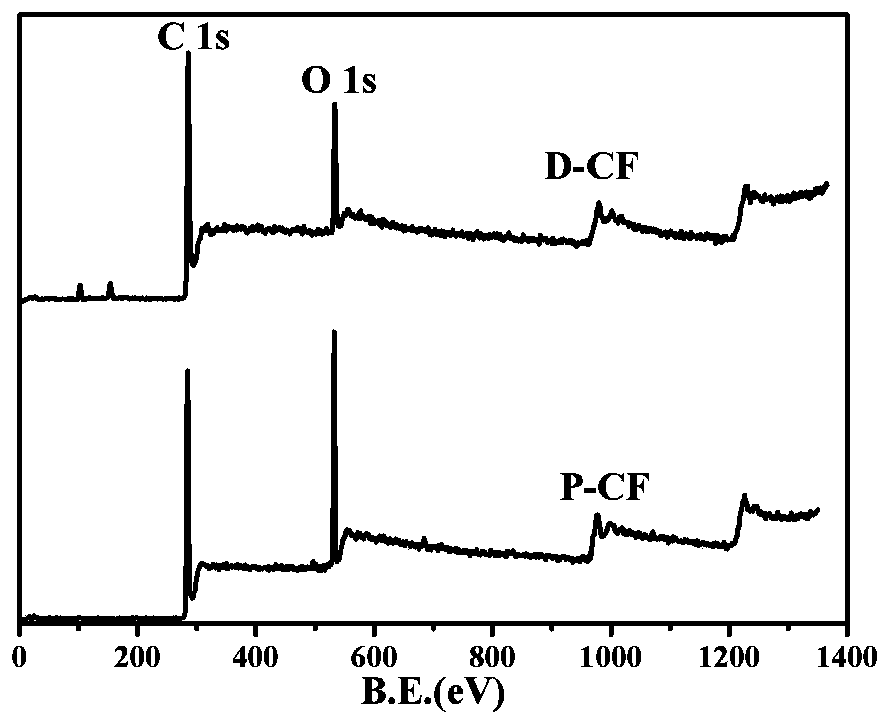

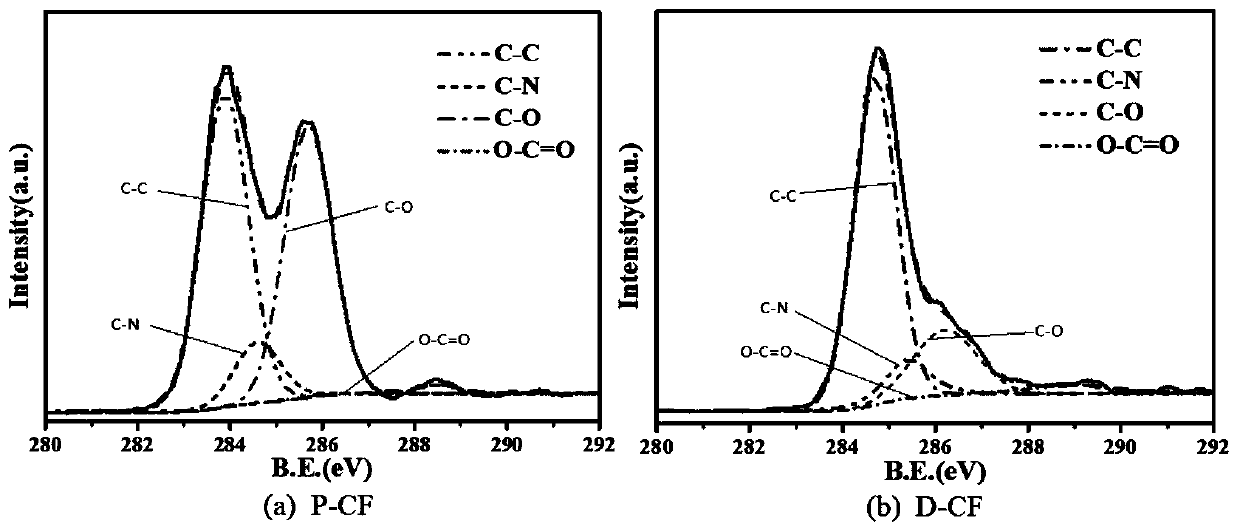

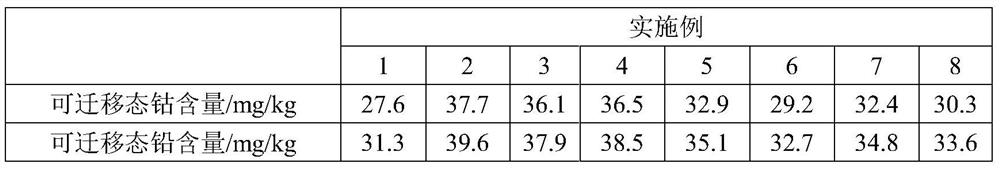

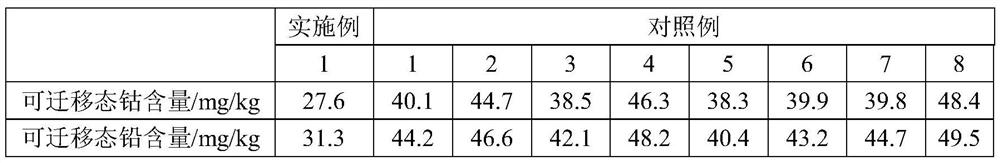

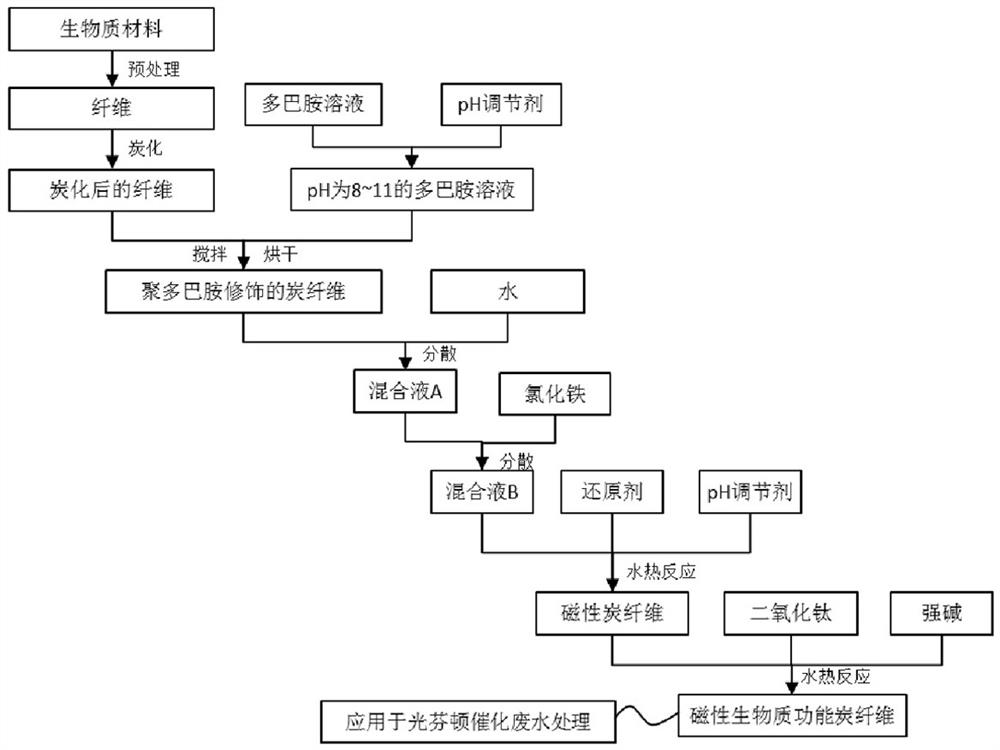

Magnetic biomass functional carbon fiber based on photo-Fenton catalysis, preparation method and application thereof

ActiveCN110330091AImprove surface chemical activitySimple recycling purposeWater/sewage treatment by irradiationOther chemical processesFiberWastewater

The invention discloses a preparation method of a magnetic biomass functional carbon fiber based on photo-Fenton catalysis. The method includes: taking a biomass material as the raw material, performing hydrothermal treatment to extract plant fiber, and then conducting charing, polydopamine modification and loading of ferriferrous oxide and titanium dioxide nanoparticles, thus obtaining the functional carbon fiber. The magnetic biomass functional carbon fiber prepared according to the invention includes carbon fiber and ferriferrous oxide nanoparticles and titanium dioxide nanoparticles loadedon the carbon fiber in situ. The magnetic biomass functional carbon fiber provided by the invention can be applied to photo-Fenton treatment of wastewater, and has the advantages of low raw materialcost, simple preparation method, magnetic recoverability in the wastewater treatment process, good treatment effect, etc.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Surface treatment agent and preparation method and application thereof

ActiveCN109852332AApplicable for a long timeSimple and fast operationNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentInsulation layerInterface bond

The invention relates to a surface treatment agent and a preparation method and application thereof, in particular, the invention relates to a surface treatment agent, a preparation method thereof andan application in bonding a silicone rubber insulation layer to a hydroxybutyl liner layer, belonging to the technical field of bonding the insulation layer of a solid rocket motor, in particular toa technology for strengthening the interface bonding between the silicone rubber insulation layer and the hydroxybutyl liner layer. Compared with the traditional surface treatment method of silicone rubber, such as corona and plasma treatment technology, the viscosity enhancement technology adopted by the invention does not need specific equipment, is simple and convenient to operate, and the treated interface has longer applicable time.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

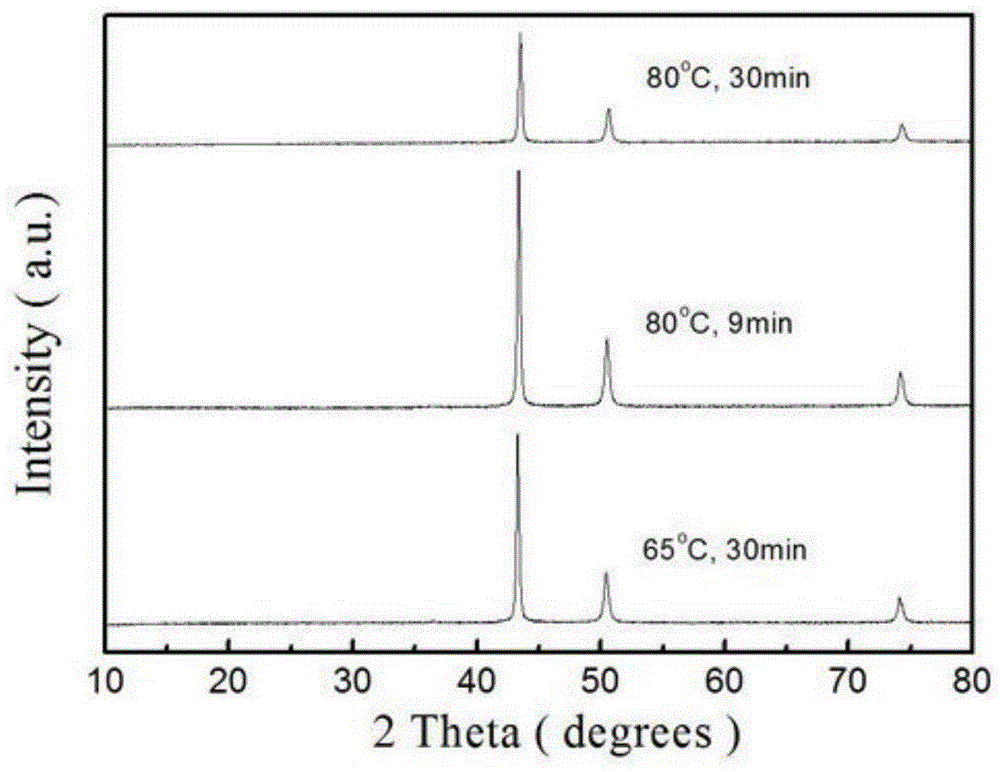

Method for simply and stably preparing micro-nano hollow copper

The invention provides a method for simply and stably preparing micro-nano hollow copper, and belongs to method for preparing hollow copper. The method includes the steps that firstly, copper sulfate is dissolved in water and placed in a water bath kettle to be heated; secondly, polyvinylpyrrolidone is added to the solution and stirred; thirdly, water is added to sodium hydroxide, and a water solution of sodium hydroxide is prepared, added to the solution in the second step and stirred; fourthly, a pre-mixed hydrazine hydrate solution is added to the solution in the third step and stirred; fifthly, the water bath kettle is adjusted to the proper temperature, sepia Cu particles are generated, solid-liquid two phases containing the Cu particles are centrifuged at a high speed, Cu solid particles are acquired and washed multiple times with anhydrous alcohol and deionized water in a cross mode, and other impurities generated in the reaction process are removed; sixthly, Cu powder containing water or alcohol is placed in a vacuum drying oven to be dried, and then the high-purity Cu micro-nano particles can be acquired. The method has the advantages of being low in cost, simple in preparation process, high in purity, good in repeatability and high in surface chemical activity.

Owner:CHINA UNIV OF MINING & TECH

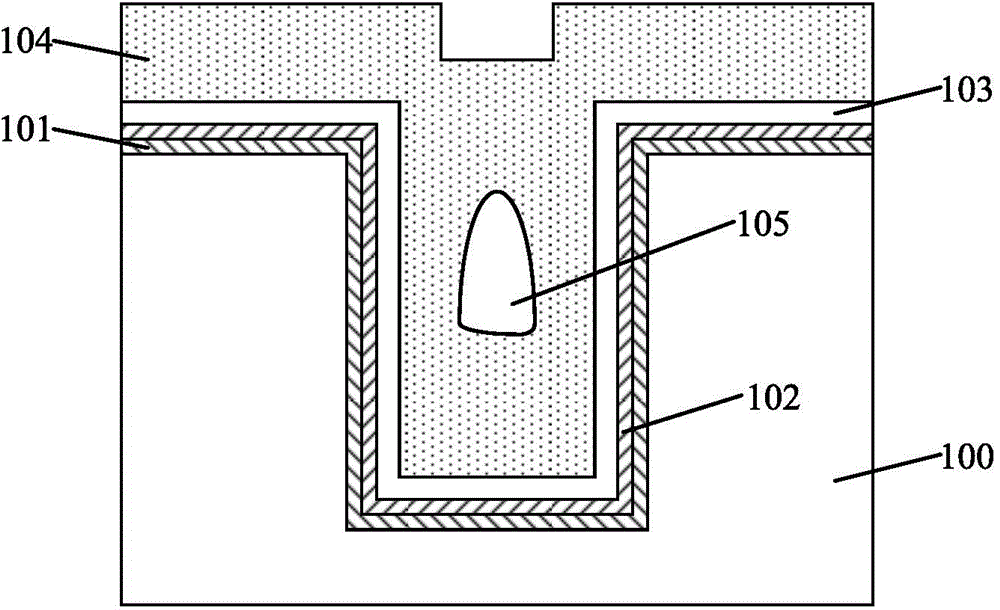

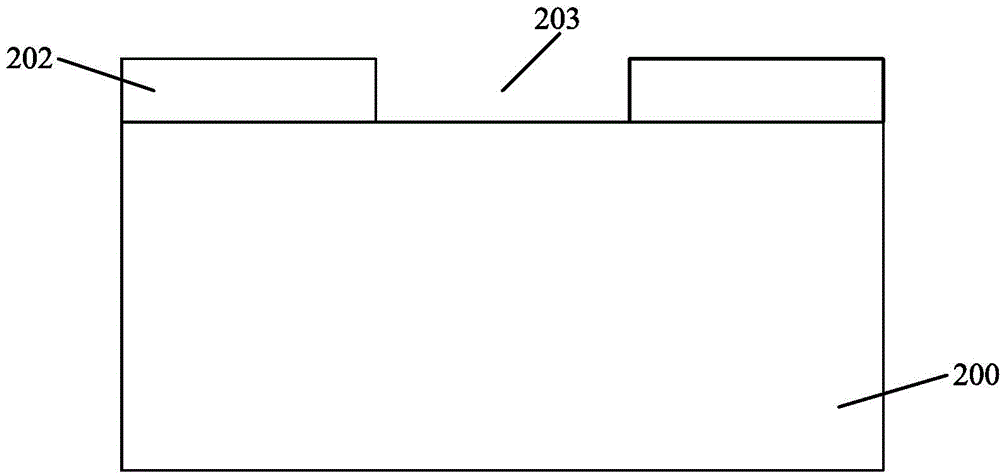

Semiconductor structure and formation method thereof

ActiveCN105336670AImprove surface chemical activityLower resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureAmorphous silicon

A semiconductor structure and a formation method thereof are disclosed. The formation method of the semiconductor structure comprises the following steps of providing a substrate and forming a through hole in the substrate; forming amorphous silicon layers on a through hole bottom and a sidewall surface; forming a barrier layer on an amorphous silicon layer surface, wherein the barrier layer preferentially orients a crystal plane (111); and forming a metal layer on a barrier layer surface, wherein the metal layer fills in the through hole and the metal layer preferentially orients the crystal plane (111). In the invention, after the amorphous silicon layers are formed on the silicon through hole bottom and the sidewall surface, the barrier layer and the metal layer which preferentially orient the crystal plane (111) are formed on the amorphous silicon layer surface so that an electromigration resistance capability of the metal layer is increased; a resistance of the metal layer is reduced; an electromigration resistance capability of the semiconductor structure is increased; an RC delayed effect of the semiconductor structure is reduced and electric performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

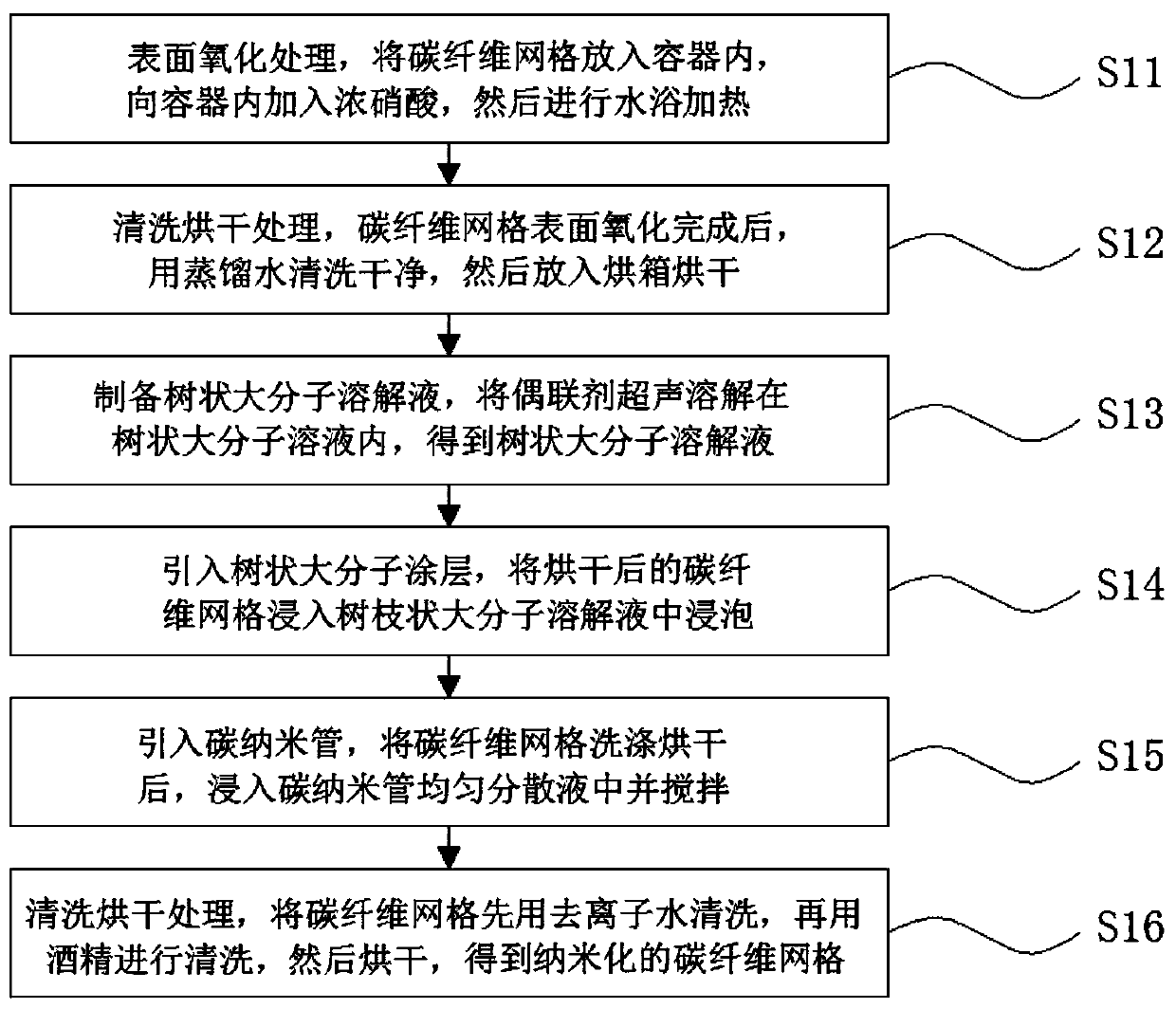

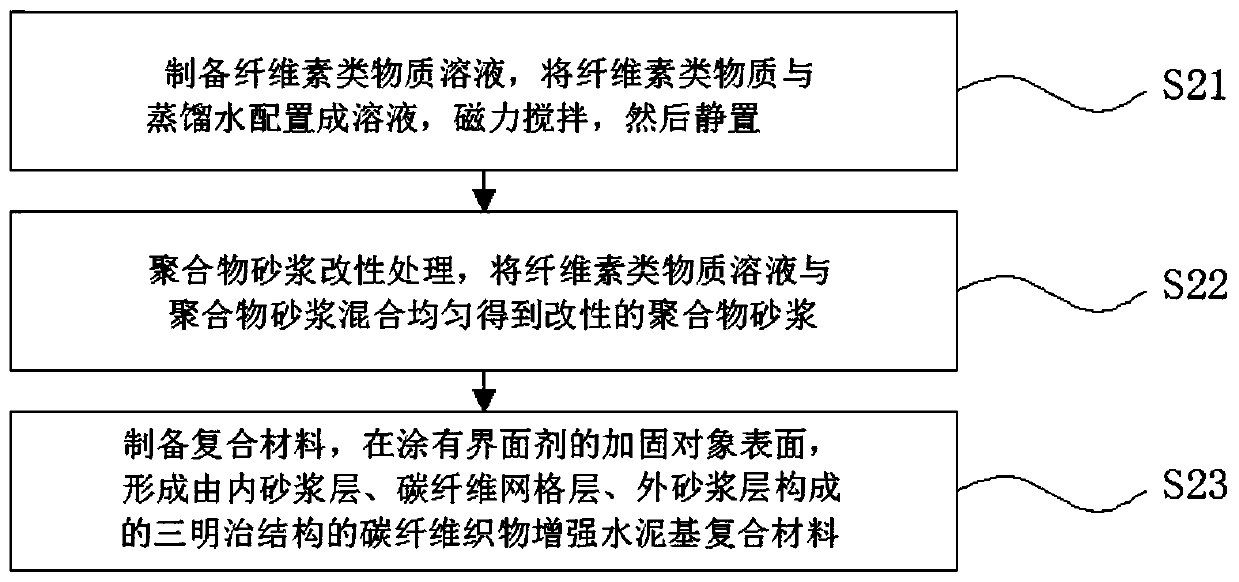

Carbon fiber grid, preparation method thereof, composite material and preparation of composite material

InactiveCN110144733AImprove mechanical propertiesMeet the mechanical performance requirementsCarbon fibresFiberCarbon fibers

The invention discloses a carbon fiber grid, a preparation method thereof, a composite material and a preparation of the composite material. The preparation method of the carbon fiber grid comprises following steps: surface oxidation treatment, cleaning and drying treatment, preparation of a dendritic macromolecular solution, introduction of a dendritic macromolecular coating, introduction of carbon nano tubes, cleaning and drying treatment and obtaining of the nano-crystallized carbon fiber grid. The bond stress of an interface of polymer mortar and the carbon fiber grid is effectively increased, so that the mechanical property requirement in a building reinforcement project is met.

Owner:CARBON TECH CO LTD

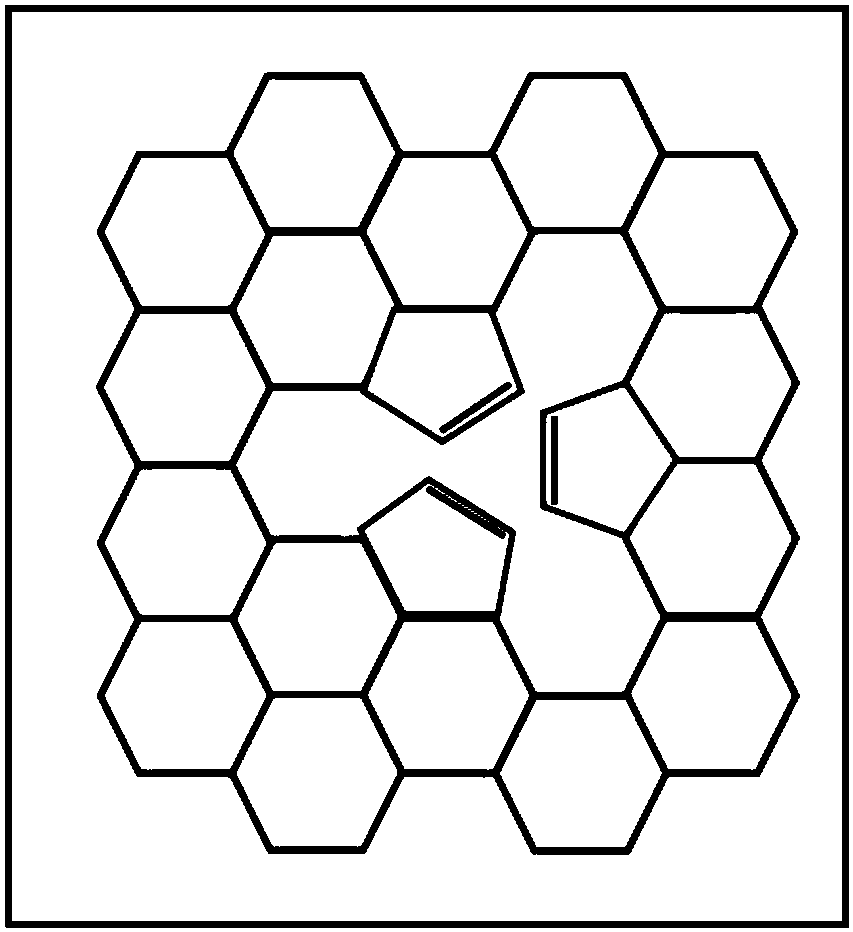

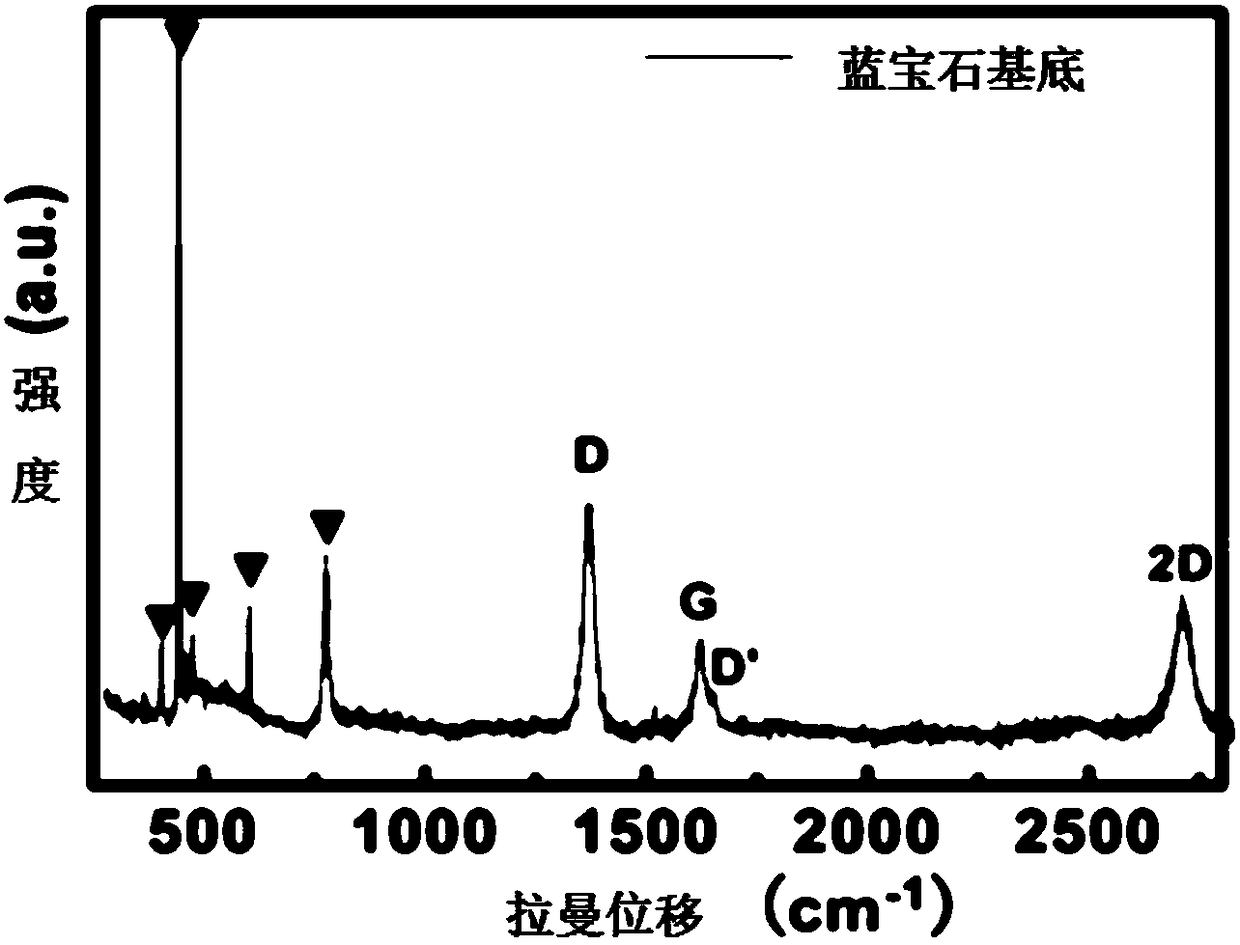

Preparation method for semiconductor material

InactiveCN109306466AImprove qualityPromotes epitaxial growthPolycrystalline material growthFrom chemically reactive gasesChemical treatmentSemiconductor materials

The invention discloses a preparation method for semiconductor material The preparation method comprises the steps that ethylene and / or acetylene are / is adopted asa carbon source; a chemical vapour deposition method is adopted, and graphene containing surface defect grows on a substrate which metal catalyst is not loaded; and in addition, the grapheme which is formed on the substrate and containsthe surface defects is adopted as a substrate body, and a semiconducting material epitaxially grows on the substrate body directly. According to the preparation method for the semiconductor materials,the graphene containing the great number of defects can be directly prepared through the chemical vapour deposition method; chemical treatment is not needed to be additionally conducted on the surface of the graphene; surface chemistry activity of the graphene can be improved; the graphene which is large in size and is uniformly provided with the great number of defects is obtained; The obtainedgraphene is directly adopted as the substrate body to grow the semiconducting material; transfer is not needed; and the problem that contamination is introduced in the substrate transfer process, so that the growing semiconducting material has macroscopic defects is avoided.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

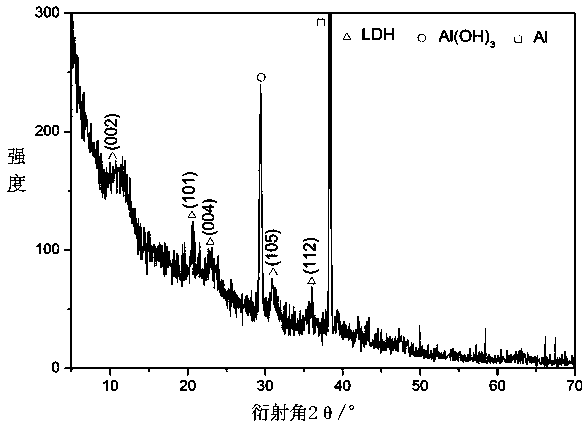

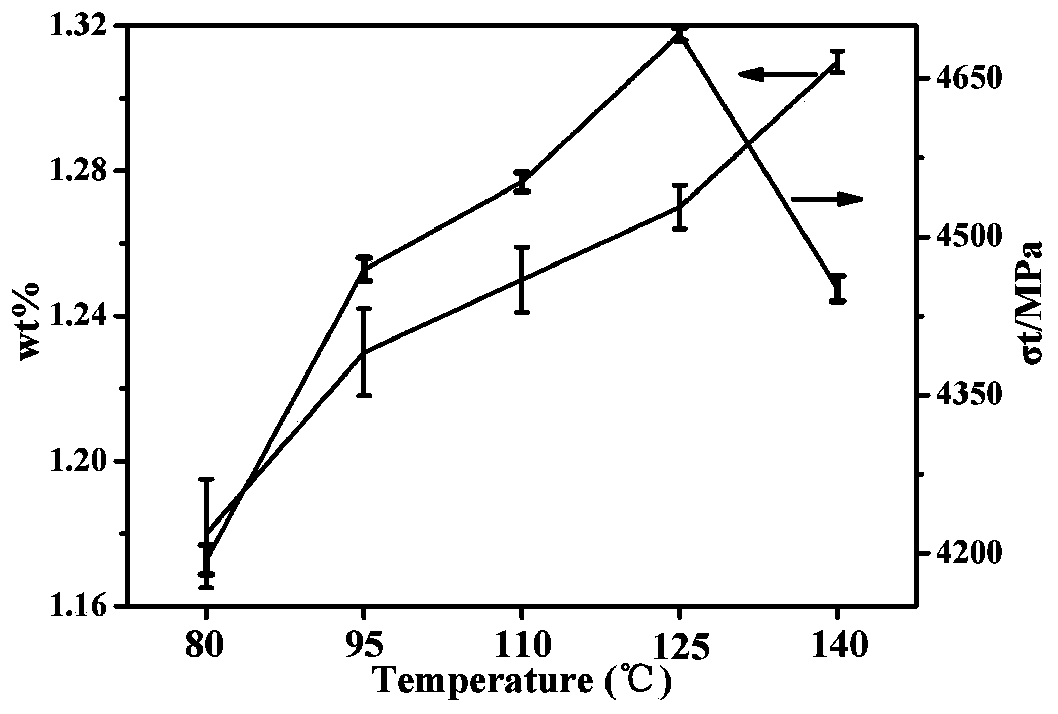

In-situ preparation method of layered dihydroxy metal oxide film on surface of Al-Cu-Li alloy

ActiveCN110684967AReduction of Second Phase ParticlesImprove surface chemical activityLiquid/solution decomposition chemical coatingEtchingLithium carbonate

The invention discloses an in-situ preparation method of a layered dihydroxy metal oxide film on the surface of an Al-Cu-Li alloy. The preparation method comprises the following steps: a, pretreating,specifically, the surface of the Al-Cu-Li alloy is pretreated by polishing, alkali etching and acid washing to the pretreated Al-Cu-Li alloy; b, preparing a lithium carbonate solution with the concentration of 0.05-0.15M and the pH of 11.5-13.0; AND c, putting the pretreated Al-Cu-Li alloy obtained in the step a into the lithium carbonate solution in the step b, heating at a constant temperaturefor 10-60min under an atmospheric environment and a temperature of 25-70 DEG C, taking out the treated Al-Cu-Li alloy, rinsing with deionized water, drying and growing the on the surface of the Al-Cu-Li alloy in situ to obtain the layered dihydroxy metal oxide film. The uniform and compact LDH film can be prepared on the surface of the Al-Cu-Li alloy in situ, the corrosion resistance of the alloyis remarkably improved, the reaction condition is mild, and the method is suitable for industrial production.

Owner:CHONGQING UNIV OF TECH

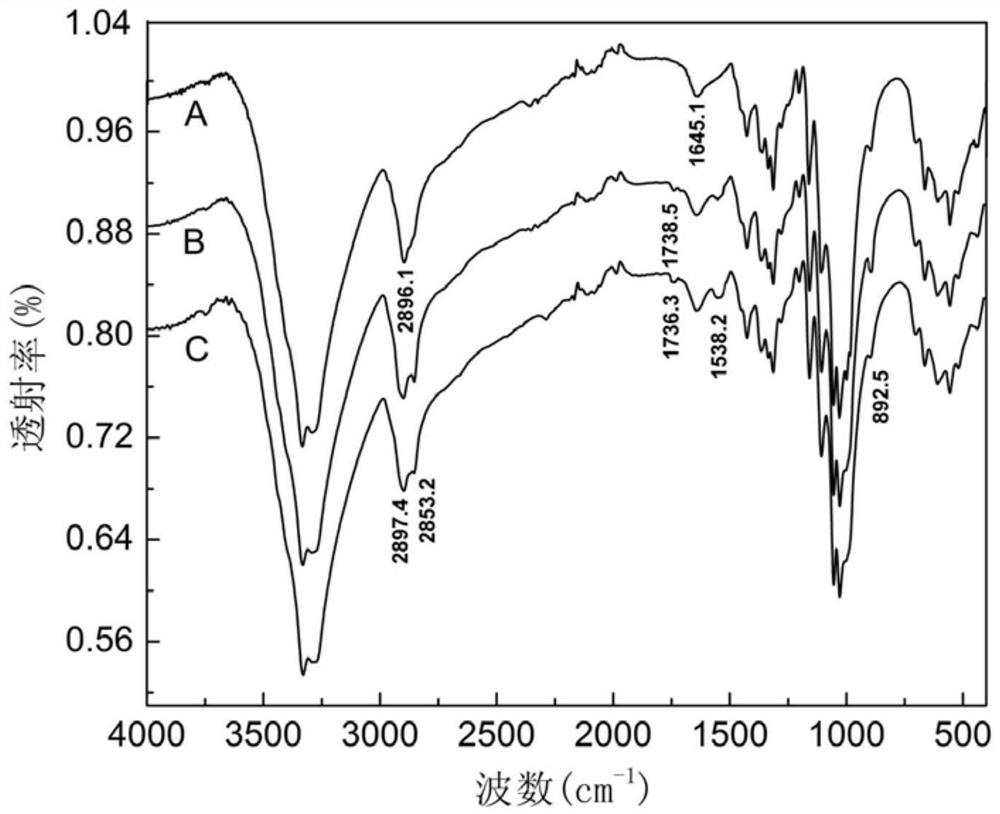

Modified carbon fiber and preparation of modified carbon fiber and nylon 6 composite materials

PendingCN111139646AReduce damageIncreasing disorderCarbon fibresElectrophoretic depositionElectrophoreses

The invention discloses modified carbon fiber. The modified carbon fiber is characterized by being prepared through firstly treating carbon fiber by a Soxhlet extractor steam molecule pretreatment method, and then carrying out electrophoretic deposition of chitosan to modify the carbon fiber, wherein the steam molecules are acetone and concentrated nitric acid. (1) A novel pretreatment method, namely the Soxhlet extractor steam molecule pretreatment method is proposed, and compared with a traditional solvent soaking treatment method, the novel pretreatment method has the advantages that the damage to the bulk property of CF is reduced and uniform and effective cleaning and oxidation treatment can be carried out on the surface of the CF. (2) In the electrophoretic deposition process, the CFis modified by positively charged chitosan molecules, so that the chemical activity of the surface of the CF and the disorder degree of a graphite layer are improved, the surface roughness is improved, the interface compatibility and associativity of the CF and PA6 are improved and the moisture and heat resistance and the mechanical properties of the CF / PA6 composite materials are improved.

Owner:GUIZHOU UNIV

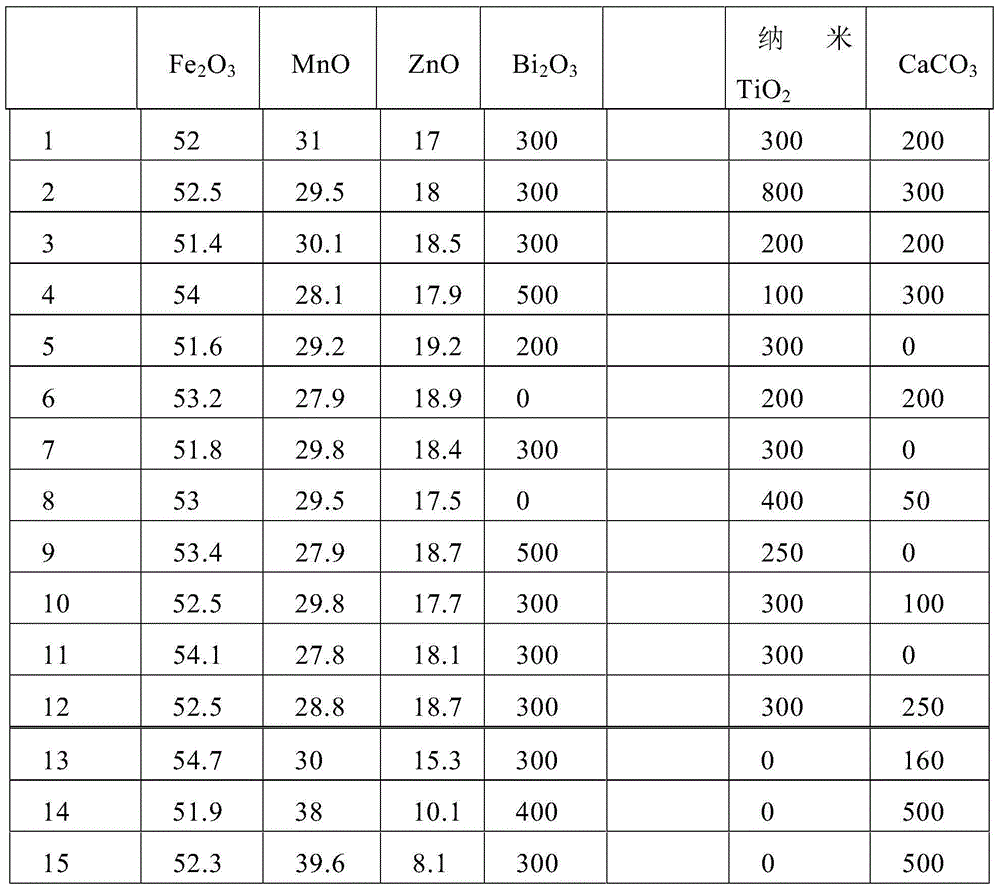

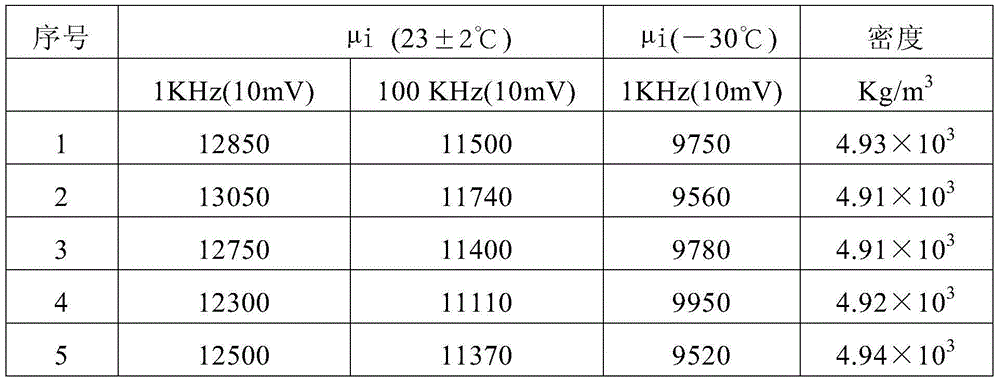

Low-temperature high-permeability soft magnetic manganese-zinc ferrite material and preparation method thereof

InactiveCN105788797AImprove permeabilityOptimized sintering methodInorganic material magnetismManganese oxideIron oxide

The invention relates to a low-temperature high-permeability soft magnetic manganese-zinc ferrite material and a preparation method thereof. The material comprises a main ingredient and trace additives, wherein the main ingredient comprises the following components in molar content: 51%-55% of ferrite, 15%-20% of zinc oxide and the balance of manganese oxide; the trace additives are selected from 100-400ppm of nanoscale TiO2 and 200-800ppm of Bi2O3 and CaCO3; and the preparation technology comprises a material weighing step, a strong mixing step, a pre-sintering step, a breaking step, a sanding step, a pulping step, a secondary spray granulation step, a pressing step and a sintering step. Compared with the prior art, the sintering method is optimized through the nanoscale TiO2; and the soft magnetic manganese-zinc ferrite material of which the high permeability ui is greater than 11,000 (25 DEG C, 10mV) and the initial permeability ui is greater than 9,000 at -10 DEG C can be produced.

Owner:上海康顺磁性元件厂有限公司 +1

Preparation method of composite magnetic material for sewage treatment

InactiveCN109225159AImprove adsorption capacityStrong physical adsorption capacityOther chemical processesWater contaminantsHexamethylenetetramineTherapeutic effect

The invention relates to a preparation method of a composite magnetic material for sewage treatment. The method comprises the following steps: 1, pulverizing sepiolite to a particle size of less thanor equal to 0.1mm, and then performing acid activation to obtain acid-activated sepiolite powder for later use; 2, dispersing the acid-activated sepiolite powder, obtained in the step 1, in ethylene glycol to obtain dispersion liquid, adding trivalent iron salt, divalent iron salt, hexamethylenetetramine, biochar, humic acid and an alkali solution into the dispersion liquid, then carrying out ultrasonic mixing uniformly, transferring into a high temperature and high pressure reaction kettle for carrying out a reaction for 4-12h, and then cooling to the room temperature to obtain a mixed solution; 3, enabling the mixed solution, obtained in the step 2, to stand for at least 24h, filtering and removing filtrate, and drying to obtain the sepiolite-loaded humic acid-modified ferroferric oxidecomposite magnetic material. The composite magnetic material prepared by the method has a very good treatment effect for pollutants and heavy metal ions in water, and can be widely applied to the sewage treatment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

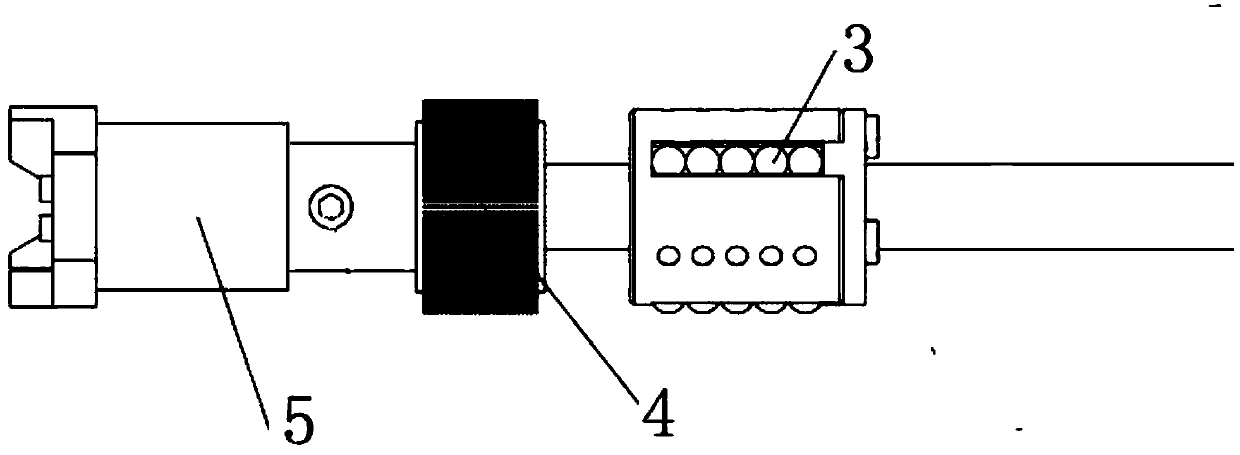

Plastic deformation method for achieving structural performance optimization of inner surface of straight pipe

ActiveCN109609743AHigh surface hardnessHigh strengthFurnace typesHeat treatment furnacesEngineeringShearing deformation

The invention belongs to the field of plastic processing, and relates to a plastic deformation method for achieving structural performance optimization of an inner surface of a straight pipe. High-speed shearing deformation is carried out on the inner surface of the metal straight pipe in a point contact mode, so that the structural performance of the inner surface of the pipe fitting is optimized. The plastic deformation method for achieving the structural performance optimization of the inner surface of the straight pipe has the following technical advantages that the point contact is introduced into the high-speed shearing plastic deformation, and effective cooling in straight pipe processing is achieved; the uniformity and the collimation degree of the wall thickness is effectively guaranteed before and after straight pipe processing; a 500-micron plastic deformation surface layer is formed on the inner surface of the straight pipe, so that the hardness and the strength of the inner surface of the straight pipe are improved by 5-20 times, and the surface quality is improved until the roughness Ra is 0.02-0.2; and the chemical activity of the inner surface of the straight pipe is greatly improved, and the temperature of chemical heat treatment such as nitrizing and carburizing is reduced by 200 DEG C or above.

Owner:YANSHAN UNIV

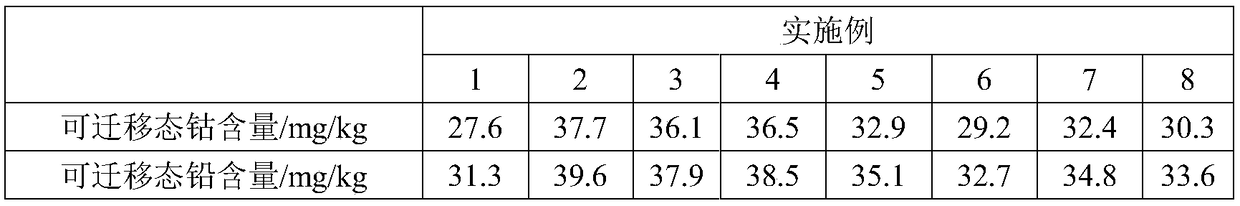

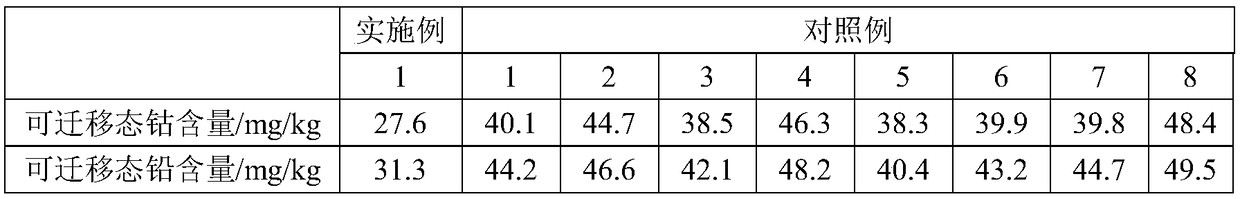

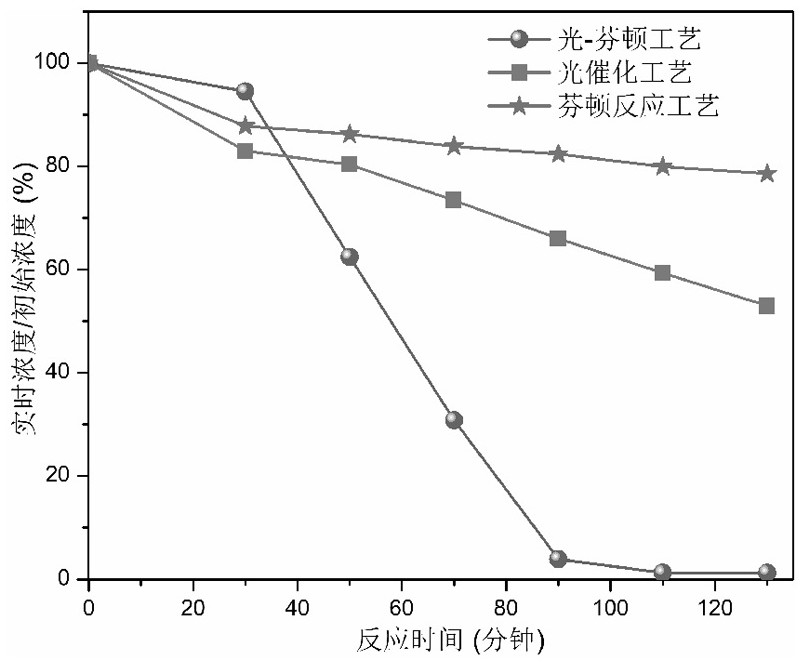

Heavy metal repairing agent for soil and preparation method thereof

ActiveCN109135759AIncrease layer spacingGuaranteed adsorption effectOrganic fertilisersSoil conditioning compositionsMercaptoacetic acidHydrogen peroxide

The invention relates to a heavy metal repairing agent for soil and a preparation method thereof. The heavy metal repairing agent for soil is prepared from modified porous ferroferric oxide, modifiedactivated carbon and modified imvite, the modified porous ferroferric oxide is prepared from porous ferroferric oxide, ethylene diamine tetraacetic acid and mercaptoethanol through a reaction, and theporous ferroferric oxide is prepared from ferric sulfate, urea, water, iron powder, ethylene diamine tetraacetic acid, trioxymethylene, oxalic acid, a KH-550 coupling agent and ethyl alcohol througha reaction; the modified activated carbon is prepared from activated carbon, hydrogen peroxide, concentrated nitric acid, ethylene diamine tetraacetic acid and 12-sulfydryl lauric acid through a reaction, and the modified imvite is prepared from imvite, ethylene diamine tetraacetic acid, mercaptoacetic acid and quadrol through a reaction. The heavy metal repairing agent for soil has excellent performance for reducing heavy metal ion content in soil.

Owner:峰景园林工程集团有限公司

Surface treatment method for improving corrosion resistance of aluminum alloy

InactiveCN111020452AImprove surface chemical activityIncrease temperatureMolten spray coatingForeign matterSand blasting

The invention discloses a surface treatment method for improving corrosion resistance of an aluminum alloy. Firstly, sand blasting treatment is carried out on the surface of the aluminum alloy, foreign matter and non-compact oxide skin adhering to the surface of the aluminum alloy are removed, and the fresh surface of the aluminum alloy is exposed; and then, a plasma spraying method is adopted forcarrying out high-temperature plasma surface oxygen-rich ion treatment on the surface of the aluminum alloy, that is, O2 is added on the basis of adopting Ar and H2 as plasma gas in traditional plasma spraying, O2 is ionized under high temperature and reacts with the aluminum alloy, a compact corrosion-resistant Al2O3 film is formed on the surface of the aluminum alloy, and therefore the corrosion resistance of the aluminum alloy is improved. Compared with the traditional aluminum alloy corrosion protection technology, the surface treatment method has the advantages of being efficient, low incost, free of waste water and waste gas pollution and the like.

Owner:王存发

Composite-carrier honeycomb monolithic denitration catalyst and preparing method thereof

InactiveCN102773091BImprove removal effectLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholCordierite

The invention discloses novel composite-carrier honeycomb monolithic denitration catalyst, in particular to honeycomb monolithic SCR (selective catalytic reduction) denitration catalyst with modified cordierite and titanium dioxide as a composite carrier and a preparing method of the honeycomb monolithic SCR denitration catalyst. The novel composite-carrier honeycomb monolithic denitration catalyst includes the following components, 10-25wt% of modified cordierite powder, 65-85wt% of titanium tungsten powder (containing 3-10wt% of WO3), 1-2wt% of V2O5, and the balance additive which is glass fiber or polyvinyl alcohol. The novel composite-carrier honeycomb monolithic denitration catalyst is prepared from following steps of mixing, mud refining, extrusion forming, drying and roasting, has the advantages of chemical stability, thermostability and wear-resisting property, and expresses higher catalytic activity of NH3-SCR and wider active temperature window. Cordierite power at low cost is utilized to substitute part of imported titanium tungsten powder and serve as the carrier for the SCR denitration catalyst which is simple to prepare, degree of dependence on imported titanium tungsten powder is reduced, and the defects that the carrier for existing SCR denitration catalyst is unstable in mechanical performance and high in price are overcome.

Owner:CHONGQING UNIV +2

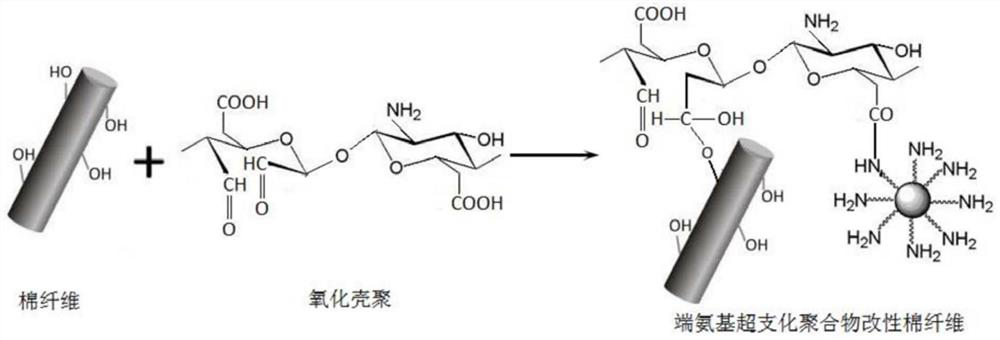

Preparation method of environment-friendly surface-modified cotton fibers

ActiveCN112111970AHuman-friendlyHigh reactivityBiochemical fibre treatmentDyeing processInorganic saltsColour fastness

The invention discloses a preparation method of environment-friendly surface-modified cotton fibers. The environment-friendly surface-modified cotton fibers are obtained by grafting oxidized chitosanon cotton fibers in a dilute acetic acid solution and then carrying out amidation chemical reaction on carboxyl in an oxidized chitosan grafted cotton fabric and amino of an amino-terminated hyperbranched polymer. The preparation method is simple and easy to implement, does not use a chemical cross-linking agent, is environment-friendly and friendly to the human body, the prepared amino-terminatedhyperbranched polymer on the surface of the modified cotton fabric is high in grafting rate, good in washing resistance and lasting in antibiosis, a layer of positive charges can be fixed to the surfaces of cotton fibers after protonation of the amino-terminated hyperbranched polymer, dye can be actively adsorbed, inorganic salt and alkali are not used, and the dye-uptake and color fastness are high, so that the method has a wide prospect in the field of salt-free ecological dyeing.

Owner:SHAOXING MAIBAO TECH CO LTD

Jade-white porcelain prepared from modified Jiefu kaolin, and preparation process thereof

The invention relates to the technical field of ceramic manufacturing, and concretely relates to a jade-white porcelain prepared from modified Jiefu kaolin, and a preparation process thereof. The jade-white porcelain prepared from the modified Jiefu kaolin comprises a ceramic green body, and the ceramic green body is prepared from the modified Jiefu kaolin, Dehua kaolin, quartz, montmorillonite, potassium feldspar, high-temperature frit and tricalcium phosphate. According to the jade-white porcelain prepared from the modified Jiefu kaolin, the modified Jiaofu kaolin is introduced as a raw material, the problems that Dehua kaolin is soft, low in iron content and high in potassium content are solved, the prepared jade-white porcelain is high in cleanliness, flawless, fine, pure, free of glazing and fine in body, the jade-white porcelain can meet the manufacturing requirements of art ceramics and daily ceramics, the production cost of traditional jade-white porcelain is reduced, the low-quality Jiefu kaolin is utilized, and the jade-white porcelain has positive economic benefits and social benefits for promoting the development of Dehua ceramic production areas and the popularizationof the jade-white porcelain.

Owner:福建省德化县腾艺陶瓷有限公司

Method for preparing titanium dioxide product for high-specific surface area denitrating catalyst

InactiveCN101318697BImprove performanceWill not polluteCatalyst carriersDispersed particle separationFiltrationHigh surface

The invention relates to a method for preparing titania raw materials with high specific surface area used by denitration catalyst, which relates to the chemical product preparation technical field. The method comprises the following steps that: a metatitanic acid produced by adoption of the sulfuric acid method is processed by an organic surfactant and then modified so as to reduce the viscosityof the metatitanic acid; and loose titania products with high specific surface area and high surface chemical activity used by the denitration catalyst are prepared through filtration and calcinationof the processed metatitanic acid. The method has a simple technique for processing the metatitanic acid and has low cost; and added organic substances are fully decomposed during the calcining stage, thereby impurities can not be brought into the final products and the environmental pollution can not be caused.

Owner:四川华铁钒钛科技股份有限公司

Production method of carbon-doped hydroxyapatite defluorination filter material

InactiveCN106745628AImprove the effect of fluoride removalLess adulteratedWater/sewage treatmentPhosphoric acidFilter material

The invention discloses a production method of a carbon-doped hydroxyapatite defluorination filter material. The method comprises the steps of adopting industrial calcium nitrate, phosphoric acid, ammonia water and ammonium bicarbonate as raw materials; and synthesizing the carbon-doped hydroxyapatite defluorination filter material, wherein the ammonia water is capable of playing a role in regulating the pH value of a reaction system to ensure the purity and defluorination capacity of a product. The doping amount of the ammonium bicarbonate is extremely low. Crystal lattices of hydroxyapatite distort due to doping of CO3<2->, the hole concentration of the surface is correspondingly increased, the structure becomes loose, and the surface chemical activity is correspondingly strengthened, so that the defluorination ability is improved; and the total defluorination capacity of the filter material is improved by 3-4 times in comparison with that of a single hydroxyapatite defluorination filter material and improved by over 7 times in comparison with that of an activated aluminum oxide defluorination filter material. The method is simple, the defluorination effect is stable for a long period of time, and the production efficiency is higher.

Owner:CHINA UNIV OF MINING & TECH

A kind of production method of carbon-doped hydroxyapatite defluoridation filter material

InactiveCN106745628BImprove the effect of fluoride removalLess adulteratedWater/sewage treatmentO-Phosphoric AcidActivated Aluminum Oxide

The invention discloses a production method of a carbon-doped hydroxyapatite defluorination filter material. The method comprises the steps of adopting industrial calcium nitrate, phosphoric acid, ammonia water and ammonium bicarbonate as raw materials; and synthesizing the carbon-doped hydroxyapatite defluorination filter material, wherein the ammonia water is capable of playing a role in regulating the pH value of a reaction system to ensure the purity and defluorination capacity of a product. The doping amount of the ammonium bicarbonate is extremely low. Crystal lattices of hydroxyapatite distort due to doping of CO3<2->, the hole concentration of the surface is correspondingly increased, the structure becomes loose, and the surface chemical activity is correspondingly strengthened, so that the defluorination ability is improved; and the total defluorination capacity of the filter material is improved by 3-4 times in comparison with that of a single hydroxyapatite defluorination filter material and improved by over 7 times in comparison with that of an activated aluminum oxide defluorination filter material. The method is simple, the defluorination effect is stable for a long period of time, and the production efficiency is higher.

Owner:CHINA UNIV OF MINING & TECH

A kind of heavy metal remediation agent for soil and preparation method thereof

ActiveCN109135759BIncrease layer spacingGuaranteed adsorption effectOrganic fertilisersSoil conditioning compositionsIron sulfateOXALIC ACID DIHYDRATE

The invention relates to a heavy metal restoration agent for soil and a preparation method thereof. The heavy metal remediation agent for soil is composed of modified porous ferric oxide, modified activated carbon and modified montmorillonite, and the modified porous ferric oxide is composed of porous ferric oxide, ethylenediaminetetraacetic acid and mercapto Prepared by ethanol reaction, the porous ferric ferric oxide is prepared by the reaction of ferric sulfate, urea, water, iron powder, ethylenediaminetetraacetic acid, paraformaldehyde, oxalic acid, KH-550 coupling agent and ethanol, the modified Activated carbon is prepared by the reaction of activated carbon, hydrogen peroxide, concentrated nitric acid, ethylenediaminetetraacetic acid and 12-mercaptododecanoic acid, and the modified montmorillonite is made of montmorillonite, ethylenediaminetetraacetic acid, thioglycolic acid and ethylenediamine The reaction is made. The heavy metal remediation agent for soil provided by the invention has excellent performance in reducing the content of heavy metal ions in soil.

Owner:峰景园林工程集团有限公司

A kind of surface treatment agent and its preparation method and application

ActiveCN109852332BApplicable for a long timeSimple and fast operationNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentPolymer scienceThermal insulation

The invention relates to a surface treatment agent and its preparation method and application, in particular to a surface treatment agent and its preparation method and its application in the bonding of the silicone rubber heat insulating layer and the butyl hydroxy lining layer, belonging to the solid rocket motor heat insulating layer bonding In the field of jointing technology, it is especially related to the technology of enhancing the interface bonding between the silicone rubber heat insulating layer and the butylated hydroxyl lining layer. Compared with traditional silicone rubber surface treatment methods, such as corona and plasma treatment techniques, the viscosity increasing technique adopted in the present invention does not require specific equipment, is easy to operate, and the treated interface has a longer application time.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Magnetic biomass functional carbon fiber based on photo-Fenton catalysis and its preparation method and application

ActiveCN110330091BImprove surface chemical activitySimple recycling purposeWater/sewage treatment by irradiationOther chemical processesCarbon fibersPlant fibre

The invention discloses a method for preparing magnetic biomass functional carbon fibers based on photo-Fenton catalysis. Biomass materials are used as raw materials, plant fibers are extracted through hydrothermal treatment, and then carbonized, polydopamine modified, ferroferric oxide and titanium dioxide nanoparticles loaded to obtain functionalized carbon fibers. The magnetic biomass functional carbon fiber prepared by the present invention includes carbon fiber and Fe3O4 nanoparticles and titanium dioxide nanoparticles loaded on the carbon fiber in situ. The present invention can be applied to photo-Fenton treatment of wastewater, and has the advantages of low raw material cost, The preparation method is simple and has the advantages of magnetic recovery in the process of treating waste water, good treatment effect and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

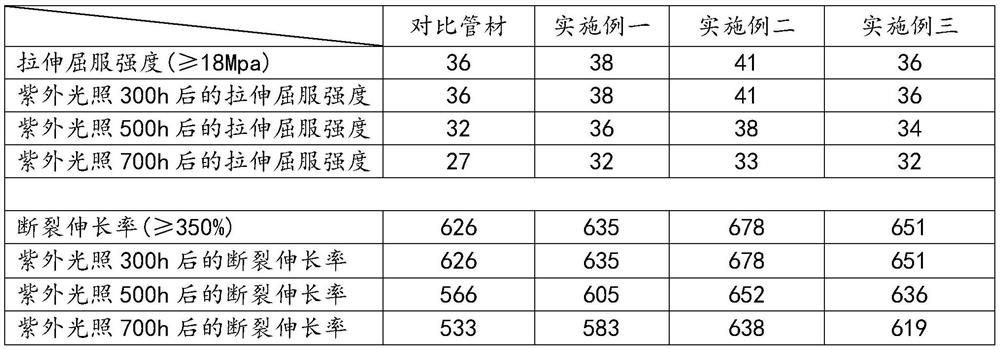

High-density polyethylene flame-retardant sub-pipe and preparation method thereof

The invention discloses a high-density polyethylene flame-retardant sub-pipe prepared from the following raw materials, by weight: 100 parts of high-density polyethylene, 3-6 parts of a plasticizer, 0.1-0.8 part of a 1010 type antioxidant, 0.2-1 part of a 168 type antioxidant, 0.3-2 part of calcium stearate, 0.2-3 part of 58 # paraffin, 8-15 parts of titanium dioxide, 4-8 parts of 2000-mesh lightcalcium carbonate and 3-6 parts of halogenated hydrocarbon. The polyethylene pipe provided by the invention has good ultraviolet resistance, can effectively delay the aging speed of the polyethylene pipe, also has good flame retardant property, and adapts to the use requirements of places such as high-rise buildings and coal mines. The invention further provides a preparation method of the high-density polyethylene flame-retardant sub-pipe, the preparation speed of the pipe can be increased, the raw materials are uniformly mixed in the reaction kettle, and the chemical reaction is stable.

Owner:苏州市皓月管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com