Modified carbon fiber and preparation of modified carbon fiber and nylon 6 composite materials

A technology for modifying carbon and carbon fiber, which is applied in the fields of carbon fiber, fiber processing, textiles and paper making, etc. It can solve difficult chemical bonding of PA6 matrix, poor wettability and bonding between CF surface and PA6 matrix, and restrict CF/PA6 composite materials. application and other issues to achieve the effect of increasing the degree of disorder, improving the interfacial compatibility and bonding, and improving the heat and humidity resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. CF surface pretreatment

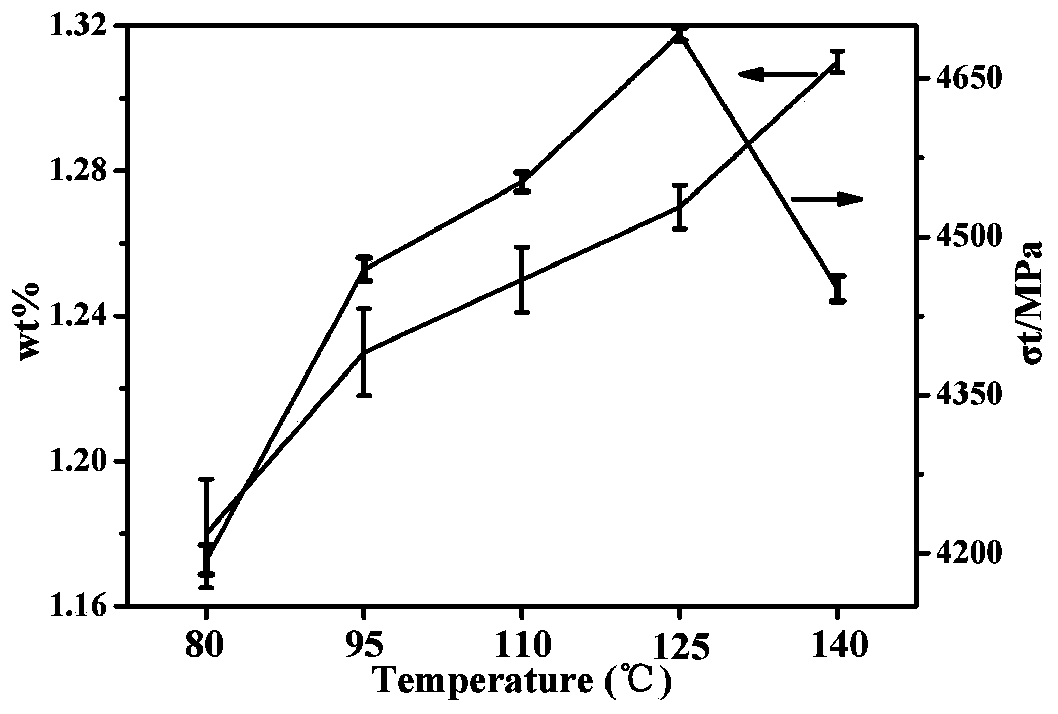

[0037] (1) Cut 10 sections of CF precursors each 3 meters long, dry, weigh and number them. For the heating device in the constant temperature oil bath experiment, open the oil bath in advance to adjust the temperature to a constant temperature, wrap the CF on the steam outlet end of the extraction tube, pour 150ml of acetone solution into the extraction bottle, connect the condenser tube to tap water, and assemble the extraction bottle, extraction tube and serpentine condenser, and then put them in a constant temperature oil bath. The acetone vapor cleaning process on the CF surface shown in Table 1 explores the influence of the system reaction time and reaction temperature (80°C is the critical temperature at which the acetone vapor reaches the steam outlet) on the cleaning of the CF surface.

[0038] Table 1 Acetone vapor cleaning treatment CF process

[0039] Serial number 1 2 3 4 5 6 7 8 9 10 Temperature(°C) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com