Preparation method for semiconductor material

A technology of semiconductor and chemical vapor deposition, which is applied in the direction of polycrystalline material growth, chemical instruments and methods, metal material coating technology, etc., can solve the problems of epitaxial growth difficulty, pollution, semiconductor material quality problems, etc., and achieve the improvement of surface chemical activity , avoid pollution, and facilitate the effect of epitaxial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] An embodiment of the present invention provides a method for preparing a semiconductor material, including:

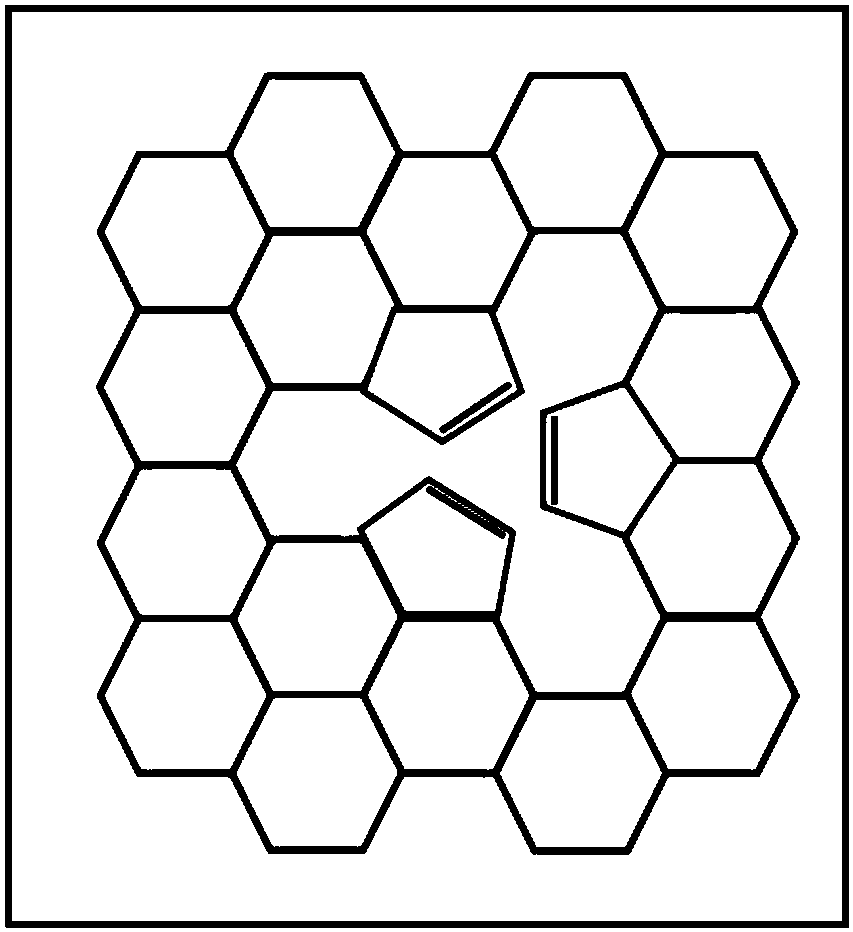

[0018] Graphene containing surface defects is grown by chemical vapor deposition on an unsupported metal catalyst substrate from ethylene and / or acetylene as a carbon source, and,

[0019] The graphene formed on the base and containing surface defects is used as a substrate, and the semiconductor material is epitaxially grown directly on the substrate.

[0020] Further, the semiconductor material includes GaN, AlN, InN, ZnO or SiC, but is not limited thereto.

[0021] Further, the reaction temperature used in the chemical vapor deposition method is 800-1200°C.

[0022] Further, the reaction atmosphere used in the chemical vapor deposition method includes any one or a combination of two or more of ethylene or acetylene, hydrogen, and argon, but is not limited thereto.

[0023] Preferably, the volume percentage of ethylene or acetylene in the reaction atmosphere...

Embodiment 1

[0036] Embodiment 1: take sapphire as substrate, ethylene is carbon source, utilize chemical vapor deposition method to grow graphene on substrate, specifically as follows:

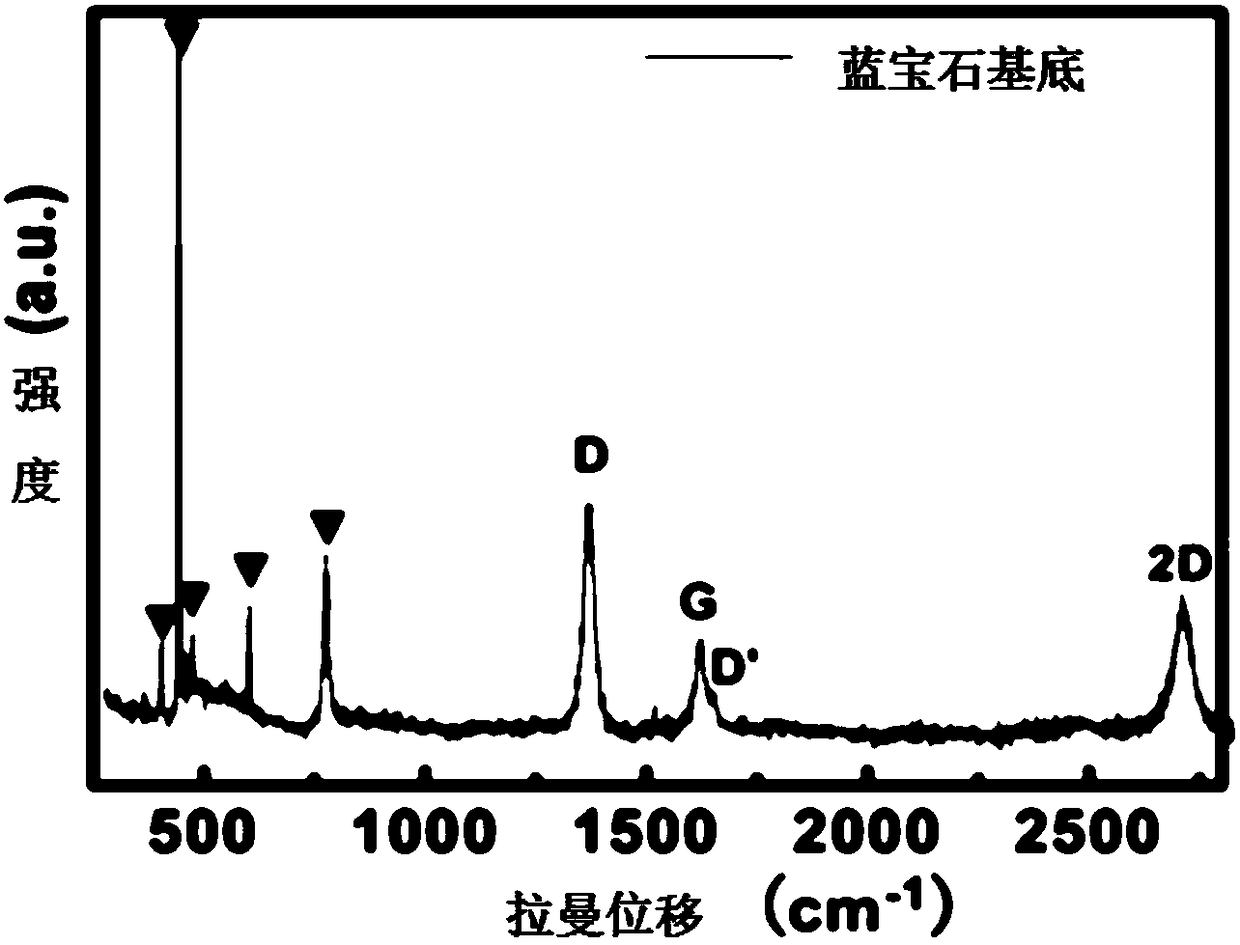

[0037] First, put the epitaxial sapphire substrate into the growth chamber, adjust the air pressure in the chamber to about 1Pa, remove the background oxygen, and then pass in argon gas of 900 sccm, and control the chamber air pressure to 5x10 by controlling the pumping speed of the dry pump. 4 Pa, raise the substrate temperature to 1200°C, keep it warm for about 10 minutes, and keep the chamber pressure constant during the process. Then pass 5sccm hydrogen gas for 2 minutes to clean the substrate surface, then pass 100sccm ethylene to grow graphene, and the growth time is 5 minutes; after the growth is completed, stop passing hydrogen and ethylene, quickly cool down to room temperature, and keep the argon gas unchanged. Keeping the pressure in the cavity constant, graphene with a large number of defects ...

Embodiment 2

[0045] Embodiment 2: take sapphire as substrate, and acetylene is carbon source, utilize chemical vapor deposition method to grow graphene on substrate, specifically as follows:

[0046] First put the epitaxial sapphire substrate into the growth chamber, adjust the air pressure in the chamber to 1Pa, remove the background oxygen, and then pass in argon gas 900sccm, and control the chamber air pressure to 5x10 by controlling the pumping speed of the dry pump. 4 Pa, raise the substrate temperature to 1000°C, keep it warm for about 10 minutes, keep the chamber pressure constant during this process, then pass 5 sccm hydrogen gas for 2 minutes to clean the substrate surface, and then pass 100 sccm acetylene to grow graphite Graphene, the growth time is 5 minutes; after the growth is completed, stop the flow of hydrogen and acetylene, quickly cool down to room temperature, keep the argon gas and the pressure in the chamber constant, and finally obtain graphene with a large number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com