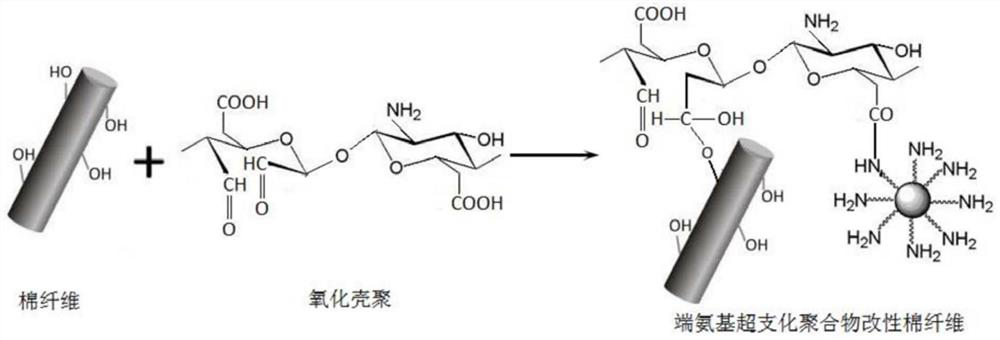

Preparation method of environment-friendly surface-modified cotton fibers

A surface modification and cotton fiber technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of high requirements for process equipment and various components of finishing liquid, so as to improve grafting rate, enhance surface chemical activity, The effect of high grafting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

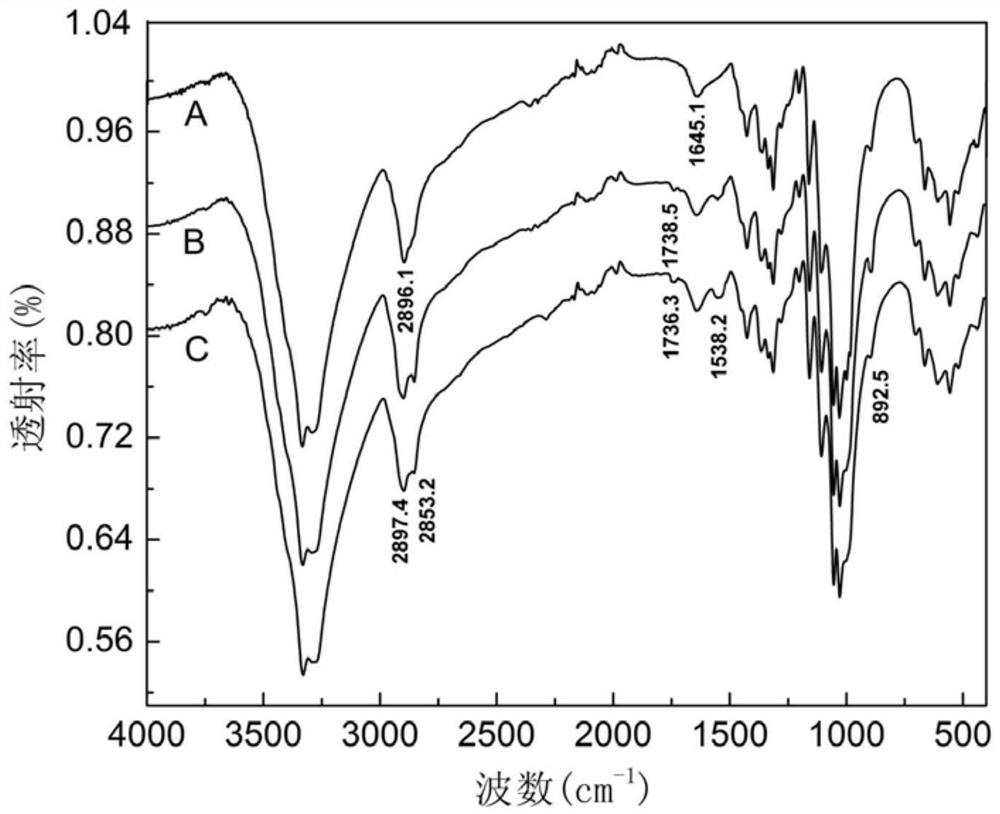

[0023] (1) Oxidized chitosan with a viscosity average molecular weight of 100,000, a degree of deacetylation of 95%, an aldehyde content of 23.16% at C2 and C3, and a carboxyl content of 40.69% at C6 was dissolved at 60°C in dilute In the acetic acid solution, be configured into the oxidized chitosan solution that mass concentration is 1%; Cotton fiber is put into the mixture of 1-ethyl-3-methylimidazolium acetate ionic liquid and deionized water that volume ratio is 1:1 In the mixed solution, treat it at 35°C for 2 hours to obtain swollen cotton fibers, add it to the chitosan solution at a bath ratio of 1:50, stir and react at 60°C for 2 hours, take out the cotton fibers and dry them at 70°C for 3 hours , to obtain oxidized chitosan grafted cotton fibers.

[0024] (2) Add oxidized chitosan grafted cotton fiber in the solution of 0.5% amino-terminated hyperbranched polymer (weight average molecular weight is 8275), stir and react at 45°C for 10min, after the reaction finishes,...

Embodiment 2

[0026] (1) Oxidized chitosan with a viscosity average molecular weight of 80,000, a degree of deacetylation of 93%, an aldehyde content of 31.58% at C2 and C3, and a carboxyl content of 40.69% at C6 was dissolved at 60°C in dilute In the acetic acid solution, be configured into the oxidized chitosan solution that mass concentration is 2%; Cotton fiber is put into the mixture of 1-ethyl-3-methylimidazole acetate ionic liquid and deionized water that volume ratio is 1:1 In the mixed solution, treat it at 40°C for 2 hours to obtain swollen cotton fibers, add it to the chitosan solution at a bath ratio of 1:50, stir and react at 70°C for 2 hours, take out the cotton fibers and dry them at 80°C for 3 hours , to obtain oxidized chitosan grafted cotton fibers.

[0027] (2) Add oxidized chitosan grafted cotton fiber in the solution of amino-terminated hyperbranched polymer (weight average molecular weight is 8275) of mass concentration 1%, stir reaction 15min at 60 ℃, after reaction f...

Embodiment 3

[0029](1) Oxidized chitosan with a viscosity-average molecular weight of 50,000, a degree of deacetylation of 92%, an aldehyde content of 31.58% at the C2 and C3 positions, and a carboxyl content of 51.71% at the C6 position was dissolved at 60°C in dilute In the acetic acid solution, be configured into the oxidized chitosan solution that mass concentration is 2%; Cotton fiber is put into the mixture of 1-ethyl-3-methylimidazole acetate ionic liquid and deionized water that volume ratio is 1:1 In the mixed solution, treat it at 40°C for 3 hours to obtain swollen cotton fibers, add it to the chitosan solution at a bath ratio of 1:50, stir and react at 80°C for 2 hours, take out the cotton fibers and dry them at 80°C for 3 hours , to obtain oxidized chitosan grafted cotton fibers.

[0030] (2) Add oxidized chitosan grafted cotton fiber in the solution of amino-terminated hyperbranched polymer (weight average molecular weight is 8275) of mass concentration 1%, stir reaction 25min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com