Patents

Literature

256 results about "4d printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

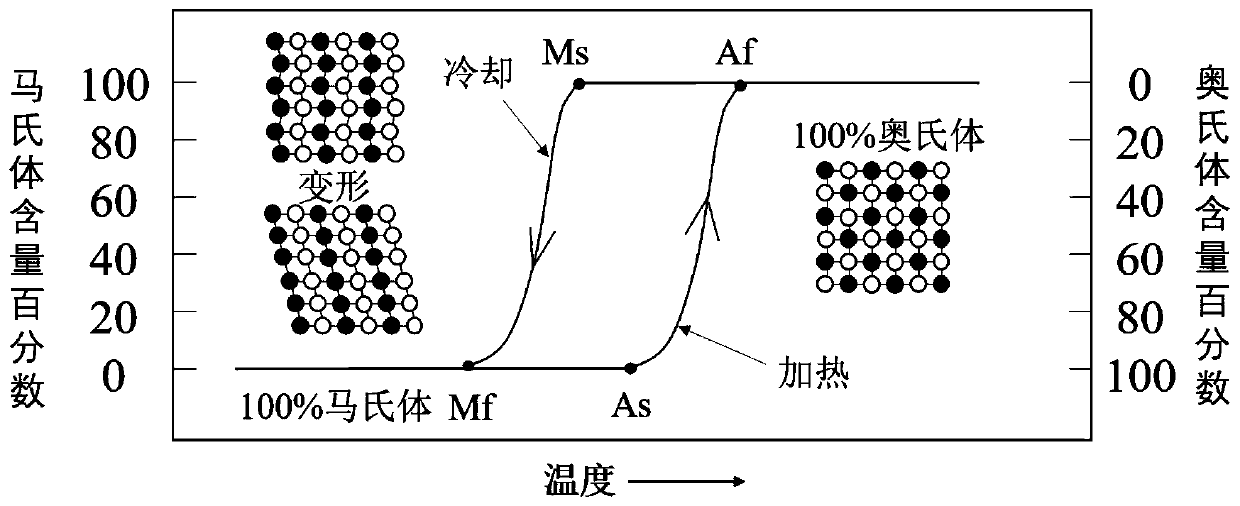

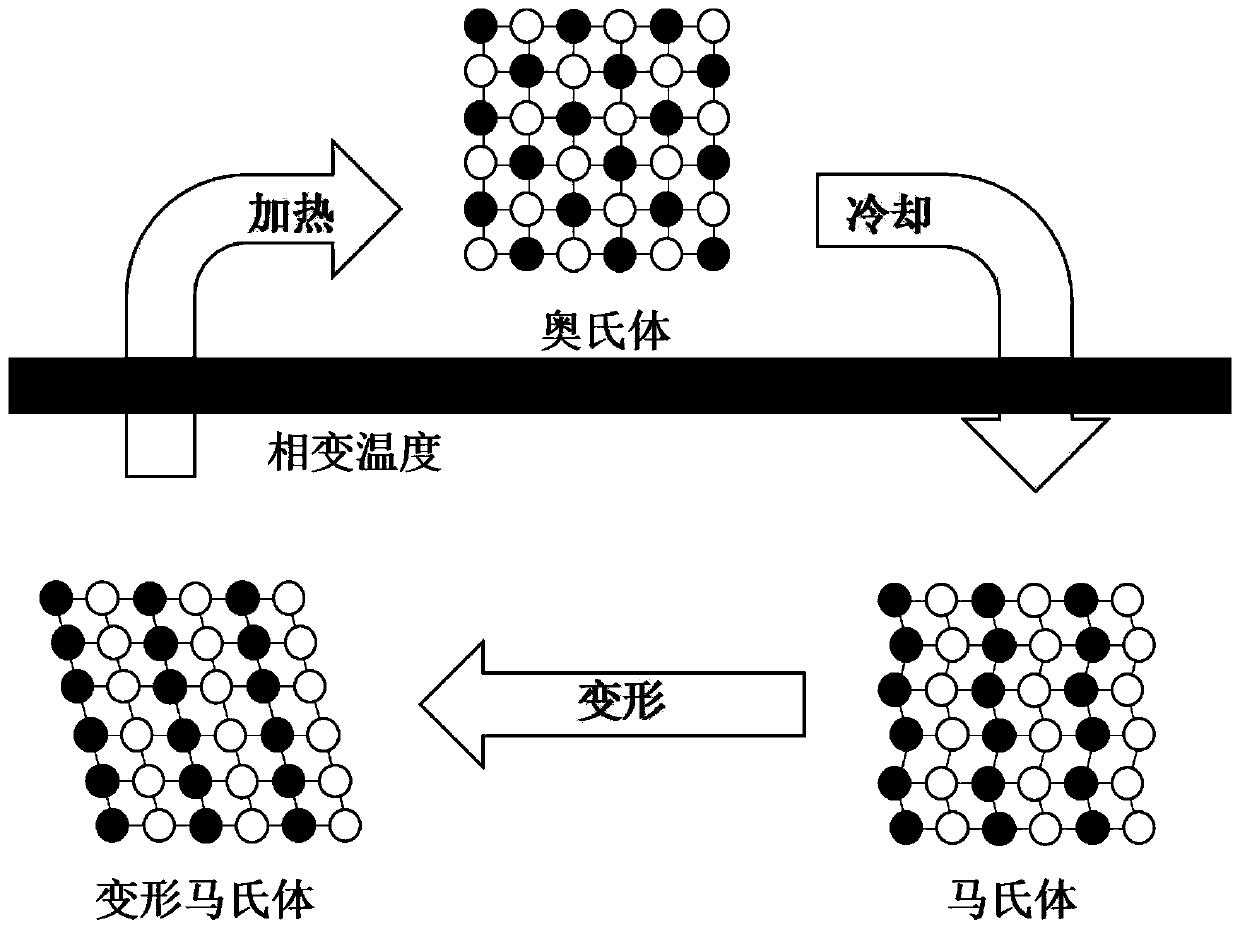

So, basically, 4D printing is a renovation of 3D printing wherein special materials to print objects that change shape post-production. A trigger may be water, heat, wind and other forms of energy.

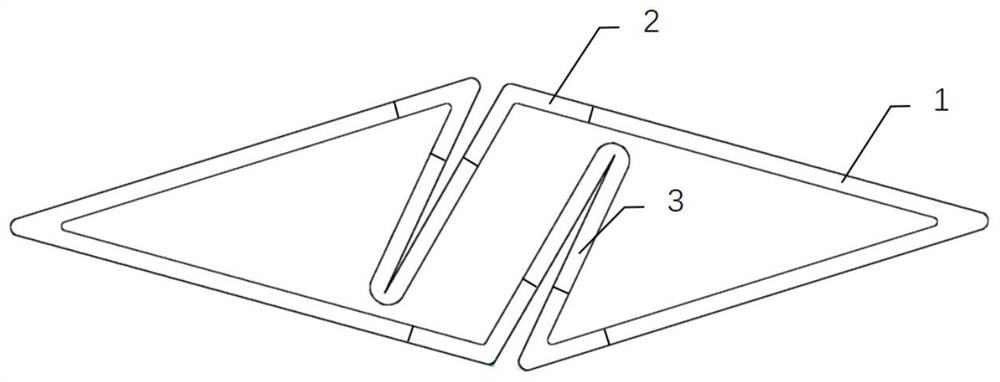

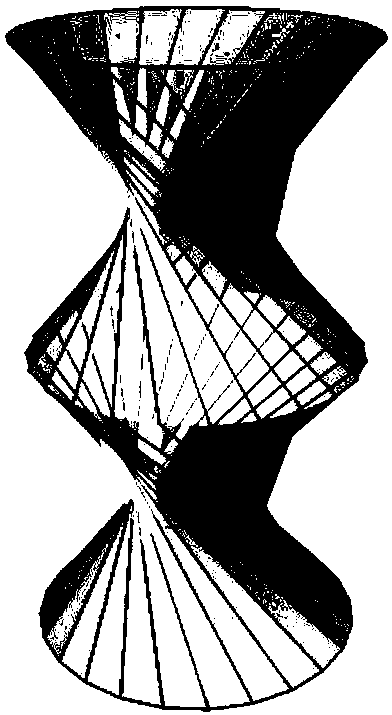

Method for forming artificial vascular stent through 4D printing

ActiveCN104116578AFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

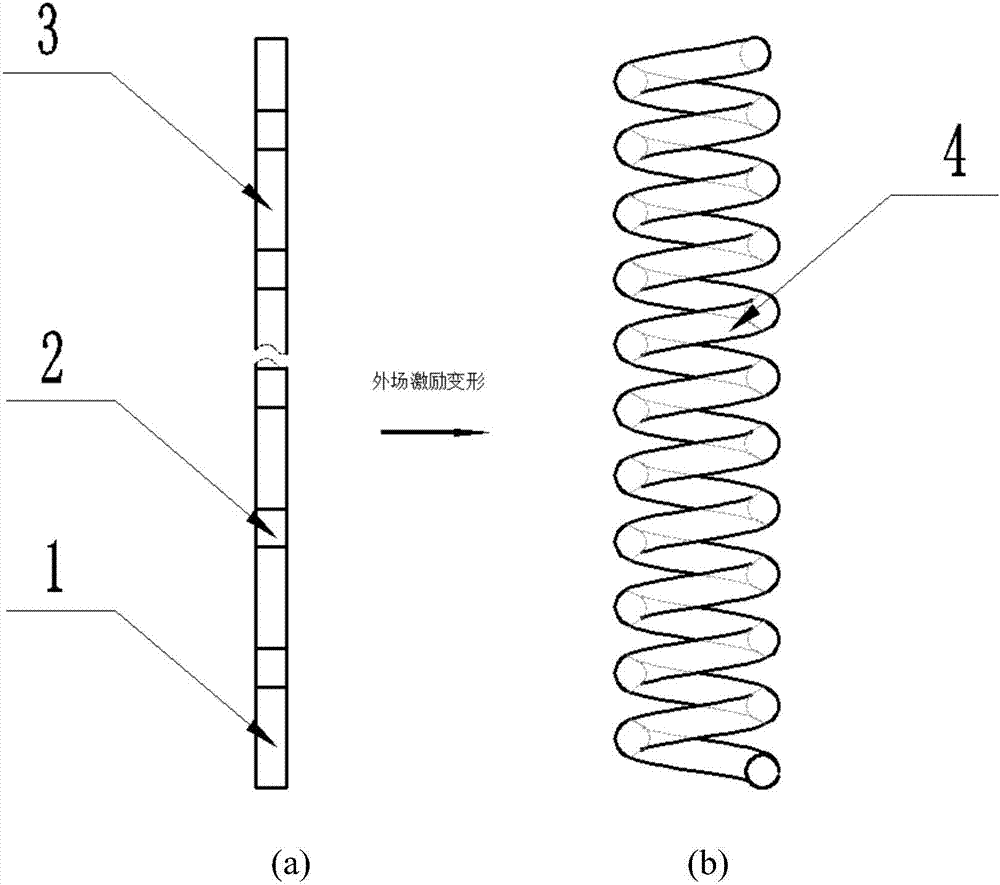

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

Object Of Additive Manufacture With Encoded Predicted Shape Change And Method Of Manufacturing Same

InactiveUS20150158244A1Improve efficiencyReduce materialOrganic chemistryMouldsShape change4d printing

Owner:MASSACHUSETTS INST OF TECH +1

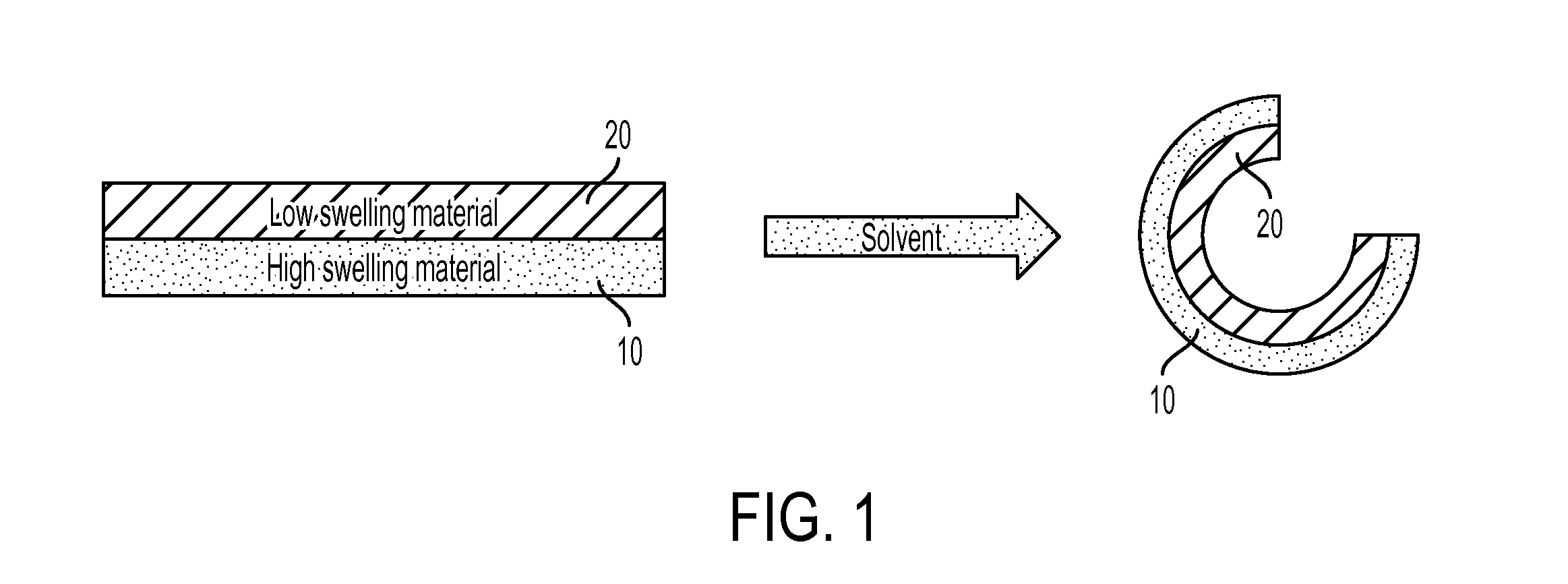

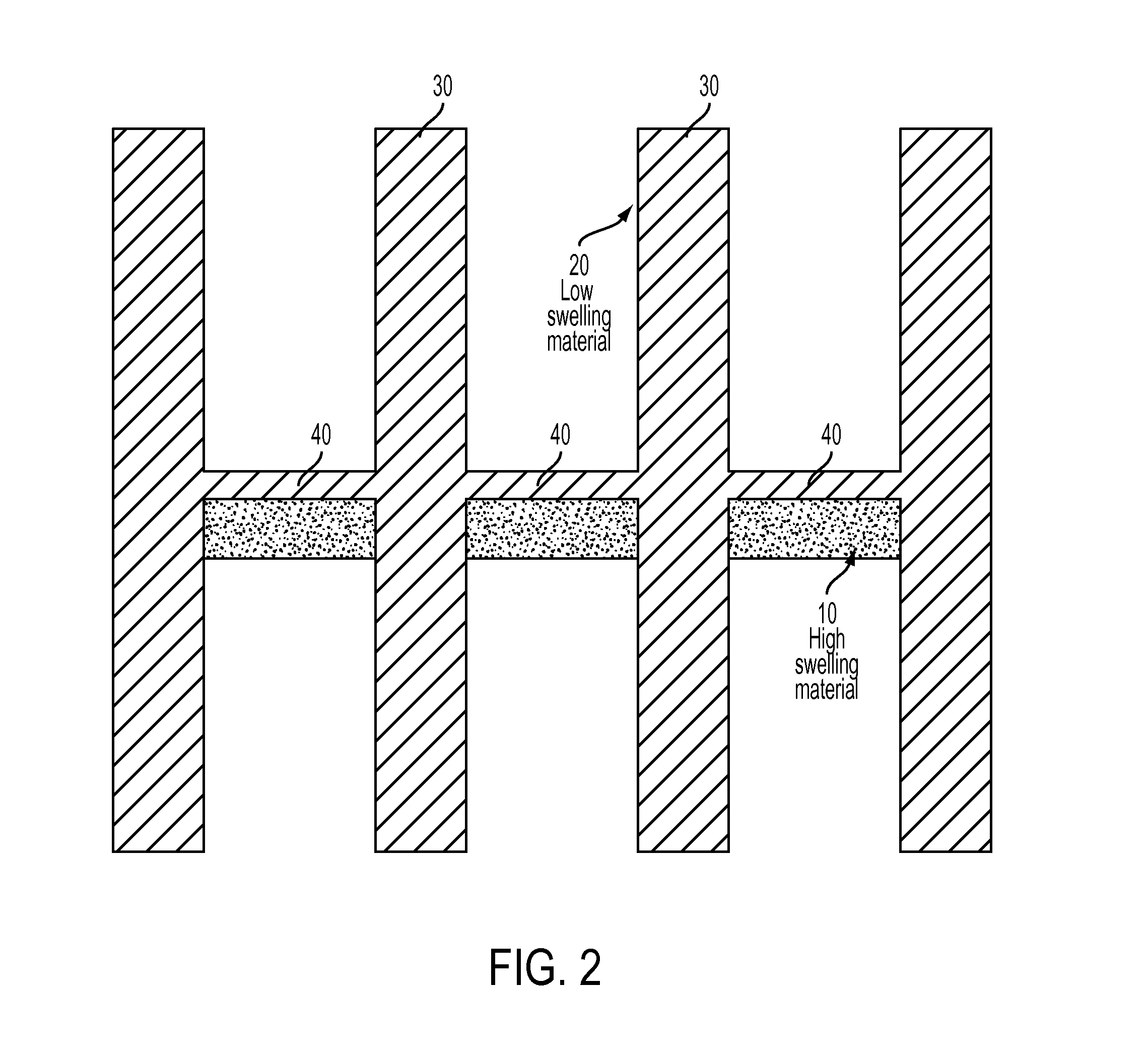

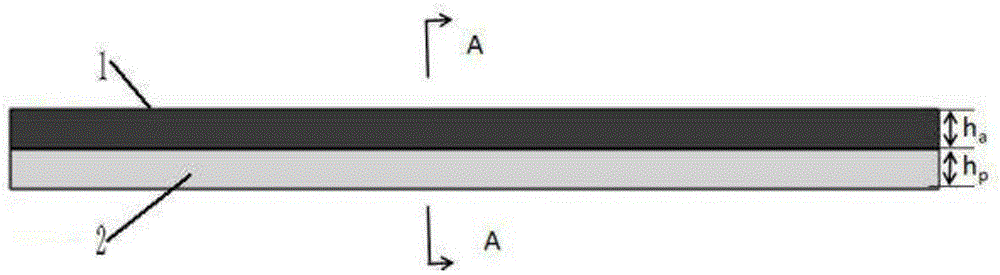

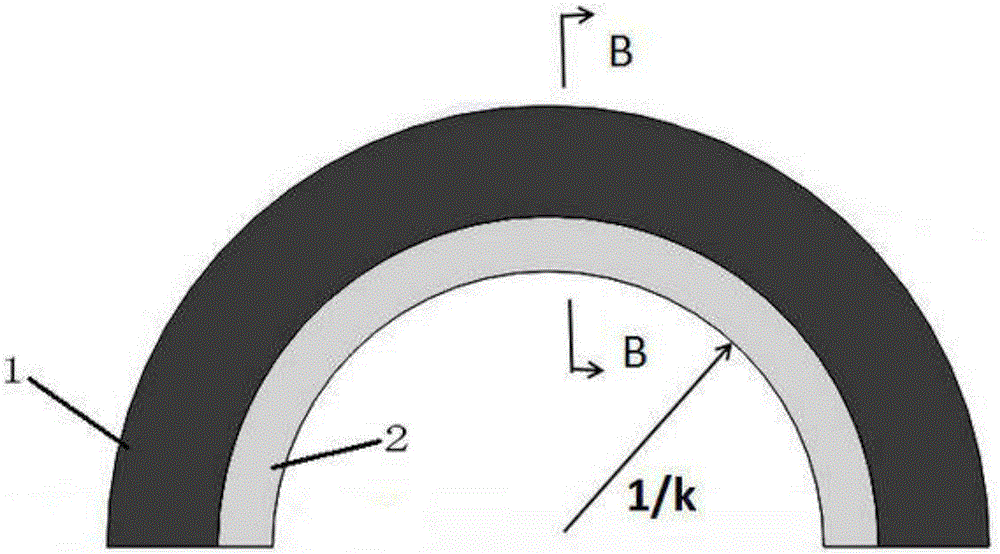

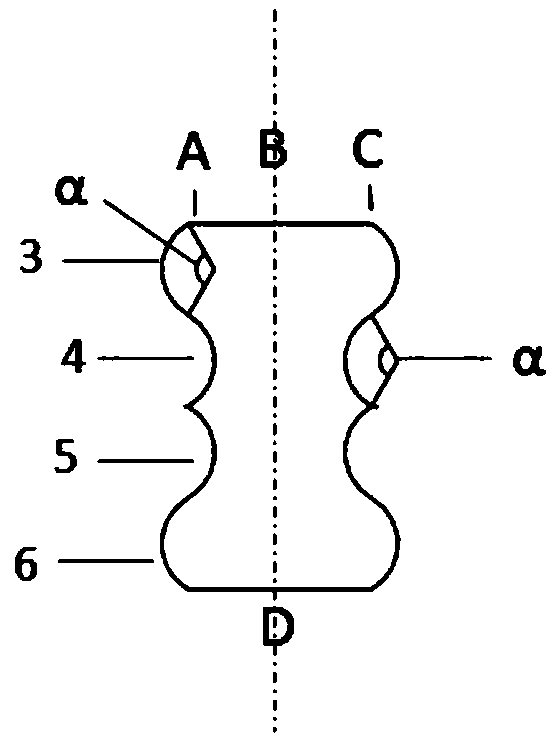

Four-dimensional printing method capable of programming curvature changes

InactiveCN106738875AProgrammableDesignableAdditive manufacturing apparatus3D object support structuresGeometric modelingEngineering

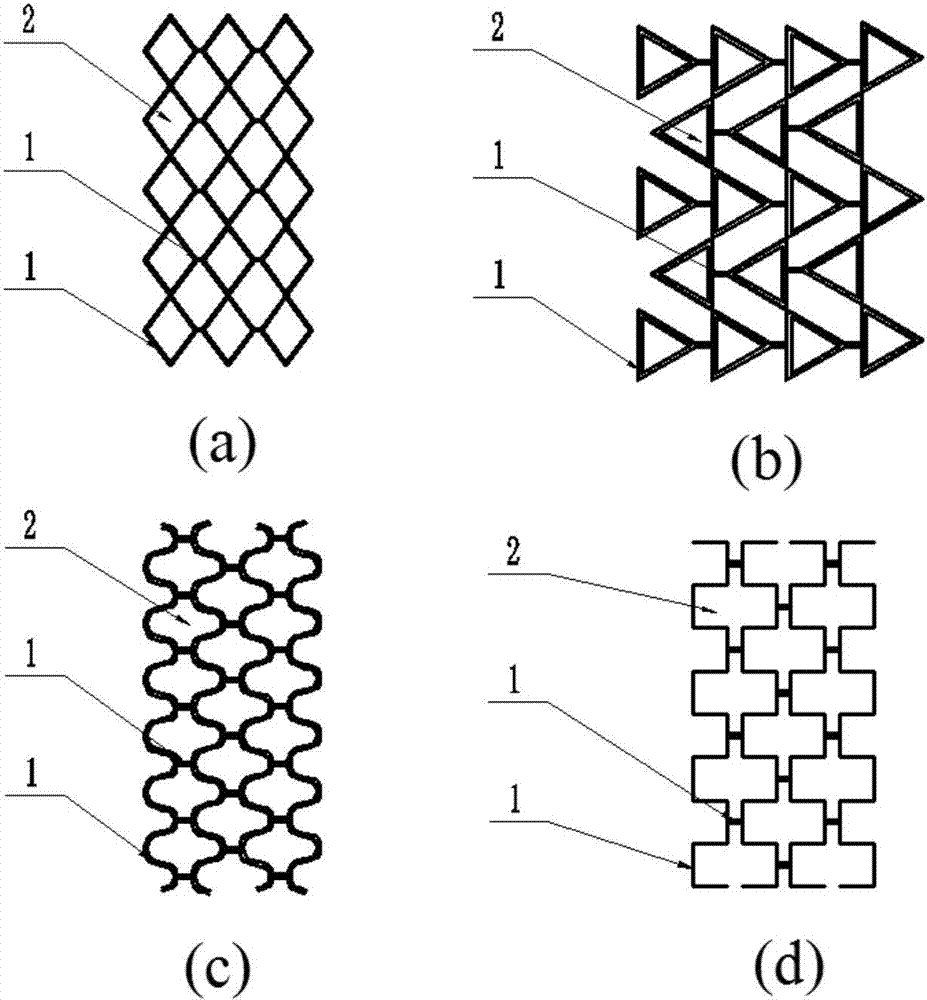

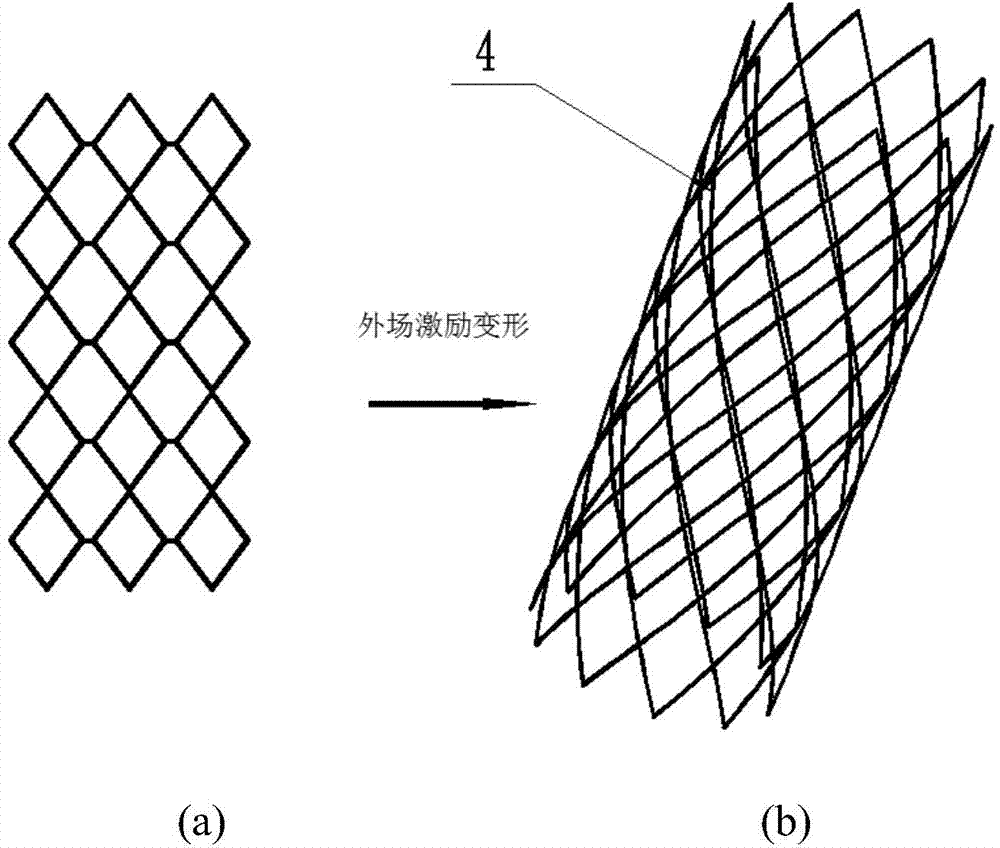

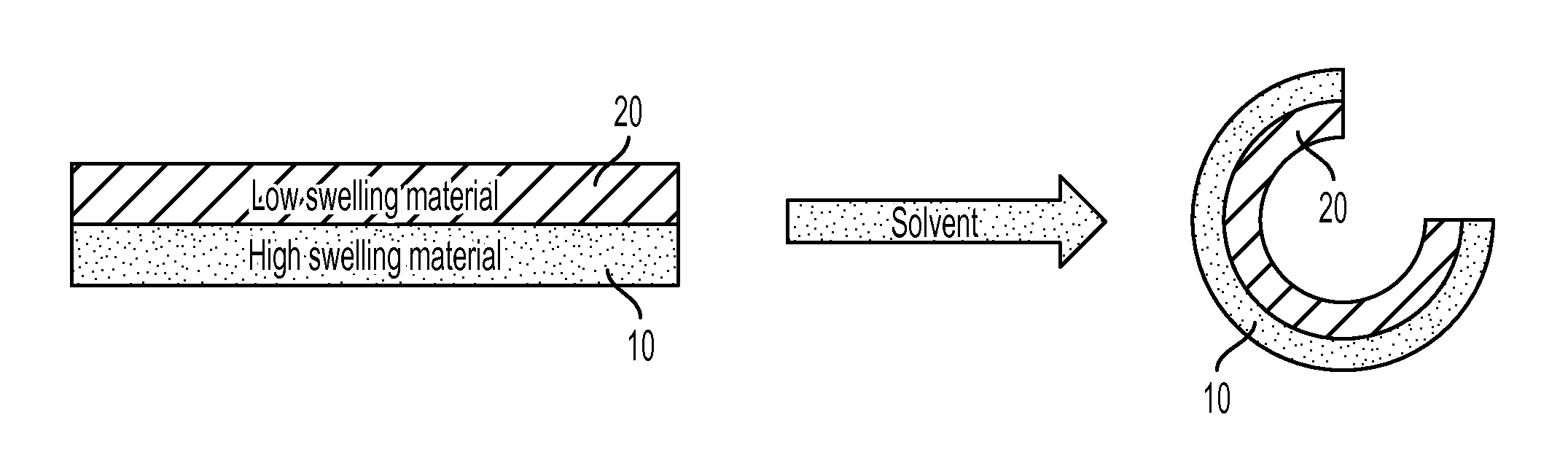

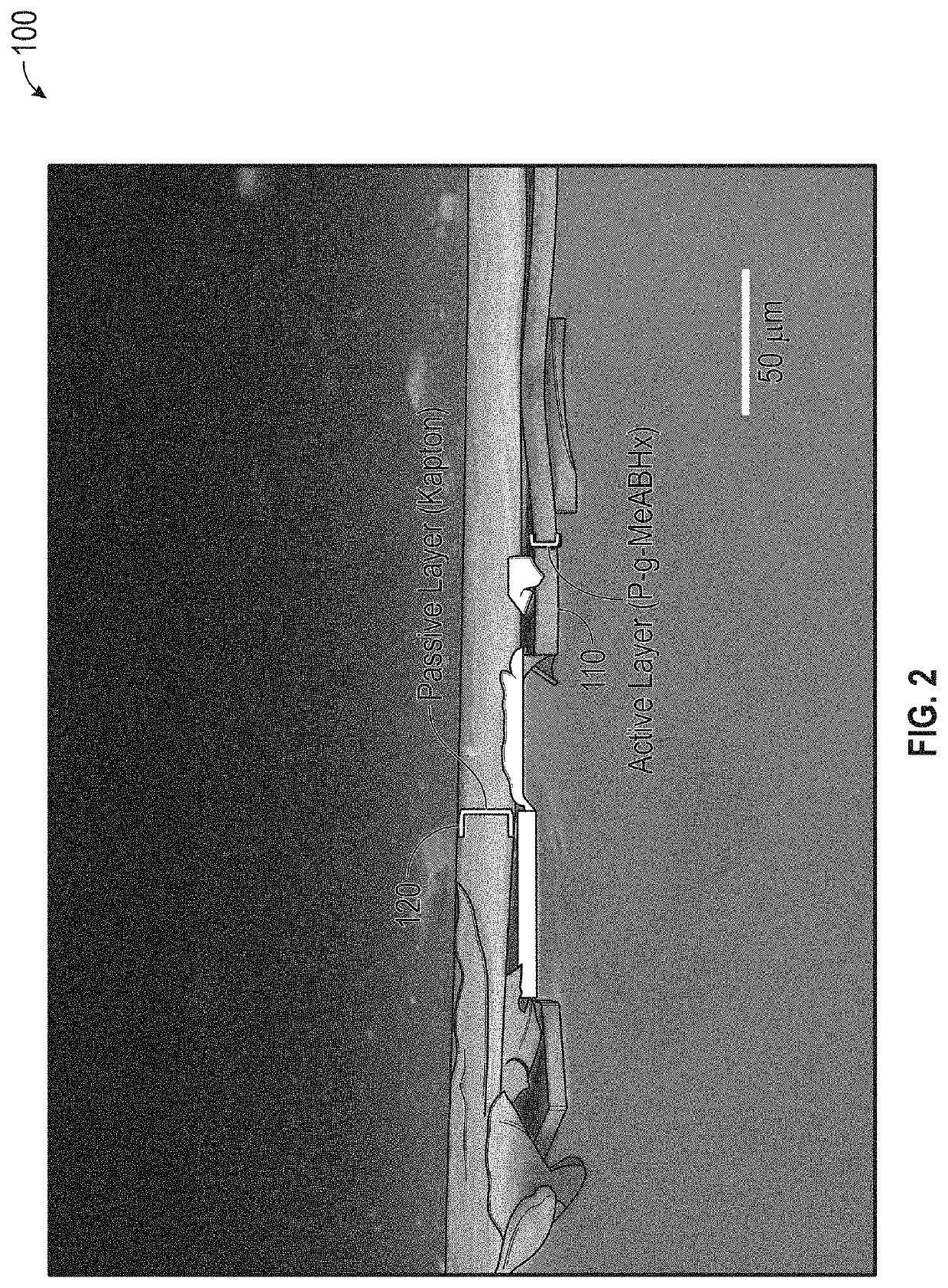

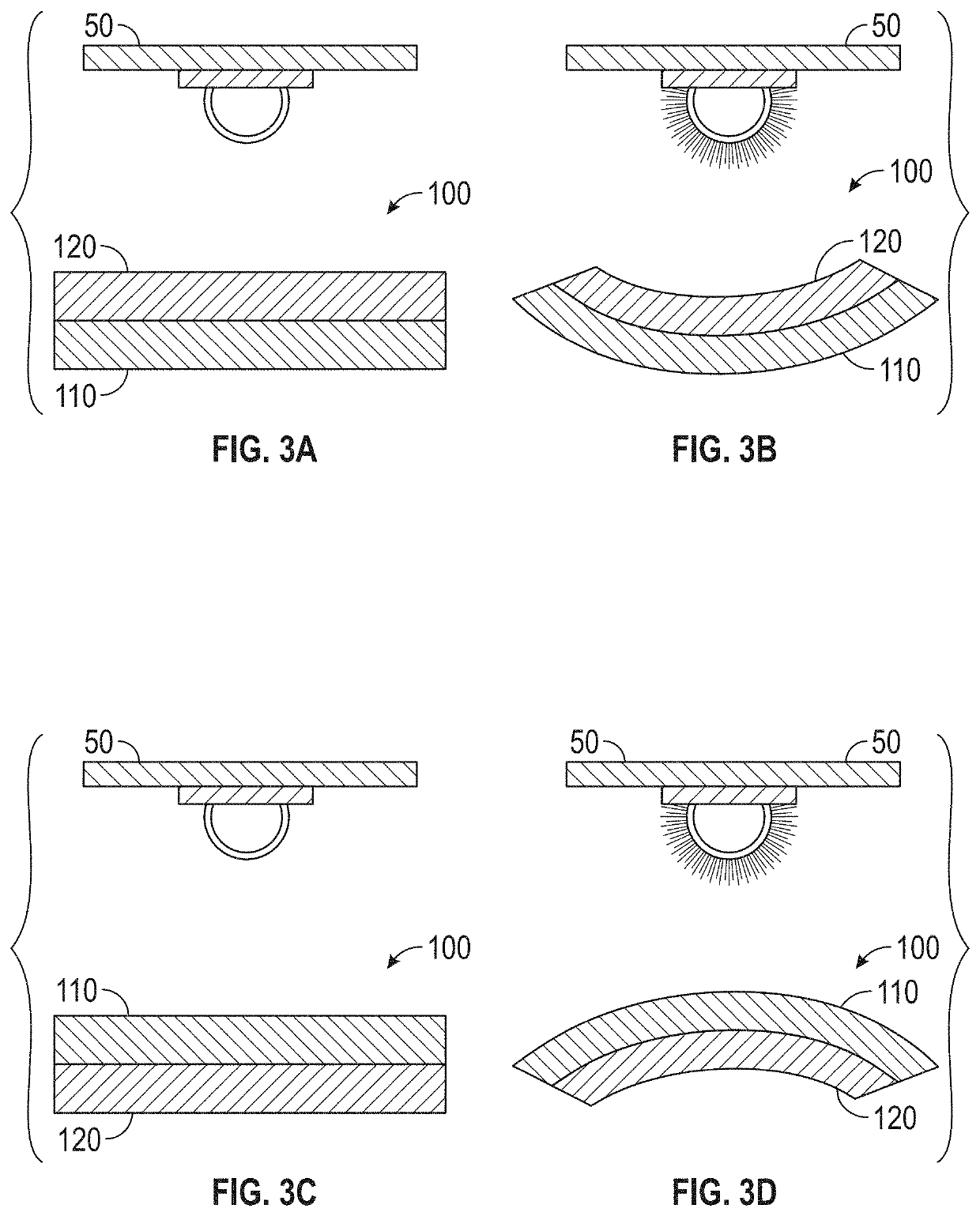

The invention relates to a four-dimensional printing method capable of programming curvature changes. The four-dimensional printing method comprises the following steps of 1 active and passive material selecting; 2 model establishing, wherein the initial states, comprising the geometrical shapes and the distribution states of an active material and a passive material, of models are designed according to the needed expected deformation shapes; 3 printing molding; 4 post-processing curing; 5 four-dimensional printing self-deforming. Therefore, the geometric models of the active material and the passive material in a molded component are designed and printed by combining a double-layer swelling deformation model theory, and then the four-dimensional printing method capable of programming the curvature changes is achieved; deformation achieves the higher designability and intelligent performance, and the advantages that the technology is simple, the materials are easy to obtain, and the cost is low are achieved.

Owner:JILIN UNIV

Preparation of shape memory micro-nano composite material and application of shape memory micro-nano composite material in 4D (four-dimensional) printing

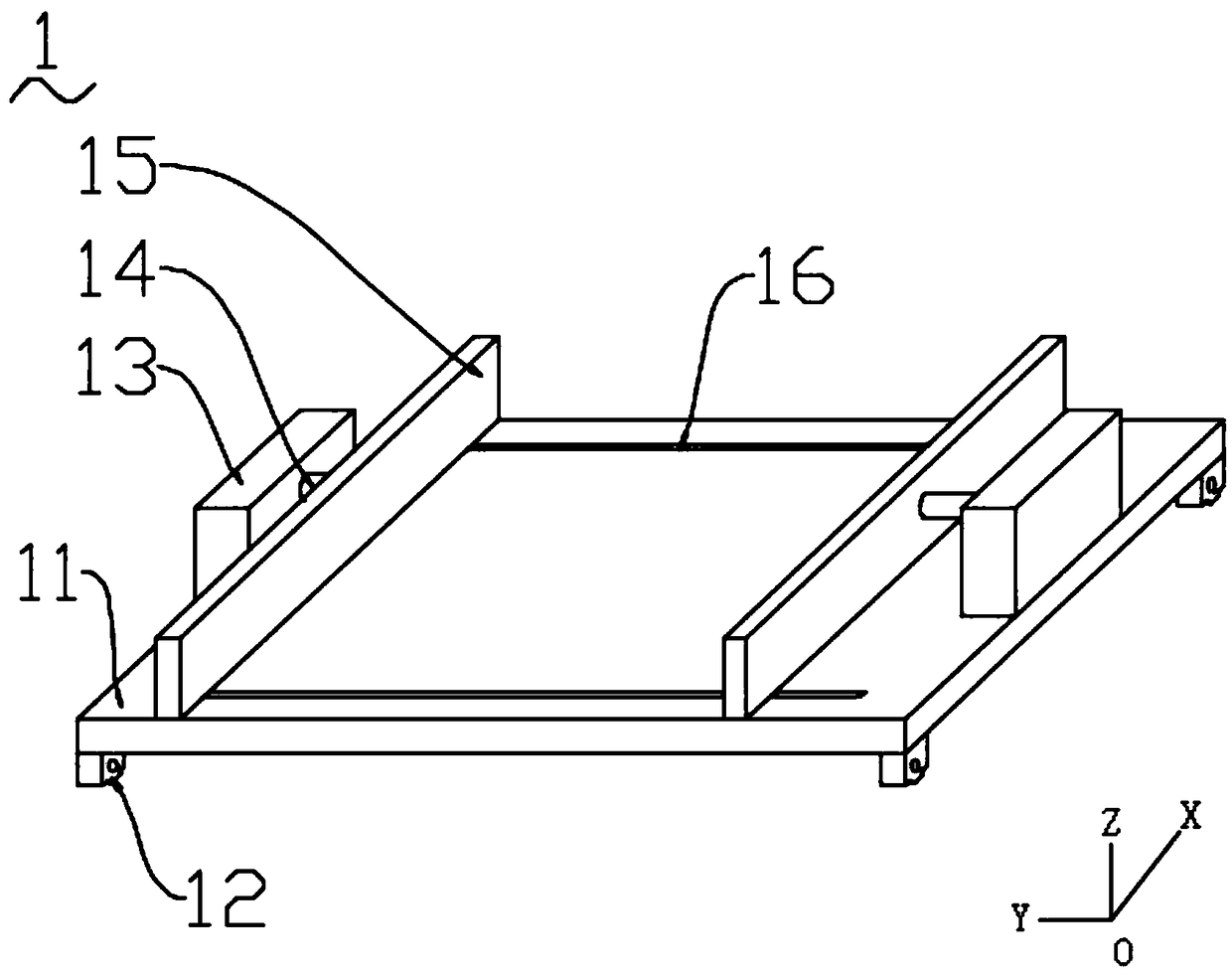

The invention discloses preparation of a shape memory micro-nano composite material and application of the shape memory micro-nano composite material in 4D (four-dimensional) printing. The invention relates to the field of the 4D printing of intelligent materials, in particular to the field that the shape memory micro-nano composite material can be applied to a 4D printing technology. The invention aims to solve the technical problem of difficulty in realizing the 4D printing of the shape memory micro-nano composite material. The shape memory micro-nano composite material disclosed by the invention is formed by means of mixing a hydrogen-abstracting type photoinitiator, functional micro-nano particles, a substance containing active hydrogen in a molecular chain and an organic solvent with a low boiling point and high volatility according to a certain mass, and performing ultrasonic treatment. The composite material is applied to the 4D printing technology by means of controlling a motion direction, a motion speed and an applied pressure of a three-dimensional movement platform on an X-axis, a Y-axis and a Z-axis through software, applying pressure force on a high-pressure dispensing needle cylinder equipped with a micro-needle head through an air pump, and constructing a required three-dimensional structure by means of casting according to a constructed model. The shape memory micro-nano composite material disclosed by the invention is applied to the 4D printing.

Owner:HARBIN INST OF TECH

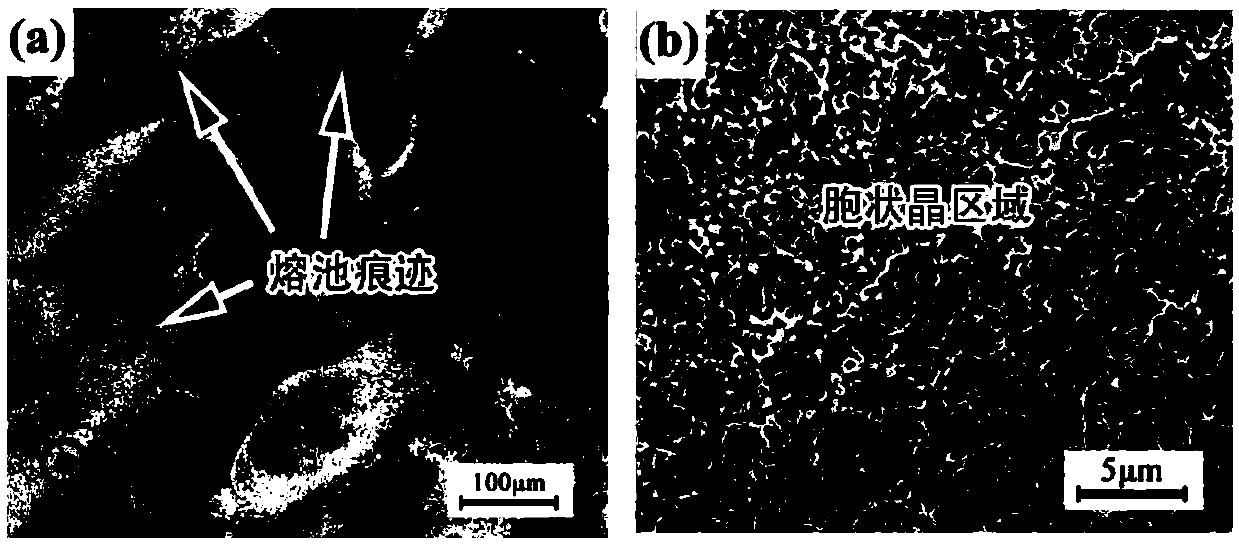

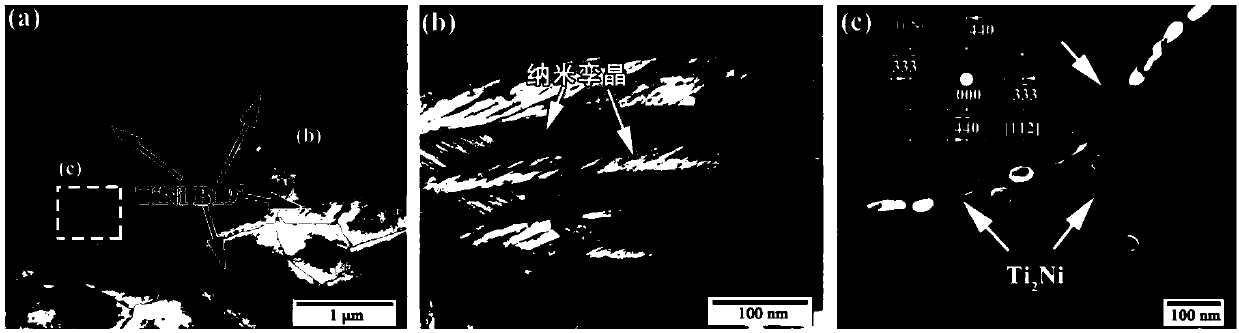

4D printing method and application of titanium-nickel shape memory alloy

ActiveCN109648082AHigh strengthHigh elongationAdditive manufacturing apparatusTransportation and packaging4d printingNickel alloy

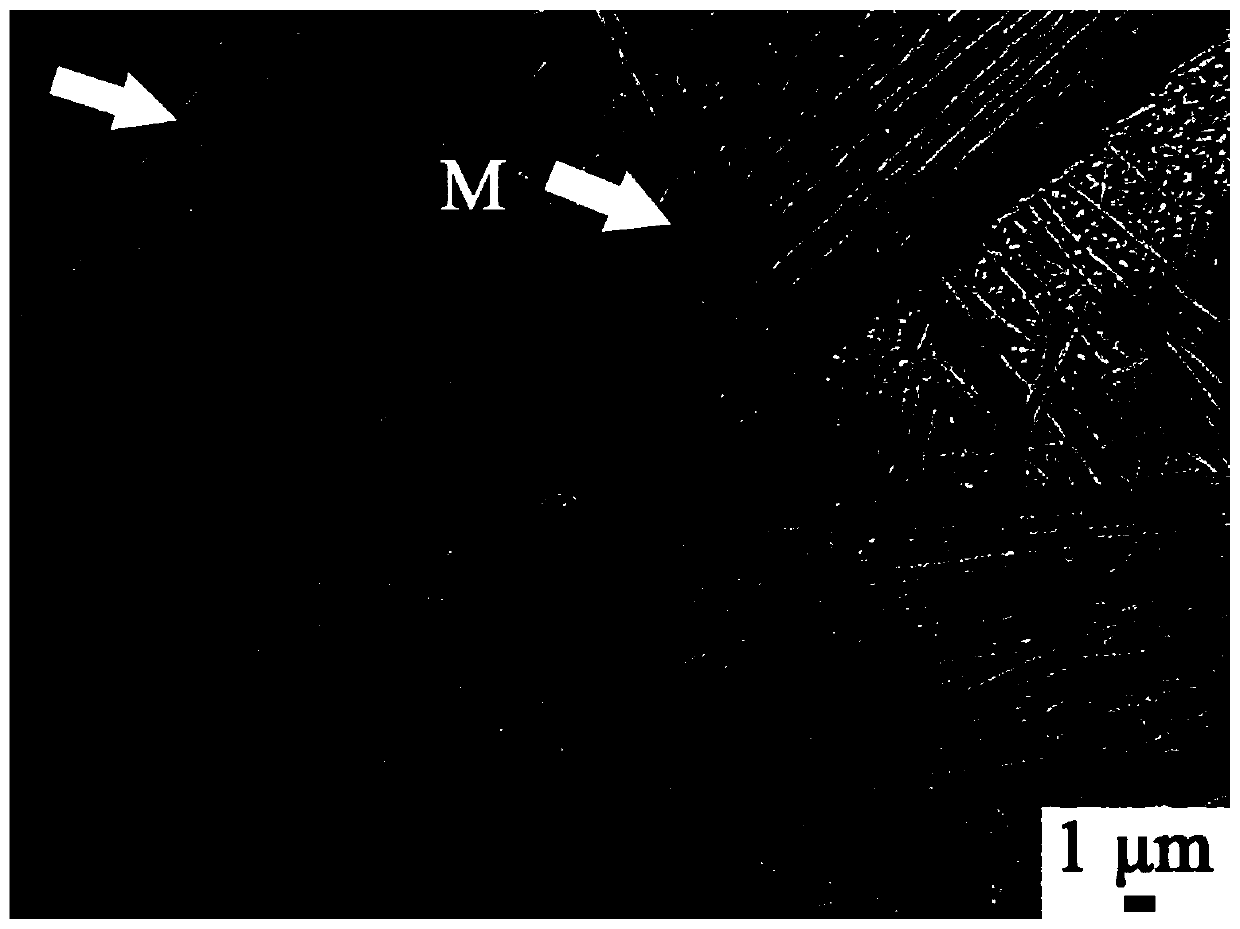

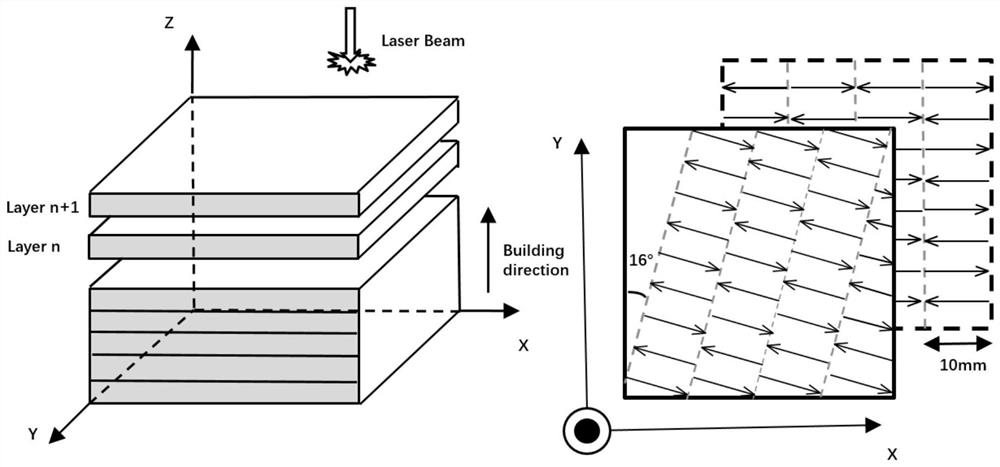

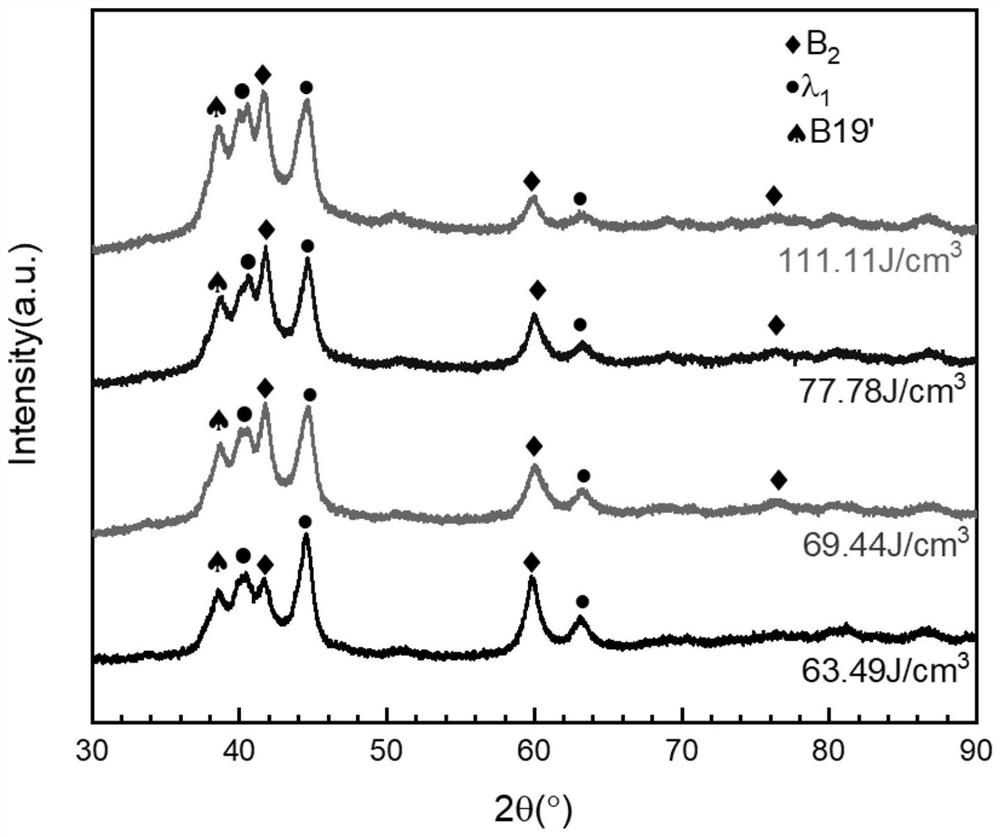

The invention belongs to the technical field of preparation of shape memory alloys, and discloses a 4D printing method and application of a titanium-nickel shape memory alloy. Pure titanium and pure nickel are matched and smelted, and titanium-nickel alloy bars are obtained; then alloy powder is prepared through a rotating electrode atomization method, the powder is screened, and titanium-nickel alloy powder with the grain size of 15 micrometers to 53 micrometers is obtained; and the obtained titanium-nickel alloy powder is placed in a discharge plasma assisted ball mill to be subjected to discharge treatment, the powder is subjected to surface modification, and finally the titanium-nickel shape memory alloy is formed by means of SLM forming. The phase composition of the obtained titanium-nickel shape memory alloy is composed of a B2 austenite phase of a CsC1 type structure, a B19' Martensite phase of a monocline structure and a Ti2Ni precipitated phase. The microstructure comprises nano-sized afterbirth-like crystals and micro dendrite, and the afterbirth-like crystals and the dendrite are alternately distributed in a layered manner. The advantages of being unique in organizationstructure, nearly fully dense and ultrahigh in performance are achieved.

Owner:SOUTH CHINA UNIV OF TECH

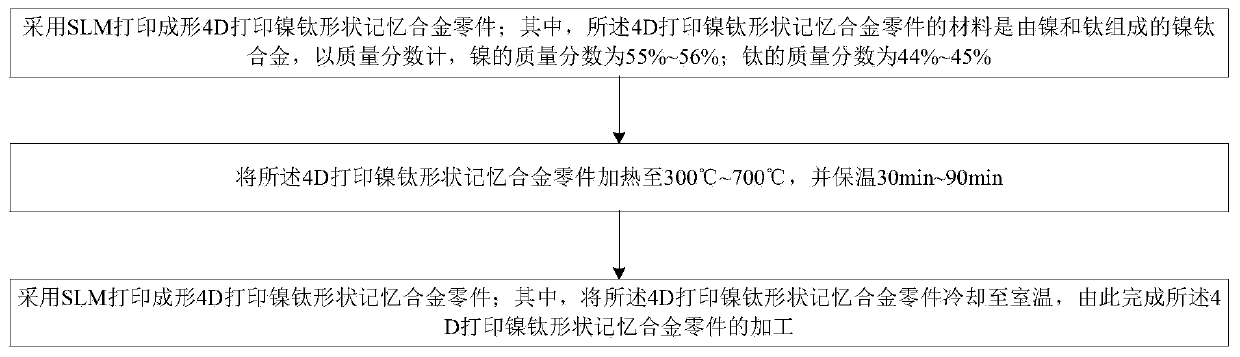

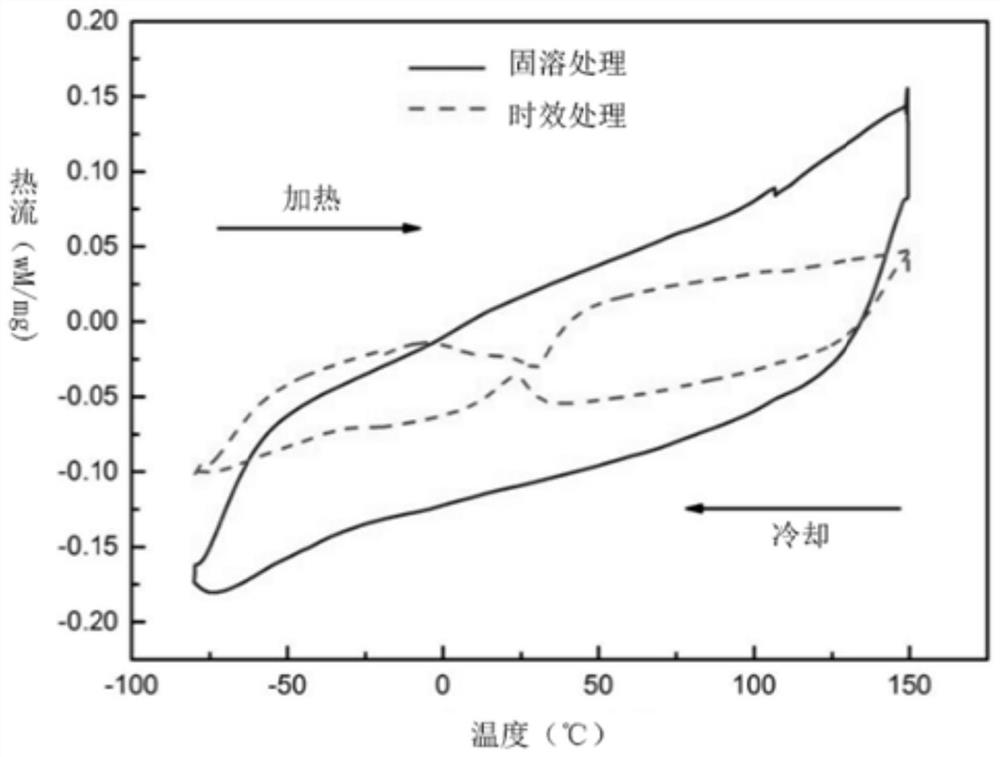

Processing method suitable for 4D printed nickel-titanium shape memory alloy

ActiveCN109746445AGood shape memory effectIncrease elasticityAdditive manufacturing apparatusIncreasing energy efficiencyRoom temperatureTitanium

The invention belongs to the technical field of alloy molding and manufacturing, and discloses a processing method suitable for a 4D printed nickel-titanium shape memory alloy. The processing method includes the following steps that (1) 4D printed nickel-titanium shape memory alloy parts are printed and molded by using an SLM, the material of the 4D printed nickel-titanium shape memory alloy partsis the nickel-titanium alloy consisting of nickel and titanium, by the mass percentage, wherein the mass percentage of the nickel is 55-56%, and the mass percentage of titanium is 44-45%; (2) the 4Dprinted nickel-titanium shape memory alloy parts are heated to 300-700 DEG C, and heat insulation is conducted for 30-90min; and (3) the 4D printed nickel-titanium shape memory alloy parts are cooledto the room temperature, so that the processing of the 4D printed nickel-titanium shape memory alloy parts is completed. The processing method is simple in process, convenient to implement, higher inflexibility and higher in applicability.

Owner:HUAZHONG UNIV OF SCI & TECH

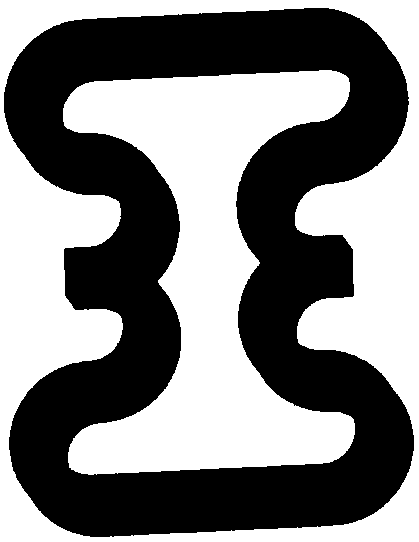

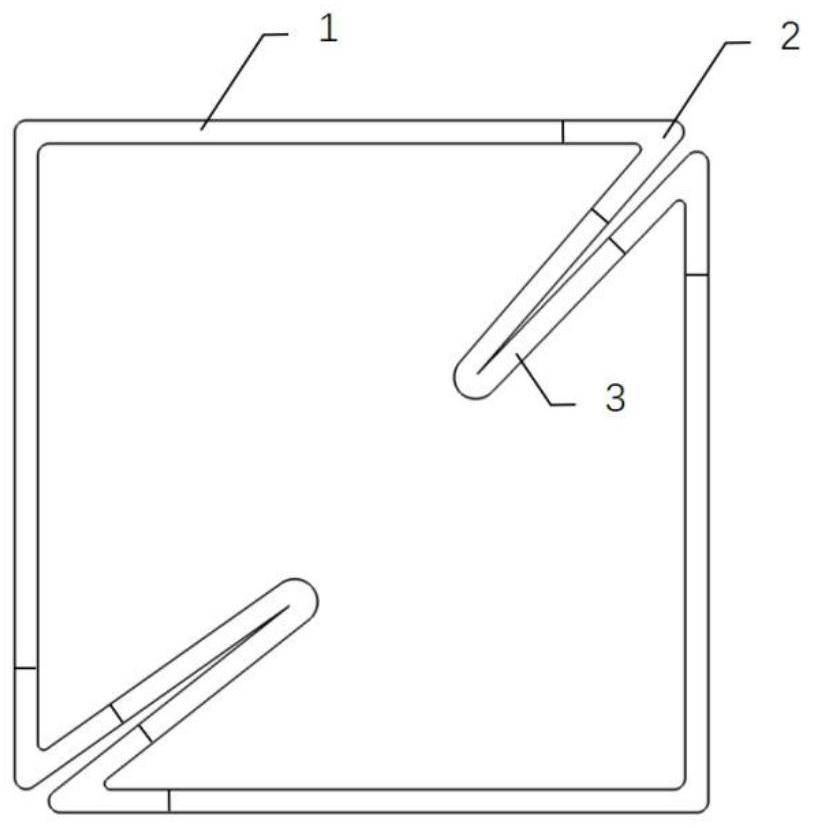

4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

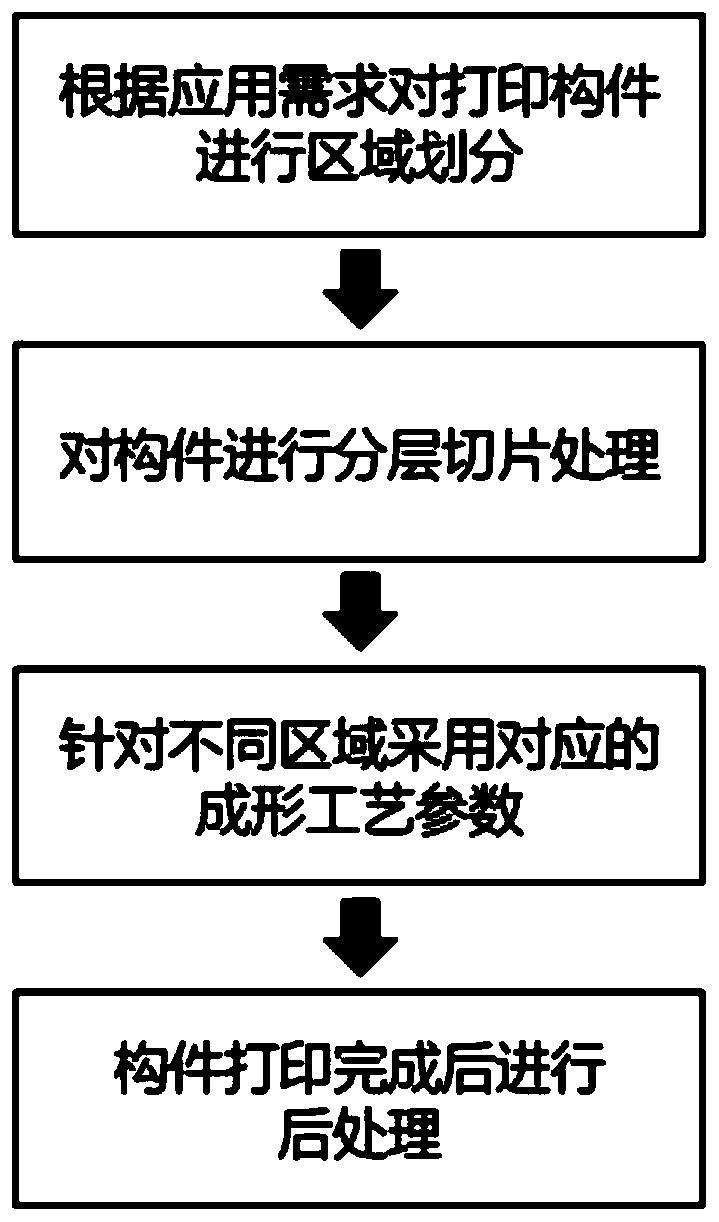

4D printing method of functional gradient copper-based shape memory alloy intelligent component, and product

ActiveCN110434331AAchieve continuous changeSimple preparation processAdditive manufacturing apparatusIncreasing energy efficiencyShape-memory alloy4d printing

The invention belongs to the field of 4D printing manufacturing, and particularly discloses a 4D printing method of a functional gradient copper-based shape memory alloy intelligent component and a product. The method comprises the following steps: dividing a three-dimensional model of the intelligent component according to the required deformation amount and function in application, setting printing parameters of a large-deformation recovery area, a small-deformation recovery area and a bearing area, and printing the large-deformation recovery area, the small-deformation recovery area and thebearing area by taking copper-based memory alloy powder as a raw material in a 4D mode respectively so as to obtain the functional gradient copper-based shape memory alloy intelligent component composed of different phases. The product is obtained by adopting the 4D printing method. According to the 4D printing method of the functional gradient copper-based shape memory alloy intelligent component and the product, through controlling the forming process parameters and printing materials of different areas, continuous variation of components, structure and super-elastic energy is realized, sothat each area can adapt to the required deformation amount and function of the intelligent component in application.

Owner:HUAZHONG UNIV OF SCI & TECH

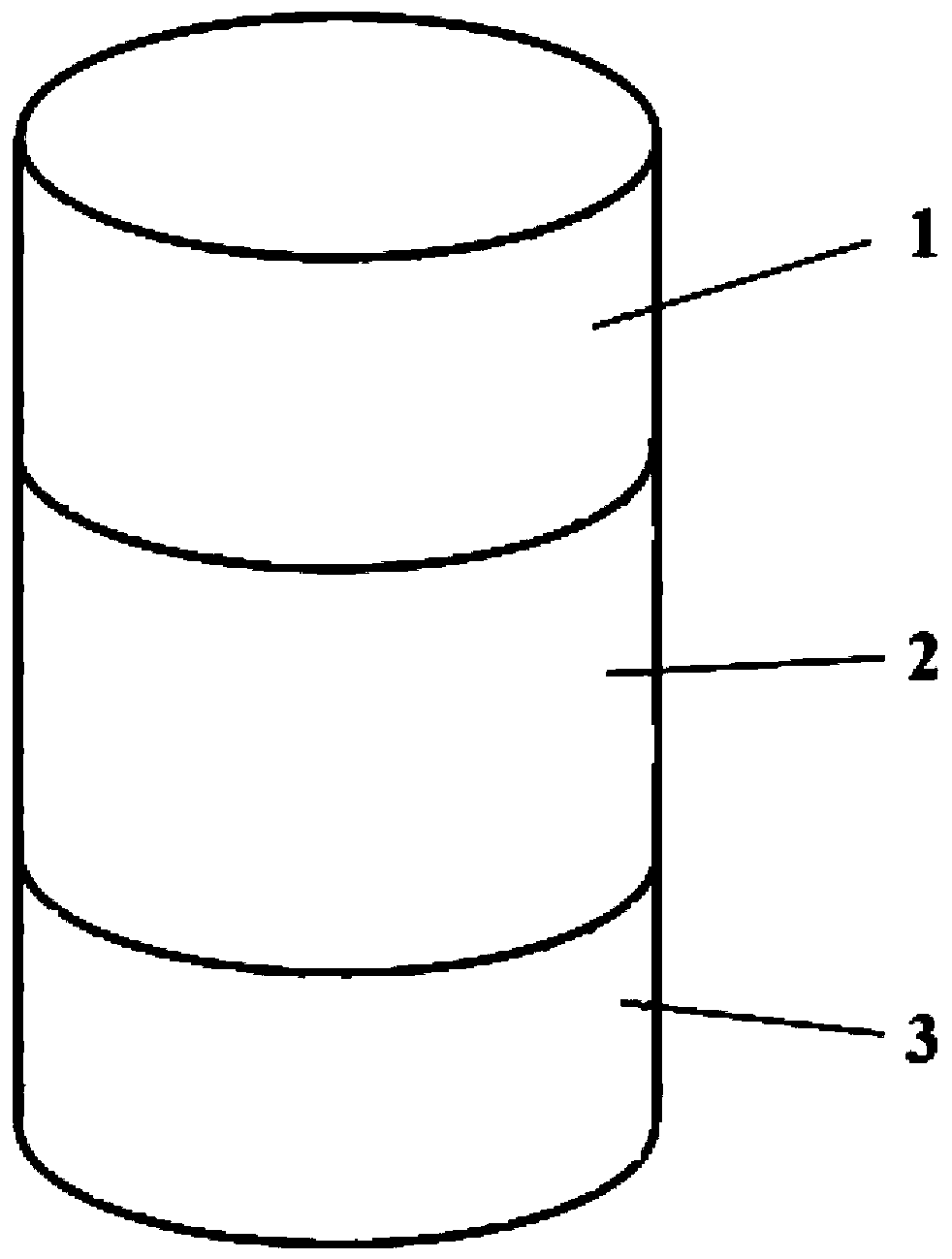

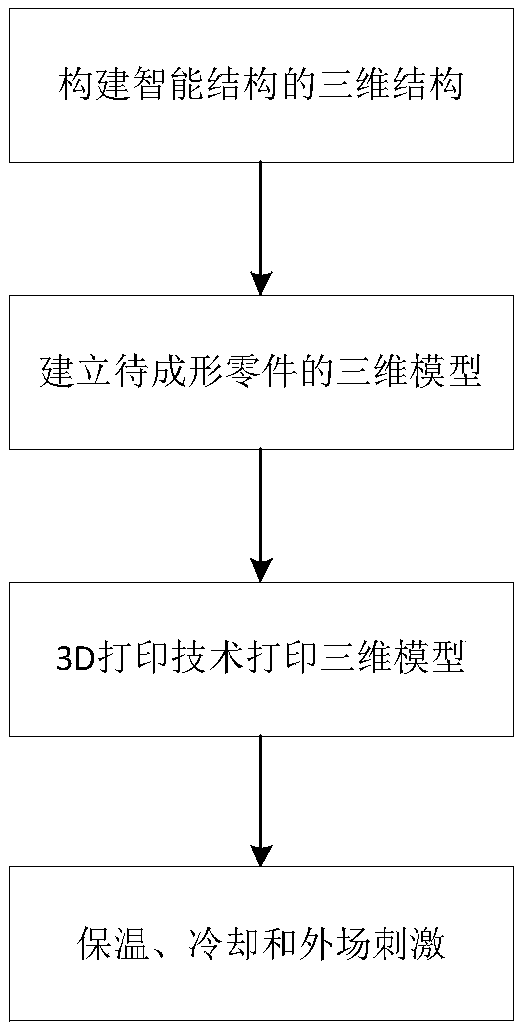

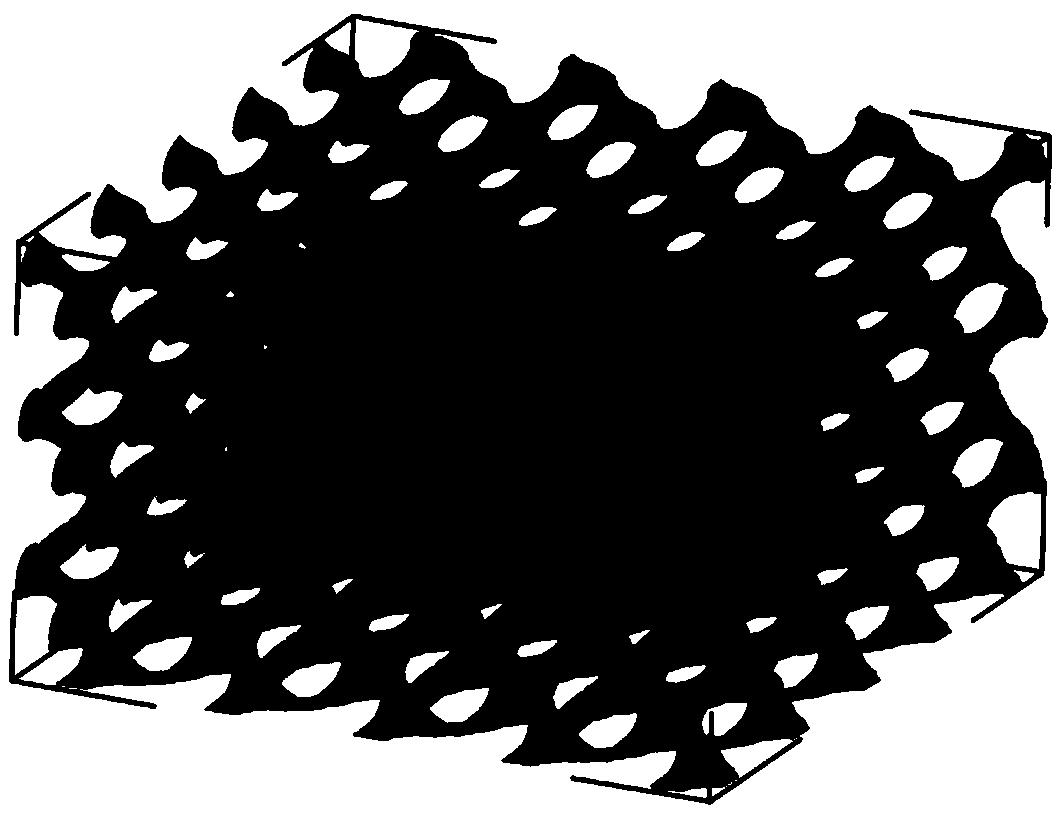

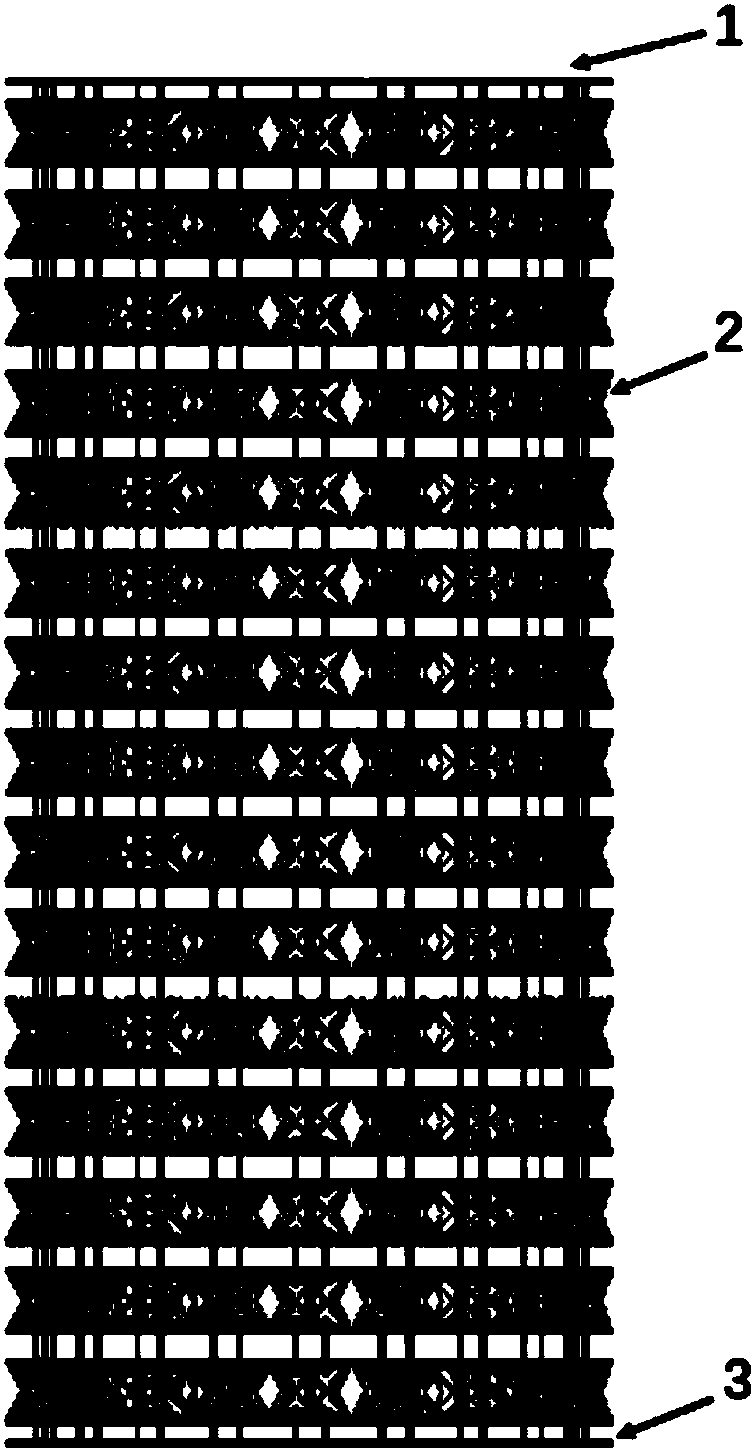

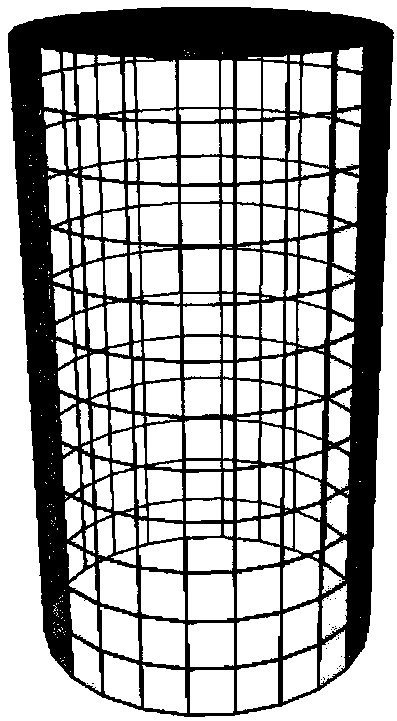

4D printing method of intelligent structure with large deformation function and product obtained through 4D printing method

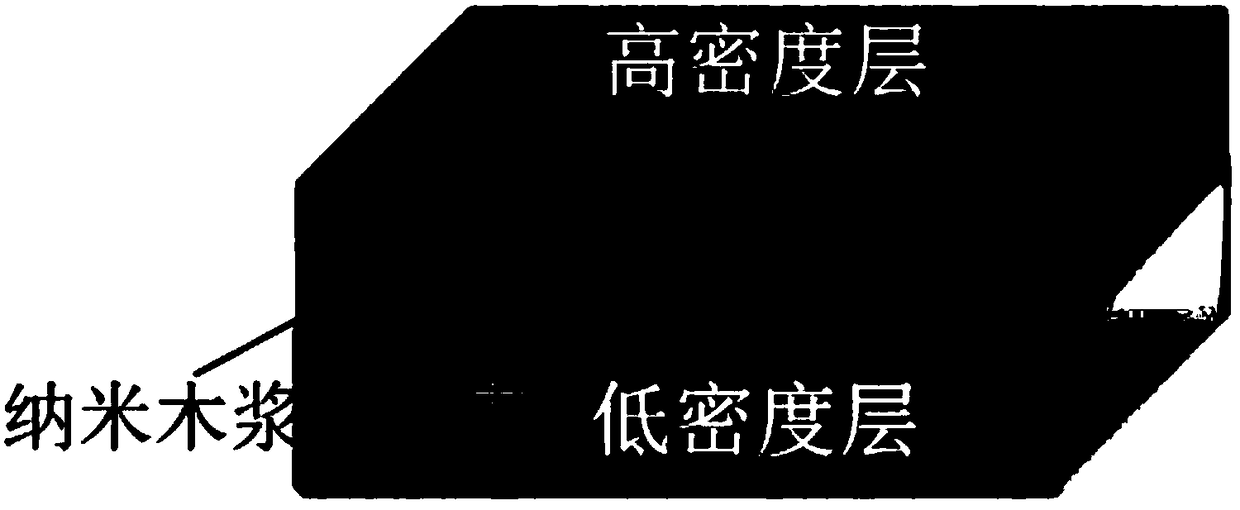

ActiveCN108788154ARelative density is smallHigh specific strengthAdditive manufacturing apparatusGradient networkNetwork structure

The invention belongs to the field of additive manufacturing, and discloses a 4D printing method of an intelligent structure with a large deformation function and a product. The method comprises the following steps that (a) a three-dimensional structure of the intelligent structure to be printed is constructed, wherein the intelligent structure to be printed is of a porous gradient network structure, and comprises three layers with the volume fractions of pores sequentially reduced from top to bottom in the vertical direction; (b) a three-dimensional model of the intelligent structure is set up; (c) memory alloy powder is selected as raw materials, and the 3D printing technology is adopted for printing the three-dimensional model; and (d) the printed intelligent structure is subjected to heat preservation, cooling and external field irrigation, the deforming intelligent structure is obtained and subjected to performance testing, and the needed intelligent structure is selected according to performance needs. By means of the 4D printing method, the obtained product responds to the changing external environment immediately, the expectant optimal state is kept all the time, meanwhile,the 4D printing method is not limited by the structure complexity, and the requirements of the mechanical property and the fatigue property are met.

Owner:HUAZHONG UNIV OF SCI & TECH

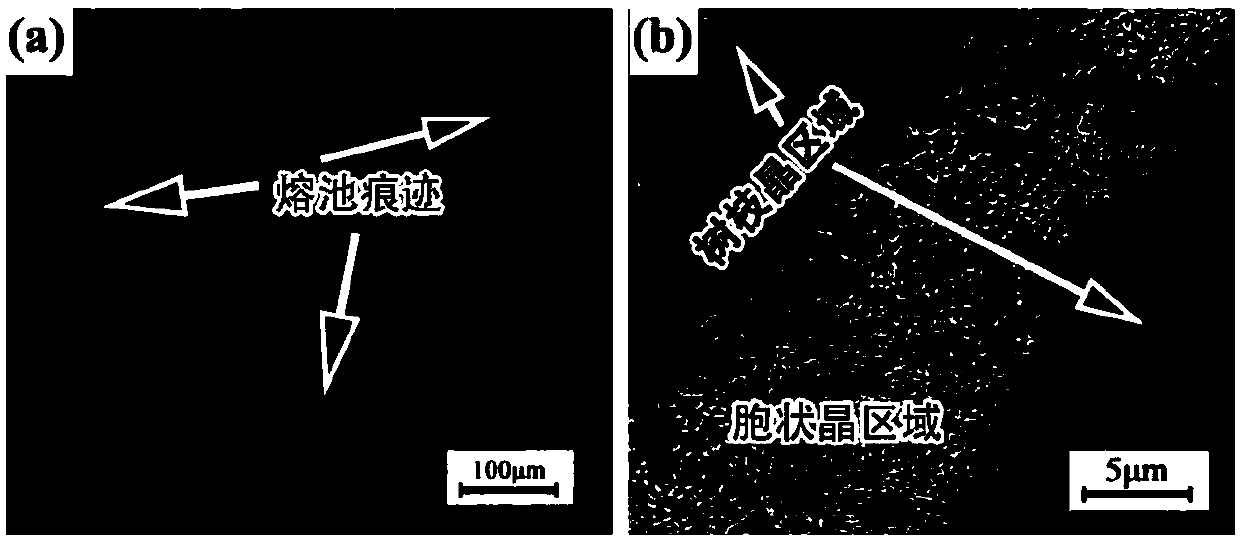

4D printing method of in-situ regulation of functional characteristics of nickel-titanium alloy and application

ActiveCN110465662ANickel content controlUniform compositionAdditive manufacturing apparatusTransportation and packagingManufacturing technology4d printing

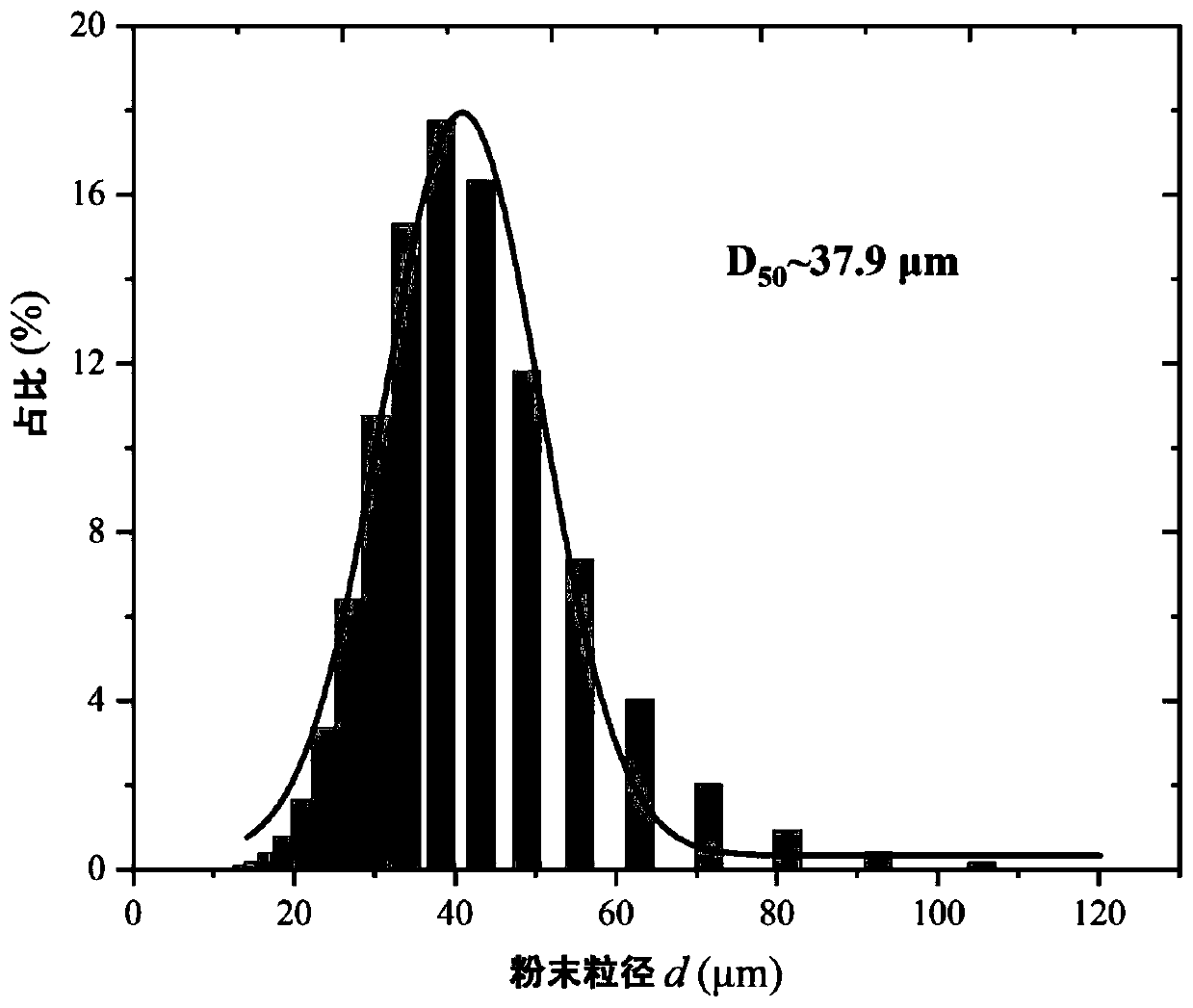

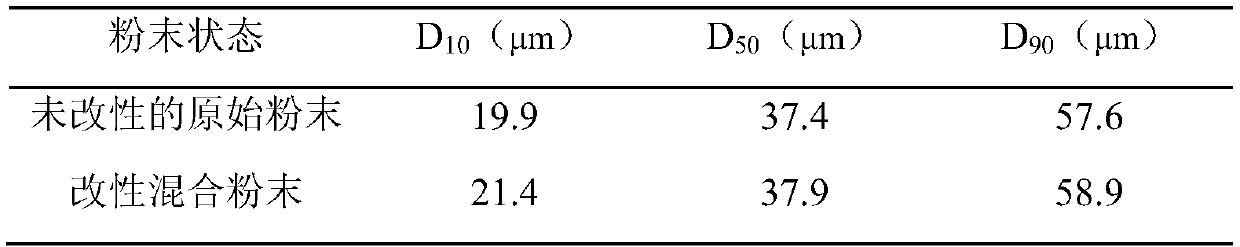

The invention belongs to the technical field of additive manufacturing, and discloses a 4D printing method of in-situ regulation of the functional characteristics of a nickel-titanium alloy and application. A nickel-titanium alloy rod material is powdered by atomization to obtain nickel-titanium alloy powder with a particle size of 15-53 [mu]m, then the nickel-titanium alloy powder is placed in adischarge plasma-assisted ball mill for discharge treatment to promote the activity activation of the powder, and then nano-scale nickel powder with the particle size being 100-800nm is added to obtain mixed powder; the discharge treatment is continued to realize metallurgical bonding between the nickel-titanium alloy powder and the nano-nickel powder to obtain modified powder; and finally the modified powder is prepared and formed by an additive manufacturing technology to obtain the functionalized nickel-titanium alloy. The metallurgical bonding is realized by adding the nano-scale nickel powder and the large-sized spherical nickel-titanium alloy powder during the discharge treatment process, so that a bulk alloy and parts thereof with uniform composition, microstructure and performanceare prepared.

Owner:SOUTH CHINA UNIV OF TECH

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

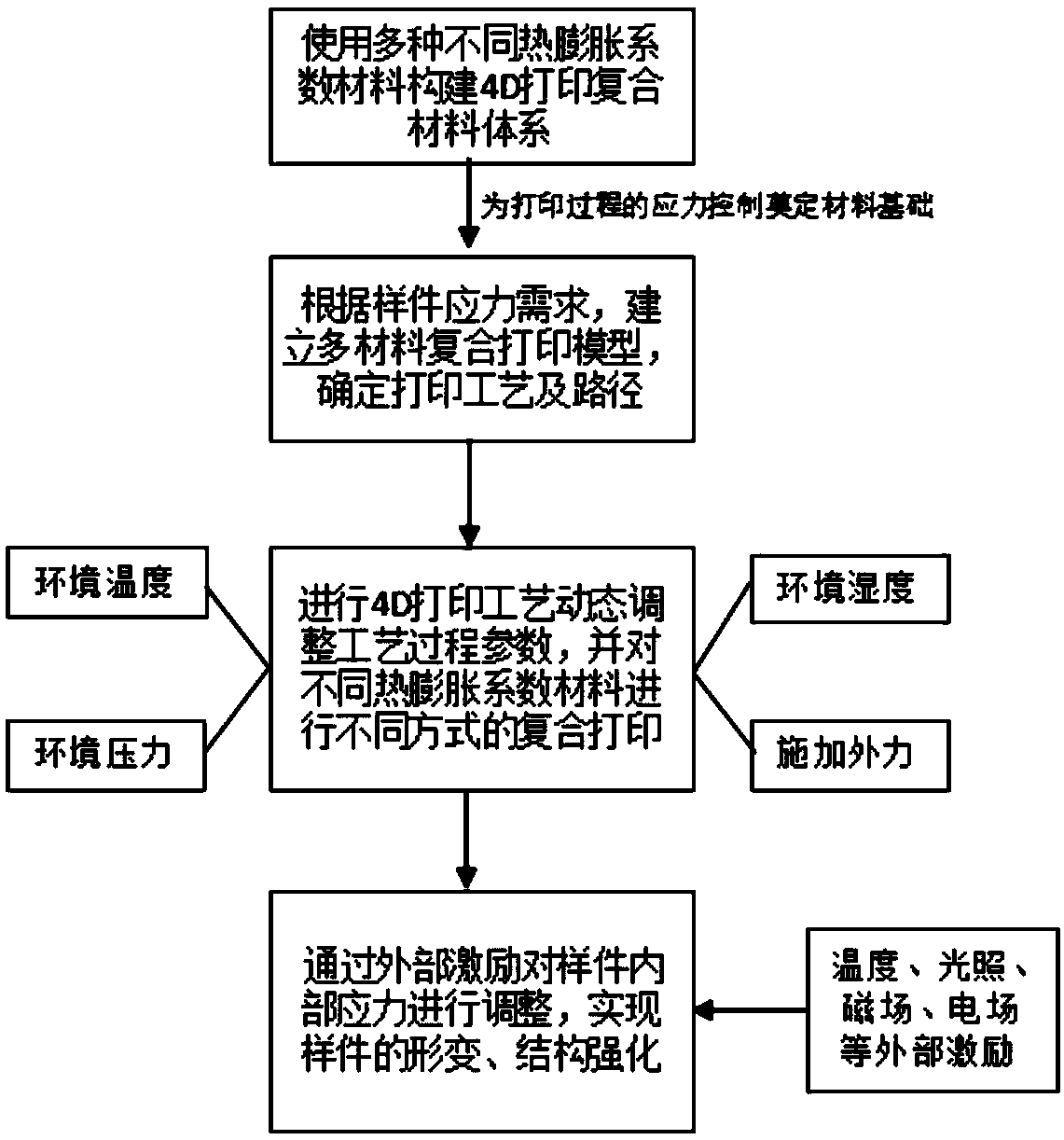

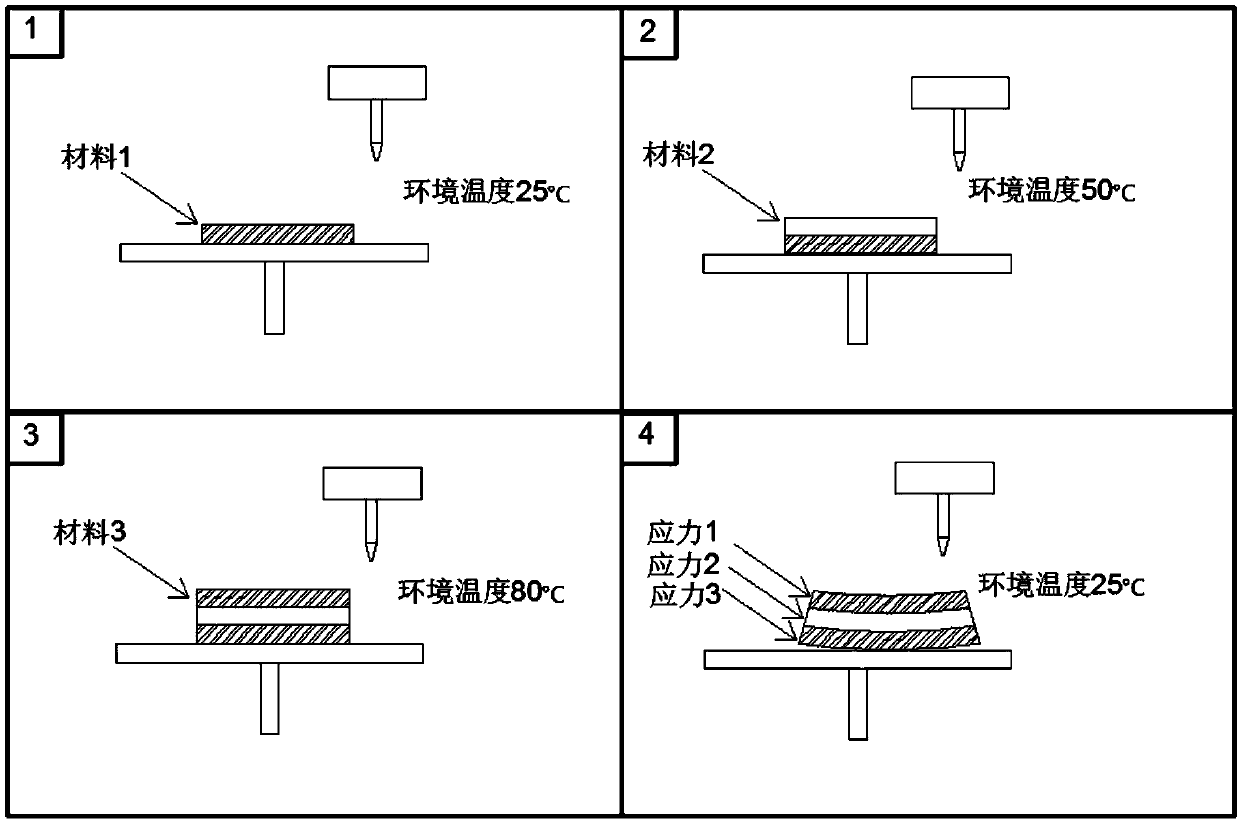

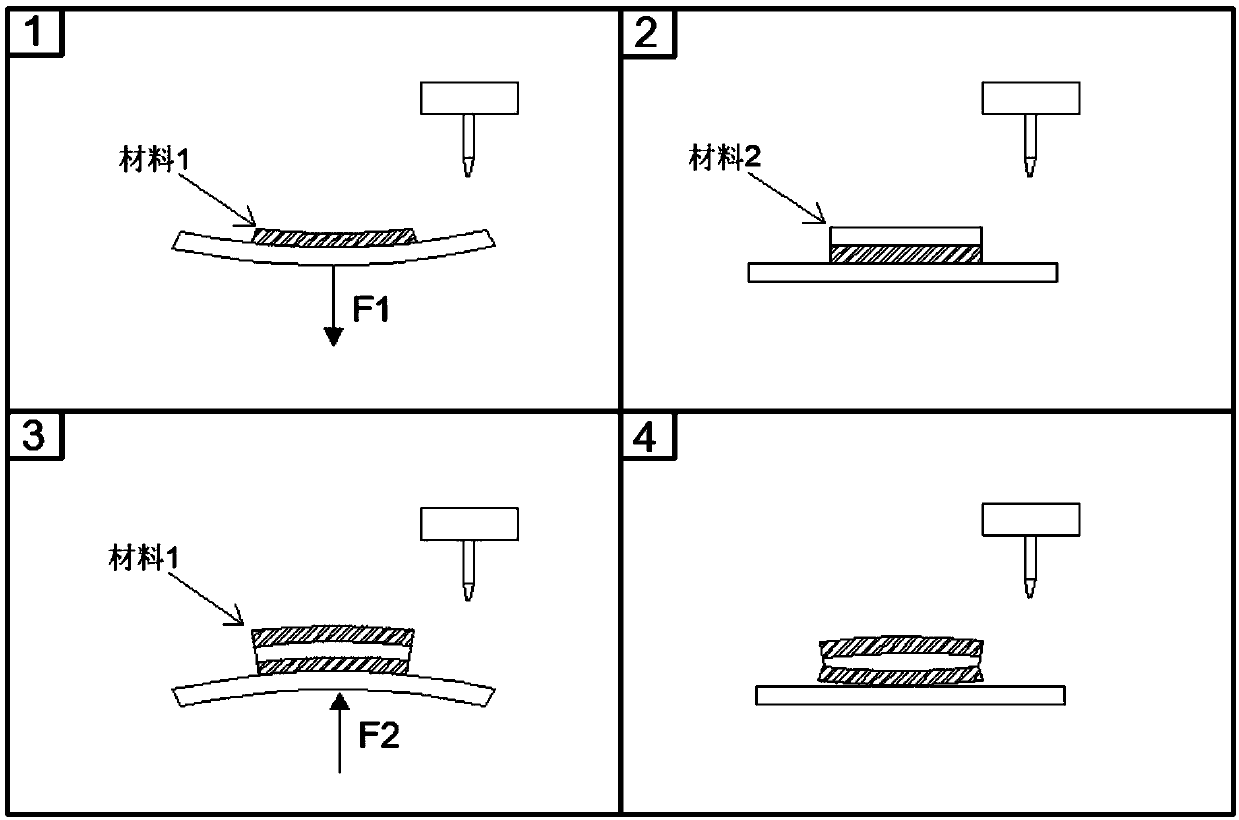

4D printing process method capable of presetting internal stress

ActiveCN109094004ARealize energy accumulationAchieve stressAdditive manufacturing apparatusAdditive manufacturing processesDistribution controlThermal expansion

The invention discloses a 4D printing process method capable of presetting internal stress. Different grades of thermal expansion coefficient materials are used to construct a composite system, so that different thermal expansion coefficient materials change with temperature environment and the like during processing to produce different degrees of strain an stress; a 3D printed additive manufacturing process or a 3D printing process and traditional processing manner mixed process is used for preparing samples; energy accumulation and internal stress distribution control of different spatial position materials are realized through ordered and controllable change of material composition manner, external environment and printing process parameters. The 4D printed composite system constructedthrough composition printing of multiple materials lays a material foundation for stress control during printing, and accurate control of stress, strain and deformation of samples during printing arerealized under the control of multiple factors such as material distribution, process parameters and environment parameters in the printing process.

Owner:XI AN JIAOTONG UNIV

4D printing based temperature control self-deformation device and preparation method thereof

ActiveCN111842887AStress reliefAlleviate bindingAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlTitanium zirconium

The invention belongs to the field of 4D printing additive manufacturing, and discloses a 4D printing based temperature control self-deformation device and a preparation method thereof. The preparation method comprises the following steps that S1, a three-dimensional model of a self-deformation device is set up, and areas obtained through division at least comprise a low-temperature deformation area, a transition area and a high-temperature deformation area; S2, laser printing parameters of the three areas are set, nickel and titanium based memory alloy powder is used for carrying out divisionforming on the three areas through the laser selective melting technology, an intelligent deformation part is obtained, and nickel-titanium-zirconium ternary alloy powder serves as the nickel and titanium based memory alloy powder correspondingly adopted by the transition area and the high-temperature deformation area; and S3, the intelligent deformation part is folded, and the temperature control self-deformation device is obtained. Zr is introduced into a nickel and titanium alloy to serve as a third component, and compared with the manner that in the prior art, manufacturing of function gradient NiTi materials can be achieved only by changing process parameters, the excitation temperature point of the NiTi based self-deformation device can be flexibly adjusted and controlled accordingto requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

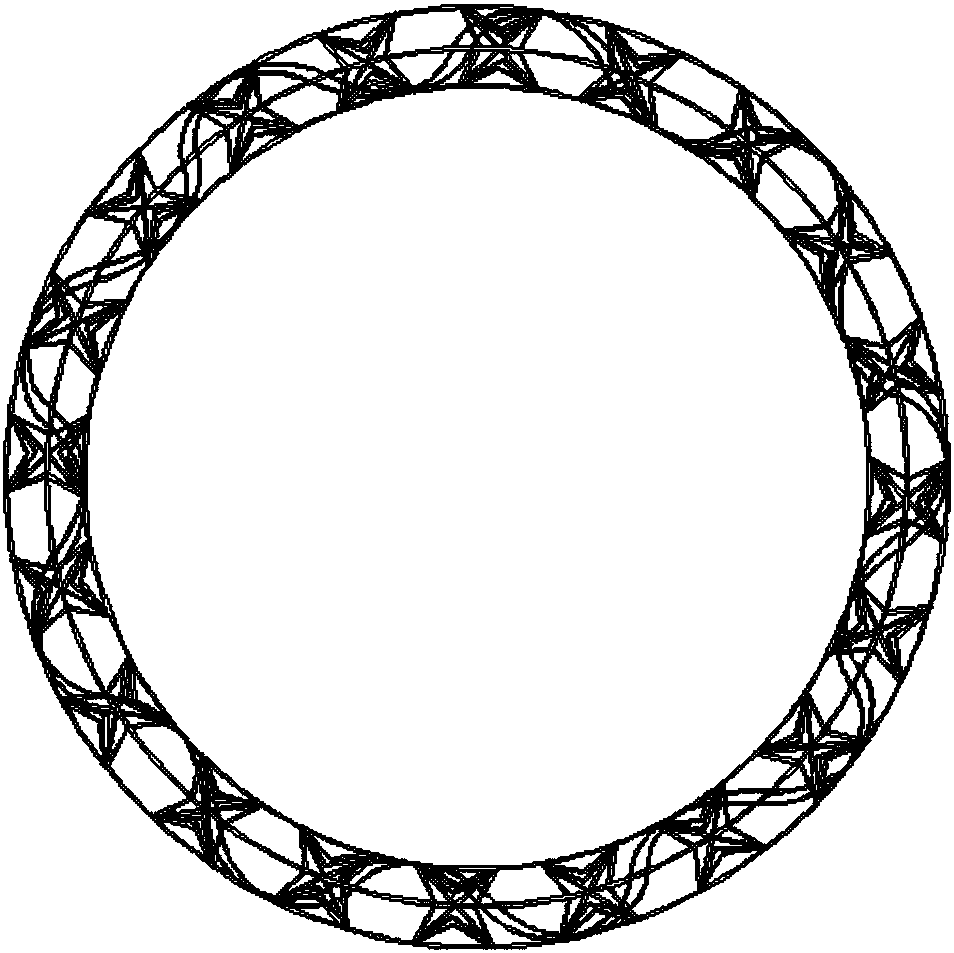

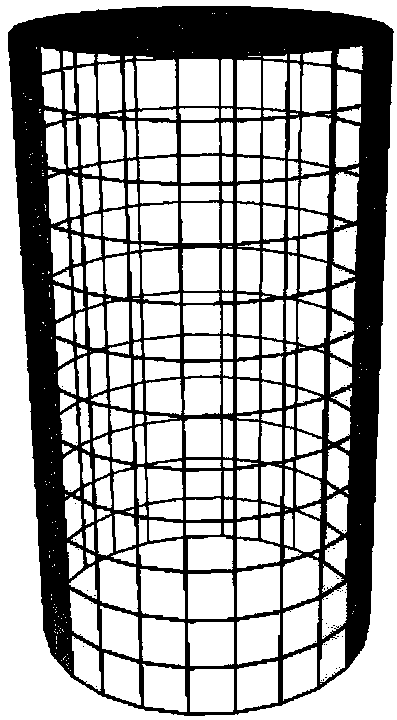

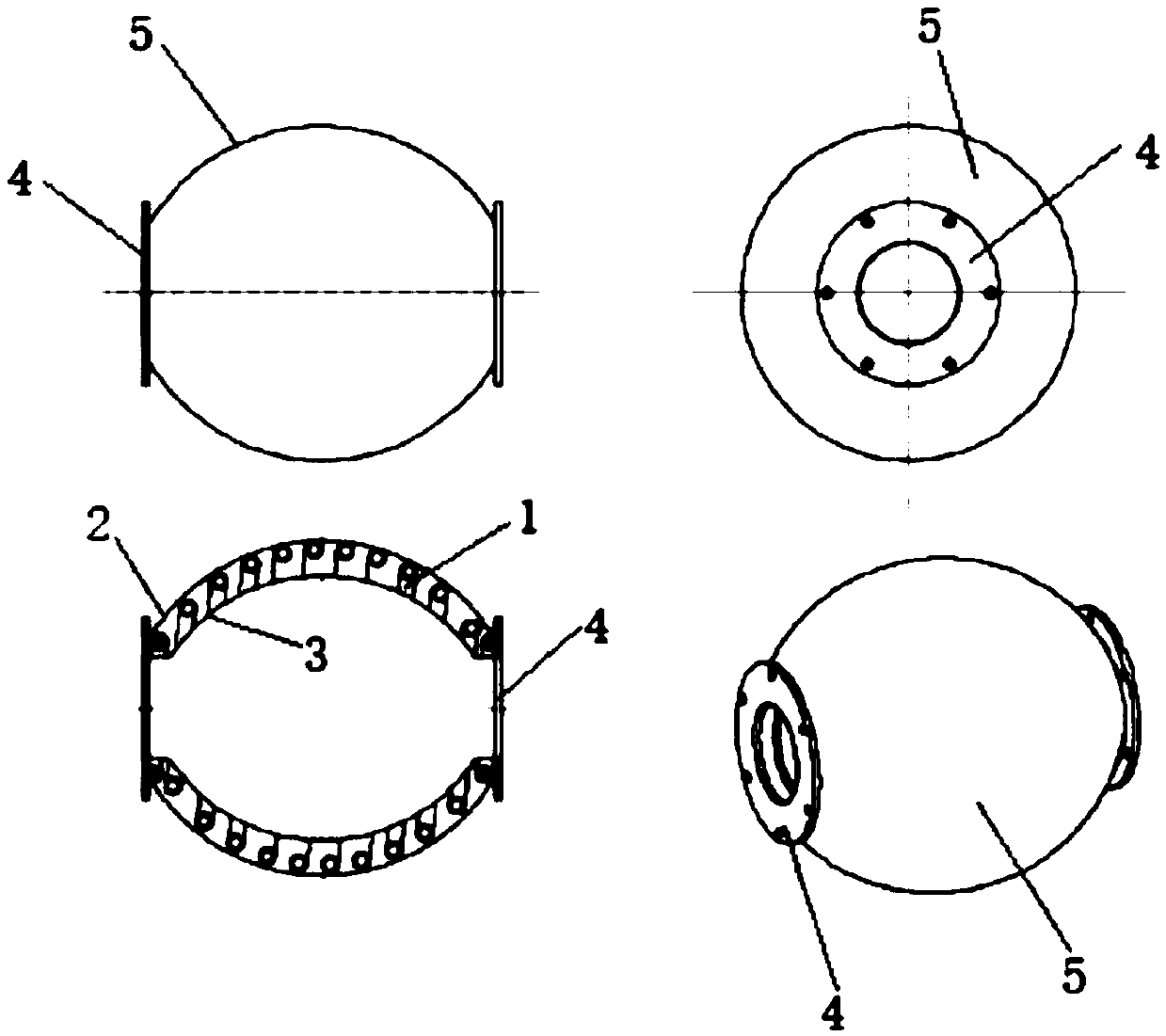

Three-dimensional vector expansion cardiovascular stent with memory effect based on 4D printing and manufacturing method

ActiveCN108403256ASufficient expansion forceReduce harmStentsAdditive manufacturing apparatusFlagellar basal bodyCardiovascular stent

The invention discloses a three-dimensional vector expansion cardiovascular stent with a memory effect based on a 4D printing and manufacturing method. The stent is made by metalprinting a metal material with a vector expansion effect and comprises multiple net annular wires uniformly arranged in the axial direction and composed of inwards concave hexahedral grid basic units, multiple layers of the net annular wires are arranged in an array to constitute a stent main body, and an upper supporting ring and a lower supporting ring are connected to the net annular wires at the two ends of the stent main body respectively and fix the stent main body. The manufacturing method of the three-dimensional vector expansion cardiovascular stent comprises the steps of controlling the energy density oflaser area selecting melting, adjusting austenite-martensite phase change temperature, using different energy densities to form different parts of a basal body structure and achieving deformation adjustability of a formed cardiovascular stent based on temperature dependence change. Thus different parts of the stent have different expansion coefficients based on temperatures, so that the stent better adapts to the specificity and the thermal expansion of the shape of the blood vessel.

Owner:SOUTH CHINA UNIV OF TECH

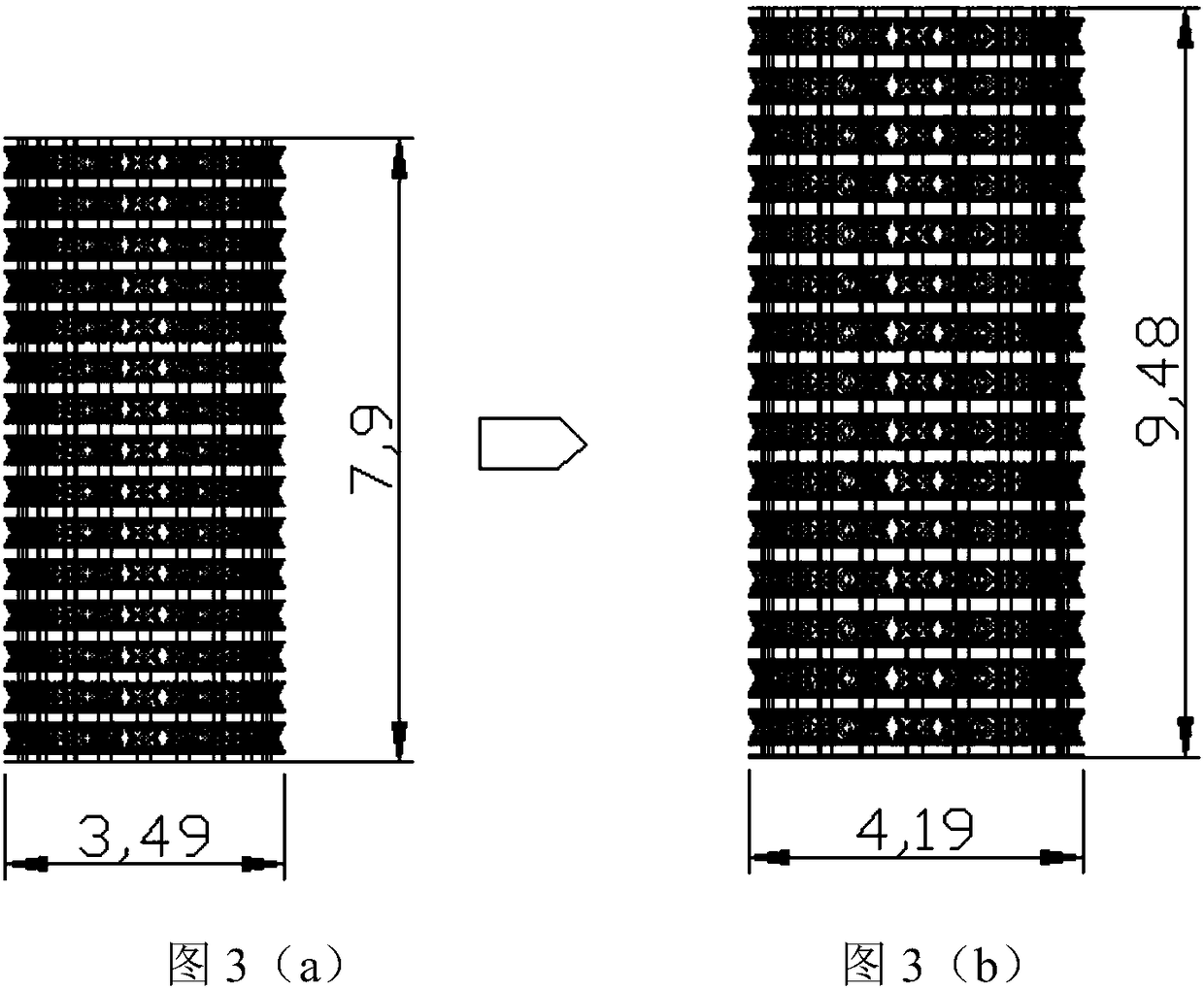

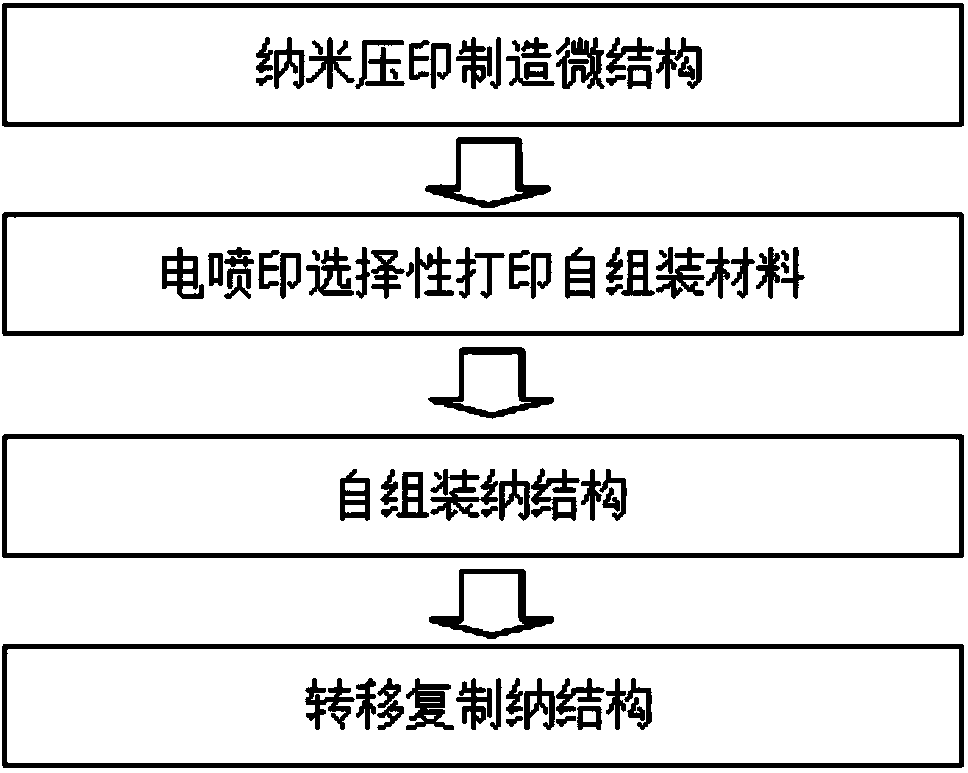

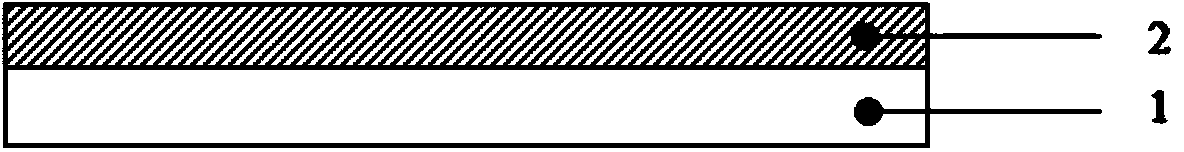

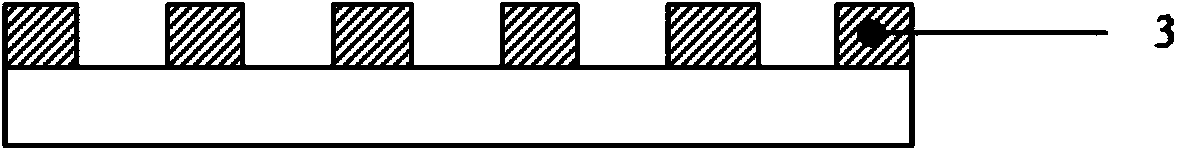

Method for manufacturing micro/nano composite structure based on 4D printing and nanoimprint lithography

The invention discloses a method for manufacturing a micro / nano composite structure based on 4D printing and nanoimprint lithography. The method comprises the following steps: (1) transferring and copying a microstructure on a mold to an imprint material by adopting a nanoimprint lithography process, and manufacturing a microstructure; (2) selectively printing and depositing a self-assembly material on the microstructure by using electronic jet printing; (3) allowing the self-assembly material to be subjected to microphase separation, and self-assembling the nano structure; and (4) transferring and copying the nano structure to a target material. According to the invention, the advantages of technologies such as nanoimprint lithography, additive manufacturing, electrical jet printing and self-assembling are combined, high-efficiency low-cost large-scale manufacturing of a large-area micro / nano composite structure is realized, and the method has the obvious characteristics of excellent controllability, repeatability and consistency and high precision.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

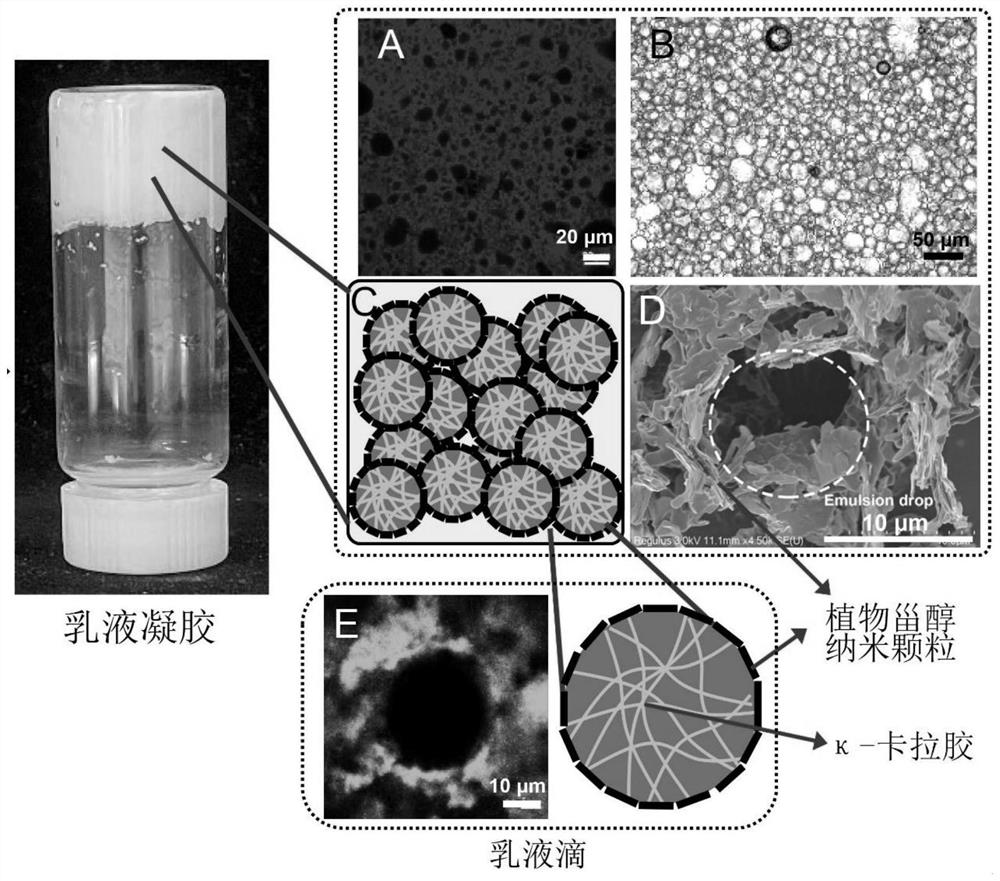

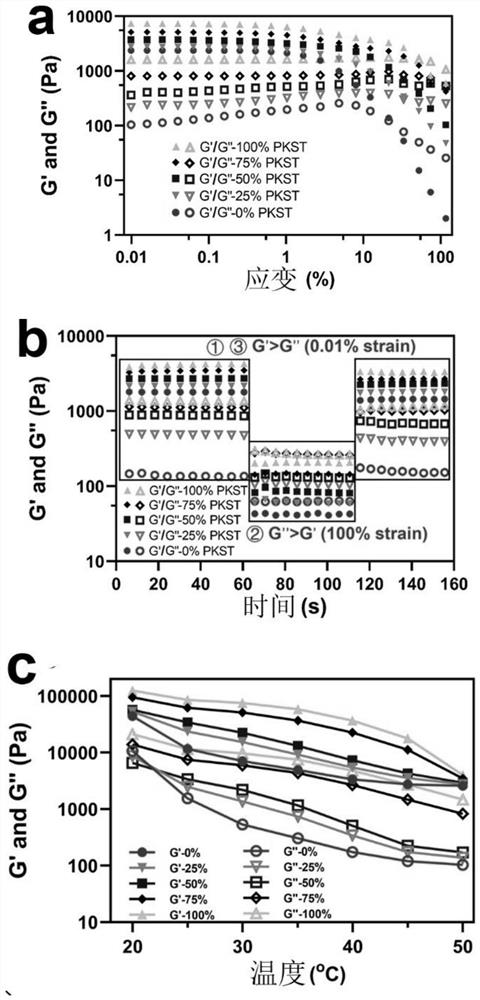

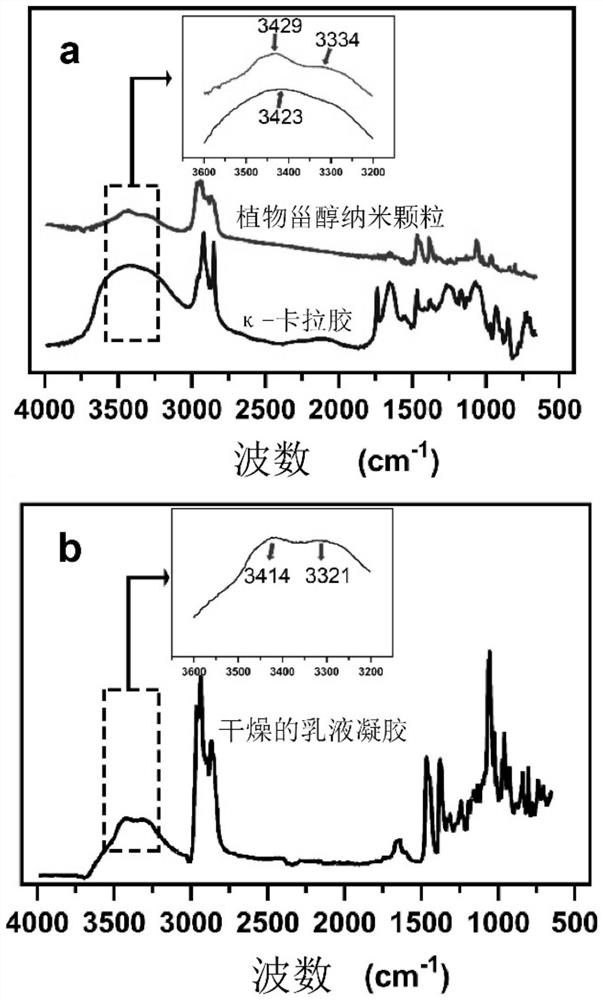

Dual-network zero-trans-fat-like emulsion gel capable of 3D/4D printing and preparation method of dual-network zero-trans-fat-like emulsion gel

ActiveCN114468062AImprove thixotropyGood shaping effectAdditive manufacturing apparatusCocoaBiotechnologyVegetable oil

The invention discloses dual-network zero-trans fat-like emulsion gel capable of 3D / 4D printing and preparation, and belongs to the technical field of healthy grease and food processing. The method for preparing the emulsion gel comprises the following steps: (1) adding a hydrophilic colloid into hot water containing emulsifier nanoparticles, and dissolving to obtain an aqueous solution; wherein the mass concentration of the nanoparticles in the aqueous solution is 0.5-15%; (2) dissolving oil-soluble small molecules in the heated vegetable fat, and uniformly mixing to obtain an oil solution; or mixing and heating a plurality of vegetable oils and fats to obtain mixed oil and fat; and (3) mixing the aqueous solution in the step (1) and the oil solution or the mixed grease in the step (2) according to a volume ratio of 1: 1-9: 1, homogenizing and emulsifying to obtain the emulsion gel. The emulsion gel provided by the invention can partially or completely replace traditional fat in chocolate, ice cream, non-dairy cream and other foods, and has the characteristics of zero trans-low saturated fatty acid nutrition and health.

Owner:JIANGNAN UNIV

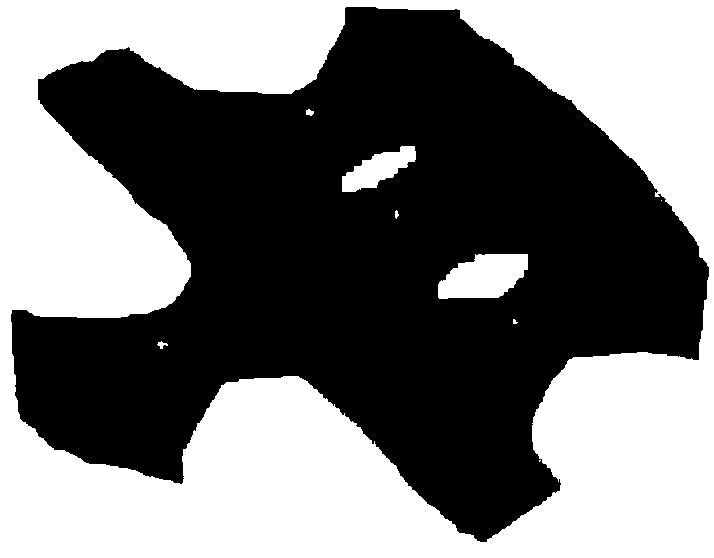

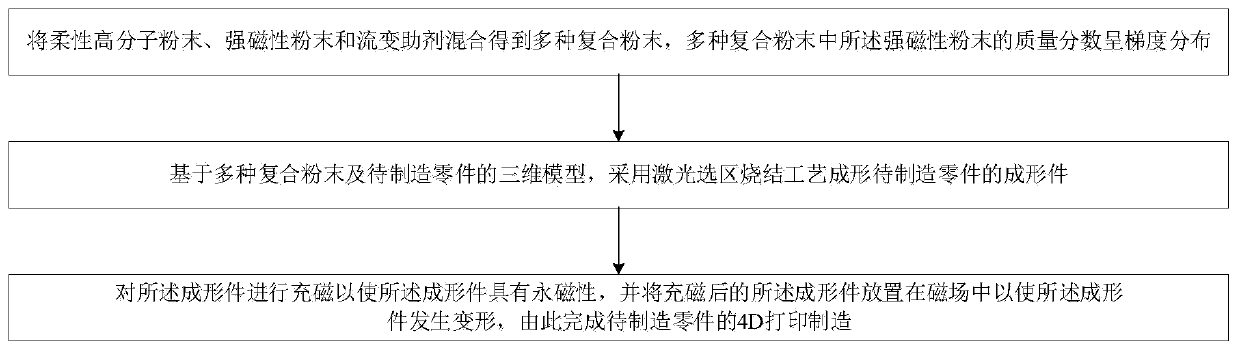

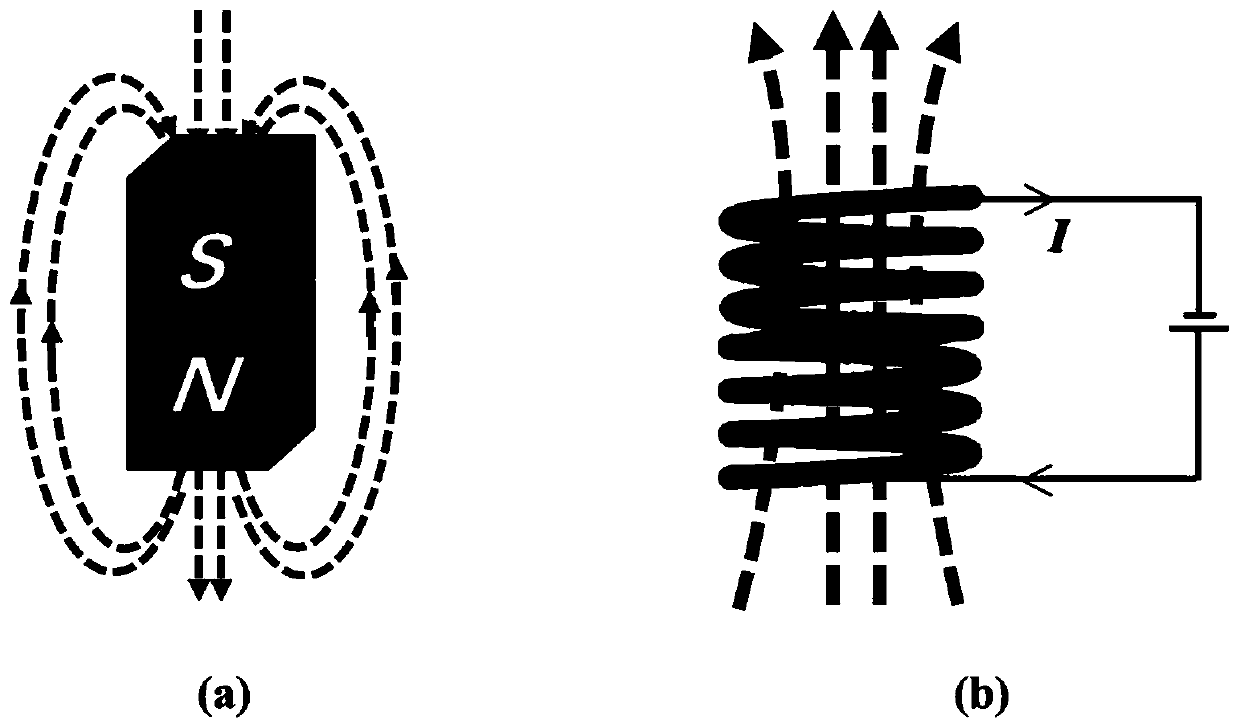

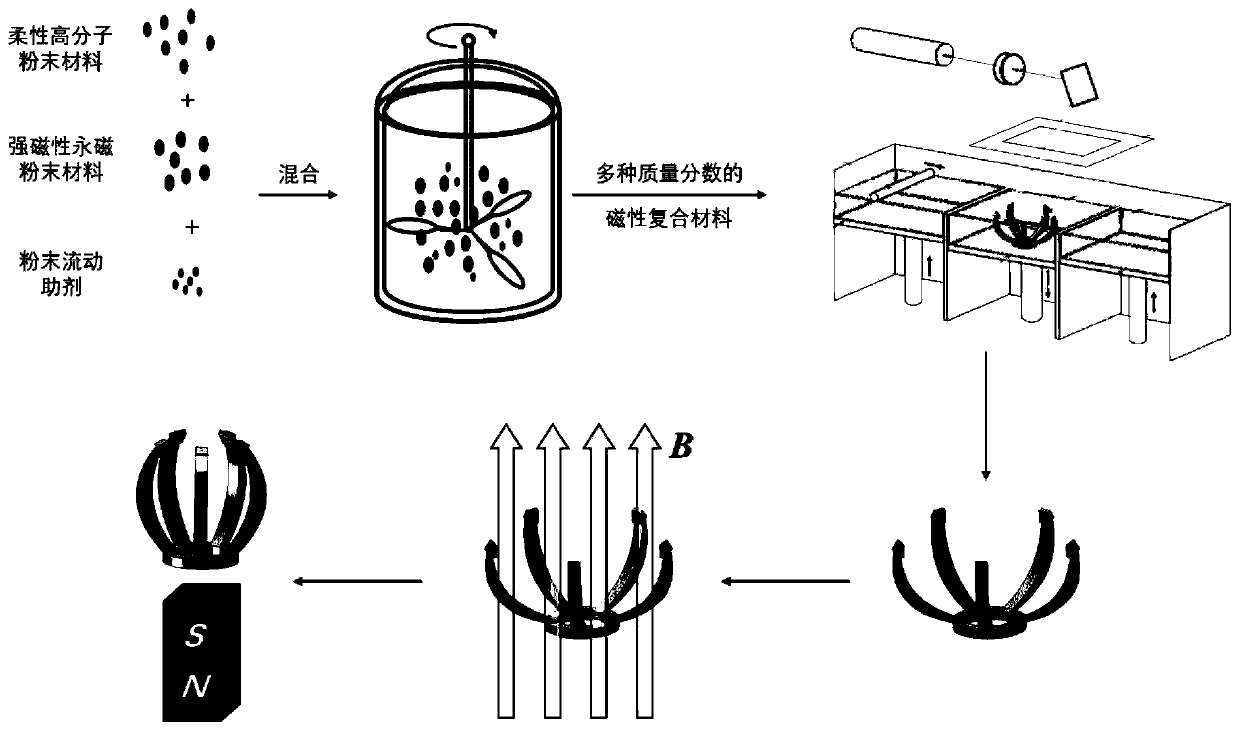

4D printing manufacturing method suitable for magnetic composite material

ActiveCN110600254AHigh bonding strength between layersImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sintering4d printing

The invention belongs to the related technical field of composite material 4D printing, and discloses a 4D printing manufacturing method suitable for the magnetic composite material. The method comprises the following steps: (1) mixing flexible polymer powder, strong magnetic powder and a rheological agent to obtain multiple kinds of composite powder, wherein the mass fractions of the strong magnetic powder in the multiple kinds of composite powder are in graded distribution; (2) forming a formed part of the to-be-manufactured gradient part by adopting a selective laser sintering process basedon the various composite powder and the three-dimensional model of the to-be-manufactured part; (3) magnetizing the formed part to enable the formed part to have permanent magnetism, and placing themagnetized formed part in a magnetic field to enable the formed part to deform, thereby completing 4D printing and manufacturing of the gradient part to be manufactured. According to the method, the performance of the part is improved, the flexibility is high, the mechanical property of the formed part is enhanced, the content of magnetic powder in the height direction of the formed part is distributed in a gradient mode, and the bending angle can be controlled.

Owner:HUAZHONG UNIV OF SCI & TECH

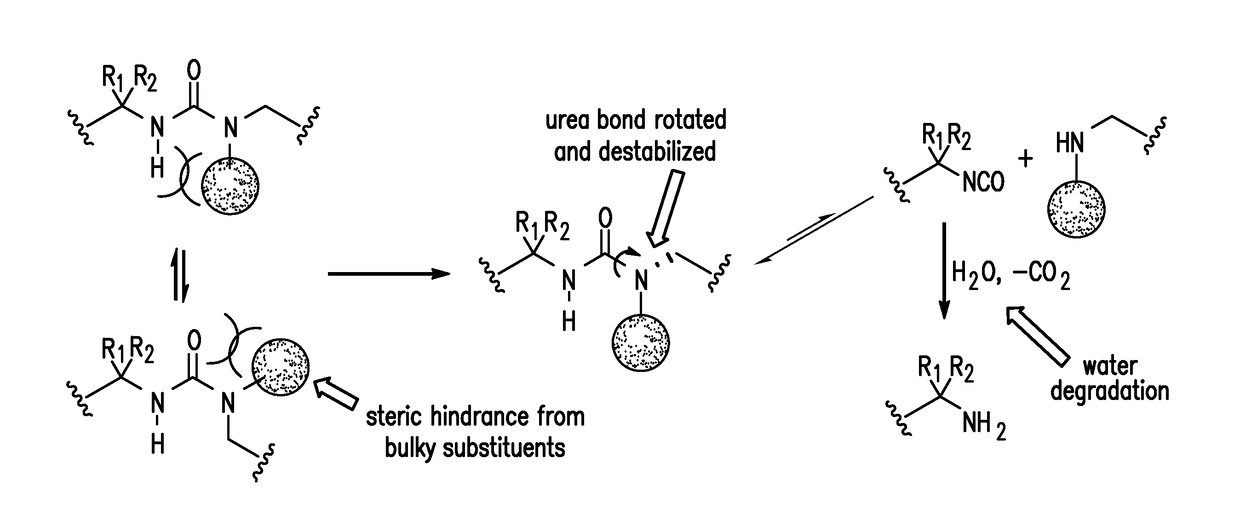

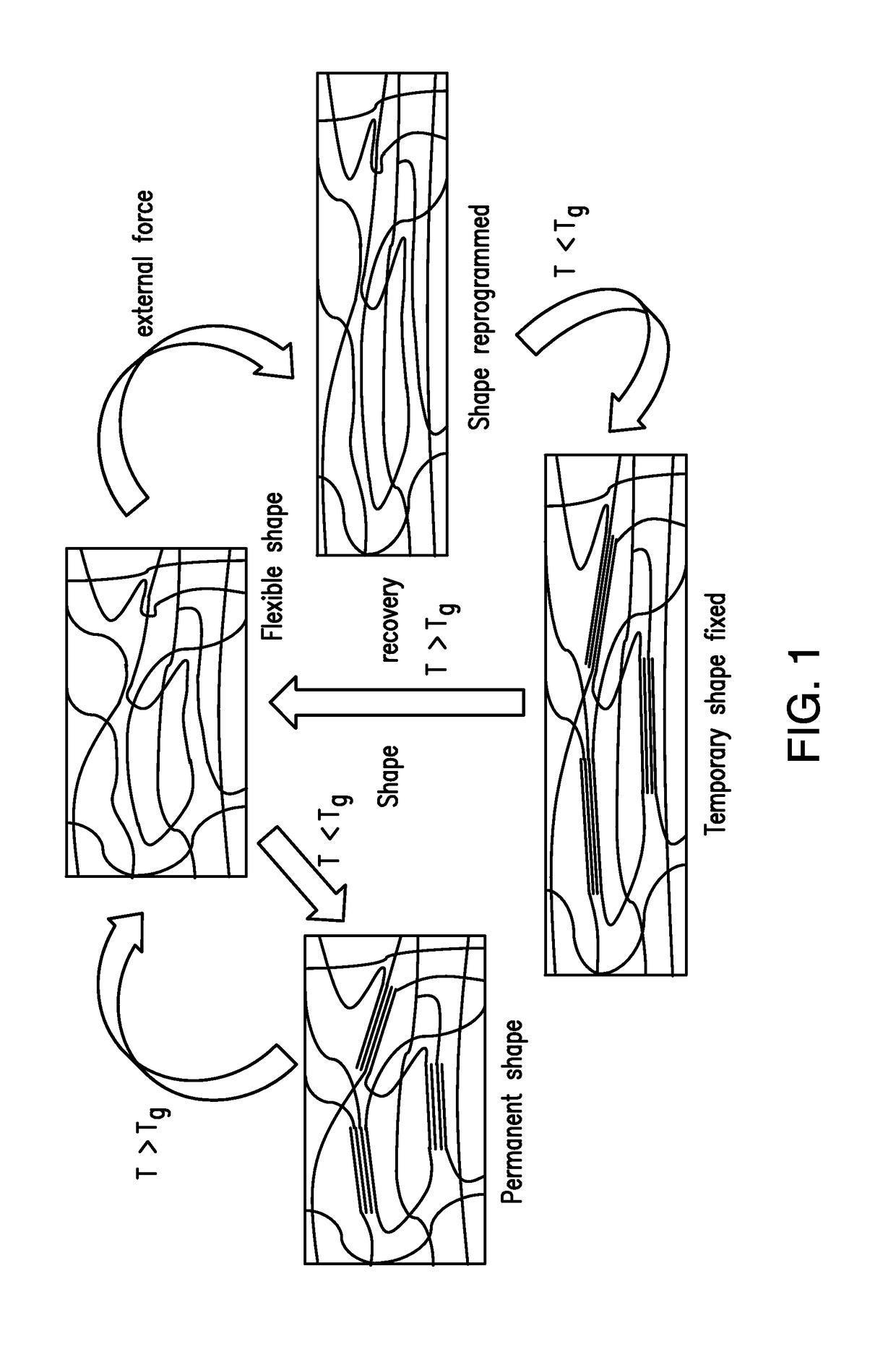

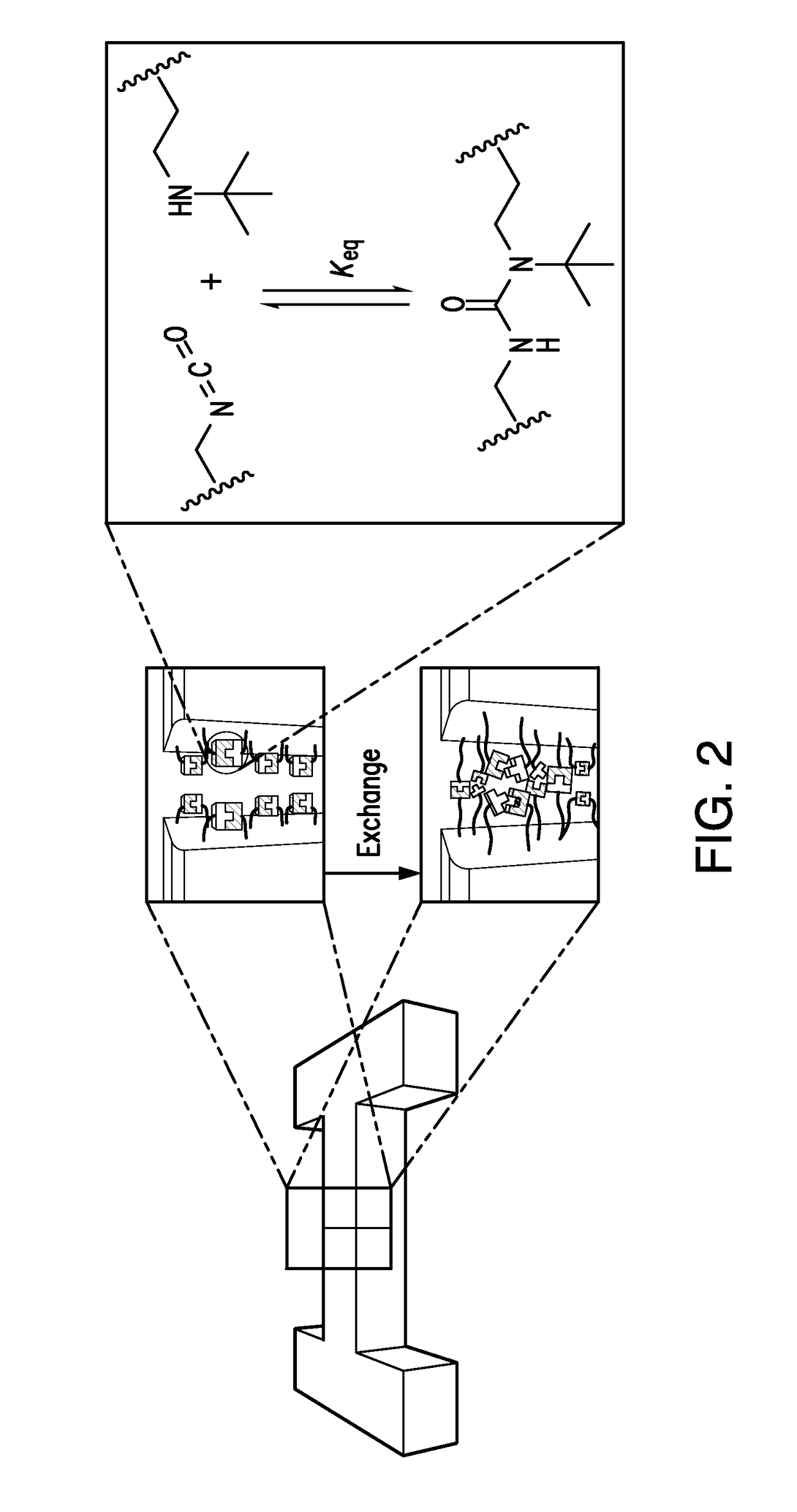

Dynamic urea bonds for polymers

InactiveUS20170327627A1Avoid bondingSuture equipmentsPharmaceutical non-active ingredientsPolyesterCross-link

The present invention relates to polymers having dynamic urea bonds and more specifically to polymers having hindered urea bonds (HUBs). The present invention also relates to: (a) malleable, repairable, and reprogrammable shape memory polymers having HUBs, (b) reversible or degradable (e.g., via hydrolysis or aminolysis) linear, branched or network polymers having HUBs, and (c) to precursors for incorporation of HUBs into these polymers. The HUB technology can be applied to and integrated into a variety of polymers, such as polyureas, polyurethanes, polyesters, polyamides, polycarbonates, polyamines, and polysaccharides to make linear, branched, and cross-linked polymers. Polymers incorporating the HUBs can be used in a wide variety of applications including plastics, coatings, adhesives, biomedical applications, such as drug delivery systems and tissue engineering, environmentally compatible packaging materials, and 4D printing applications.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

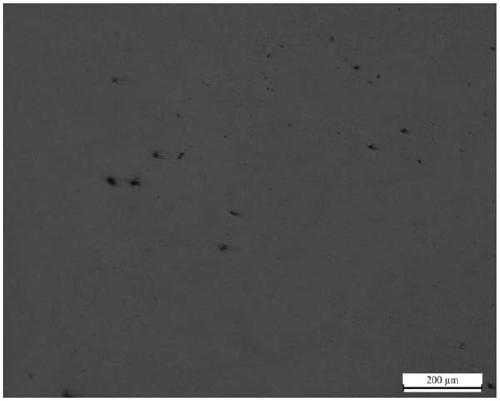

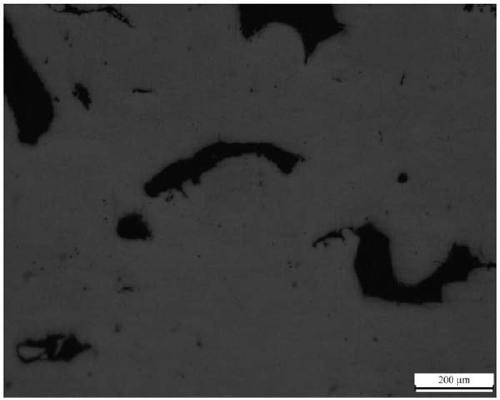

Crack-free 4D printing titanium-nickel shape memory alloy and preparation method thereof

ActiveCN109022920AInhibitionImprove recovery effectAdditive manufacturing apparatusIncreasing energy efficiencyCrack freeShape-memory alloy

The invention discloses crack-free 4D printing titanium-nickel shape memory alloy and a preparation method thereof. The crack-free 4D printing titanium-nickel shape memory alloy comprises, by mass, 40%-80% of Ni, 10%-60% of Ti and 2%-10% of Zr. The surface of the prepared 4D printing titanium-nickel shape memory alloy is free of crack, mechanical properties are excellent, tensile strength is 740 MPa or above, and hardness is 280 HV or above.

Owner:CENT SOUTH UNIV

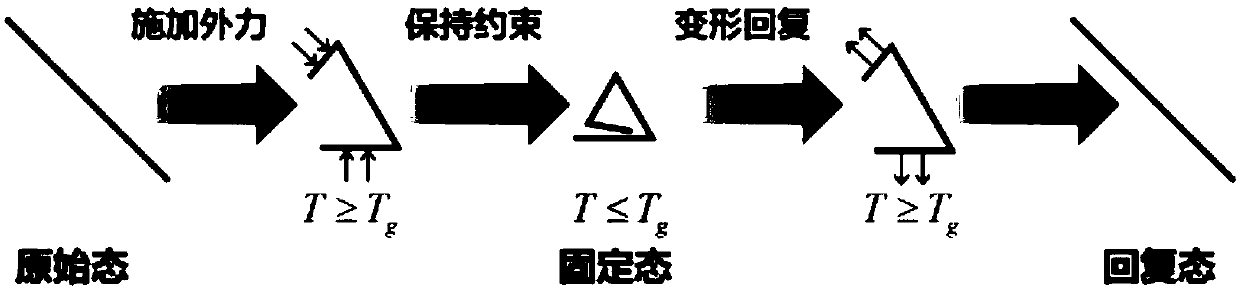

Drug releasing method based on 4D printing shape memory polymer structure

ActiveCN108553300AControl release timeStrong slow and controlled release performanceAdditive manufacturing apparatusPharmaceutical product form changeVitrificationSustained release drug

The invention relates to a drug releasing method based on a 4D printing shape memory polymer structure. The invention aims at solving the problems that according to an existing sustained-release drug,the drug preparation technology is complex, preparation cost is higher, and repeatability is lower. Shape memory polymers and a drug are mixed at the indoor temperature, a shape memory polymer carrying the drug is obtained, an initial constructed drug releasing structure is prepared through a 4D printing technology, the structure is heated to the glass transition temperature, the initial constructed drug releasing structure is converted to a temporary constructed drug releasing structure with a smaller superficial area, the temporary constructed drug releasing structure is placed in the environment which is prepared for simulating human body fluid, external motivators are given, the initial constructed drug releasing structure is recovered, and the whole process is completed. According tothe method, the preparation cost is low, the method is simple, and it is due to the fact that 4D printing process parameters are consistent, the repeatability is high. The method is applied to the field of intelligent drug releasing.

Owner:HARBIN INST OF TECH

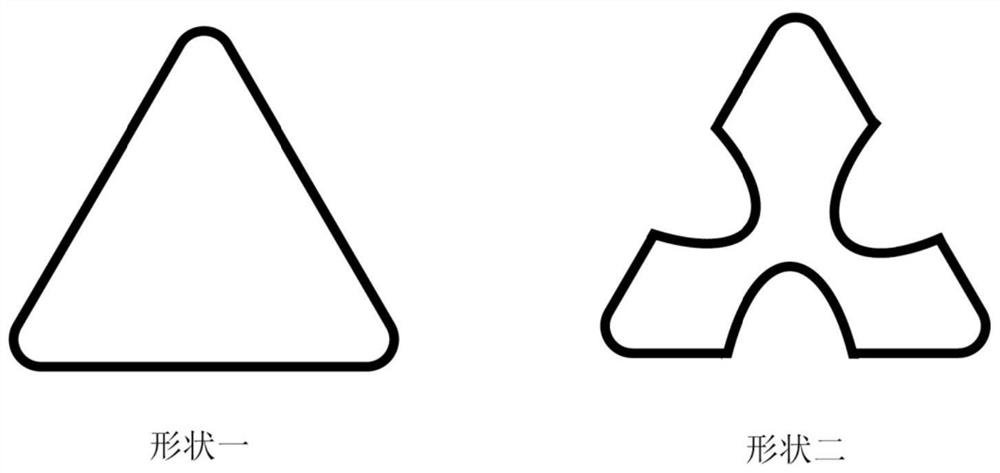

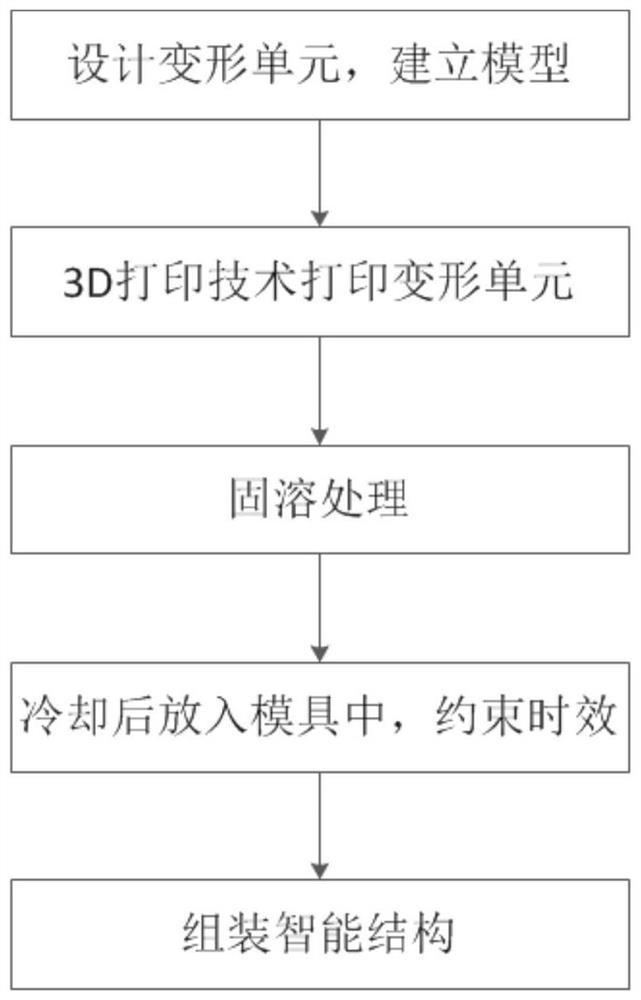

Method for preparing nickel-titanium two-way memory deformation part and intelligent structure through 4D printing

PendingCN111957966ARealize Programmable ControlImplemented with programmable controlAdditive manufacturing apparatusSolution treatmentMemory effect

The invention discloses a method for preparing a nickel-titanium two-way memory deformation part and an intelligent structure through 4D printing, and belongs to the technical field of metal additivemanufacturing. The method aims to design a part structure, determine a first shape and establish a three-dimensional digital model of the structure according to the two-way deformation requirement. The method comprises the following steps that a nickel-titanium alloy is printed into a part by adopting a 3D printing technology; the printed nickel-titanium memory alloy part is heated, water-coolingquenching is carried out after heat preservation, and solution treatment is carried out; the part subjected to solution treatment is installed in a deformation mold to be fixed into a second shape, and then the mold and the part are fixed into the second shape to be heated and subjected to heat preservation; and finally, the part is cooled to the room temperature, and a two-way memory effect is obtained. According to the method, the two-way memory effect of the nickel-titanium shape memory alloy is achieved in a constraint aging mode, the aging process is completed in the state of the second shape through a deformation die constraint component, and the method is a training method of the two-way memory effect; and the programmable deformation of the intelligent structure can be realized byassembling the small deformation parts and controlling the deformation of each unit.

Owner:SOUTHEAST UNIV

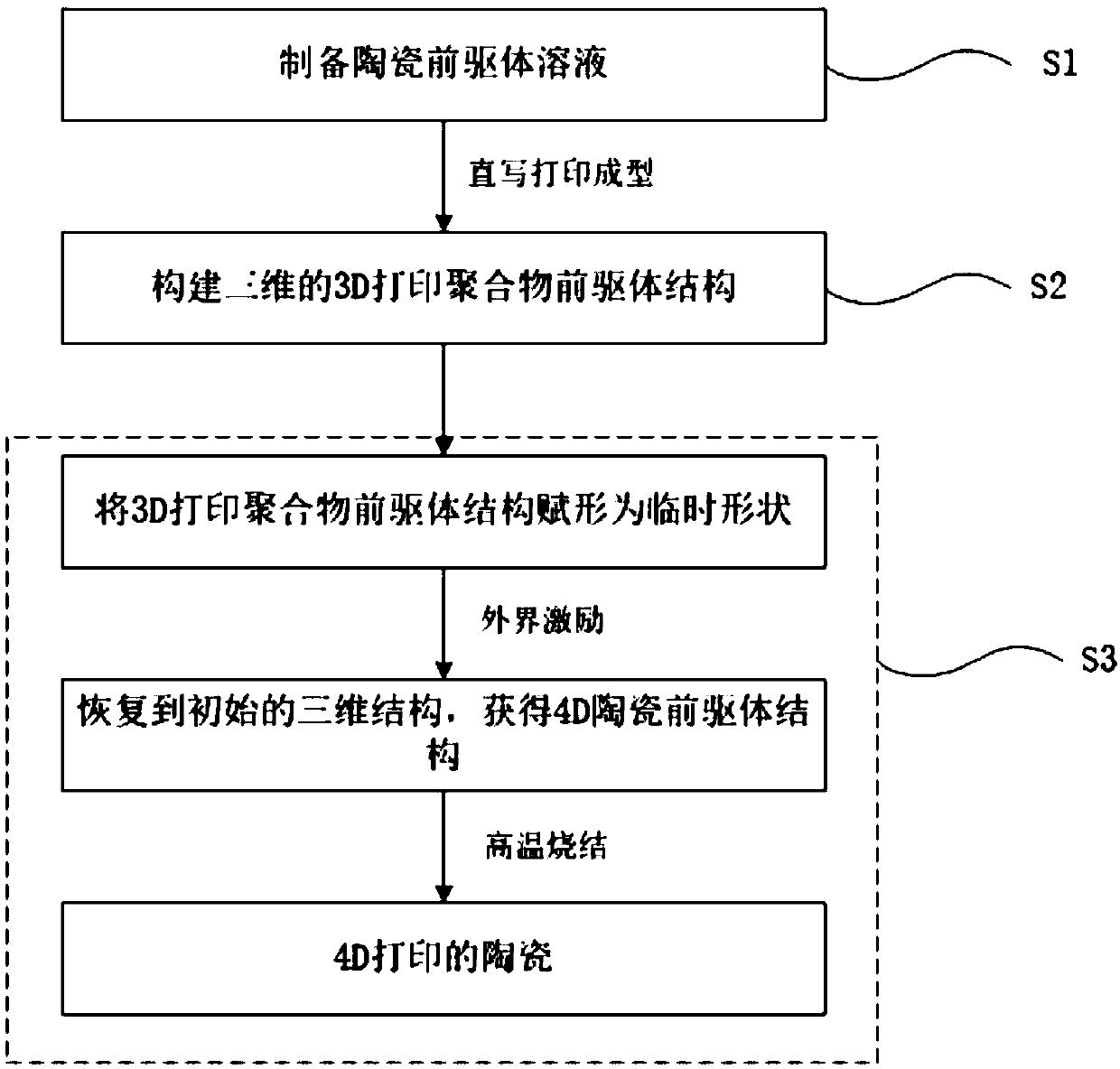

4D-printed ceramic preparation method and 4D-printed space capsule and unfolding method thereof

ActiveCN109678527AIncrease multi-dimensional designabilityIncreased structural deformation controllabilityCosmonautic vehiclesCosmonautic partsElastomer4d printing

The invention provides a 4D-printed ceramic preparation method and a 4D-printed space capsule and an unfolding method thereof. Specific steps for preparing the 4D-printed ceramic is as follows: preparing a ceramic precursor solution, wherein a matrix material of the ceramic precursor solution is shape memory polymer or shape memory polymer and elastomer mixture; performing write-through printing on the ceramic precursor solution to construct a 3D-printing polymer precursor structure; shaping the 3D-printing polymer precursor structure as a temporary shape, and recovering the 3D-printing polymer precursor structure to the initial three-dimensional structure after receiving external excitation so as to acquire the 4D ceramic precursor structure; and finally performing high-temperature sintering on the 4D ceramic precursor structure to obtain the 4D-printed ceramic. Through the 4D-printed ceramic preparation method provided by the invention, the multi-dimensional designability of the ceramic precursor three-dimensional structure shape can be increased, and the application range of the 4D-printed ceramic field can be broadened.

Owner:HARBIN INST OF TECH

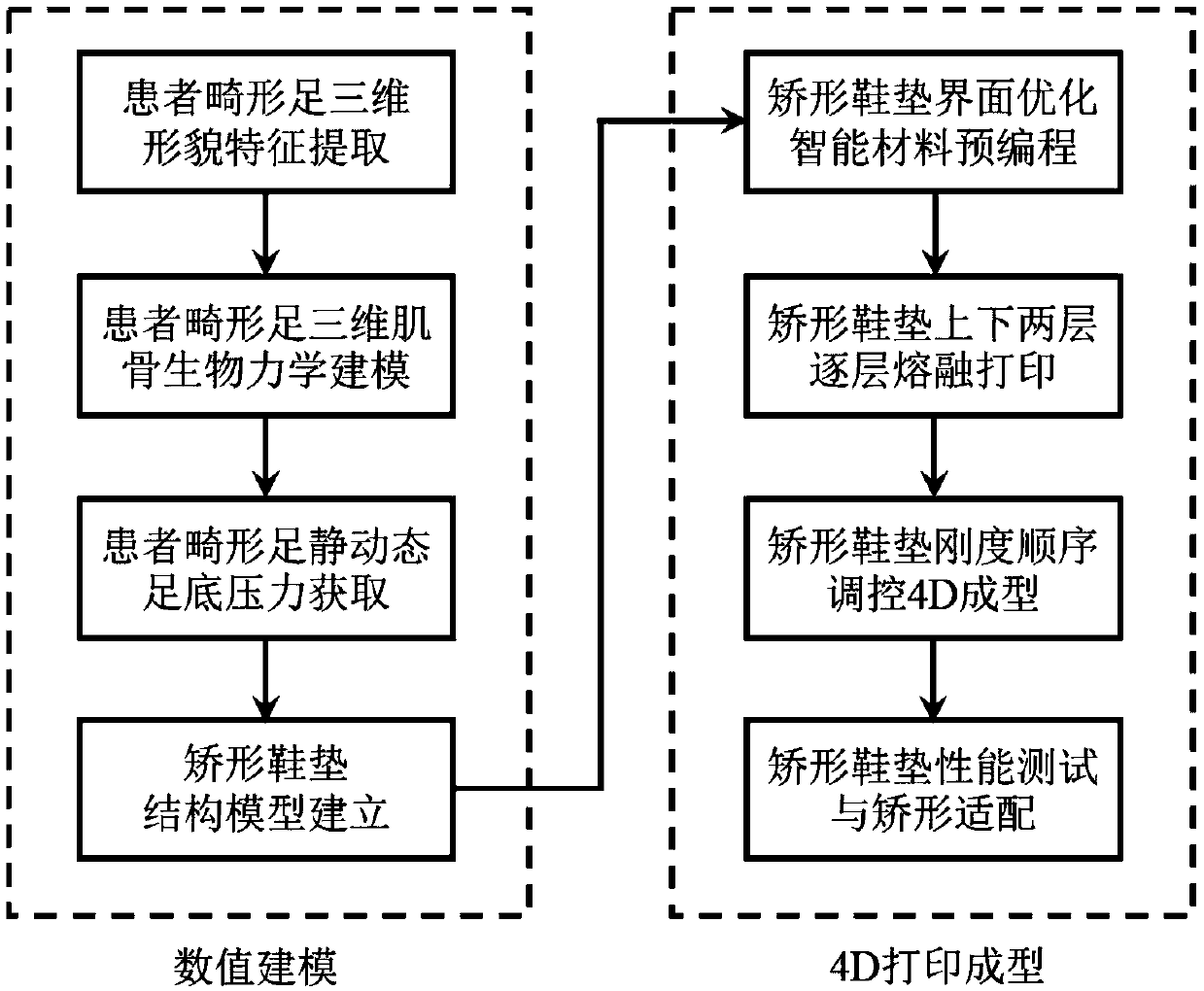

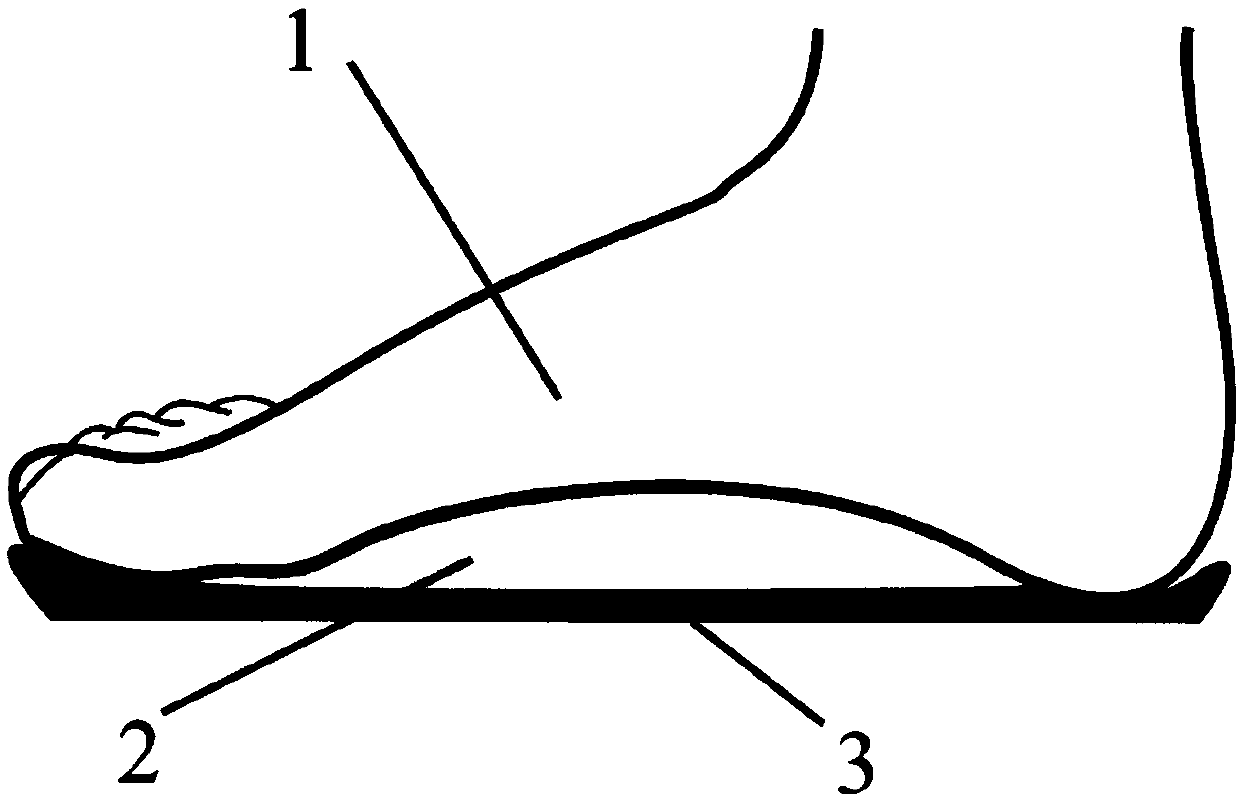

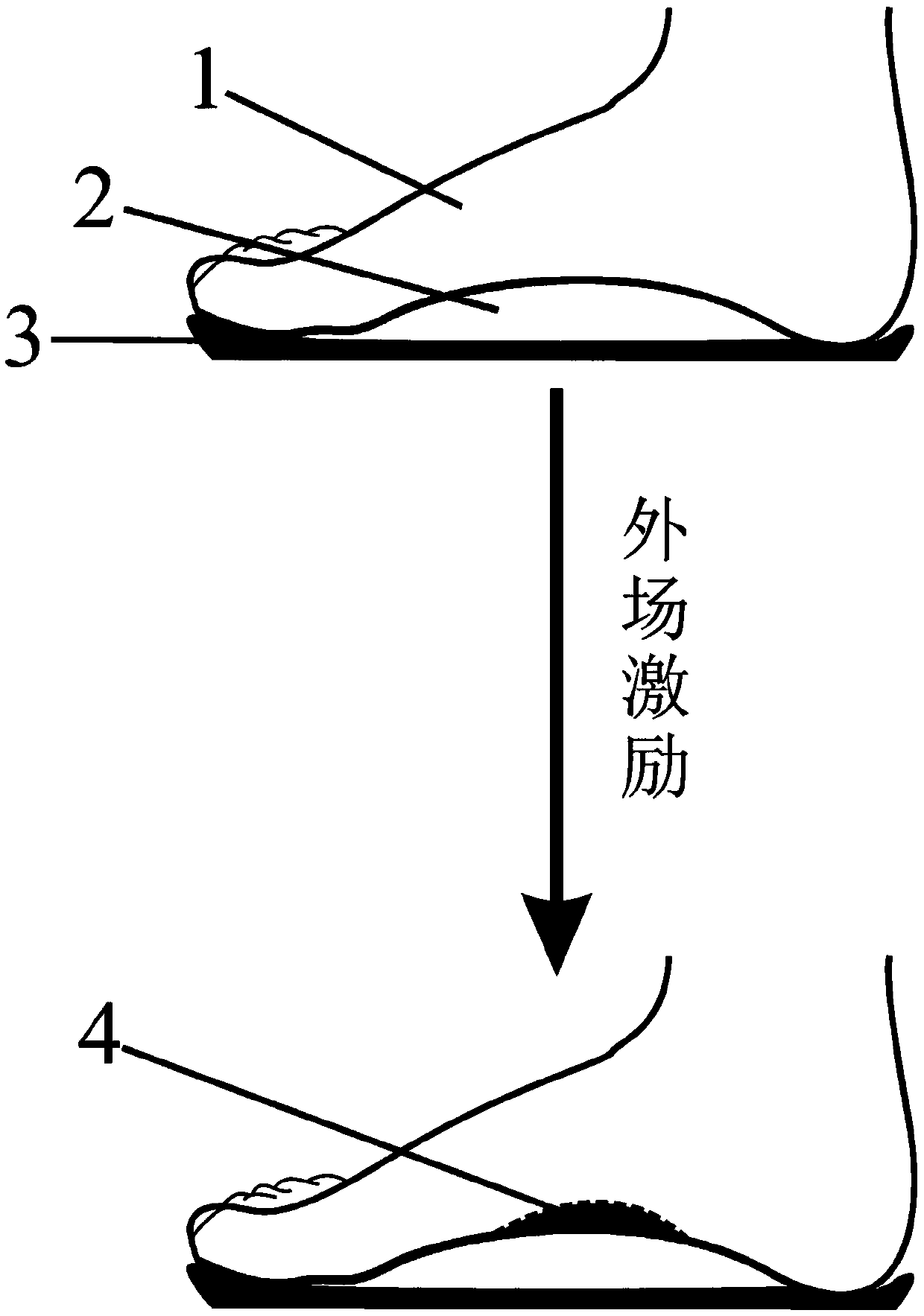

Rigidity-adjustable orthopedic insole and 4D printing forming method thereof

ActiveCN109567316ARealize the adjustable functionSatisfy the rigidity requirementAdditive manufacturing apparatusInsoles4d printingBiomedical engineering

The invention provides a rigidity-adjustable orthopedic insole. The insole is made of upper and lower layers including an intelligent deformation layer and a structural support layer, wherein the intelligent deformation layer is closely attached to the sole of a patient, made of a flexible polymer intelligent material and non-uniformly distributed in a foot arch area of the insole; the structuralsupport layer is the lowest layer and made of a structure material with bearing capacity. The intelligent deformable material is added to the orthopedic insole, time dimension is introduced on the basis of existing 3D printing, and 4D printing is formed. With change of the recovery condition of foot malformation degree of the patient in the orthopedic process, the intelligent deformation layer inthe orthopedic insole obtained through 4D printing forming has self-deformation such as expansion, bending, shrinkage and folding under excitation of an external field, and orthopedic insole shape andrigidity timely coordinated with foot malformation of the patient are formed, so that personalized customization of the orthopedic insole and timely self-adjustment of rigidity and shape are realized.

Owner:国家康复辅具研究中心

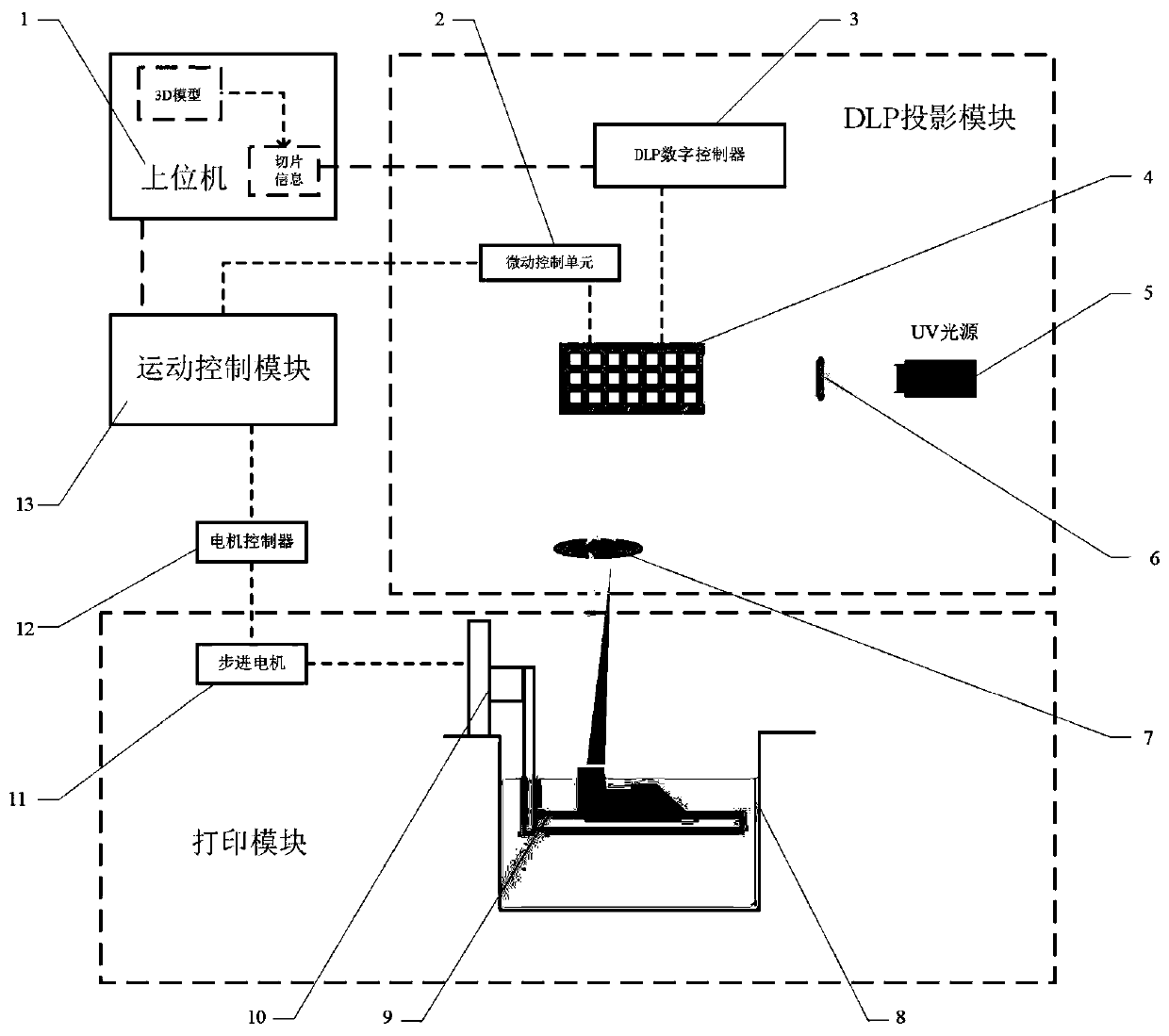

Programmable 4D printing method with function of projecting with multiwavelength ultraviolet light

ActiveCN110509546AHigh positioning accuracyImprove printing accuracyAdditive manufacturing apparatus3D object support structuresUltraviolet lightsSpray nozzle

The invention discloses a programmable 4D printing method with a function of projecting with multiwavelength ultraviolet light. The programmable 4D printing method comprises the following steps of 1,selecting a light-sensitive material which has curing performance and has selectivity to different wavelengths in an ultraviolet band according to the function design of a printed product; 2, selecting a light source containing required wavelengths and optical filters correspondingly penetrating through the wavelengths according to the characteristics of the selected light-sensitive material; 3, determining adopted cured wavelengths at different position points according to the function requirement of the printed product, completing the performance programming of different positions of the whole product, and writing a program in a DLP projecting module of a light curing system; and 4, curing the printed material layer by layer according to the written program, thereby printing the designed4D product which has a difference in performances of different positions. The programmable 4D printing method performs light curing at different position points on each layer of materials with ultraviolet light with different wavelengths, the working procedures of replacing spray nozzles, material pools and cleaning the surface of a sample are reduced, and therefore, the flow is simpler, and theprinting efficiency is higher.

Owner:XIAN TECHNOLOGICAL UNIV

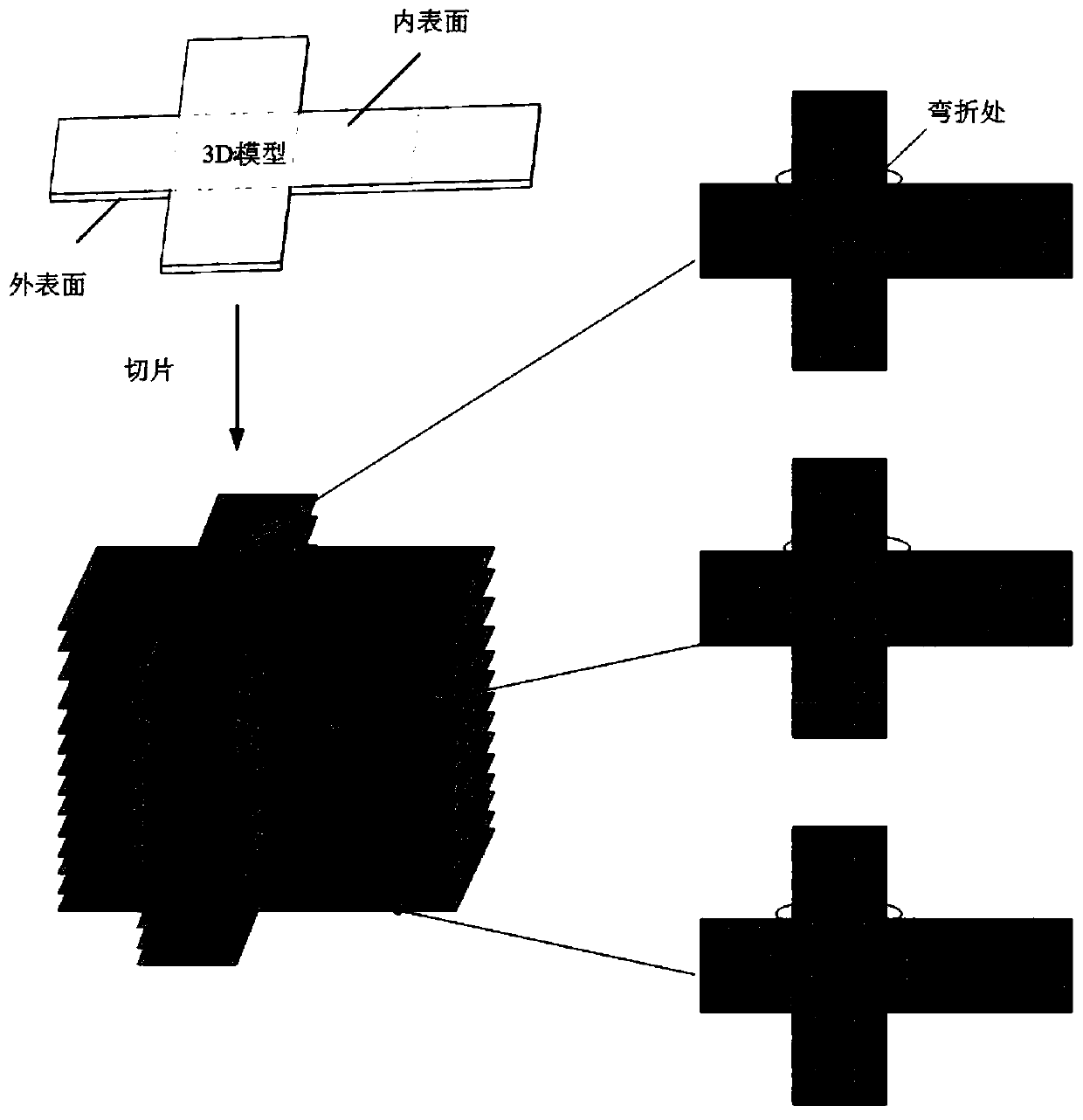

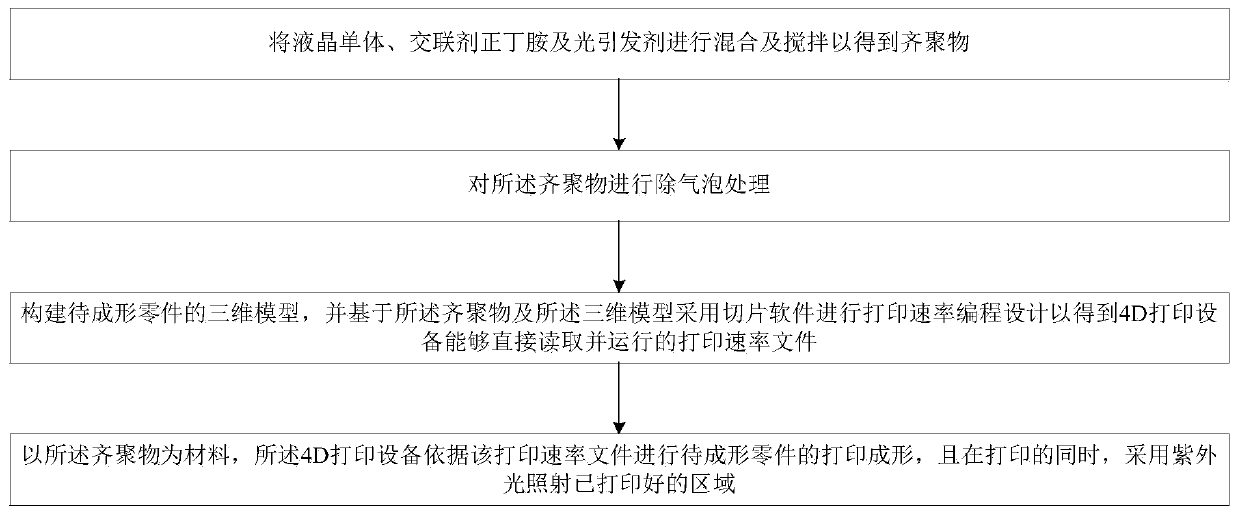

Preparation method based on liquid crystal elastomer and 4D printing and product

InactiveCN110172116AImprove efficiencyLow costLiquid crystal compositionsAdditive manufacturing apparatusCrystallographyOligomer

The invention belongs to the technical field of advanced material preparation and forming, and discloses a preparation method based on a liquid crystal elastomer and 4D printing and a product. The preparation method comprises the following steps of (1) mixing and stirring a liquid crystal monomer, a crosslinking agent n-butylamine and a photoinitiator to obtain an oligomer and carrying out bubbleremoval treatment on the oligomer; (2) constructing a three-dimensional model of a to-be-formed component, and adopting slicing software for carrying out printing rate programming design and slicing on the basis of the oligomer and the three-dimensional model to obtain a file which can be directly read and run by a 4D printing device; (3) taking the oligomer as a material, carrying out printing forming of the to-be-formed component through the 4D printing device according to the file, and using ultraviolet light for irradiating printed parts during printing. The method can realize the preparation of complex deformable liquid crystal elastomer components.

Owner:HUAZHONG UNIV OF SCI & TECH

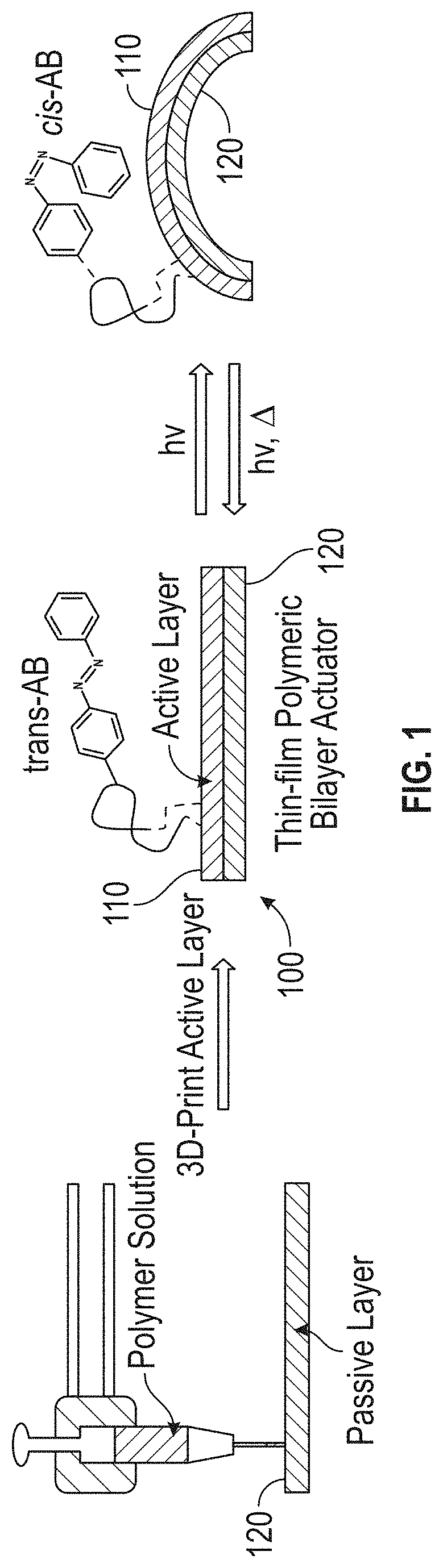

Externally Activated Shape Changing Device

ActiveUS20190367692A1Reduce the amount requiredReduce the number of partsAdditive manufacturing apparatusMachines/enginesShape changeEngineering

The present invention provides a 4D printed component that uses the photoisomerization stimulus as a method of activation. Other 4D printing methods use heat, moisture, a combination of heat and stress, and the heat from a light source as methods of activation. The present invention takes advantage of 3D printing capability and adds the capability of providing a printable material that dynamically changes shape over time when exposed to an external stimulus. The invention reduces the number of required 3D printed parts to create a moving object. This characteristic reduces the amount of onboard weight of the 3D printed components by reducing the number of parts required to create motion. The present invention removes the need for onboard sensors, processors, motors, power storage, etc. This characteristic will allow for manufacturing of, inter alia, novel medical devices, automated actuators, packaging, smart textiles, etc.

Owner:DREXEL UNIV

Method for preparing temperature driven programmable 4D printing intelligent material

InactiveCN108484940AImprove processing efficiencyEasy to prepareAdditive manufacturing apparatusAdditive manufacturing with liquidsTemperature responseSmart hydrogels

The invention discloses a method for preparing a temperature driven programmable 4D printing intelligent material. According to the method, on the basis of high efficiency of mold shaping, N-isopropylacrylamide type temperature intelligent hydrogel is adopted as a main body material, and a temperature driven 4D printing intelligent deformation material which has temperature response anisotropismin a spatial dimension is prepared through 'one-step method' in-situ free radical polymerization. In addition to high interface bonding strength, the temperature driven programmable 4D printing intelligent deformation material prepared by using the method has the characteristics of programmability, high response speeds, high mechanical strength, high deformation complexity and high practicability,in addition is low in production cost, convenient to process and manufacture and wide in application range, and is capable of providing a feasible and effective novel method for solving practical application problems of temperature driven programmable 4D printing intelligent deformation materials.

Owner:JILIN UNIV

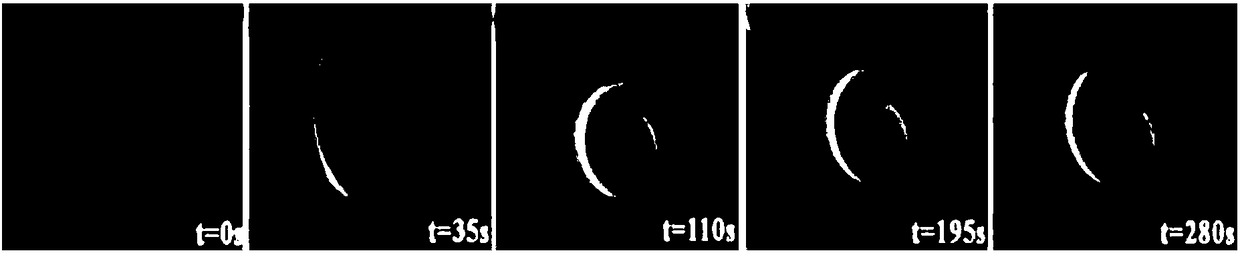

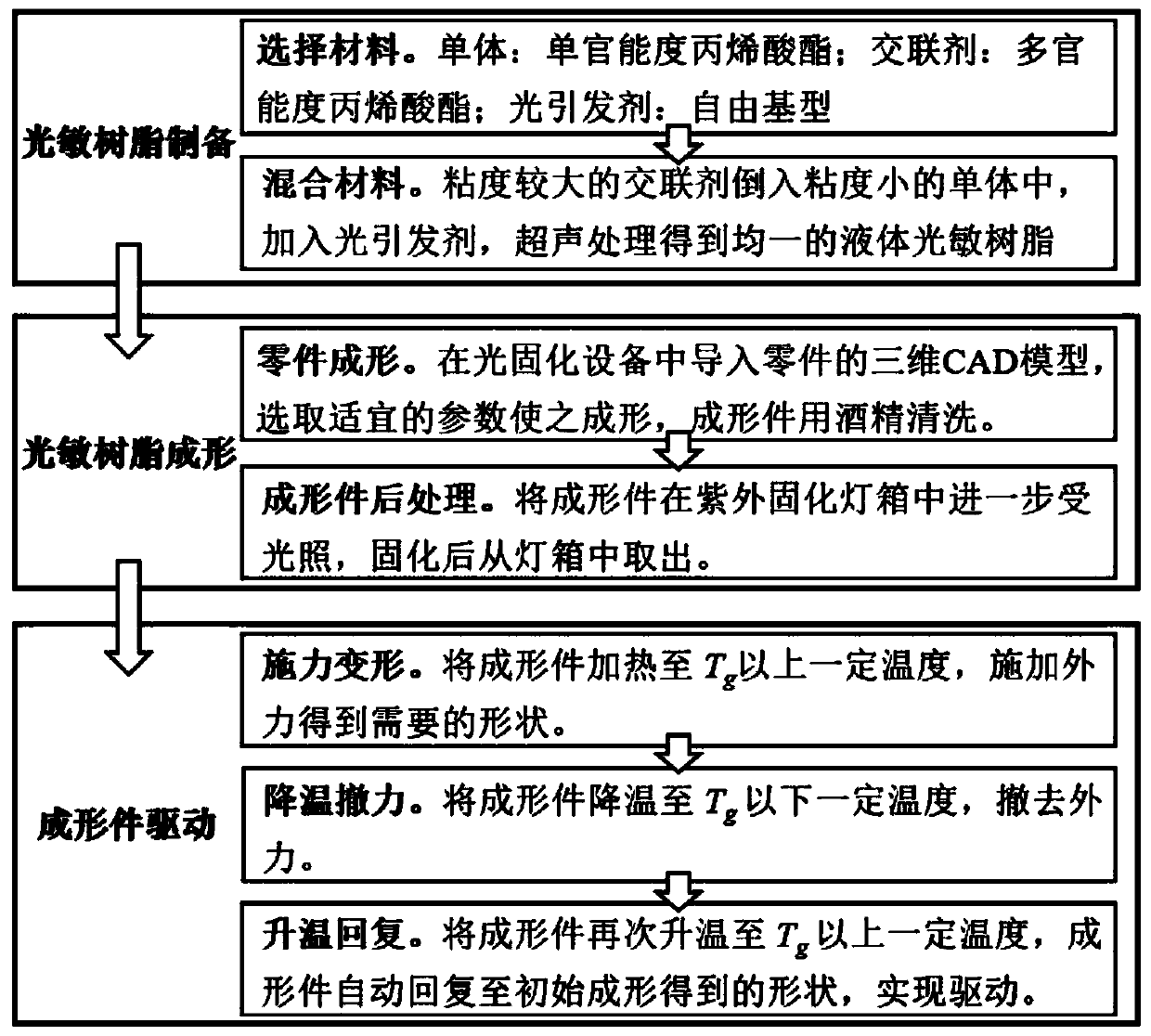

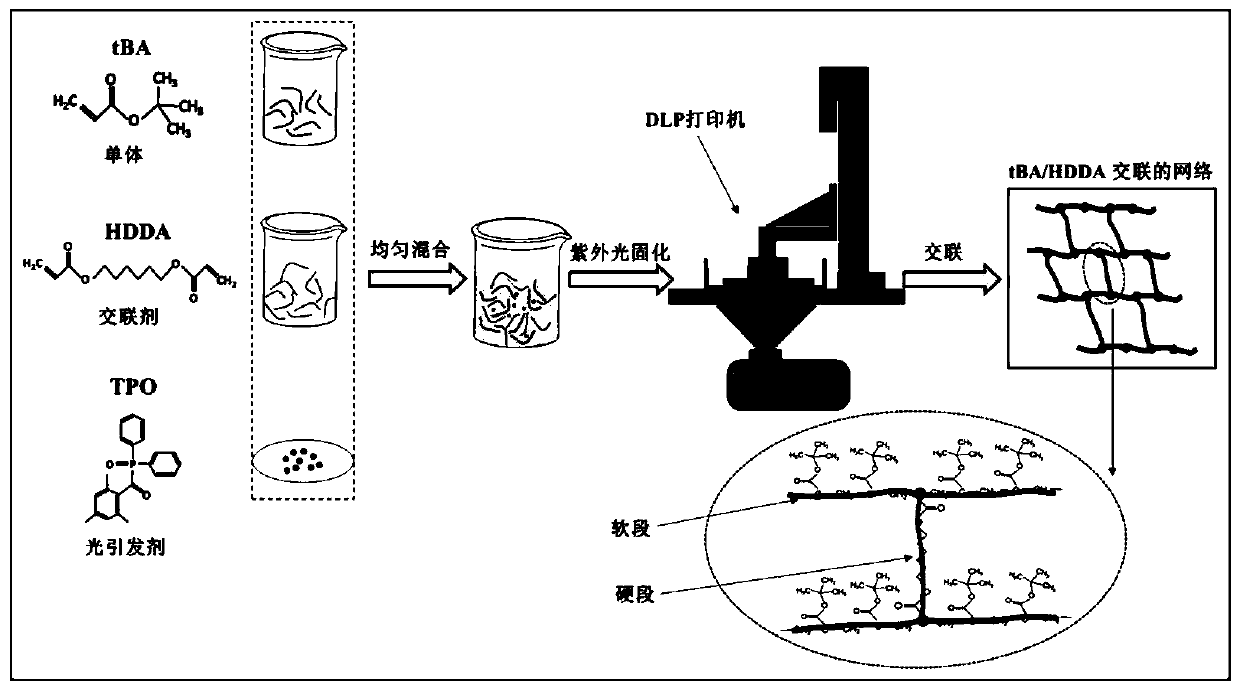

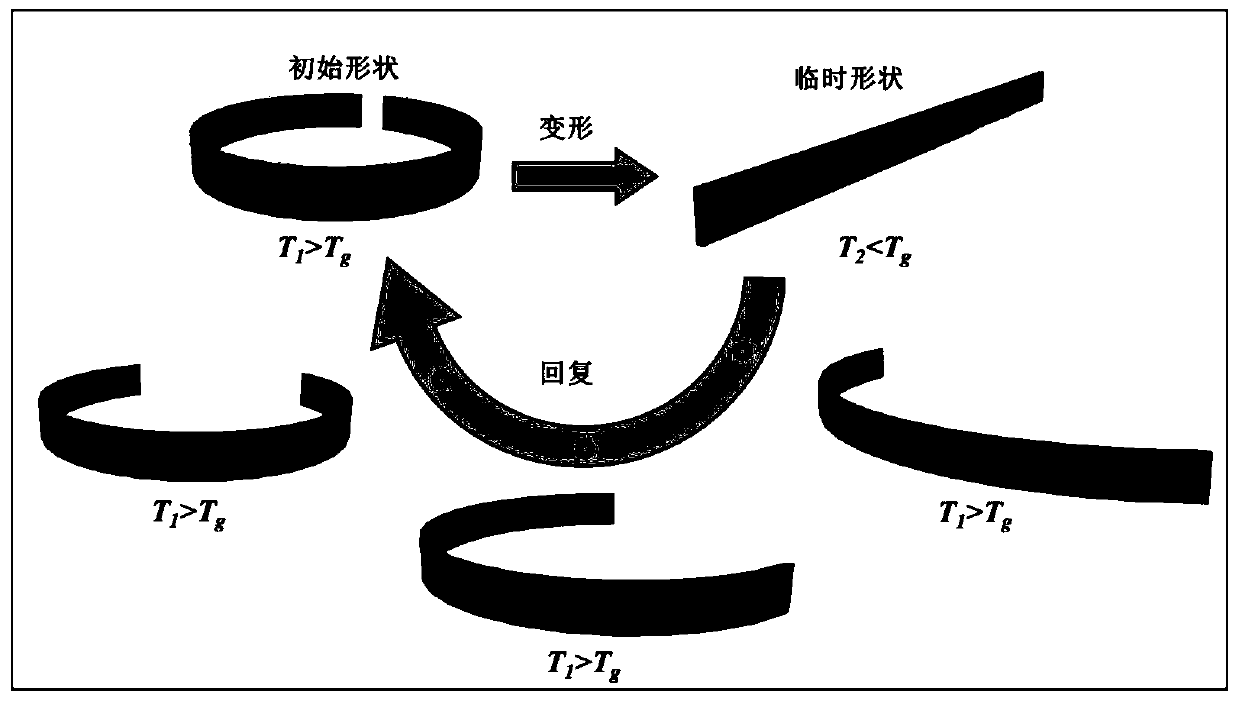

Preparation, formation and drive methods of photosensitive resin for 4D printing

ActiveCN110003380AImprove thermal performanceImprove mechanical propertiesAdditive manufacturing apparatus3D object support structures4d printingPhotoinitiator

The invention belongs to the field of polymer 4D printing and discloses preparation, formation and drive methods of photosensitive resin for 4D printing. The preparation method comprises steps as follows: S11, a polyfunctional acrylate cross-linking agent is added to single-functional acrylate monomers firstly, then a photoinitiator is added, and a mixture is obtained; S12, the mixture is subjected to ultrasonic treatment until a colorless and transparent liquid is formed, and the photosensitive resin for SLA (stereolighography apparatus) or DLP (Digital light processing) technological printing is obtained. The invention further provides the corresponding formation and drive methods of the photosensitive resin. With the adoption of a free radical type photosensitive resin system, the photocuring rate is increased, the photosensitive resin prepared by adoption of the acrylate system with single functionality and polyfunctionality is suitable for SLA or DLP technological formation, a formed part contains a hard segment and a soft segment in SMP (shape memory polymer) and shows good shape memory performance, and a formed thermosetting network has excellent heat performance and mechanical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

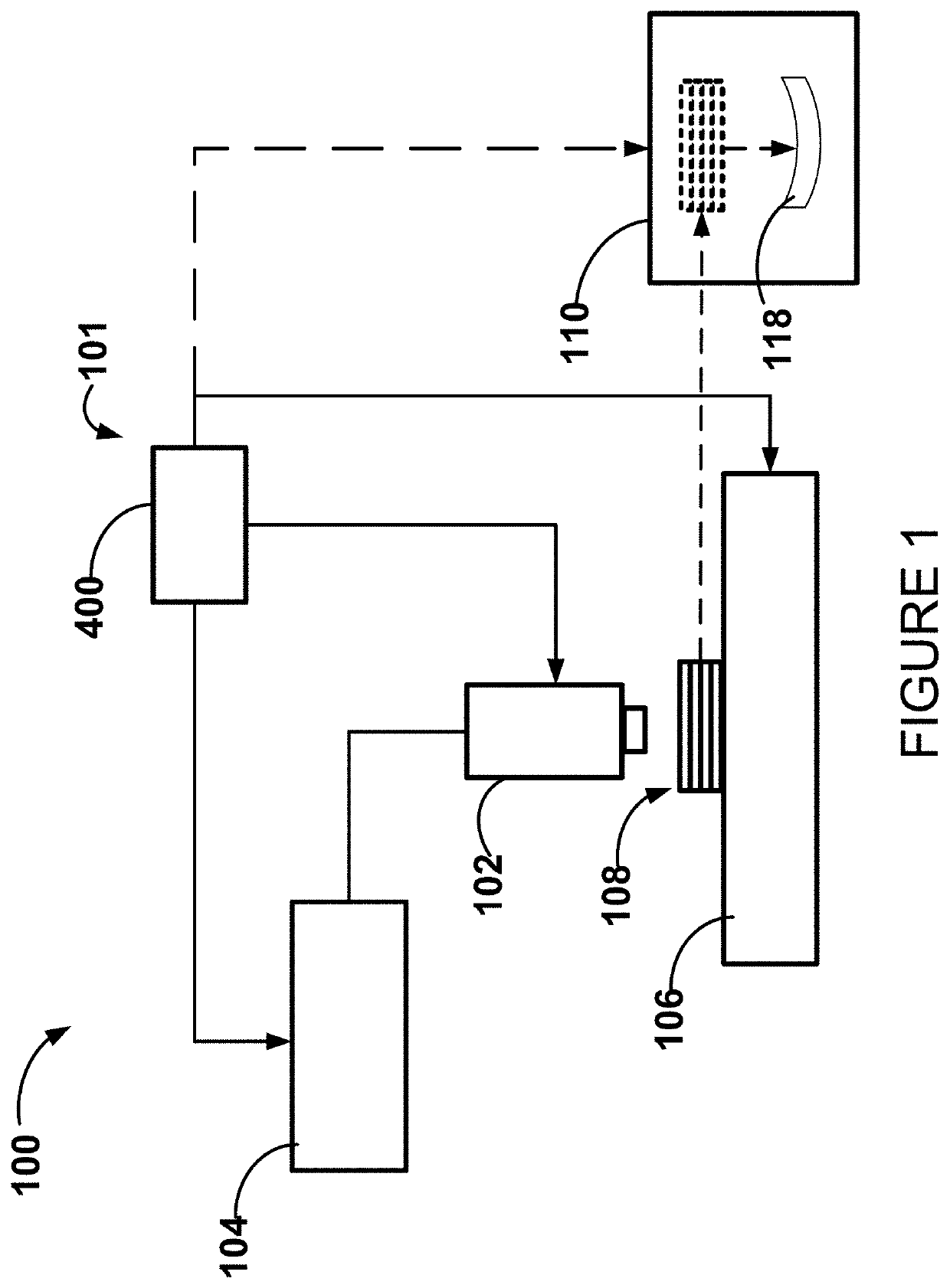

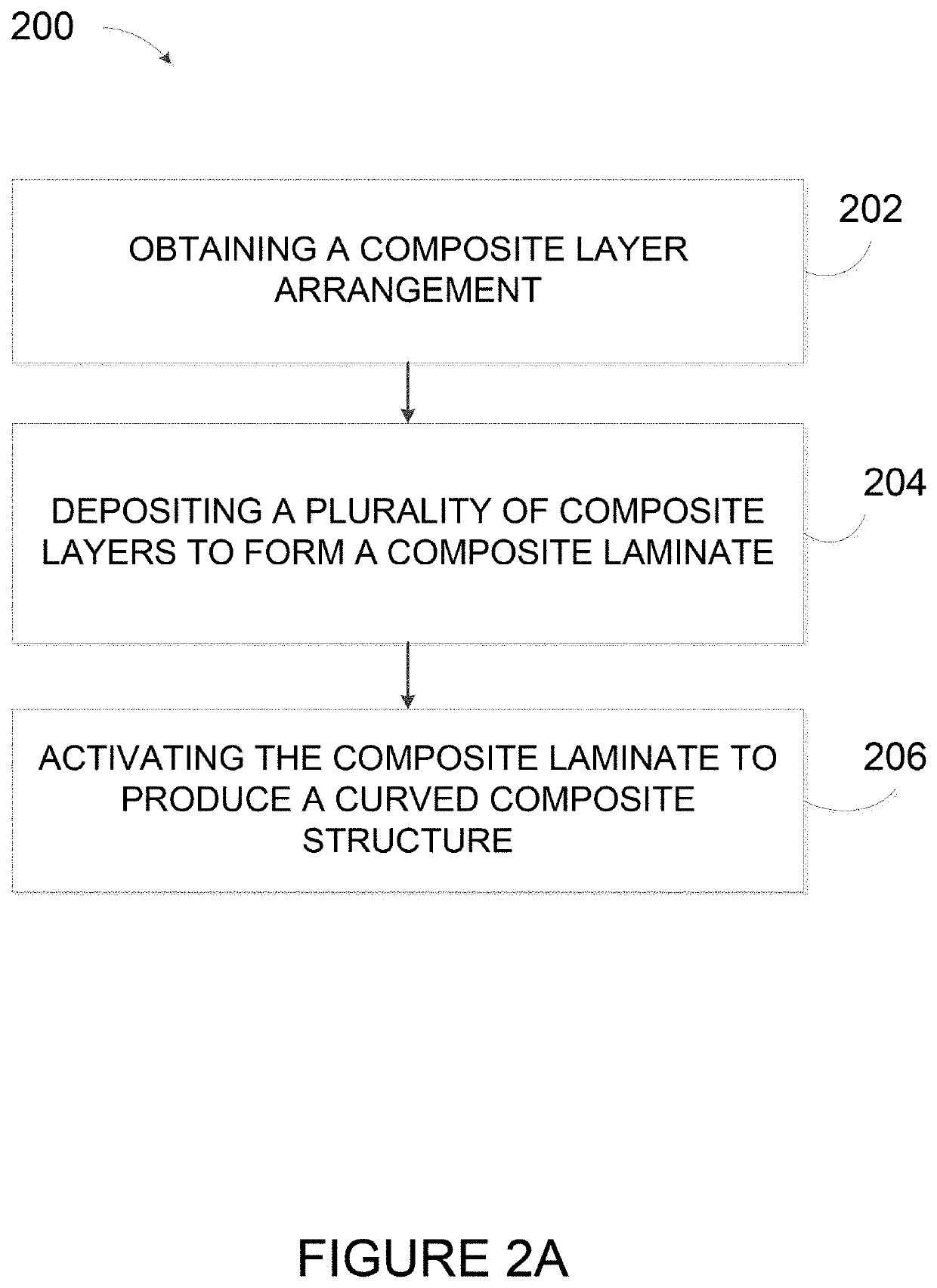

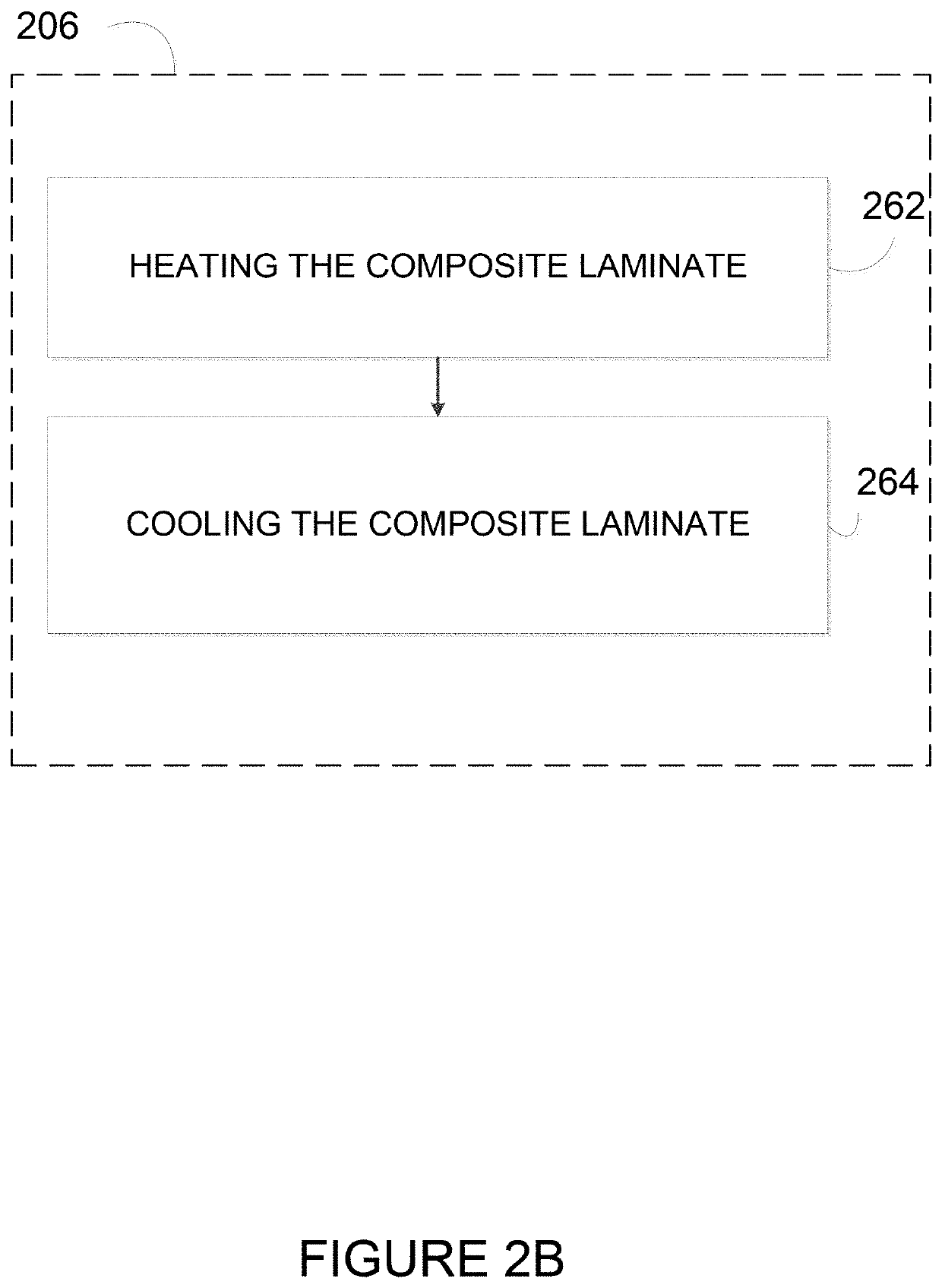

Method and system for 4d printing of composites

InactiveUS20200023569A1Additive manufacturing apparatus3D object support structuresComposite laminates4d printing

Systems and methods for 4D printing of composites are described herein. A composite layer arrangement is obtained for forming a composite laminate having a substantially flat profile. A plurality of composite layers are deposited according to the composite layer arrangement to form the composite laminate. The composite laminate is activated to produce a curved composite structure.

Owner:VALORBEC PARTNERSHIP

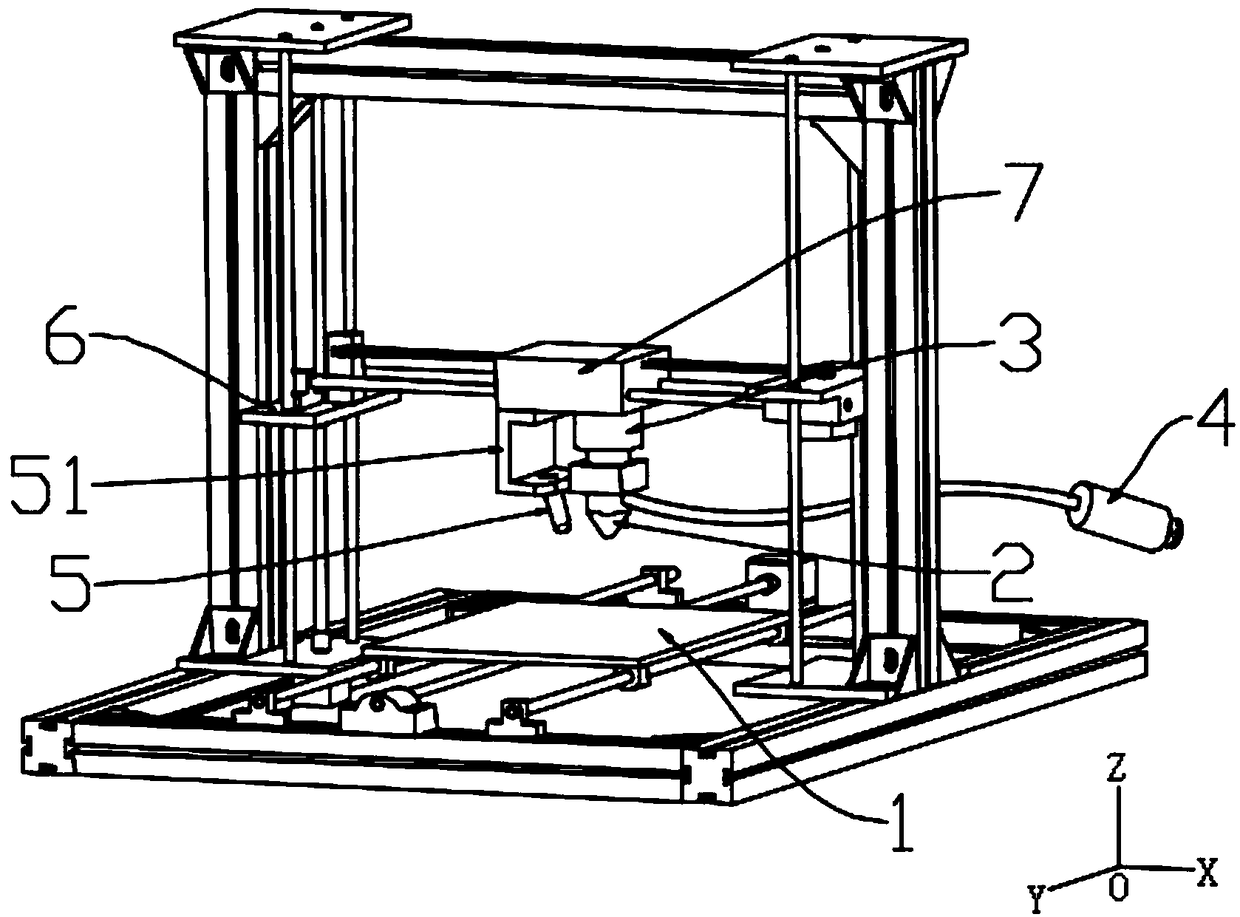

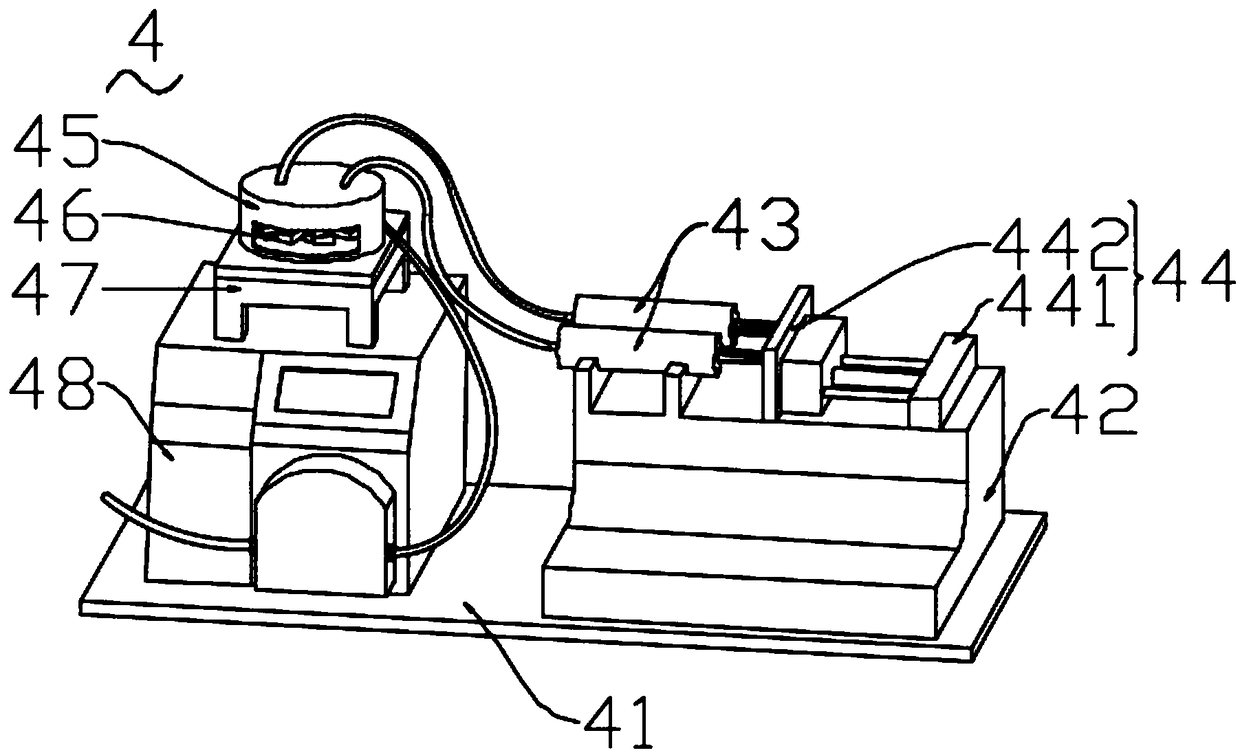

Device for on-track 4D printing of thermosetting shape memory polymers

ActiveCN109483869AOvercoming Unprintable ProblemsAvoid demandManufacturing driving means3D object support structures4d printingInjection pump

The invention discloses a device for on-track 4D printing of thermosetting shape memory polymers, and relates to the technical field of printing. The problem that an existing 4D printing device cannotwork on track is solved. The device for on-track 4D printing of the thermosetting shape memory polymers comprises a printing platform, a printing spray-head, a driving device, a feeding device, a curing device and a three-axis motion device, wherein the printing spray-head is adapted to spray thermosetting materials; the driving device is connected with the printing spray-head and drives the printing spray-head to spray the thermosetting materials, and the driving device is a piezoelectric vibration device; the feeding device comprises an injection pump and is connected with the printing spray-head through a feeding pipe; the curing device is fixedly connected with the printing spray-head, and the curing device heats the thermosetting materials sprayed on the printing platform by the printing spray-head in real time; and the three-axis motion device drives the printing spray-head, the curing device and the printing platform to move in the three-dimensional direction. The device for on-track 4D printing of the thermosetting shape memory polymers solves the problem that printing cannot be performed in weightlessness environment, improves the flexibility of a space station, and effectively reduces the dependence of the space station on ground supply.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com