Device for on-track 4D printing of thermosetting shape memory polymers

A memory polymer and thermosetting technology, applied in the field of printing, can solve the problems of difficult photosensitive resins, achieve the effect of eliminating material waste, improving flexibility and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

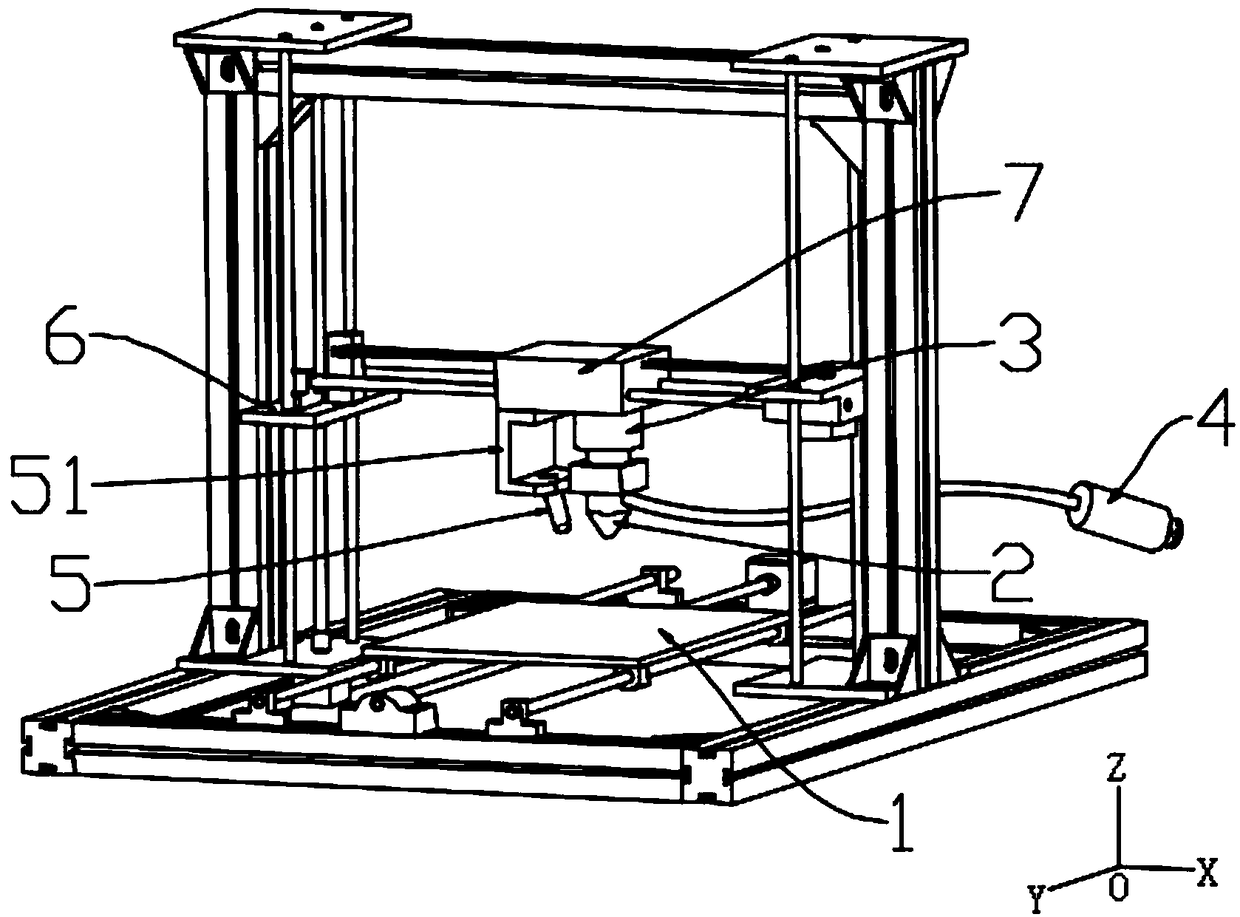

[0032] Such as figure 1 As shown, the present invention provides a device for on-orbit 4D printing of thermosetting shape memory polymers, which can solve the problem that conventional 4D printing devices cannot normally supply materials under the action of microgravity when the spacecraft is in orbit, and liquid thermosetting materials appear. For the problem of interruption or inability to transport during the printing process, the on-rail 4D printing device described in the present invention includes a printing platform 1 , a printing nozzle 2 , a driving device 3 , a feeding device 4 , a curing device 5 and a three-axis motion device 6 .

[0033] The printing platform 1 is a flat plate, which can be used as a forming platform for the thermosetting shape memory polymer ejected by the printing nozzle 2 .

[0034] The printing nozzle 2 is connected to the feeding device 4 through the feeding tube. The side of the printing nozzle 2 is provided with a threaded feeding port, and...

Embodiment 2

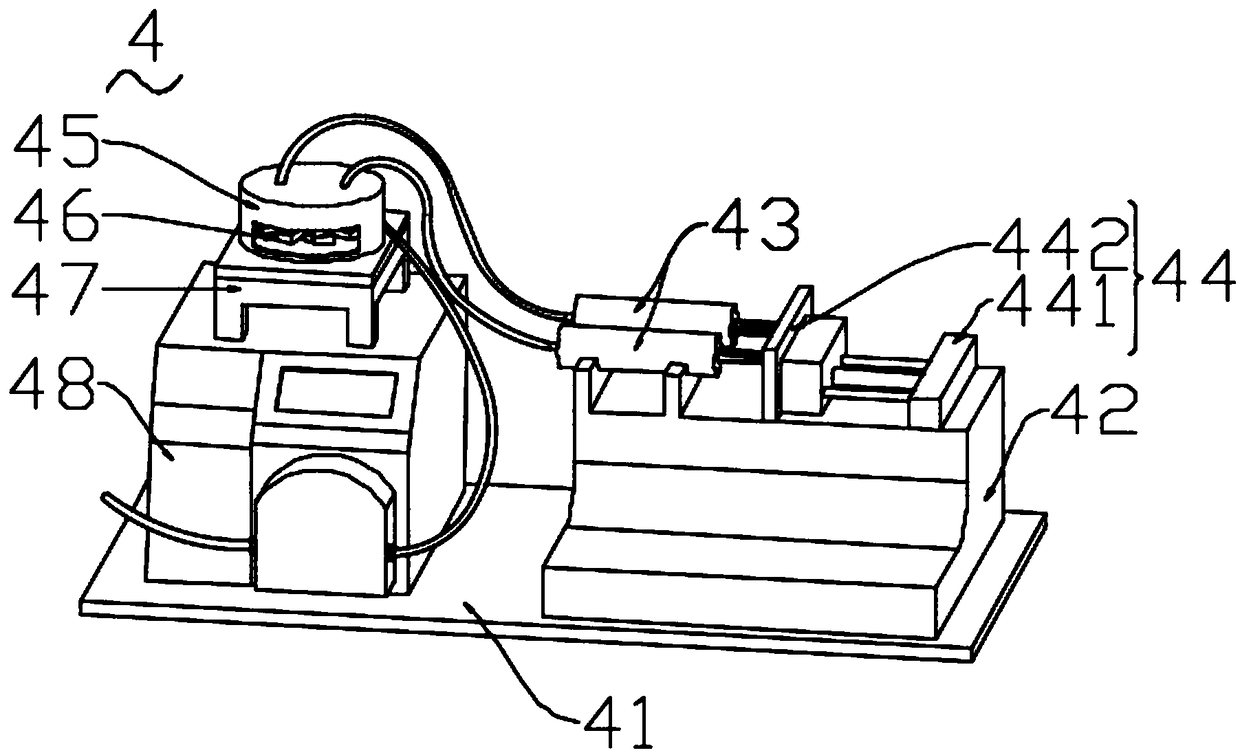

[0044] In order to prevent the printing materials from deteriorating or solidifying after being stored in space for a long time, this implementation is based on the above-mentioned embodiments, combined with figure 2 As shown, the feeding device 4 includes a fixed plate 41, an abutment 42, an injection pipe 43, a propulsion device 44, a mixing cabin 45, an agitator 46, a support frame 47 and a peristaltic pump 48, and the fixed plate 41 is a base plate. The plate 41 is fixedly connected with the bottom platform of the three-dimensional motion device 6, and a base 42 is fixed on one side of the fixed plate 41. The base 42 is provided with a propulsion device 44, and the propulsion device 44 includes a second rotating motor 441 and a push block 442. A screw is arranged between the second rotating motor 441 and the push block 442. The rotation of the second rotating motor 441 drives the screw to rotate, and the rotation of the screw drives the push block 442 to move along the axi...

Embodiment 3

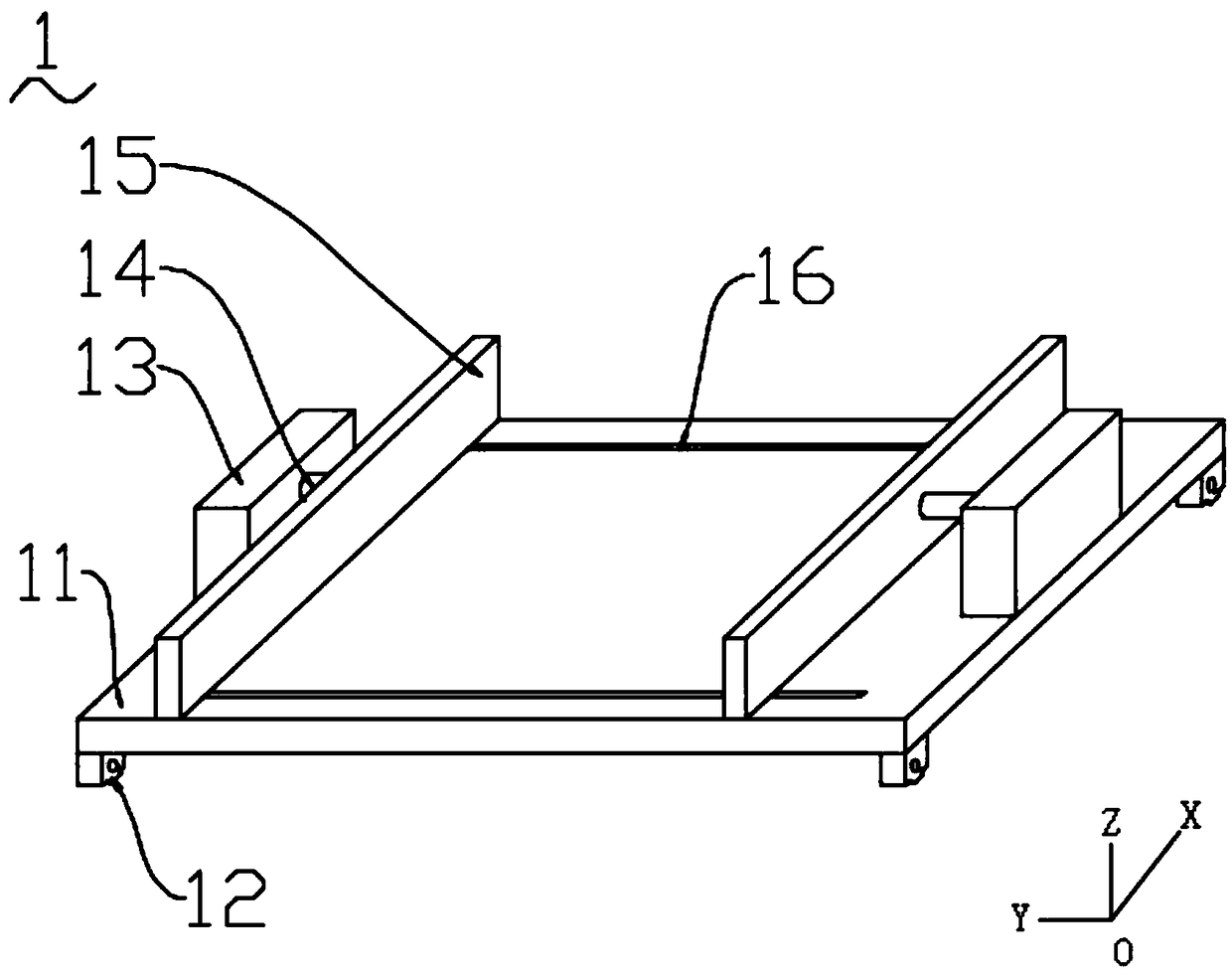

[0050] On the basis of the above-mentioned embodiments, this embodiment combines image 3 As shown, the printing platform 1 includes a support table 11, a slider 12, a first rotating motor 13, a push rod 14, a clamping plate 15 and a guide rail 16. The support table 11 is in the shape of a plate, which can be square, circular or other shapes. The slider 12 is arranged at the bottom of the support platform 11. Preferably, there are at least four sliders 12 and they are respectively located at the four feet at the bottom of the support platform 11. The slider 12 is set on the slide bar of the three-axis motion device 6. Realize the sliding connection between the printing platform 1 and the three-axis motion device 6; the support platform 11 is provided with two first rotating motors 13 at both ends of the Y-axis direction, and the support platform 11 is provided with two parallel guide rails on both sides of the X-axis direction 16. The direction of the length of the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com