4D-printed ceramic preparation method and 4D-printed space capsule and unfolding method thereof

A ceramic preparation and space capsule technology, which is applied in transportation and packaging, aerospace equipment, space navigation equipment, etc., can solve the problems of limited application range and field, heavy weight of rigid space capsule, and inability to adapt to the space environment. The effect of heavy, small size, and large launch space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

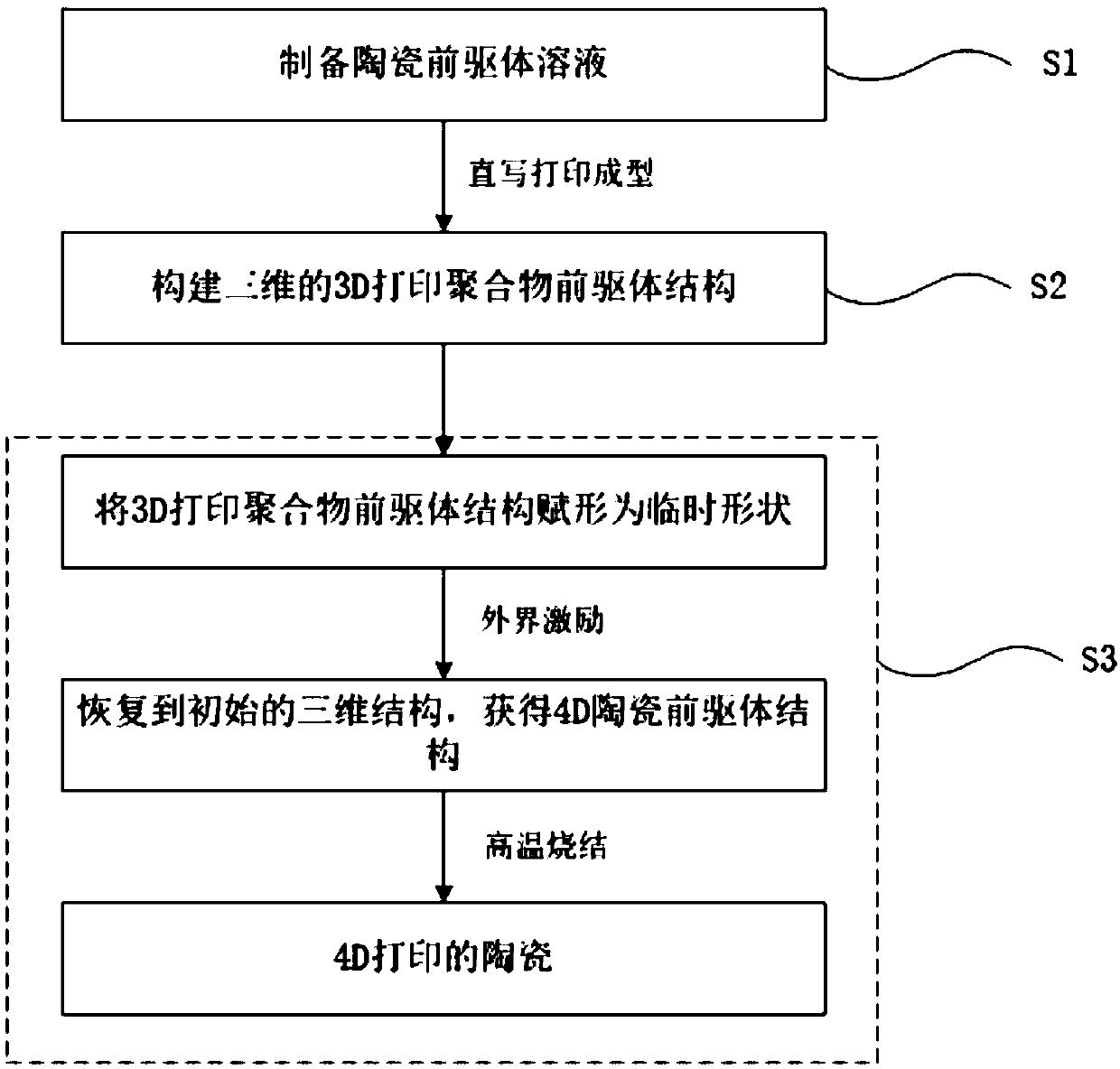

[0050] This embodiment provides a preparation method suitable for 4D printing ceramics, the specific steps are:

[0051] S1. Prepare a ceramic precursor solution for 3D printing, the matrix material of the ceramic precursor solution is a shape memory polymer or a mixture of a shape memory polymer and an elastomer;

[0052] S2. The ceramic precursor solution is formed by direct writing printing to construct a 3D printing polymer precursor structure, and the 3D printing polymer precursor structure is a three-dimensional structure with a shape memory effect;

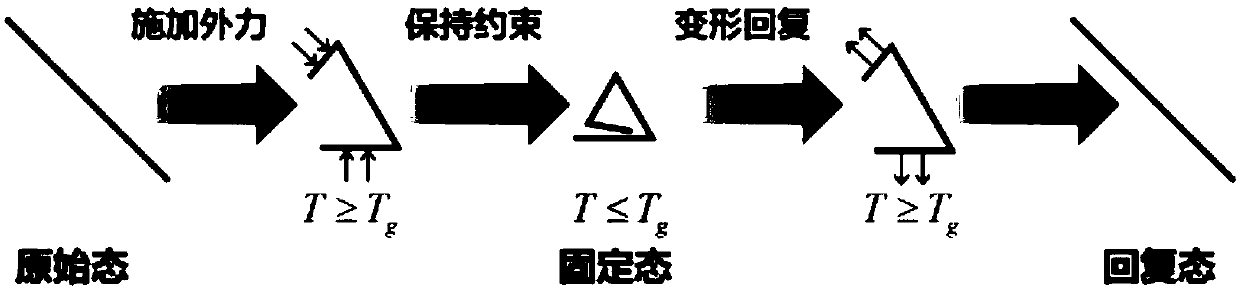

[0053] S3. Shape the 3D printed polymer precursor structure into a temporary shape. After being stimulated by the outside world, the 3D printed polymer precursor structure returns from the temporary shape to the original three-dimensional structure to obtain a 4D ceramic precursor structure with a shape The 3D printed polymer precursor structure of memory effect can still change shape after being manufactured, showing the c...

Embodiment 2

[0092] This example takes polyetherimide shape memory polymer as an example to illustrate the preparation process of a 4D printed ceramic:

[0093] 1. Dry polyetherimide in a vacuum oven at 50°C for 12 hours to remove water;

[0094] 2. Mix the dry polyetherimide and PDMS at a volume ratio of 7:1 and use it as a ceramic precursor matrix solution;

[0095] 3. Mix the ceramic precursor matrix solution and the silica reinforced particles according to the volume ratio of 7:3 with a three-roll machine to obtain the ceramic precursor solution; during the whole solution preparation process, seal the bottle cap with a sealing film Sealed to prevent volatilization or contamination of water-based solutions;

[0096] 4. Degas the ceramic precursor solution and seal it for use. At the same time, all steps are carried out in a dry environment to prevent moisture adsorption;

[0097] 5. The ceramic precursor solution is directly printed with ink to form a three-dimensional 3D printing pol...

Embodiment 3

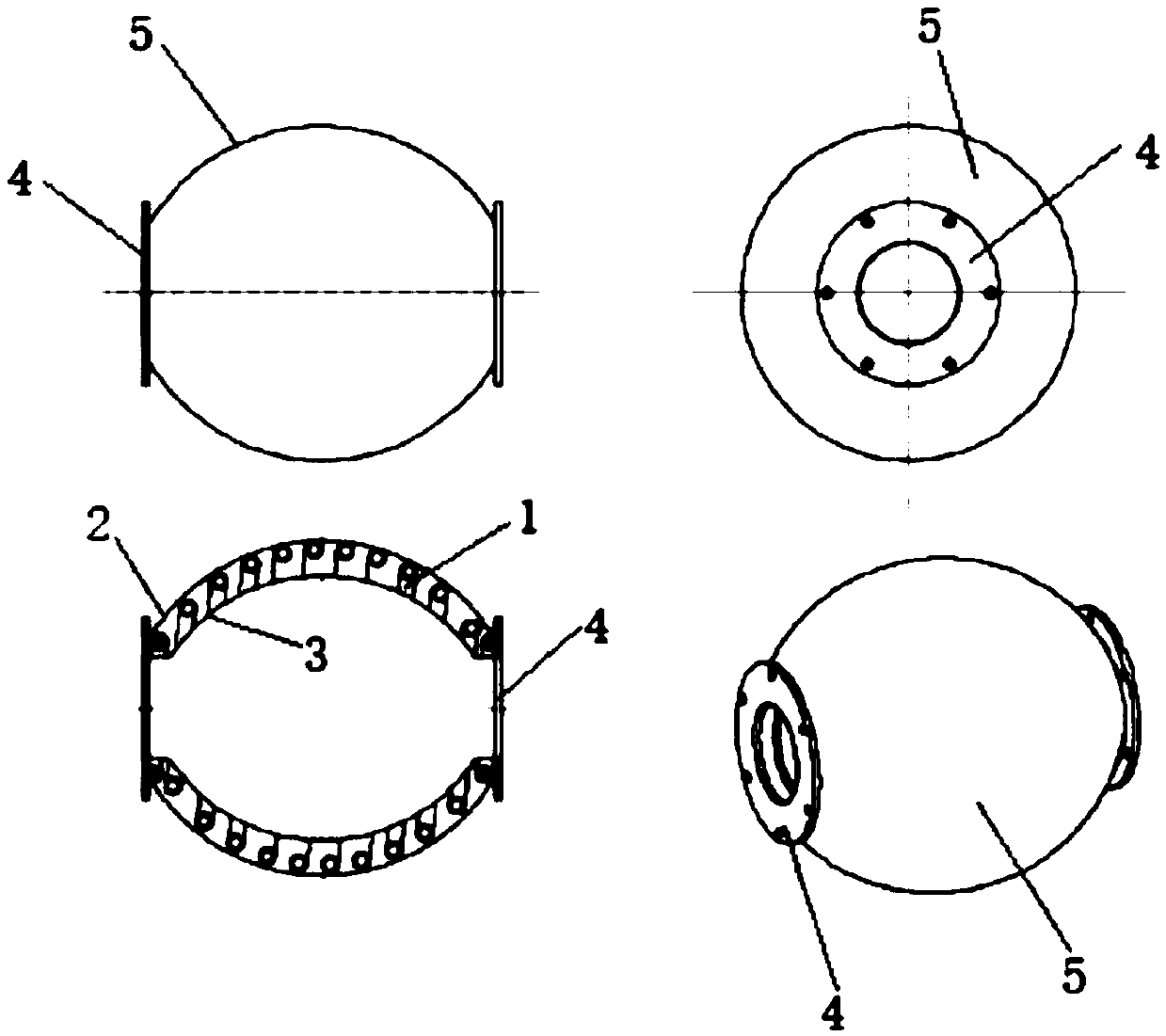

[0105] combine Figure 3-4 As shown, this embodiment provides a 4D printing space capsule, including a cabin body 5 and a docking port 4, the cabin body 5 is prepared by the above-mentioned 4D printing ceramic preparation method; the cabin body 5 is open at both ends Hollow cavity, the docking port 4 is fixedly connected with the open end of the cabin body, the cabin body 5 can be formed into a temporary shape at the material transition temperature, and return to the original shape after being stimulated by the outside. That is, before the launch of the space capsule, the body of the capsule is a 3D printed polymer precursor structure in a temporary shape prepared by a 4D printing ceramic preparation method. After the space capsule is transported to a predetermined space position, the 3D printed polymer precursor can be The structure is heated back to the initial unfolded state to become a 4D ceramic precursor; then continue to increase to the sintering temperature to sinter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com