4D printing method of intelligent structure with large deformation function and product obtained through 4D printing method

An intelligent structure and large deformation technology, applied in the field of additive manufacturing, can solve problems such as difficult to meet mechanical properties and fatigue properties, products cannot respond in time, and limited application range, etc., to achieve light weight, simplify product design, and expand application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

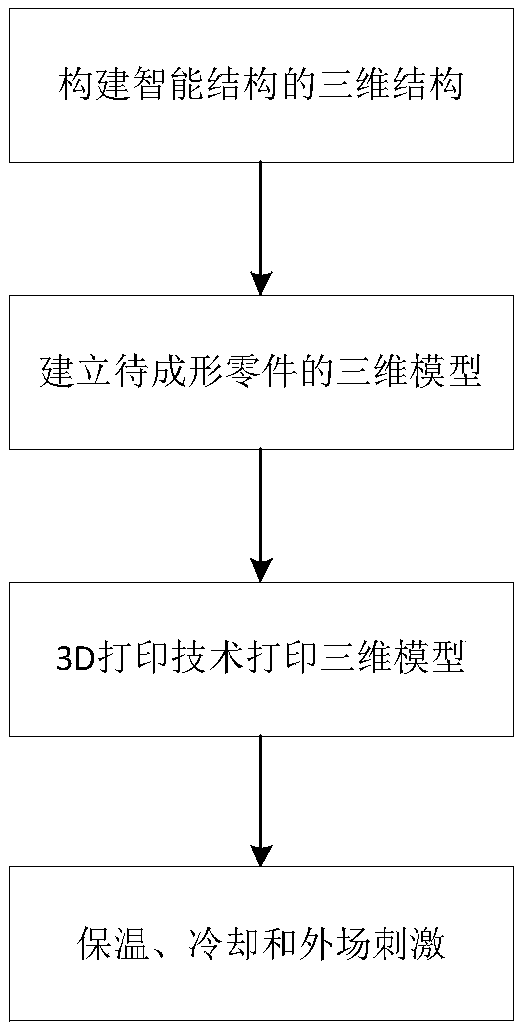

[0052] see figure 1 , this embodiment provides a 4D printing preparation method of a Cu-Al-Ni-based shape memory alloy intelligent deformation structure, the method comprising the following steps:

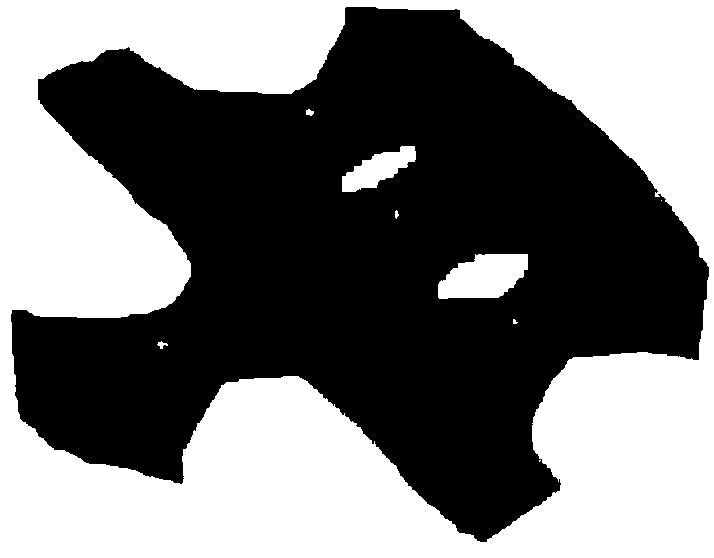

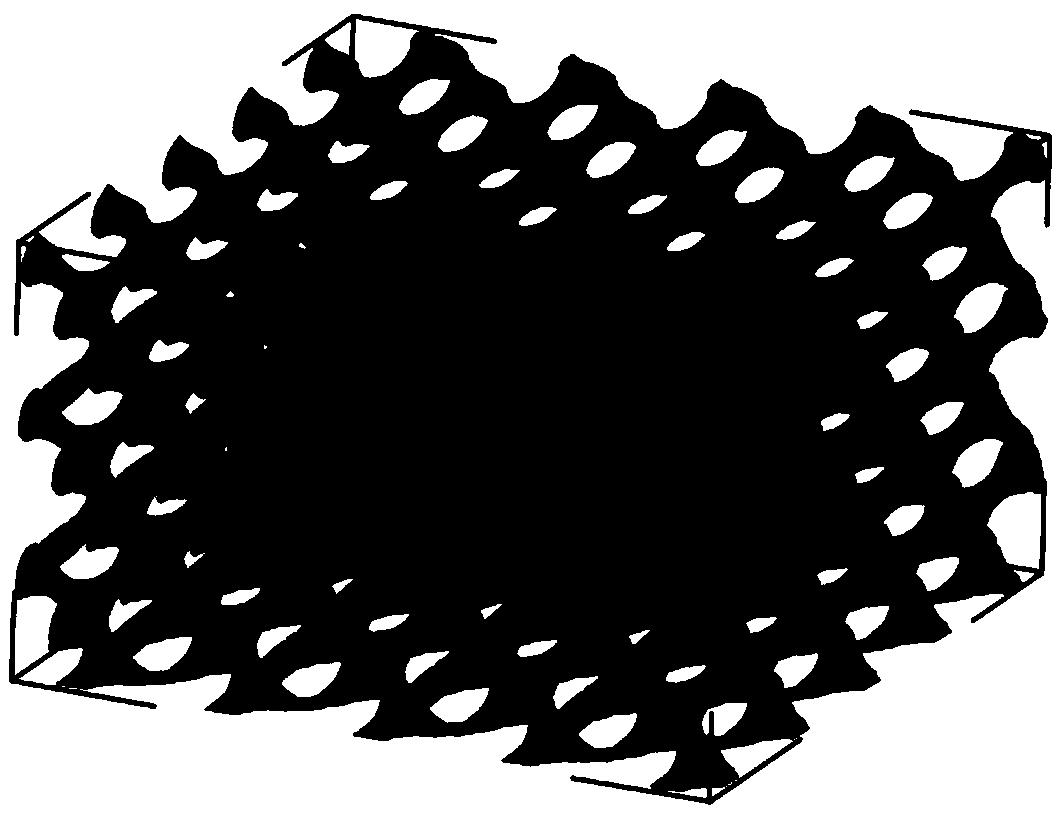

[0053] 1) First, design the initial configuration of the intelligent structure with large deformation function, and establish its computer three-dimensional model. Cu-Al-Ni series shape memory alloy is used as the material of the deformation matrix. Its structure is a gradient porous lattice structure with a porosity of 85%. Among them, the volume fraction of the unit topology in the proximal layer is 5%, and the units in the distal layer The volume fraction of the topology is 15%, the mesh type of the porous structure is rhombus, the diameter and wall thickness of the designed intelligent deformation structure unit cell, and the mesh type of the porous structure is rhombus;

[0054] 2) Using laser selective melting additive manufacturing technology as a shape memory alloy forming...

Embodiment 2

[0058] see figure 1 , this embodiment provides a 4D printing preparation method of a Cu-Zn-Al-based shape memory alloy intelligent deformation structure, the method comprising the following steps:

[0059] 1) First, design the initial configuration of the intelligent structure with large deformation function, and establish its computer three-dimensional model. Cu-Zn-Al series shape memory alloy is used as the material of the deformation matrix. Its structure is a gradient porous lattice structure with a porosity of 75%. Among them, the volume fraction of the unit topology in the proximal layer is 7.5%, and the unit topology in the distal layer is 7.5%. The volume fraction of the topology is 25%, the grid type of the porous structure is rhombus, the diameter and wall thickness of the designed intelligent deformation structure unit cell, and the grid type of the porous structure is rhombus;

[0060] 2) Using laser selective melting additive manufacturing technology as a shape m...

Embodiment 3

[0064] This embodiment provides a 4D printing preparation method of a Ni-Ti-based shape memory alloy intelligent deformation structure, the method comprising the following steps:

[0065] 1) First, design the initial configuration of the deformable structure with large deformation function, and establish its computer three-dimensional model. The shape memory alloy of Ni-Ti series is used as the material of the deformation matrix. Its structure is a gradient porous lattice structure with a porosity of 80%. Among them, the volume fraction of the unit topology in the proximal layer is 10%, and the unit topology in the distal layer is The volume fraction is 20%, the grid type of the porous structure is rhombus, the diameter and wall thickness of the designed intelligent deformation structure unit cell, the grid type of the porous structure is rhombus;

[0066] 2) Using laser selective melting additive manufacturing technology as a shape memory alloy forming method to print intelli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com