Four-dimensional printing method capable of programming curvature changes

A curvature change and 4D technology, applied in the field of additive manufacturing, can solve problems such as poor programming ability and poor repeatability of material deformation, and achieve the effects of low cost, easy-to-obtain materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

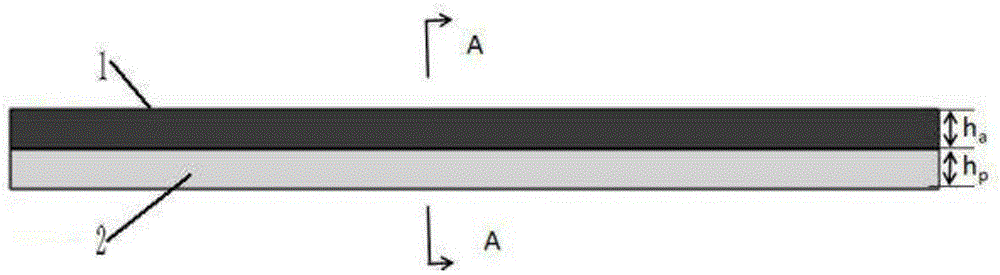

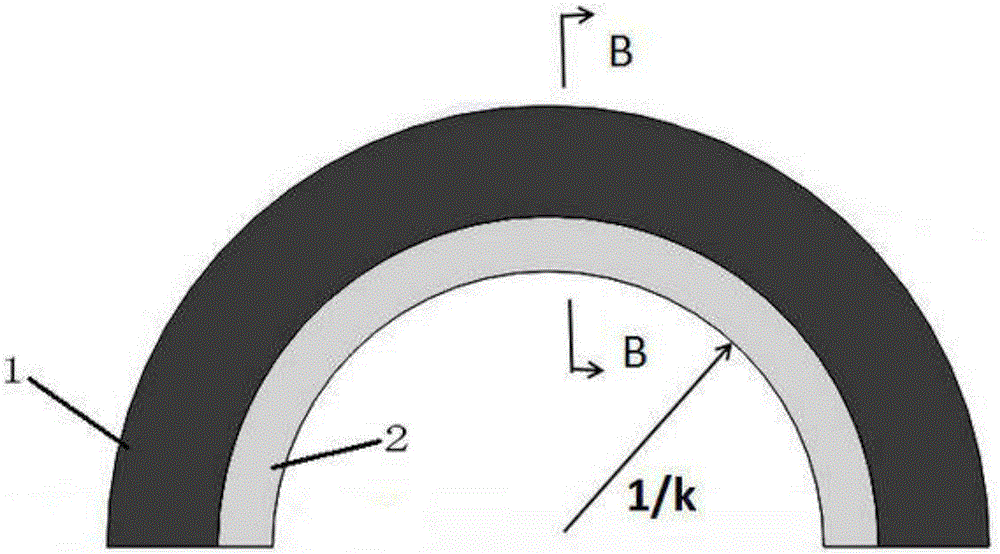

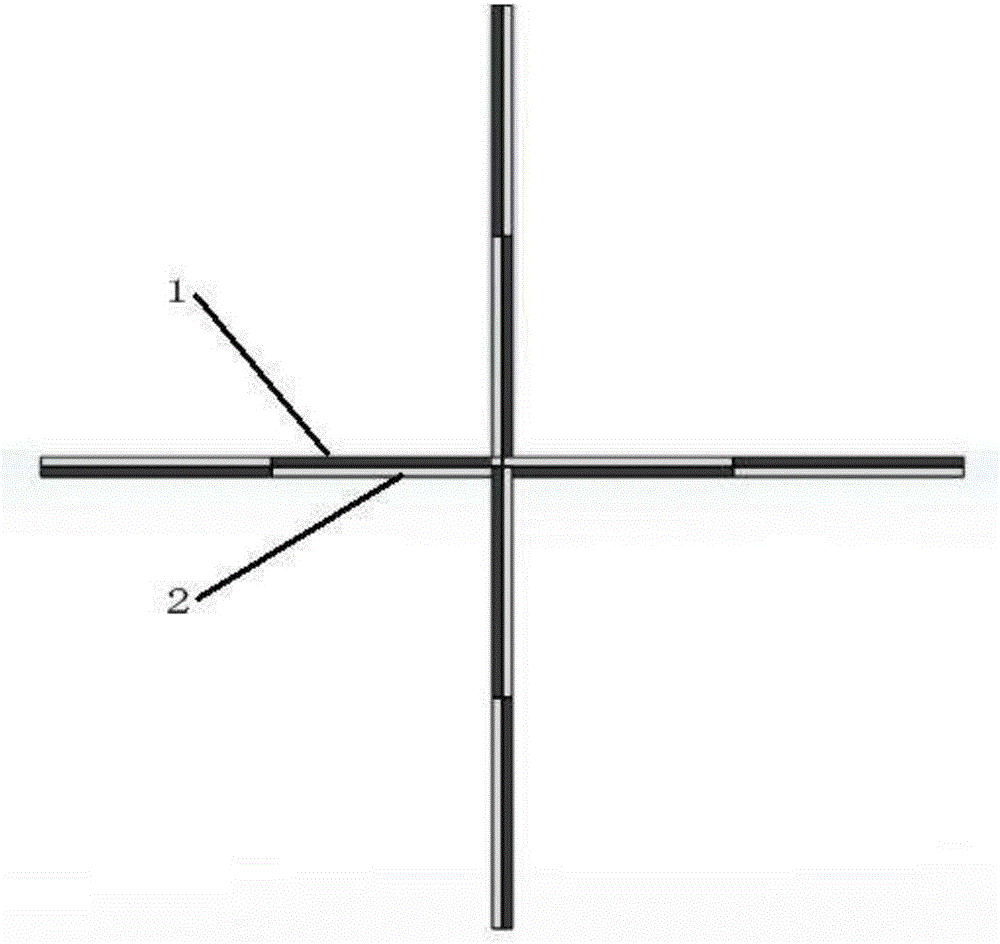

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a 4D printing method with programmable curvature changes includes the following steps:

[0034] 1. Selection of active layer material 1 and passive layer material 2:

[0035] Selection of active layer material 1: Select one-component, high-strength, high-modulus polyurethane water-swellable rubber cured by room temperature moisture;

[0036] Selection of passive layer material 2: Select polyurethane moisture-cured rubber that does not expand when exposed to water;

[0037] 2. Model establishment: Design the initial state according to the expected deformation shape, including the geometric shape and the distribution state of the active layer material 1 and the passive layer material 2 respectively. The width of the model deformation unit is 10mm, and the height of the active layer material 1 is 3mm. Passive layer material 2 has a height of 3 mm and a lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com