High-speed high-resolution selective transfer printing method

A high-resolution, transfer printing technology, applied in the direction of printing, copying/marking methods, etc., can solve the problem of difficult debonding of components, and achieve the effect of low cost, high speed and large throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

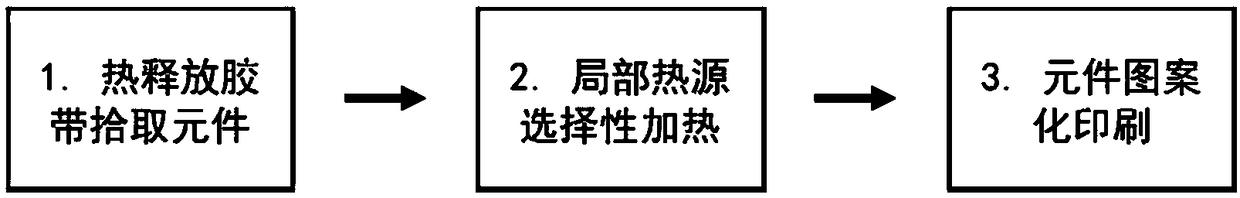

[0039] figure 1is the flowchart of the programmable transfer proposed in the present invention. First contact the component on the donor substrate with a thermal release tape, and after applying uniform pressure, the component is picked up from the donor substrate by relying on the strong adhesion of the thermal release tape to the component; then use a high-resolution local heat source to selectively heat the adhered component The thermal release tape, heating part of the tape loses its viscosity; finally, the components are printed on the receptor substrate, and the components are selectively printed from the thermal release tape to the receptor substrate.

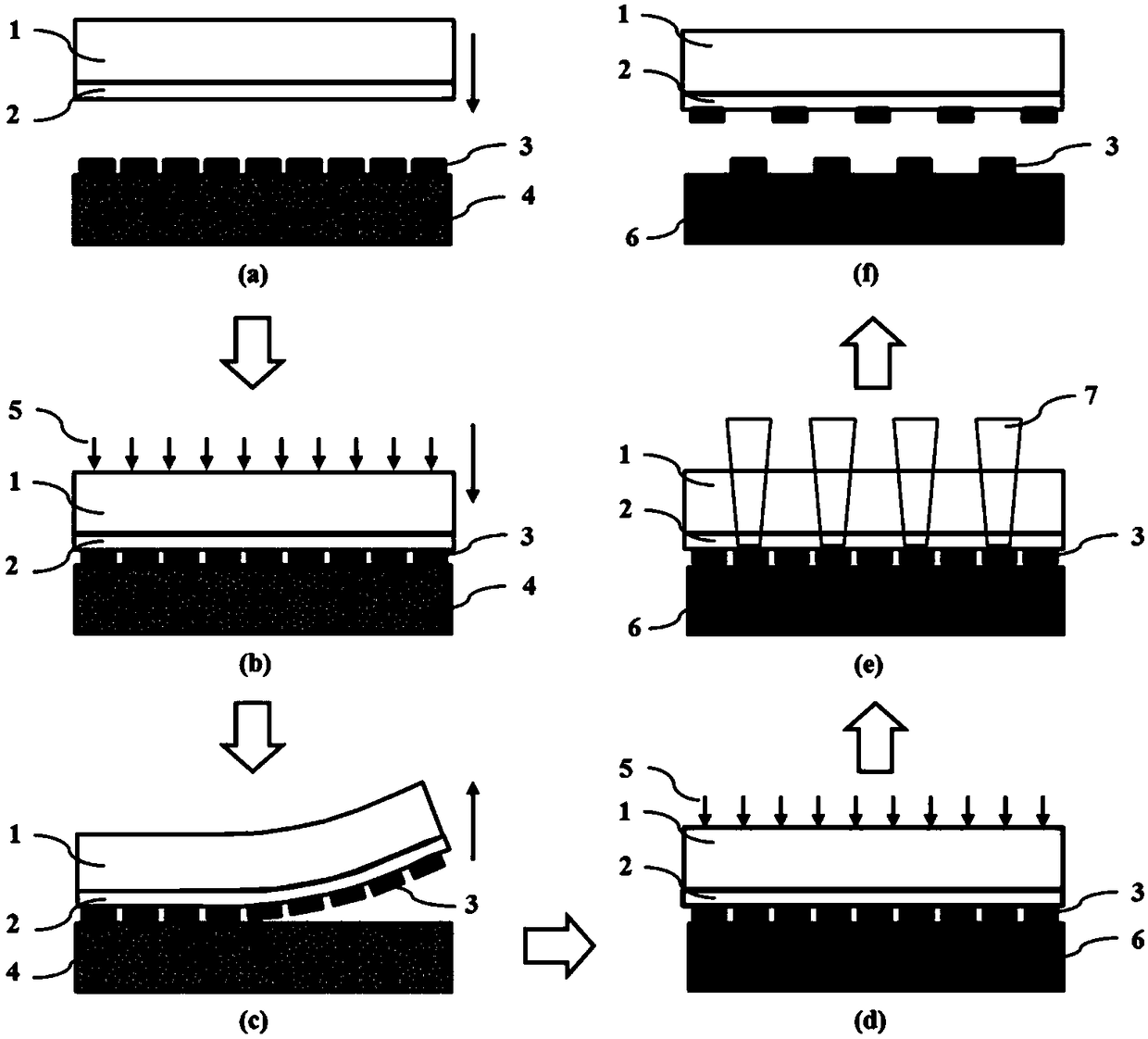

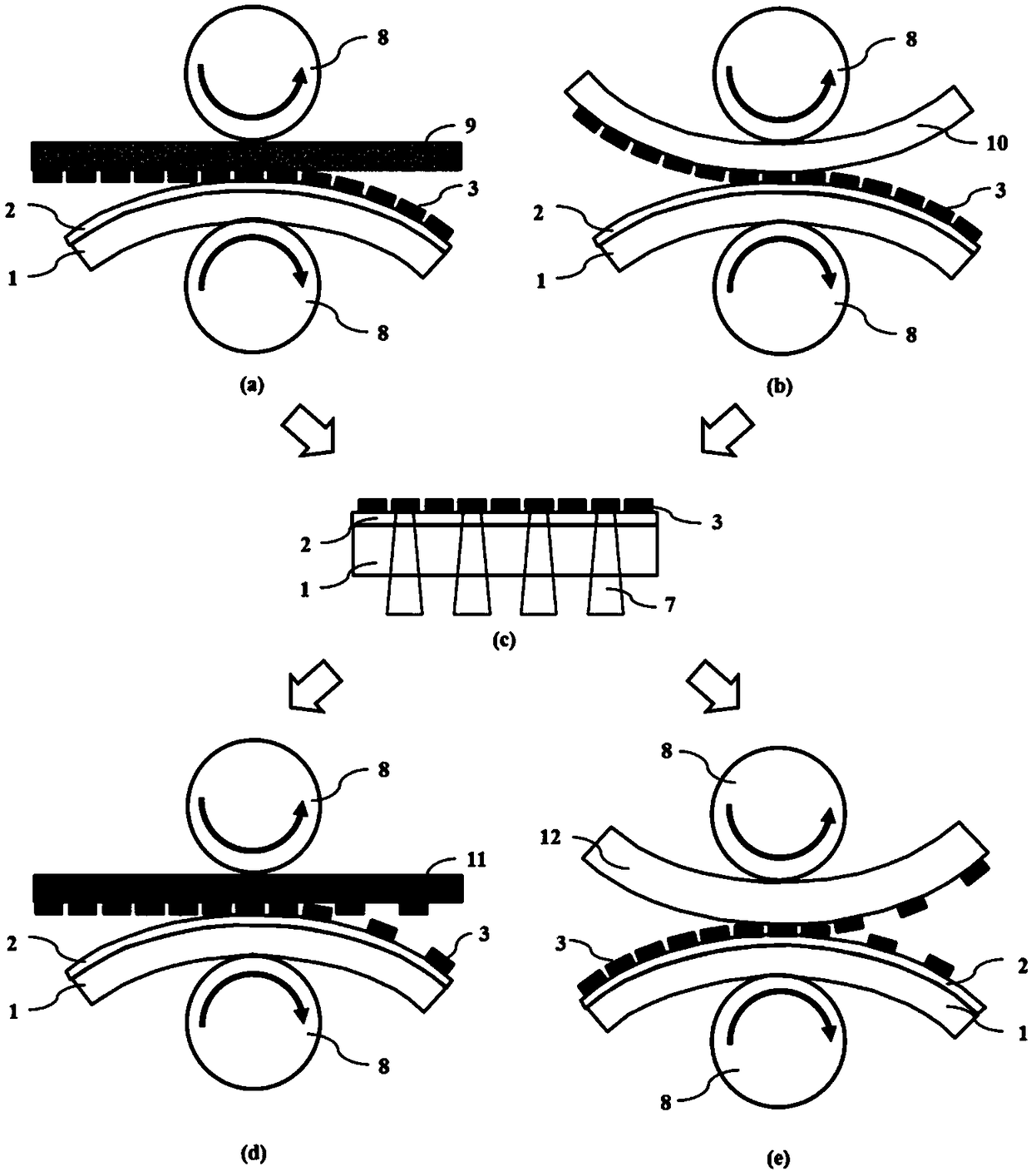

[0040] As an example, but not to limit the scope of the invention, figure 2 is a schematic diagram of the batch programmatic transfer proposed in the present invention. Stamp tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com