4D printing method of nickel-titanium-based ternary shape memory alloy

A memory alloy and ternary alloy technology, which is applied in the additive manufacturing of NiTiZr ternary shape memory alloy and the field of 4D printing of nickel-titanium-based ternary shape memory alloy, can solve the problem of difficult to meet the manufacturing requirements of 4D printing components, single shape, Problems such as low forming accuracy, to avoid uneven composition of components, increase stability, and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

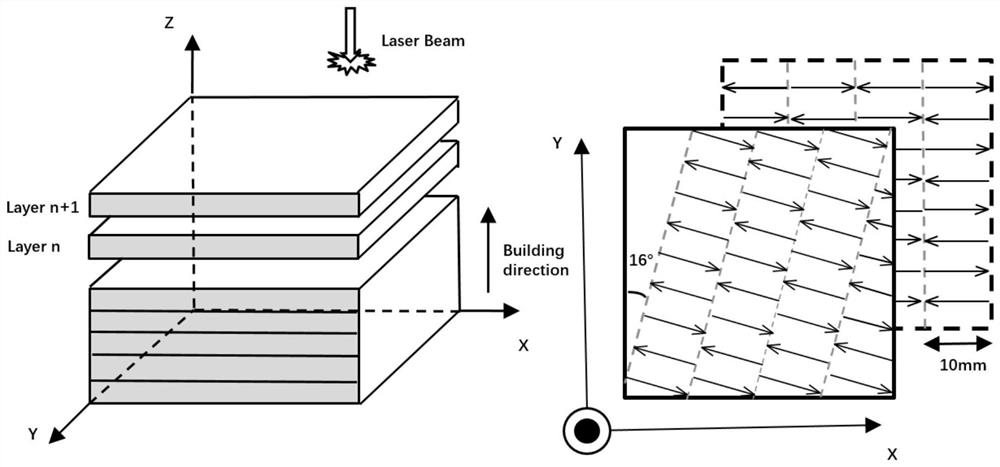

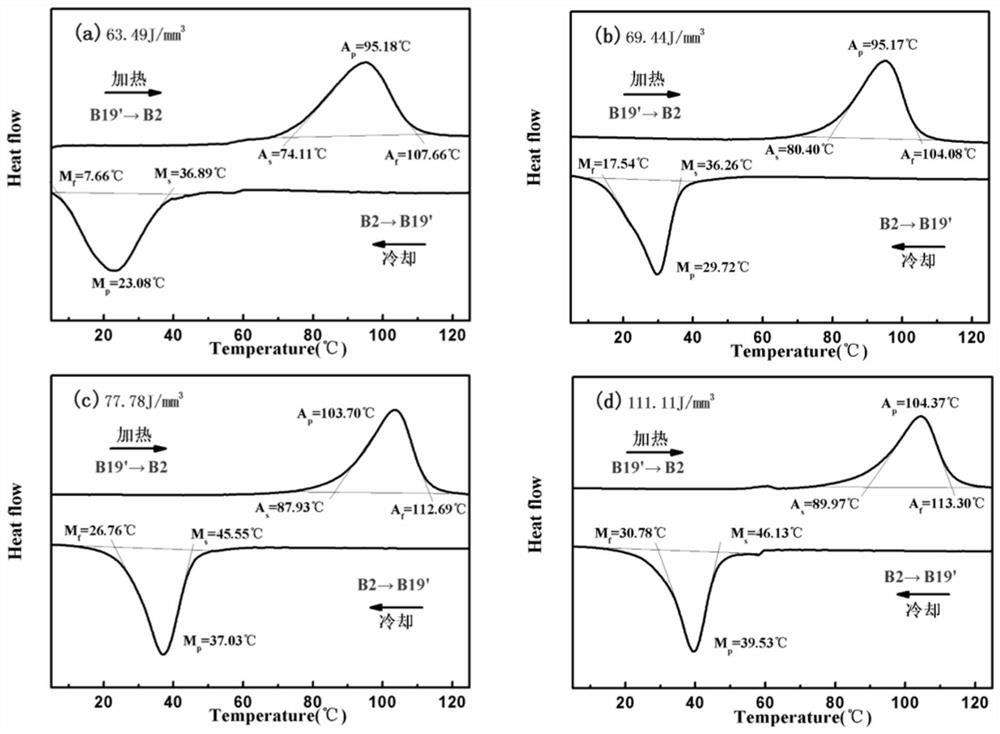

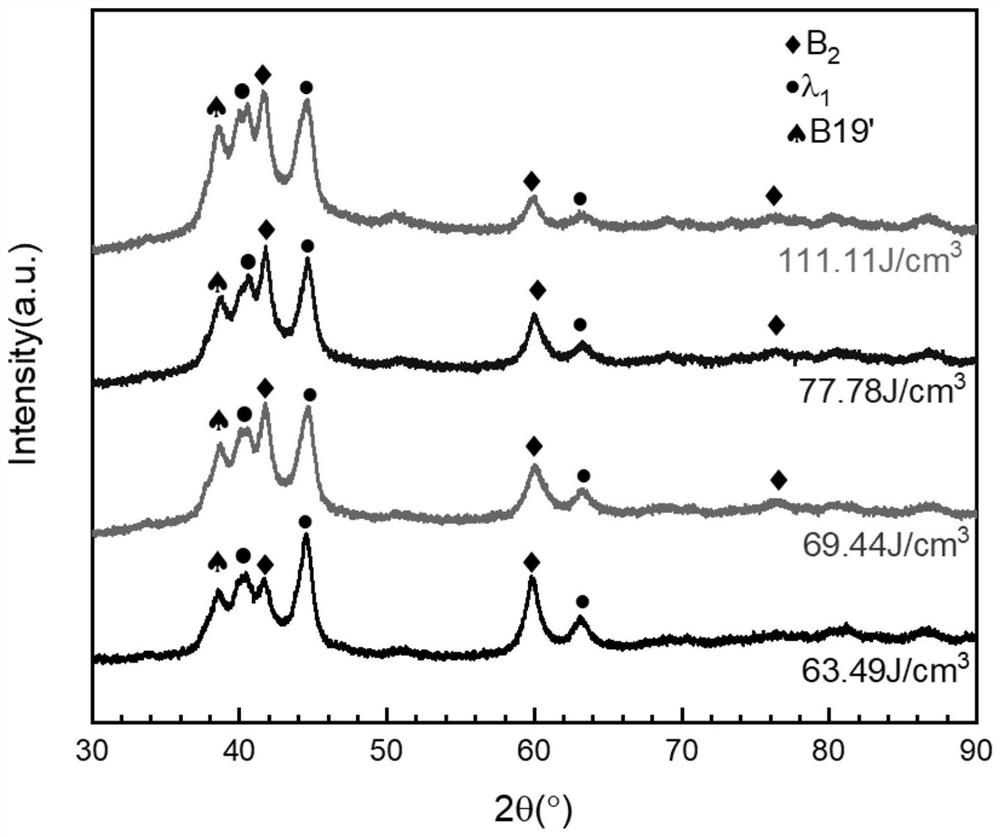

[0037] Laser selective melting manufacturing process parameters are as follows: laser power 160W, scanning speed 700mm / s. The scanning distance and the powder layer thickness are the same as those in other embodiments, being 0.12mm and 0.03mm respectively. The final calculated energy density is 63.94J / mm 3 .

Embodiment 2

[0039] The manufacturing process parameters of selective laser melting are as follows: laser power 250W, scanning speed 1000mm / s. The scanning distance and the powder layer thickness are the same as those in other embodiments, being 0.12mm and 0.03mm respectively. The final calculated energy density is 69.44J / mm 3 .

Embodiment 3

[0041] Laser selective melting manufacturing process parameters are as follows: laser power 280W, scanning speed 1000mm / s. The scanning distance and the powder layer thickness are the same as those in other embodiments, being 0.12mm and 0.03mm respectively. The final calculated energy density is 77.78J / mm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com