sticky shellac for tree trunk

A kind of sticky shellac, tree trunk technology, applied in the directions of epoxy resin glue, shellac adhesive, natural resin adhesive, etc., can solve the problems of poor stretch resistance and environmental protection of sticky shellac, and improve energy dispersion. effect, improve the ability to absorb CO2, good effect of anti-stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

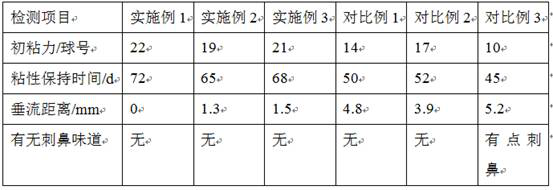

Examples

preparation example Construction

[0030] The preparation method of compound sticky shellac base-material comprises the steps:

[0031] (1) At 25~35℃, mix polyethylene glycol, dichloroethane and triethylamine according to the mass ratio of 1:6~10:13, stir magnetically at 350~600r / min for 30~55min, then move to Ice-water bath, add reagent A with 12-20 times the mass of polyethylene glycol to mix, shake at 250-300r / min for 25-50min, remove from the ice-water bath, let stand at room temperature for 20-24h, filter, take the filtrate according to the mass ratio of 7-12 : 5 Add ether at 2~5°C and mix, let it stand for 15~30min, filter with suction, take the filter residue and dry it in an oven at 60~80°C for 4~8h to obtain a dried product;

[0032] (2) According to the mass ratio of 3:1~2:15~25:5, take 2-vinyl-4,6-diamino-1,3,5-triazine, N,N-dimethylacrylamide, di Methyl sulfoxide and dry matter are mixed in a reaction kettle, magnetically stirred at 500~800r / min for 30~60min, and TiO with 8~15% dry matter is added ...

Embodiment 1

[0041] Reagent A: Mix acryloyl chloride, dichloromethane and water at a mass ratio of 1:3:15 to obtain Reagent A.

[0042] Reagent B: Mix NaOH solution with a mass fraction of 20% and sodium carbonate solution with a concentration of 0.1mol / L at a mass ratio of 1:10 to obtain Reagent B.

[0043] Self-made auxiliaries: at 35°C, take 60 parts of (N-amidino) dodecyl acrylamide, 30 parts of polyethylene glycol phosphate, and 4 parts of p-dichlorobenzene in CO 2 Mix under atmosphere, and stir with 400r / min magnetic force for 40min to obtain the self-made adjuvant.

[0044] Rubber material: mix peach gum, shellac and donkey-hide gelatin according to the mass ratio of 5:1:1 to get the rubber material.

[0045] Pretreatment of longicorn beetle feed: take longicorn longicorn adults and feed them with sawdust for 3 days. During the feeding process, spray them with hawthorn juice twice the weight of longicorn longicorn adults every 4 hours. After the cultivation is completed, pre-cultiv...

Embodiment 2

[0059] Reagent A: Mix acryloyl chloride, dichloromethane, and water in a mass ratio of 1:6:15 to obtain Reagent A.

[0060] Reagent B: Mix NaOH solution with a mass fraction of 20% and sodium carbonate solution with a concentration of 0.1mol / L at a mass ratio of 1:15 to obtain Reagent B.

[0061] Self-made auxiliaries: at 45°C, take 80 parts of (N-amidino) dodecyl acrylamide, 50 parts of polyethylene glycol phosphate, and 8 parts of p-dichlorobenzene in CO 2 Mix under atmosphere, and stir with magnetic force at 700r / min for 60min to obtain the self-made adjuvant.

[0062] Rubber material: Mix peach gum, shellac and donkey-hide gelatin according to the mass ratio of 5:3:1 to get the rubber material.

[0063] Pretreatment of longicorn beetle feed: take longicorn longicorn adults and feed them with sawdust for 5 days. During the feeding process, spray them with hawthorn juice that is 4 times the weight of longicorn longicorn adults every 7 hours. After the cultivation is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com