Patents

Literature

30results about How to "Has shape memory effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

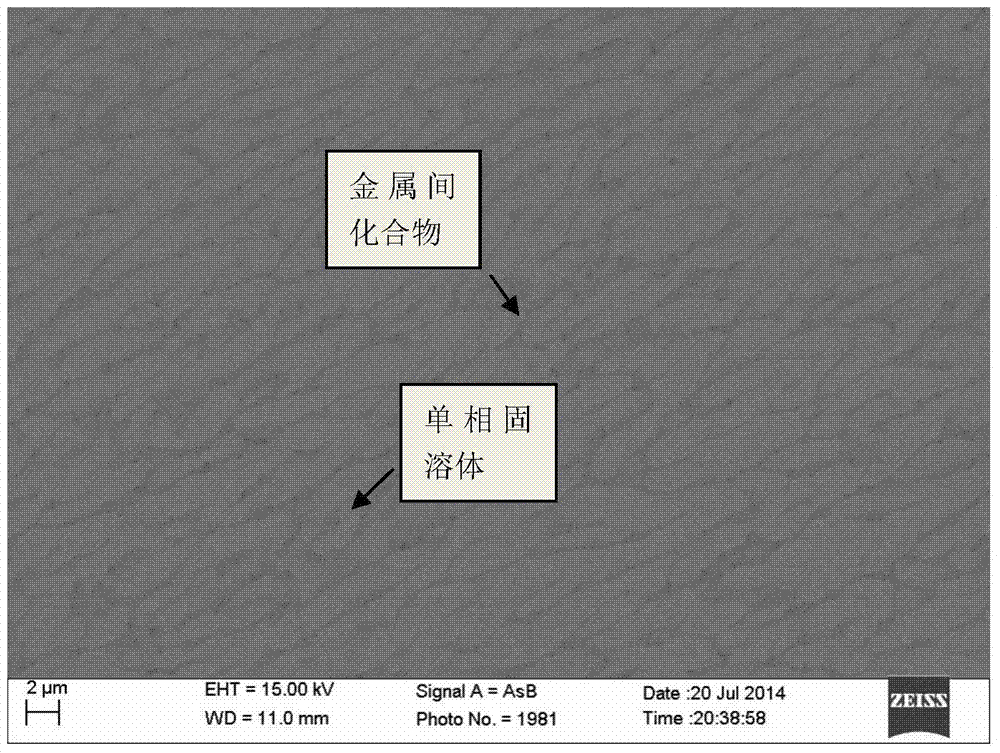

NxMy high-entropy alloy with shape memory effect and preparing method thereof

ActiveCN105296836APhase transition temperature wideHas shape memory effectHigh entropy alloysSingle phase

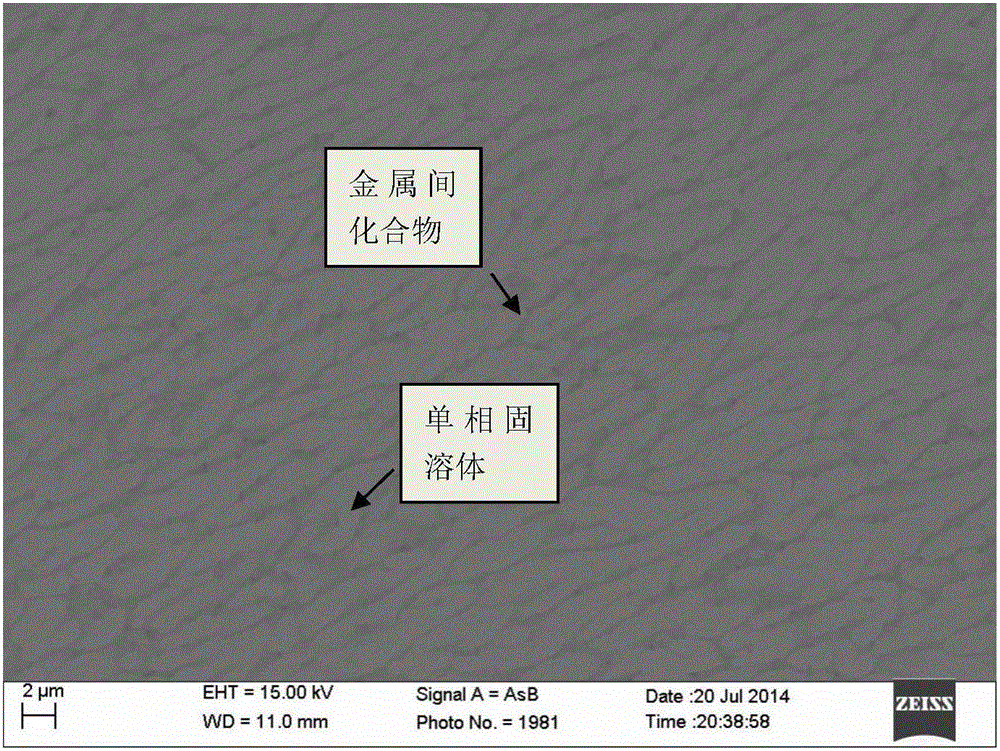

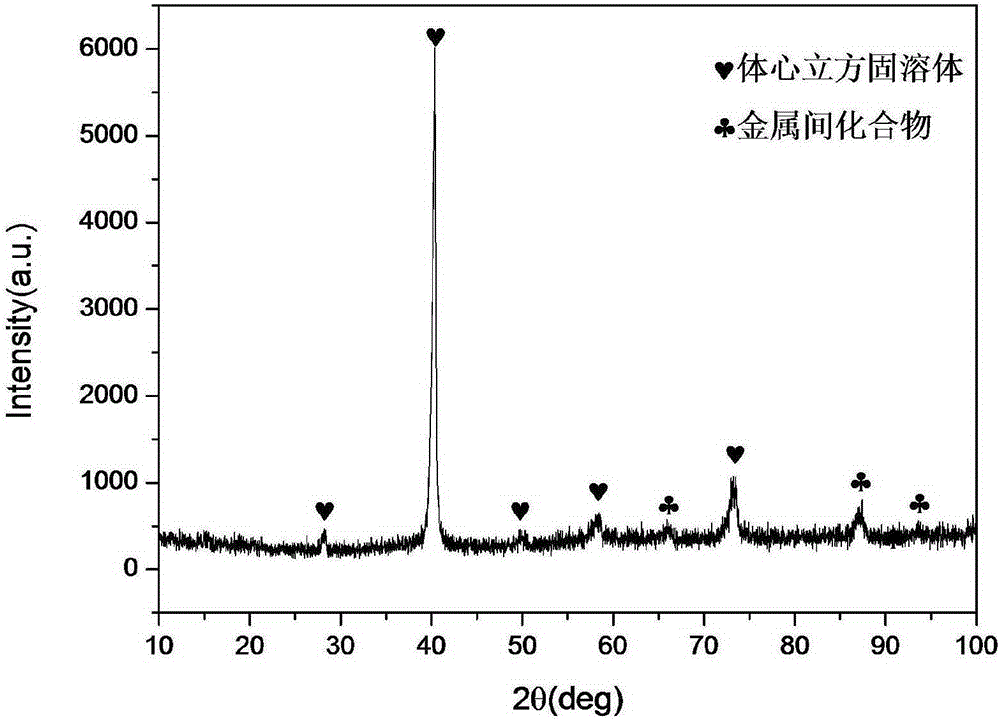

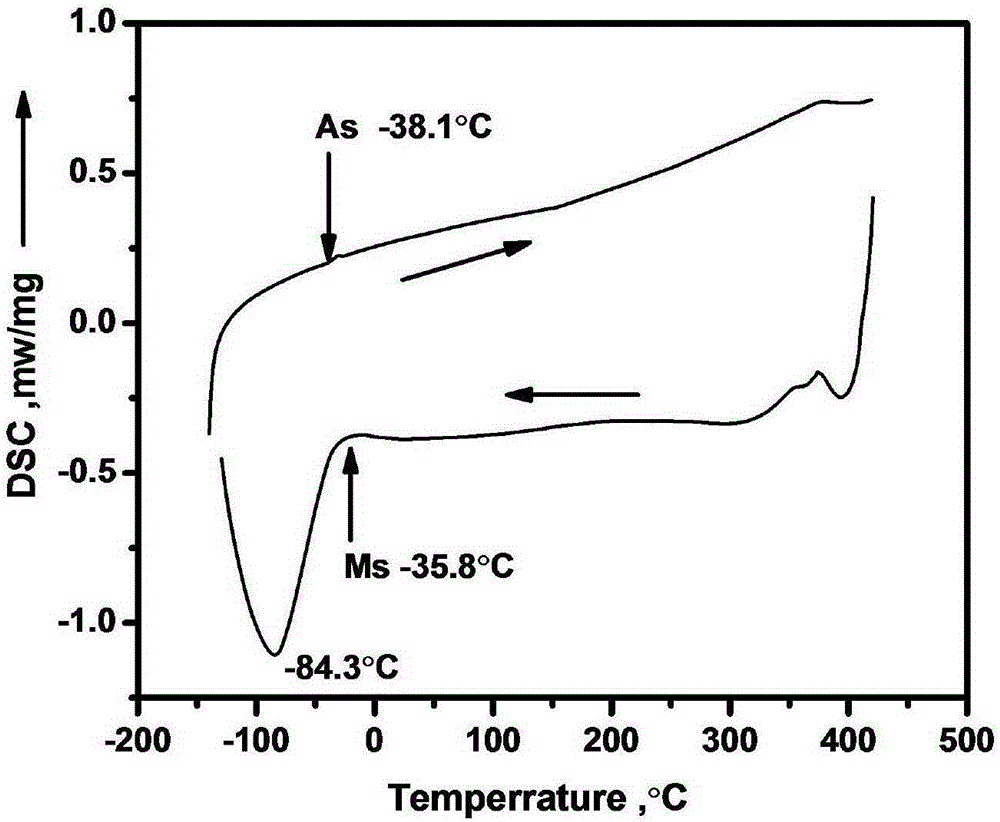

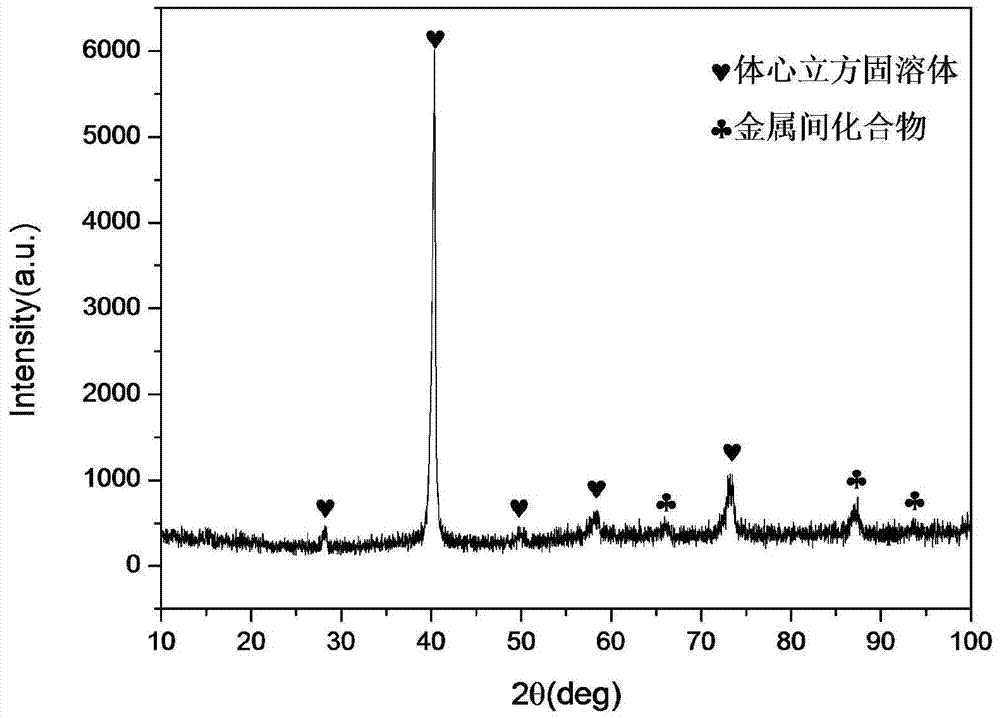

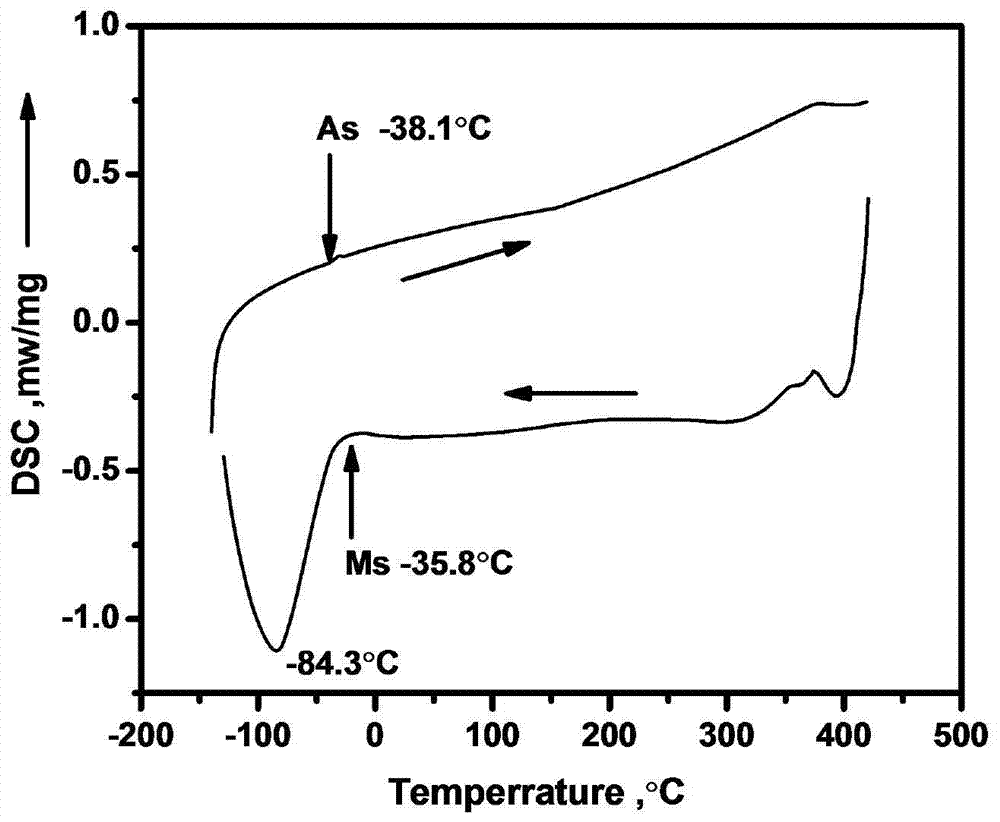

The invention relates to NxMy high-entropy alloy with a shape memory effect and a preparing method thereof. The alloy comprises NxMy, wherein x is larger than or equal to 45 and smaller than or equal to 55, y is larger than or equal to 45 and smaller than or equal to 55, the N is any two or more of Ti, Zr, Hf, V, Nb, Ta, Mo and W and the M is any two or more of V, Mn, Fe, Co, Ni, Cu, Cr and Zn; and the content of the Ti, the content of the Zr, the content of the Hf, the content of the V, the content of the Nb, the content of the Ta and the content of the Mo in the N are each larger than or equal to 5% and smaller than or equal to 35%, and the content of the V, the content of the Mn, the content of the Fe, the content of the Co, the content of the Ni, the content of the Cu, the content of the Cr and the content of the Zn are each larger than or equal to 5% and smaller than or equal to 35%. A body-centered cubic single-phase solid solution with the volume fraction not lower than 95% and an intermetallic compound form the alloy phase structure. The alloy is prepared through an electric arc melting method. The alloy has the shape memory effect within a wider temperature range and meanwhile has the high-entropy alloy feature. The NxMy high-entropy alloy and the preparing method have wide application prospects in the fields of aerospace, mechanical electronic products and low-temperature industries.

Owner:UNIV OF SCI & TECH BEIJING

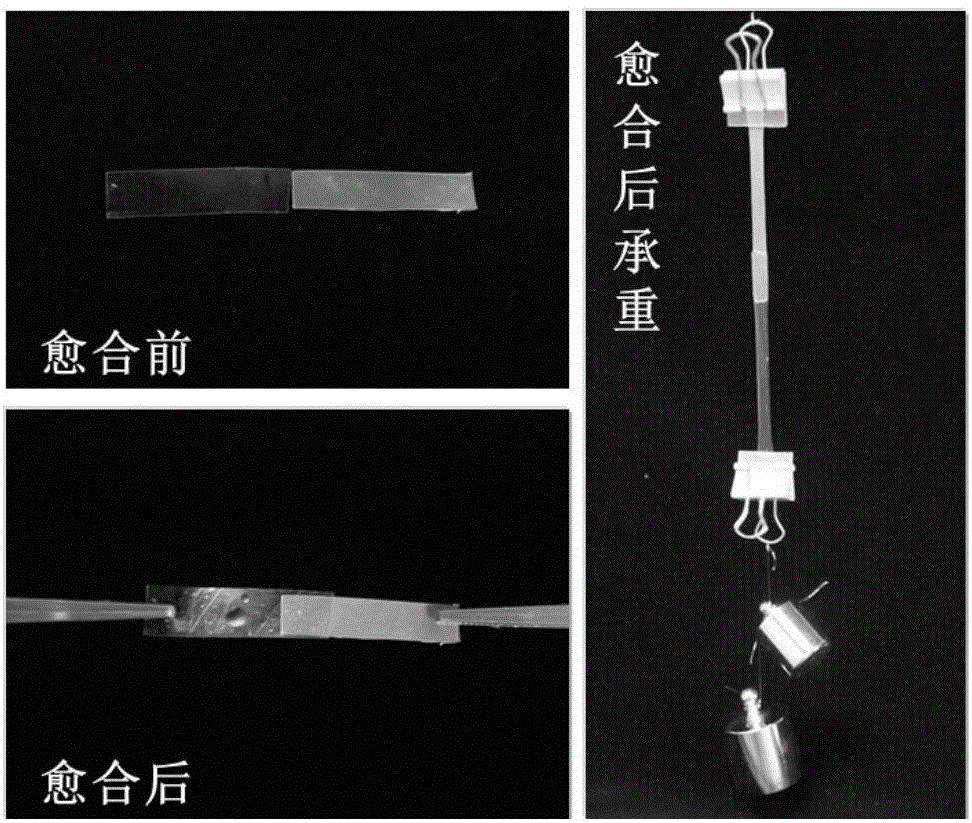

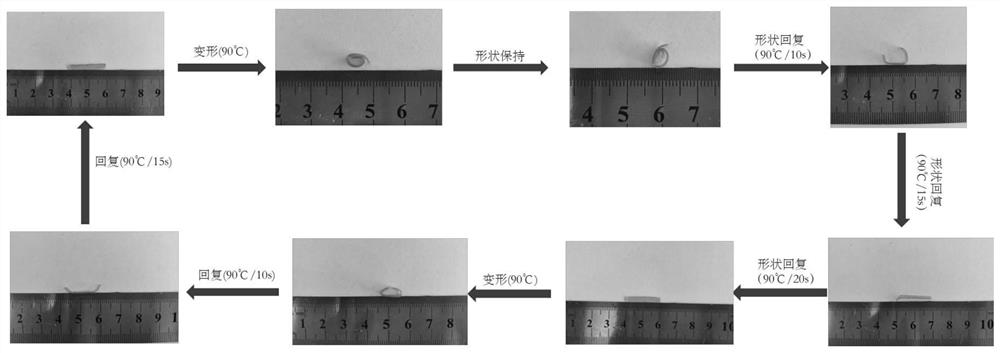

Self-repair material and article with shape memory effect and preparation method thereof

InactiveCN106633721ARich preparation methodImprove reliabilitySurgeryPharmaceutical delivery mechanismSelf-healing materialMemory functions

The invention discloses a self-repair material with a shape memory effect. The self-repair material is prepared from a shape memory polymer material, a shape memory function can be achieved under the stimulation of light, heat, electricity and magnetism, and moreover, the self-repair and healing purposes are achieved. The composition and preparation method of the self-repair material are diversified, the shape change and self-repair functions of the shape memory material can be achieved through different manners, and the application of the shape memory material in the fields such as spaceflight, aviation, medical treatment and bioengineering is expanded.

Owner:SHENZHEN INST OF ADVANCED TECH

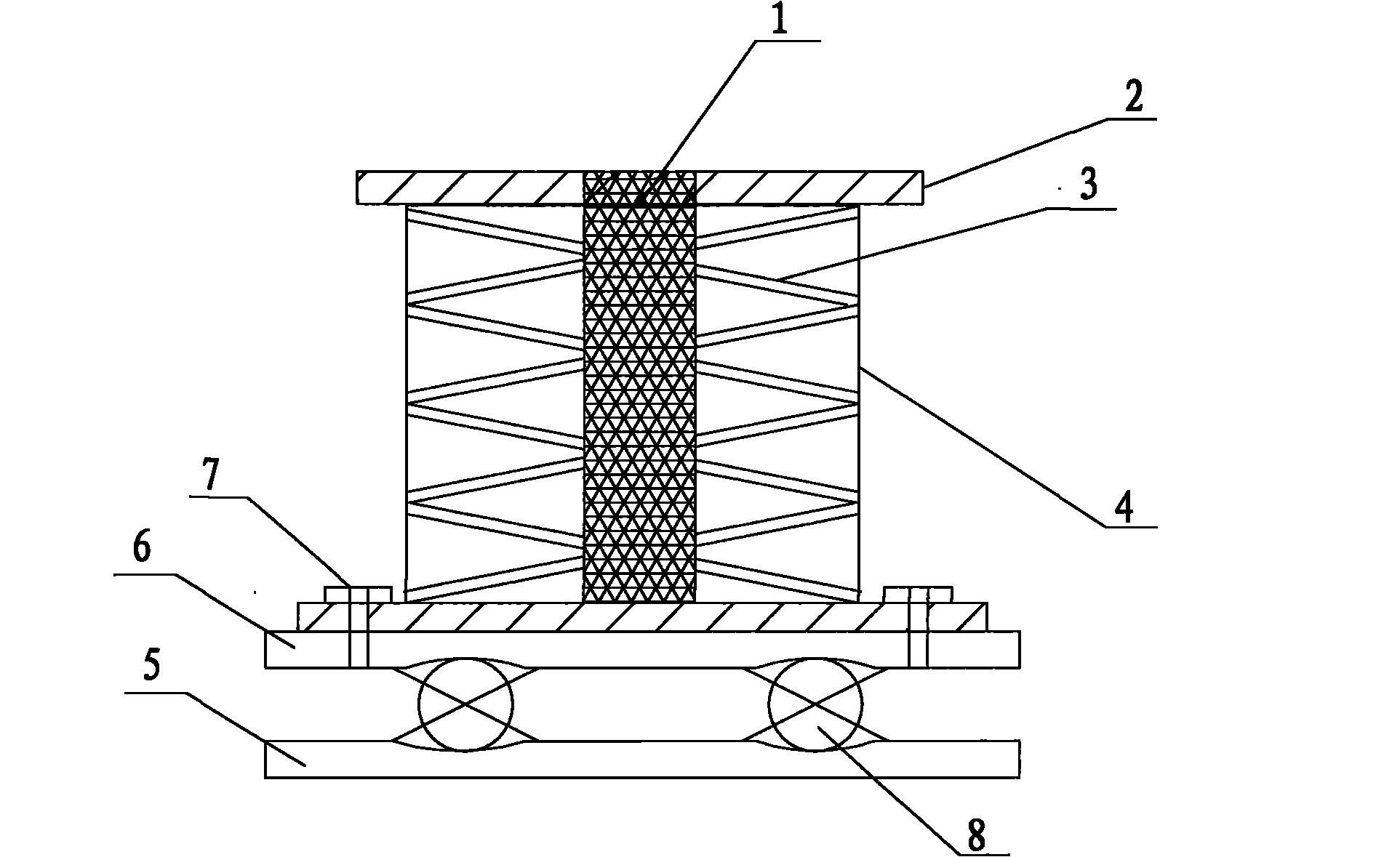

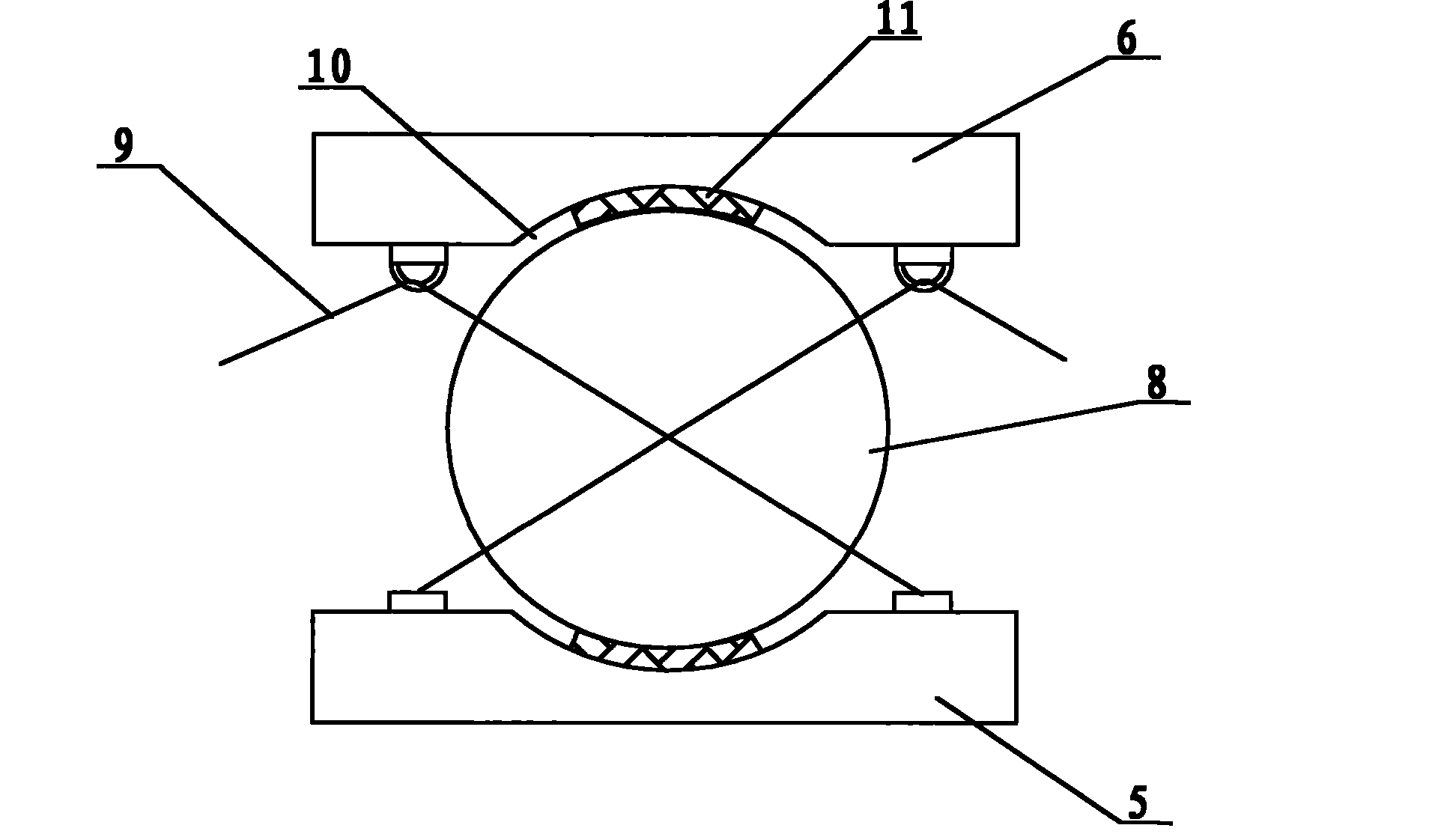

Ball/disc spring vibration-isolating device

InactiveCN102337761AImprove securityDesign freedomBridge structural detailsShock proofingVibration isolationInstrumentation

The invention relates to a vibration-isolating device, in particular to a combined vibration-isolating device. A ball / disc spring vibration-isolating device comprises a vibration-isolating support, and the upper end of the vibration-isolating support is connected with a damper. The device is not only suitable for a newly-built structure, but also suitable for anti-seismic reinforcement and post-earthquake repair of an original structure. Moreover, the device is applicable to ordinary civilian housings, civil engineering such as structures, bridges and the like, as well as storey-increased buildings and shifting buildings. The device can also be applied in vibration isolation and reduction of instruments and equipment and has low manufacturing cost and broad application prospects.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

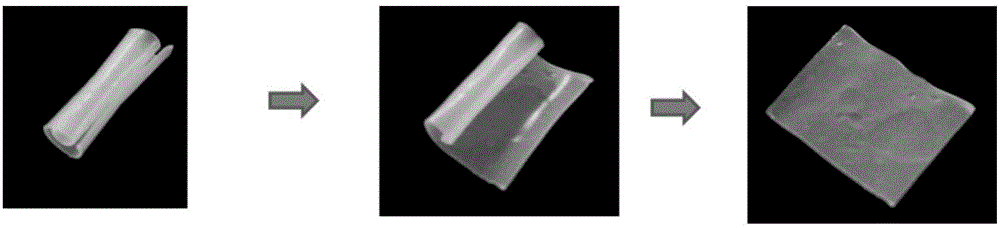

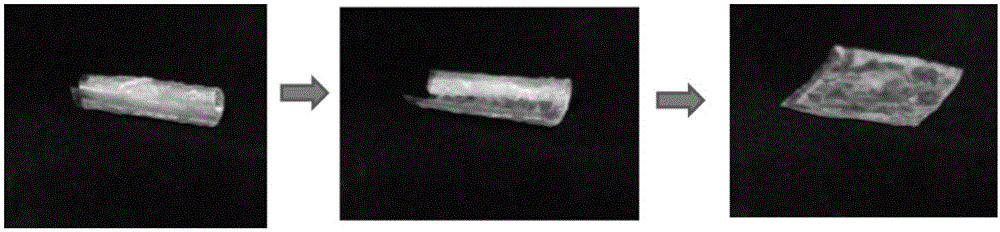

4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

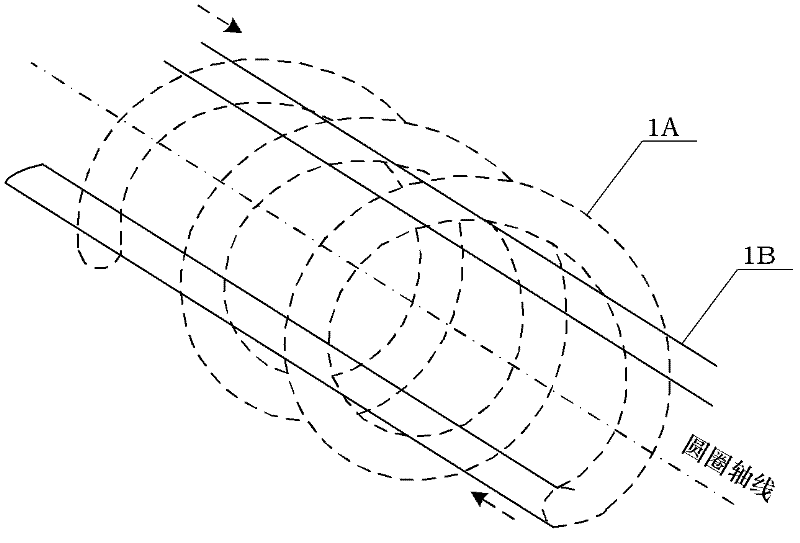

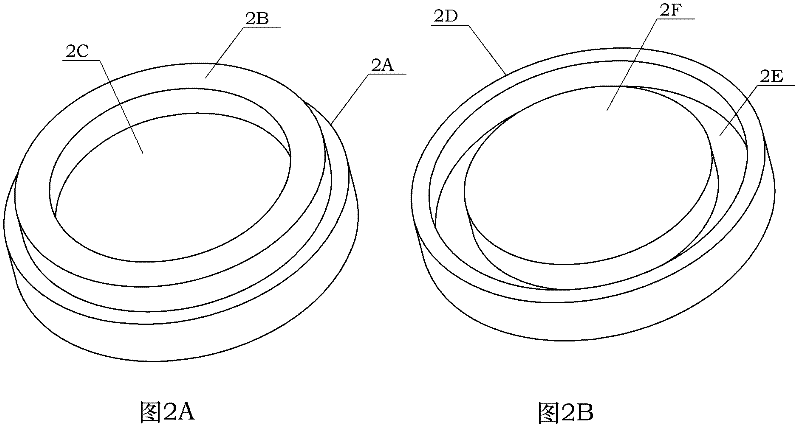

Method for manufacturing damping structural piece of aviation engine supporting system

InactiveCN102644686AWith shape memoryBoth featuresHigh internal friction springsAviationMetal rubber

The invention discloses a method for manufacturing a damping structural piece of an aviation engine supporting system; a shape memorizing alloy wire is manufactured into metal rubber through the combined processes of manufacturing an elastic wire at low temperature, heat setting, winding and full-constraint heat setting; and the damping structural piece which is manufactured through the method has a shape memorizing effect and a variable rigidity characteristic. According to the method for manufacturing the damping structural piece of the aviation engine supporting system, a damping material in the metal rubber structure is integrated with a shape memorizing alloy, and a novel metal structural functional material with the advantages of the metal rubber and the shape memorizing alloy is developed. The material has good damping performance, high deformation capability and high bearing capability, and has the advantages of active and controllable elastic modulus, strong environment adaptability and stable and reliable structure. Because the advantages of the metal rubber and the shape memorizing alloy are integrated, the method can be applied in aviation engine rotor supporting and a non-peak rotor can be realized.

Owner:BEIHANG UNIV

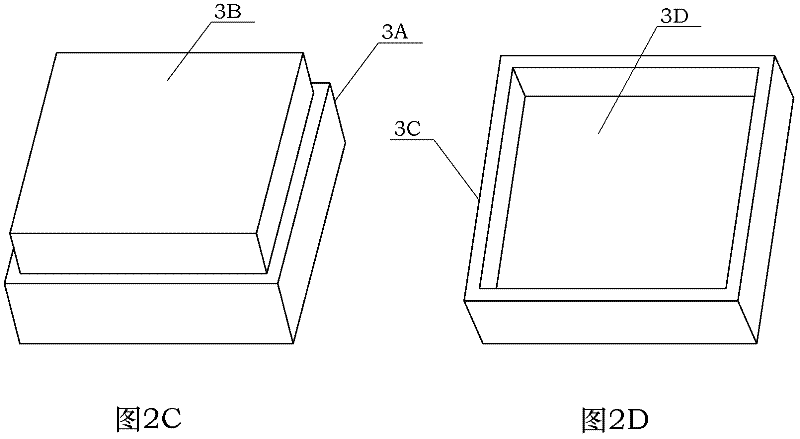

4D printing method of nickel-titanium-based ternary shape memory alloy

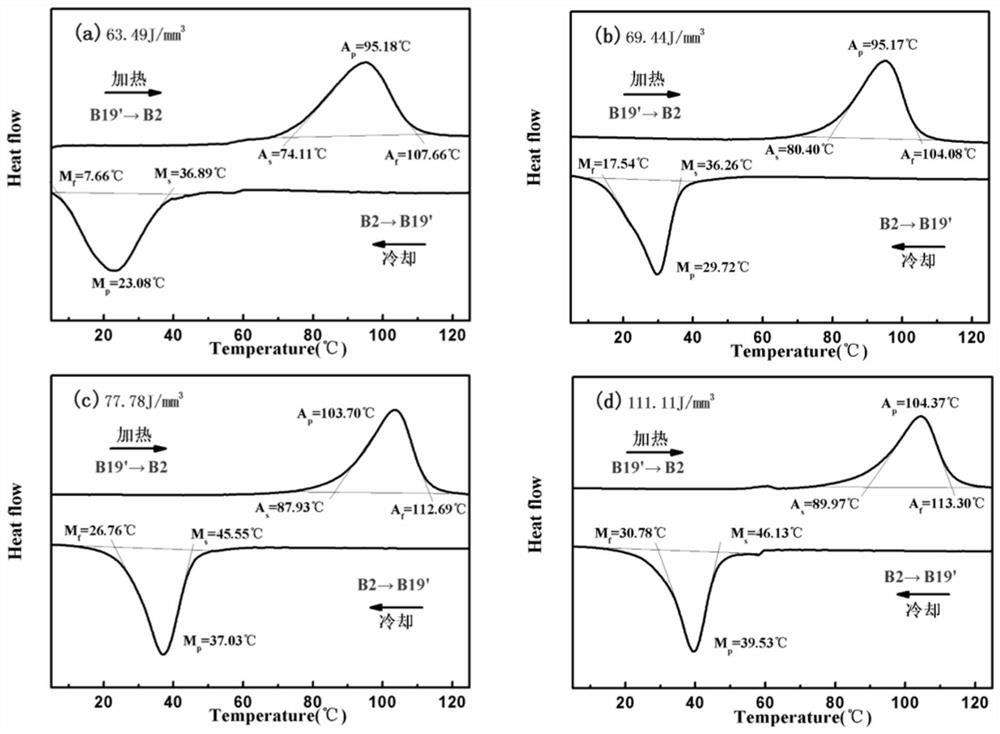

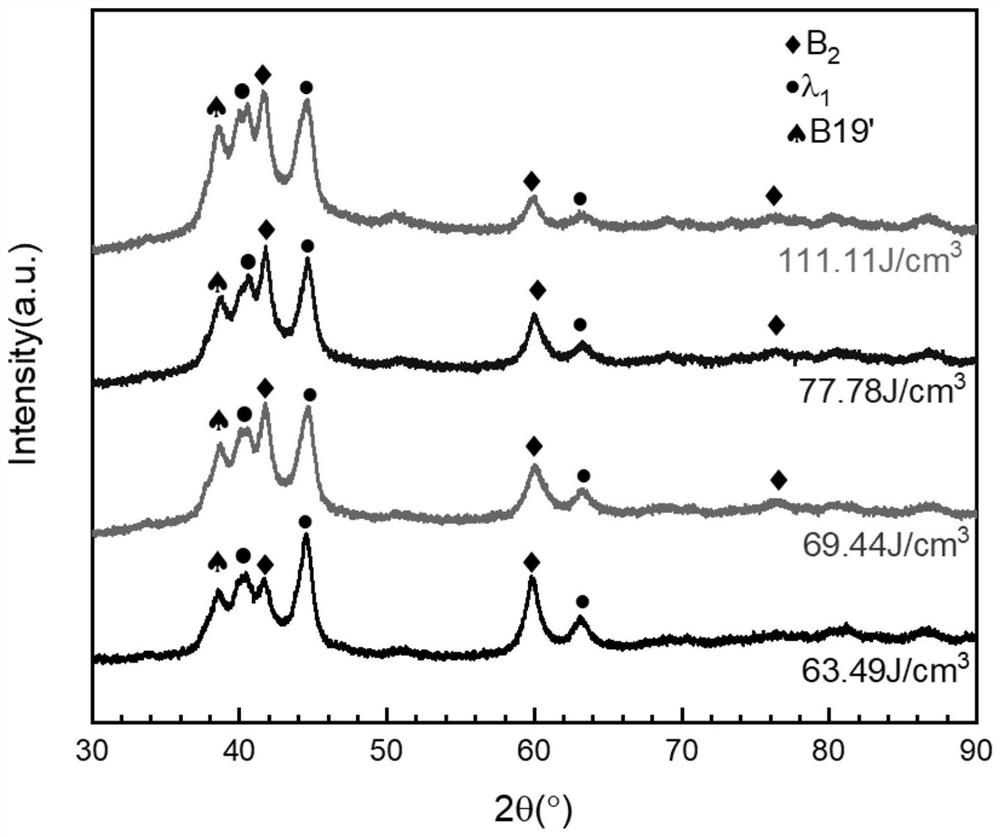

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

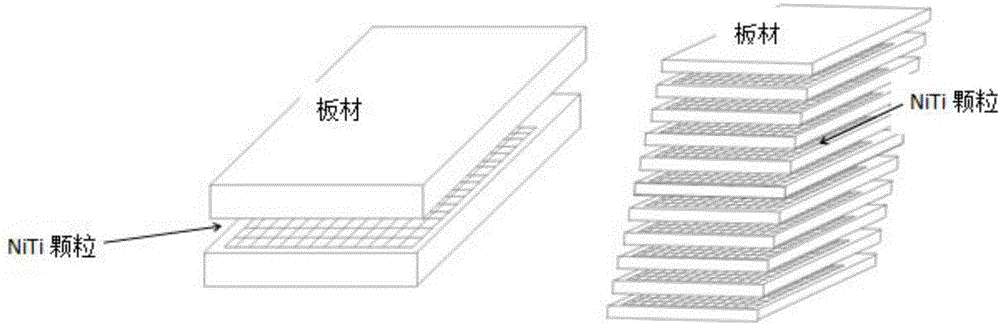

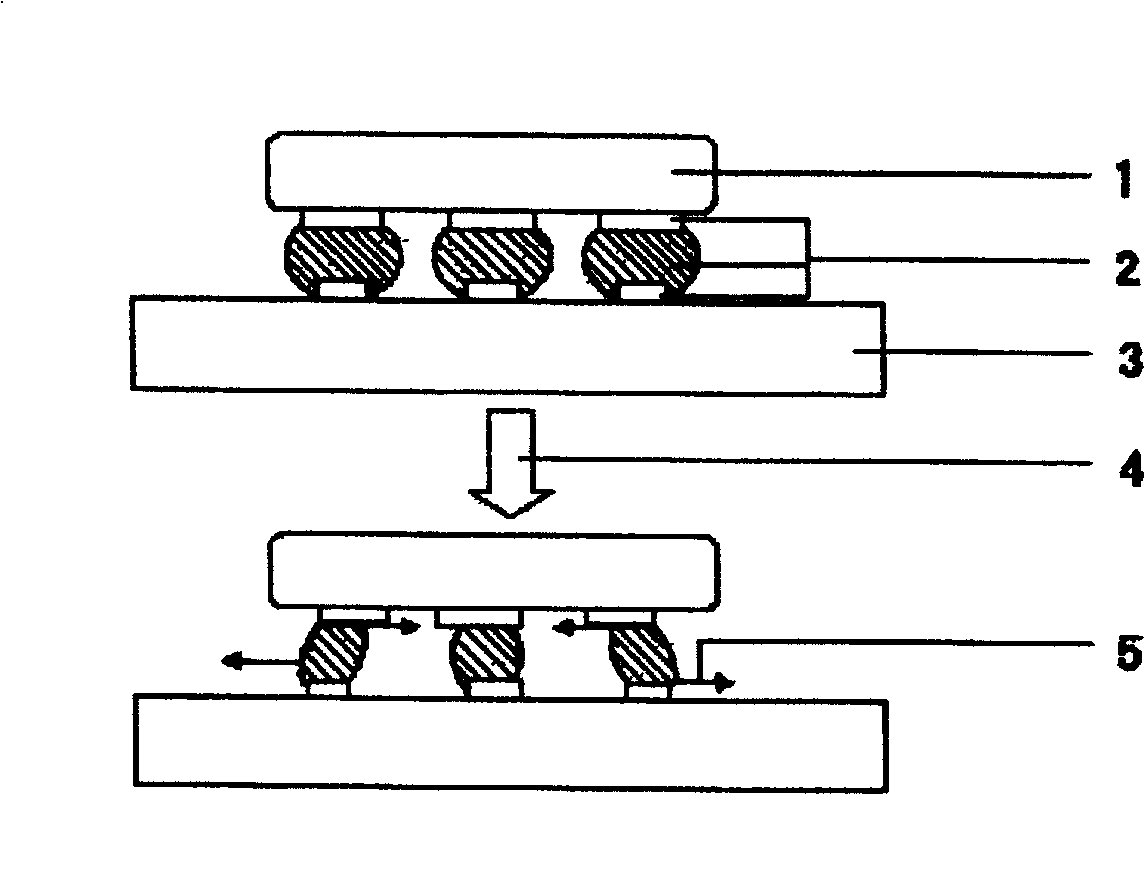

Shape memory alloy particle reinforced light metal-based composite material and preparation method thereof

The invention provides a shape memory alloy particle reinforced light metal-based composite material and a preparation method thereof. The composite material comprises a substrate and shape memory alloy particles, wherein the volume content of the shape memory alloy particles is 5-40% and the thickness of the composite material is 2-20 millimeters. The method is characterized by prearranging the shape memory alloy particles in an aluminium alloy or magnesium alloy plate by adopting the dot matrix porous particle prearranging mode to prepare the shape memory alloy particle reinforced light metal-based composite material through the friction stir processing technology. The composite material has the following advantages: the particles in the composite material are uniformly distributed; the interface between the particles and the substrate is clean and no reactants are generated on the interface; and the composite material has the shape memory effect and excellent damping property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

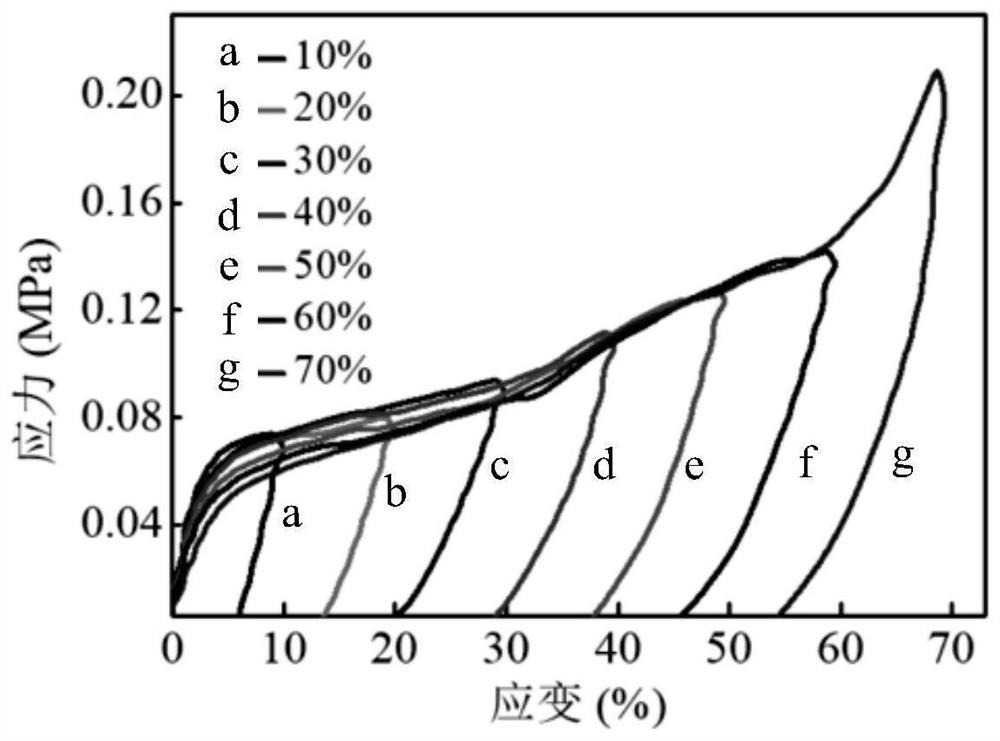

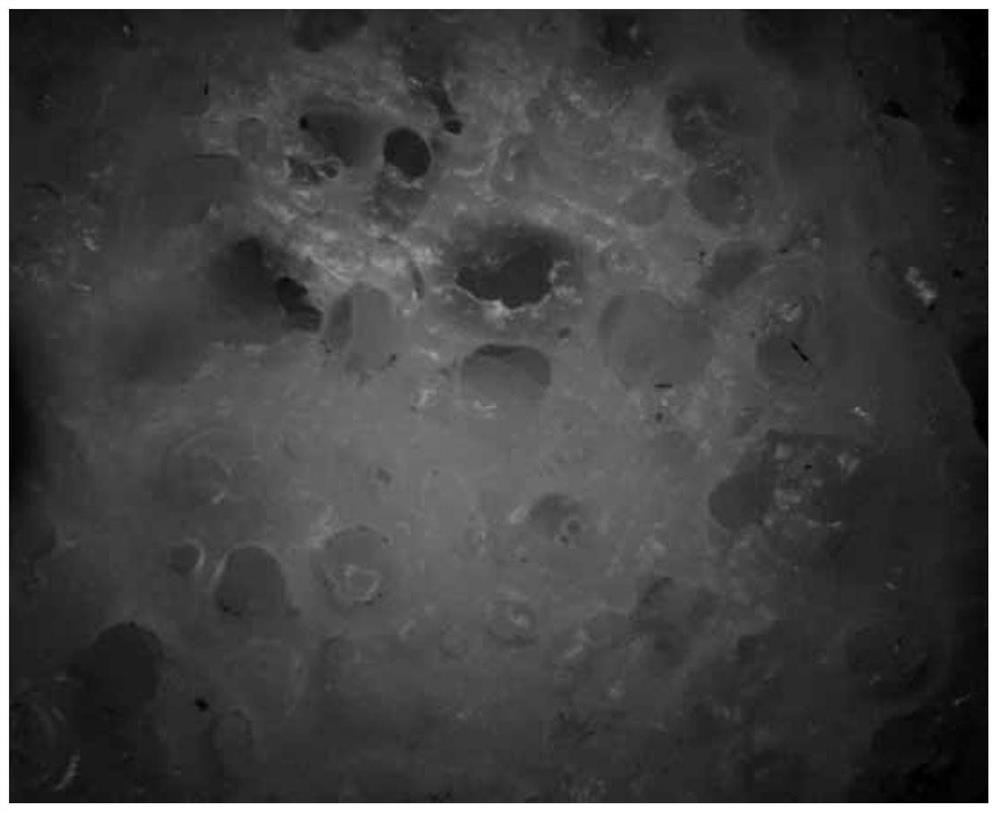

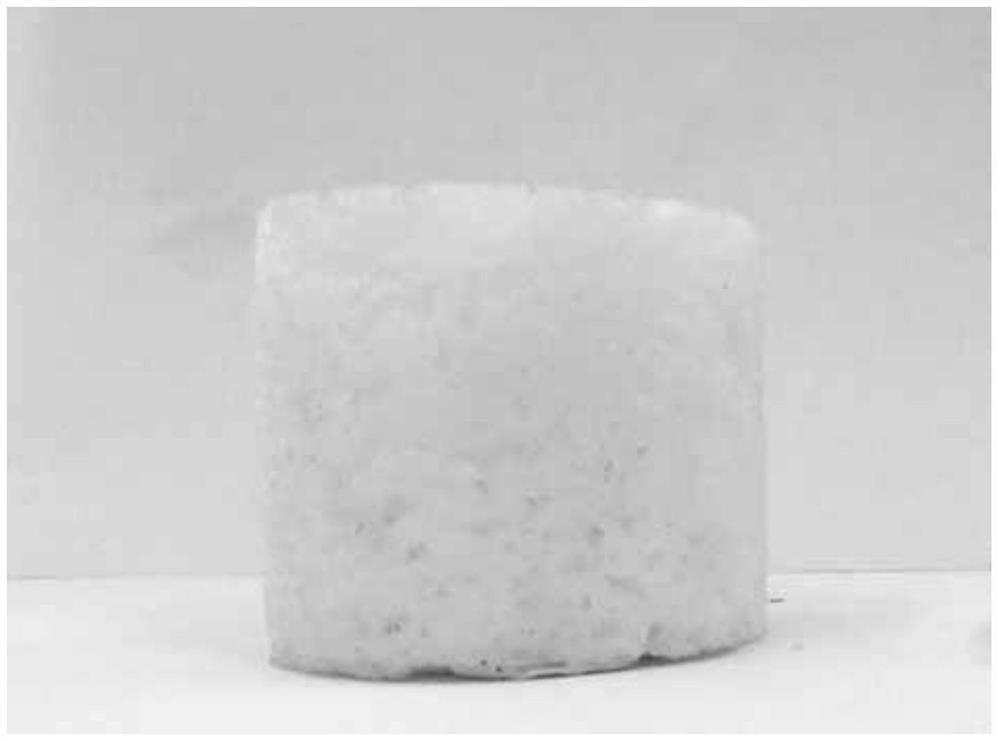

Preparation method and driving method of shape-memory polycaprolactone foam

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

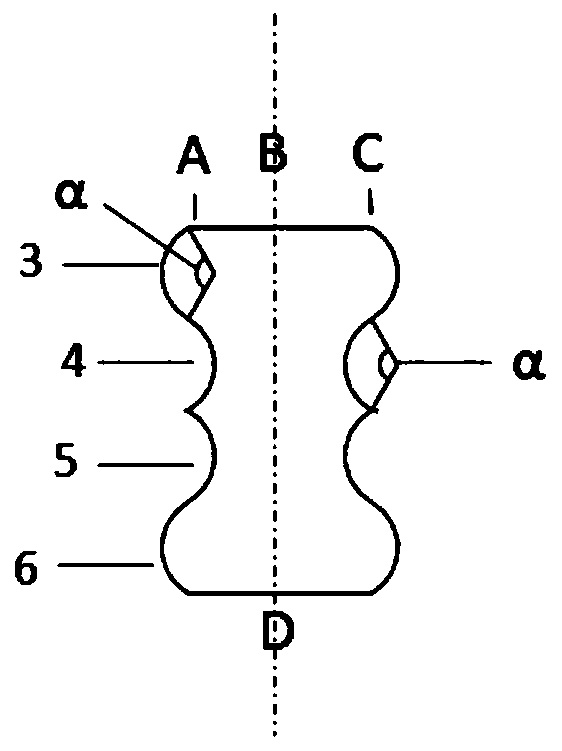

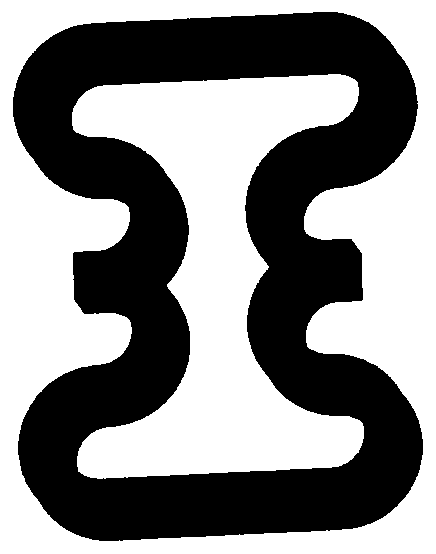

Soft-palate super-elastic NiTi carriage for treating obstructive sleep apnea low-ventilation syndrome and preparing method

The present invention relates to a soft palate superelastic NiTi support for curing obstructive sleep aponea low-ventilation syndrome and its preparation method. It is characterized by that the described support is formed into a closed tongue-shaped structure made up by using superelastic NiTi marmem wire material through a certain winding process. Besides, said invention also provides the concrete steps of its preparation method.

Owner:江阴佩尔科技有限公司

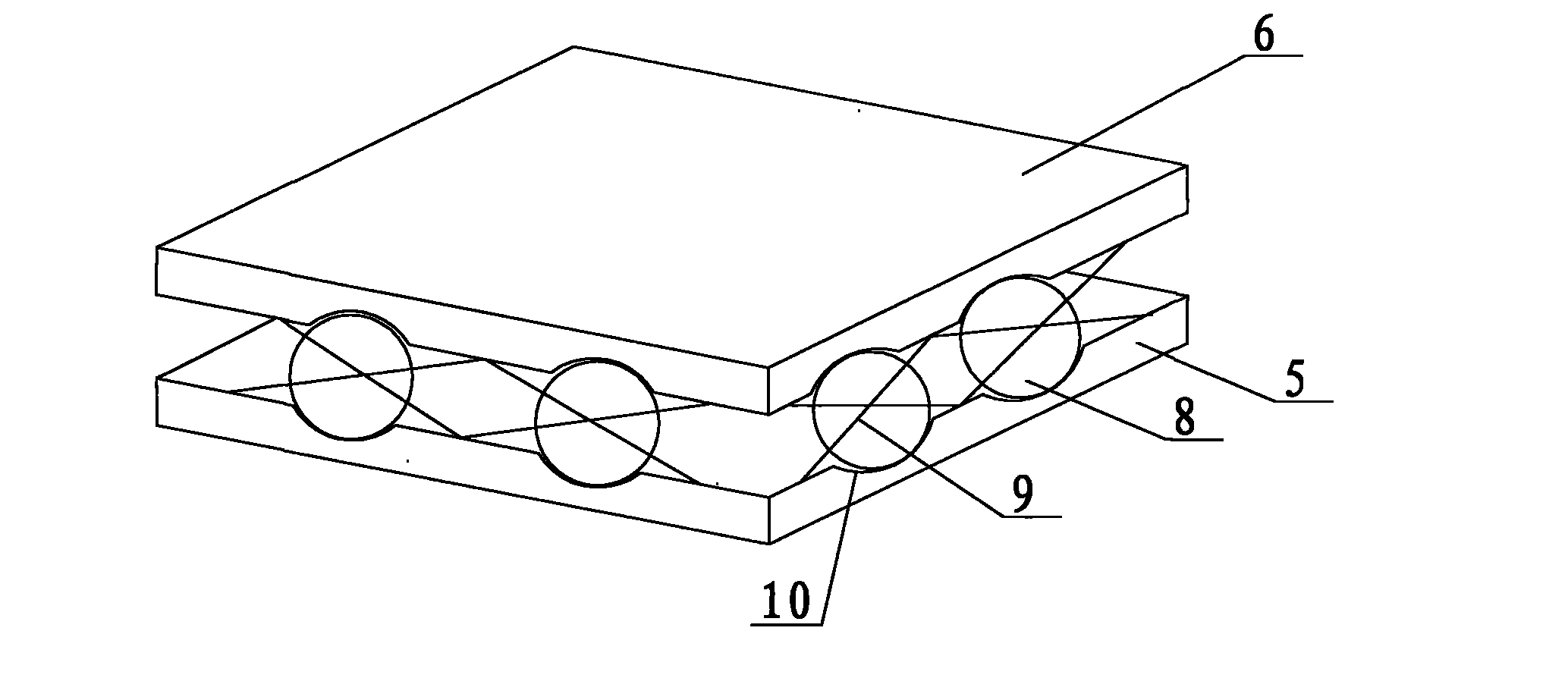

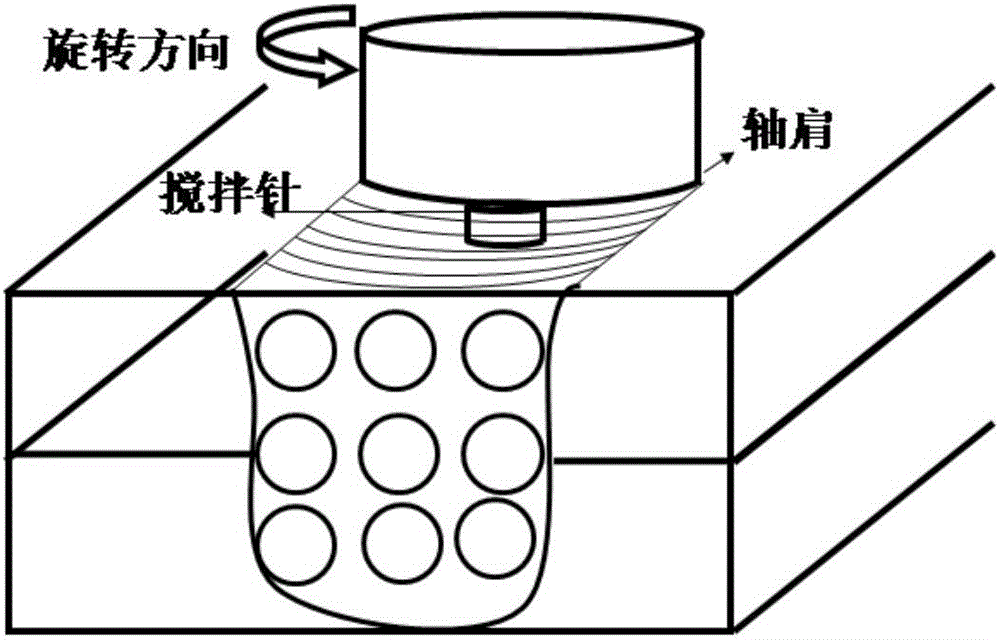

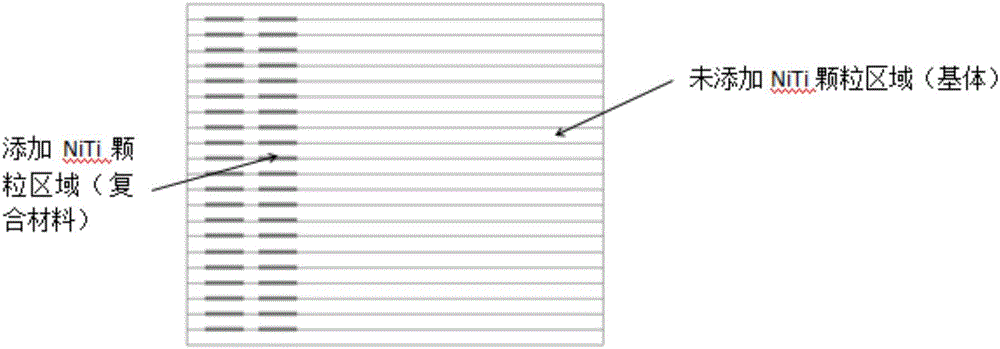

Preparation method of metal-based shape memory composite

ActiveCN107520448AEvenly dispersedReduce lossesMetal rolling arrangementsReduction rateComposite plate

The invention discloses a preparation method of a metal-based shape memory composite. The preparation method comprises the steps that NiTi metal powder layers are laid between to-be-prepared adjacent metal plates to obtain laminated plates, the laminated plates are subjected to accumulative ply rolling treatment to obtain a composite plate, it is guaranteed that the corresponding NiTi metal powder layer is laid between any two adjacent metal plates in the accumulative ply rolling treatment process, and the composite plate is subjected to friction stirring processing treatment to obtain the metal-based shape memory composite. The reduction rate of each pass of accumulative ply rolling ranges from 40% to 55%, and the number of the rolling passes of accumulative ply rolling ranges from 2 to 8; and the rotating speed of friction stirring processing ranges from 375 r / min to 1,180 r / min, the advancing speed of friction stirring processing ranges from 75 mm / min to 235 mm / min, and the reduction rate of friction stirring processing ranges from 0.2 mm to 0.5 mm. Through the adoption of the laminating welding deformation method, the metal plates on different layers are changed, SMAs different in particle size and content are evenly and flatly laid between the plates, metal materials with different structures and properties can be prepared out, and the novel functional material in different service environments is met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

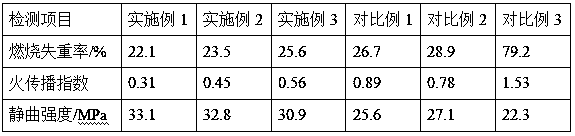

High-stability wood flame retardant

InactiveCN109822702AImprove mechanical propertiesImprove energy dispersion effectWood impregnation detailsMemory effectCavity size

The invention belongs to the technical field of flame retardants and discloses a high-stability wood flame retardant. By an inorganic treatment substance, nonuniform dispersion of flame-retardant effective components is prevented, and after action on wood, mechanical properties of the wood can be improved through combination with hydroxyl in wood components; under the action of CO2, reversible volume and modulus changes can be realized, and carbon dioxide affinity of a system is improved; by CO2 release, a memory effect of the system is achieved, excellent flame-retardant and anti-stretching effects are realized, and combined improvement of mechanical properties of the wood is realized. Due to amphipathicity of an additive, the vesicle cavity size of the system is increased, contact effects of components are enhanced, and high stability can be achieved under the action of a colloid stable composite structure of a composite flame-retardant component A. By the high-stability wood flame retardant, problems of poor flame retardation effects of existing common wood flame retardants and influences on mechanical properties of the wood are solved.

Owner:王金华

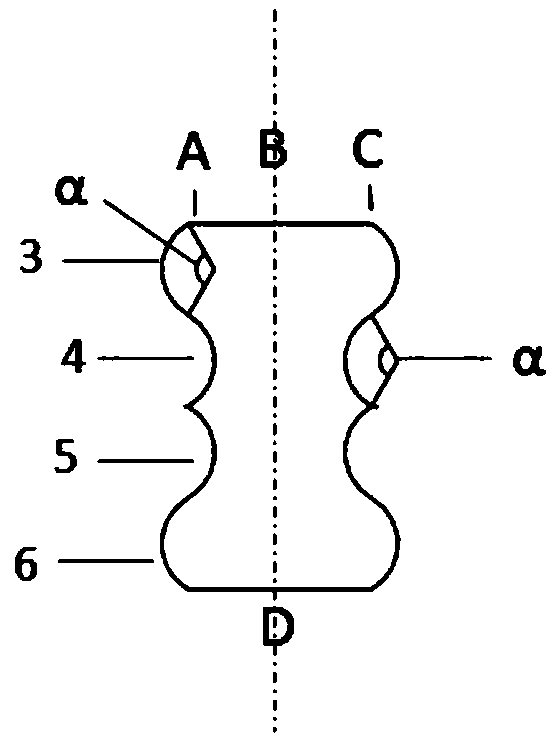

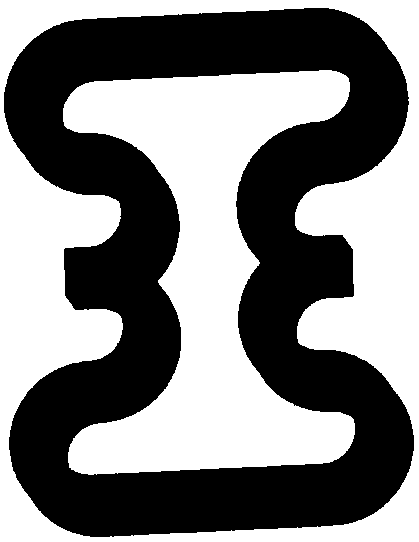

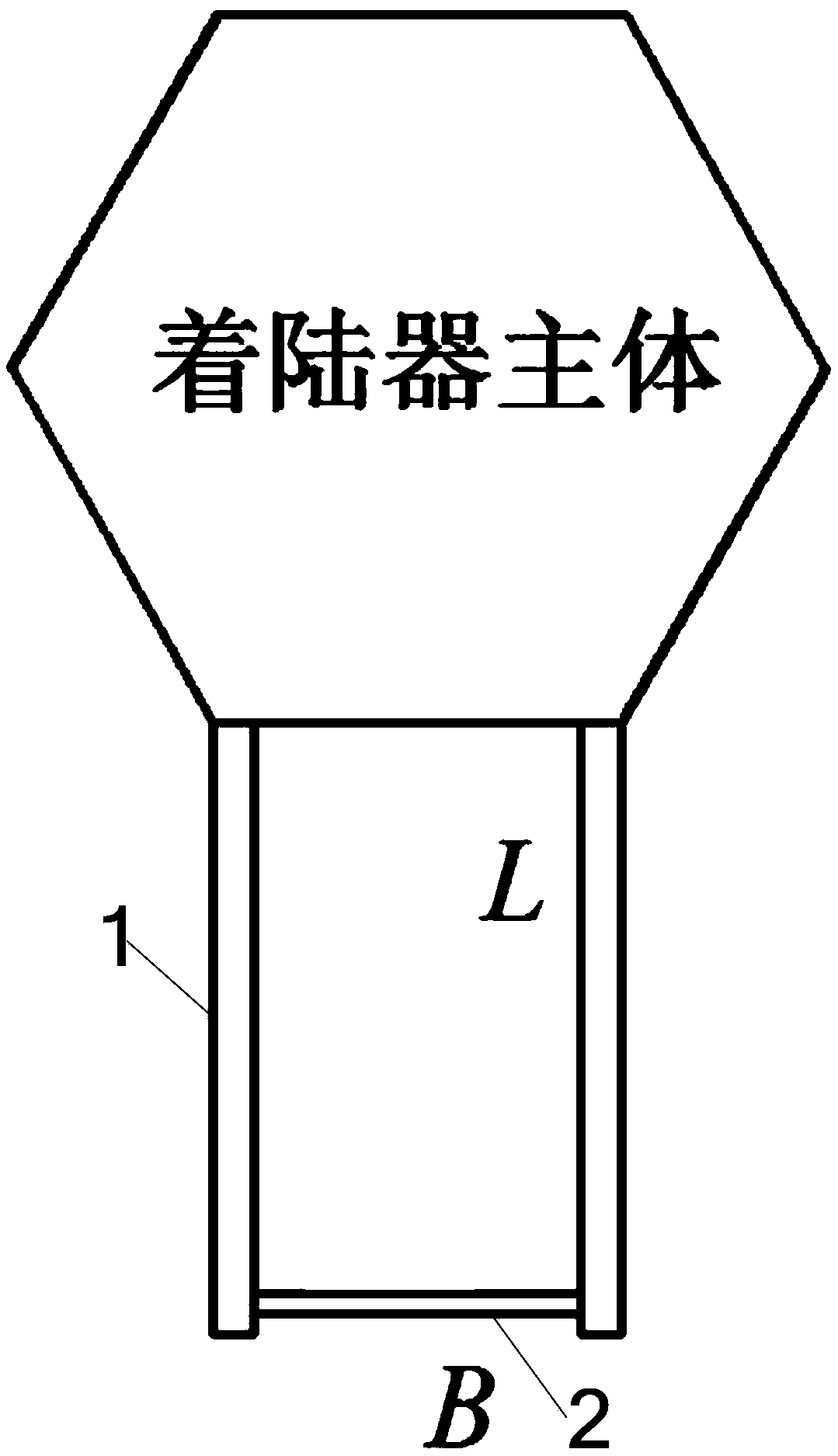

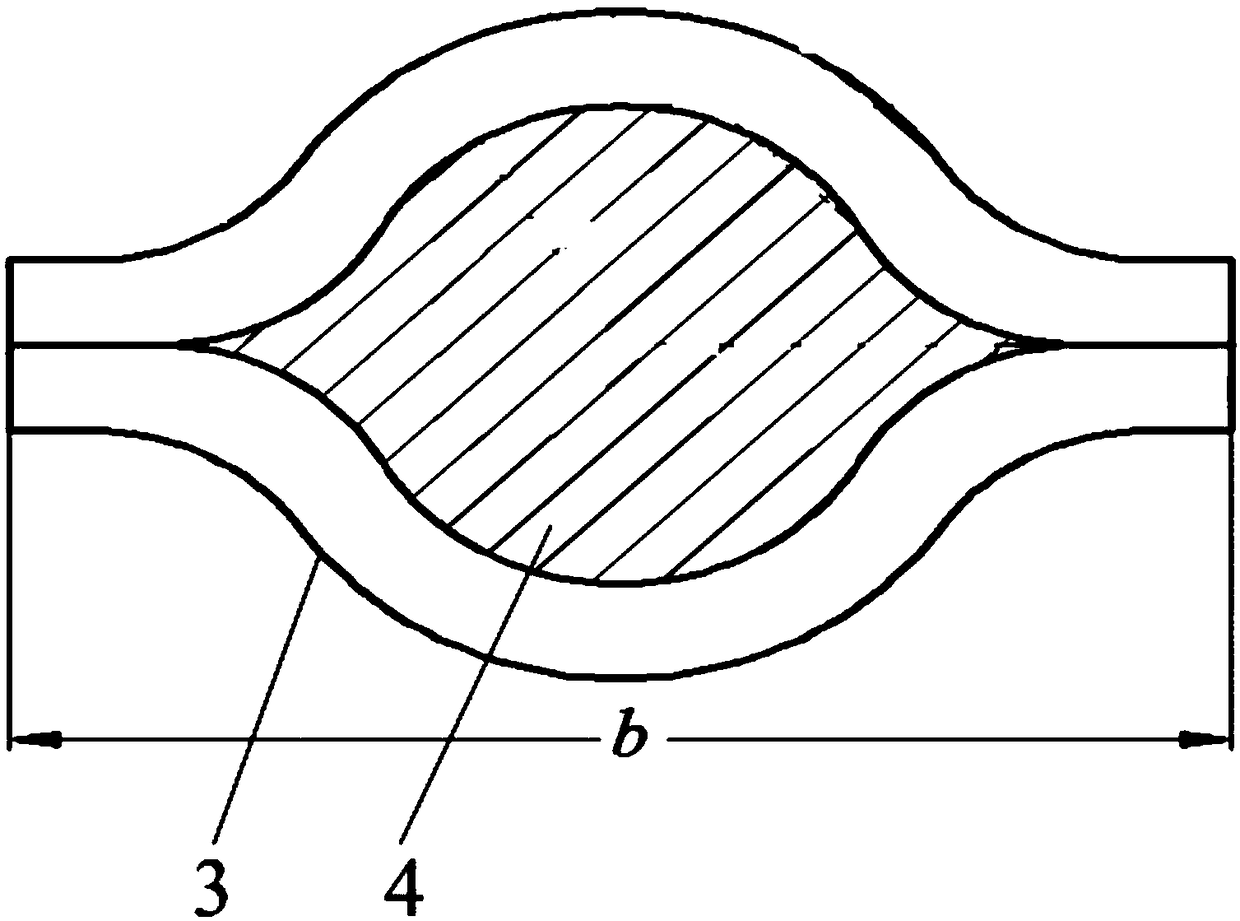

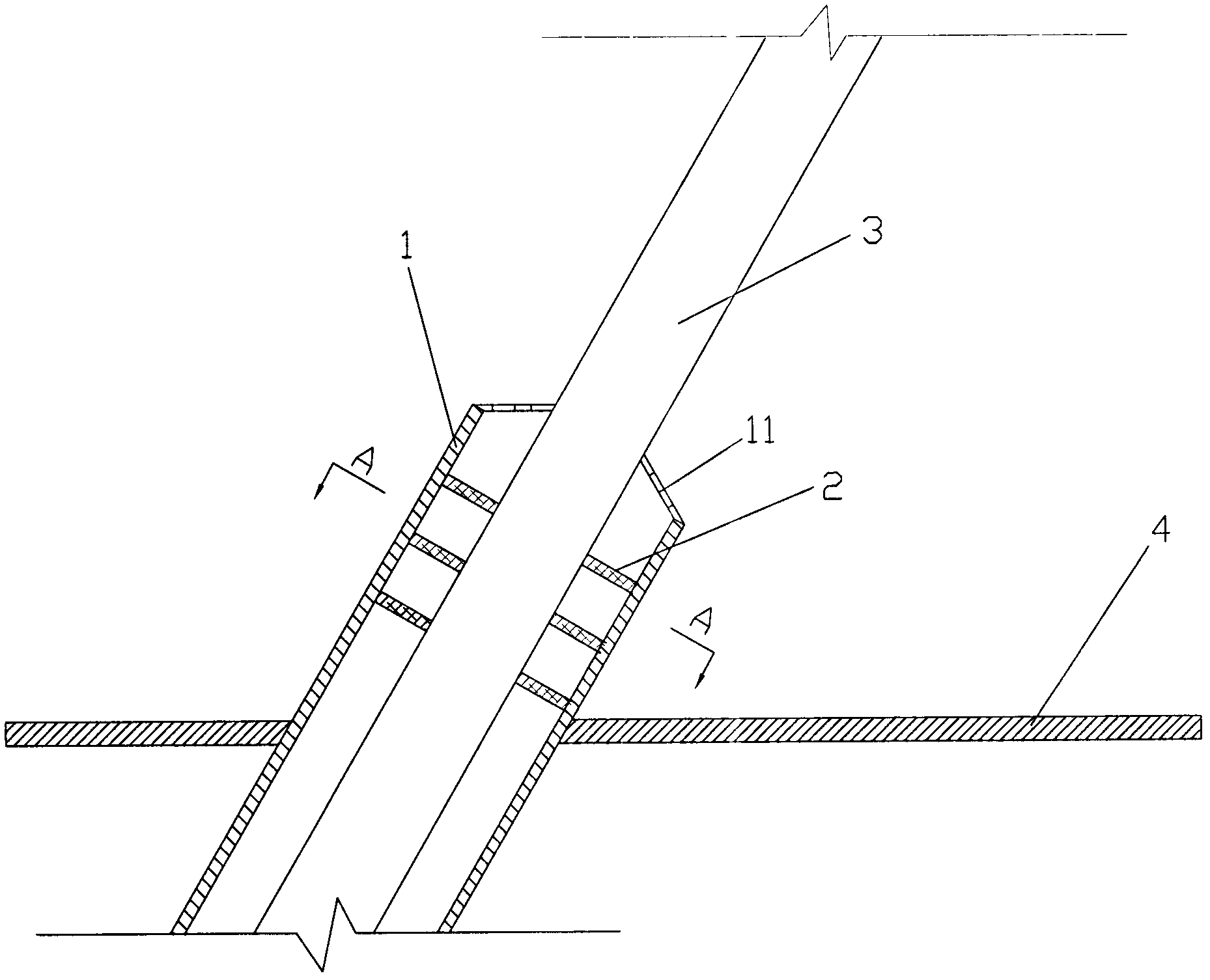

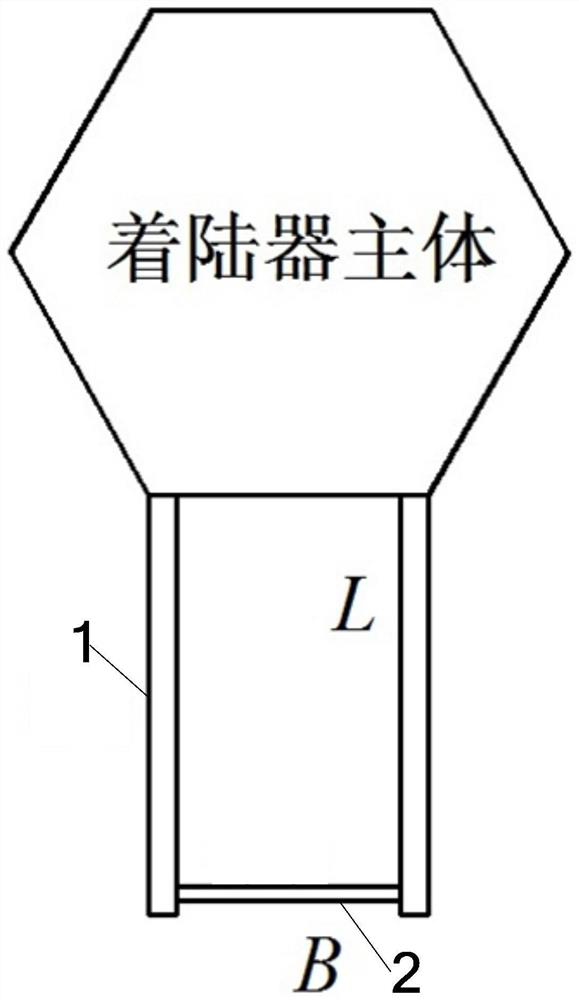

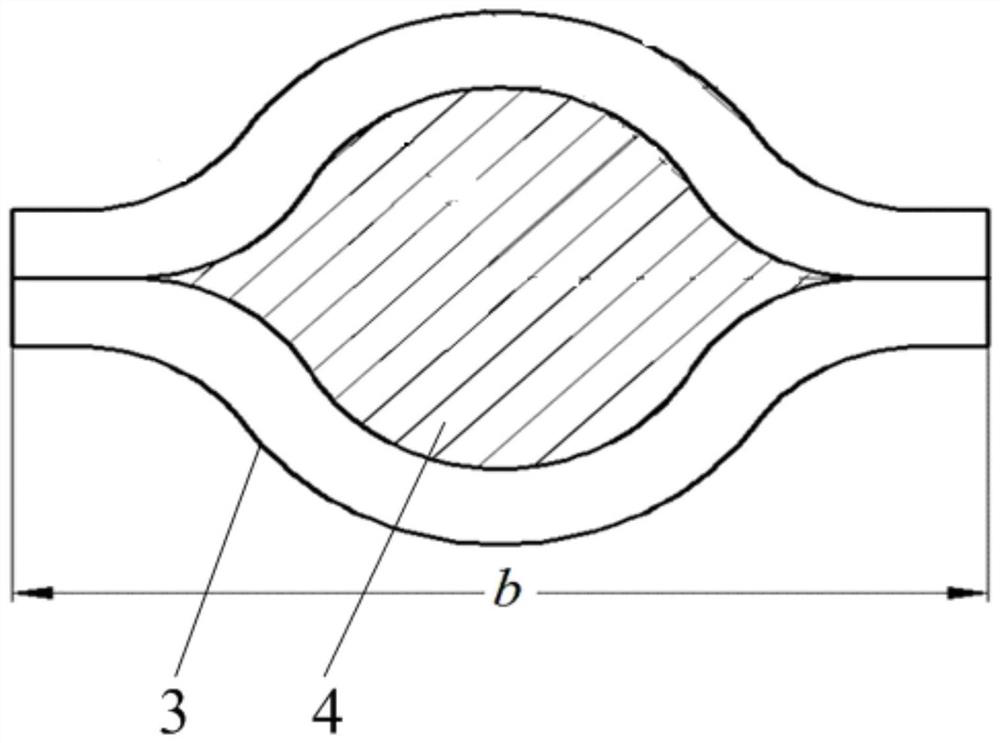

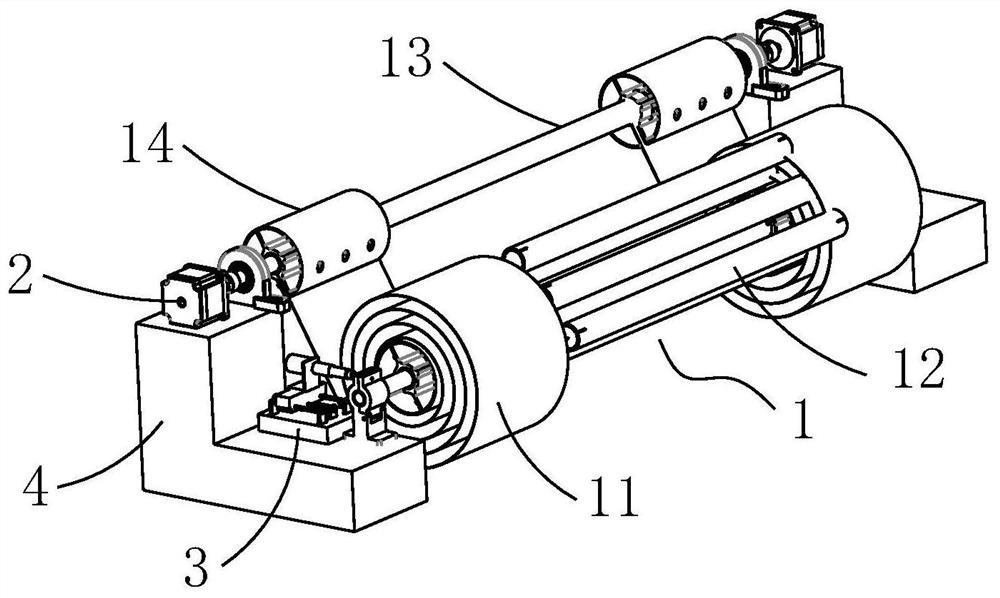

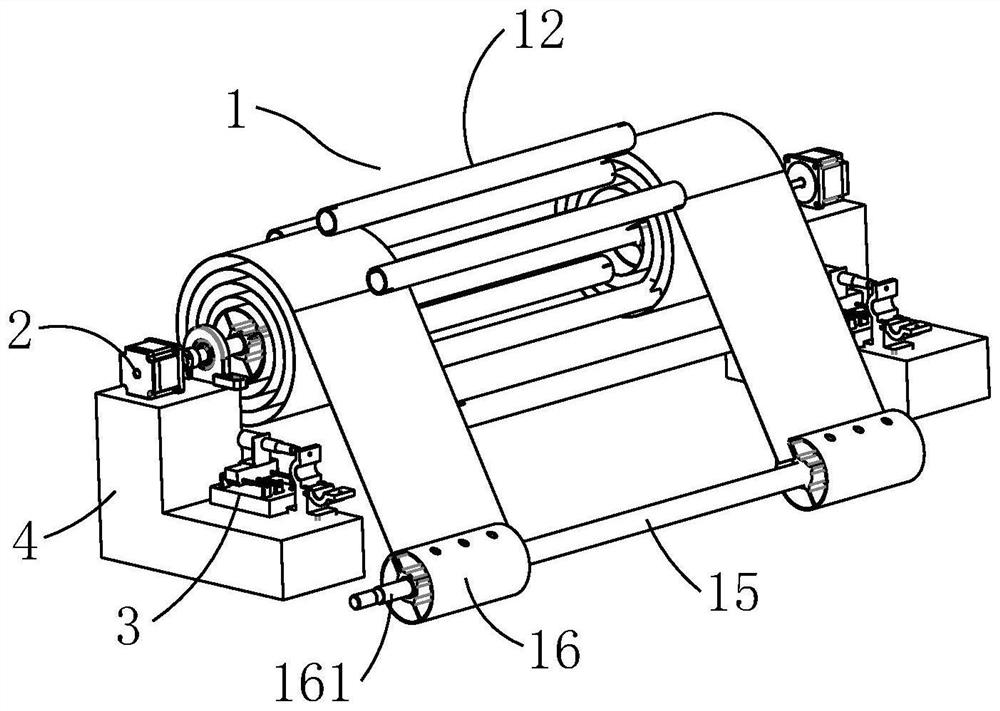

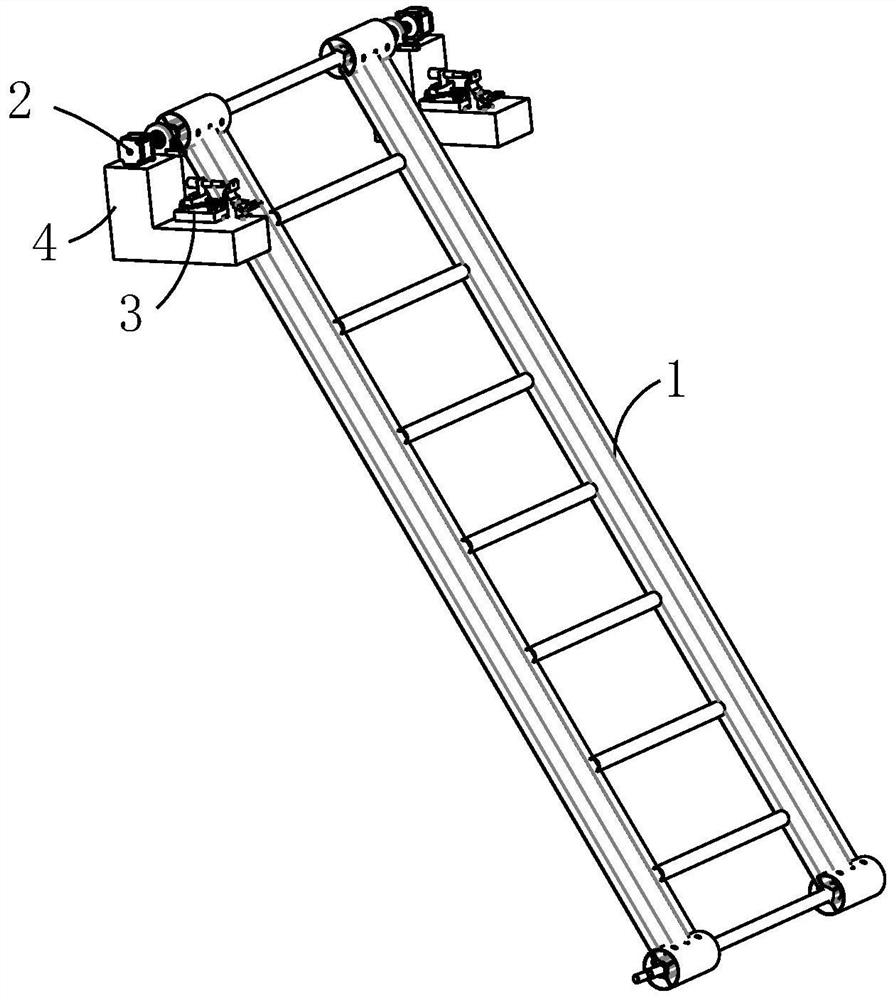

Expandable landing ladder with shape memory effect

ActiveCN108657471AHighly compressibleReduce volumeSystems for re-entry to earthCosmonautic landing devicesMemory effectShape-memory alloy

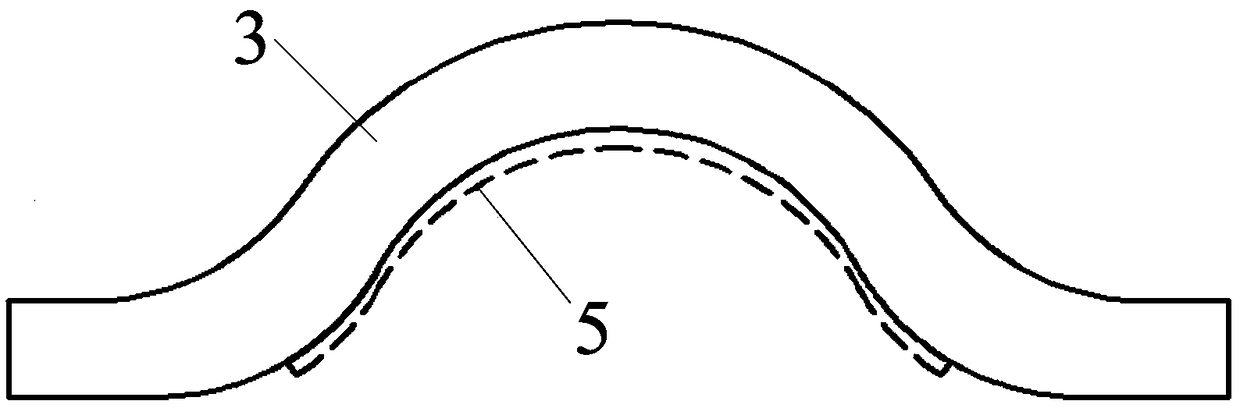

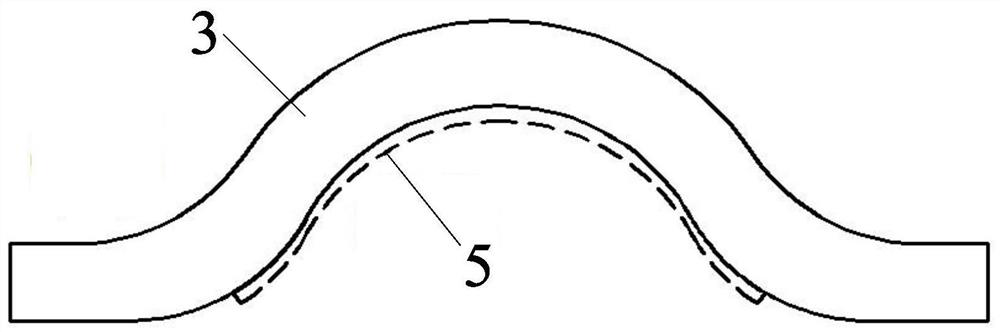

The invention discloses an expandable landing ladder with a shape memory effect and relates to the field of spaceflight. The expandable landing ladder is used for solving the problem that an existinglanding ladder is complex in structure and large in weight and consequently bears the large weight during launching. Two omega-shaped shape memory composite beams are oppositely closed; a gap betweenthe two omega-shaped shape memory composite beams is filled with shape memory foam; two resistance-type heating sheets are pasted to the inner surfaces of the two omega-shaped shape memory composite beams correspondingly, and the resistance-type heating sheets are used for increasing the temperature of the omega-shaped shape memory composite beams to be larger than the glass-transition temperatureof the omega-shaped shape memory composite beams in the power-on state, so that the omega-shaped shape memory composite beams are expanded; and the shape memory foam has compressibility and is used for providing the extra bearing capacity for expanding of the omega-shaped shape memory composite beams. The expandable landing ladder serves as an important bridge for connecting a lander with the surface of a planet.

Owner:HARBIN INST OF TECH

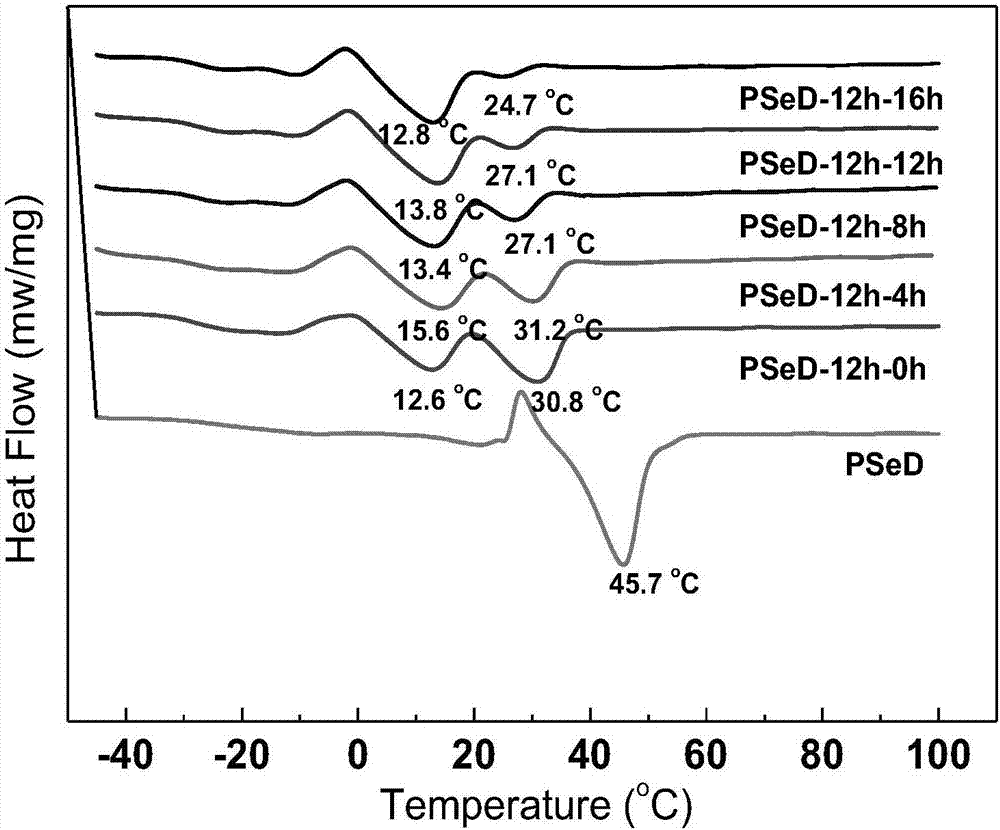

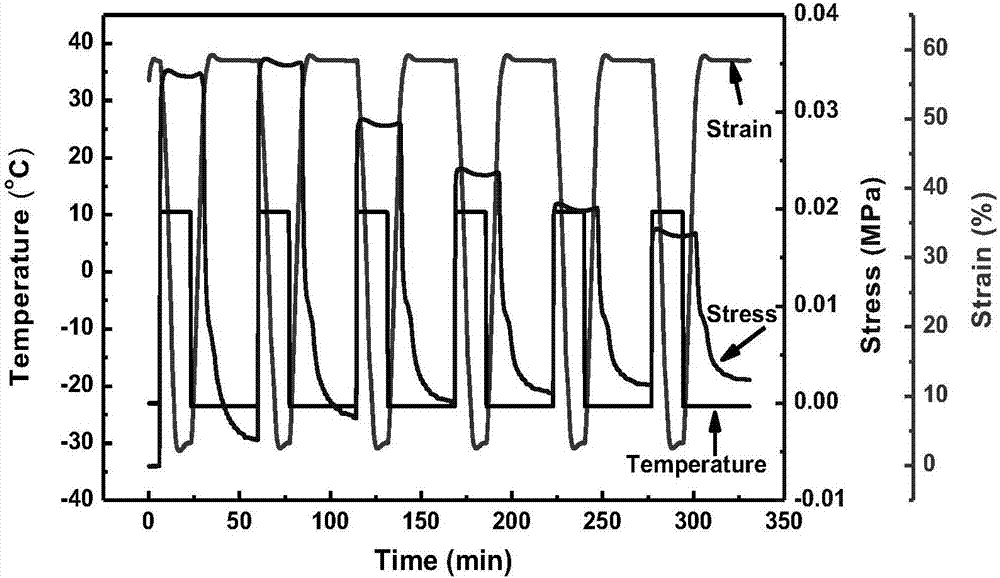

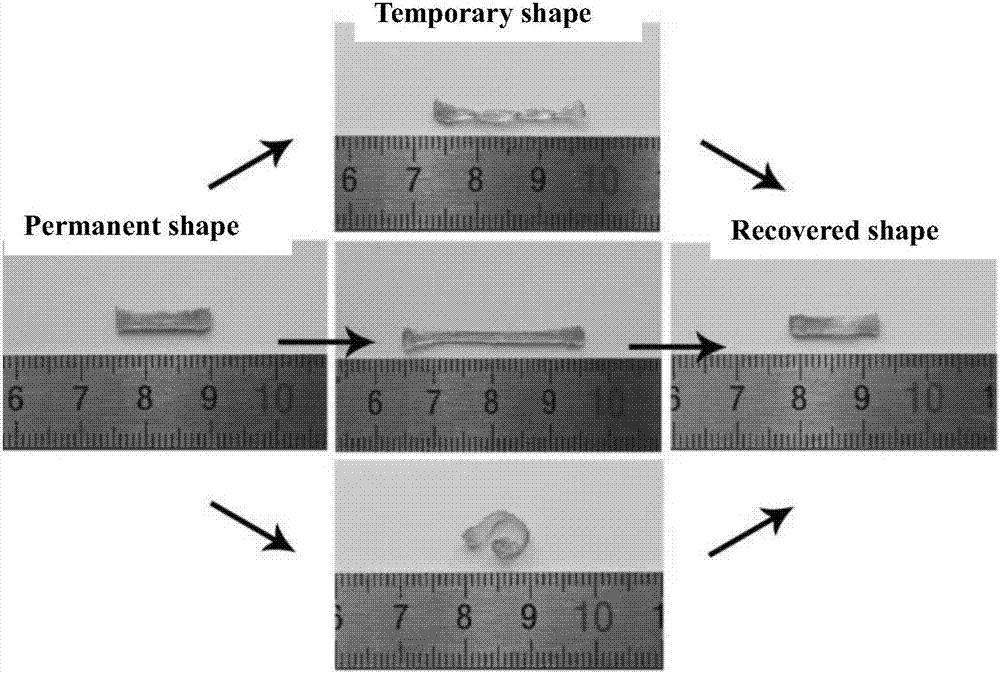

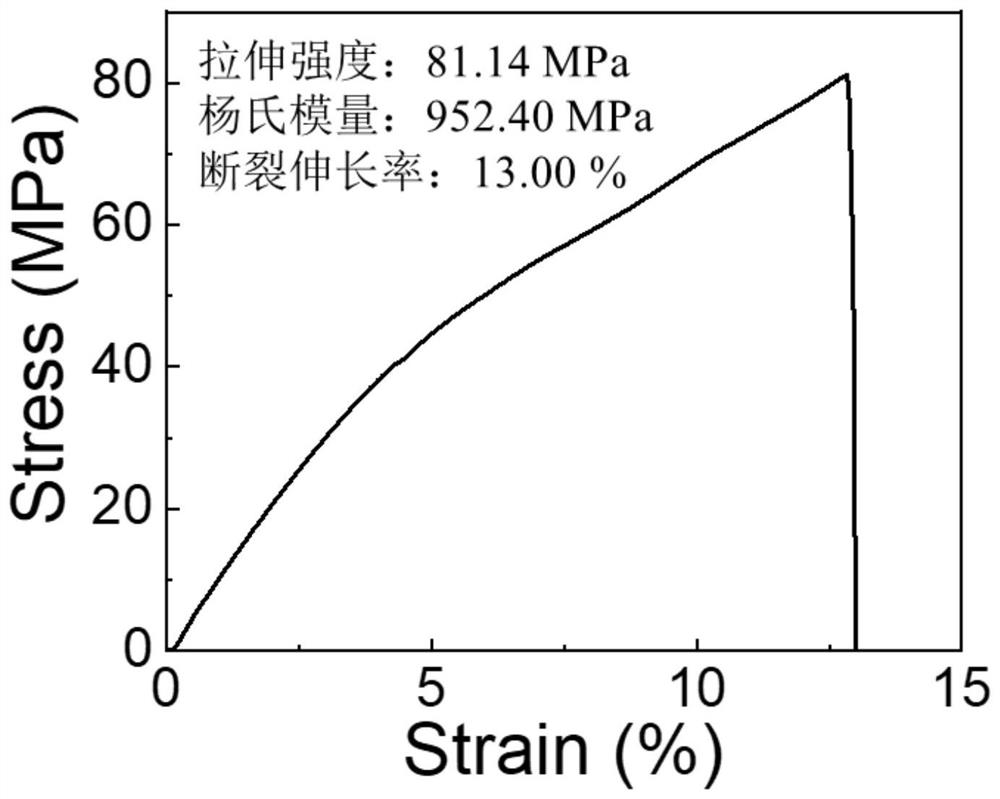

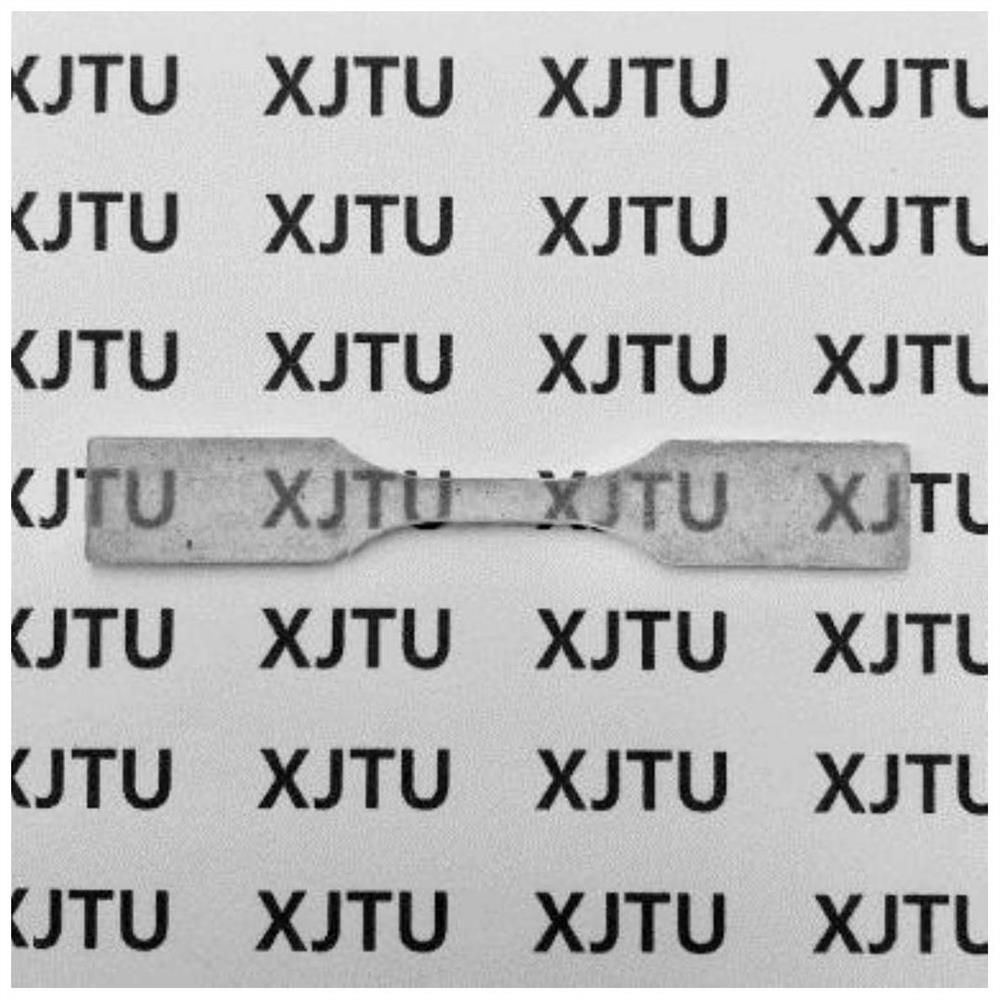

Preparation method of poly(sebacoyl diglyceride) shape memory elastomer

The invention relates to a preparation method of poly(sebacoyl diglyceride) shape memory elastomer. The preparation method \ comprises the following steps: (1) preparing a monomer sebacoyl glycidyl ester; (2) preparing poly(sebacoyl diglyceride); and (3) preparing the poly(sebacoyl diglyceride) shape memory elastomer. The crosslinking degree of PSeD is adjusted to make the crosslinked PseD have elasticity, shape memory effect and thermoplasticity; and the crosslinked PSeD has good shape memory performance, the shape transition temperature is between room temperature and the human body temperature, and the crosslinked PSeD is expected to be developed temperature response shape memory smart materials (the shape memory performance nearby the human body temperature is realized).

Owner:DONGHUA UNIV

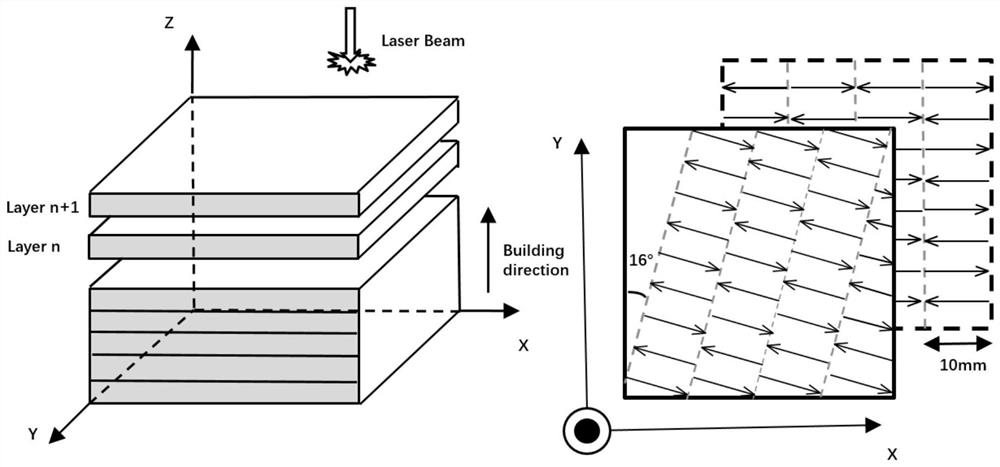

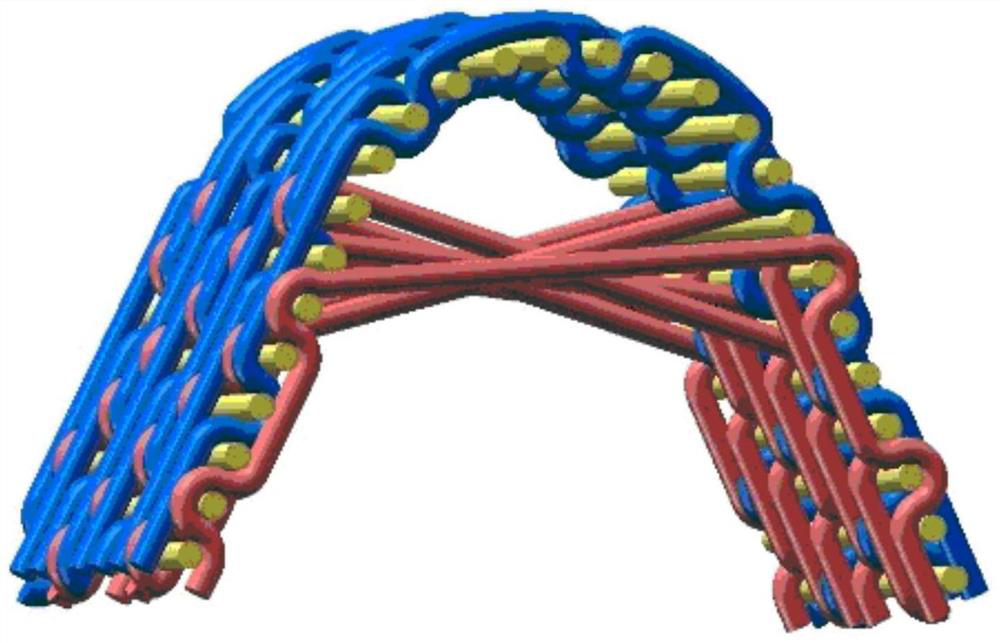

Manufacturing method of nickel-titanium alloy component, and nickel-titanium alloy component

PendingCN113351880AHigh precisionExcellent repeatable energy absorption - repeated recovery performanceAdditive manufacturing apparatusIncreasing energy efficiencyNi elementLarge deformation

The invention provides a manufacturing method of a nickel-titanium alloy component, and the nickel-titanium alloy component. The manufacturing method comprises the following steps: 1) nickel-titanium alloy powder is pre-arranged to form a to-be-treated layer, and in the nickel-titanium alloy powder, the atomic percent of Ni element is 49.8%-50.8%, and the balance is Ti atoms; 2) laser melting treatment is carried out on the to-be-treated layer according to printing process parameters to form a target layer; 3) the step 1) to the step 2) are repeatedly executed, and the nickel-titanium alloy component is formed; in the laser melting treatment, the laser power ranges from 90 W to 150 W, and the laser scanning speed ranges from 400 mm / s to 1200 mm / s; and the nickel-titanium alloy component is of a porous structure. The method is simple and easy to operate, the raw materials and the manufacturing parameters of the nickel-titanium alloy component are limited, the prepared nickel-titanium alloy component can show high shape recovery after large deformation greater than or equal to 50%, and a high shape recovery rate can still be kept after multiple times of cyclic deformation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of n with shape memory effect x m y High entropy alloy and its preparation method

ActiveCN105296836BPhase transition temperature wideHas shape memory effectChemical compositionHigh entropy alloys

Owner:UNIV OF SCI & TECH BEIJING

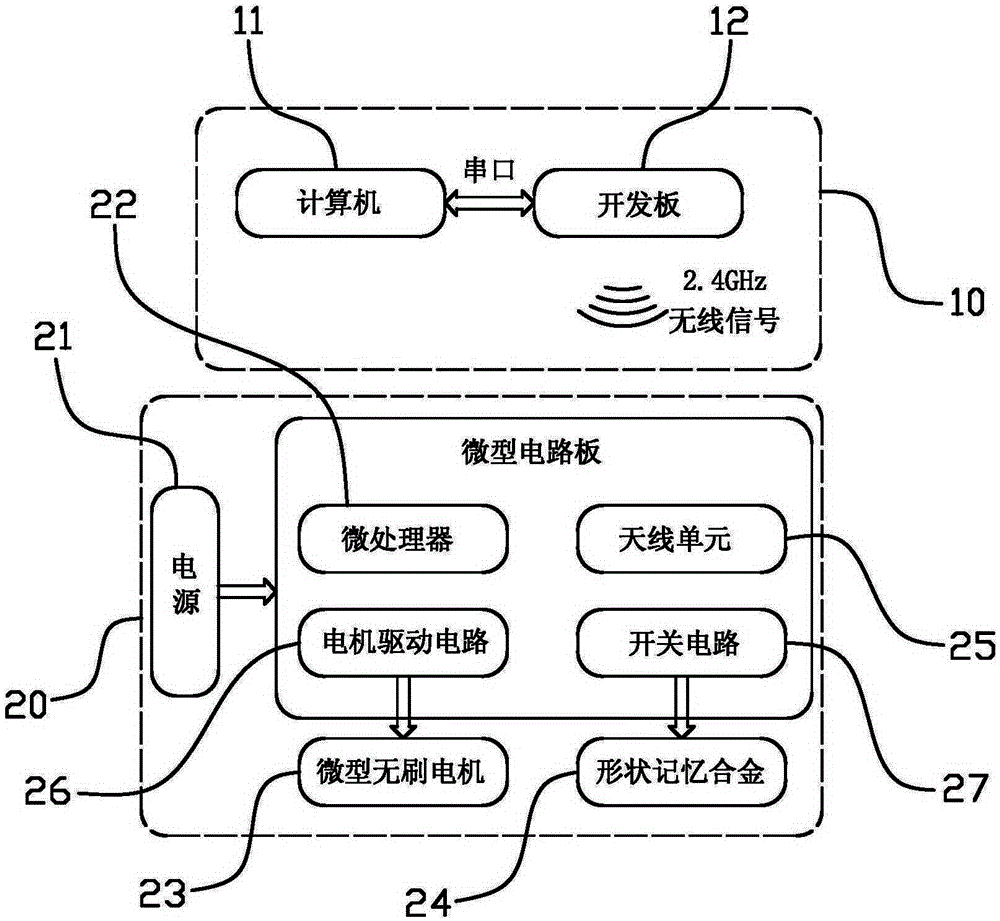

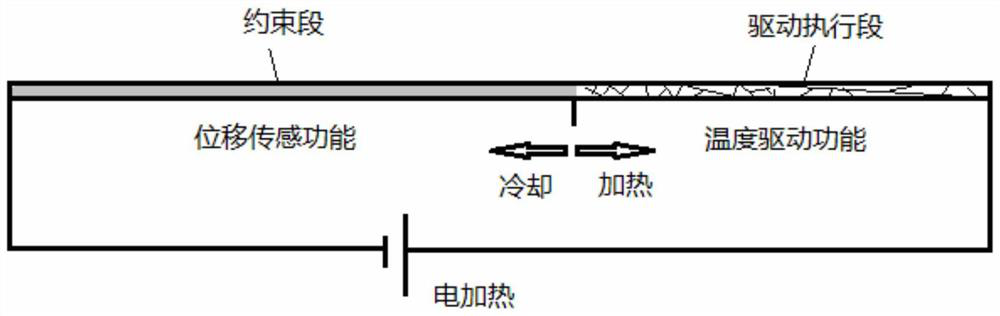

Miniature wireless control platform

InactiveCN105388810AHas shape memory effectSimple structureProgramme controlComputer controlAutomatic controlAutomatic train control

The invention belongs to the technical field of automatic control, and particularly relates to a miniature wireless control platform. The miniature wireless control platform includes a general control platform that transmits a control signal and a miniature control module that receives the control signal, wherein the miniature control module includes a power supply, a microprocessor, a miniature brushless motor and a shape memory alloy, the power supply supplies power to the microprocessor, the microprocessor processes the control signal and drives action of the miniature brushless motor and the shape memory alloy, and the shape memory alloy acts to realize rotor position detection of the miniature brushless motor. The shape memory alloy has a shape memory effect, and can realize shape changes of stretch and contraction according to the temperature of itself, and through replacement of a position sensor with the shape memory alloy, the miniature wireless control platform is simple in structure, small in size and low in cost, and has a relatively long service life at the same time.

Owner:CHERY AUTOMOBILE CO LTD

Self adaptive lead-free solder component and preparation method thereof

InactiveCN1962157ATightly boundHas shape memory effectWelding/cutting media/materialsSoldering mediaNickel titaniumSelf adaptive

The invention relates to a tin-silver-zinc self-adapt leadless solder with shape memory function and relative preparation, wherein in the tin-silver-zinc leadless solder whose purity is 99.99% and mass percentages are 96.5-93: 3.0-4.5: 0.5-2.5, there is silver-zinc metal phase with shape memory function; then it adds 0-2.5 gallium and 0-4 indium to improve humidity. The invention uses the silver-zinc thermoelasticity martensite of solder to obtain shape memory function. And it has compact combination and uniform distribution, compared with nickel-titanium alloy leadless solder.

Owner:TIANJIN UNIV

A kind of novel non-magnetic stainless steel and preparation method thereof

The invention discloses novel non-magnetic stainless steel which consists of the following components in percentage by weight (% hereinafter being percentage by weight): 0.15%-0.21% of carbon, 3%-5% of nickel, 8%-13% of chromium, 8%-11% of manganese, 4%-5% of silicon, 0.48%-0.65% of niobium, 0.13%-0.47% of vanadium, 1.2%-1.7% of molybdenum, 3%-4% of titanium, 0.27%-0.33% of rare earth, less than or equal to 0.035% of phosphor and sulfur, and the balance of iron and other inevitable impurities. Based on the original non-magnetic stainless steel, the novel non-magnetic stainless steel has highly improved mechanical performance by changing alloy components and adding a novel component; meanwhile, the structural texture of steel is changed by changing a preparation process and controlling the parameters in the process, so that the obtained steel is good in various performances, high in corrosion resistance, good in shape memory effect and especially suitable for pipeline connection on ships and warships.

Owner:东莞市雅鲁实业有限公司

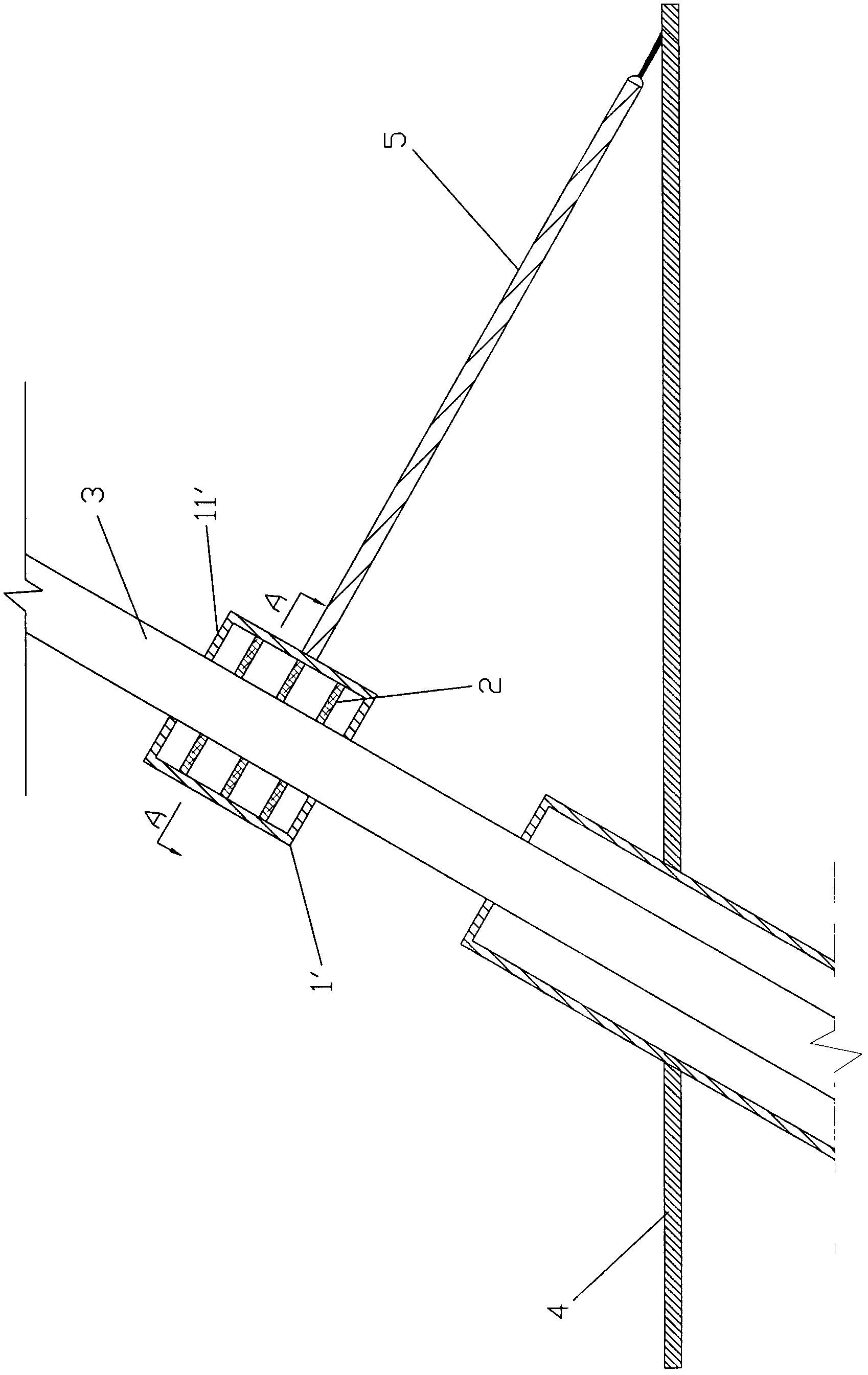

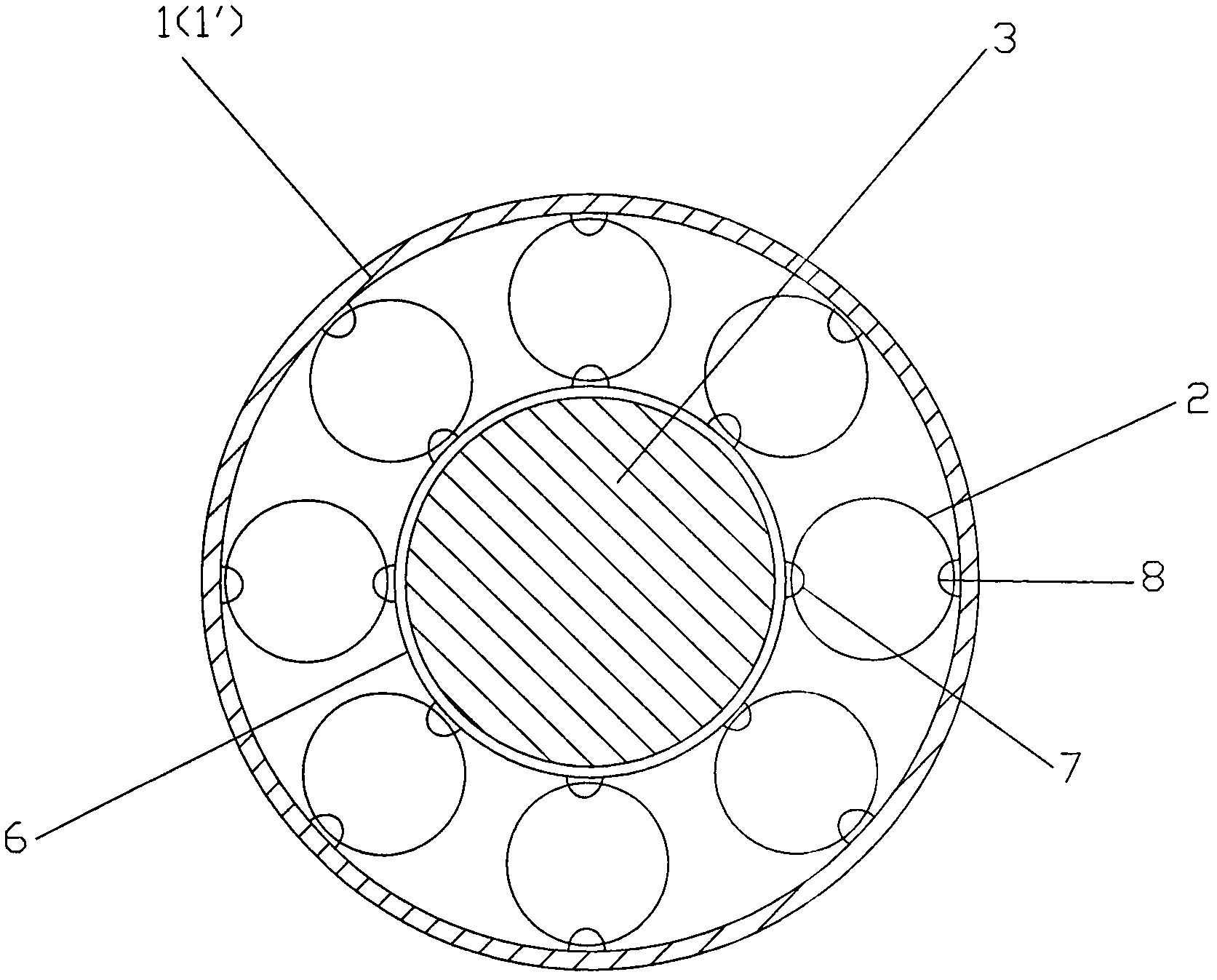

Shock absorption damping device for bridge cable or suspender

ActiveCN102518040BSimple structureSolution to short lifeBridge structural detailsMemory effectSelf recovery

The invention relates to a shock absorption damping device for a bridge cable or suspender. The device comprises a sleeve and a shock absorption ring, wherein the sleeve is sleeved on the cable or suspender; a space exists between the inner side wall of the sleeve and the cable or suspender; and the shock absorption ring is made from shape memory alloy and located between the sleeve and the cable (or suspender). In the shock absorption damping device provided by the invention, as the shock absorption ring is made from shape memory alloy which has excellent characteristics such as shape memory effect, super elasticity and the like, the energy consumption performance and great-deformation self-recovery ability of the shock absorption cable (or suspender) device can be enhanced, and a good durability is obtained at the same time. The shock absorption ring is located between the cable (or suspender) and the sleeve to form a damping structure system with the sleeve, thereby improving the vibration damping of the cable (or suspender) and effectively suppressing vibration caused by various excitations. Moreover, the shock absorption damping device also has the advantages of simple structure, long service life and the like, and is convenient to construct and maintain and easy to manufacture and mount.

Owner:SHENZHEN UNIV

A preparation method of shape memory polycaprolactone foam and its driving method

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

A 4D printing photosensitive resin based on dynamic covalent bond and its preparation method

ActiveCN112707984BAchieve remodelingAchieve degradationAdditive manufacturing apparatusMethacrylateThiocarbamate

The invention discloses a 4D printing photosensitive resin based on a dynamic covalent bond and a preparation method thereof. The photosensitive resin is a reaction product of a dihydric mercaptan, a (meth)acrylate monomer containing an isocyanate group, and a photoinitiator. The preparation method of the photosensitive resin comprises the following steps: After mixing a certain proportion of dihydric mercaptan, (meth)acrylate containing isocyanate group and catalyst, reacting at room temperature for 1 to 3 hours, and then adding photoinitiator , to obtain a remodelable, degradable and recyclable, high-strength 4D printing photosensitive resin. The entire synthesis process does not involve the use of solvents. The photosensitive resin of the present invention utilizes the dynamic reversibility of the thiourethane bond to achieve remodeling and degradation. Recycling , using the double bond radical polymerization in (meth)acrylate to realize photocuring 3D printing, and using the shape memory effect of the material to realize 4D printing.

Owner:XI AN JIAOTONG UNIV

A deployable landing ladder with shape memory effect

ActiveCN108657471BHighly compressibleReduce volumeSystems for re-entry to earthCosmonautic landing devicesStructural engineeringSpaceflight

An expandable landing ladder with shape memory effect relates to the aerospace field. The invention aims to solve the problem that the existing landing ladder has a complex structure and a large weight, which causes a large weight to be carried during launch. Two Ω-shaped shape-memory composite beams butt joints, the shape-memory foam is filled in the gap between the two Ω-shaped shape-memory composite beams, and the inner surfaces of the two Ω-shaped shape-memory composite beams are pasted with A resistive heating sheet, a resistive heating sheet, is used to raise the temperature of the Ω-shaped shape-memory composite beam above its glass transition temperature in the energized state, so that the Ω-shaped shape-memory composite beam expands, and the shape-memory foam Being compressible, shape-memory foam is used to provide additional load-carrying capacity for the deployment of Ω-shaped shape-memory composite beams. It serves as an important bridge between the lander and the planet's surface.

Owner:HARBIN INST OF TECH

A 4D printing shape memory polymer composite tracheal stent and its preparation method

ActiveCN108969165BPromote degradationGood biocompatibilityGeometric CADStentsElectrospinning4d printing

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

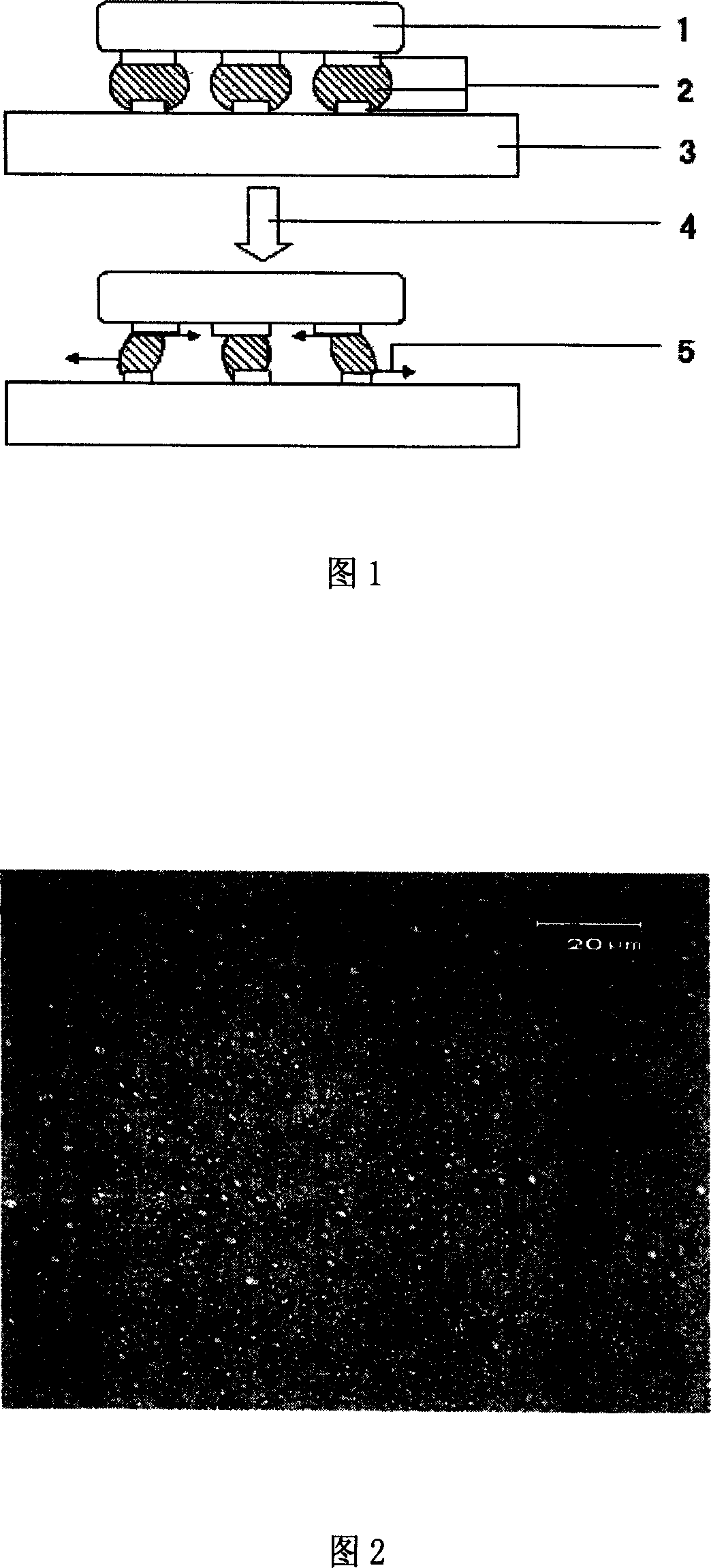

Shape memory Co-Zn-Al alloy grains reinforced composite Sn-Ag welding material and its prepn process

InactiveCN1313240CHas shape memory effectImprove wettabilityWelding/cutting media/materialsSoldering mediaWorking temperatureShape-memory alloy

The present invention belongs to the field of composite lead-free welding material technology. The composite welding material contains lead-free welding material of Sn and Ag in the weight ratio of 96.5 to 3.5 and shape memory alloy of Cu, Zn and Al in the weight ratio of 66-74 to 24-28 to 2-6 and grain size of 20-50 microns in the content of 1-5 wt%. The preparation process of the composite welding material includes the following steps: preparing eutectic lead-free welding material through smelting with Sn and Ag in purity of 99.99 %; preparing the shape memory alloy thermoelastic martensite of Cu, Zn and Al; and hot mixing the shape memory alloy grains and the eutectic lead-free welding material and water cooling. The composite welding material can prolong the service life of weld spot in varying work temperature owing to the shape memory effect.

Owner:TIANJIN UNIV

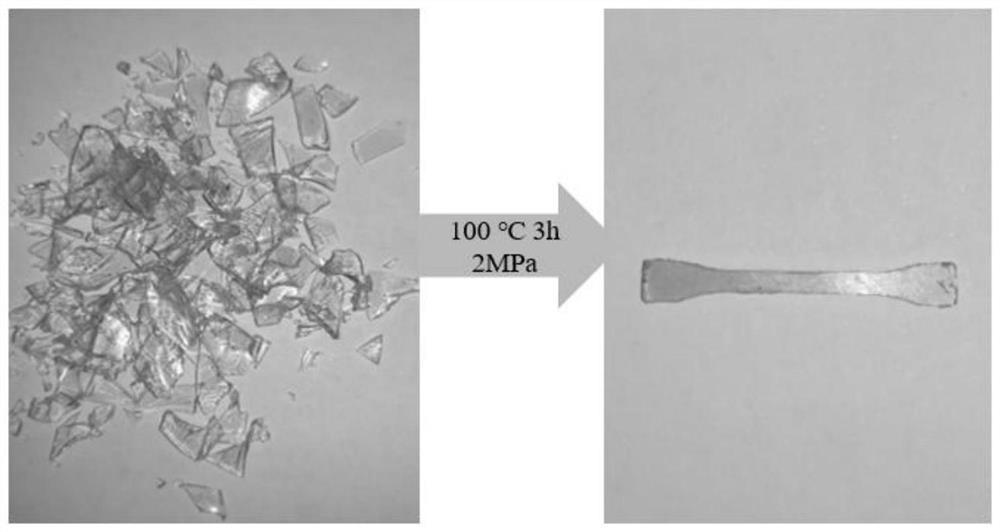

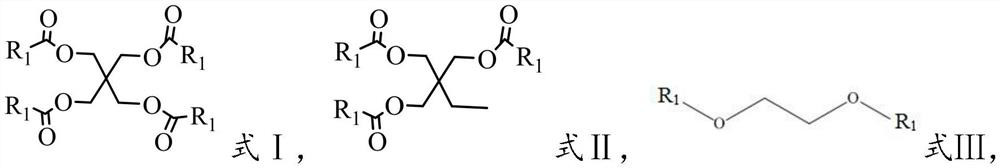

Non-isocyanate-based polyurethane monomer, thermosetting non-isocyanate-based shape memory polyurethane and preparation and recycling methods of non-isocyanate-based polyurethane monomer and thermosetting non-isocyanate-based shape memory polyurethane

PendingCN114773307AIncrease the degree of cross-linkingHigh mechanical strengthOrganic chemistryPlastic recyclingPolymer scienceDouble bond

The invention provides a non-isocyanate-based polyurethane monomer and thermosetting non-isocyanate-based shape memory polyurethane as well as preparation and recycling methods thereof, and relates to the technical field of polyurethane synthesis. The non-isocyanate group polyurethane monomer provided by the invention has a structure as shown in a formula I to a formula III. The non-isocyanate-based polyurethane monomer provided by the invention has a plurality of five-membered cyclic carbonates, and polyurethane generated after a cross-linking reaction with polybasic primary amine has a shape memory effect and is programmable in shape; the polyurethane has excellent mechanical properties, and is high-strength non-isocyanate-based polyurethane; recycling can be achieved through simple hot pressing, and therefore durability and environment friendliness are achieved. According to the preparation method of the non-isocyanate polyurethane monomer, cyclic carbonate with double bonds and mercaptan are subjected to a click reaction to prepare the polyurethane monomer with multiple five-membered cyclic carbonate, the reaction is rapid and efficient, and the reaction time does not exceed 10 min.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

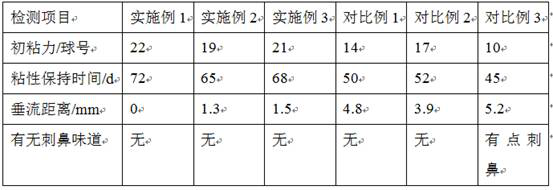

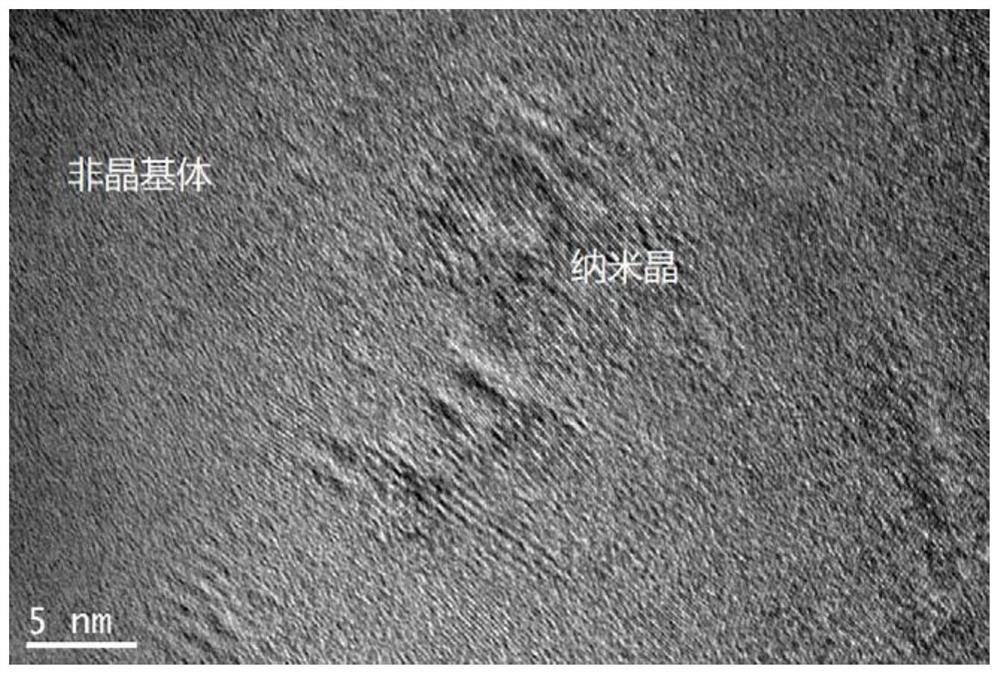

sticky shellac for tree trunk

ActiveCN109280538BHas shape memory effectEasy to stretchNon-macromolecular adhesive additivesWax adhesivesTree trunkChemical compound

The invention relates to an insect sticking glue for tree trunks, and belongs to the technical field of diseases and insect pests prevention and treatment. A hydrogen-bond-reinforced tear-resistant shape memory hydrogel base material is synthesized with polyethylene glycol, N,N-dimethylacrylamide and other raw materials, the base material has good tensile properties, and the good tensile resistance effect can be realized without the need for external additives to realize driving; an added self-made auxiliary agent has an amphiphilic property, and vesicles can be formed in the system by self-assembly of the auxiliary agent, and an environment-friendly multi-related insect sticking glue system is formed through relations of environment-friendly insect sticking and insecticidal effects, photosynthesis of plants and the growth of the vesicles; and longicorn beetles are subjected to the pretreatment culture to stimulate the secretion of gastric juice and hormone-like compounds in vivo, themildew of the insect sticking glue is avoided by the cooperation with a porous structure of the colloid, and then the high tensile resistance and the environment-friendly performance can be maintainedfor a long time. The problems of poor tensile resistance and poor environment-friendly performance of commonly used insect sticking glues at present are solved.

Owner:刘伟萍

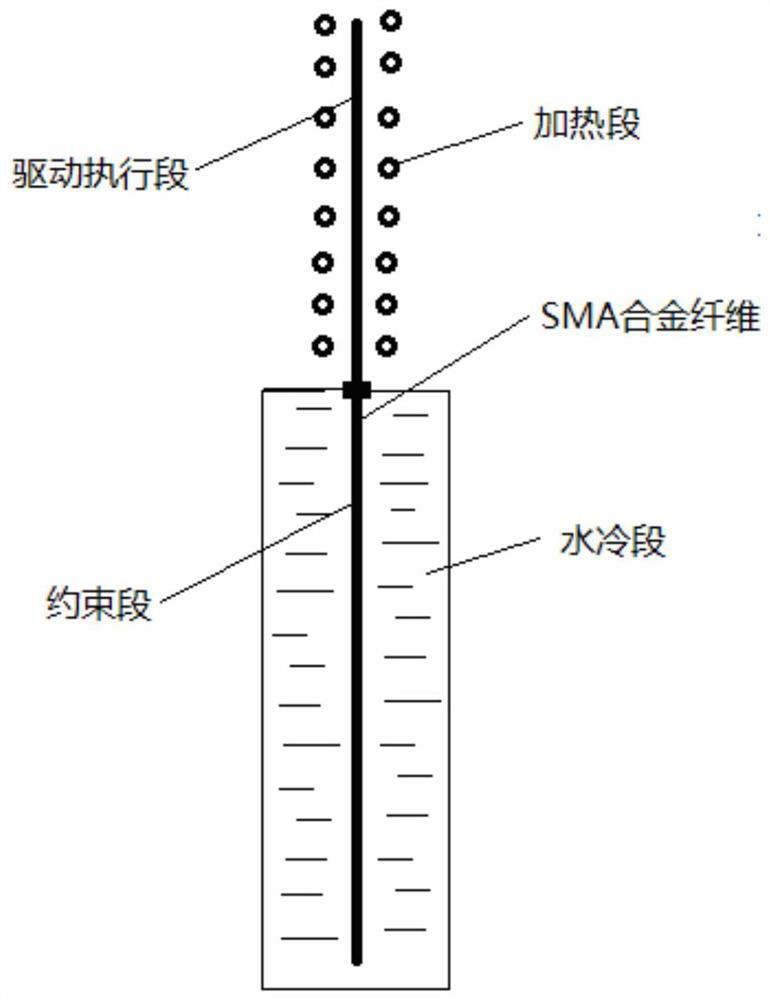

Shape memory alloy driving element

PendingCN114109752AHas shape memory effectHigh strengthMachines/enginesMechanical power devicesPhysicsSurgical instrument

Owner:SHANGHAI JIAO TONG UNIV

Self adaptive lead-free solder component preparation method

InactiveCN100411804CHas shape memory effectGood serviceWelding/cutting media/materialsSoldering mediaIndiumZinc metal

Owner:TIANJIN UNIV

A landing ladder with dual functions of unfolding and retracting

ActiveCN109533395BHas shape memory effectReduce consumptionCosmonautic vehiclesCosmonautic partsStructural engineeringMechanical engineering

The invention provides a landing ladder having the dual functions of unfolding and take-back. The landing ladder comprises a main ladder structure, a locking mechanism and a rotary take-back mechanism; the main ladder structure has a shape memory effect and comprises a first end and a second end; the rotary take-back mechanism is connected with the first end and drives the first end to rotate; thelocking mechanism is detachably connected with the second end and locks or unlocks the second end, wherein the main ladder structure can be unfolded or taken back and is curled at the first end or the second end when the locking mechanism locks the second end, and the main ladder structure is unfolded when the locking mechanism unlocks the second end. The main ladder structure is matched with thelocking mechanism and the rotary take-back mechanism to realize unfolding and curling, and the problems are solved that in a traditional design, mass is large, and the structure is complex.

Owner:HARBIN INST OF TECH

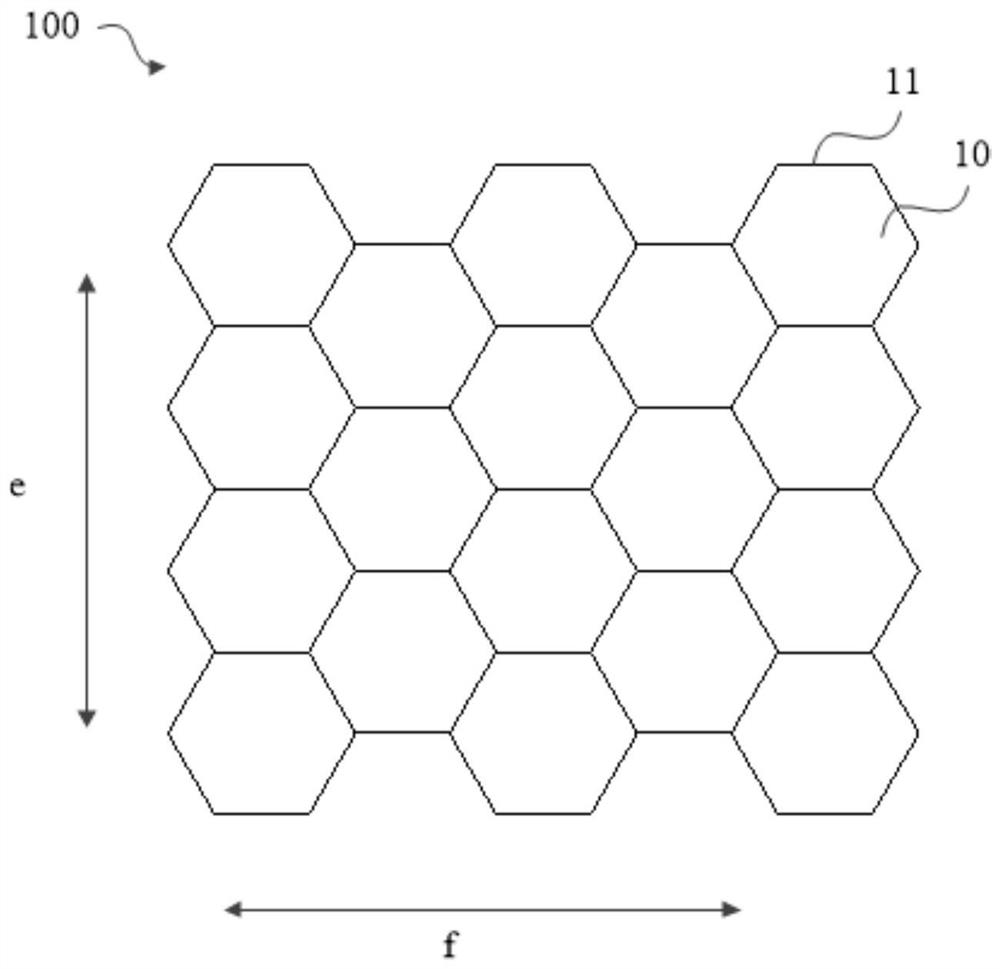

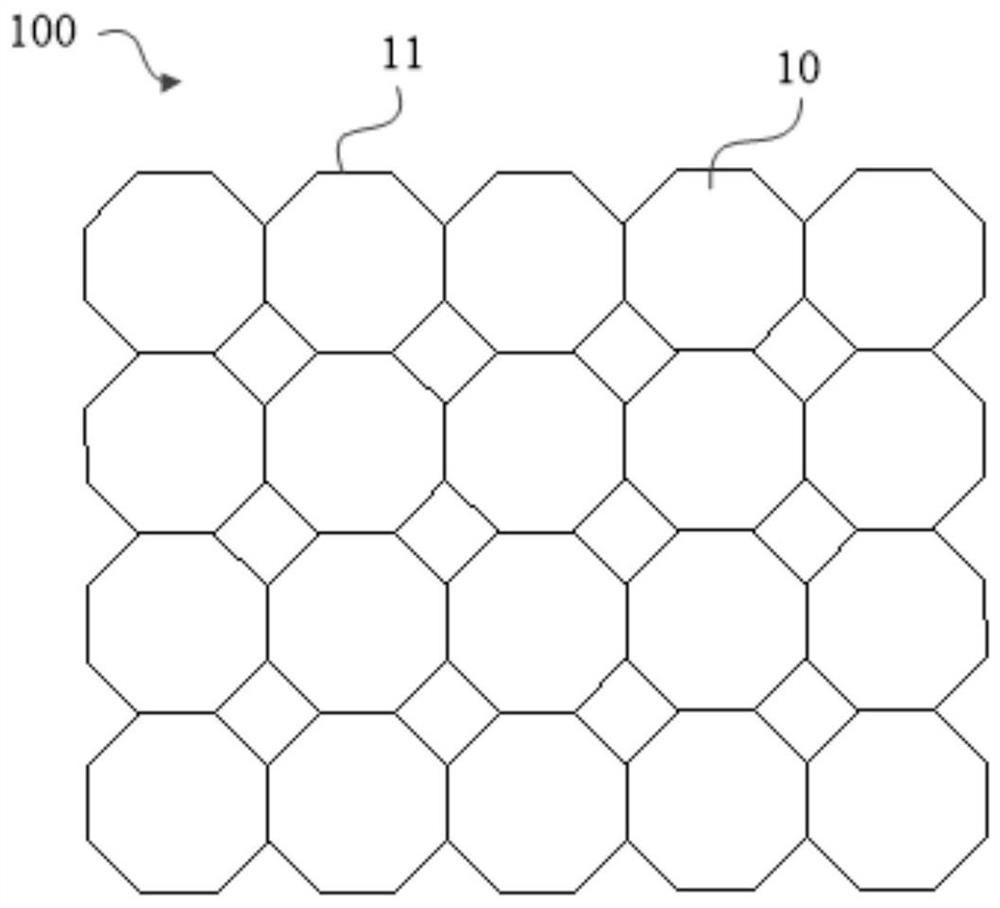

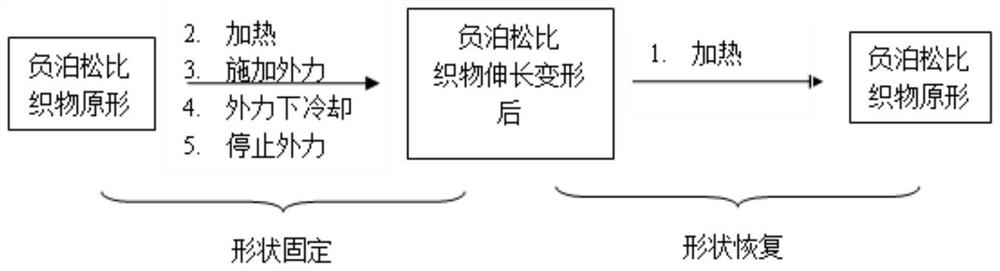

Forming method and application of high-shape-memory, high-flexibility and negative-Poisson-ratio fabric

PendingCN113897723AHas a negative Poisson's ratio effectHas shape memory effectPattern making devicesMulti-ply fabricsYarnStructural engineering

The invention discloses a forming method and application of a high-shape-memory high-flexibility and negative-Poisson-ratio fabric. The forming method comprises the steps of drawing a design drawing of a negative-Poisson-ratio fabric of a folding structure, and distinguishing a non-folding area and a folding area composed of a convex area and a concave area; selecting elastic yarns and non-elastic yarns; designing a fabric weave structure adopted by the elastic yarns and the non-elastic yarns; laying a weave on the design drawing according to the fabric weave structure; generating a pattern file; performing weaving on a weaving machine to form the negative-Poisson-ratio fabric of the folding structure; and loading a shape memory material on the woven negative-Poisson-ratio fabric or directly weaving the shape memory material in the weaving process. The weaving method is adopted for one-time forming; the fabric is endowed with the folding diversity, the structural stability, the negative-Poisson-ratio effect and the shape memory effect; the folding structure is subjected to bidirectional large deformation under excitation so as to generate the negative-Poisson-ratio effect and high flexibility; and the fabric can be restored to the initial form after excitation is removed.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com