Shape memory alloy driving element

A technology of memory alloy and driving components, which is applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., and can solve the problem that the volume of the intelligent actuator system cannot be further reduced, affects the accuracy of the actuator, and the design of the reed structure is complex, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0085] Example 1

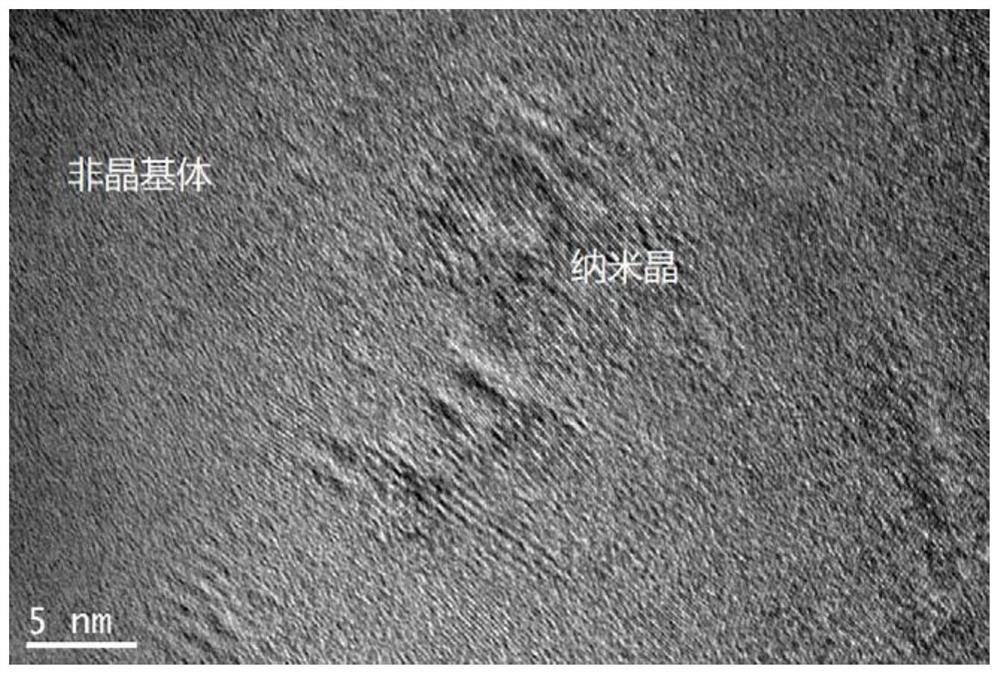

[0086] Select Ni 50.2 Ti 49.8 Shape memory alloy wire, continuous cold drawn, lowered the diameter of the wire, which makes it a fiber, and the fibers have a diameter of 1 mm. In the multi-channel cutting process, the first annealing process is performed between the adjacent two steps. In addition to the end cold drawing process outside the end cold drawing process, processing of 3 mold processing, single cold drawing, and the first annealing treatment is heated as a protective atmosphere. The temperature of the first annealing treatment was 450 ° C, and the time was 30 seconds, and the wire was pulled into a fiber having a diameter of 0.2 mm. After machining at 9% reduction rate, the first annealing treatment is no longer carried out, and only the non-crystalline / crystal correction structure is obtained. The intensity of non-crystalline / crystalline complex structure is ≥1800MPa, and the strain is ≥4%.

[0087] Then, the shape memory alloy fibers are divided...

Example Embodiment

[0089] Example 2

[0090] Select Ni 50.2 Ti 49.8Shape memory alloy wire, continuous cold drawn, lowered the diameter of the wire, which makes it a fiber, and the fibers have a diameter of 1 mm. In the multi-channel cutting process, the first annealing process is performed between the adjacent two steps. In addition to the end cold drawing process in the end cold drawing process, the processing of 6% reduction is processed, and the single cold pull is pulled out of 3 mold processing. The first annealing treatment is heated as a protective atmosphere. The temperature of the first annealing treatment was 400 ° C, and the time was 40 seconds, and the wire was pulled into a fiber having a diameter of 0.03 mm. After processing at a 7% reduction rate, the end cold drawing process is not processed, and only the first annealing treatment is carried out, only the obtained shape memory alloy fiber is straightened, and the non-crystalline / crystal correction structure is obtained. The intens...

Example Embodiment

[0093] Example 3

[0094] Select Ni 45 Ti 50 Cu 5 The shape memory alloy wire material is continuous, and the diameter of the wire material is continuous, so that it is fiber, the fiber has a diameter of 1.5 mm. In the multi-channel cutting process, the first annealing process is performed between the adjacent two steps. In addition to the end cold drawing process in the end cold drawing process, the processing of 6% reduction is processed, and the single cold pull is pulled out of 3 mold processing. The first annealing treatment is heated as a protective atmosphere. The temperature of the first annealing treatment was 550 ° C, the time was 30 seconds, and the wire was pulled to a fiber having a diameter of 0.1 mm. After machining at the end cold drawing process, the first annealing treatment is no longer carried out, and only the non-crystalline / crystal complex structure is obtained. The intensity of non-crystalline / crystalline complex structure is ≥1800MPa, and the strain is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com