Forming method and application of high-shape-memory, high-flexibility and negative-Poisson-ratio fabric

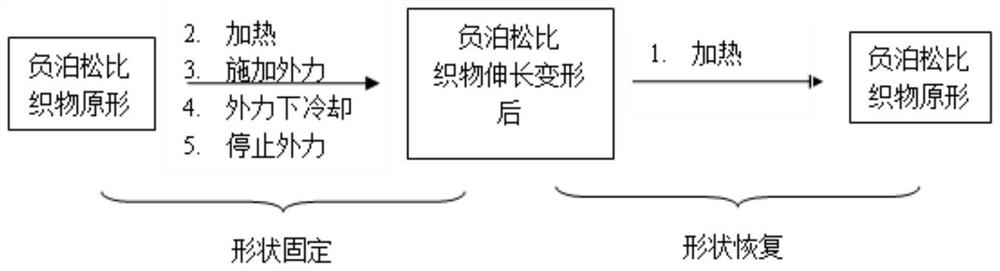

A technology of negative Poisson's ratio and forming method, which is applied in pattern design devices, textiles, papermaking, textiles, etc., can solve the problems of fixed wrinkle direction, small wrinkle cycle, and permanent effect, so as to improve structural stability, Increased diversity, promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

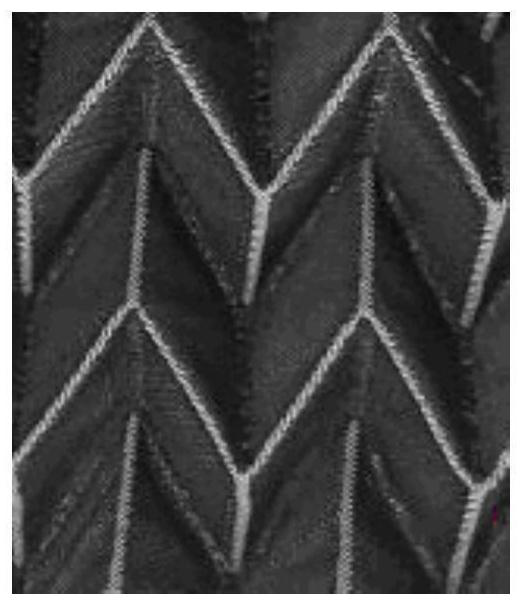

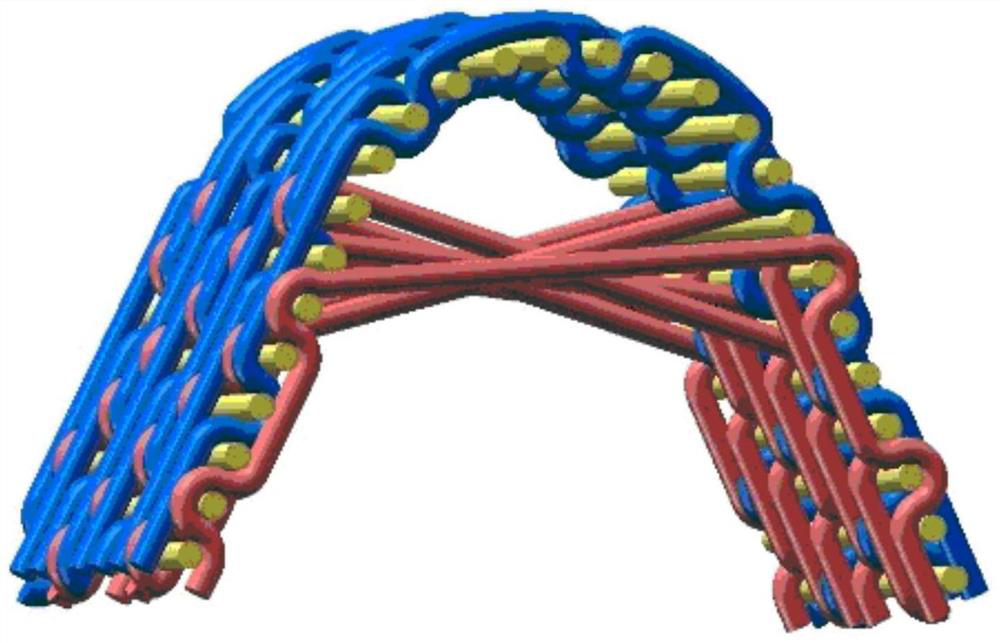

Embodiment 1

[0047] The non-elastic pure polyester is used as the warp yarn, the cotton-spandex blended yarn is used as the elastic weft yarn, and the shape-memory yarn is used as the core yarn in the elastic yarn. The shape-memory yarn has shape-memory function. At the same time, pure cotton yarn is used as non-elastic weft yarn, and weft double weaving is adopted. Elastic yarn in non-folding area uses four pieces of warp surface to make twill, non-elastic yarn uses eight pieces of three-flying weft surface twill, and elastic yarn in raised area For the whole warp weave point, the non-elastic yarn uses four pieces of right twill on the weft surface, the elastic yarn in the concave area is used as the full weft weave point, and the non-elastic yarn uses four pieces of right twill weave on the warp surface, using Miura folding structure to weave the fabric, Because the shape-memory yarn in the weft turns into a straightened spiral state at high temperature and can be fixed, a high-stretch fa...

Embodiment 2

[0049] Use pure cotton yarn as warp yarn, cotton-spandex blended yarn as elastic weft yarn, pure cotton yarn as non-elastic weft yarn, double weft weaving, plain weave for elastic weft yarn in non-folding area, plain weave for non-elastic weft yarn, and elastic in raised area The weft yarn is used as the whole warp weave point, the non-elastic weft yarn uses four pieces of right twill on the weft surface, the elastic weft yarn in the concave area is used as the full weft weave point, and the non-elastic weft yarn uses four pieces of warp surface right twill weave, weaving with Miura origami structure, after weaving The surface of the fabric is coated with temperature-sensitive shape-memory polyurethane. Under high temperature, the overall structure of the fabric shrinks and the fabric becomes thicker, thus ensuring the safety of the human body.

Embodiment 3

[0051] Elastic nylon yarn is used as warp yarn, cotton and ammonia wrapped yarn is used as elastic weft yarn, pure cotton yarn is used as non-elastic weft yarn, double weft weaving is adopted, elastic weft yarn in non-folding area uses four warp surfaces to make twill, and non-elastic weft yarn uses mountain line Twill weave, the elastic weft yarn in the convex area is used as the whole warp weave point, the non-elastic weft yarn is made of four weft right twill weaves, the elastic weft yarn in the concave area is used as the full weft weave point, the non-elastic weft yarn is used four warp surface right twill weave, weaving has a three-dimensional shape The wedding dress is coated with temperature-sensitive shape memory polymer. Due to its high elasticity, this wedding dress can be applied to more customers, especially suitable for the clothing rental market. At the same time, due to the shape memory function, this wedding dress can be worn on different customers. The same sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com