Patents

Literature

226results about How to "Good consolidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

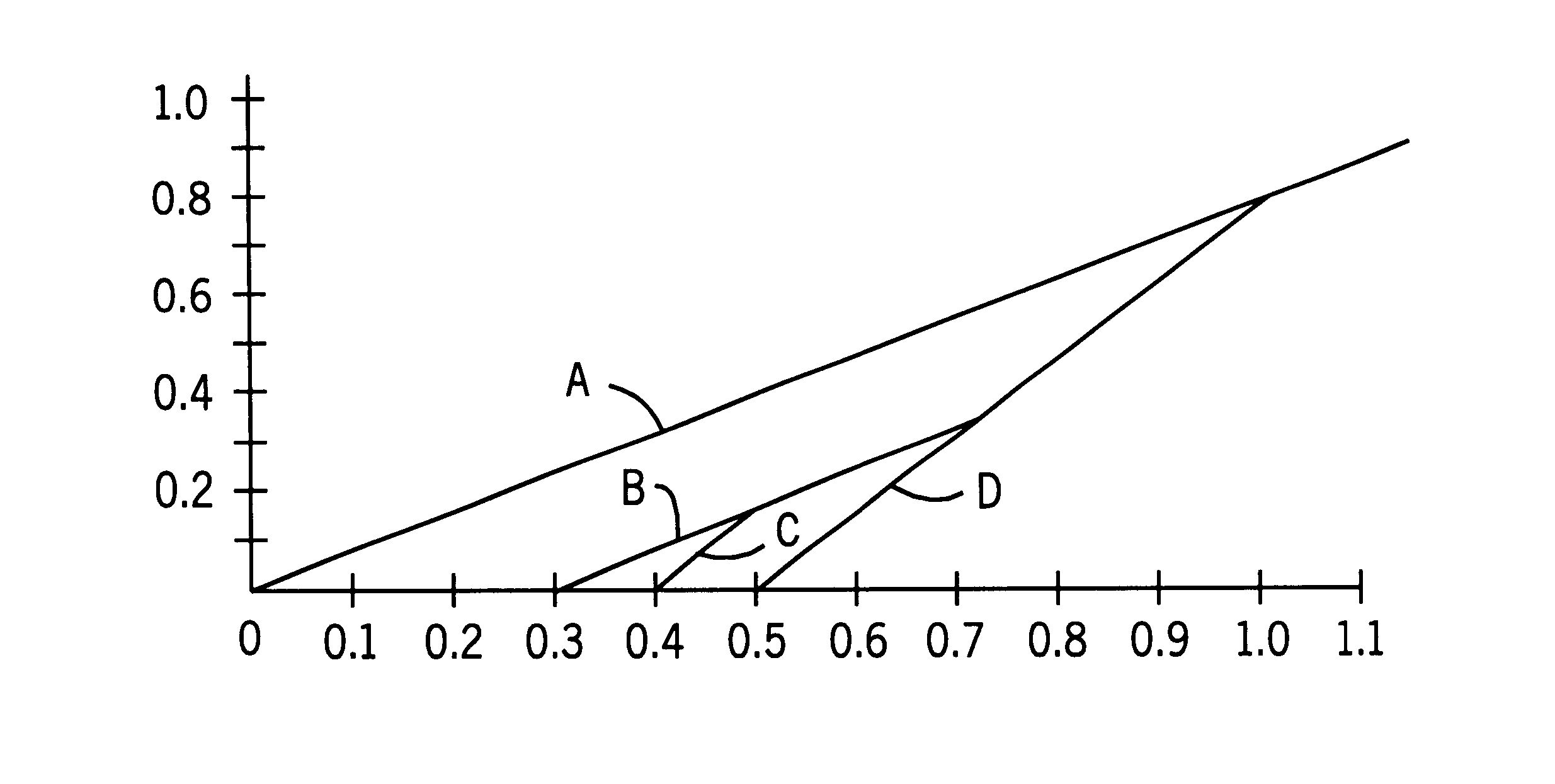

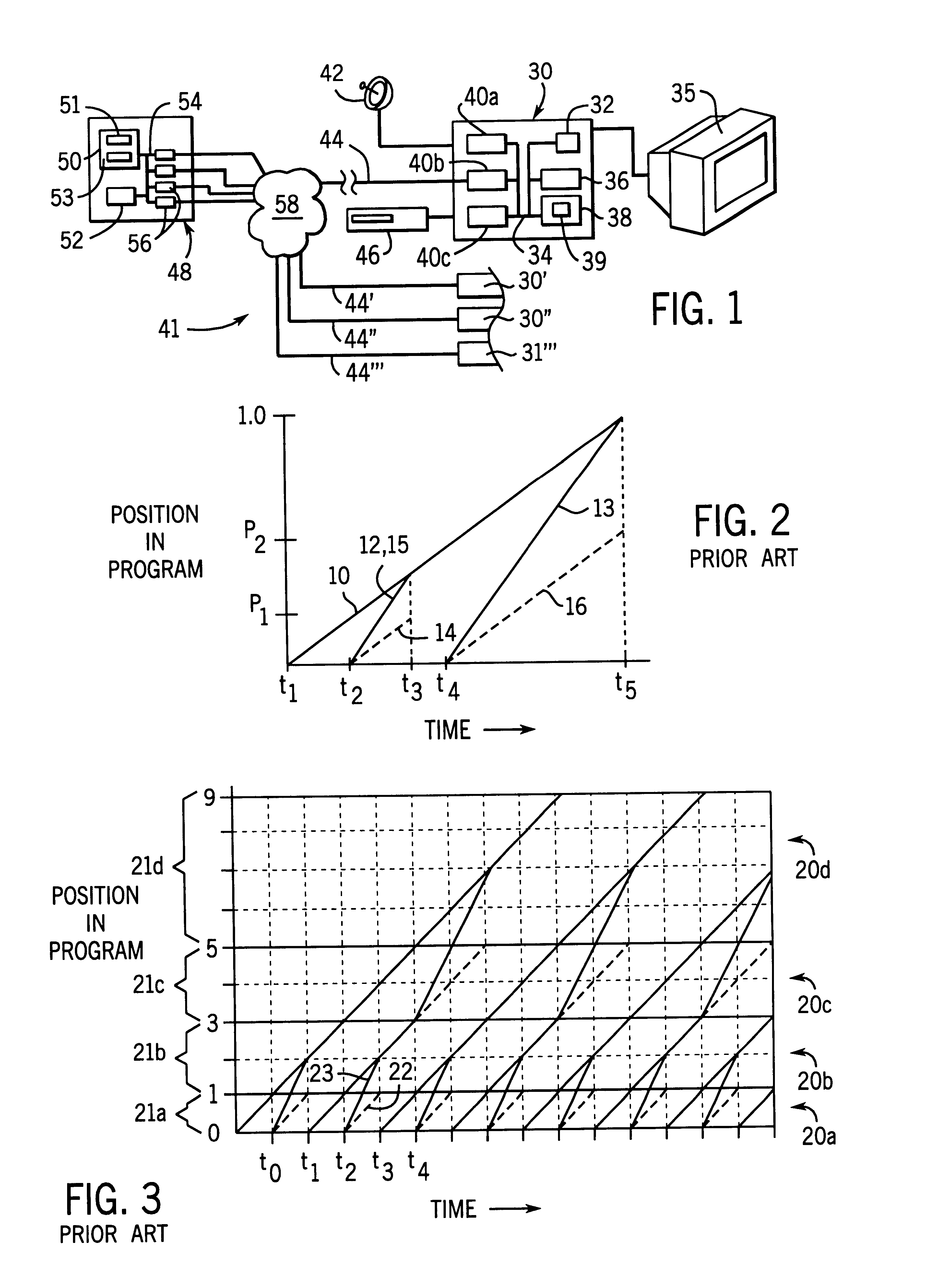

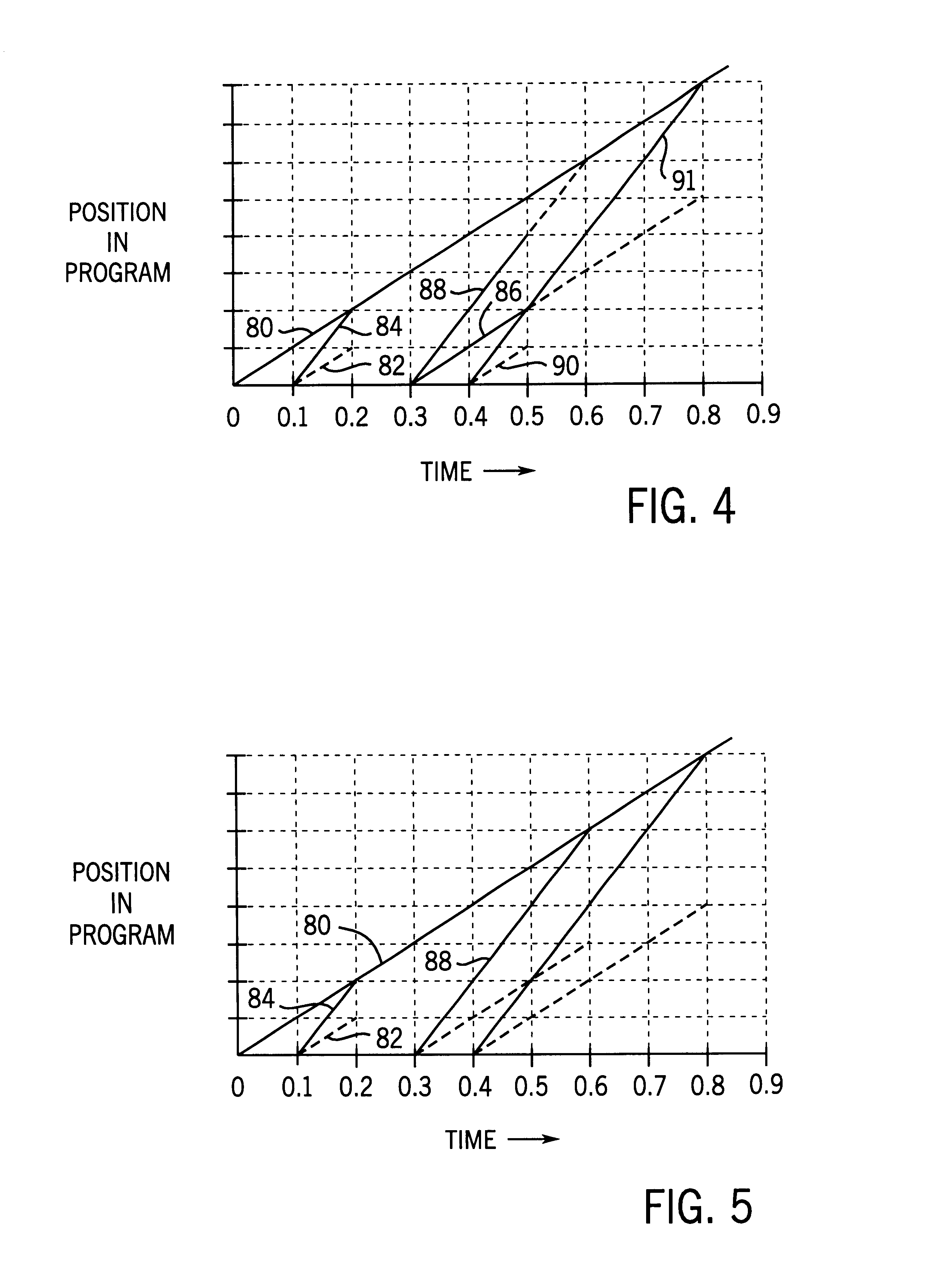

Bandwidth reduction of on-demand streaming data using flexible merger hierarchies

InactiveUS6859839B1Reduce bandwidth requirementsImprove good performanceMultiple digital computer combinationsTwo-way working systemsData streamStream data

A method of efficiently transmitting streamed data of a program to multiple clients requesting the program at different times ranks the requests in a multilevel hierarchy, which describes merging of data streams servicing the requests. The multilevel hierarchy changes dynamically as new requests arrive or existing data streams are merged to reduce the bandwidth or other costs required to serve the requests. The hierarchy may be established by simple rules or by a modeling of the actual cost of possible hierarchies.

Owner:WISCONSIN ALUMNI RES FOUND

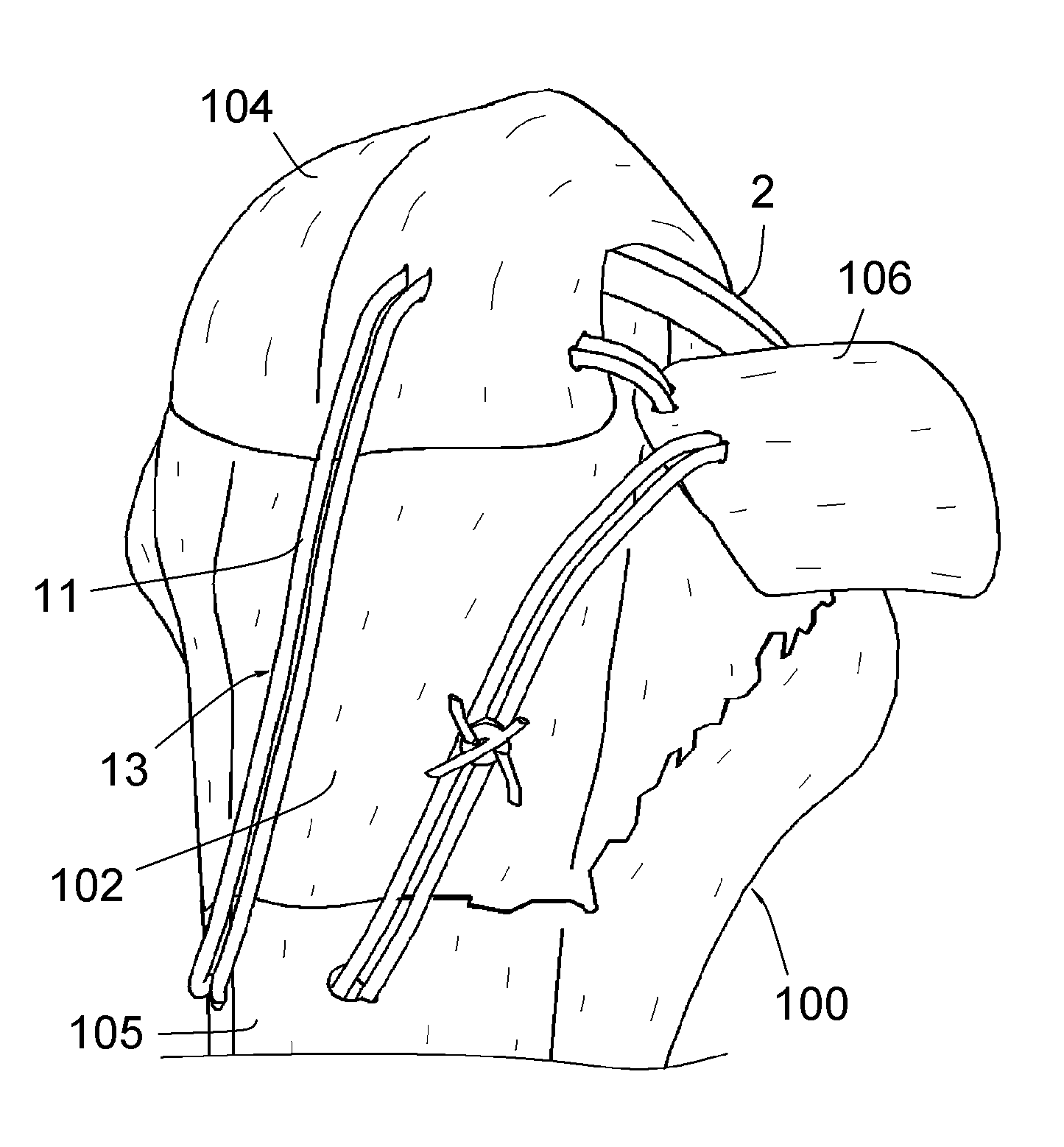

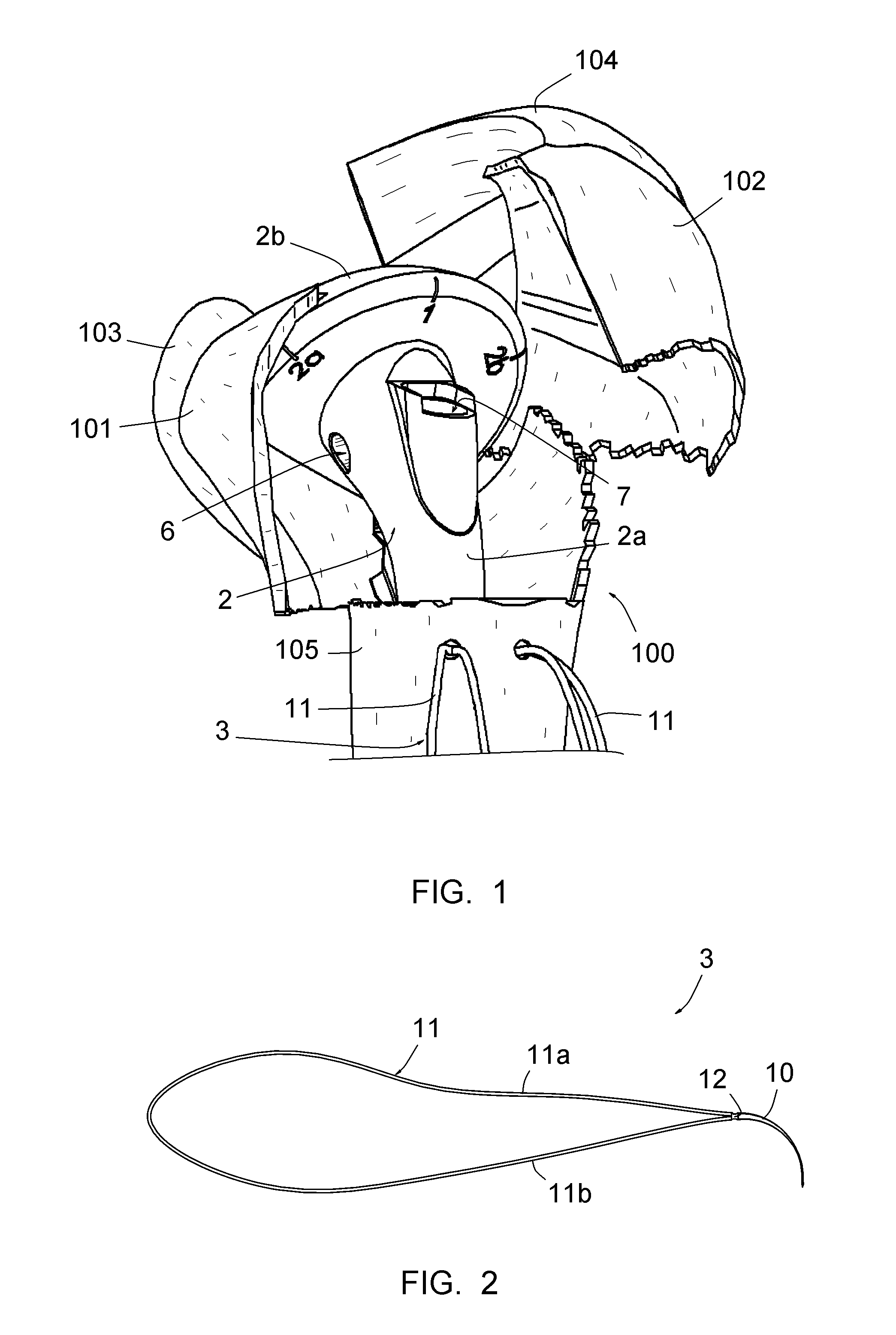

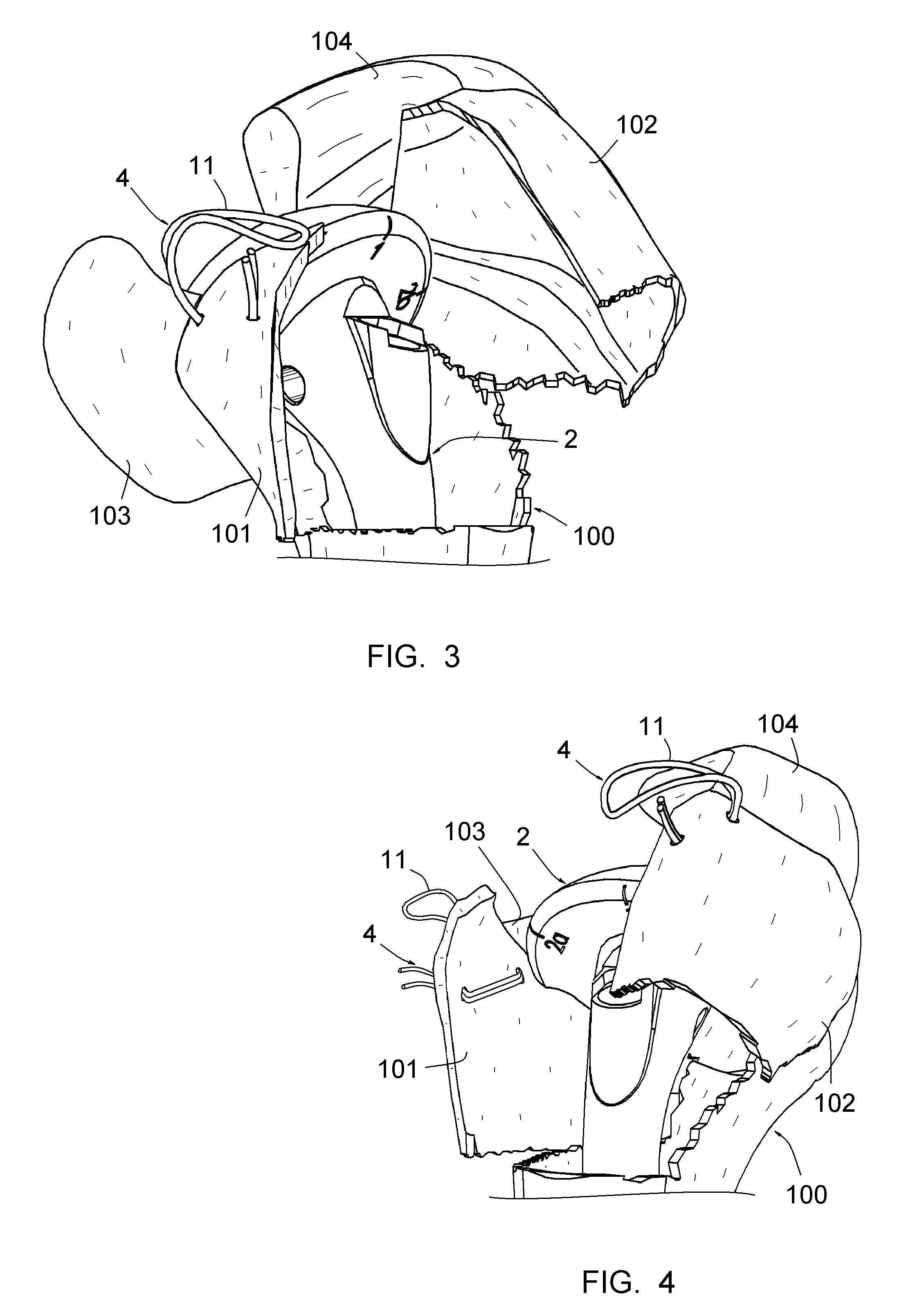

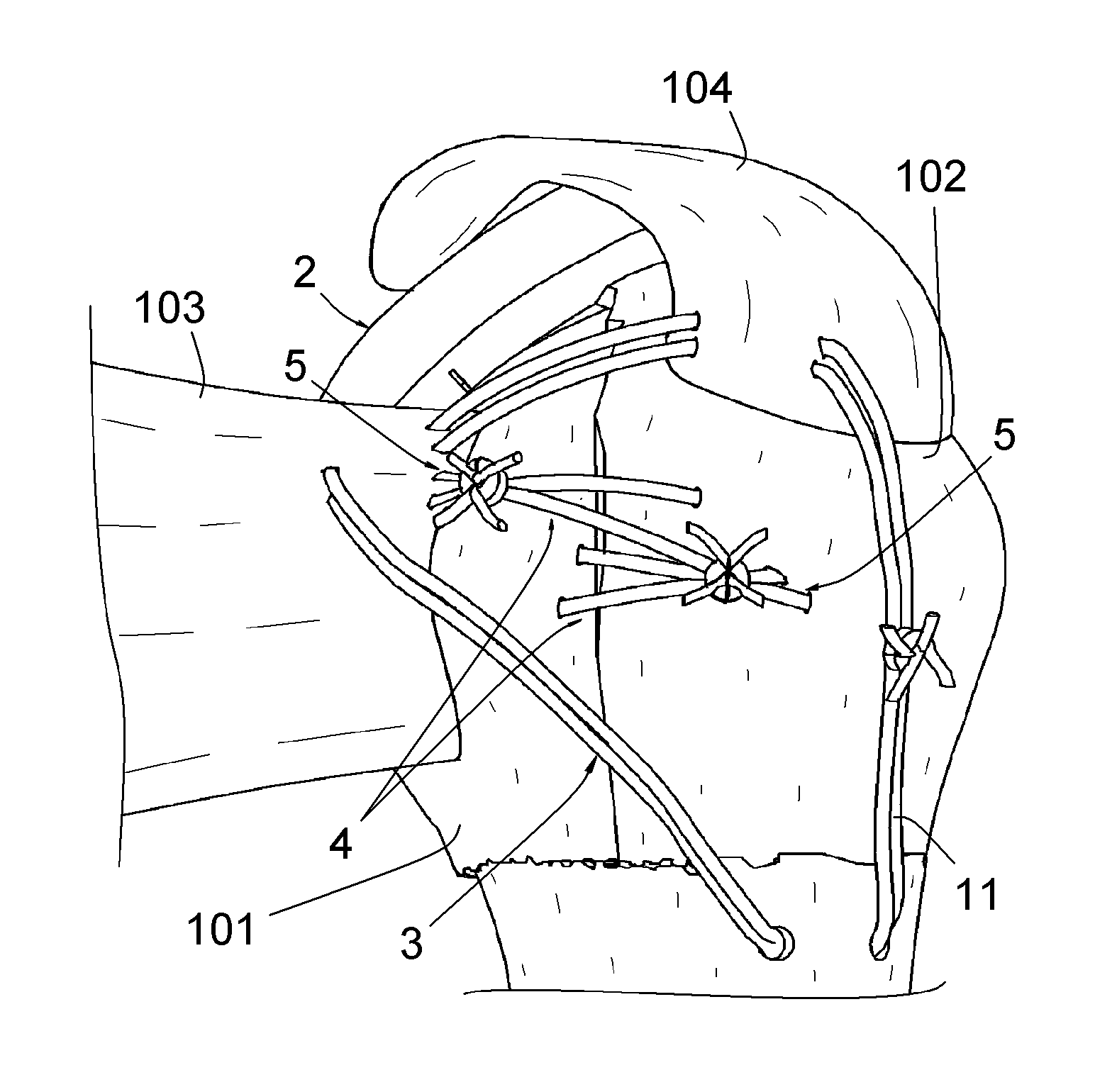

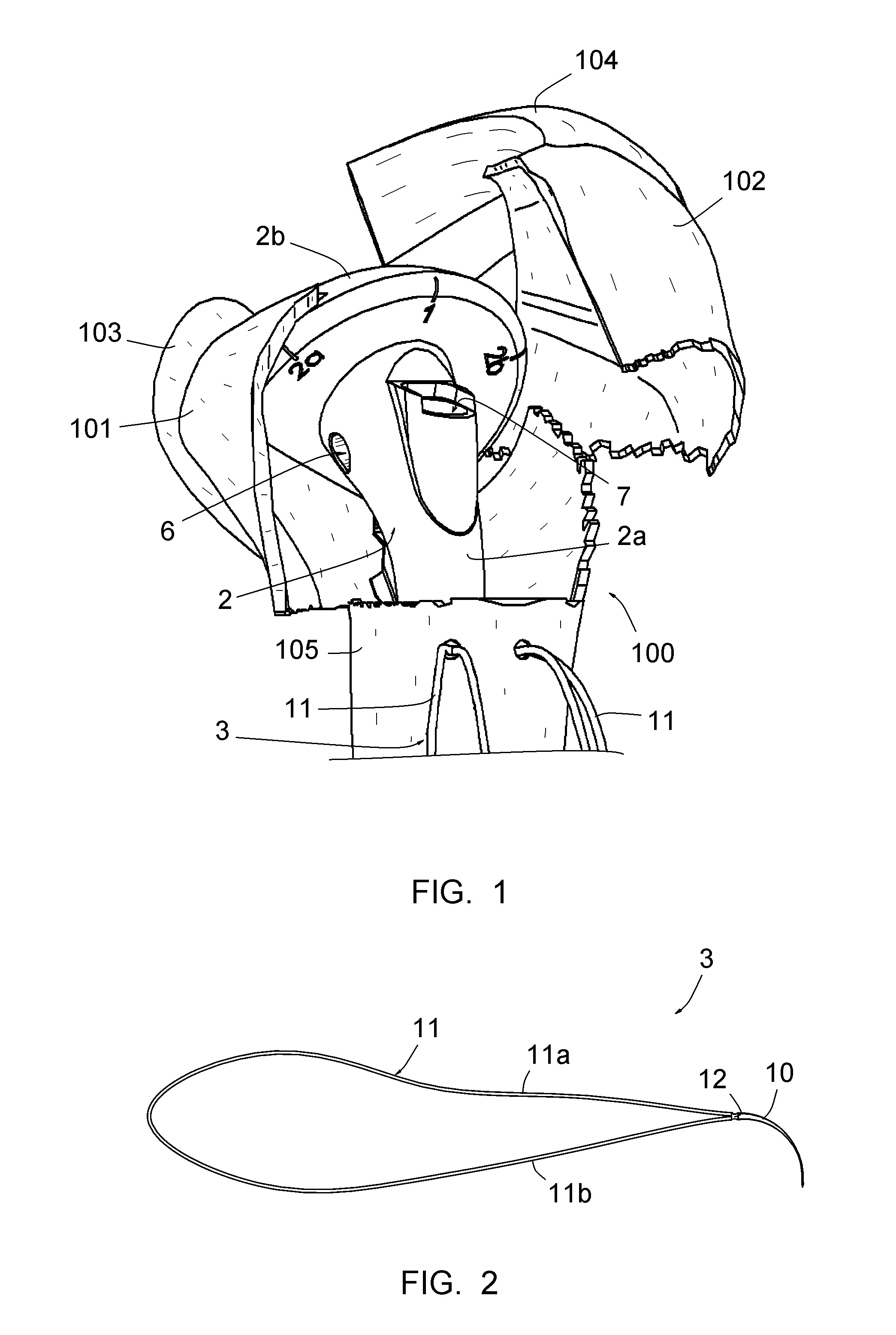

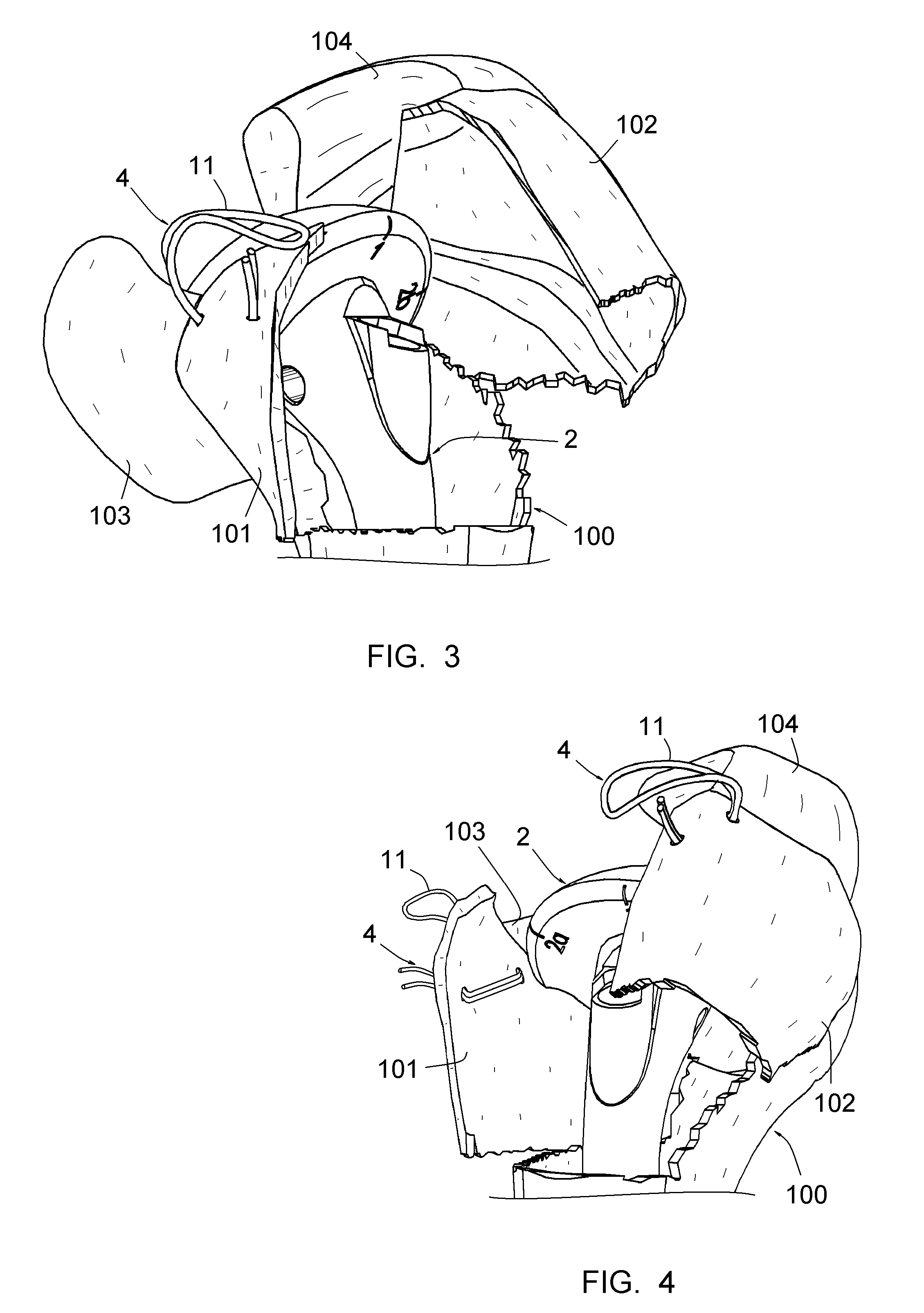

Surgical method for repairing a fractured shoulder joint

ActiveUS20120089143A1Good consolidationSuture equipmentsInternal osteosythesisBone marrow cavityEngineering

This method comprises the use of a repair equipment including a humeral rod (2) intended to be placed in the medullary cavity of the humerus, comprising at least one hole (6) for receiving a thread (11) for repositioning the tuberosities (101, 102) and for maintaining the latter with respect to the rest of the bone. Said hole (6) is formed in the metaphyseal portion of the humeral rod (2), in the anteroposterior direction thereof; and the repair equipment further comprises a so-called “guying” subassembly (3), to maintain the tuberosities (101, 102) when they re-installed, two second so-called “traction” subassemblies (4), for pulling of the tuberosities (101, 102) one toward the other, and two so-called third “pressing” subassemblies (5), for tackling the tuberosities (101, 102); each of these sub-assemblies comprises a needle and thread (11) connected to this needle, this thread (11) forming a loop.

Owner:FX SOLUTIONS

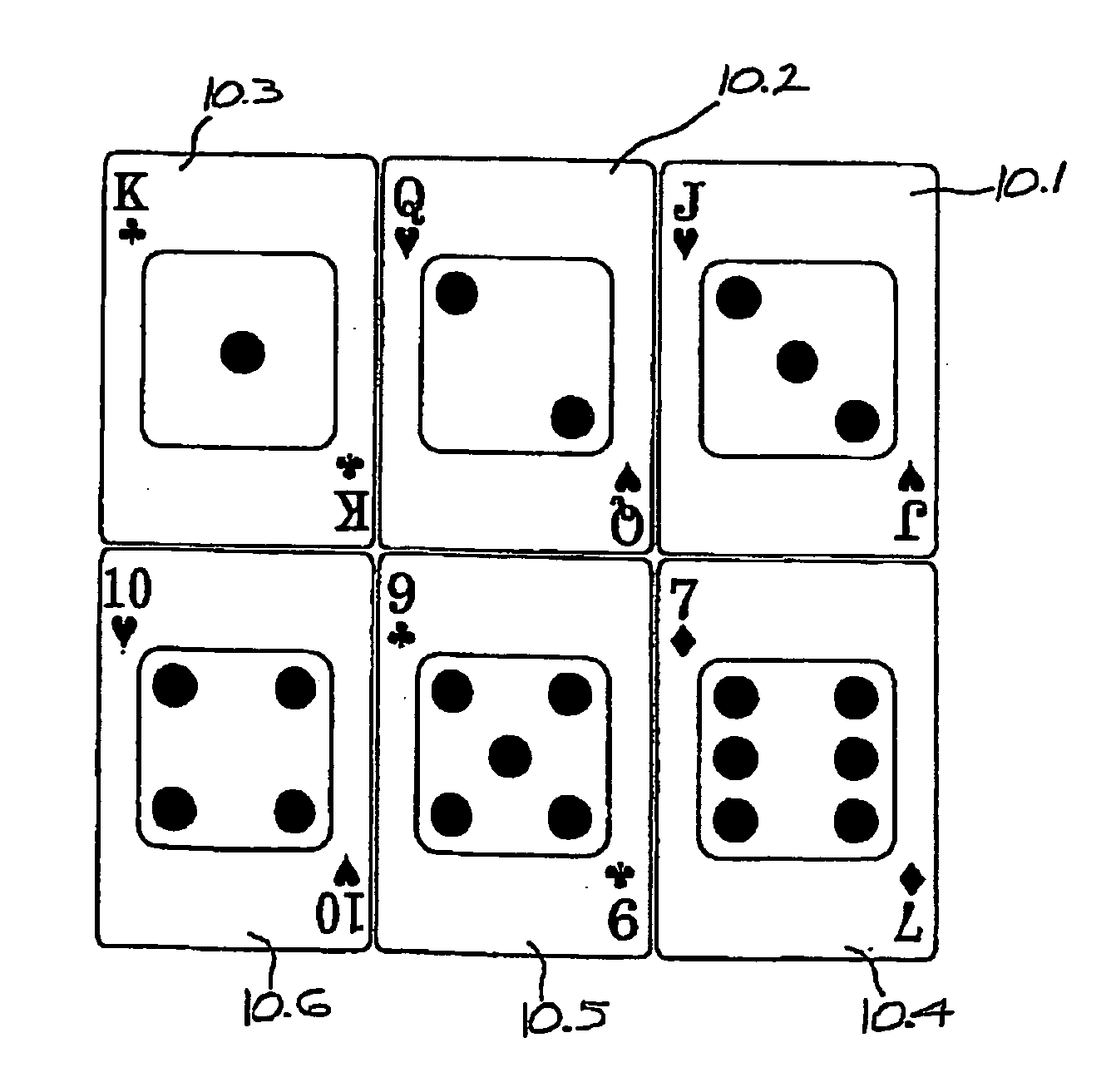

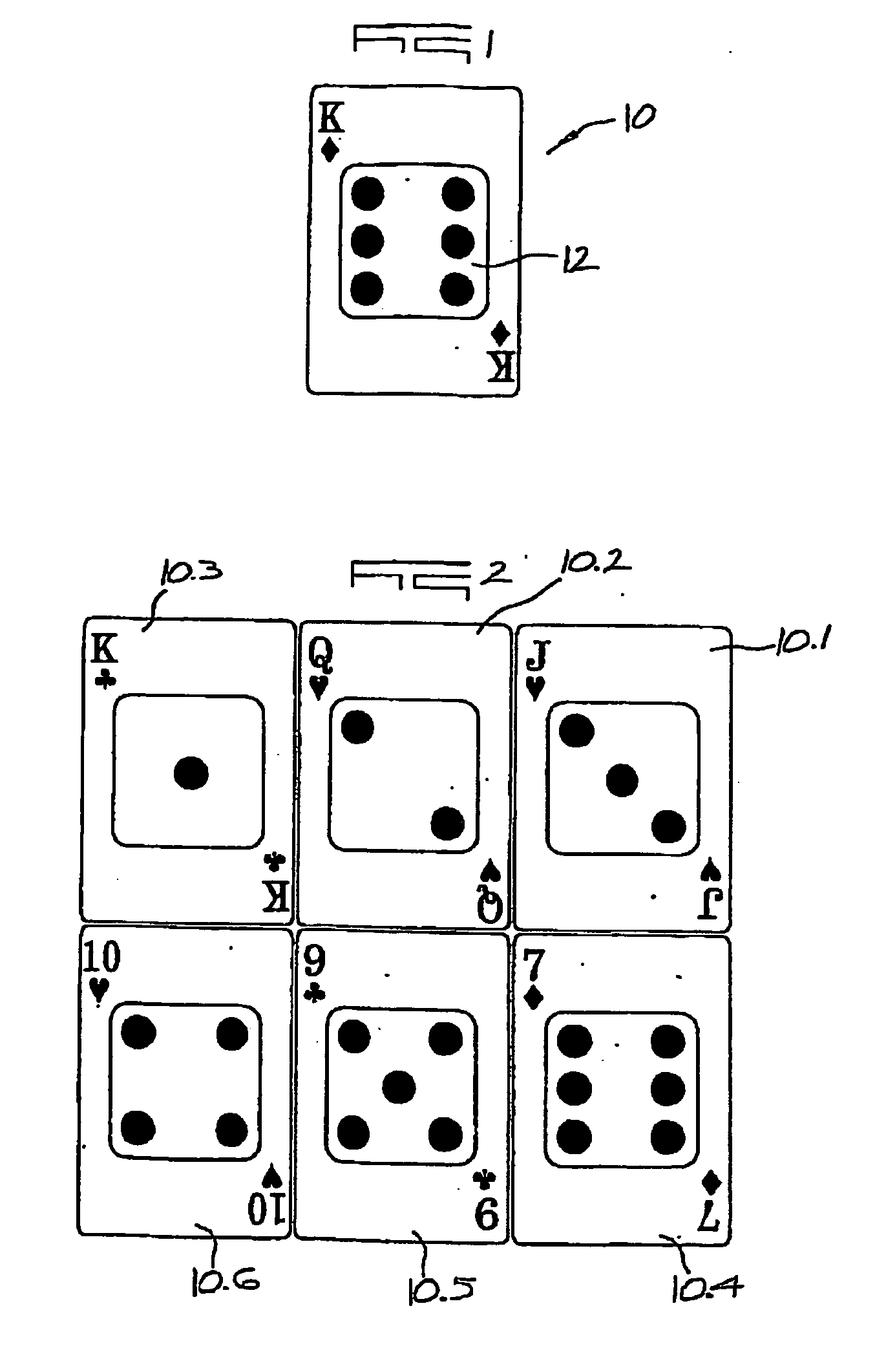

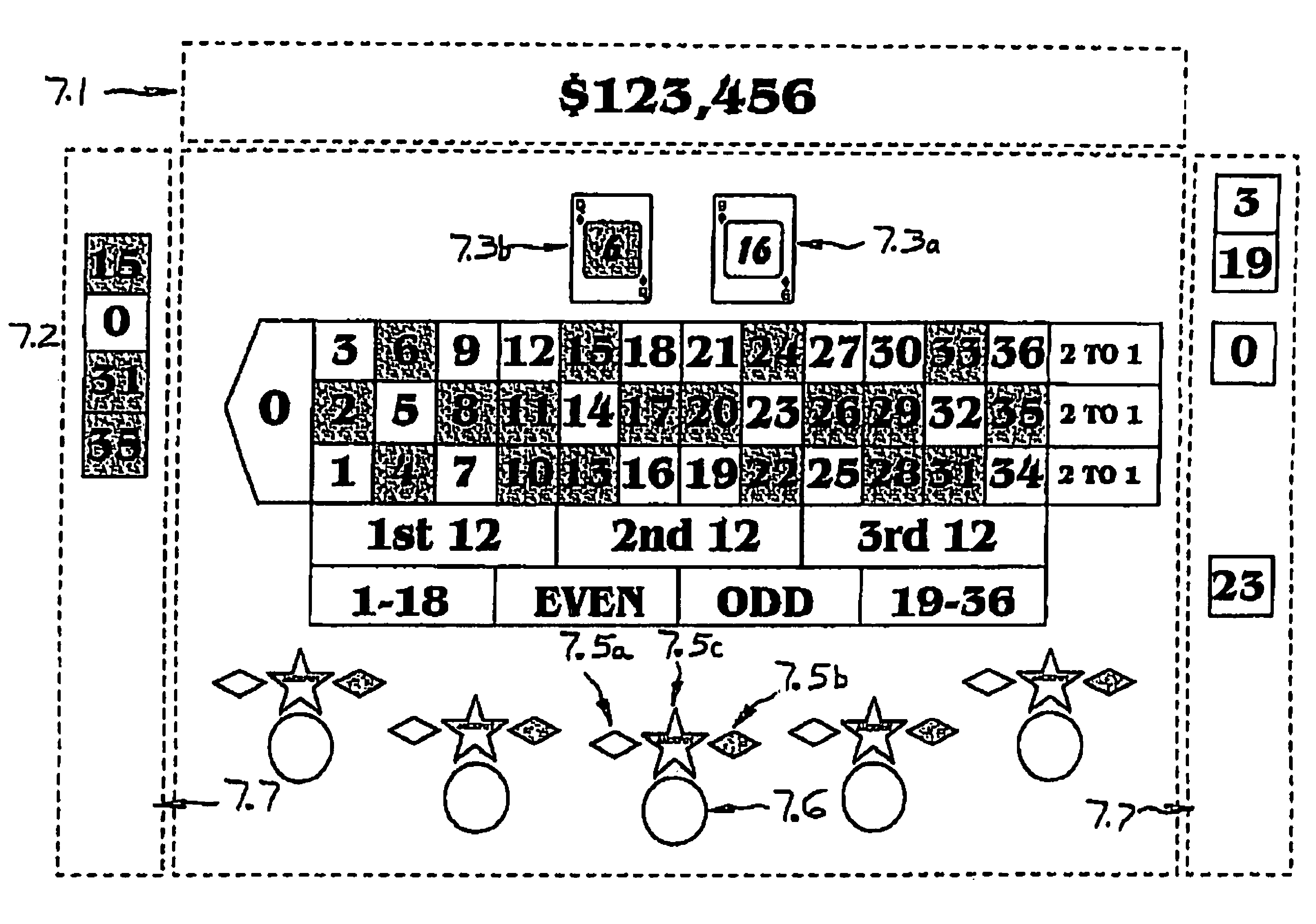

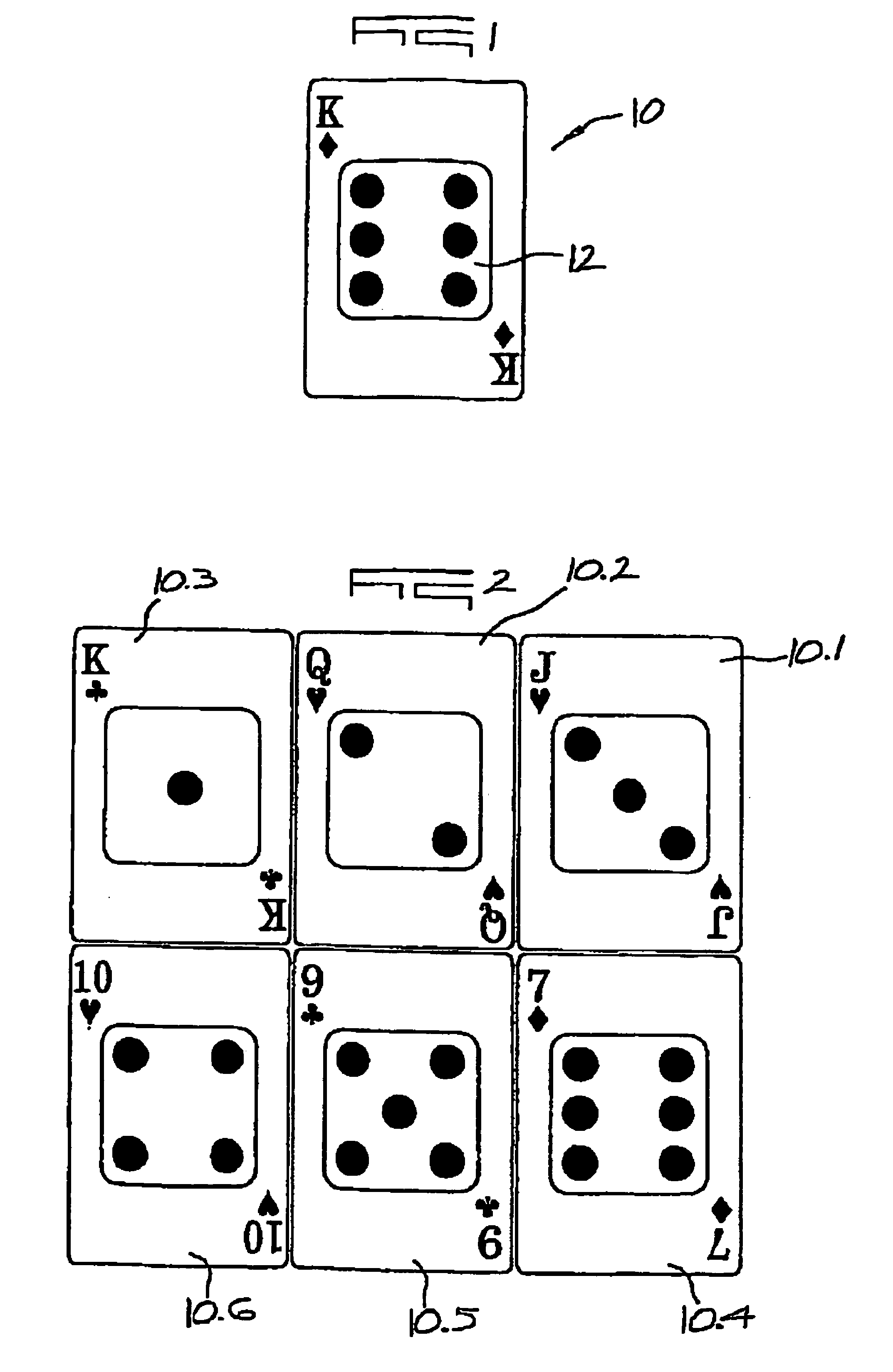

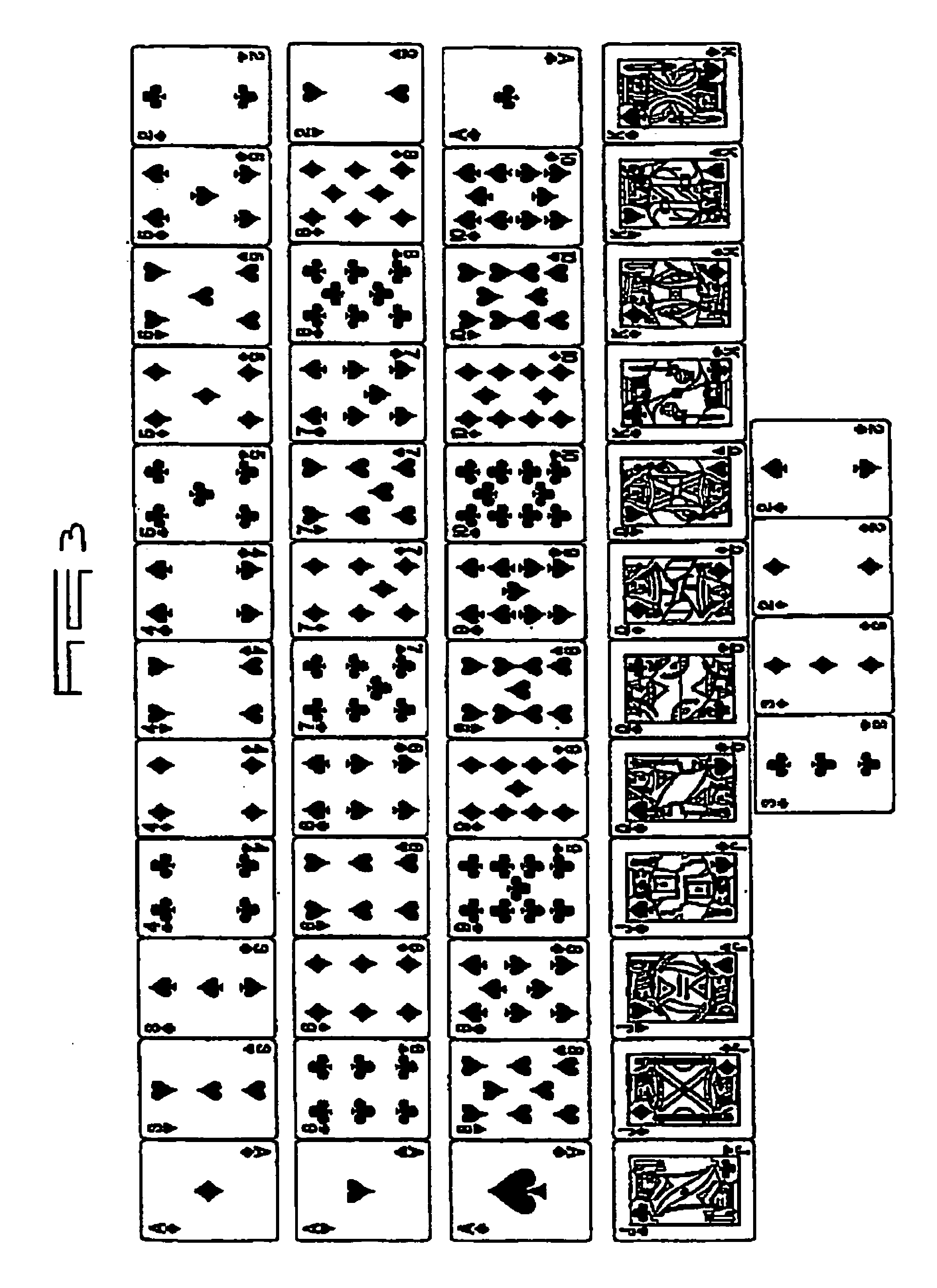

Method of and apparatus for playing a card game

InactiveUS20070018406A1Advantageous economicallyReduce operating expensesBoard gamesCard gamesComputer hardwarePlaying card

A deck of cards have conventional markings and at least some of the cards carry symbols associated with events in an independent game of chance.

Owner:VEGAS AMUSEMENT INC

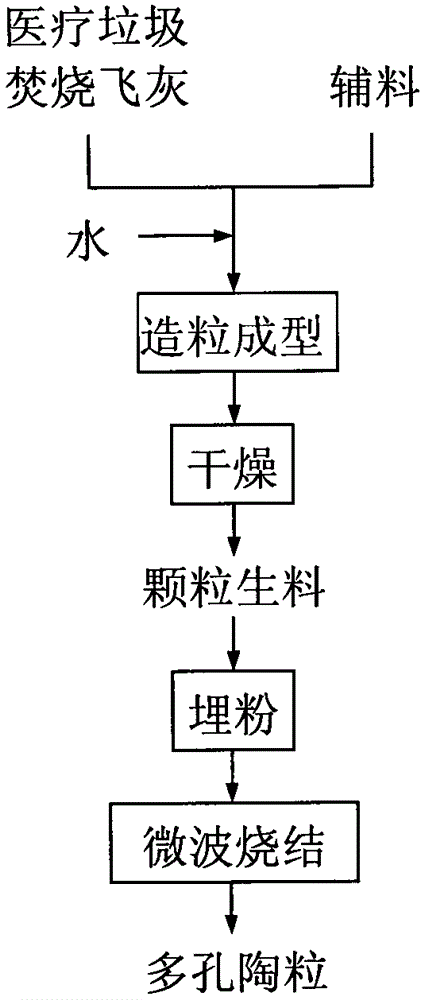

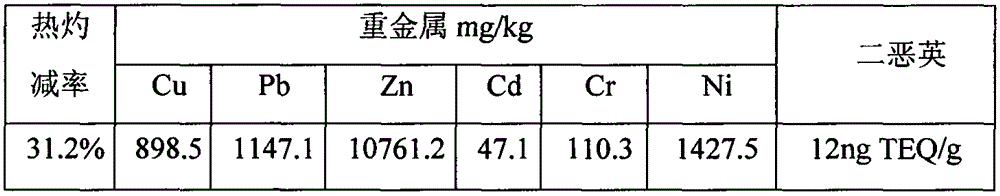

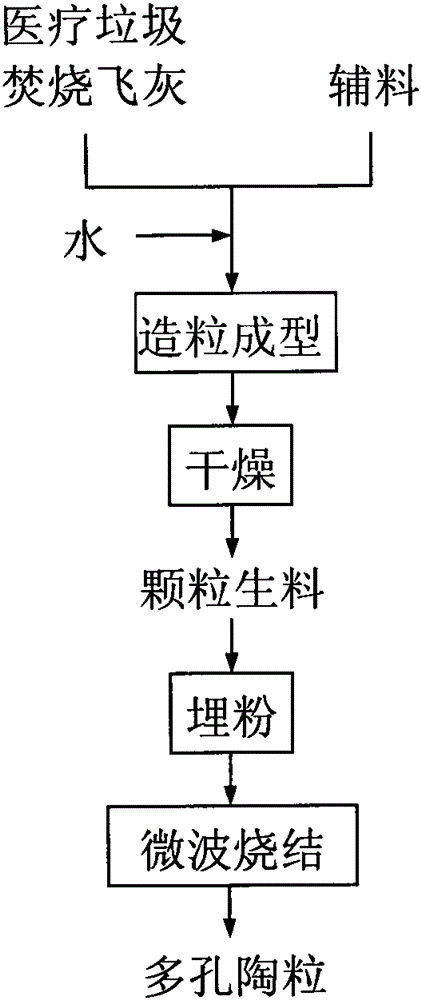

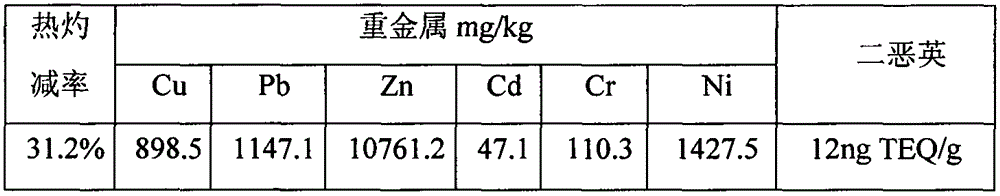

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

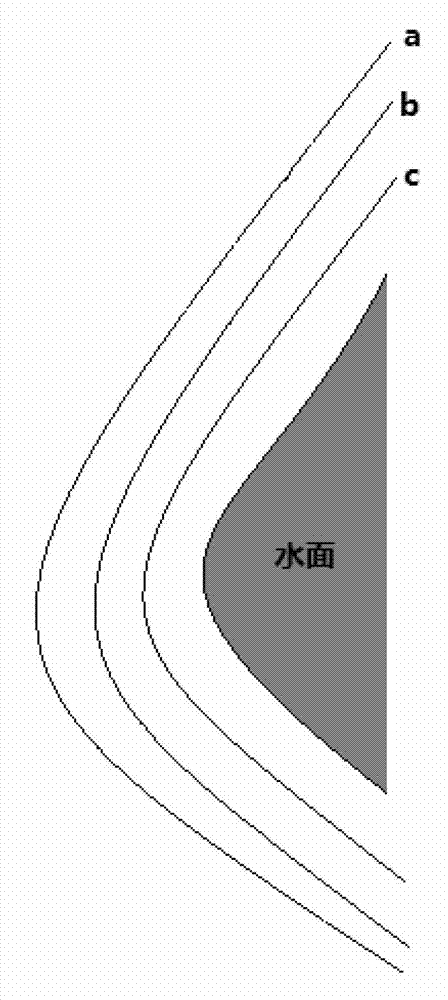

Comprehensive restoration method for salt-alkali degraded marsh wetland in plain area

InactiveCN102845156AEasy maintenanceGood consolidationClimate change adaptationHorticultureMarshRestoration method

The invention relates to a comprehensive restoration method for a salt-alkali degraded marsh wetland in a plain area, in particular to a restoration method for the salt-alkali degraded marsh wetland, and solves the problem that a satisfactory effect cannot be achieved as a land leveling technology, a hydrologic control technology or a wetland plant cover restoration technology is singly used in the conventional restoration process for the salt-alkali degraded marsh wetland in the plain area. The comprehensive restoration method comprises the steps as follows: 1, leveling land; 2, hydrologically controlling the salt-alkali degraded marsh wetland to be restored in the plain area; and 3, carrying out plant cover technology treatment on the salt-alkali degraded marsh wetland in the plain area. The comprehensive restoration method can be applied to the field of a restoration project for the salt-alkali degraded marsh wetland in the plain area.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

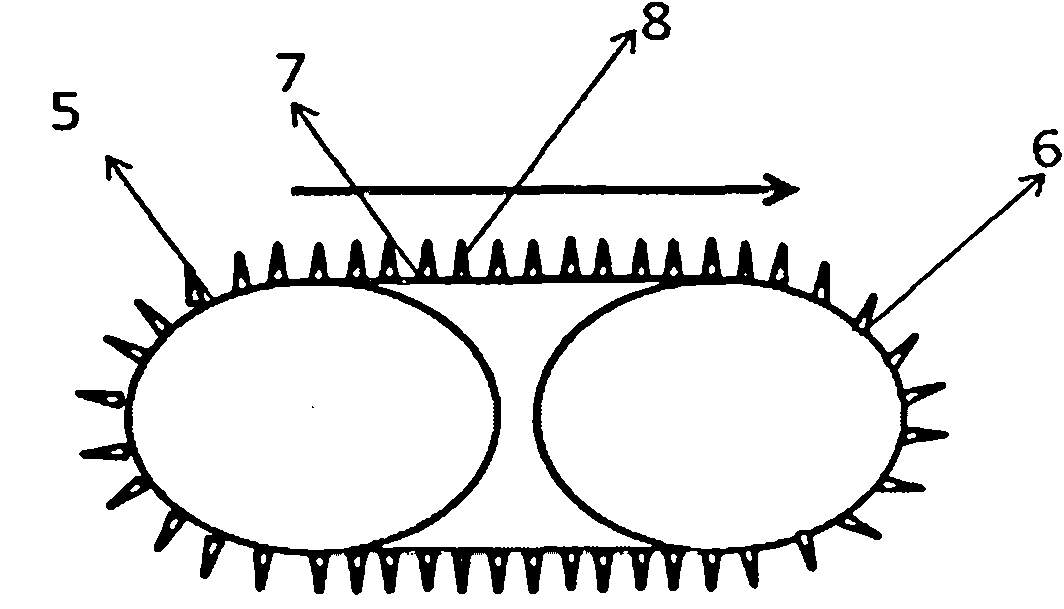

Agglomeration method for iron containing dust slime of iron and steel plants

The invention discloses an agglomeration method for iron containing dust slime of iron and steel plants; according to the method, the iron containing dust slime is shunted independently, is briquetted, is mixed with other iron ore powder, flux and coke powder, and then is sintered on the basis of the traditional technology. The agglomeration method comprises the following detailed steps of: 1), firstly, mixing the iron containing dust slime with composite binder, mixing uniformly, briquetting, so as to obtain dust slime briquette; 2), mixing the dust slime briquette with other iron ore powder, flux and coke powder, pelletizing, so as to obtain sintered mixture material; and 3), distributing the sintered mixture material by adopting the existing sintering method, igniting, sintering, cooling, granulating, finally the finished product of sintered ore is obtained. Compared with the traditional method of directly returning, sintering and mixing the dust slime, by adopting the agglomeration method, the ratio of the iron containing dust slime in the mixture material is greatly improved, and in addition, the sintered product quality index is improved. By adopting the agglomeration method, the problem on large-scale use of the iron containing dust slime of iron and steel plants is effectively solved, and the agglomeration method is beneficial for industrial production.

Owner:CENT SOUTH UNIV

Grouting method for anchoring with polymer

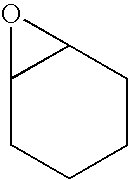

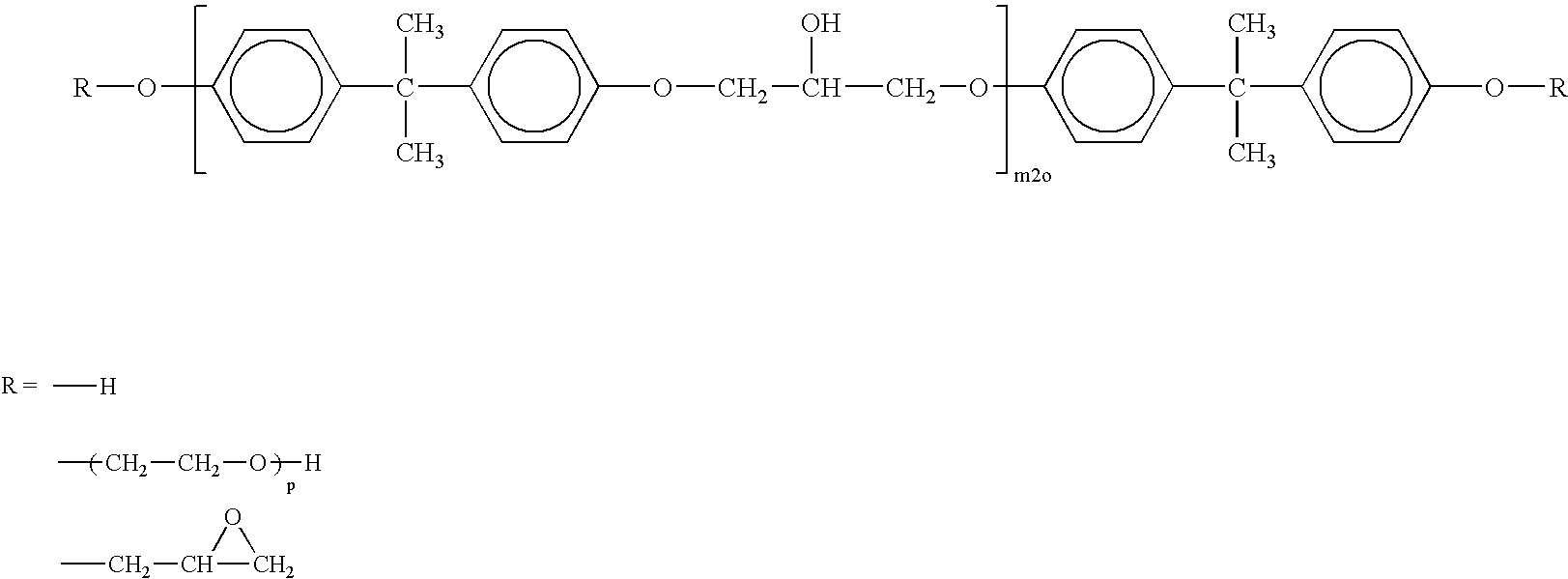

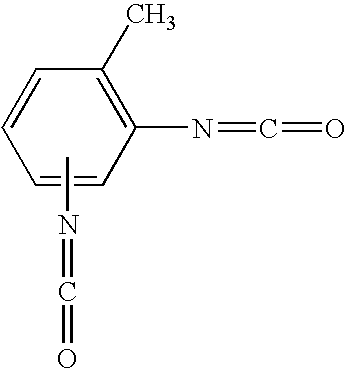

ActiveUS20140314503A1Rapid, safe, lightweight and high strength polymer groutingSafe and advanced and economicOrganic fertilisersAnchoring boltsPolymer scienceRock bolt

A grouting method for anchoring with polymer is provided, wherein the method includes steps of: a) rod body processing; b) tying up a geotextile bag and grouting tubes on the anchoring rod body; c) hole drilling; d) polymer grouting: I. hole sealing grouting; II. anchoring grouting. The present invention has advantages of a sufficient adaptability, non-water reaction, convenient and fast construction, being economic, a high strength and a high durability. An expansive polymer material has an obvious compacting effect on soil, and is capable of increasing a friction force between a grout and a base; the water-proofing polymer material is an impermeable material for a steel rod body, and is of benefit to anti-corrosion and durability of the rod body; a solidifying time of the polymer material is short and no maintenance is needed in such a manner that construction periods are shortened.

Owner:WANG FUMING

Products and method of core crush prevention

InactiveUS20030190452A1High ASTM stiffness valueGood consolidationFibre treatmentSynthetic resin layered productsHoneycombEngineering

Stiffness-treated honeycomb sandwich structures which exhibit reduced core crush and / or reduced void content are provided. Additionally, stiffness-treated prepreg plies which exhibit increased frictional resistance when disposed on other prepreg plies are also provided. Further, associated starting materials and methods are provided.

Owner:CYTEC TECH CORP

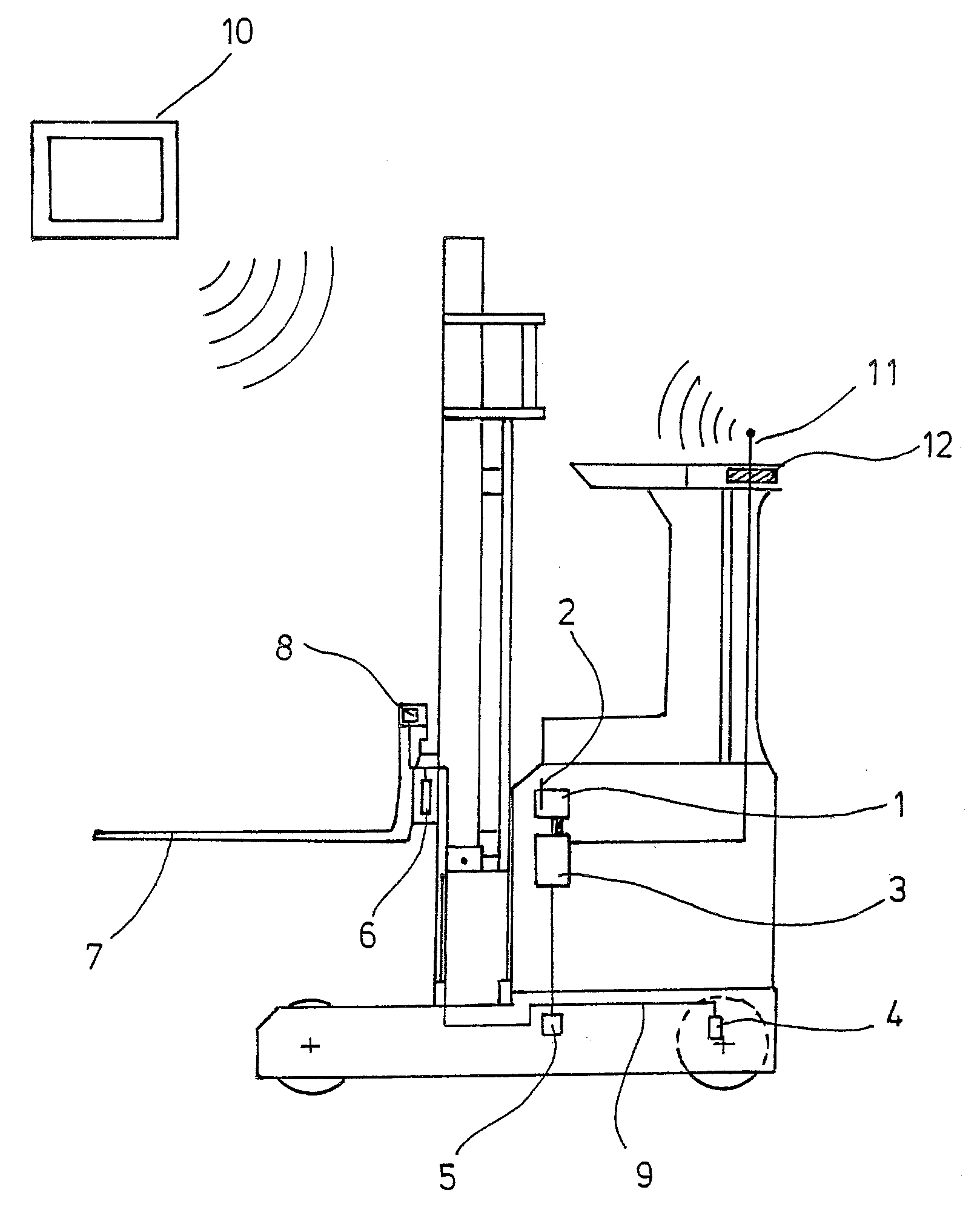

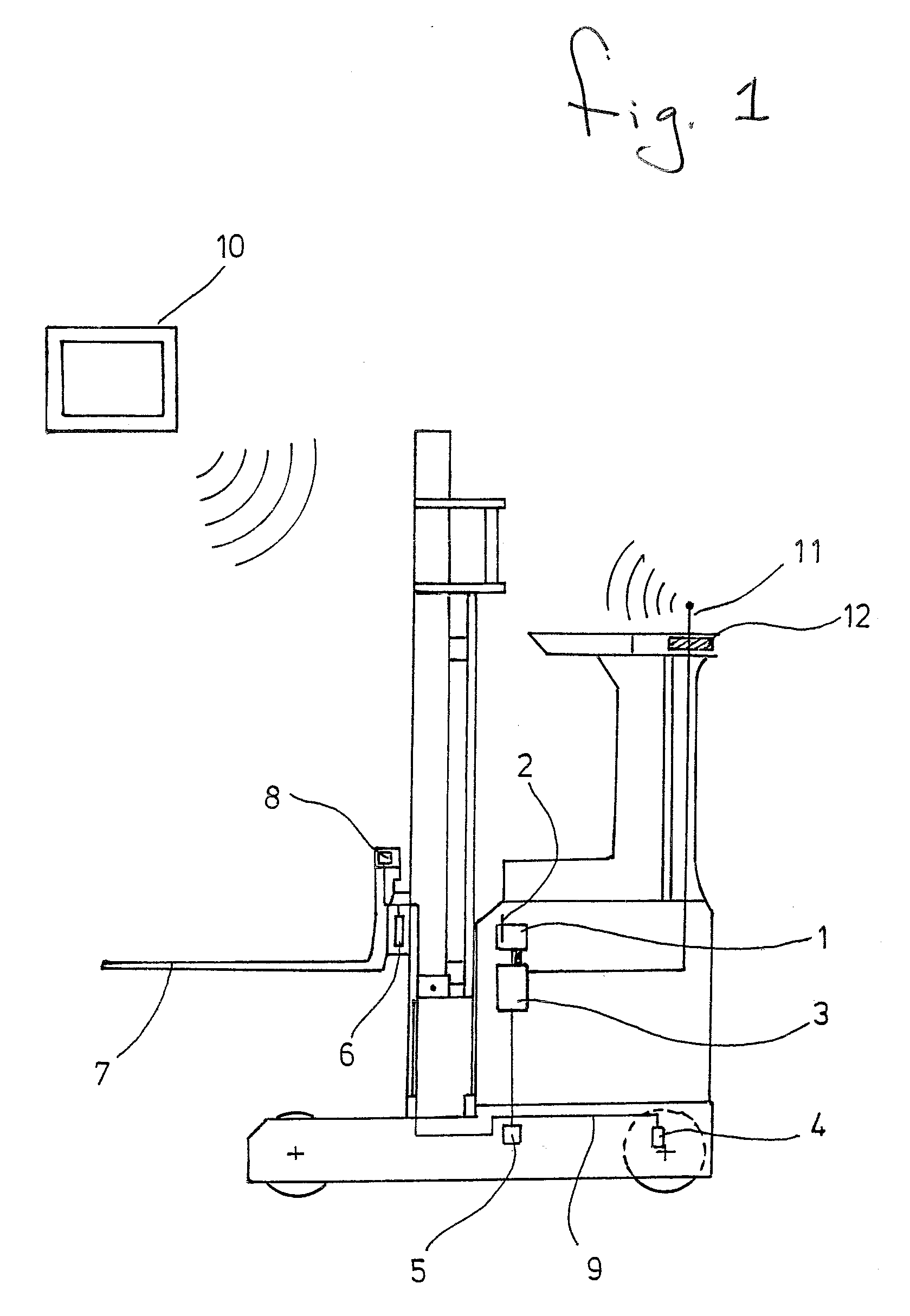

Industrial truck with acquirement of utilization data

InactiveUS20070208476A1Improve overall utilizationGood consolidationVehicle testingAnalogue computers for trafficData transportControl cell

An industrial truck with an electronic memory and / or a data transfer unit, an equipment for acquiring utilization data and a control unit, which is connected with the equipment for acquiring utilization data and the memory and / or the data transfer unit, characterised in that the control unit continuously generates an utilization protocol from the acquired utilization data and files it in the memory or transmits it to the data transfer unit.

Owner:JUNGHEINRICH AG

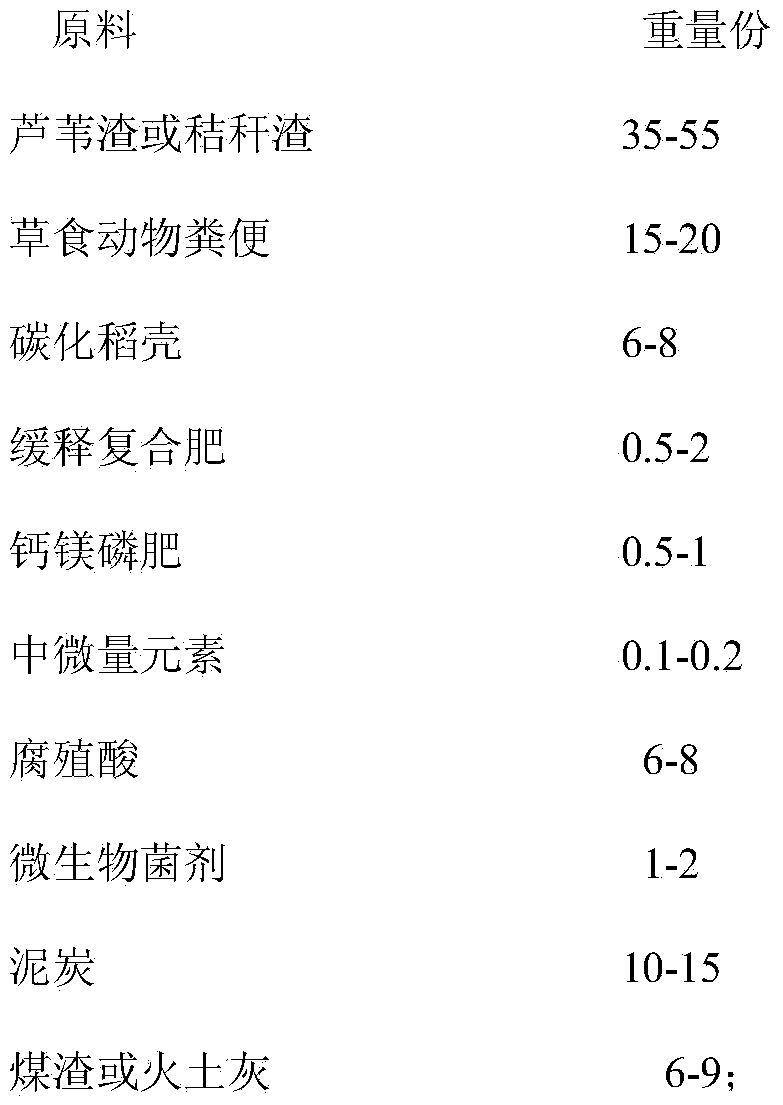

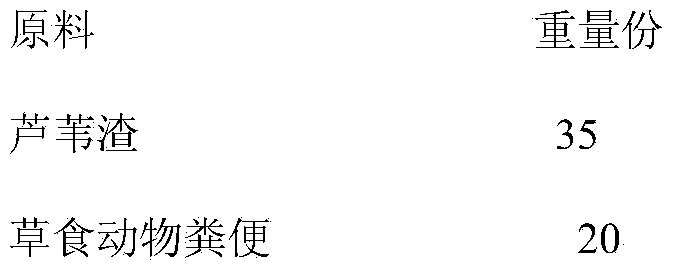

Vegetable and fruit biological activity seedling culture matrix as well as preparation method and application thereof

ActiveCN103626586ASufficient quantityThe source is stable and controllableFertilizer mixturesRoot systemDisease

The invention discloses a vegetable and fruit biological activity seedling culture matrix as well as a preparation method and application of the vegetable and fruit biological activity seedling culture matrix. The vegetable and fruit biological activity seedling culture matrix is prepared by adding auxiliary ingredients such as excrements of plant-eating animals, soil ash or coal slag, peat, a slow-release fertilizer, a calcium-magnesium phosphate fertilizer, medium trace elements and a microbial agent into papermaking wastewater serving as a main ingredient. The matrix is soft, loose, ventilating, water-saving and drought-resisting. The matrix for culturing vegetable and fruit seedlings can achieve the effects of high seedling emerge speed, short seedling age, seedling strengthening, quality improvement, root activity enhancement, disease resistance and improvement on seedling emerge rate and seedling rate; furthermore, the vegetable and fruit biological activity seedling culture matrix is convenient to transplant; the slow seedling period is short; stable yield and high yield of vegetables and fruits are guaranteed.

Owner:长沙浩博生物技术有限公司

Method of and apparatus for playing a card game

InactiveUS7980933B2Reduce operating expensesIncrease wagerBoard gamesCard gamesComputer hardwareDisplay device

Owner:VEGAS AMUSEMENT INC

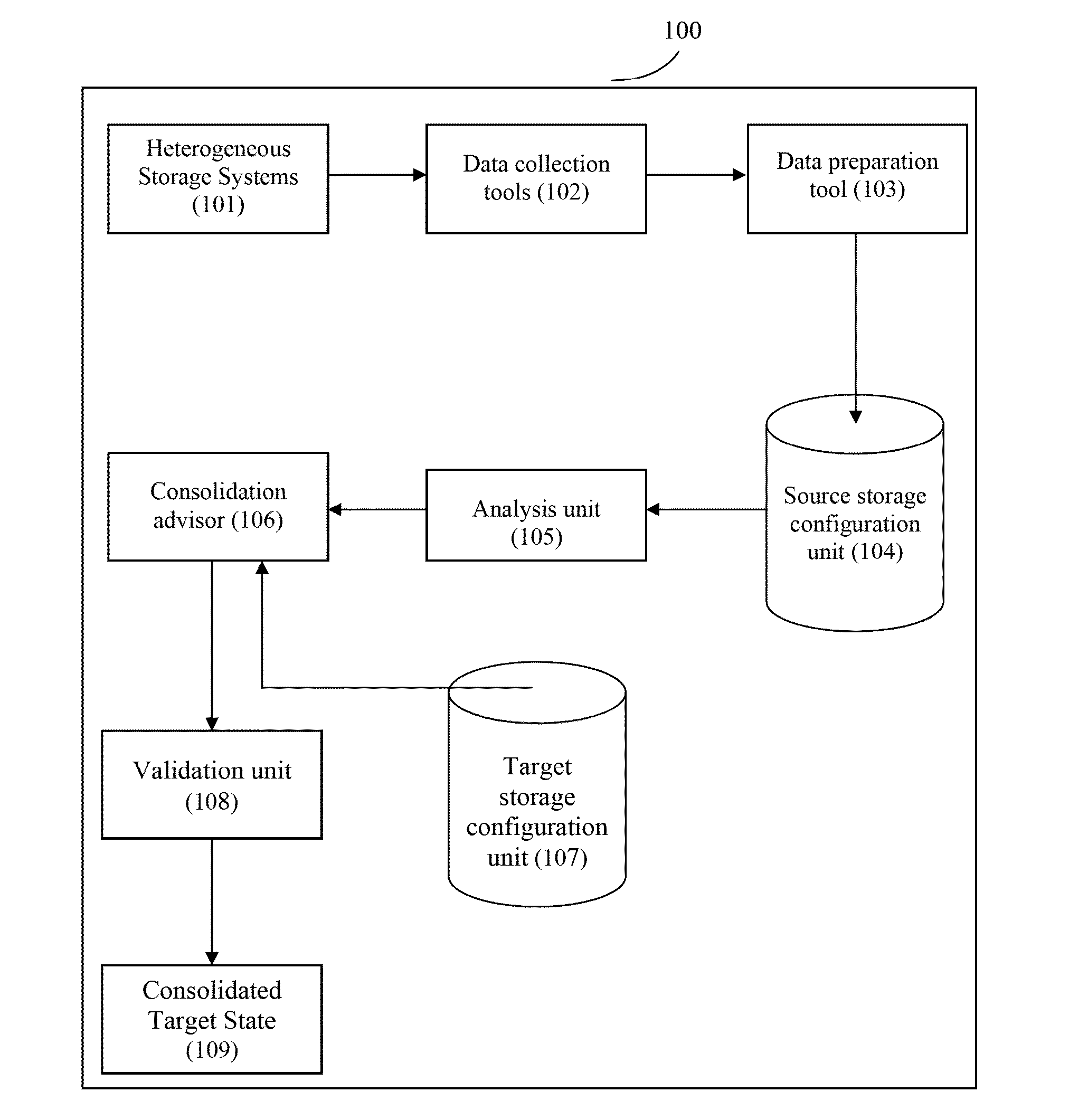

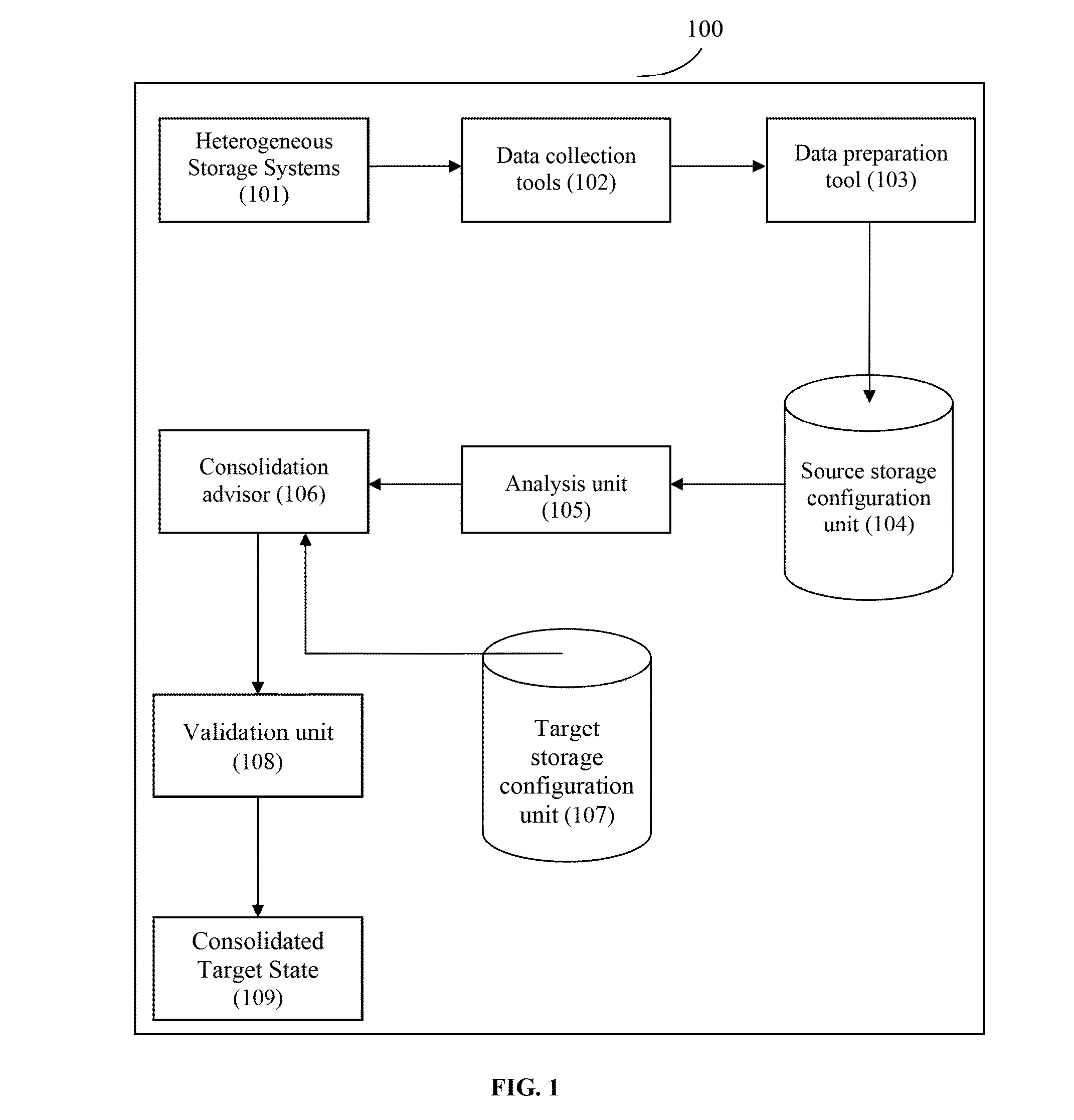

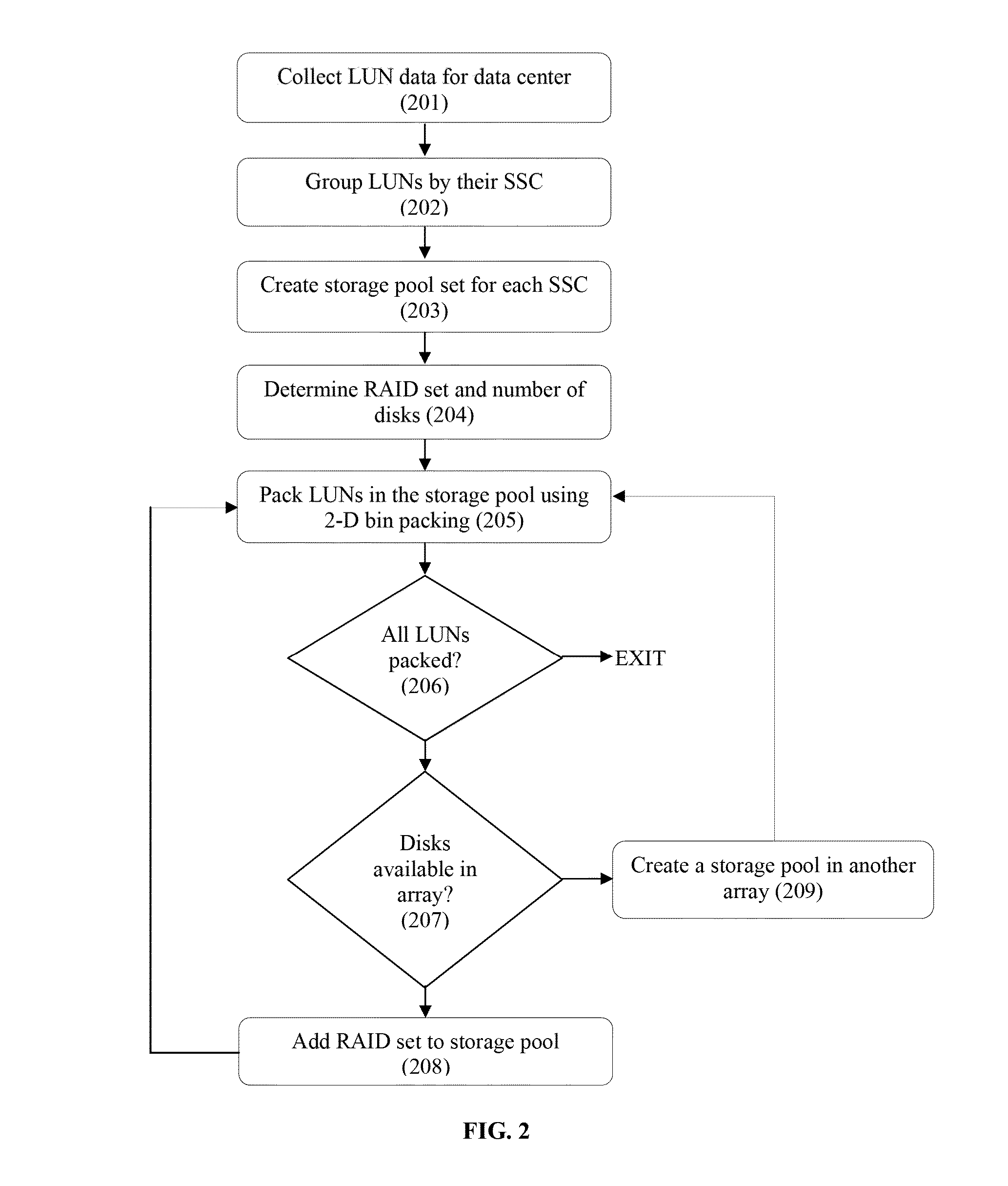

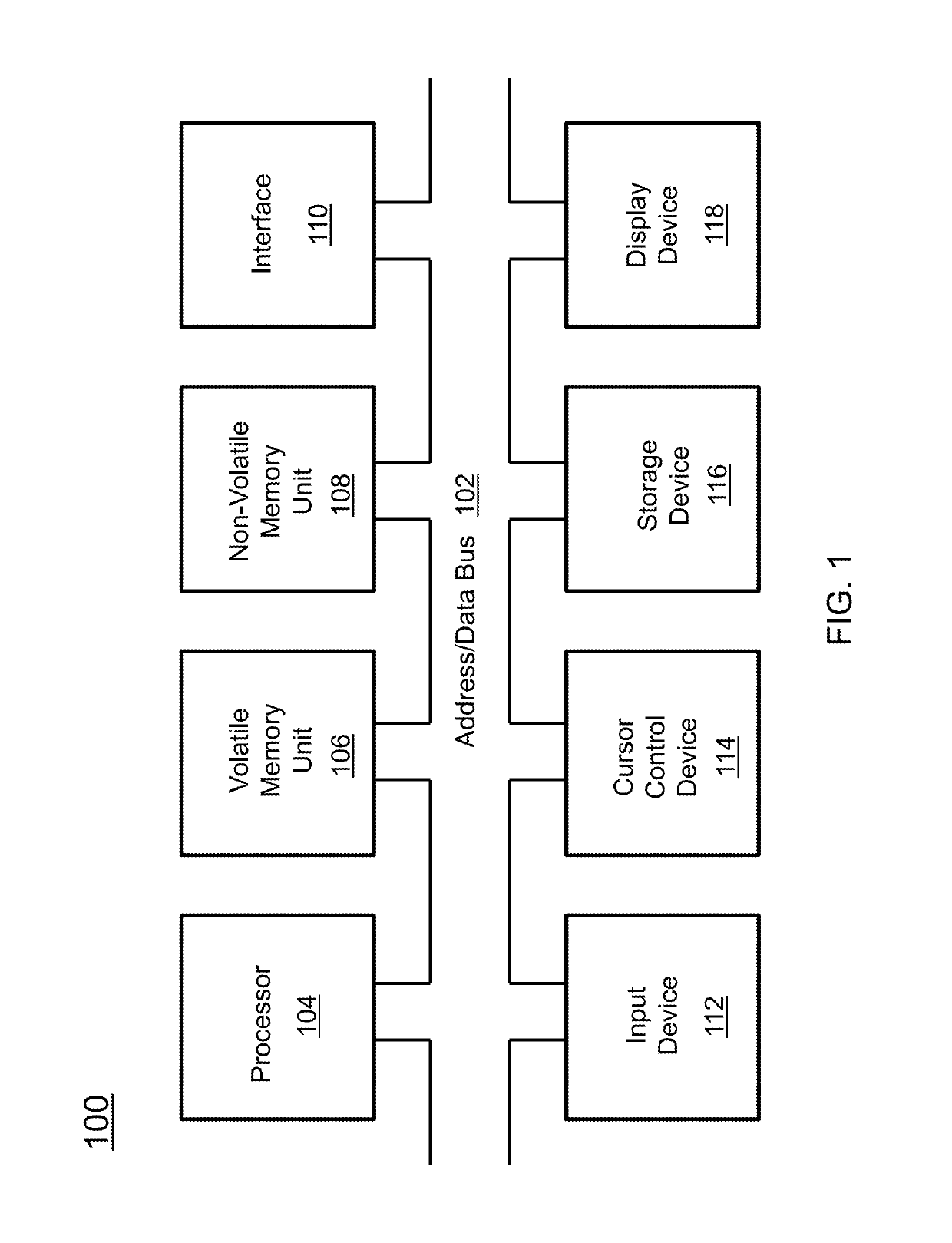

Method and system for consolidating a plurality of heterogeneous storage systems in a data center

ActiveUS20140325149A1Reduce storage administrationReduce operational expenditureInput/output to record carriersMemory systemsLogic cellData filling

A system and method for consolidating a plurality of heterogeneous storage systems in a data center comprising collecting data from a plurality of heterogeneous storage devices (101) using data collection tools (102), using Data PreparationTool (103) for extracting and translating the collected data, populating a Data Model stored in source storage configuration unit (104) suitable for analysis, analyzing and classifying the collected data by an analysis unit (105) based upon a plurality of attributes, comprising of a Consolidation Advisor that uses the analyzed data and candidate Target System Configurations, Preferences & Constraints (106) for generating optimum number, specification & configuration of the Consolidate Target State (109) infrastructure and mappings of logical units from as-is data center storage infrastructure to the target state, and iteratively validating the same in a Validation task (108) till the final desired consolidation and objectives are met.

Owner:TATA CONSULTANCY SERVICES LTD

A method of microwave firing porous ceramsite from medical waste incineration fly ash

ActiveCN103601526BPromote formationGood consolidationSolid waste disposalCeramicwarePrillResource utilization

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

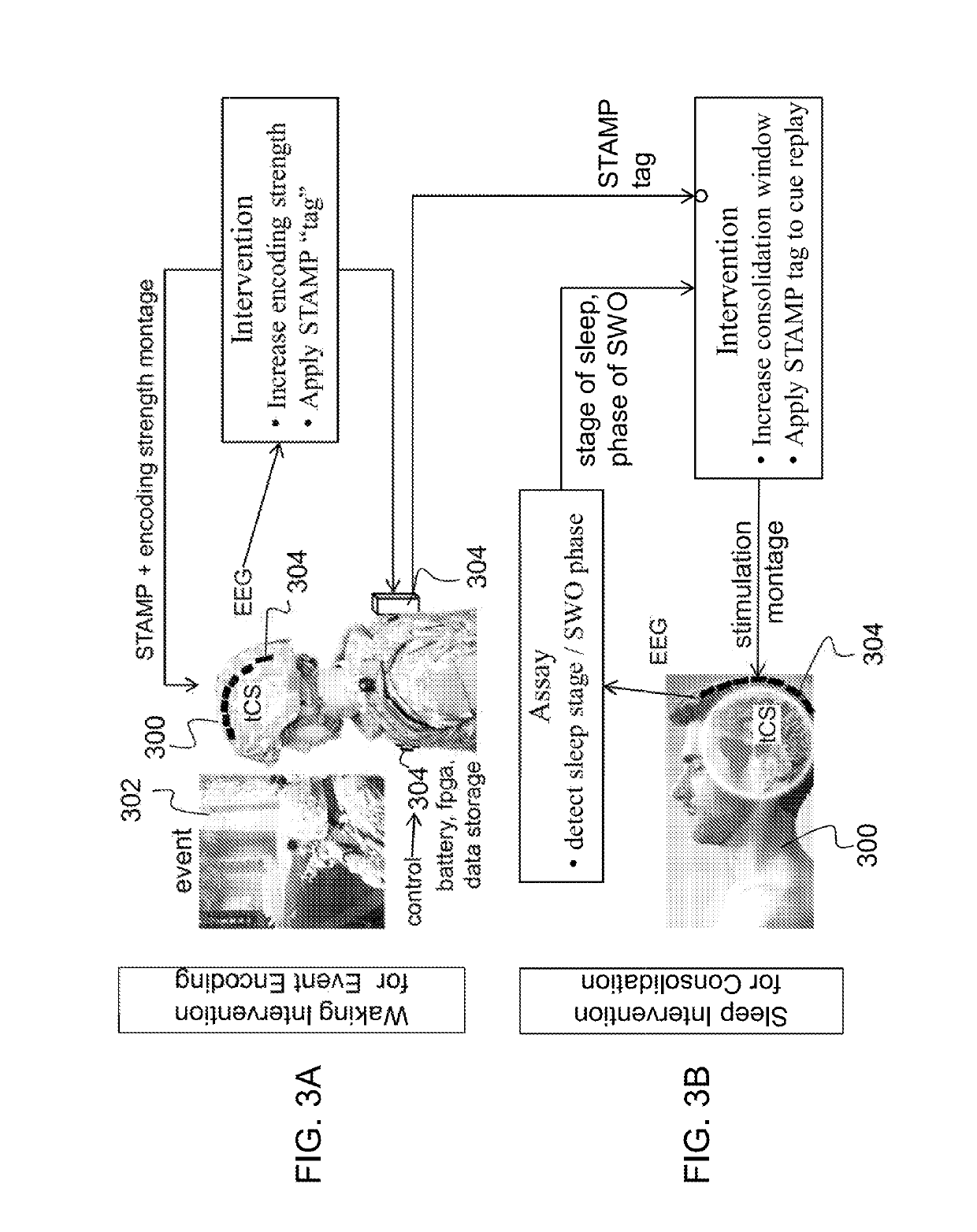

Method and system to accelerate consolidation of specific memories using transcranial stimulation

ActiveUS10307592B1Promote consolidation of memoryGood consolidationElectroencephalographyElectrotherapyTranscranial alternating current stimulationSubject specific

Described is a system for consolidation of specific memories of events. A sleep state detector assesses a subject's sleep state from neural recordings obtained from a high-density electroencephalogram (HD-EEG) device. During a memory encoding phase, a high-definition transcranial current stimulation (HD-tCS) system simultaneously applies a spatiotemporal amplitude-modulated pattern (STAMP) tag and a transcranial direct current stimulation (tDCS) signal to the subject as an event is experienced by the subject. During a memory consolidation phase, the HD-tCS system applies a transcranial alternating current stimulation (tACS) signal to the subject during a sleep or quiet waking state of the subject.

Owner:HRL LAB

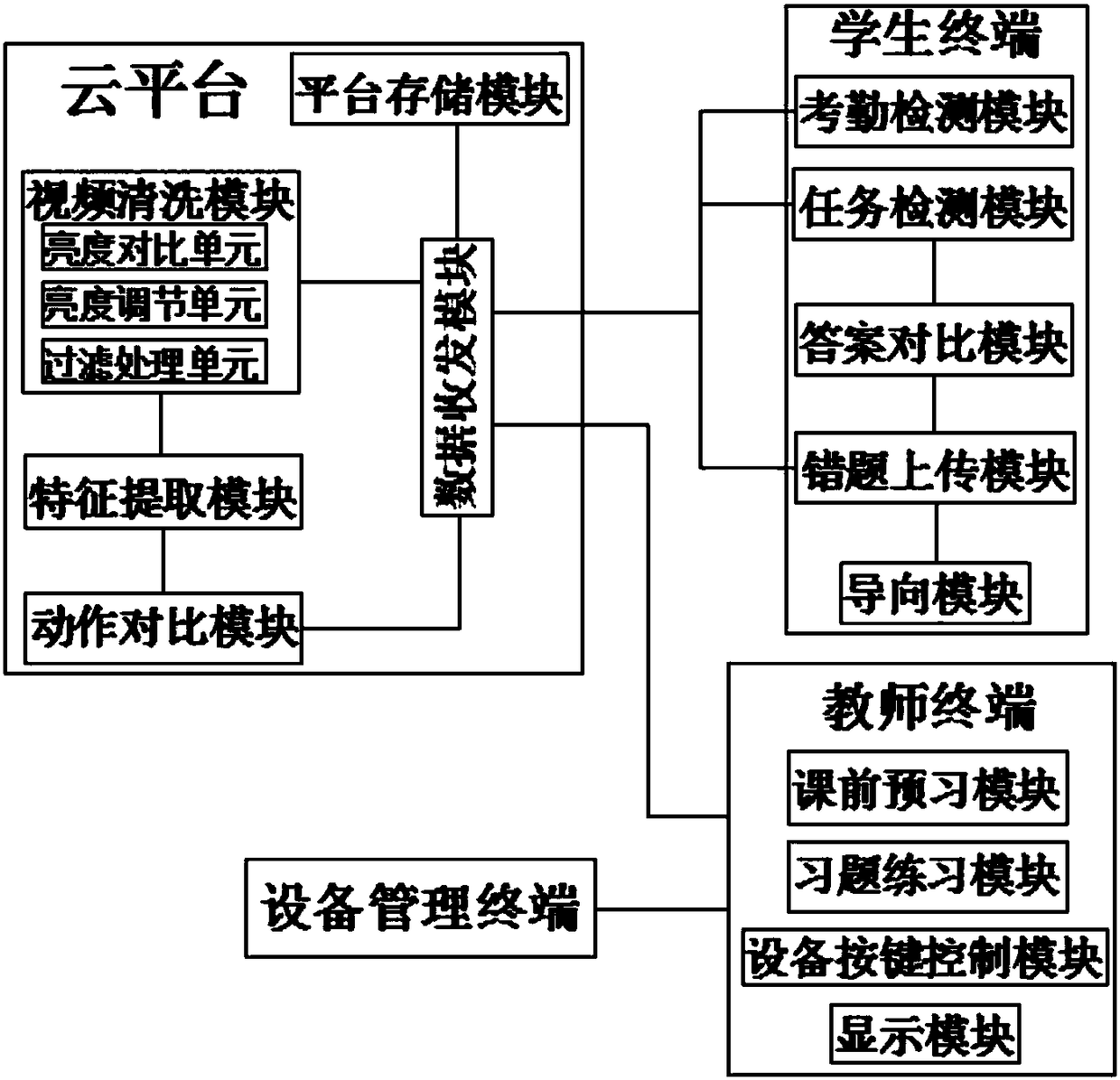

Intelligent classroom teaching system based on cloud platform

InactiveCN108492650AReduce work intensityEffective controlRegistering/indicating time of eventsData processing applicationsFeature extractionComputer terminal

The present invention discloses an intelligent classroom teaching system based on a cloud platform. The system comprises a cloud platform, and a teacher terminal and a student terminal which are connected with the cloud platform, and the teacher terminal is connected with a device management terminal; the cloud platform comprises a platform storage module, a video cleaning module, a feature extraction module, a motion comparison module and a data receiving-transmitting module. The teacher terminal comprises a preview-before-class module, an exercise practice module, a device button control module and a display module; the student terminal comprises an attendance detection module, a task detection module, an answer comparison module, a wrong question uploading module and a guide module. Teachers can understand students' attendance rates, learning and grasping conditions and wrong question distribution conditions through the teacher terminal so as to facilitate the teachers' special teaching, reduce the teachers' working intensity, enhance consolidation of the student knowledge points and improve the school records.

Owner:广州建翎电子技术有限公司

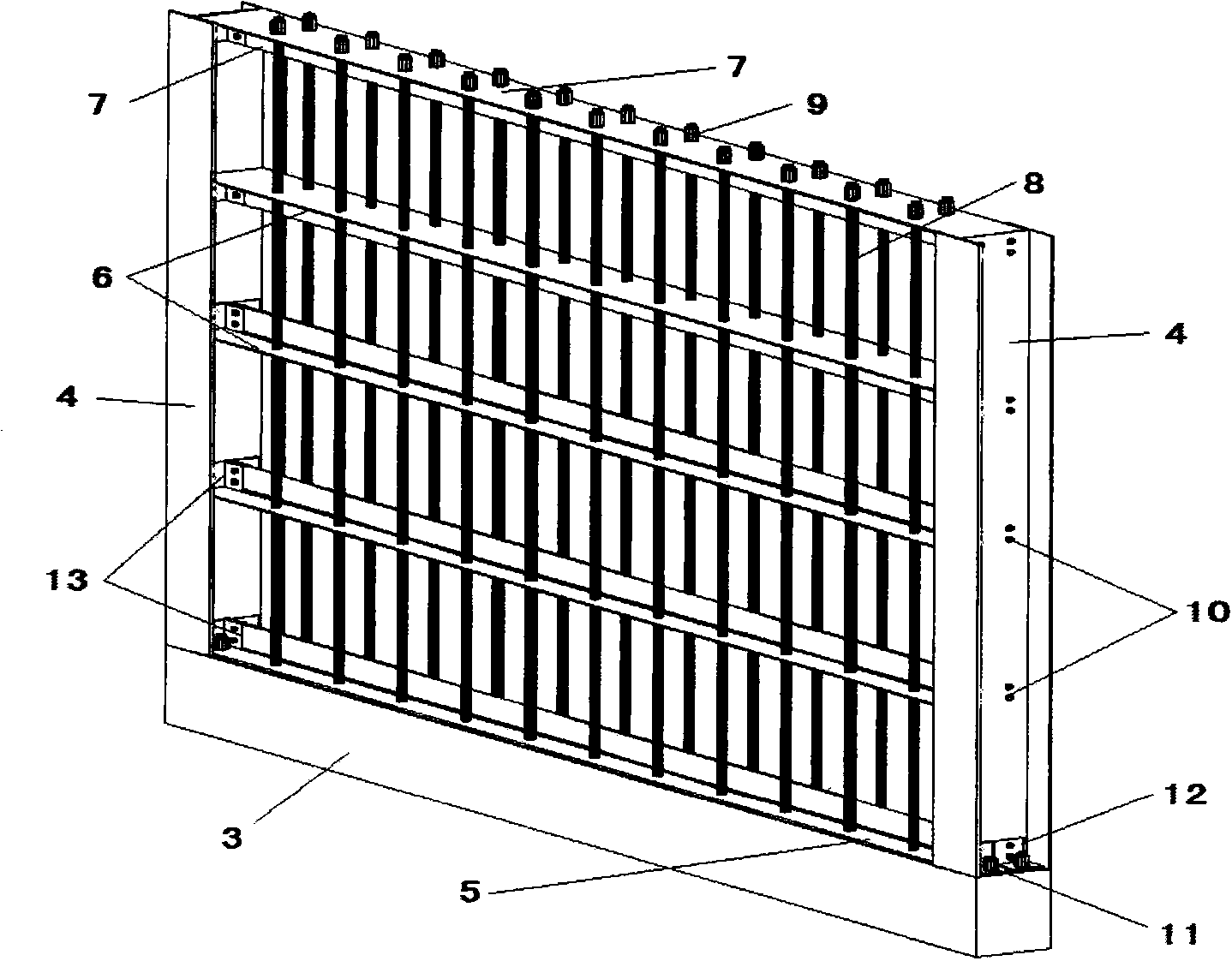

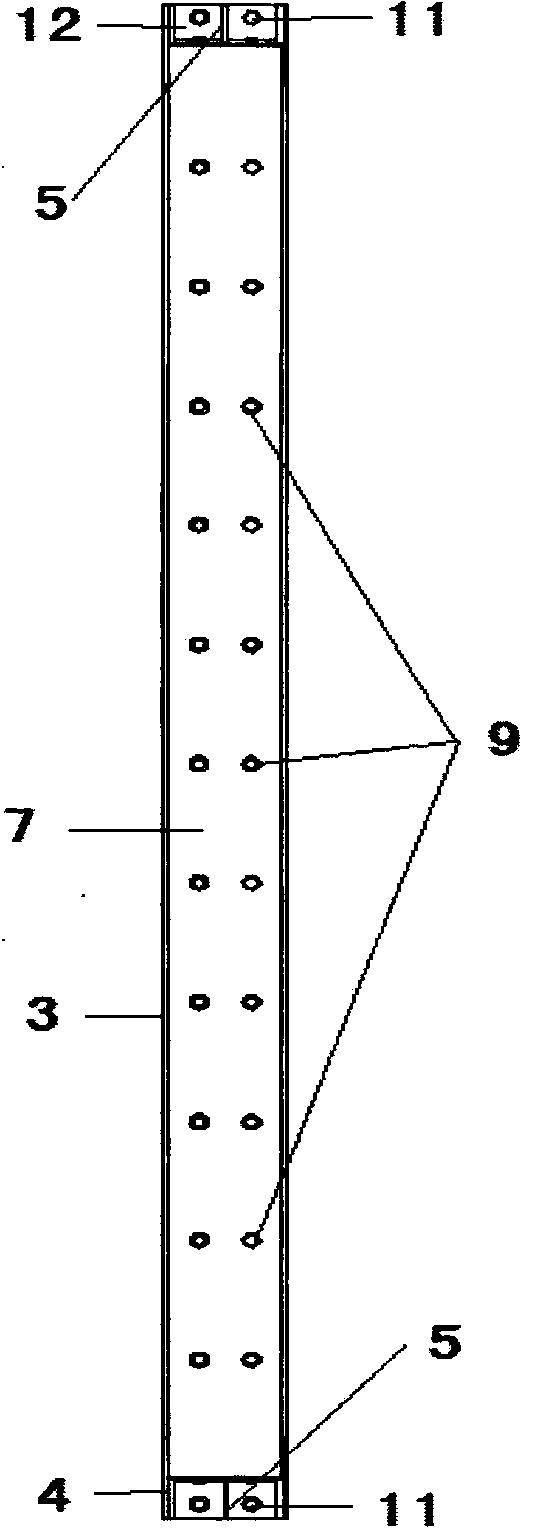

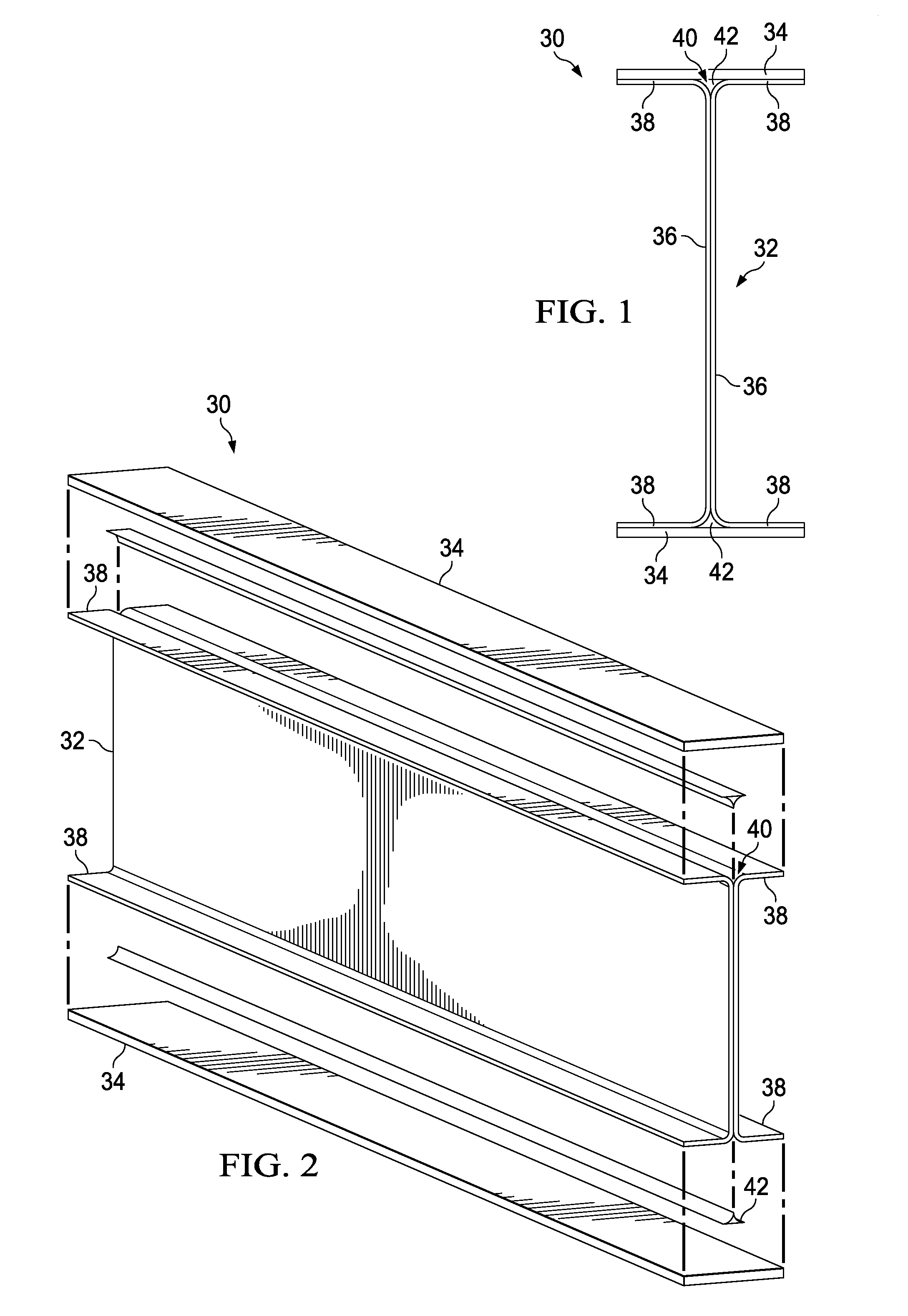

Concrete explosion-proof wall with embedded steel framework

InactiveCN103437460ASimple processing technologyHigh degree of standardizationWallsShock proofingFlangeH shaped

The invention relates to concrete explosion-proof wall with an embedded steel framework. The wall comprises a wall body (1) and a foundation (2), wherein the foundation (2) together with the wall body (1) are integrally cast with concrete, and a steel framework is embedded between the wall body (1) and the foundation (2). The wall is characterized in that the steel framework consists of two side vertical columns (4), a plurality of transverse beams and an embedded steel piece (3) of the foundation (2), wherein the two ends of each transverse beam are respectively, horizontally and fixedly connected with the two side vertical columns (4) according to different elevations, each vertical column (4) is made of H-shaped steel, the surface direction of an H-shaped steel wing flange (16) is consistent with the length direction of the wall body (1), each transverse beam is made of T-shaped steel, the embedded steel piece (3) of the foundation (2) is fixedly connected with the lower side of the bottom transverse beam (5), the upper side of each transverse beam is provided with a plurality of screw rod holes (15), a screw rod (8) penetrates through each screw rod hole (15), the top part of each screw rod (8) is fixedly connected with the top transverse beam (7), and the bottom of each screw rod (8) is fixedly connected with the embedded steel piece (3).

Owner:SOUTHWEAT UNIV OF SCI & TECH

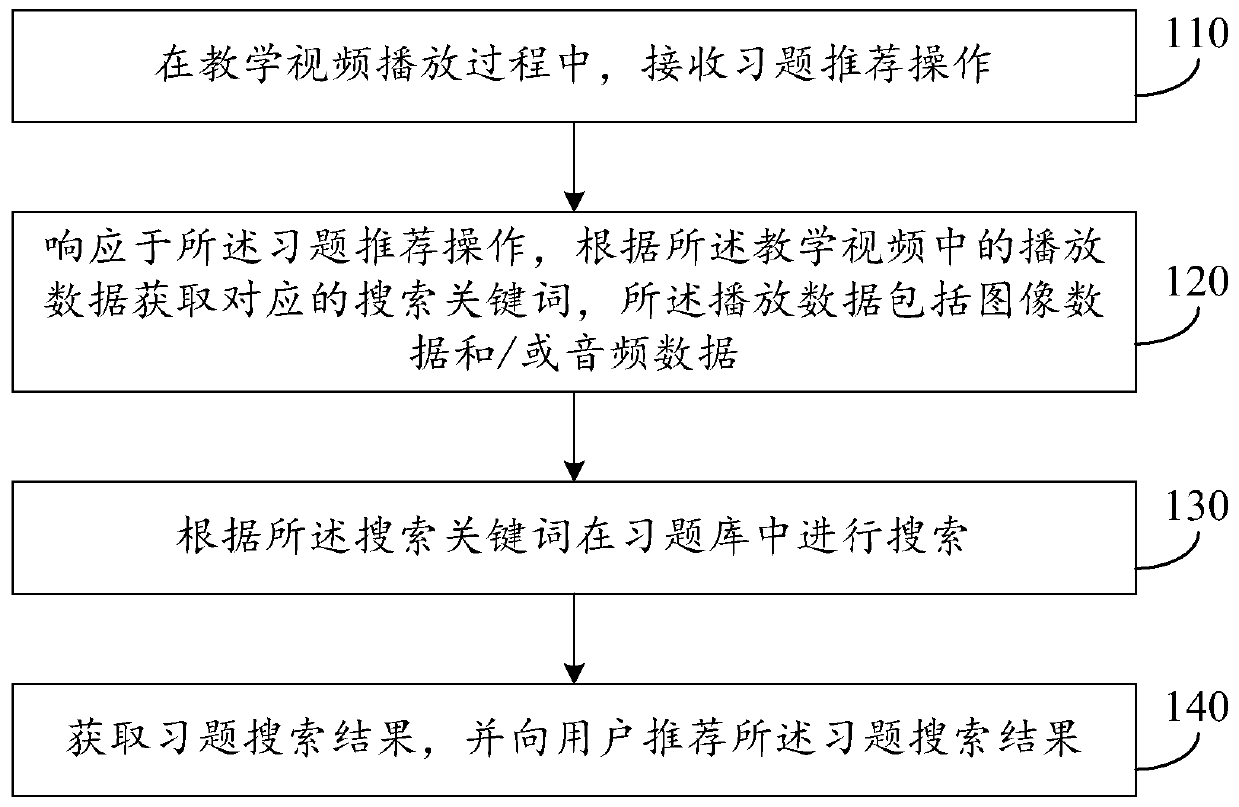

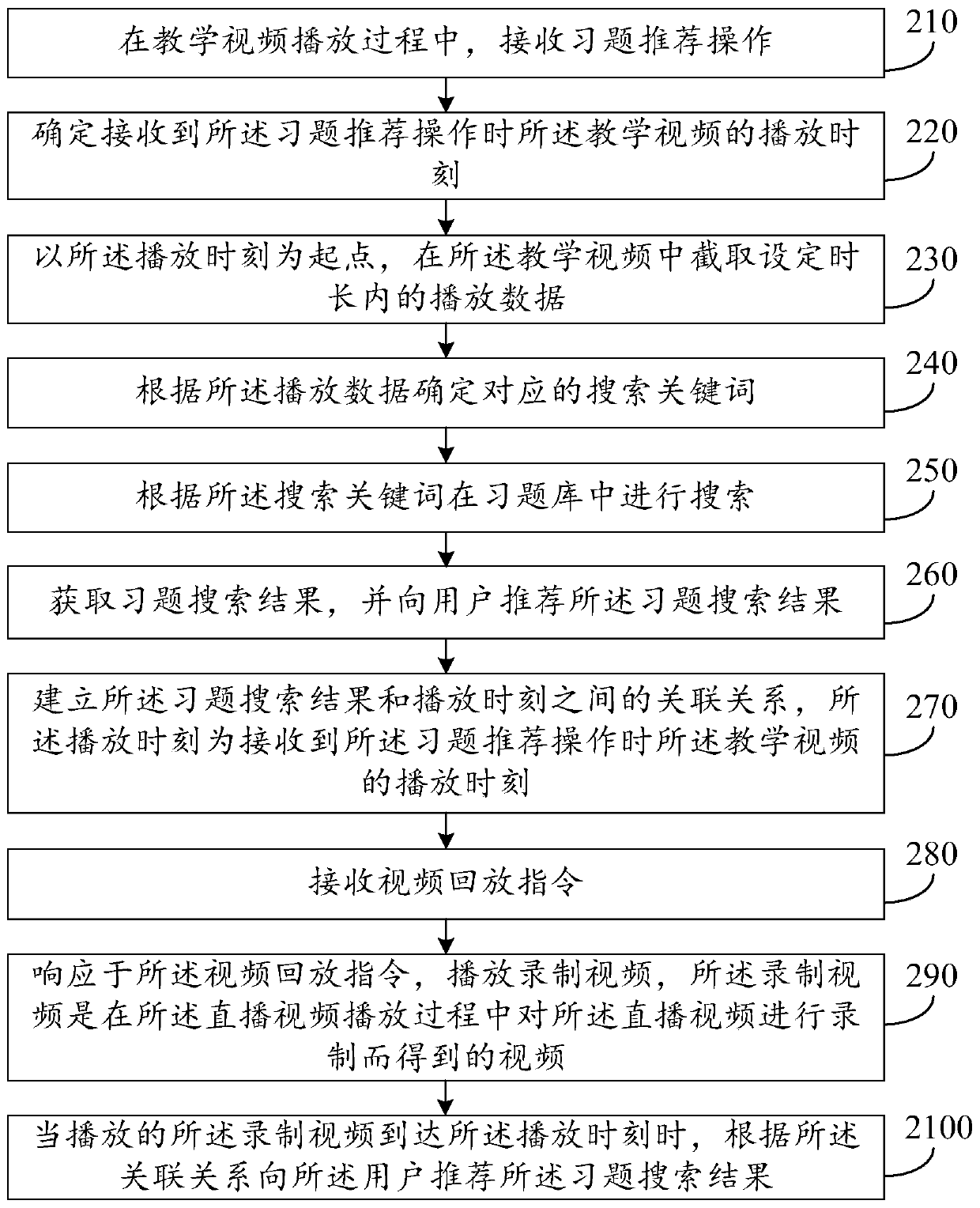

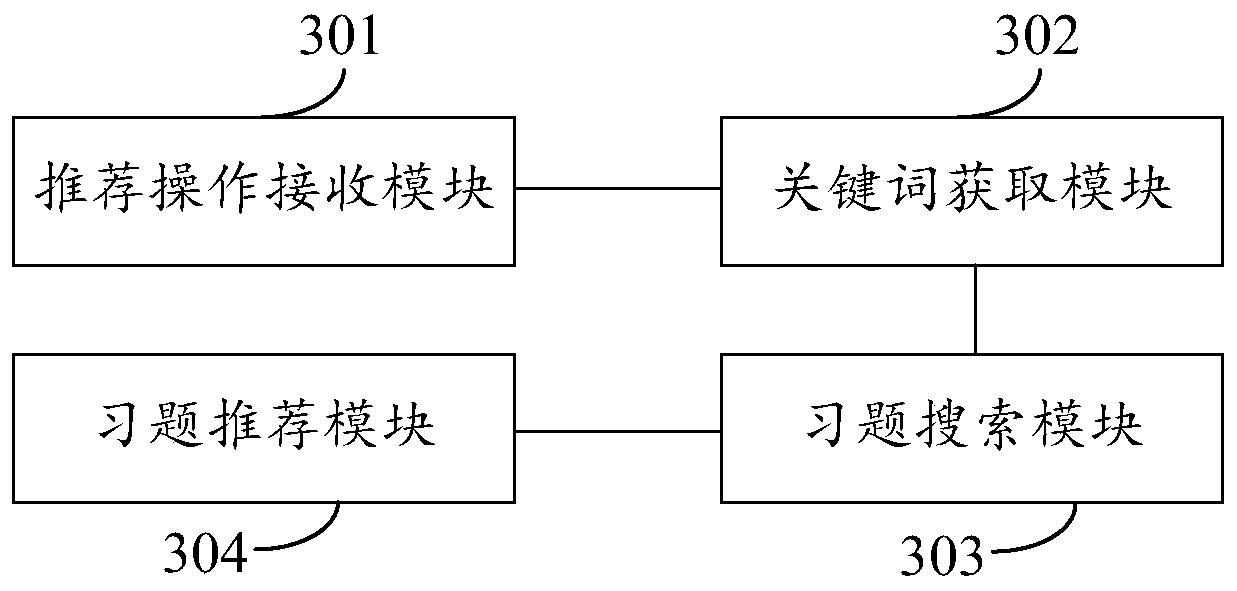

Exercise recommendation method, apparatus and device, and storage medium

PendingCN111522970AAvoid the situation where it is impossible to clarify the exercises assigned by the teacherImprove user experienceDigital data information retrievalData processing applicationsData packEngineering

The embodiment of the invention discloses an exercise recommendation method and device, equipment and a storage medium, and relates to the technical field of network teaching. The method comprises thefollowing steps: receiving an exercise recommendation operation in a teaching video playing process; in response to the exercise recommendation operation, obtaining a corresponding search keyword according to playing data in the teaching video, the playing data including image data and / or audio data; searching in an exercise library according to the search keyword; and obtaining an exercise search result, and recommending the exercise search result to the user. By adopting the scheme, the technical problem that students cannot perform consolidation practice in the teaching process in the prior art can be solved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

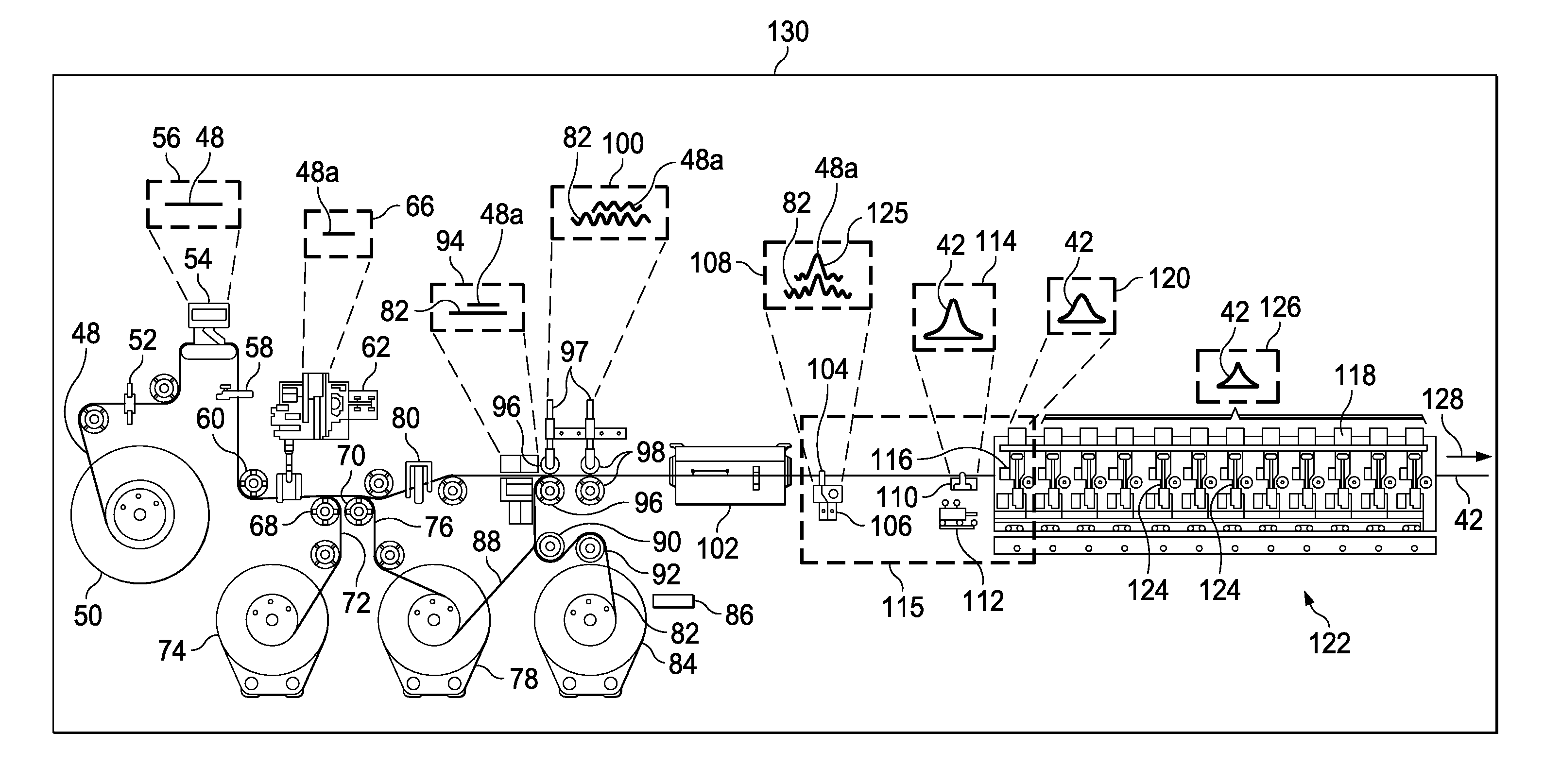

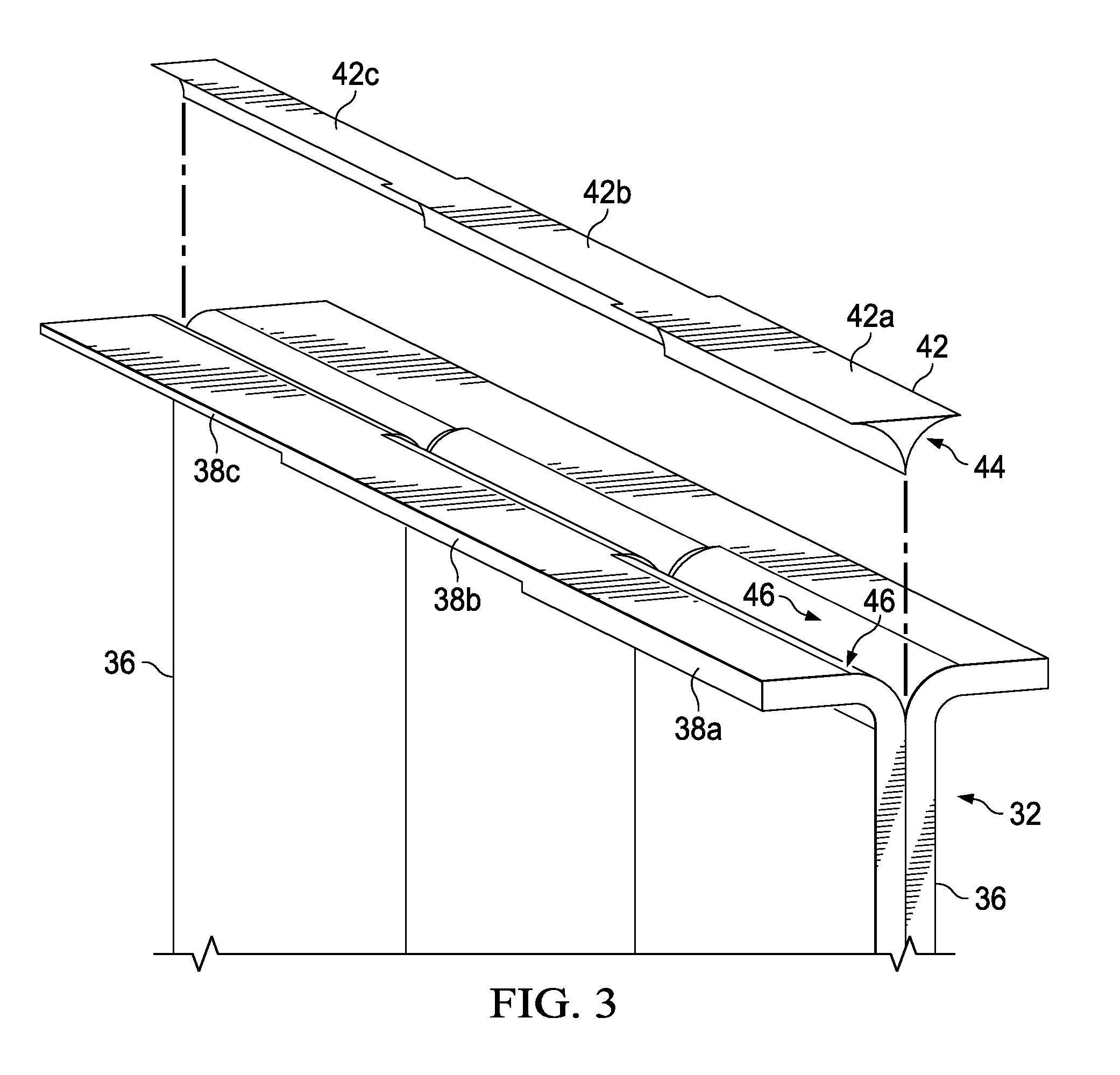

Automated fabrication of composite fillers

ActiveUS9415577B1Good size controlGood quality compactionLamination ancillary operationsLaminationPre conditioningFull width

A composite radius filler having a varying cross-sectional shape is pre-conditioned before being pultruded through forming dies. The composite filler radius filler includes a tab ply having a varying width that is laminated onto a supporting, full width base ply.

Owner:THE BOEING CO

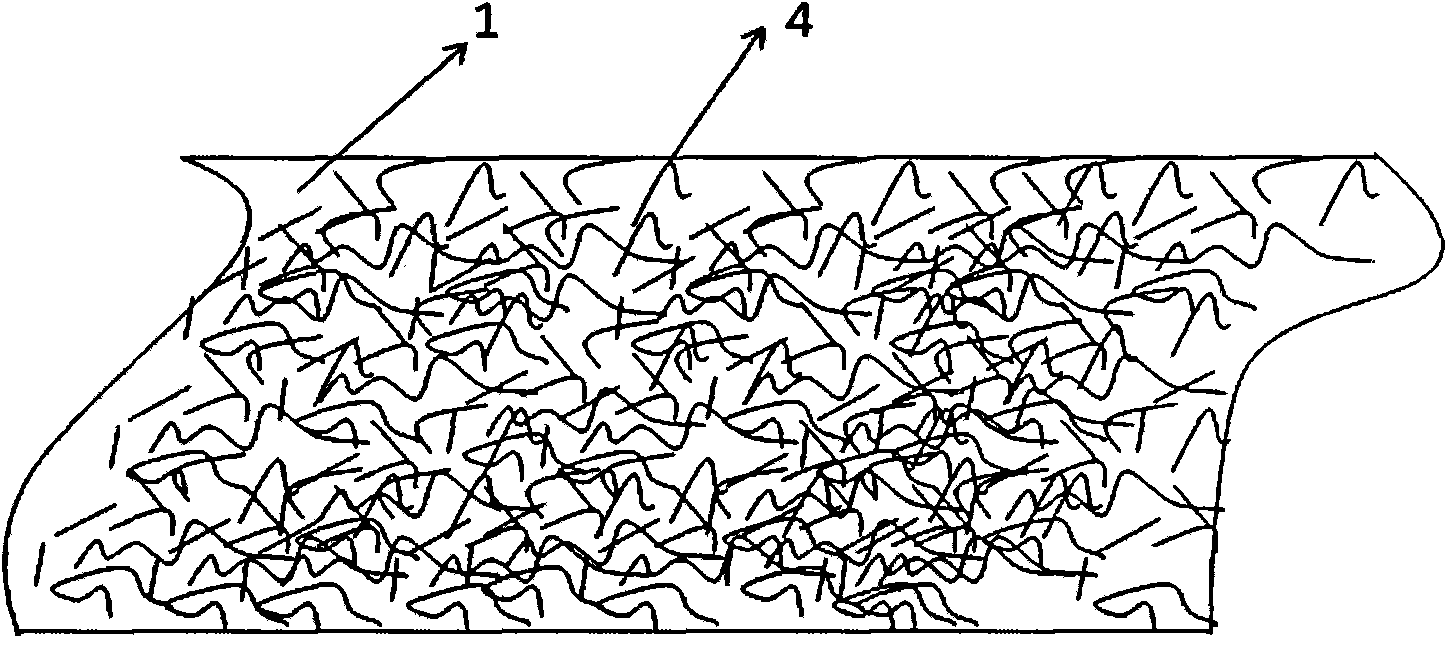

Physically-modified non-woven fabric and manufacturing method thereof

InactiveCN101974829AEasy to implementReduce manufacturing costNon-woven fabricsRougheningFiber layerWoven fabric

The invention discloses a physically-modified non-woven fabric and a manufacturing method thereof. The physically-modified non-woven fabric is manufactured by forming a fluffy fiber layer on a non-woven fabric through physical modification and napping the fluffy fiber layer. As for the physically-modified non-woven fabric, processing is carried out after fabric formation, thus being easy to implement and having low production cost. Due to the fluffy fiber layer on the surface thereof, the physically-modified non-woven fabric has soft handle, and is affine and comfortable for human bodies; and by adopting a physical method to change the structure thereof instead of adopting a chemical additive for post-processing and other means to change the handle, and the fabric has safer materials.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

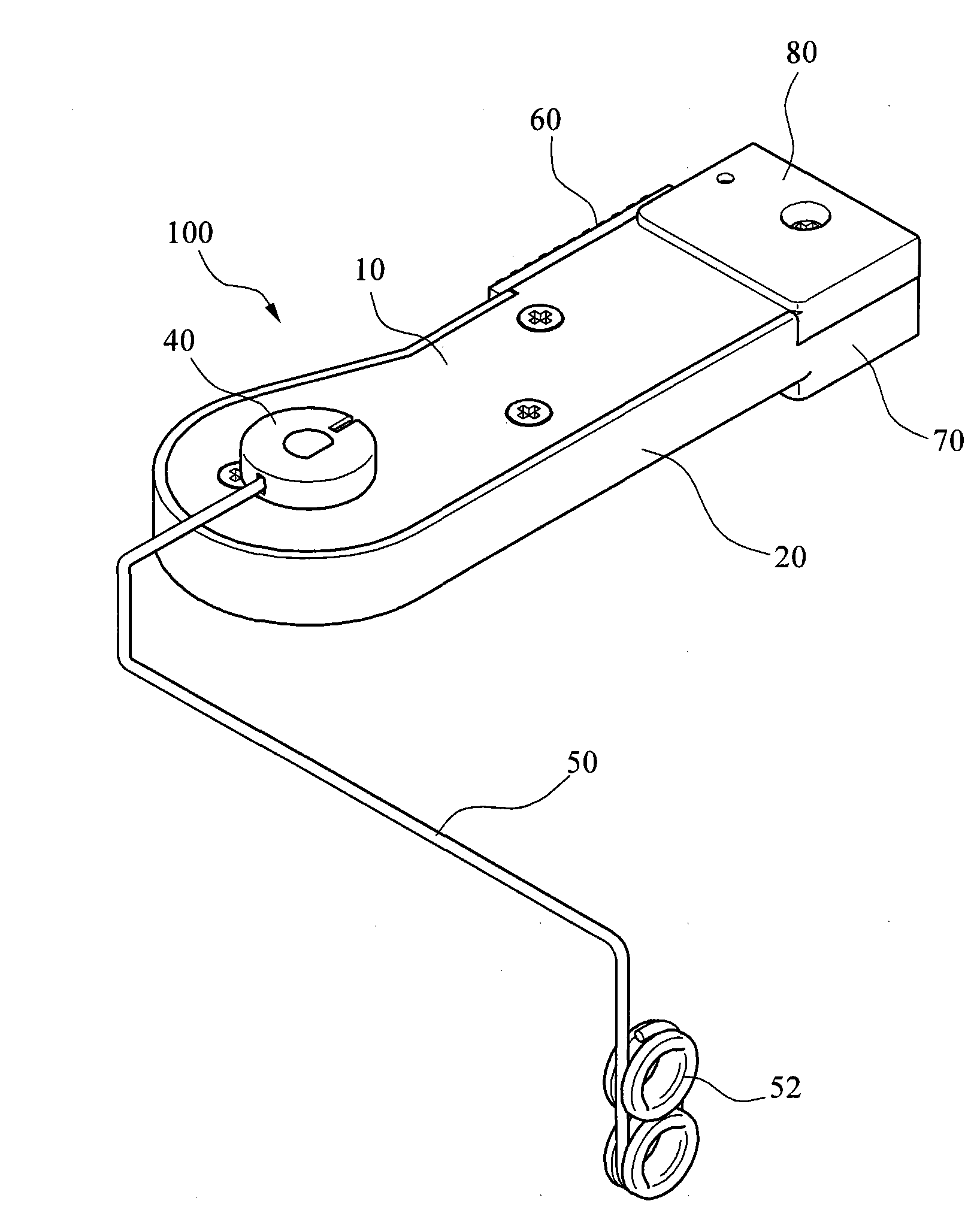

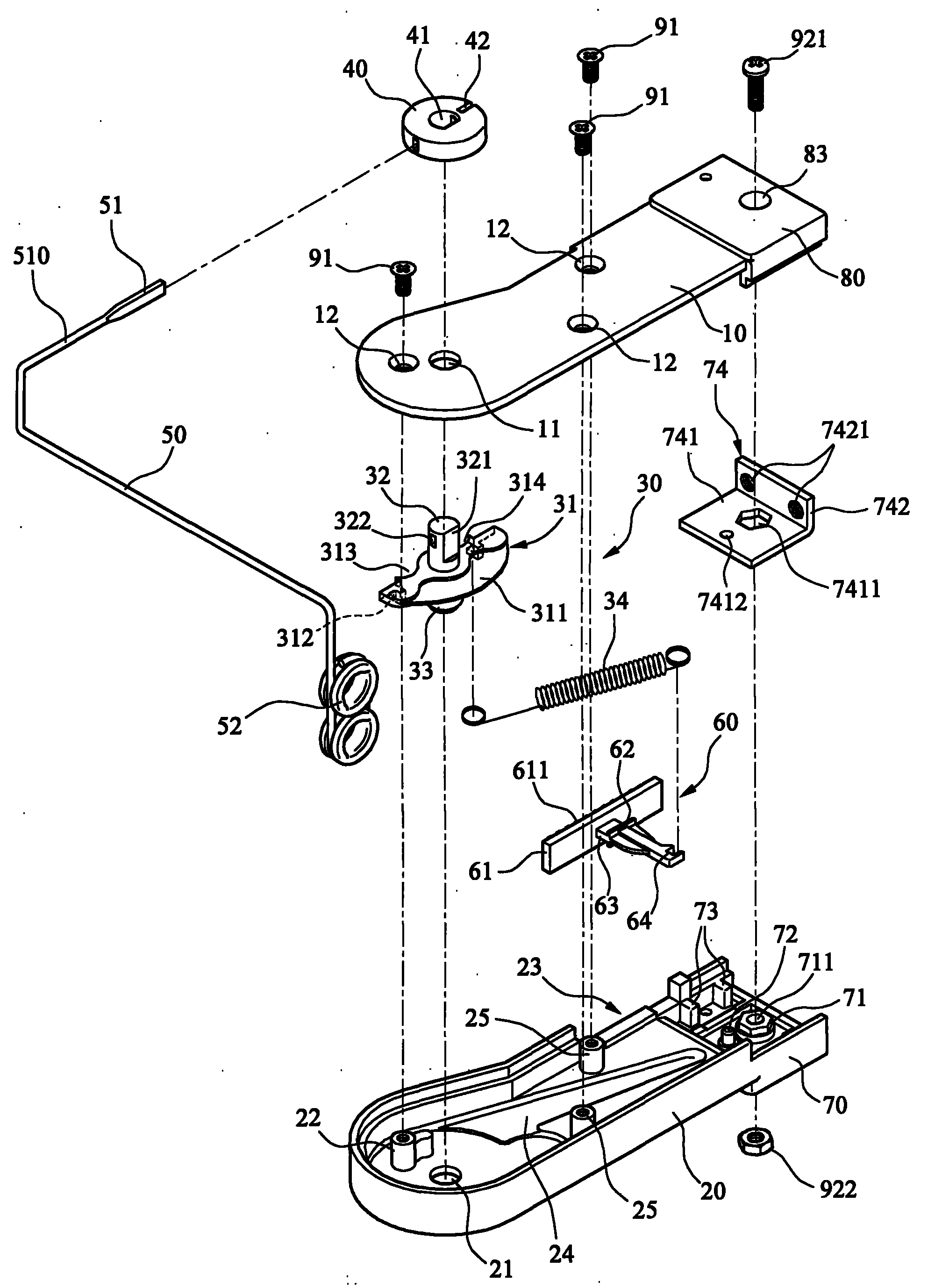

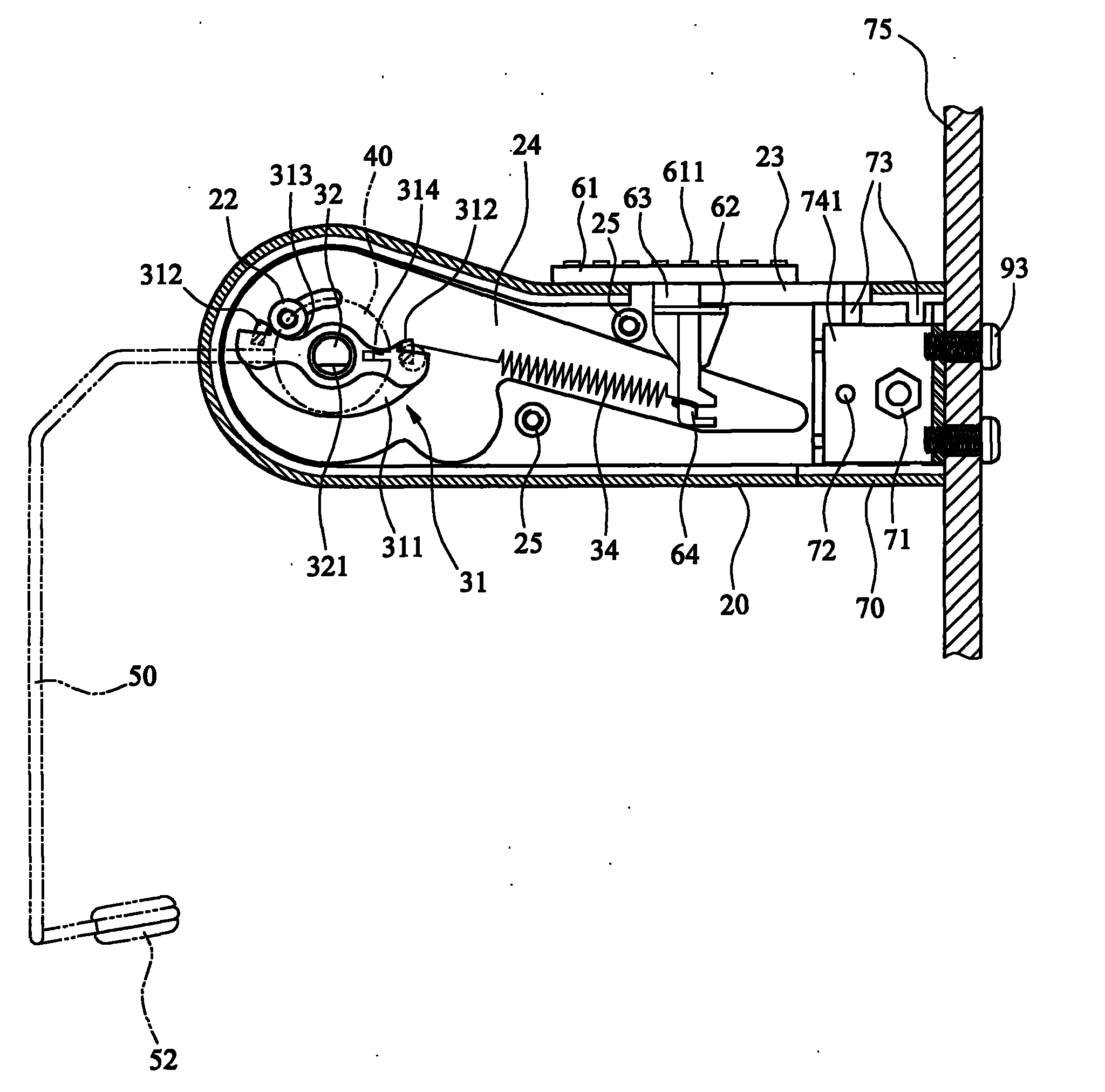

Improved single-arm yarn carrier

The invention provides an improved single-arm yarn carrier comprising a shell consisting of a cover body and a base, a pivoting device arranged in the shell, a connecting piece connected with the pivoting device, a yarn guiding arm connected with the connecting piece and a yarn guiding eye arranged at the free end of the yarn guiding arm, wherein the pivoting device comprises a swing member; the swing member is provided with a body, as well as a first pivot shaft and a second pivot shaft which are integrally extended out of the body; at least one hook rod is arranged on the body; a spring is connected between the hook rod and the base; the swing member is arranged in the cover body and the base in a pivoting manner through the first pivot shaft and the second pivot shaft; and after penetrating through the cover body, the first pivot shaft is connected with the connecting piece so that the swing member can be interlocked with and drive the yarn guiding arm arranged on the connecting piece to swing through the first pivot shaft.

Owner:陈仁惠 +2

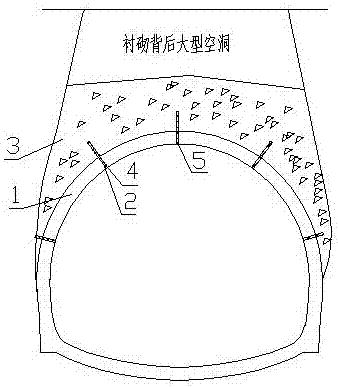

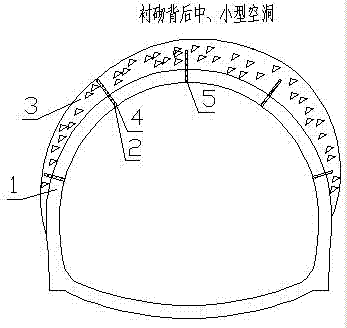

Construction method for back cavity of tunnel lining and constructed composite lining structure

PendingCN107387095AEnsure safetyReduce crystallization attackUnderground chambersTunnel liningFoam concreteLandslide

The invention relates to a construction method for a back cavity of a tunnel lining and a constructed composite lining structure. The construction method comprises the following steps: drilling a grouting hole in the surface of a lining; mounting a grouting tube in the grouting hole; filling the cavity on the back of the lining with foam concrete through the grouting tube to form a buffer layer; filling cavities or a large landslide section or other road sections; closing and compacting the grouting tube by using waterproof mortar, and enabling the surface of the grouting tube to be level and parallel to the lining. According to the composite lining structure formed after construction, the grouting hole is formed in the lining, the grouting tube is arranged in the grouting hole, the length of a part, which enters the cavity, of the grouting tube is 1-4 m, the grouting hole and the grouting tube are hermetically combined in a sleeving manner, the outer side of the lining is a foam concrete layer, and a waterproof mortar column is arranged in the grouting tube. By the construction method, impact of stones falling from the top of the cavity to the lining is reduced effectively, and the safety of the lining structure is guaranteed.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

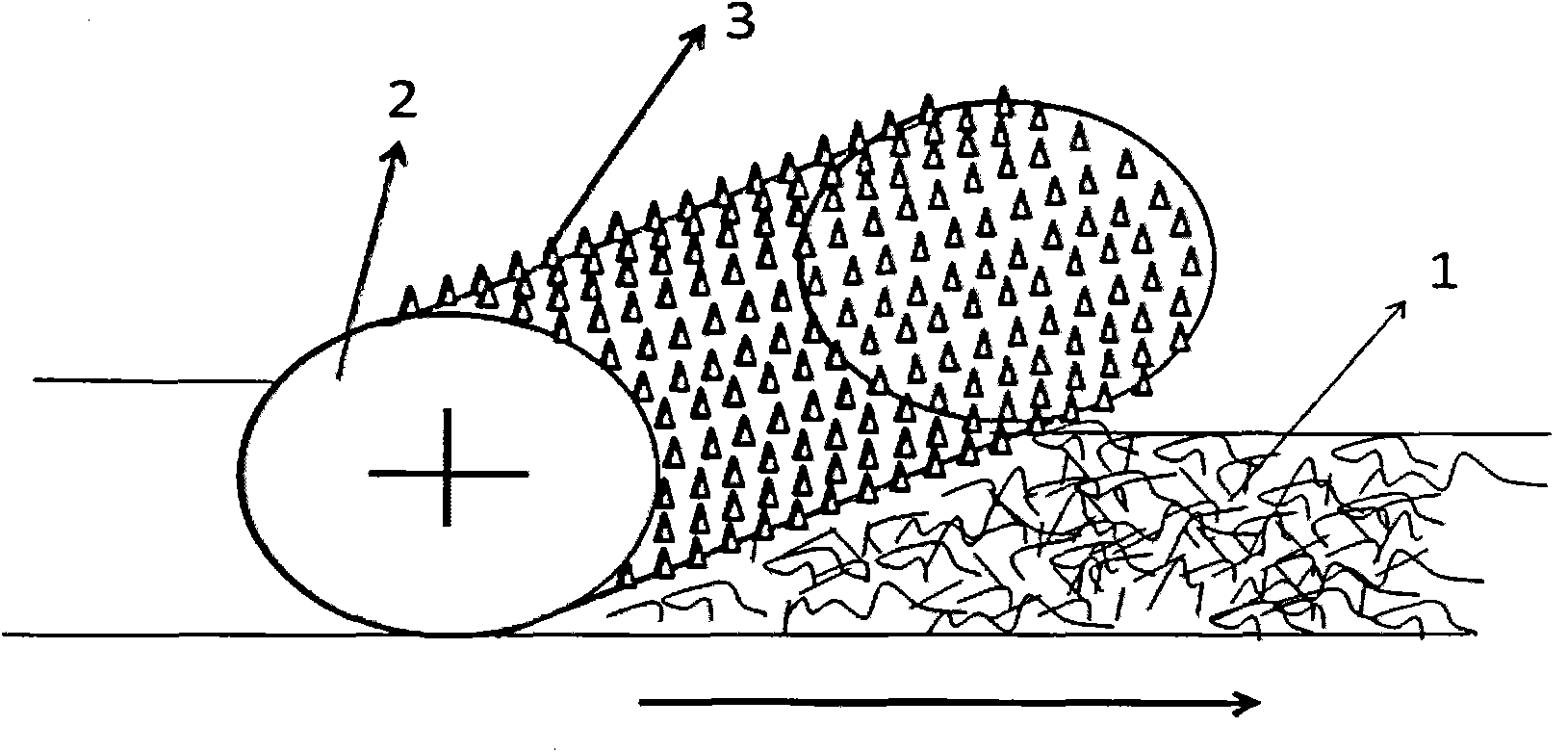

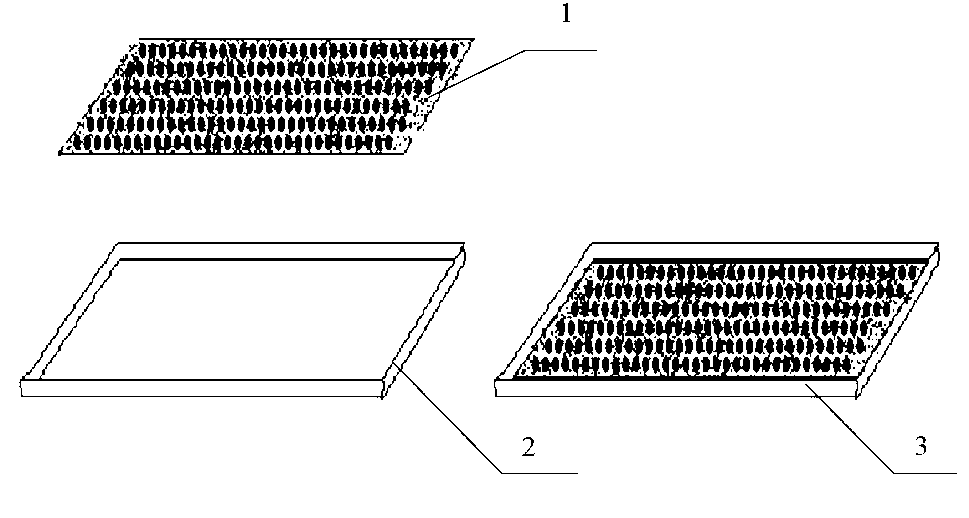

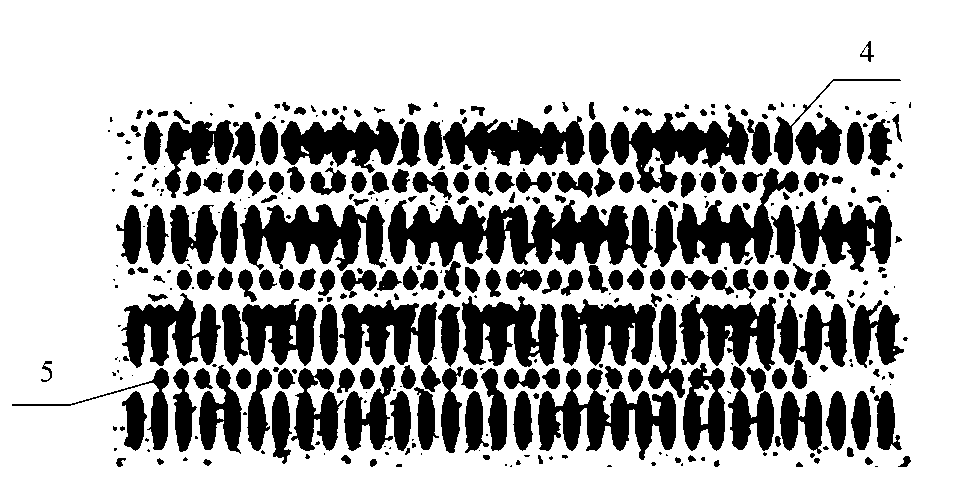

Rice seedling machine seedling planting diaphragm and manufacture method of rice seedling machine seedling planting diaphragm

ActiveCN103070045AGood consolidationPromote growth and developmentCultivating equipmentsNon-woven fabricsMechanical stretchingEconomic benefits

The invention discloses a rice seedling machine seedling planting diaphragm and a manufacture method of the rice seedling machine seedling planting diaphragm. By aiming at the problems that the seedling root winding effect in the rice seedling machine seedling planting is poor, the seedlings can easily get scattered, and the operation is complicated, the invention provides the rice seedling machine seedling planting hemp-base diaphragm, which consists of a hemp fiber diaphragm substrate and rice seeds fixedly carried on the substrate. The hemp fiber raw materials are subjected to loosening, scattering and mechanical stretching to form a net, then, biodegradable bonding agents are adopted for bonding, baking is carried out, the hemp fiber diaphragm substrate is formed, and next, the rice seeds are uniformly scattered and pasted on the hemp fiber diaphragm substrate through the biodegradable bonding agents. When the rice seedling machine seedling planting hemp-base diaphragm provided by the invention is adopted, the seedling culture operation can be greatly simplified, farmers can realize the seedling culture without seeding, in addition, the seedling root system winding effect can be obviously promoted, the winding force is improved, seedlings conforming to the machine seeding requirements are formed, meanwhile, because the seedling quality is improved, the green returning speed of the seedlings after the machine seedling planting is high, the tillering effect is good, the rice yield is obviously improved, and good economic benefits are realized.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

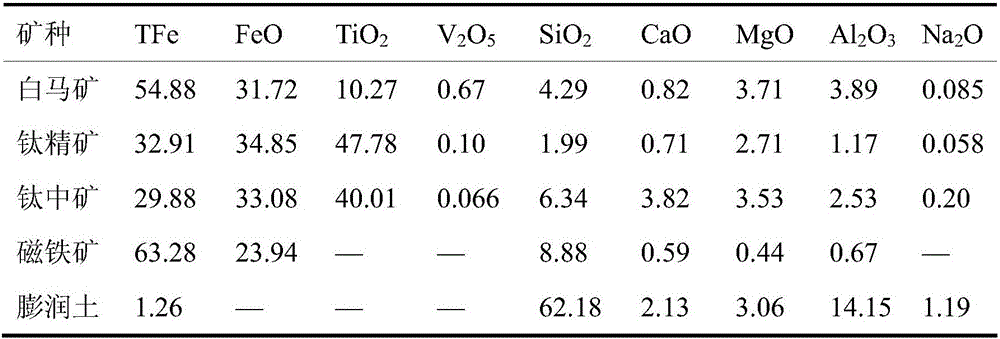

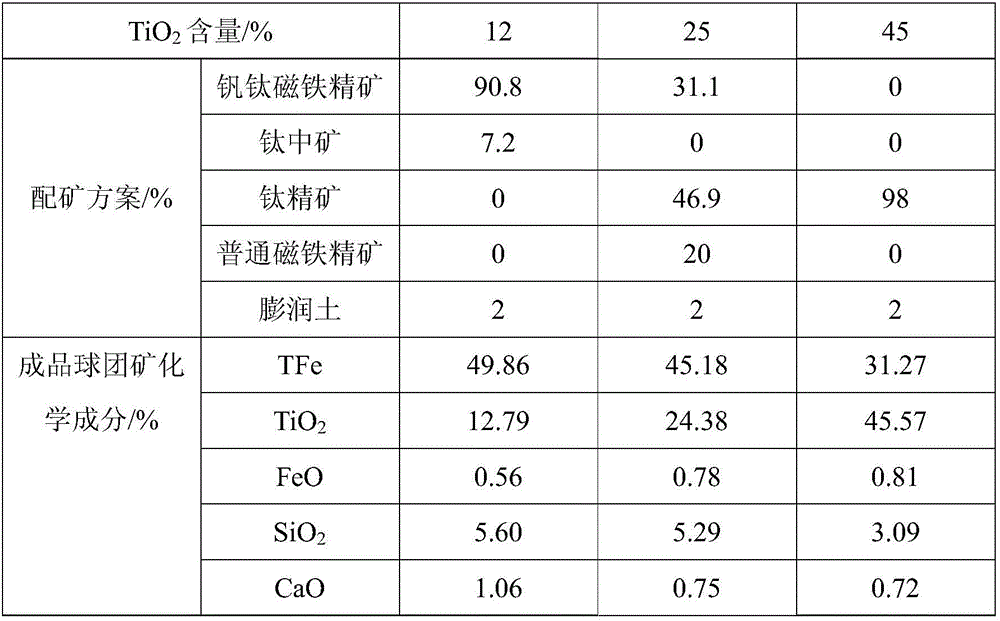

Preparation method of high-strength high-titanium pellets

The invention discloses a preparation method of high-strength high-titanium pellets. According to the method, a mixed material with TiO2 content of 12-45wt% is subjected to high pressure roller grinding and wet grinding treatment to prepare pellets; after being dried, the pellets are placed in an oxidizing atmosphere to be subjected to low-temperature oxidizing roasting, and the roasted pellets are cooled after being sintered at high temperature, thus obtaining the high-titanium pellets with strength of greater than 2500N / P and TiO2 content of 12-45%; and the high-titanium pellets can meet the requirements of large blast furnaces of more than 2500m<3> for the strength of pellets, so as to play a role of protecting the lining of the blast furnace.

Owner:CENT SOUTH UNIV

Harbor construction sea reclaimed material utilizing silt and preparation method thereof

InactiveCN102617078ASolve the way outSave natural resourcesSolid waste managementNatural resourceUltimate tensile strength

The invention relates to a harbor construction sea reclaimed material utilizing silt, which is prepared by mixing gangue sand, the silt and cement. Water content of the silt is 60%-100%, and the weight ratio of the silt, the gangue sand and the cement is 1: 3-5: 0.04-0.06. A preparation method of the harbor construction sea reclaimed material utilizing silt is further disclosed. The material and the method achieve waste object utilization of the gangue sand and the silt. The material is high in strength, low in construction cost and capable of achieving quick solidification of silt and saving a large amount of natural resources. The material can be applied to projects such as sand quilt blowing filling, filtering guide layers, sand cushion layers and land area backfilling.

Owner:连云港港口工程设计研究院有限公司

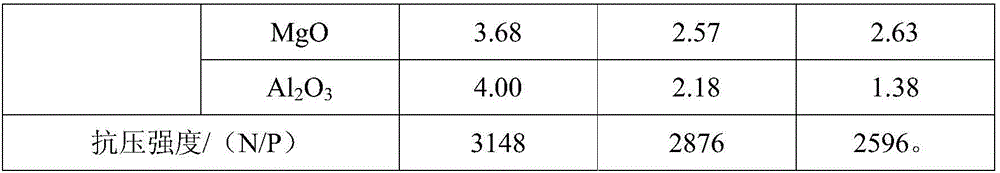

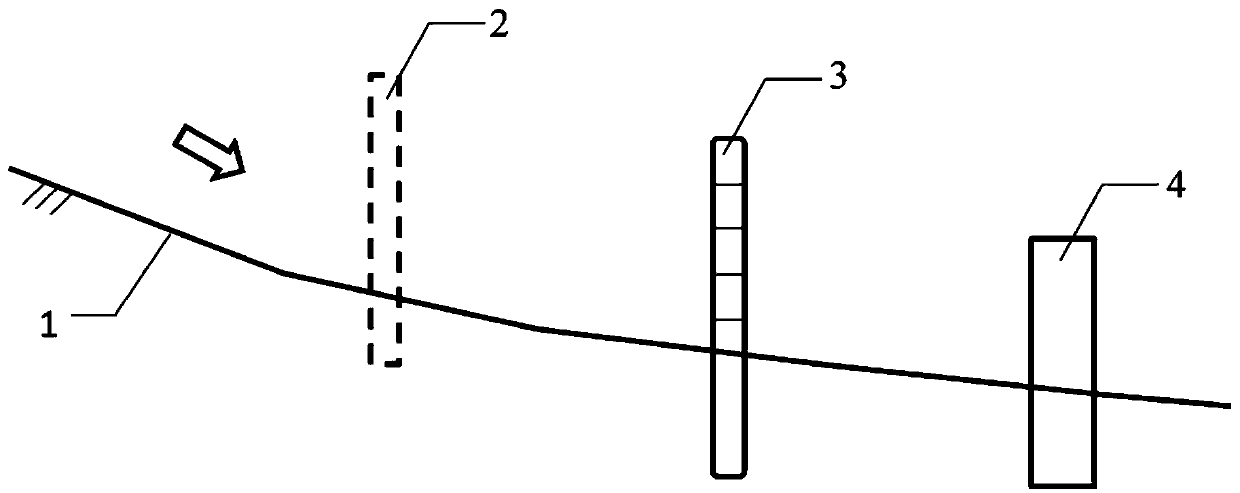

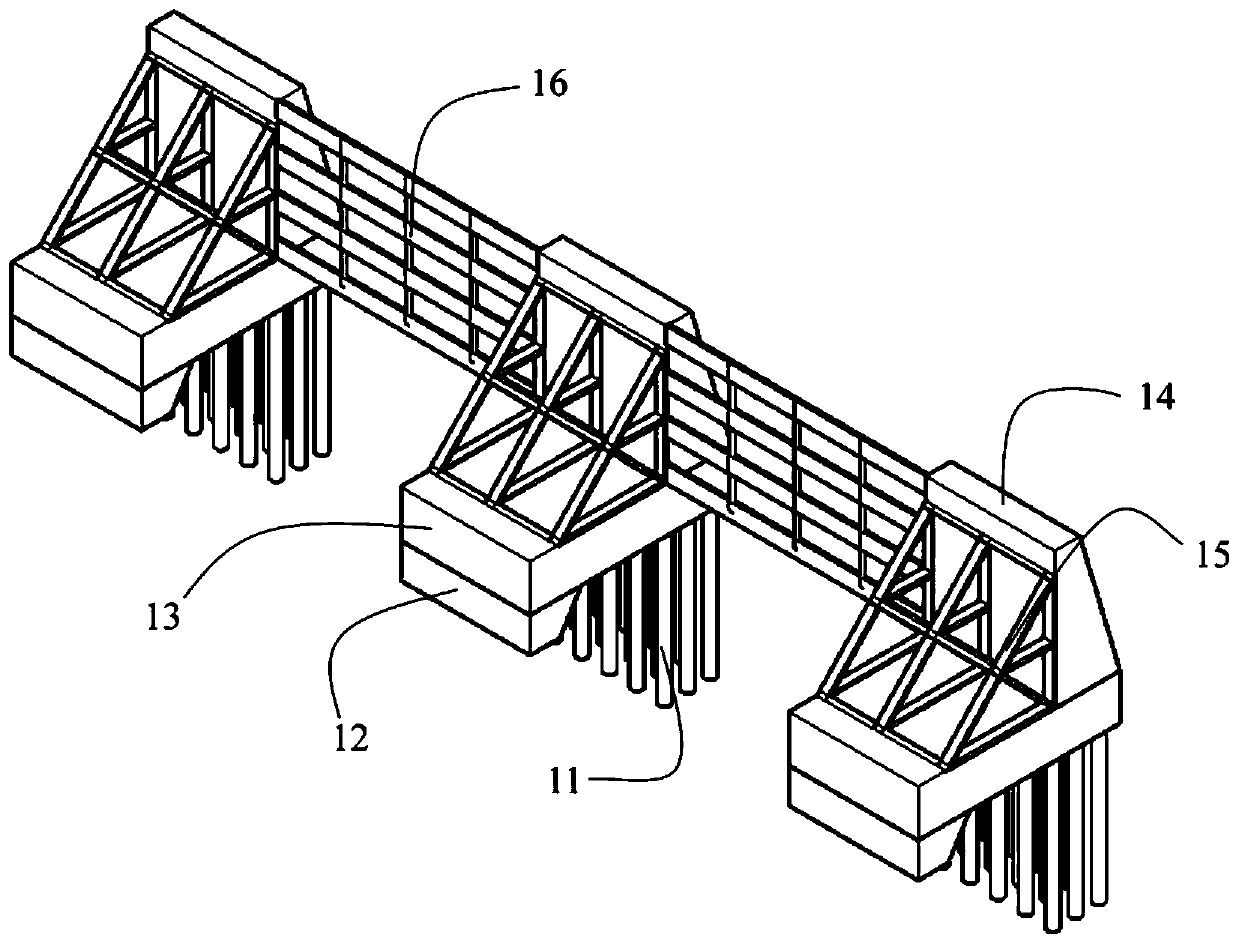

Debris flow multi-stage dissipative blocking structure

PendingCN110004882AConsume impact energyReduce shockProtective constructionFoundation engineeringButtressEngineering

The invention relates to the technique of prevention of geological hazards, in particular to a debris flow prevention technique. The invention discloses a debris flow multi-stage dissipative blockingstructure, thus damage action of a debris flow can be lowered, and the disaster loss is relieved. According to the debris flow multi-stage dissipative blocking structure, from flowing area of the debris flow to the accumulation area, the debris flow multi-stage dissipative blocking structure is arranged in a step-by-step mode along debris flow channels from the upstream to downstream, and at leastincludes a flexible blocking net, a pile-carrying-type grid wall and a permeable buttress-type gravity dam. According to the debris flow multi-stage dissipative blocking structure, according to different geological conditions, types of the debris flows and the like, the matching structure of the flexible blocking net 2, the pile-carrying-type grid wall 3 and the permeable buttress-type gravity bam is reasonably selected, benefits of the investment in engineering construction can be given full play to the maximum extent, and cost benefit optimization is achieved. The debris flow multi-stage dissipative blocking system is very suitable for prevention of the debris flow disasters.

Owner:SOUTHWEST JIAOTONG UNIV

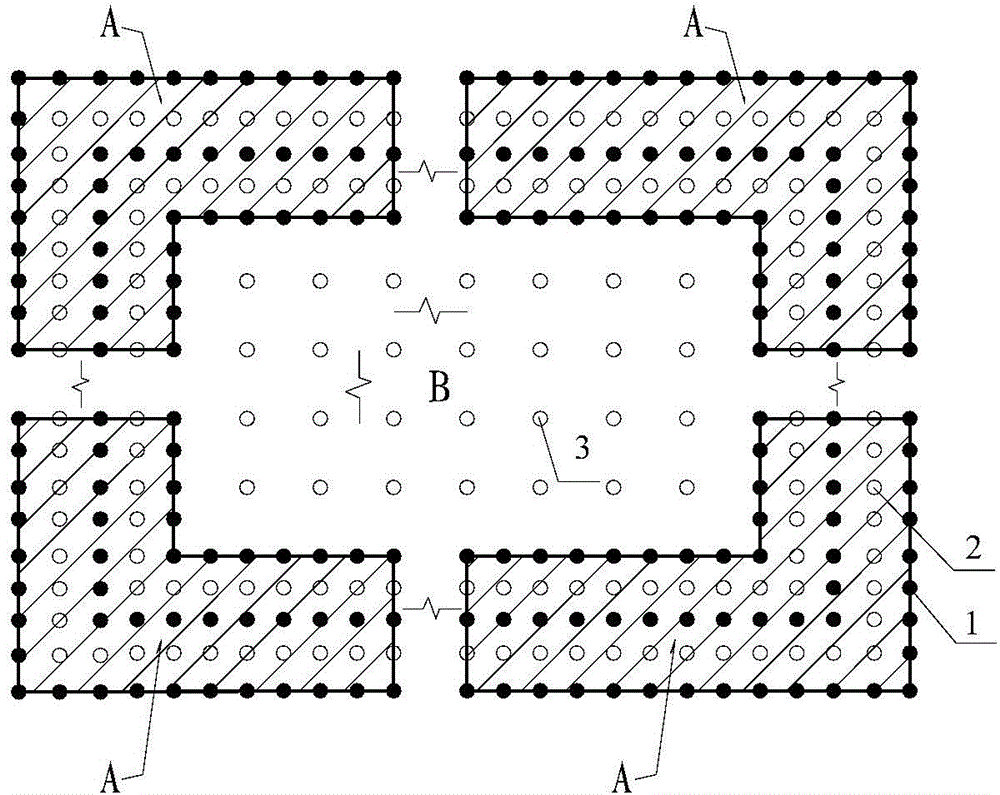

High-pressure water-rich goaf grouting reinforcement method

ActiveCN106149677AImprove reinforcement effectReduce the effects of stressSoil preservationWater sourceHigh pressure water

Disclosed is a high-pressure water-rich goaf grouting reinforcement method. Through the high-pressure water-rich goaf grouting reinforcement method, many defects of existing goaf grouting reinforcement methods are overcome, so that high-pressure water-rich goaf grouting reinforcement construction is feasible and fast, and the construction cost is saved. According to the high-pressure water-rich goaf grouting reinforcement method, artificial explosion is used for forming goaf top plate caving zones, high-pressure grouting is adopted in the caving zones under the action of high-pressure water on the two sides for forming curtain reinforcement bodies, and the problem that curtains are difficult to be formed by grouting liquid in a high-pressure water-rich goaf is solved. Grouting reinforcement is started from the periphery to the inside of a goaf reinforcement area, the pressure influence of high-pressure water on the periphery of the goaf reinforcement area and non-section supplement of a water source can be reduced gradually, grouting holes are used for water pumping and drainage so that the pressure of the high-pressure water in the goaf can be reduced, thus the condition that each grouting hole adopts high pressure grouting can be avoided, meanwhile, deposition and solidification of the grouting liquid are facilitated, accordingly, the construction time is saved, and the construction cost is reduced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

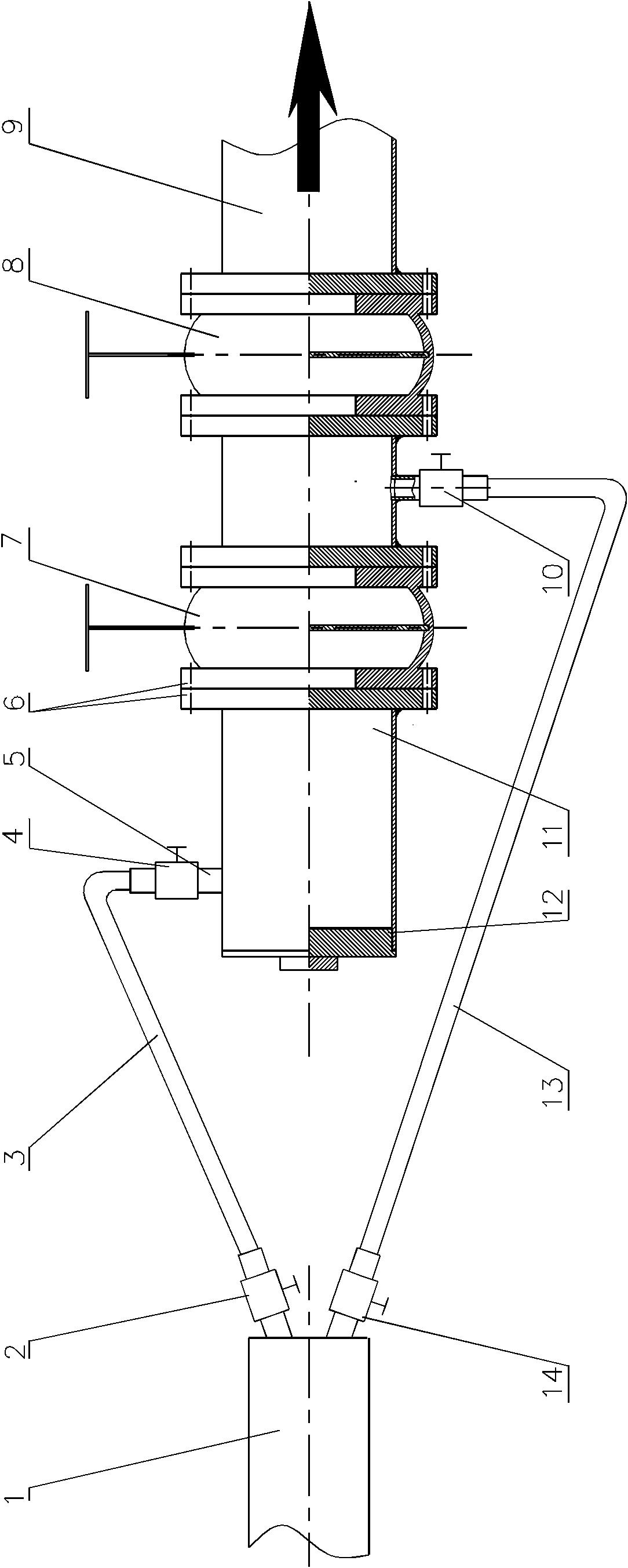

Underground gushing water borehole aggregate addition system and process thereof

InactiveCN101967828AEasy to settleGood consolidationFoundation engineeringHigh pressureConstruction aggregate

The invention relates to an underground gushing water aggregate addition system and a process thereof. In the invention, aggregate can be smoothly and continuously injected into a borehole under the high-pressure gushing water condition to block up bigger guide water-contained fractures or overflow structures so as to drag the flow rate of gushing water, promote the materials to be settled and solidified and reduce the material loss, thereby achieving the goal of grouting to plug the water. The system comprises a grouting pipe. The grouting pipe is respectively communicated with a grouting casing pipe through a water injection pipeline I and a water injection pipeline II; the grouting casing pipe is provided with a sluice valve I and a sluice valve II; the joints of the water injection pipeline I and the grouting casing pipe are at the front end of the grouting casing pipe and the front part of the sluice valve I, and the joints of the water injection pipeline II and the grouting casing pipe are arranged between the sluice valve I and the sluice valve II, i.e. the water injection pipeline I and the water injection pipeline II are divided into two independent water injection systems through the sluice valve I.

Owner:SHANDONG UNIV

Wheat straw biomass particles and preparation method thereof

The invention relates to the technical field of biofuel, in particular to wheat straw biomass particles. The wheat straw biomass particles comprise 55-75 parts of wheat straw, 30-45 parts of rice husk, 25-32 parts of corn stalk, 15-18 parts of waterweeds, 22-40 parts of sawdust, 20-35 parts of desulfurized coal slag, 50-60 parts of Chinese herbal medicine dregs, 5-12 parts of gypsum, 0.8-5 parts of swelling agent, 10-30 parts of paraffin wax, and 8-20 parts of squalane powder. A preparation method is also provided and comprises the steps of drying, segmenting, pulverizing, mixing, stirring, press forming, drying, granulating and packaging. According to the invention, the desulfurized coal slag and sawdust are added to the raw materials, so that the burning value of the biomass particles are higher than that of conventional biomass particles; the gypsum is added, and the prepared biomass particles are high in molding rate and not easy to loose due to good consolidation property of the gypsum; and the swelling agent is added, so that the biomass particles are loosened and can be fully burned when burned.

Owner:亳州市创亿生物质燃料科技有限公司

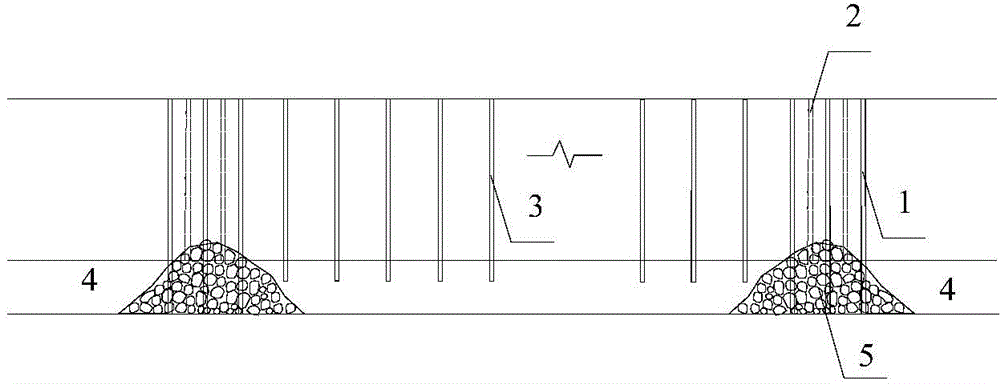

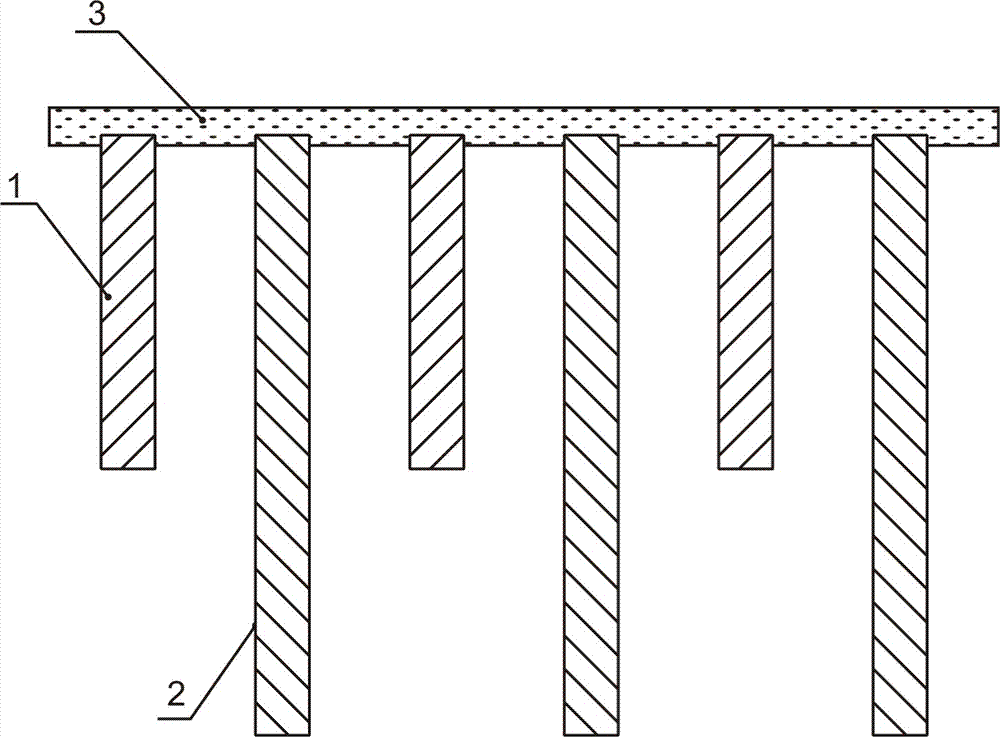

Gravel pile and plain concrete pile combined composite foundation

InactiveCN103046530AGood consolidationHigh compressibilitySoil preservationCrushed stoneCompressibility

The invention discloses a gravel pile and plain concrete pile combined composite foundation. Gravel piles and plain concrete piles are alternately arranged in a field needing to be treated, gravel cushion layers are paved at the tops of the piles, and the length ratio of the gravel piles to the plain concrete pile is 1:2. The gravel piles can effectively compact earth among the piles to solve the problem of uncompleted concretion of new fill stratums and can form drainage channels to achieve the effects of replacing and forming the drainage channels, and meanwhile, foundation liquefaction can be further eliminated by compaction vibration during construction of the gravel piles. The gravel piles, the plain concrete piles and an original natural foundation jointly form the combined composite foundation, and effects of compacting soil mass, replacing and forming the drainage channels, eliminating liquefaction and benefiting soil mass concretion are achieved while bearing capacity can be greatly improved and soil compressibility of the foundation is lowered. The gravel piles and the plain concrete piles are combined, disadvantages are avoided while advantages are complemented, treatment effects are guaranteed while the requirements of a superstructure are met, and effects of capital saving and project period shortening are further achieved.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

Surgical method for repairing a fractured shoulder joint

This method comprises the use of a repair equipment including a humeral rod (2) intended to be placed in the medullary cavity of the humerus, comprising at least one hole (6) for receiving a thread (11) for repositioning the tuberosities (101, 102) and for maintaining the latter with respect to the rest of the bone. Said hole (6) is formed in the metaphyseal portion of the humeral rod (2), in the anteroposterior direction thereof; and the repair equipment further comprises a so-called “guying” subassembly (3), to maintain the tuberosities (101, 102) when they re-installed, two second so-called “traction” subassemblies (4), for pulling of the tuberosities (101, 102) one toward the other, and two so-called third “pressing” subassemblies (5), for tackling the tuberosities (101, 102); each of these sub-assemblies comprises a needle and thread (11) connected to this needle, this thread (11) forming a loop.

Owner:FX SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com