High-pressure water-rich goaf grouting reinforcement method

A technology of grouting reinforcement and goaf, which is applied in construction, infrastructure engineering, soil protection, etc., to achieve the effect of low engineering investment, simple operation, and favorable deposition and consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] refer to figure 1 and figure 2 , the high-pressure water-rich goaf grouting reinforcement method of the present invention comprises the following steps:

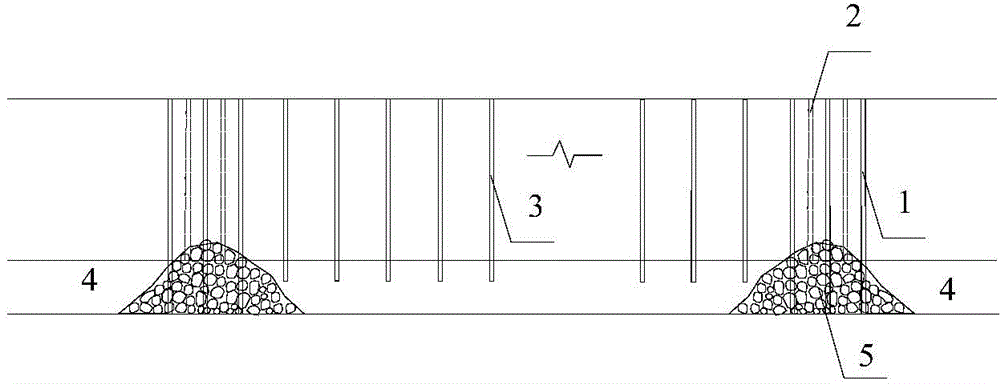

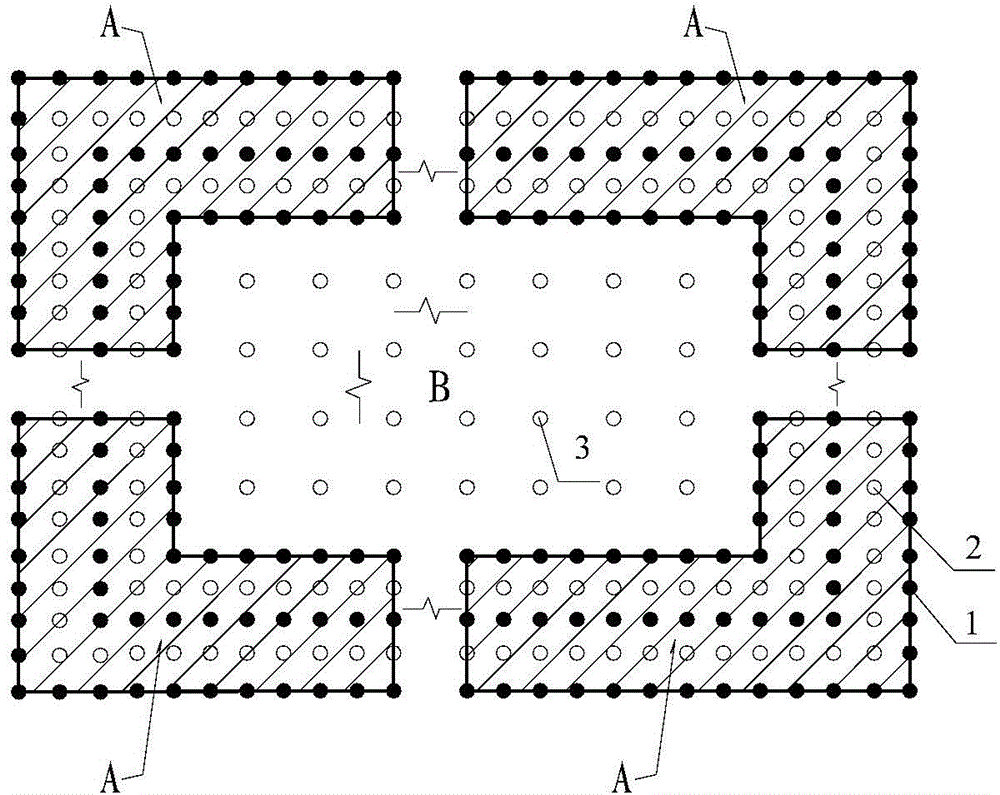

[0019] 1) Divide an annular zone 10-20m outside the goaf reinforcement area, and use geological drilling rigs to drill 5-10 rows within the annular zone. The drilling depth reaches the top of the high-pressure water-rich goaf 4. The flexible grouting pipe 1, the explosive bundle 2, and the high-strength flexible grouting pipe 1 extend to the bottom of the high-pressure water-rich goaf 4;

[0020] 2) Within the scope of the goaf reinforcement area, use a geological drilling rig to drill holes to the top of the high-pressure water goaf 4 according to the design requirements, and extend the ordinary grouting pipe 3 into the high-pressure water-rich water goaf 4;

[0021] 3) Segmentally detonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com