Repairing and reinforcing method for vertical shaft wall collapsed fiercely

A shaft and shaft wall technology, applied in the field of shaft wall repair and reinforcement, can solve problems such as unimaginable consequences and shaft wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

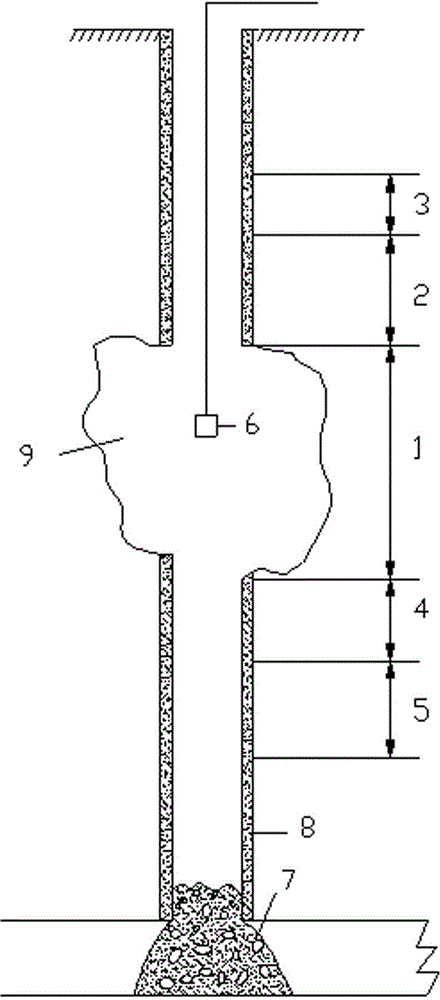

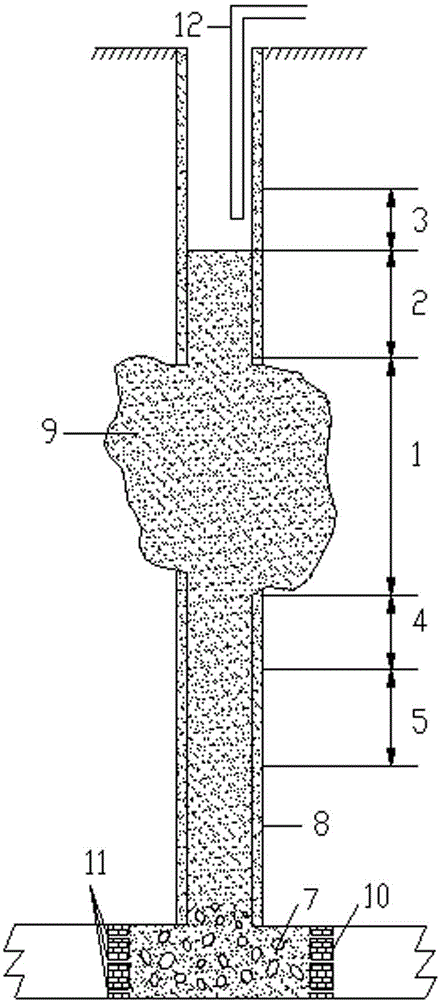

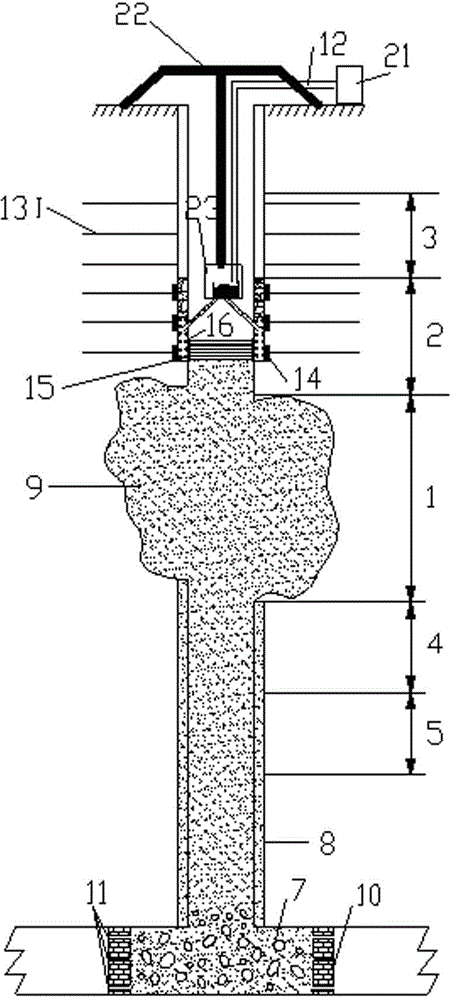

[0037] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0038] The invention is a repairing and strengthening method for severe collapse of a vertical shaft, which is mainly aimed at the situation that the vertical shaft collapses violently, the shaft lifting system and the ladder are severely damaged, the shaft wall is in danger of collapse at any time, and personnel cannot directly enter the collapsed area for construction operations.

[0039] Glossary:

[0040] The violent collapse of the shaft wall, or the violent collapse of the shaft wall, is a state in which the ground pressure at the collapsed part of the shaft wall has not stopped moving, and the splintering of the vertical shaft occurs from time to time. Usually, the wellbore hoisting system and the ladder are severely damaged, the well wall is in danger of collapse at any time, and personnel cannot directly enter the collapsed area for construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com