Improved single-arm yarn carrier

A yarn guide device and single-arm technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems affecting the tension transmission of the mandrel and the tension spring, loosening or shaking of the yarn guide rod, and instability, etc., to achieve Ensure normal operation, avoid loosening, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make your review committee members have a further understanding and understanding of the technical characteristics and the achieved effects of the present invention, the detailed descriptions are as follows with better embodiment diagrams and coordination:

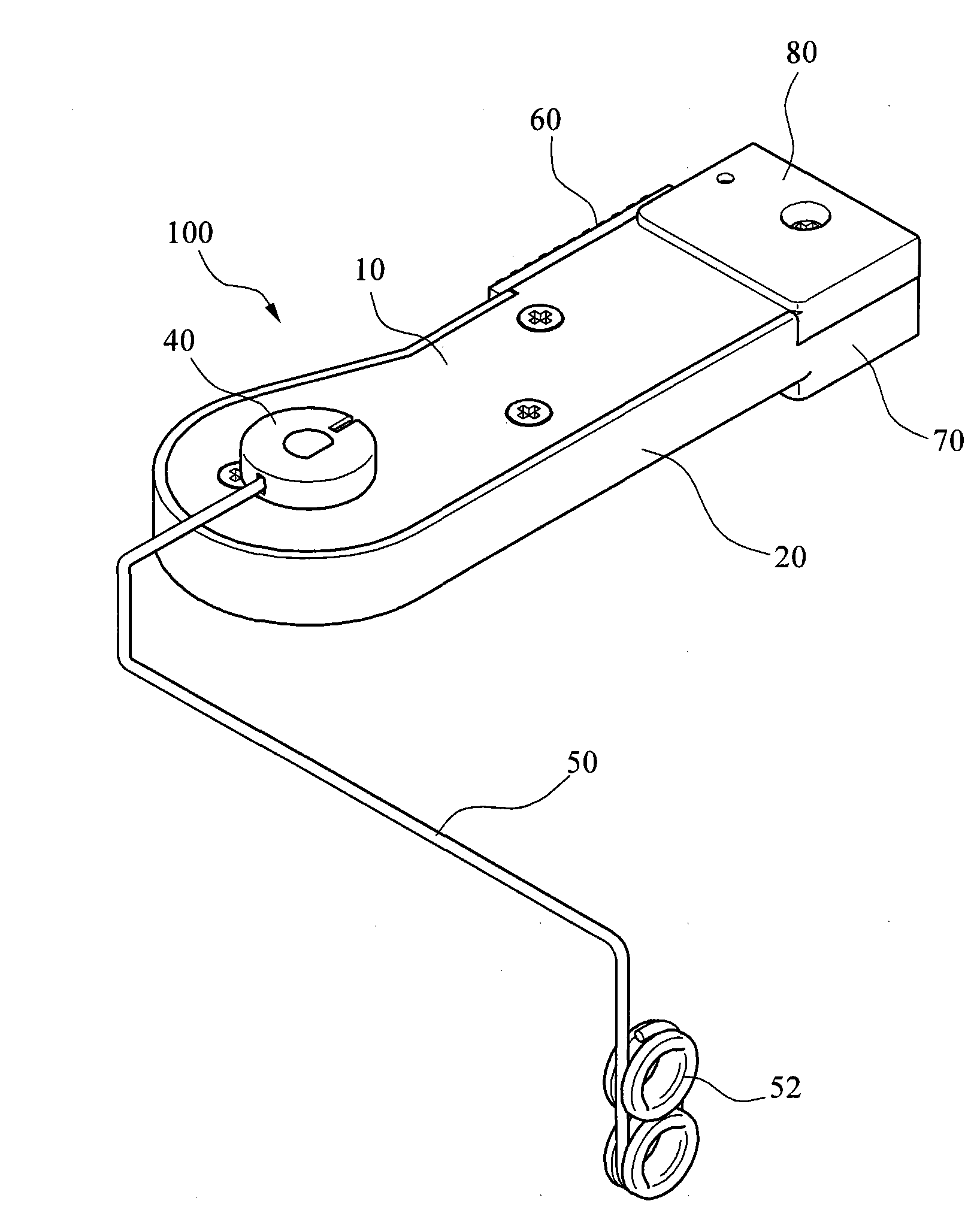

[0032] see figure 1 , is a perspective view of the first embodiment of the present invention, the single-arm yarn guide device 100 includes a housing composed of a cover 10 and a base 20, a pivoting device 30 (not shown in the figure), a connecting piece 40, a yarn guide arm 50 and an adjustment 60 pieces. One end of the base 20 is provided with a fastening seat 70 , and the cover 10 is extended with a seat cover 80 corresponding to the fastening seat 70 .

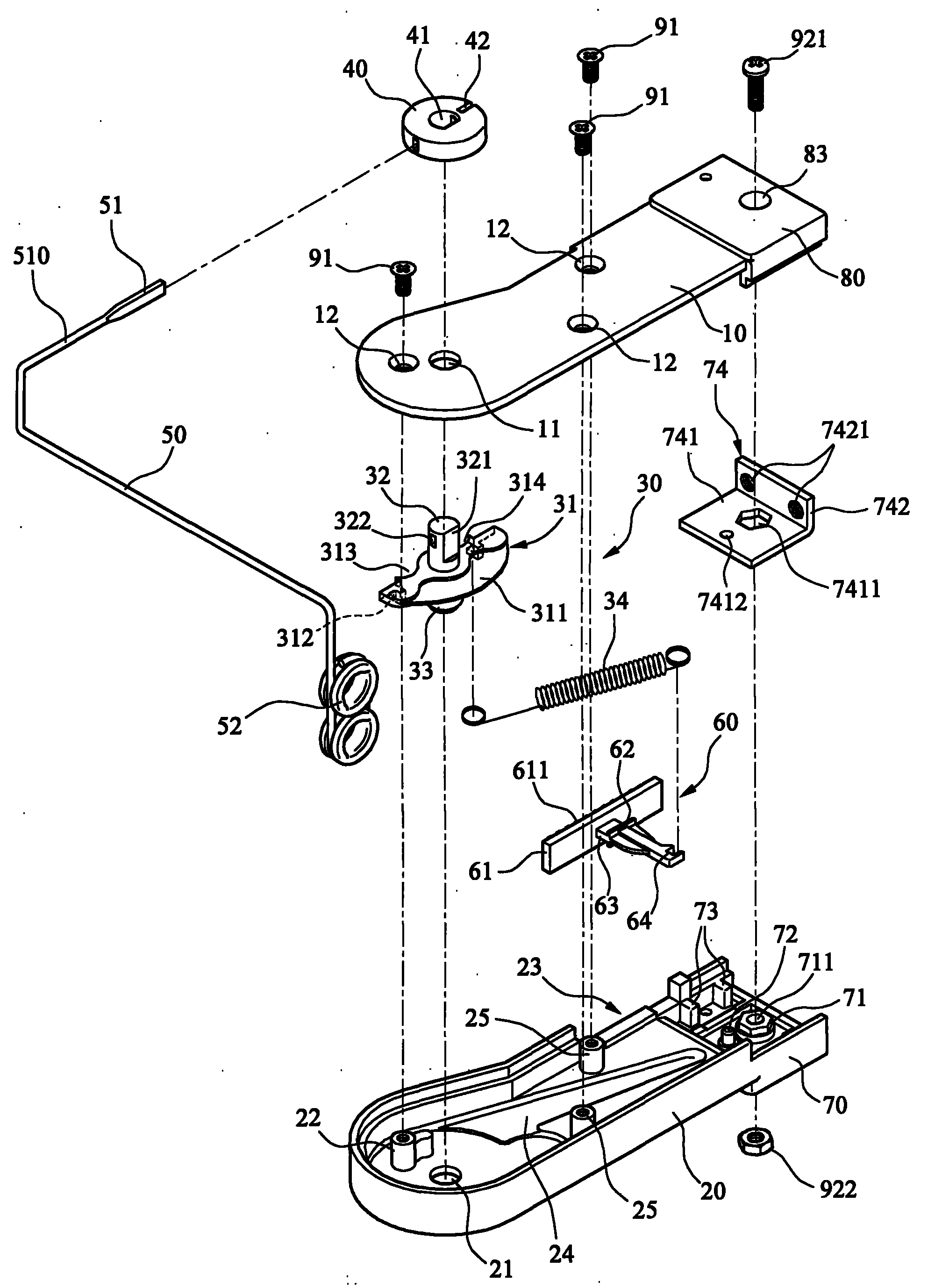

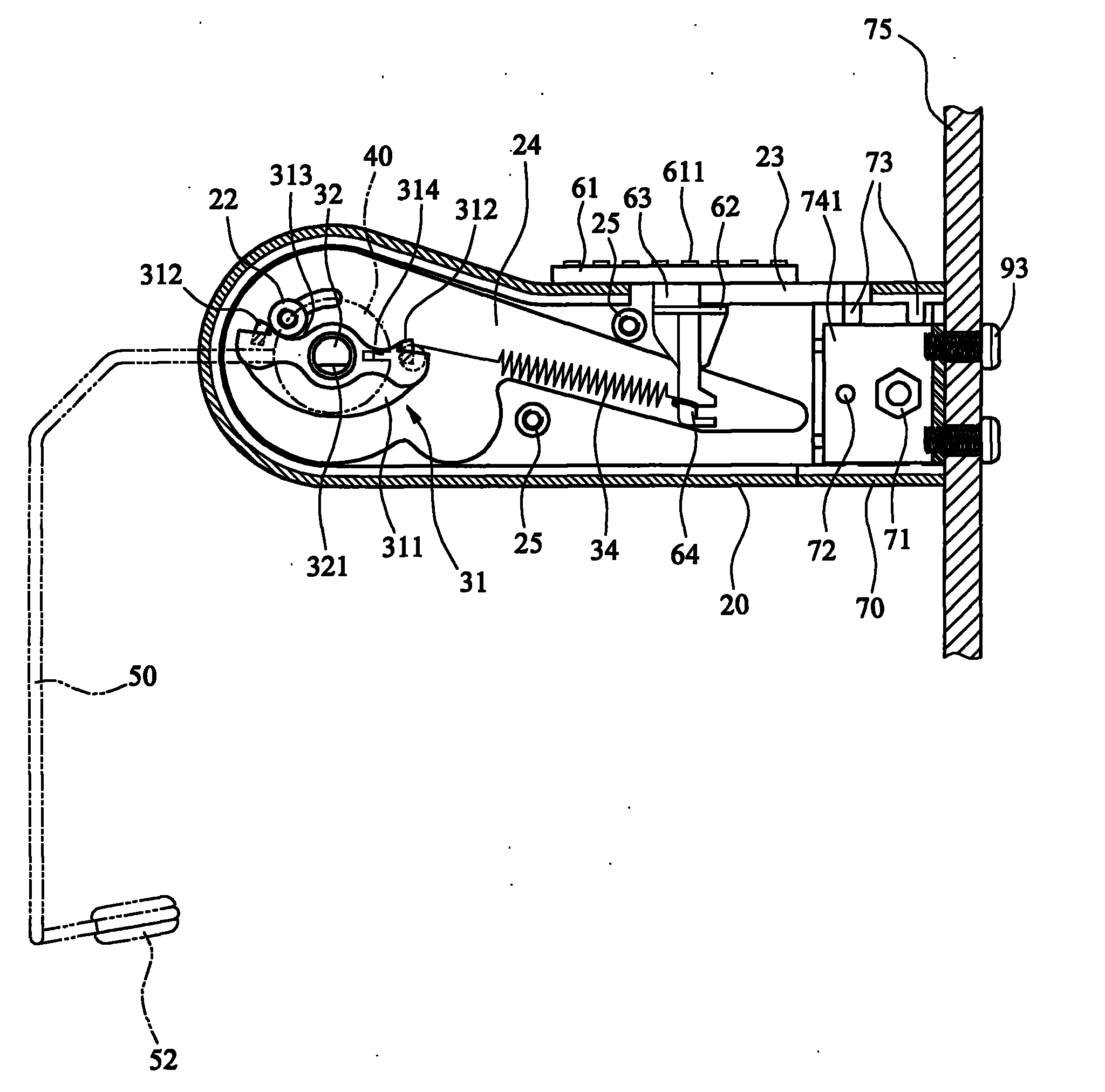

[0033] Such as figure 2 As shown in , it is a combined perspective view of the first embodiment of the present invention. The pivoting device 30 is arranged in the housing formed by the cover 10 and the base 20, and the pivoting device 30 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com