Underground gushing water borehole aggregate addition system and process thereof

A kind of aggregate and process technology, which is applied in the field of aggregate addition system for underground water gushing drilling, can solve the problems of grouting material collapse, high cost, waste, etc., and achieve the effect of reducing material loss and promoting precipitation and consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

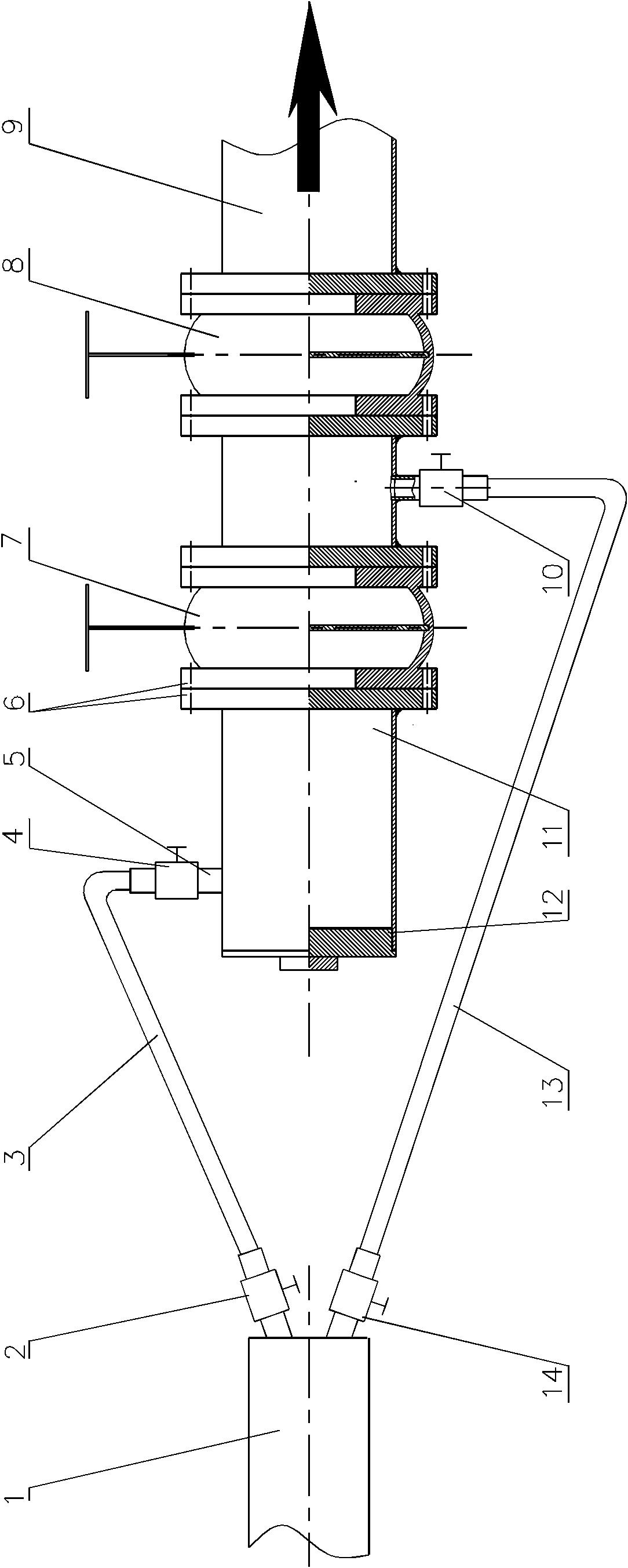

Image

Examples

Embodiment

[0029] There is a large amount of water gushing from the roof near the F1 fault in the Second Auxiliary Transportation Road of Longgu Coal Mine, and a waterproof shed is required for pedestrians and vehicles to pass through the roadway. During the construction of the roof spraying grouting and water blocking project, the borehole leading to the fault zone in the 3# chamber: the water inflow of hole 3-2 at 58m is 130m 3 / h, 3-3 holes at 43m, the water gushing volume is 70m 3 / h; 4# chamber (in the water tank) drilled holes leading to the fault zone: 4-6 holes have a water inflow of 120m at 69m 3 / h, 4-7 holes at 79m, the water gushing volume is 135m 3 / h. Due to the large water passage and the large water gushing volume exposed by the above four holes, and the short distance from the roof spraying area, the grout is not easy to consolidate and settle during the grouting process, and almost all the grout is lost, so the water passage cannot be effectively controlled. of block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com