Construction method for back cavity of tunnel lining and constructed composite lining structure

A construction method and composite lining technology, applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of increasing lining load, cracking of concrete lining, cavity expansion, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The construction method of the cavity behind the tunnel lining, the steps are as follows:

[0041] (1) Drill grouting holes on the lining surface, the inner diameter of the grouting holes is 40cm, the longitudinal spacing of the grouting holes is 3m, and the circumferential spacing is 3.5m;

[0042] (2) Install the grouting pipe in the grouting hole. The outer diameter of the grouting pipe is 40cm, the thickness of the grouting pipe is 3.5mm, and the length of the grouting pipe entering the back of the lining is 3.5m. Seal the grouting hole and the grouting the space between the tubes;

[0043] (3) Pour foam concrete into the cavity behind the lining through the grouting pipe to form a buffer layer to reduce the additional load on the tunnel lining;

[0044] The raw material composition of the foamed concrete, in parts by weight: 245 parts of cement, 2.1 parts of anti-cracking fiber, 2.4 parts of coagulation accelerator, 16.5 parts of foaming agent, 6 part...

Embodiment 2

[0053] Embodiment 2 The construction method of the cavity behind the tunnel lining, the steps are as follows:

[0054] (1) Drill grouting holes on the lining surface, the inner diameter of the grouting holes is 32cm, the longitudinal spacing of the grouting holes is 4m, and the circumferential spacing is 2.5m;

[0055] (2) Install the grouting pipe in the grouting hole, the outer diameter of the grouting pipe is 31.5cm, the thickness of the grouting pipe is 3mm, the length of the grouting pipe entering the back of the lining is 2m, seal the grouting hole and the grouting pipe the gap between

[0056] (3) Pour foam concrete into the cavity behind the lining through the grouting pipe to form a buffer layer to reduce the additional load on the tunnel lining;

[0057] The raw material composition of the foamed concrete, in parts by weight: 210 parts of cement, 1.6 parts of anti-cracking fiber, 2.1 parts of coagulation accelerator, 11 parts of foaming agent, 8 parts of foam stabil...

Embodiment 3

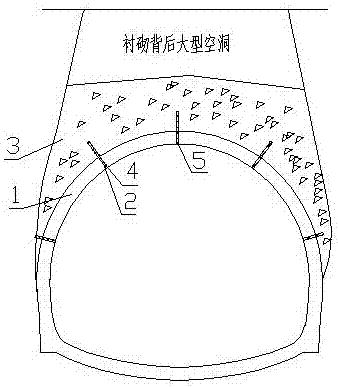

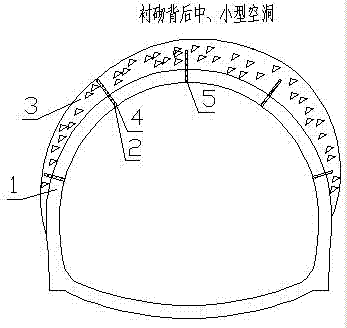

[0068] Example 3 Composite lining structure after treatment of voids behind the lining

[0069] Such as figure 1 and figure 2 As shown, the composite lining structure includes a lining 1, a grouting hole 2, a grouting pipe 3, a foam concrete layer 4 and a waterproof mortar column 5, and the lining 1 is provided with a grouting hole 2, and the inner diameter of the grouting hole 2 is 40cm , the longitudinal spacing of the grouting hole 2 is 3m, the circumferential spacing is 3.5m, the grouting hole 2 is provided with a grouting pipe 3, the length of the grouting pipe 3 entering the cavity is 3.5m, and the outer diameter of the grouting pipe 3 is 40cm, the thickness of the grouting pipe is 3.5mm, the grouting hole 2 is sealed with the grouting pipe 3, the outer side of the lining 2 is a foam concrete layer 4, and the inside of the grouting pipe 3 is a waterproof mortar column 5;

[0070] When the cavity behind the lining is in the large collapse section, the minimum height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com