Physically-modified non-woven fabric and manufacturing method thereof

A non-woven fabric, physical modification technology, applied in the field of non-woven fabrics, can solve the problems of skin irritation, diapers falling off, poor air permeability, etc., and achieve the effects of low production cost, easy implementation, and human body affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

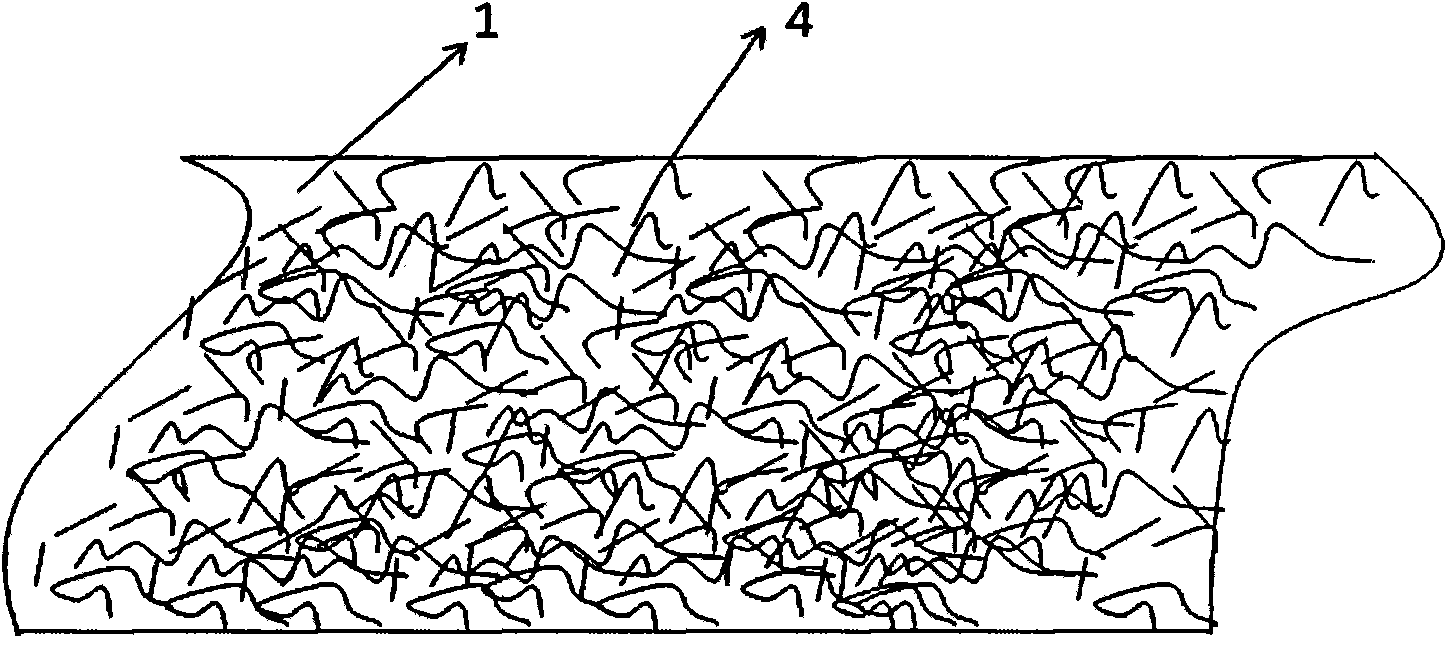

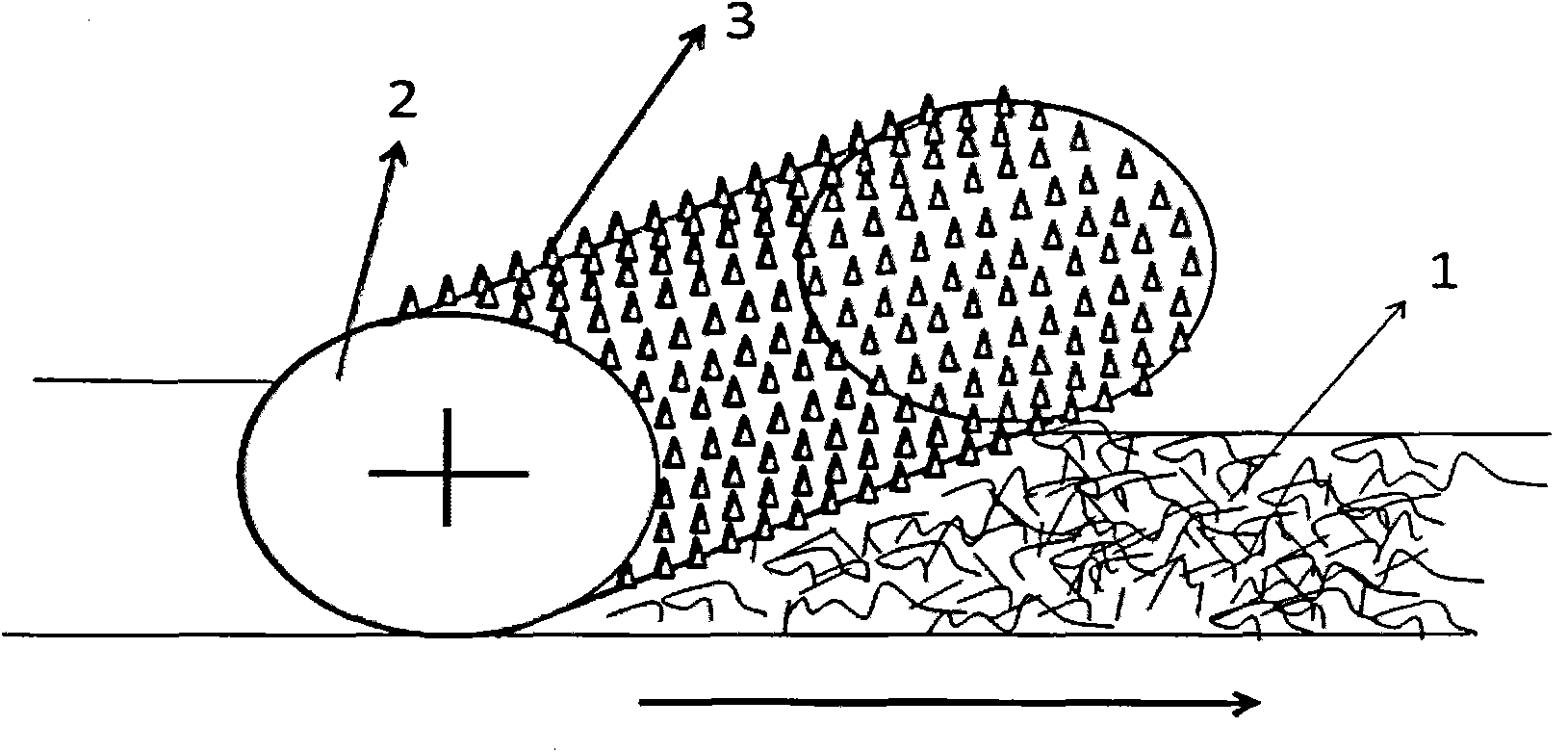

[0023] In this example, following the production process of the nonwoven fabric, after the nonwoven fabric is consolidated into a cloth, the nonwoven fabric 1 is fluffed by the licker-in roller 2 . Please refer to figure 2 As shown, the licker-in roller 2 is arranged with the needles 3, and the effect of the needles on the fluffing of the nonwoven fabric is adjusted by parameters such as the speed, needle density, needle length, and needle inclination angle. Several such licker-in rollers can be arranged on a production line. , Repeatedly fluffing the non-woven fabric. The fleece-like fibers of the fleece-like fiber layer on the surface of the non-woven fabric can protrude from the surface of the non-woven fabric to a length between 0.5 mm and 5 mm to meet the needs of most applications.

Embodiment 2

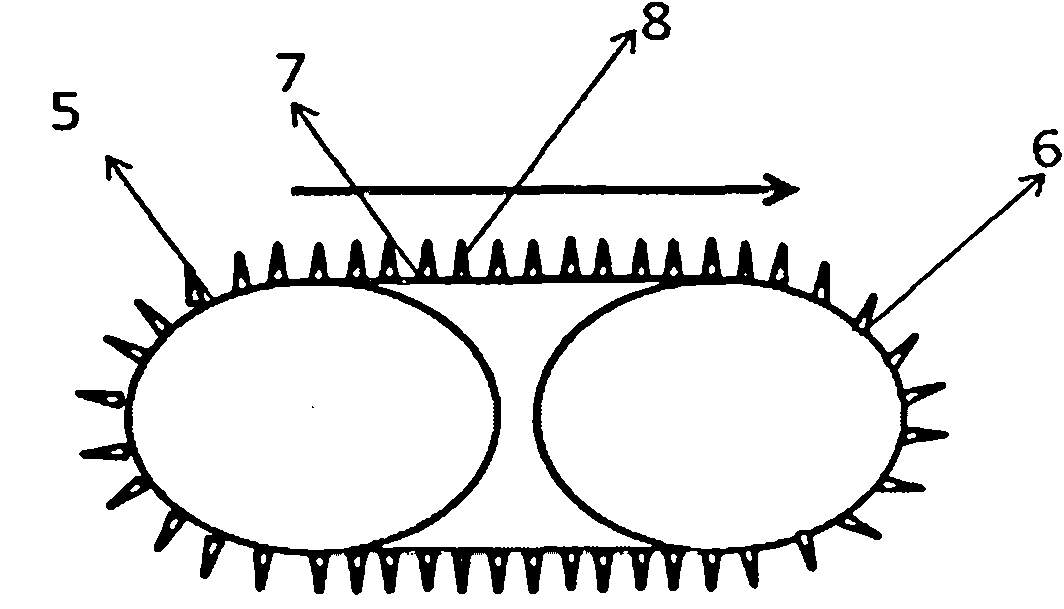

[0025] In this example, following the production process of the nonwoven fabric, after the nonwoven fabric is consolidated into a cloth, the nonwoven fabric 1 is fluffed through a mesh belt with needles. Please refer to image 3 As shown, needles 8 are arranged on mesh belt 7, and roller 5 and roller 6 are driven by motor, and roller 5 and roller 6 drive mesh belt 7; Parameter adjustment can change the effect of the needle on the fluffing of the nonwoven fabric.

Embodiment 3

[0027] In this example, the non-woven fabric 1 is fluffed through the fiber brush 9, and the fiber brush 9 may be composed of carbon fibers, or may be composed of metal fibers or other flexible and not easily broken fibers. The fluffing effect can be adjusted through parameters such as the frequency, speed, and size of the contact surface of the fiber brush 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com