Patents

Literature

86results about How to "Not prone to shedding" patented technology

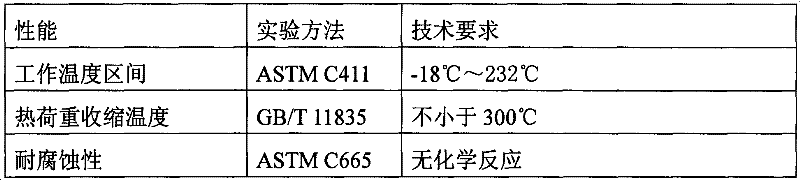

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser forming electro-galvanizing wire conducting roller and manufacturing method thereof

InactiveCN101457378AImprove wear resistanceImprove corrosion resistanceElectrolysis componentsMetallic material coating processesWear resistanceCo2 laser

A laser forming electrogalvanizing line conducting roll comprises a substrate. The surface of the substrate is coated with a laser cladding layer, the thickness of the laser cladding layer is 3-10mm, the laser cladding layer and the substrate are bonded in a metallurgical manner, and the laser cladding layer is a nickel base alloy powder layer or a cobalt base alloy powder layer or a combination of the nickel base alloy powder layer and the cobalt base alloy powder layer. A manufacturing method of the laser forming electrogalvanizing line conducting roll comprises the following working procedures: A. fabricating the substrate of the conducting roll; and B. cladding an intermediate transition layer by laser: firstly cladding a layer of the nickel base alloy powder or the cobalt base alloy powder on the substrate of the conducting roll for rendering by a transverse-flow continuous CO2 laser device as the intermediate transition layer; removing surface laser cladding oxide scale by machining, and then cladding the nickel base alloy powder or the cobalt base alloy powder with better wear resistance and corrosion resistance on the intermediate transition layer by the transverse-flow continuous CO2 laser device as a surface functional layer. The manufacturing method has the advantages of strong adaptability, simple convenient operation, high normativeness, low production cost and great practical value.

Owner:SHENYANG DALU LASER TECH

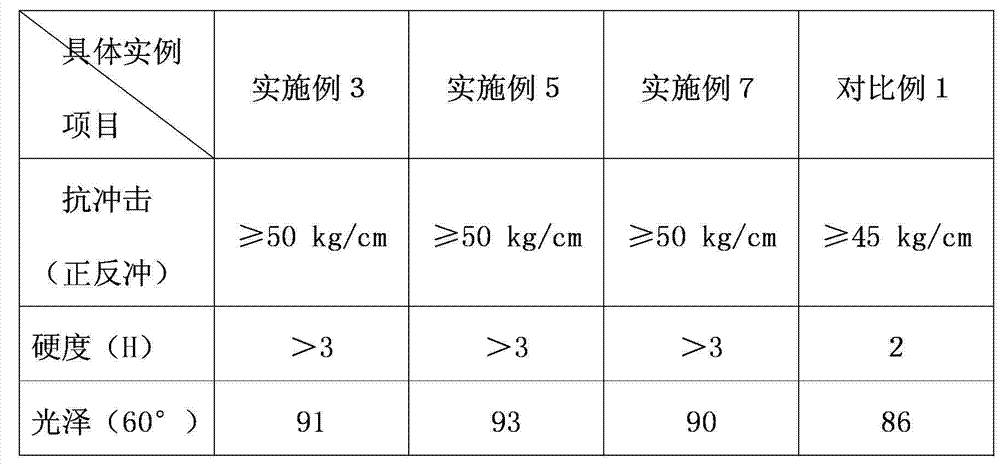

Super wear-resistant metal powder coating

InactiveCN102876203AImprove anti-agingImprove antifreeze effectPowdery paintsEpoxy resin coatingsPolyesterEpoxy

The invention relates to a super wear-resistant metal powder coating, and belongs to the technical field of coating materials. Aiming to solve the technical problems of poor wear resistance and low product hardness in the prior art, the invention provides the super wear-resistant metal powder coating which is mainly prepared from the following components by weight percent: 25 to 35 percent of polyester; 25 to 35 percent of epoxy resin; 0.5 to 1.5 percent of flatting agent; 0.5 to 1.5 percent of brightening agent; 5.0 to 15 percent of super wear-resistant additive; 1.0 to 3.0 percent of silver powder; 15 to 20 percent of coupling agent; and 5.0 to 10 percent of crosslinker. After being coated with the coating provided by the invention, the surfaces of products achieve high hardness which can be above 3H, and after rubbing against each other for thirty times, the surfaces of the products are not abraded, thereby having strong wear resistance; and the super wear-resistant metal powder coating has high stability and cohesiveness.

Owner:浙江嘉泰塑粉有限公司

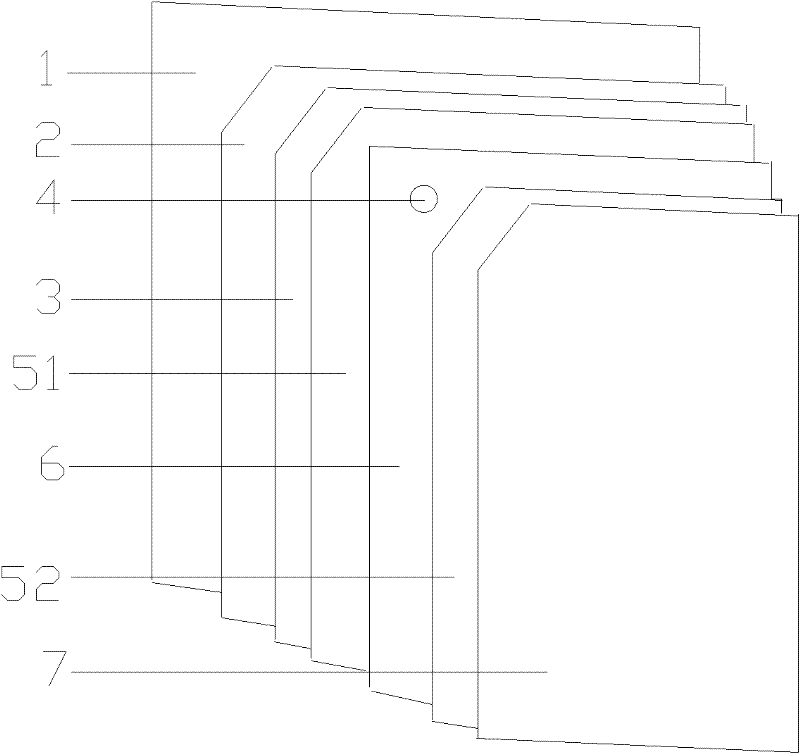

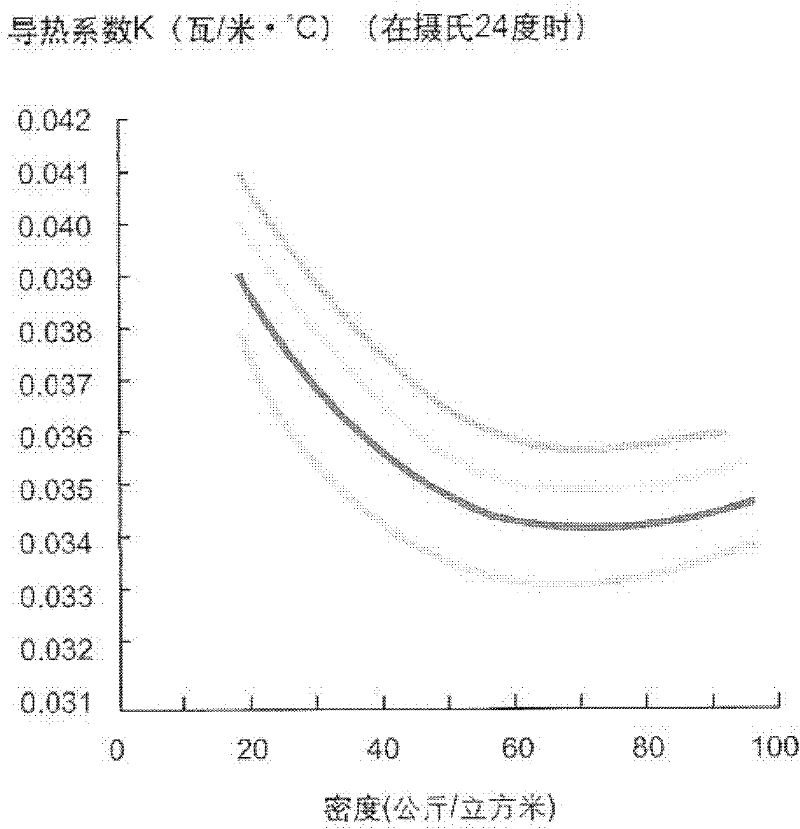

Outer wall heat-preserving system

InactiveCN102444213AGood safety and fire resistanceGuaranteed safety and reliabilityHeat proofingCorrosionFiberglass mesh

The invention relates to an outer wall heat-preserving system, which comprises a bonding mortar layer, a heat-preserving layer, a surfactant layer, a rendering coat mortar layer, glass fiber gridding cloth, an anchoring piece and a finishing coat, wherein the inner surface of the heat-preserving layer is bonded on a wall body by coating the bonding mortar layer; the surfactant layer is coated on the outer surface of the heat-preserving layer; the inner surface of the glass fiber gridding cloth is bonded on the surfactant layer through the rendering coat mortar layer; the finishing coat is bonded on the outer surface of the glass fiber gridding cloth through the rendering coat mortar layer; and the anchoring piece is arranged on the outer side of the glass fiber gridding cloth, and is fixed on the wall body by passing through the heat-preserving layer. Compared with the prior art, the outer wall heat-preserving system has the advantages of safety, moisture resistance, corrosion resistance, insect pest resistance, molding resistance, high heat-preserving performance, high sound insulating performance, high fire resistance, high durability, and the like.

Owner:SHANGHAI QIHONG TECH DEV

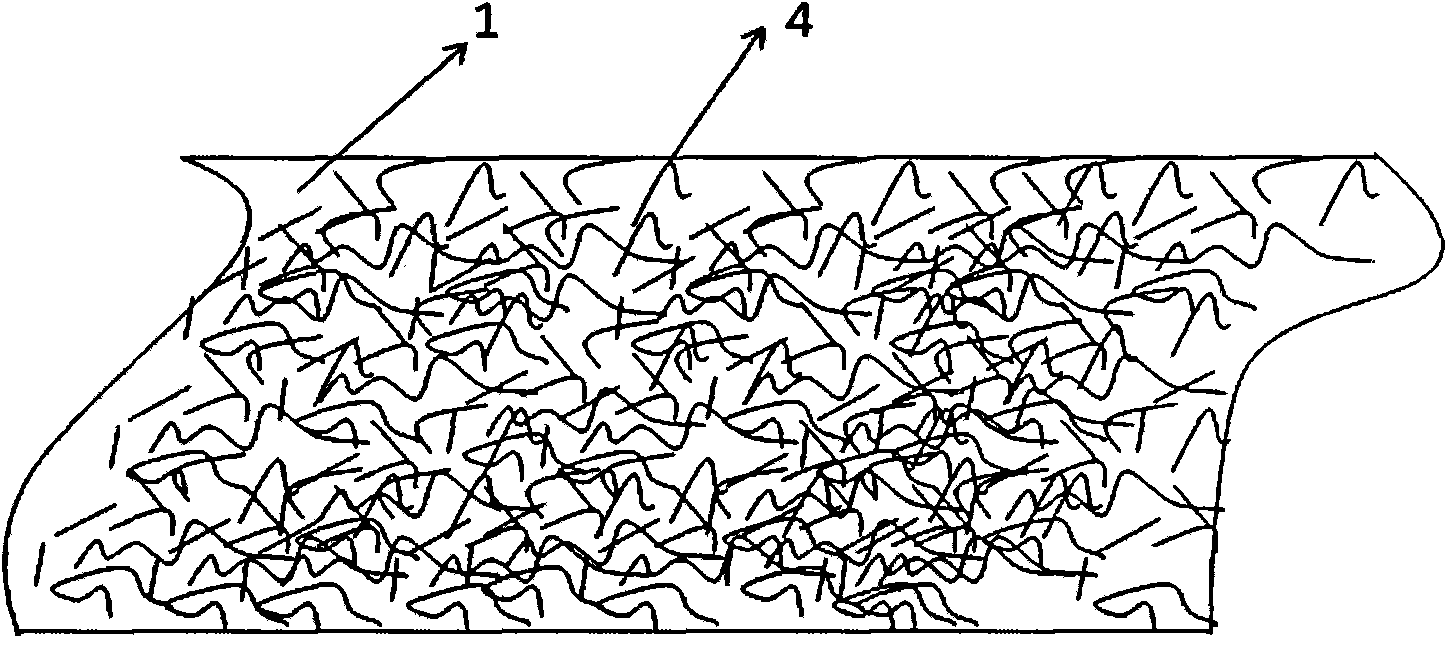

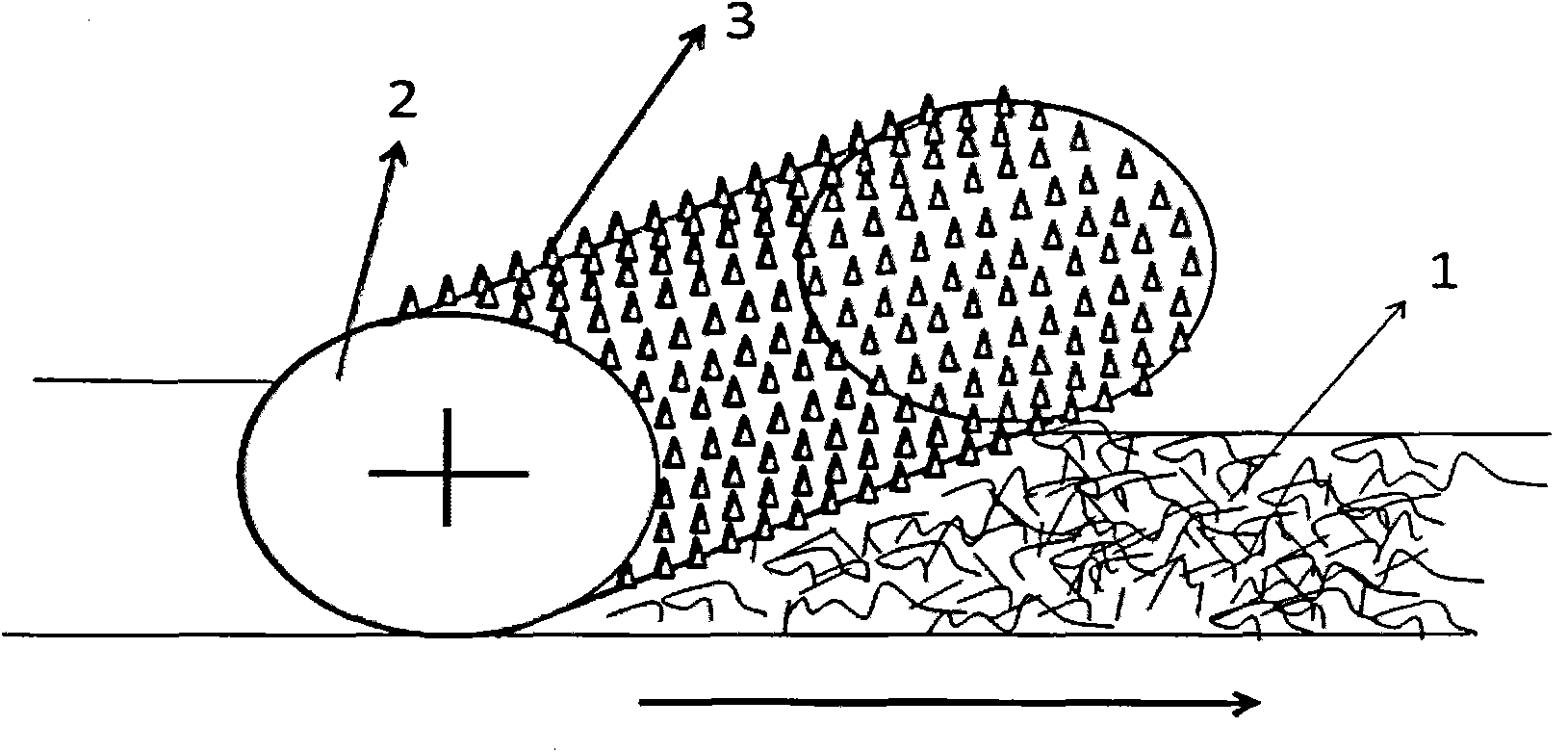

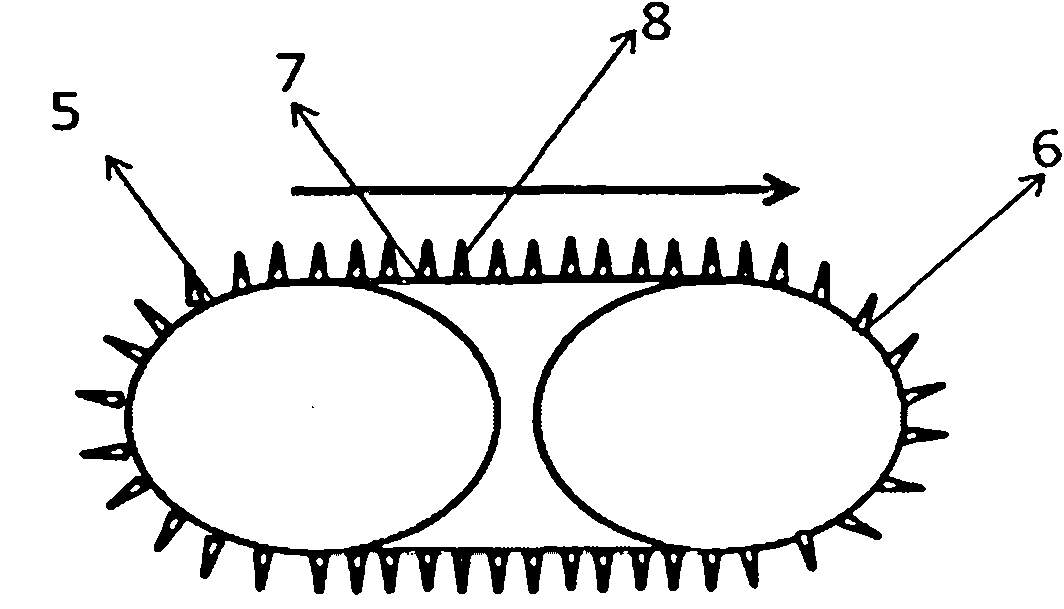

Physically-modified non-woven fabric and manufacturing method thereof

InactiveCN101974829AEasy to implementReduce manufacturing costNon-woven fabricsRougheningFiber layerWoven fabric

The invention discloses a physically-modified non-woven fabric and a manufacturing method thereof. The physically-modified non-woven fabric is manufactured by forming a fluffy fiber layer on a non-woven fabric through physical modification and napping the fluffy fiber layer. As for the physically-modified non-woven fabric, processing is carried out after fabric formation, thus being easy to implement and having low production cost. Due to the fluffy fiber layer on the surface thereof, the physically-modified non-woven fabric has soft handle, and is affine and comfortable for human bodies; and by adopting a physical method to change the structure thereof instead of adopting a chemical additive for post-processing and other means to change the handle, and the fabric has safer materials.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

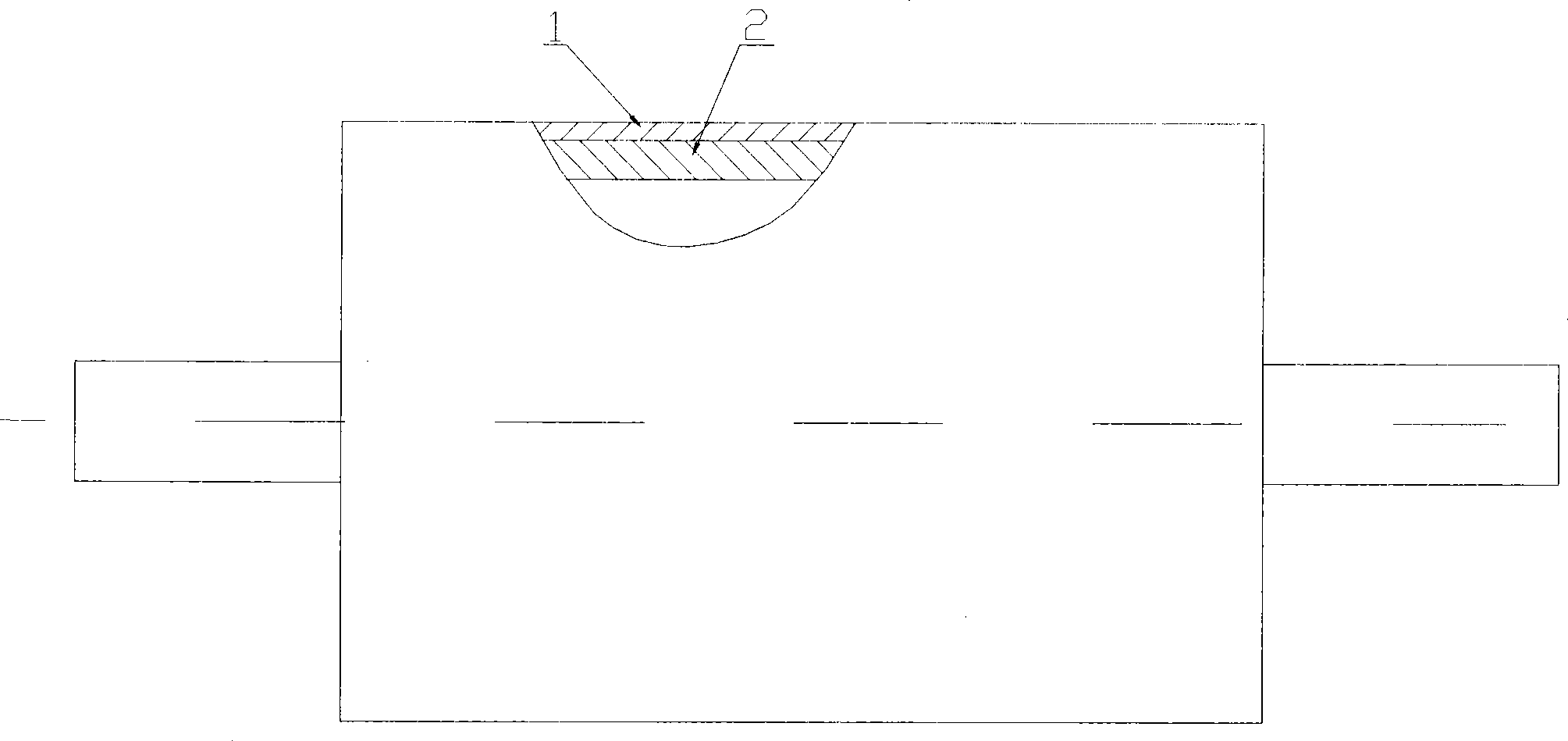

On-line quick repair material for rotary kiln

The invention relates to an on-line quick repair material for a rotary kiln. The on-line quick repair material comprises the following components in percentage by weight: 55-85 percent of Al2O3, 10-25 percent of SiO2, 0.1-15 percent of MgO, 0.01-5 percent of Fe, 0.01-3 percent of Al, 0.1-3 percent of Fe2O3 and silica sol binding agent, wherein the silica sol binding agent accounts for 8-20 percent of the total amount. According to the on-line quick repair material, on-line spray pair can be realized; the spray pair is performed on a furnace lining foundation without cleaning; the repair quality is stable; a stripping phenomenon is not easily produced; the maintenance cost is reduced from hundreds of thousands of yuan required at one time at present to tens of thousands of yuan, i.e., the maintenance cost is saved by one tenth; and the application period can be increased by 50 percent or more.

Owner:武汉钢铁有限公司

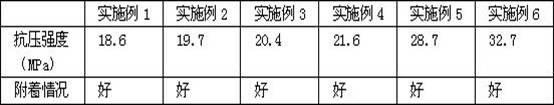

Concrete structure repairing method based on carbonization hardening

ActiveCN111320424ARapid development of strengthRaise the intensity levelRepair materialCarbonization

The invention discloses a concrete structure repairing method based on carbonization hardening. The concrete structure repairing method comprises the following steps: cleaning an area that needs repairing; filling or smearing a repairing material, wherein the repairing material is prepared from the following components in parts by weight: 100 parts of a carbonized cementing material, 1 to 10 partsof a carbonization reinforcing agent, 5 to 70 parts of fine aggregate, 2 to 6 parts of a water reducing agent and 6 to 16 parts of water; sealing the to-be-repaired area by using a sealing device; and introducing carbon dioxide repairing gas into the closed to-be-repaired area. Based on a carbonization hardening principle, the repairing material is high in strength development speed and strengthgrade, and the repaired area can be quickly put into the service process. The volume of the repairing material can slightly expand in the carbonization process, the volume stability is excellent in the later service process, the repairing material is tightly combined with a matrix, the cohesiveness is high, and the falling phenomenon is not likely to occur. The fluidity of the repair slurry can bedesigned and regulated, the repair slurry is suitable for various processes such as smearing, spraying and irrigation, and the engineering applicability is high.

Owner:WUHAN UNIV OF TECH

Transparent pavement coating for photocatalytic purification of automobile exhaust and preparation method

InactiveCN111471371AGood effectRealize the loadGas treatmentDispersed particle separationFirming agentPhoto catalysis

The invention relates to the technical field of air purification coating, and provides transparent pavement coating for photocatalytic purification of automobile exhaust and a preparation method of the transparent pavement coating. The coating is composed of a photocatalytic filler, epoxy resin, water, a dispersing agent, a curing agent, a leveling agent and an antioxidant, wherein the photocatalytic filler is composed of nano titanium dioxide loaded on a framework formed by glass powder. A coating prepared from the coating has good adsorption capacity for automobile exhaust and good transmission capacity for natural light, and it can be guaranteed that a photocatalyst fully adsorbs the exhaust and makes full contact with the natural light. Particularly, according to the method, the photocatalyst is loaded in through hole channels of the carrier framework, the loading firmness is improved through bonding, and the situation that the tail gas purification effect is reduced due to fallingof the photocatalyst can be prevented.

Owner:成都市水泷头化工科技有限公司

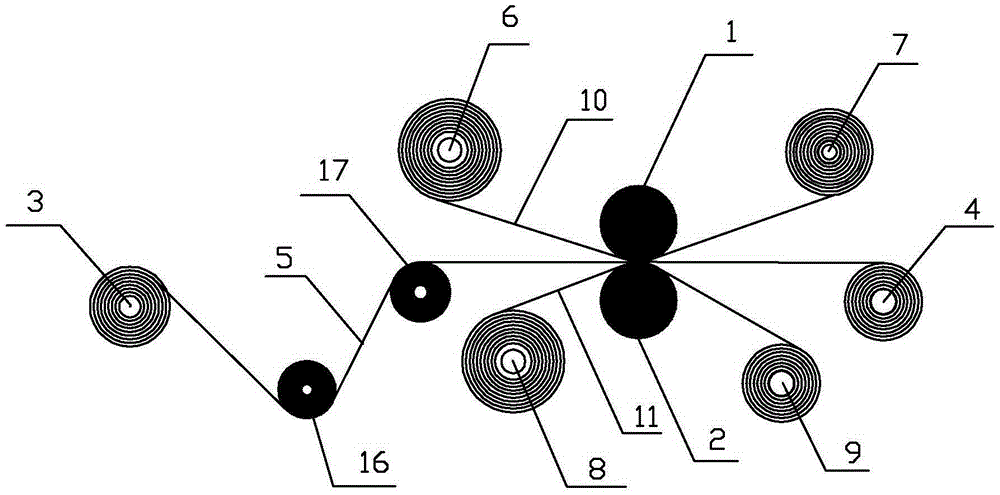

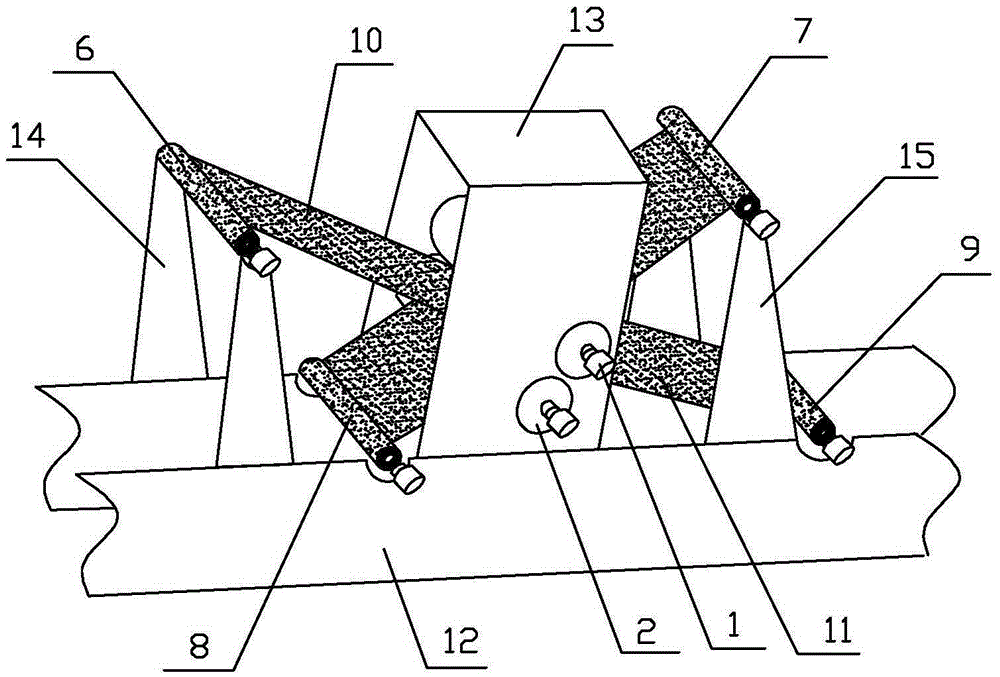

Rolling method and device for battery pole piece

ActiveCN105583226AImprove electrochemical performanceImprove securityTemperature control deviceCell electrodesElectrical batteryPole piece

The invention relates to rolling method and device for a battery pole piece. The rolling method comprises twice rolling process, wherein a foil is not added in primary rolling; secondary rolling adopts a rolling method with addition of a foil; and the rolling method in secondary rolling comprises the following steps: an upper foil piece, a lower foil piece and a pole piece with the two surfaces coating with powder simultaneously penetrate through a space between a upper roll and a lower roll, and the upper roll and the lower roll respectively roll the pole piece through the upper foil piece and the lower foil piece, wherein the upper foil piece and the lower foil piece are arranged on the upper and lower surfaces of the pole piece respectively. The rolling device comprises a rack, the upper roll, the lower roll, a pole piece releasing roll, a pole piece retracting roll, an upper foil piece releasing roll, an upper foil piece retracting roll, a lower foil piece releasing roll and a lower foil piece retracting roll. According to the rolling method and device, during secondary rolling, the upper roll and the lower roll apply pressure to the two surfaces of the pole piece through the upper foil piece and the lower foil piece respectively to ensure particle intervals of the pole piece in vertical direction to be uniform and a battery manufactured thereby to be difficult in powder dropping phenomenon occurrence in the charging and discharging process and particularly in the later period of circulation and improve the electrochemical performance and the using safety of the battery.

Owner:杭州师腾新能源科技有限公司

Composite fibre containing light catalyst, its production and polluted fluid purification

InactiveCN1940152AIncrease the fixation areaImprove reaction efficiencyHollow filament manufactureWater/sewage treatmentPolyamidePolyvinyl alcohol

It was a composite fiber with Photocatalyst, containing the first organic polymer as the first part and the mixture of the first, the second organic polymer and a Photocatalyst as the second part. The second part was paralleled or coated in the first part. The first and second organic polymer can be the same or different, which elected respectively from polyester, polycarbonate, polyamide, polyolefin, polyacrylate, polyvinyl alcohol, polyvinyl chloride, polyvinyl fluoride, Polystyrene and a combination of these. Another preparation of composite fiber with Photocatalyst and purification methods of contaminated fluid using it was contained in this invention. The invention was the composite fiber with Photocatalyst which can make anchor Photocatalyst stable, effectively increase the efficiency of photocatalytic reaction, prolong service life and be reused.

Owner:KANG & HSIUNG ENTERPRISE

Coated magnesium alloy, aluminum alloy or plastic substrate and manufacturing method thereof

ActiveCN105177500AImprove wear resistanceHigh light transmittanceVacuum evaporation coatingSputtering coatingDiamond-like carbonTransmittance

The invention relates to a coated magnesium alloy, aluminum alloy or plastic substrate and a manufacturing method thereof, belonging to the technical field of material surface treatment. The invention aims to enhance the binding property, rub resistance and light transmittance of the substrate surface. The method comprises the following steps: carrying out alkali washing on the substrate prepared from magnesium alloy, aluminum alloy or plastic according to the required size, and drying for later use; SiO2 film coating: coating the SiO2 film on the front surface of the cleaned substrate prepared from magnesium alloy, aluminum alloy or plastic; and DLC-COX (diamond-like carbon-cyclooxygenase) layer coating: coating the nano DLC-COX film on the surface of the SiO2 film. The coated magnesium alloy, aluminum alloy or plastic substrate has higher rub resistance and light transmittance; and the technical process is simple and easy to operate.

Owner:ZHEJIANG XINGXING TECH CO LTD

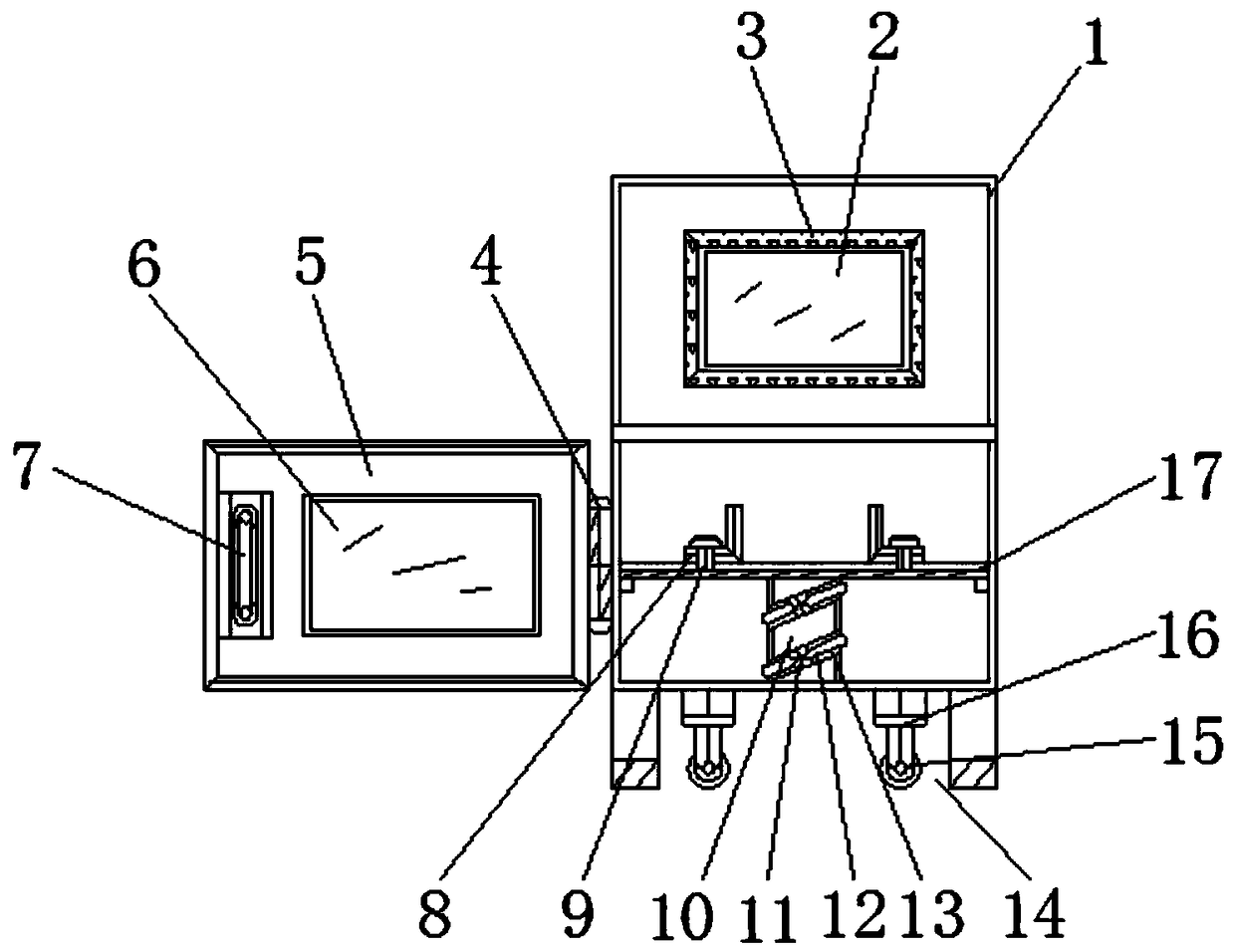

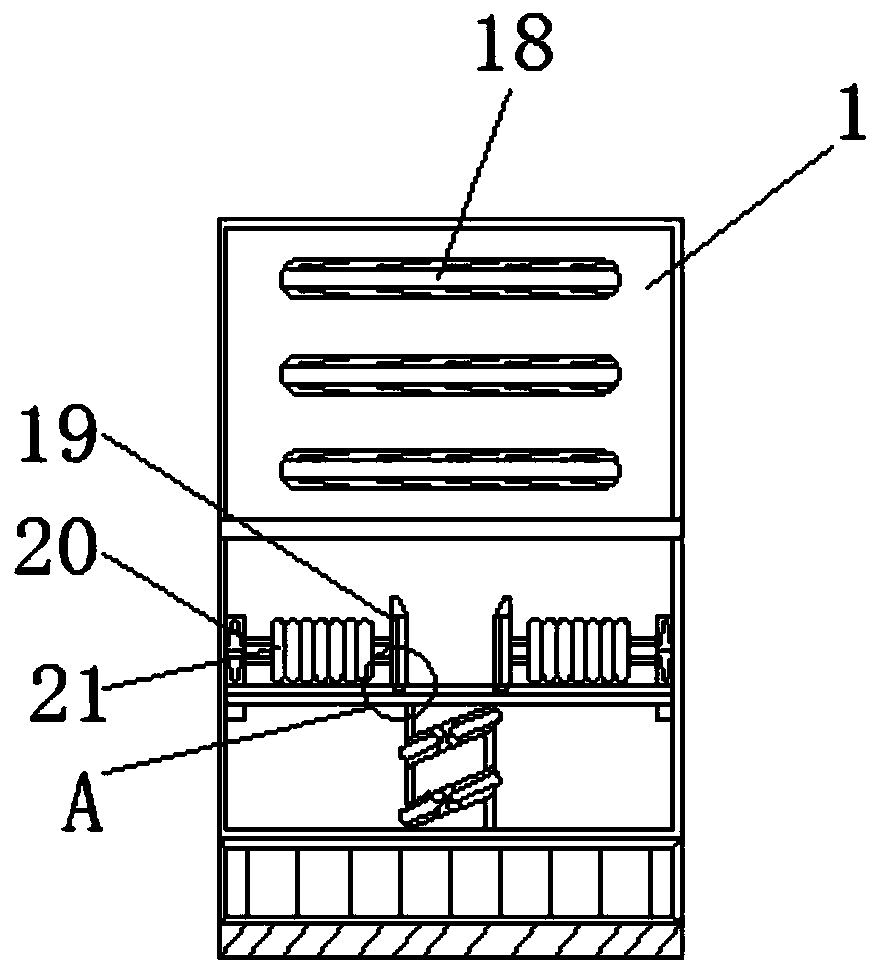

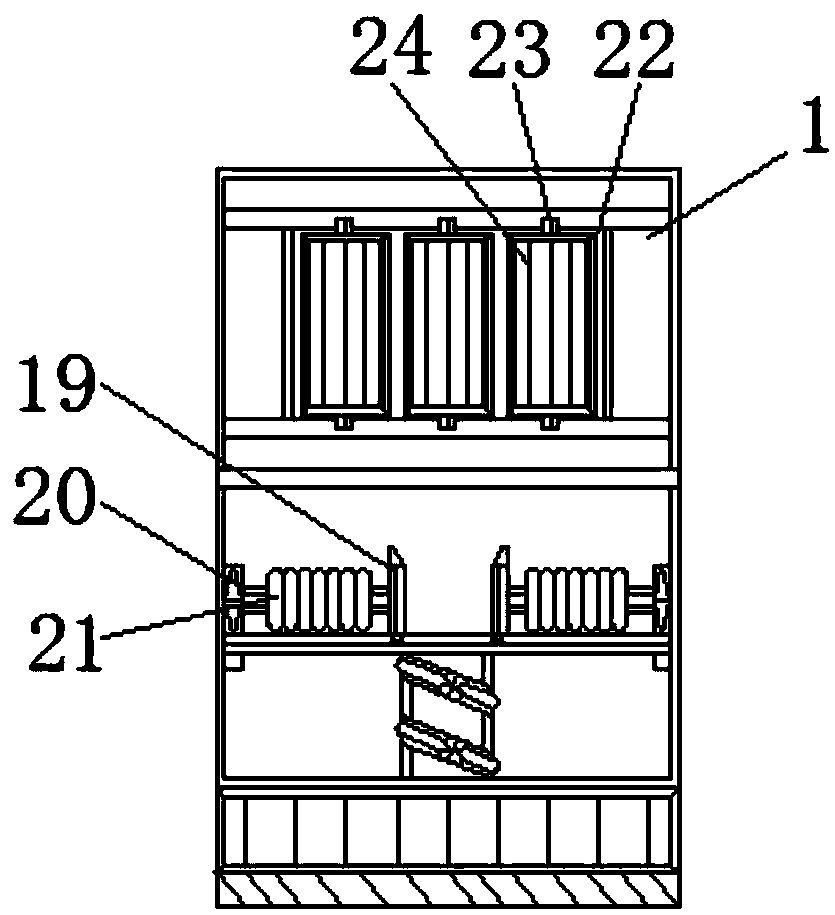

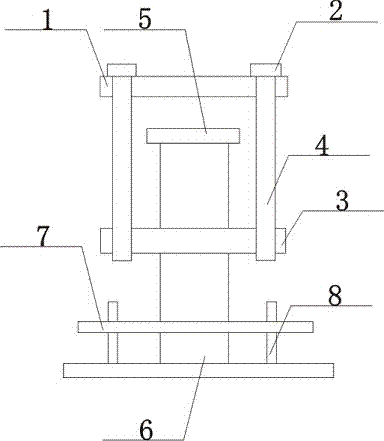

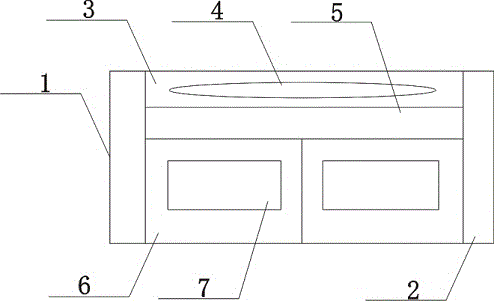

Elasticsupporting-pulling reset structure for forging and pressing machinery

InactiveCN109175192AReset phenomenonGuaranteed stabilityForging/hammering/pressing machinesEngineering

The invention relates to an elasticsupporting-pulling reset structure for forgingand pressing machinery. The elasticsupporting-pulling reset structure for the forgingand pressing machinery comprises amain body, a bracing plate and clamping plates. A display screen is arranged on the inner side of the main body, a protective frame is arranged on the outer wall of the display screen, a door spindleis arranged on the outer side of the mainbody, and a movable door is arranged on the outer wall of the doorspindle in a movable mode. An observing window is fixed to the inner side of the movable door, a handle is installed in the movable door, the bracing plate is arranged on the inner side of the main body, and fixing blocks are arranged at the top of the bracing plate. The elastic supporting-pulling reset structure for the forgingand pressing machinery has the beneficial effects that according to the arrangement of springs, the clamping plates, connecting blocks and the bracing plate, the clamping plates and the connecting blocks form an elastic extensible structure through the springs, when a forged object is subjected to the arranging operation by the elastic supporting-pulling resetstructure for the forgingand pressing machinery, through thesupporting and pullingelastic effect of the springs, a clamping operation is carried out on the forged object from two sides by the clampingplates; and after the forged object is taken out when a series of operations are completed, the elastic supporting-pulling resetstructure can be reset under the self-effect of the springs.

Owner:黄德龙

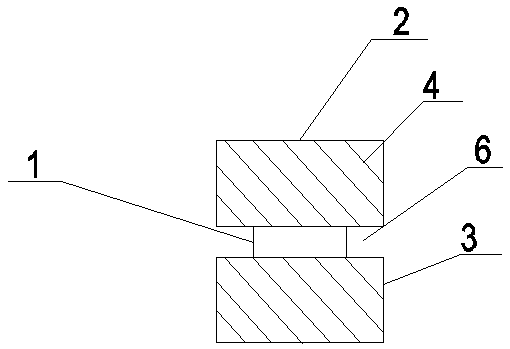

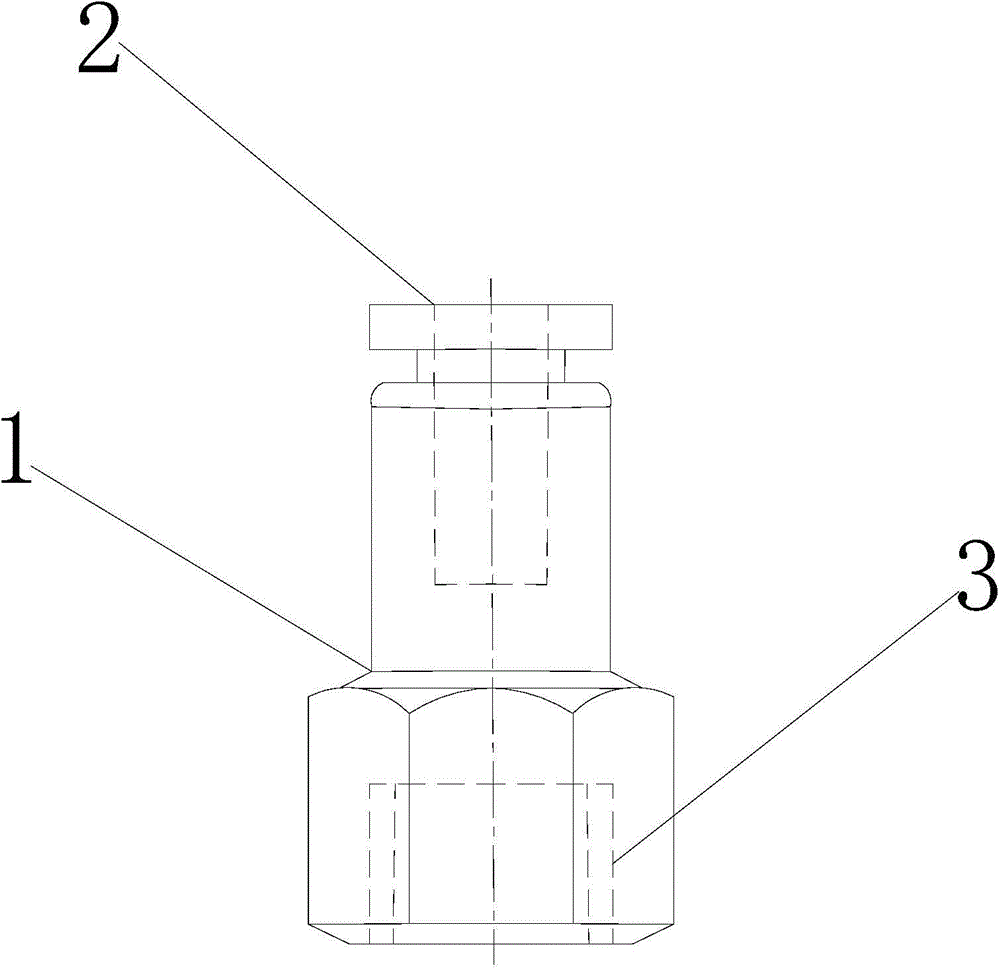

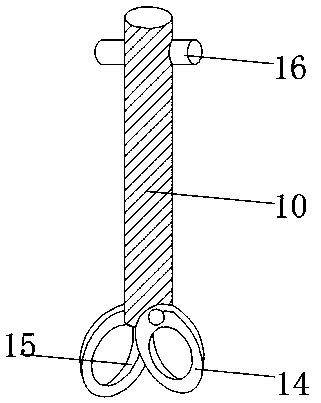

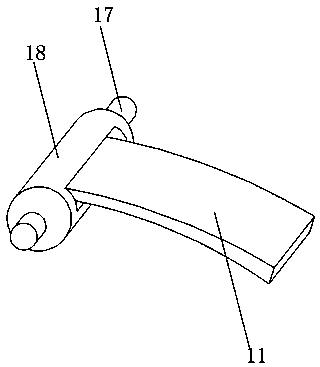

Injection molding nut

The invention discloses an injection molding nut, which comprises a nut main body, wherein the top of the nut main body is provided with an upper injection molding block, and the bottom of the nut main body is provided with a lower injection molding block; the outer surfaces of the upper injection molding block and the lower injection molding block are provided with oblique teeth respectively; a threaded hole is formed in the middle of the nut main body; a groove is formed in the middle of the upper injection molding block and the lower injection molding block respectively; the upper injection molding block and the lower injection molding block of the injection molding nut are formed in two circuit boards to be connected by injection molding respectively; and then the circuit boards are fixed by screwing a screw into the threaded hole in the middle of the nut main body. Since the outer surfaces of the upper injection molding block and the lower injection molding block are provided with the oblique teeth respectively, and after the injection molding nut is formed into the circuit boards by injection molding, plastic pulp is cooled and solidified in a gap of the oblique teeth to firmly clamp the injection molding nut in the circuit boards; and after the injection molding nut is formed into the circuit board by injection molding, the upper injection molding block and the lower injection molding block are wrapped by the plastic pulp on the two circuit boards respectively to form a plastic film in the grooves respectively; and the injection molding nut is further fixedly arranged in the circuit boards, so that the phenomenon of stripping is not easily caused, and the durability is high.

Owner:SUZHOU XINJIESHUN HARDWARE ELECTROMECHANICAL

Ground anchor structure

InactiveCN104264672APrevent lateral movementSimple constructionBulkheads/pilesEngineeringPositioning system

Owner:CHENGDU LYUDI TECH

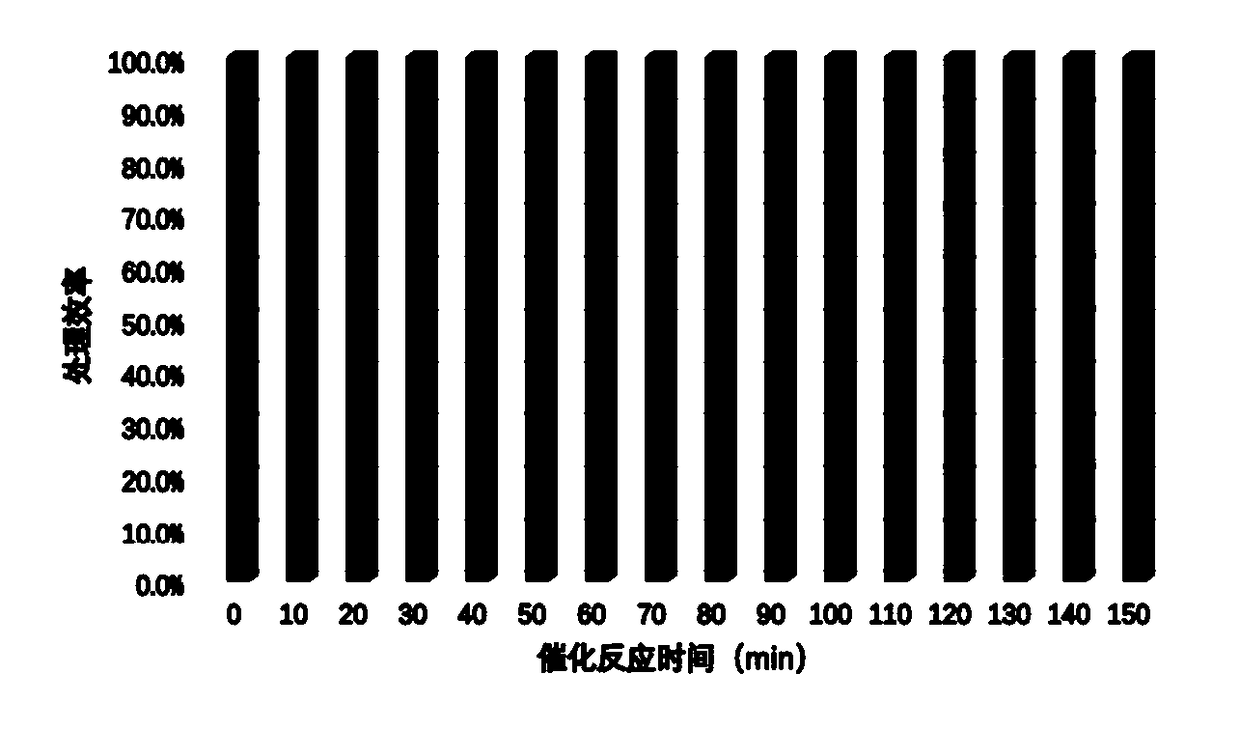

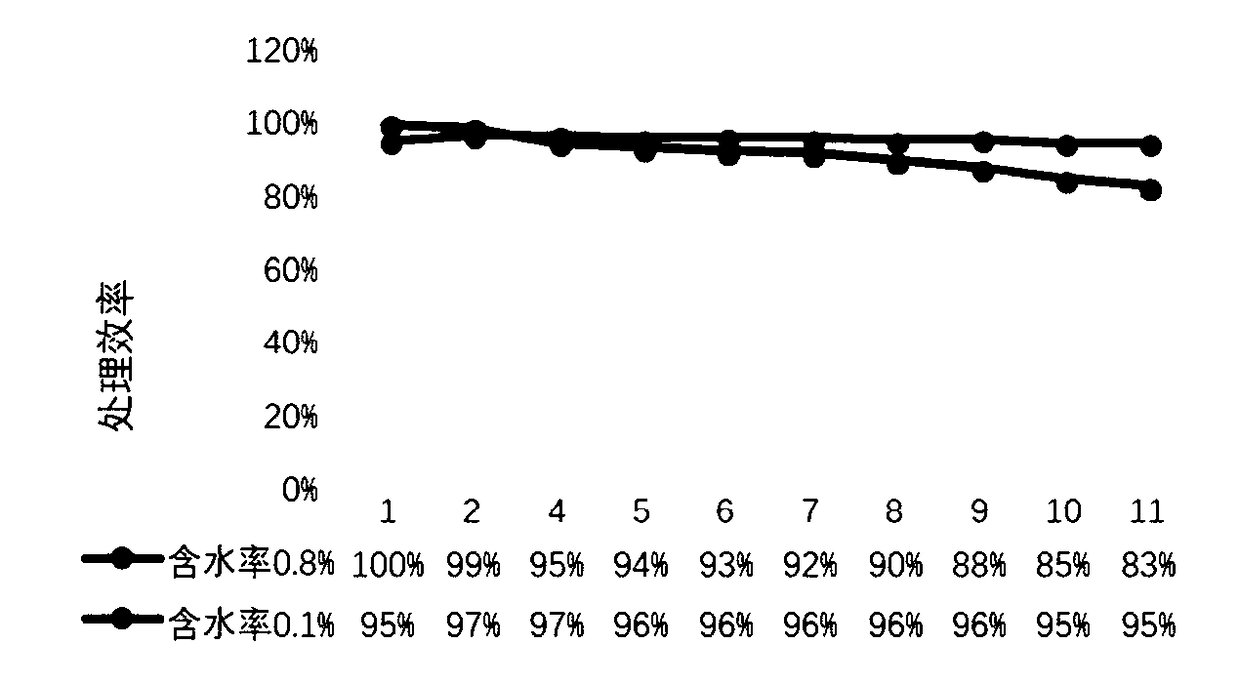

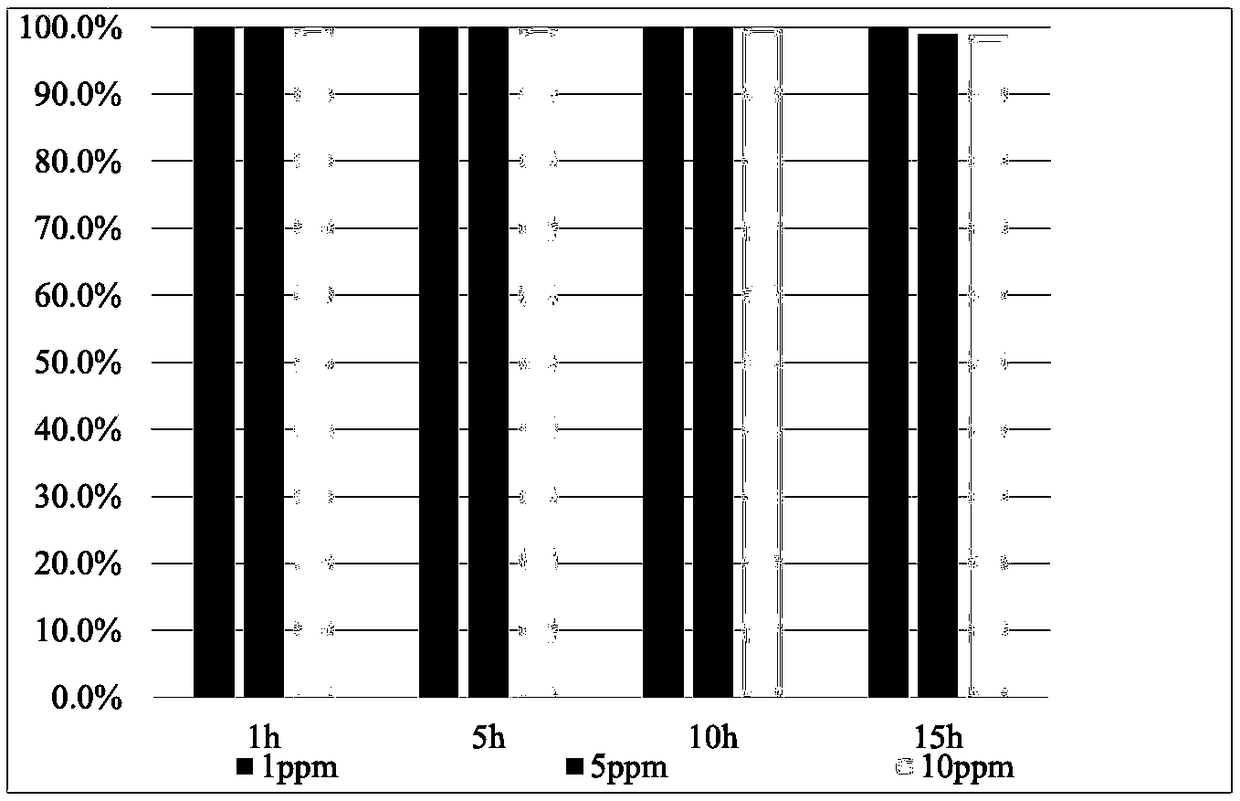

Preparation method of efficient water-resistant copper-doped manganese-based catalyst and application thereof in low-concentration ozone decomposition

InactiveCN109289863ACatalytic degradation of ozone effect is goodImprove water resistanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMANGANESE ACETATEDecomposition

The invention discloses a preparation of an efficient water-resistant copper-doped manganese-based catalyst and an application thereof in low-concentration ozone decomposition. The efficient water-resistant ozonolysis catalyst of the invention uses manganese and copper as active components, and the preparation method thereof is a hydrothermal method. The preparation process is characterized by dissolving a certain amount of potassium permanganate and manganese acetate in deionized water to form a uniform solution; slowly adding a manganese acetate solution to a potassium permanganate solution,and uniformly stirring the materials to form a uniform solution; adding copper nitrate solid to the above uniform solution, and the uniformly stirring the materials by ultrasonication, transferring the solution to a hydrothermal reaction vessel, adjusting the temperature to 140 DEG C for 2 hours, after the reaction, naturally cooling a mixture, and performing steps of centrifugation washing and acid treatment and drying to obtain the final material. The preparation method of the invention is simple and the material is easy to obtain. At the same time, the catalyst has excellent water resistance, which solves the problem that the catalyst is not water resistant, can adapt to various industrial production environments, and has good market application prospects.

Owner:广东科之源环保科技设备有限公司 +1

Composite partition board

The invention discloses a composite partition wall board, which comprises a wall board body, wherein sound isolation grooves are formed in positions near two side surfaces of the wall board body; the sound isolation grooves and the wall board body are integrally connected through cement casting; a polyurethane heat insulation composite board is arranged in a position, near the upper surface and positioned between the two sound isolation grooves, of the wall board body; the polyurethane heat insulation composite board is fixedly arranged between the two sound isolation grooves; a sponge body is filled in the polyurethane heat insulation composite board; the lower surface of the polyurethane heat insulation composite board is provided with a hollow fiber concrete board; the hollow fiber concrete board and the polyurethane heat insulation composite board are connected in a sealed way; and the lower surface of the hollow fiber concrete board is provided with a concrete fiber board. The composite partition wall board has the advantages that a cold bridge phenomenon generated by a building body can be effectively prevented; good sound isolation performance is realized; board bodies are tightly connected, and the falling phenomenon cannot easily occur; a certain vibration reduction efficacy is realized; the damage to the wall board due to too great vibration amplitude is avoided; the durability is high; the fire-resistant grade is high; the environment is protected; the energy is saved; and the requirements of the modern building industrialization are met.

Owner:SHENZHEN BUILDING DECORATION (GRP) CO LTD

Internal-thread pneumatic quick coupling

The invention relates to an internal-thread pneumatic quick coupling. The internal-thread pneumatic quick coupling is provided with a coupling body of a stage shape. One end of the coupling body is provided with a sleeve pipe and an inner wall at the other end of the coupling body is provided with an internal-thread part. The internal-thread pneumatic quick coupling has following beneficial effects: the internal-thread pneumatic quick coupling is simple in structure, convenient in application and easy in manufacture and processing; air leakage is avoided; an air pipe is prevented from falling down; and working efficiency is enhanced.

Owner:许炎章

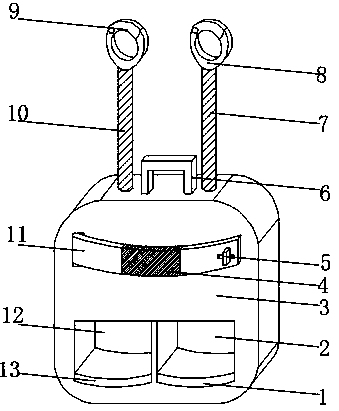

Firefighting equipment special for high-rise building

InactiveCN108744325AAvoid shaking phenomenonEasy to installBuilding rescueFirefightingArchitectural engineering

The invention discloses firefighting equipment special for a high-rise building. The firefighting equipment special for the high-rise building comprises a high-rise escape device main body, the outersurface of the front end of the high-rise escape device main body is fixedly provided with a telescopic waistband, the middle of the outer surface of the telescopic waistband is fixedly provided withan elastic band, and the side, close to the elastic band, of the outer surface of the front end of the telescopic waistband is movably provided with a fixing buckle. A second fixing groove is formed below the position, close to the telescopic waistband, of the inner surface of the front end of the high-rise escape device main body, a first fixing groove is formed in the side, close to the second fixing groove, of the inner surface of the front end of the high-rise escape device main body, and the outer surface of the lower end of the first fixing groove is fixedly provided with a first shock pad. The firefighting equipment special for the high-rise building is provided with a second fixing rope and the telescopic waistband, the application range of the equipment can be effectively broadened, the safety of the equipment is improved, and better use prospect is brought.

Owner:叶彩英

Fast connector

ActiveCN101728706BFirmly connectedAccurate connectionCoupling contact membersEngineeringMechanical engineering

The invention discloses a fast connector for fast connection. The fast connector comprises a hollow shell. A section of horizontal partition board for partitioning the inner part of the shell into a front cavity and a rear cavity is arranged on one side on the inner part of the shell; the front cavity and the rear cavity of the shell are mutually communicated; a longitudinal partition board is arranged in the rear cavity to separate the rear cavity into two parts; a pair of insertion grooves are arranged in the rear cavity respectively and positioned on two edge sides in the shell; one end ofone spring leaf and one end of the other spring leaf are inserted in the two insertion grooves respectively; positioning blocks propped against the end parts of the spring leaves are arranged on the inner bottom surface of the shell rear cavity respectively; the other end of each of the spring leaves penetrates through the connecting part between the front cavity and the rear cavity and tilts upwards; a connecting part is arranged between each of the spring leaves and the horizontal partition board; a longitudinal guide block is arranged on one side of the inner wall of the shell front cavity; and a longitudinal guide groove is arranged on the outer wall of the shell front cavity. The fast connector has the advantages that the fast connector with the structure enables the connection to befast and accurate, and the falling phenomenon between connecting terminals is prevented.

Owner:ZHANGJIAGANG UCHEN NEW ENERGY TECH CO LTD

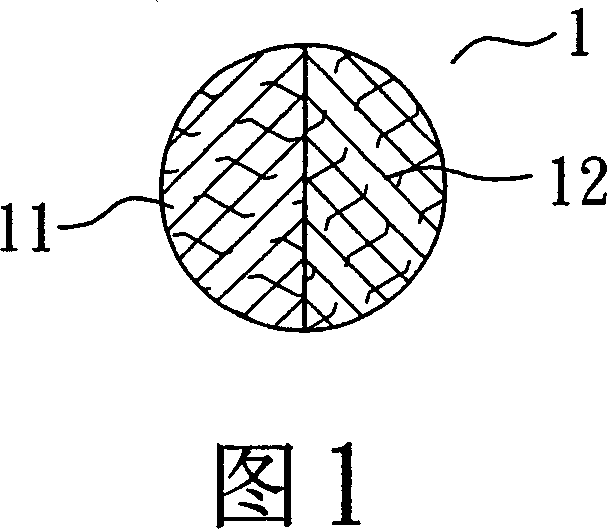

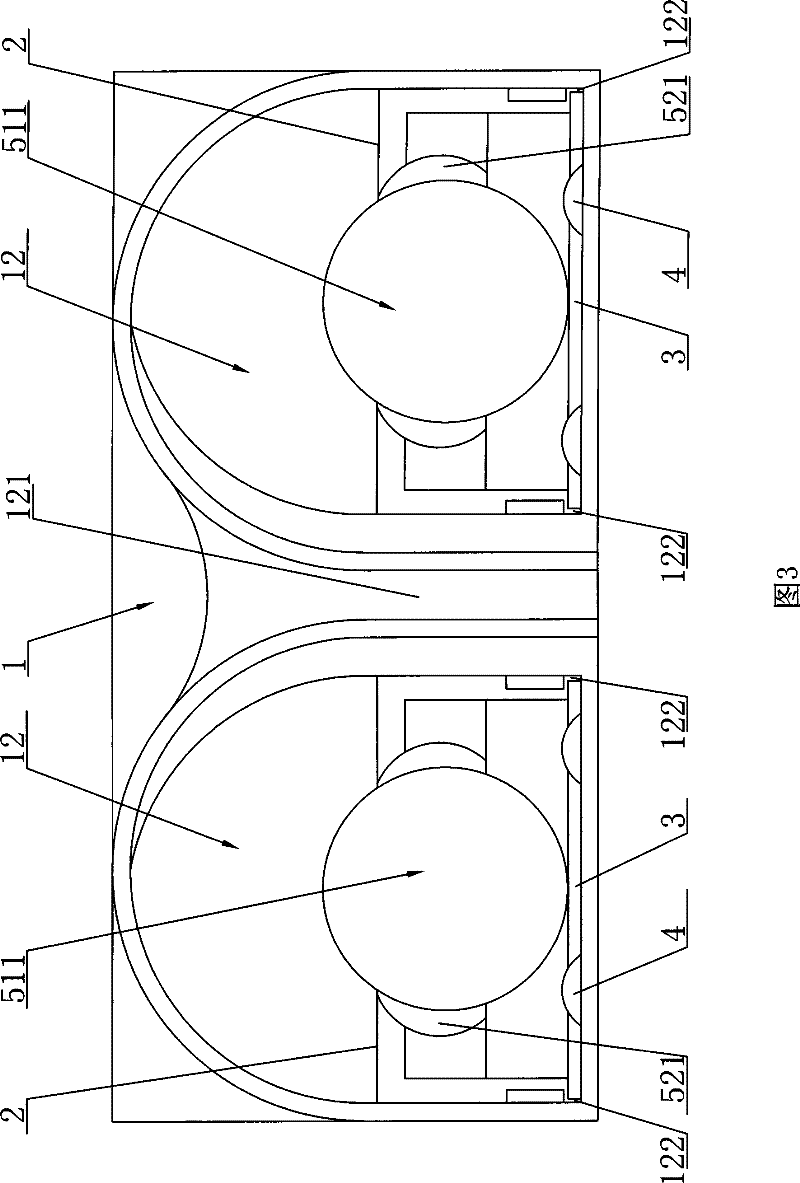

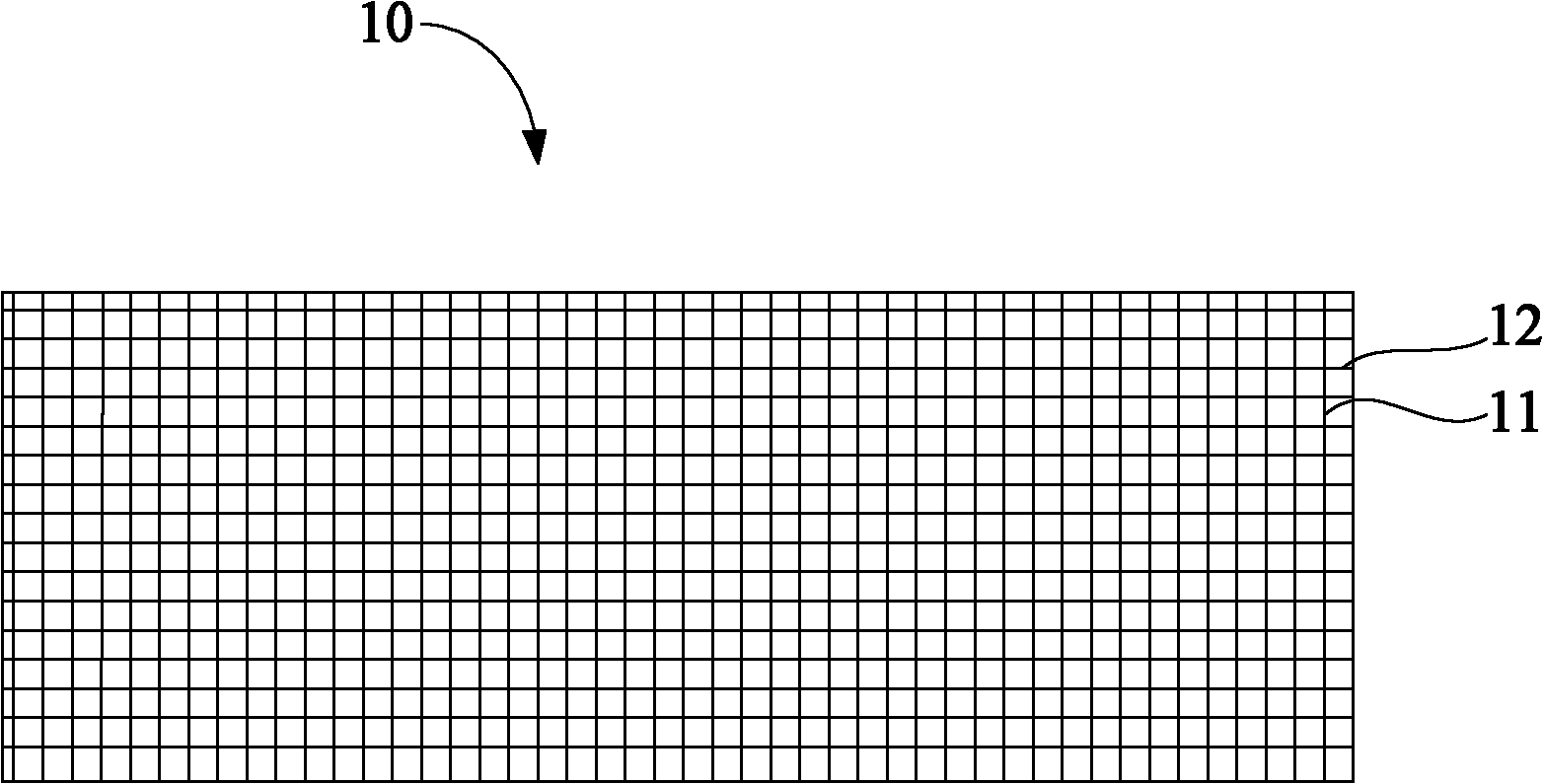

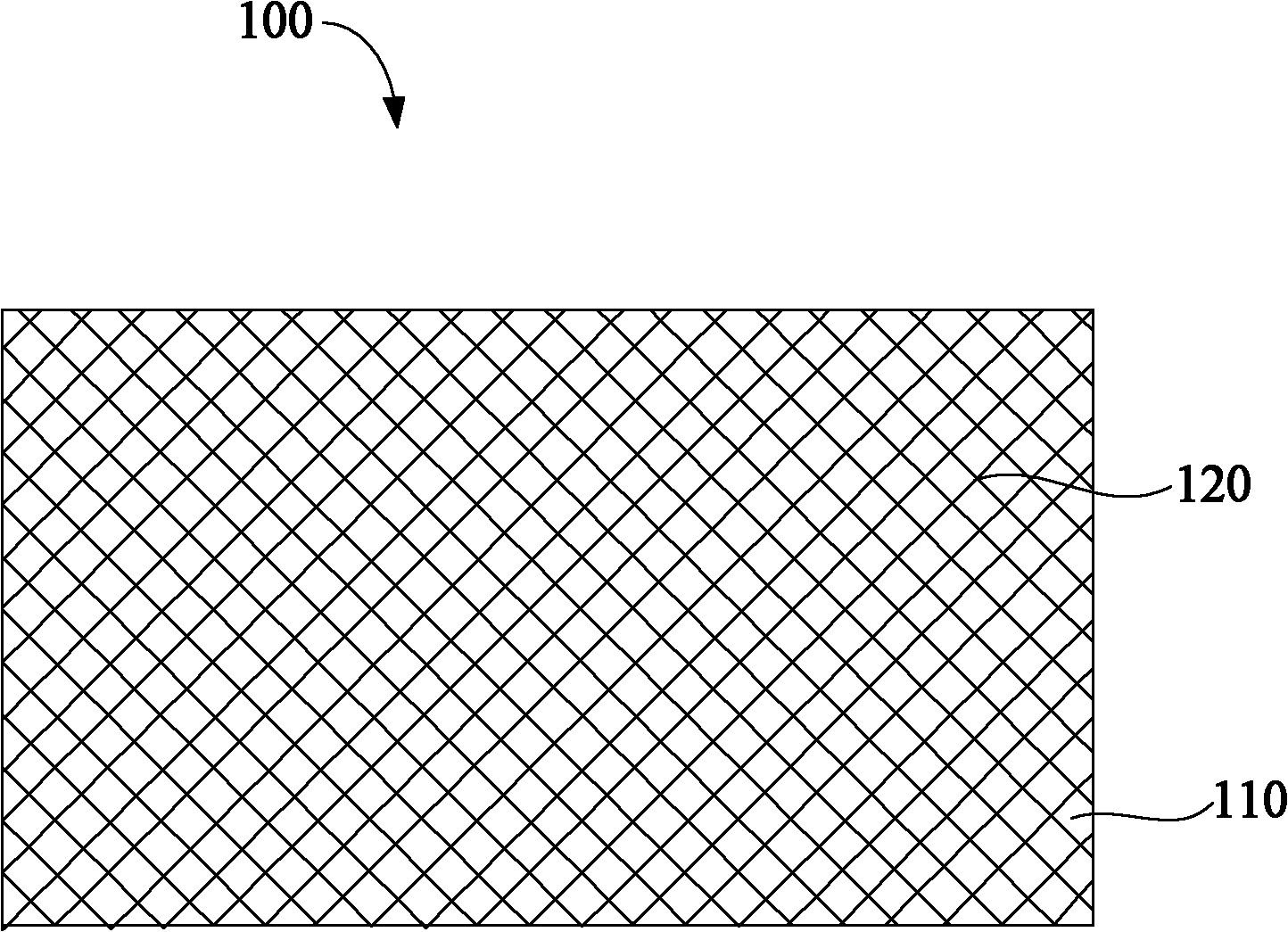

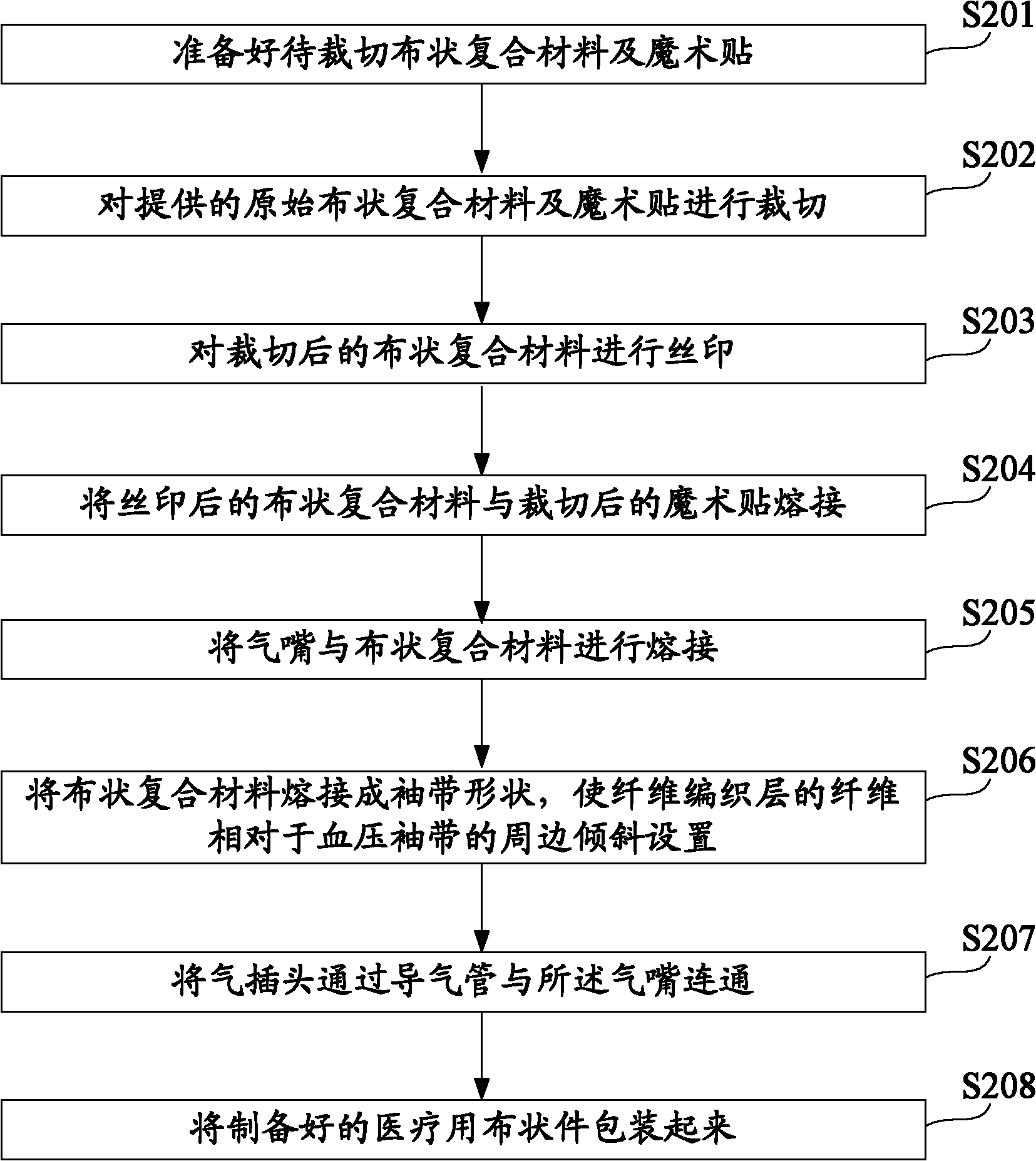

Blood pressure cuff

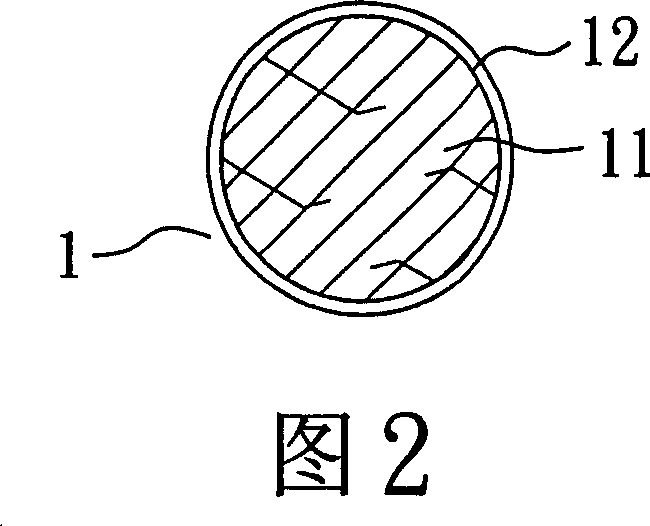

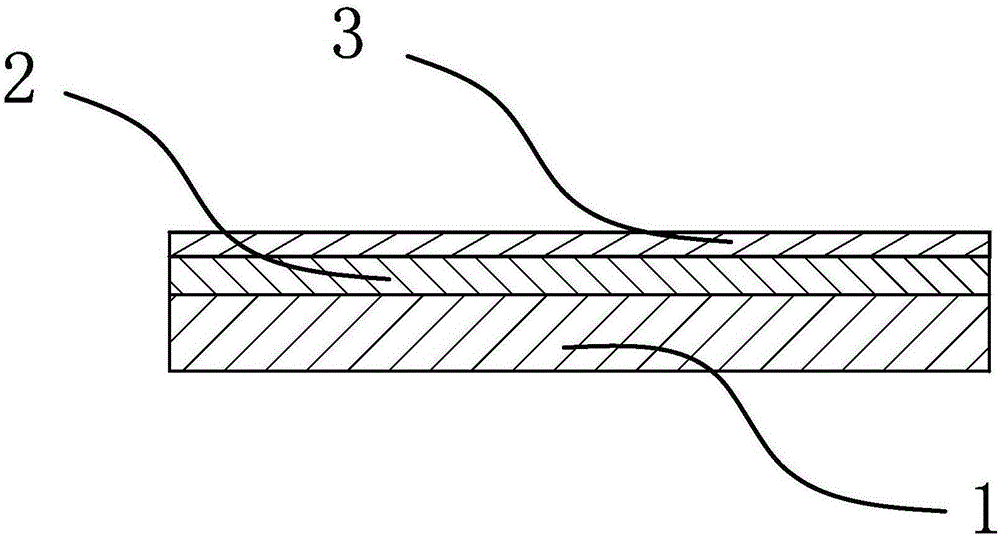

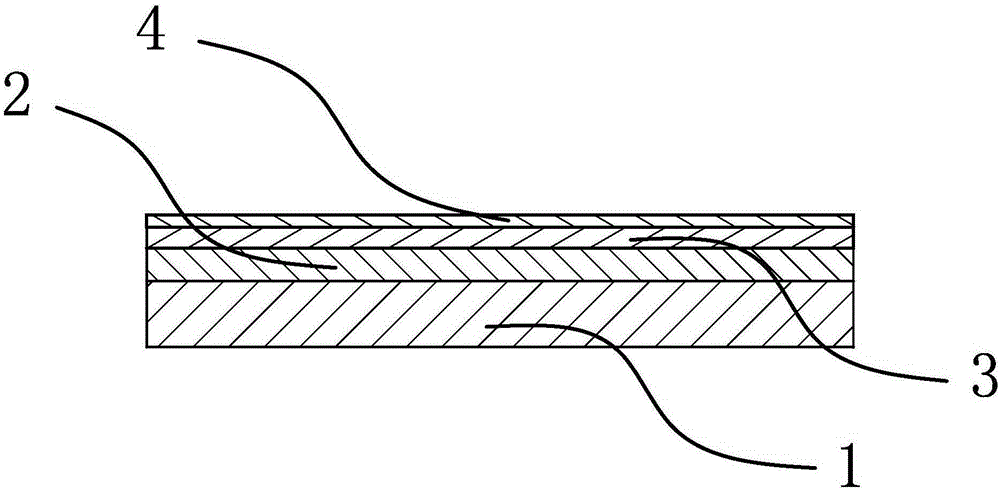

ActiveCN103142220AImprove abrasion resistanceNot easy to fluffEvaluation of blood vesselsAngiographyFiberBlood pressure cuffs

The invention provides a blood pressure cuff which comprises a main body made from a cuff wrapping cloth material. The fiber distributing direction of the cuff wrapping cloth material is inclined by a certain angle relative to the periphery of the blood pressure cuff. After the crossed direction between the fibers of a fiber layer of the blood pressure cuff and the periphery of the blood pressure cuff is changed, a certain inclined angle is available between the fiber distributing direction and the periphery of the blood pressure cuff rather than a parallel or perpendicular relationship, and the friction resistance of the blood pressure cuff can be improved due to the fiber direction. Therefore, the phenomena, i.e. the fuzzing and the fiber falling, hardly appear at the periphery of the blood pressure cuff.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

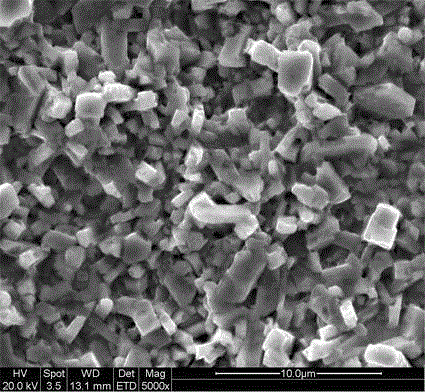

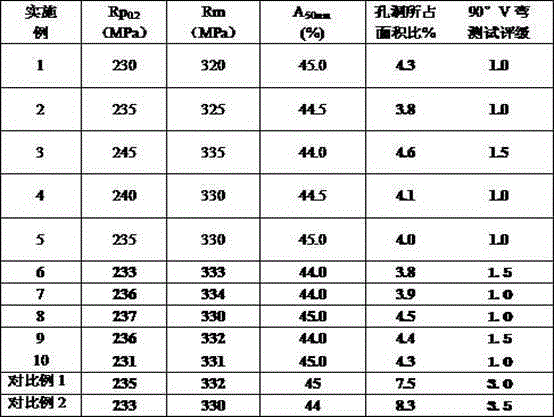

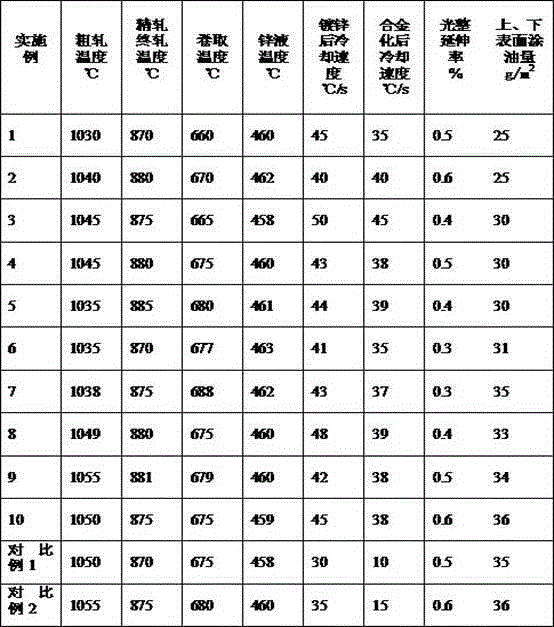

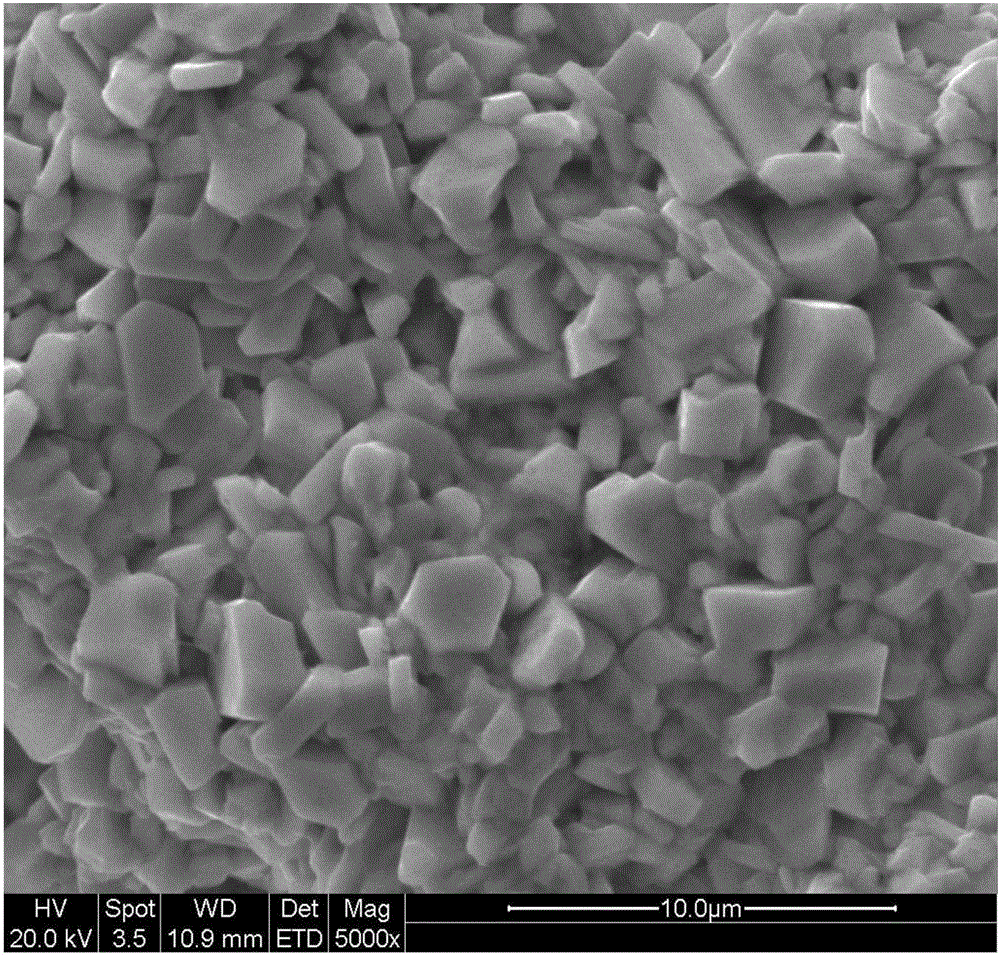

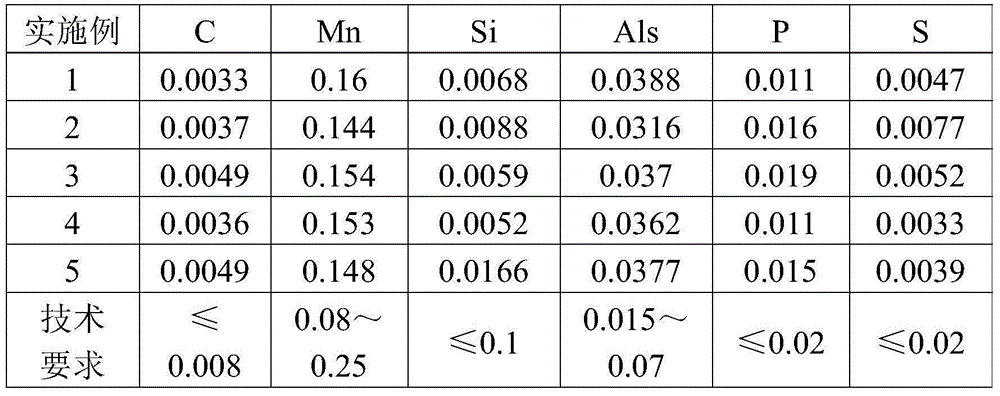

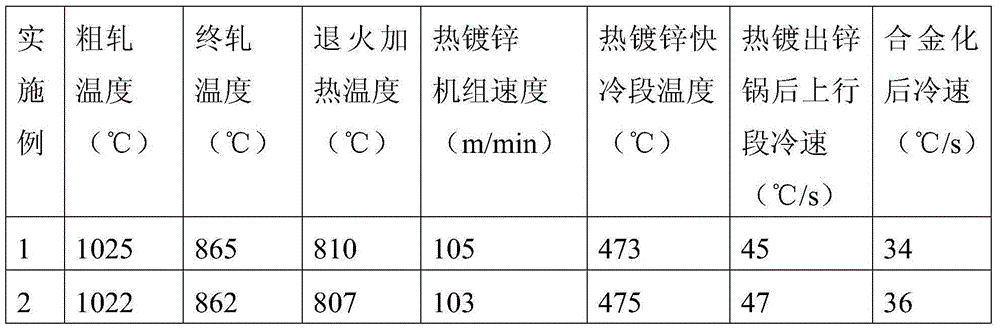

Method for producing iron-zinc alloy coated steel plate with yield strength being equal to or higher than 220 MPa

ActiveCN105274301AFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

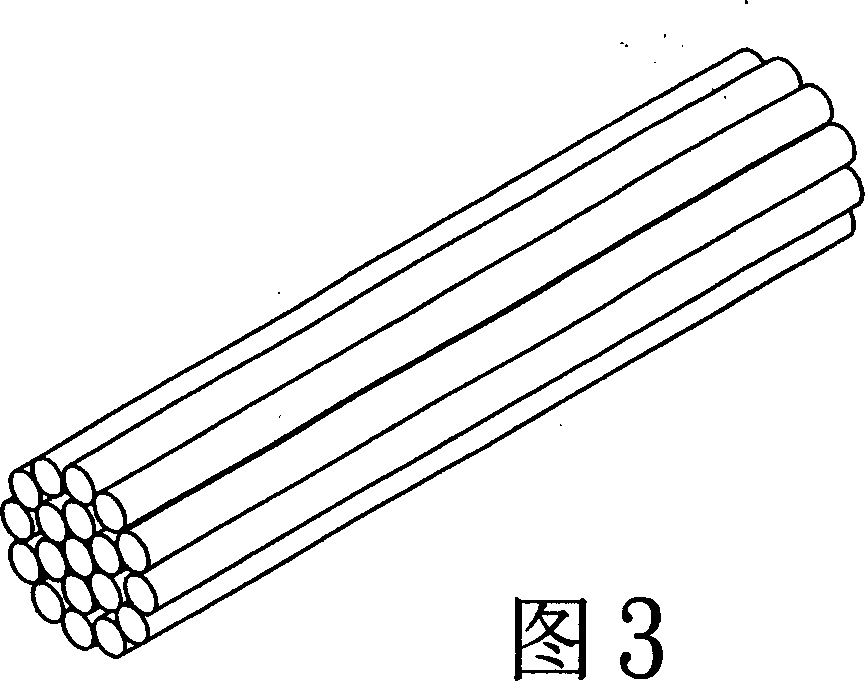

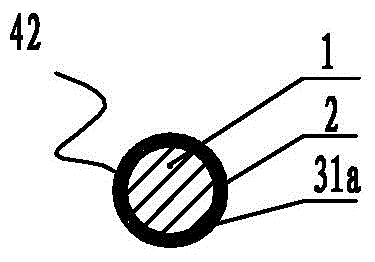

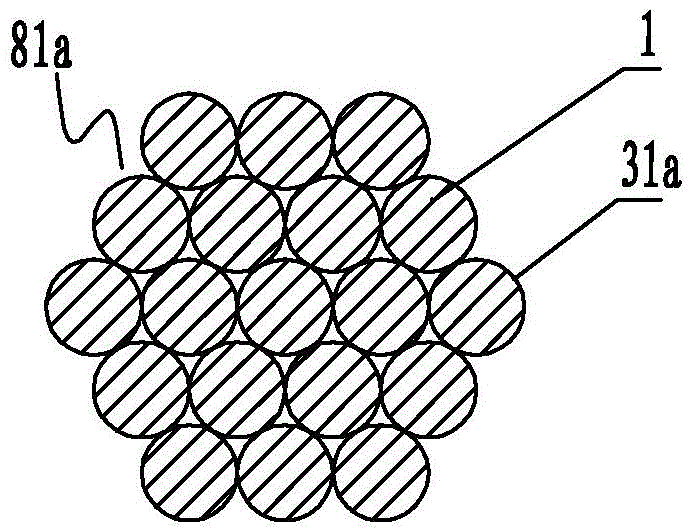

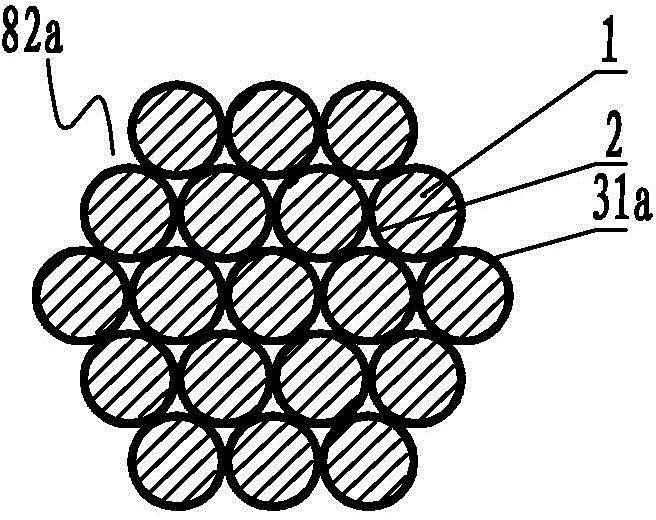

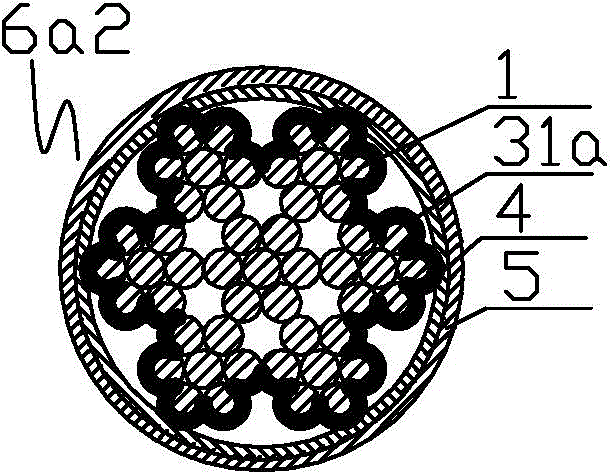

Manufacturing method for steel wire inhaul cable with polyurea protective coating

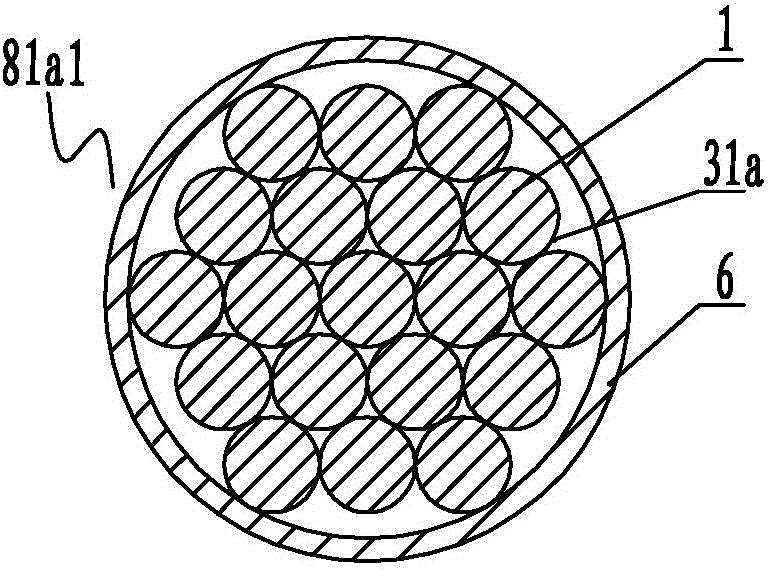

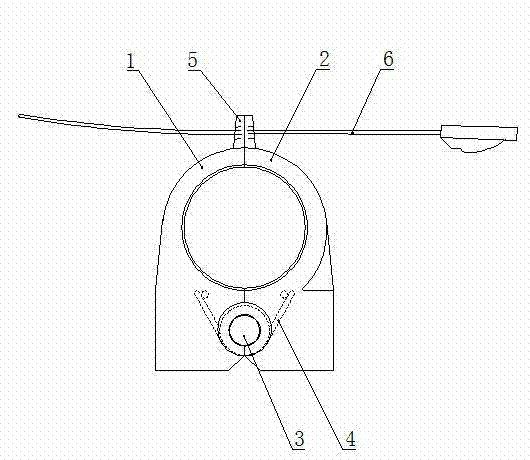

InactiveCN105088948AImprove shock absorptionImprove skid resistanceRope making machinesBridge structural detailsPolymer scienceProtection layer

The invention relates to a manufacturing method for a steel wire inhaul cable with a polyurea protective coating. The manufacturing method includes the steps that steel wires with polyurea protective coatings are manufactured, the steel wires with the polyurea protective coatings pass through the polyurea material filling process through wire dividing, after the positions between the steel wires with the polyurea protective coatings are filled with polyurea materials, a steel wire combination with the polyurea protective coating is formed through the step of coalescence, the positions between the steel wires, with the polyurea protective coatings, of the steel wire combination are filled with the polyurea materials to form steel wire inhaul cable bodies Iae and IIae with the polyurea protective coatings; the steel wire inhaul cable bodies which are of two structures and are provided with the polyurea protective coatings serve as basic structures, and the steel wire inhaul cable which has multiple protection layers and is provided with the polyurea protective coating is formed through one or more of the wrapping and packaging molding process, the PE sleeve extrusion molding processes I and II and polyurea material coating processes II, III, IV and the like. The manufacturing method is economical and practical, and the manufactured steel wire inhaul cable with the polyurea protective coating is compact in structure and antiseptic, reduces shocks, and is good in skid resistance and abrasive resistance.

Owner:LIUZHOU OVM MASCH CO LTD

Preparation method of alkyd resin coating capable of forming flat surface

InactiveCN107868590AStrong compactnessImprove compactnessPolyurea/polyurethane coatingsPolyester coatingsGas phasePolyamide

The invention discloses a preparation method of an alkyd resin coating capable of forming flat surfaces. The method comprises the steps as follows: polyvinyl alcohol and bamboo charcoal powder are stirred, a silane coupling agent is added, grinding is performed, agarose is added, ultrasonic treatment is performed, and a first material is obtained; fumed silica, wollastonite powder, vermiculite powder, nano talcum powder, acetic ether, the first material and water are mixed, ultrasonic treatment is performed, and a second material is obtained; phenolic aldehyde modified alkyd resin, acrylic acid modified alkyd resin, diethylene glycol methyl ether acetate, ethylene glycol, waterborne polyurethane resin, polyamide polyamine epoxy chloropropane resin and oxidized polyethylene wax are uniformly stirred, the second material, polyoxypropylene glycerol ether, hydroxyl silicone oil, sodium lauryl sulfate, a wetting agent and a preservative are added, the mixture is stirred continuously, and the alkyd resin coating capable of forming the flat surfaces is obtained. The method is simple, and the obtained coating has good base material adhesion and film compactness, is not prone to peeling offand has good heat and damp resistance and temperature change resistance.

Owner:合肥林邦门业有限公司

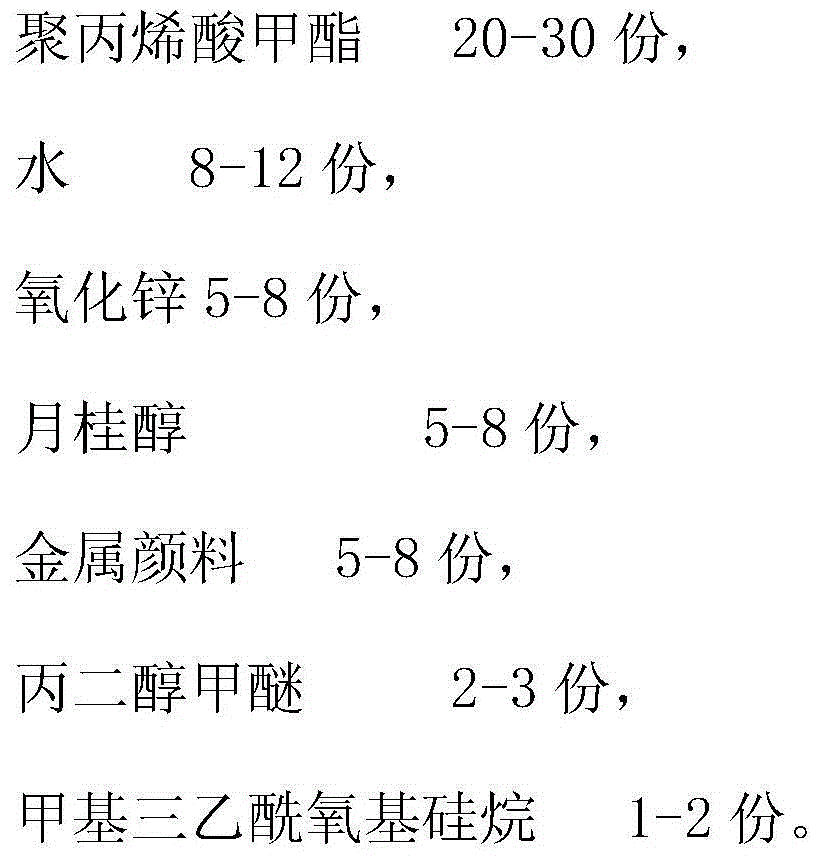

Metallic paint composition and preparation method thereof

InactiveCN104356837AImprove the protective effectImprove bindingCoatingsMonomethyl etherHYDROGENATED SOYBEAN OIL

The invention discloses a metallic paint composition and a preparation method thereof. The metallic paint composition is prepared from the following components in parts by weight: 20-30 parts of polymethyl acrylate, 8-12 parts of water, 5-8 parts of zinc oxide, 5-8 parts of laurinol, 5-8 parts of metallic pigment, 2-3 parts of propylene glycol monomethyl ether and 1-2 parts of methyltriacetoxysilane. The invention also provides the preparation method of the metallic paint composition. The preparation method comprises the following steps: (1) weighing 20-30 weight parts of polymethyl acrylate, 5-8 weight parts of laurinol, 5-8 weight parts of zinc oxide, 5-8 weight parts of metallic pigment and 1-2 weight parts of methyltriacetoxysilane; and (2) adding the weighed components to a homogenizer for evenly mixing at a temperature ranging from 60-75 DEG C, and then orderly adding 8-12 weight parts of water, 0-2 weight parts of hydrogenated soybean oil and 2-3 weight parts of propylene glycol monomethyl ether, stirring at a high speed for 10-15 minutes, and defoaming for 1-2 hours under the vacuum condition, thereby obtaining the metallic paint composition.

Owner:苏州冰心文化用品有限公司

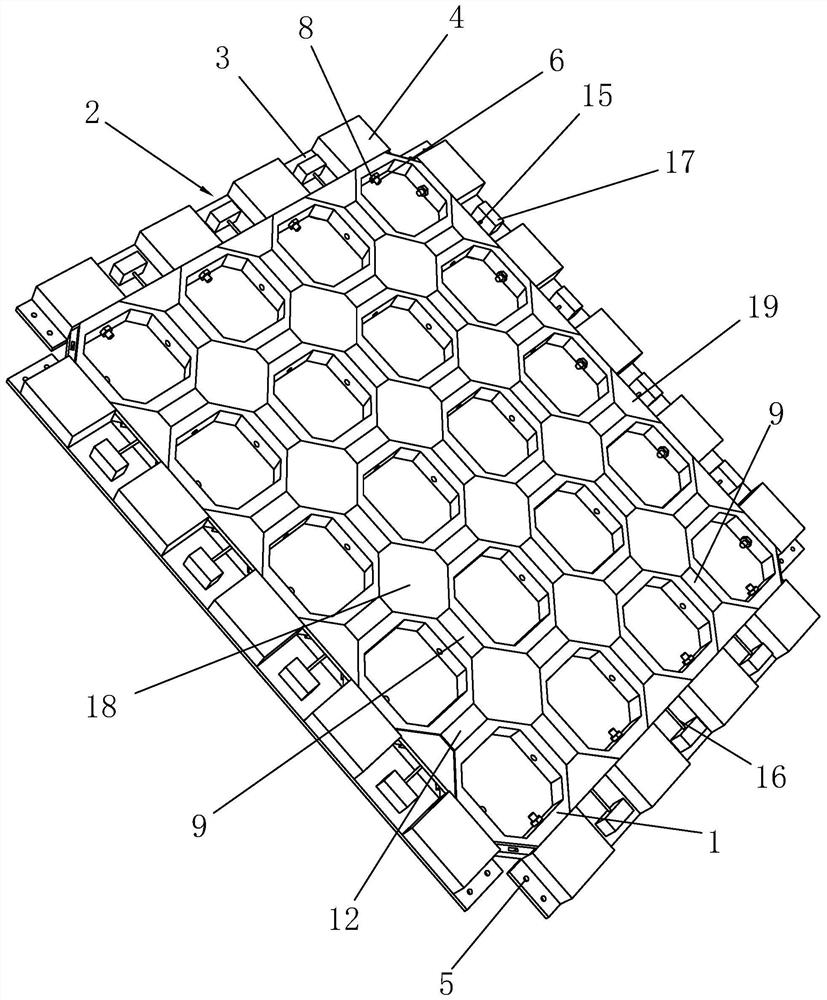

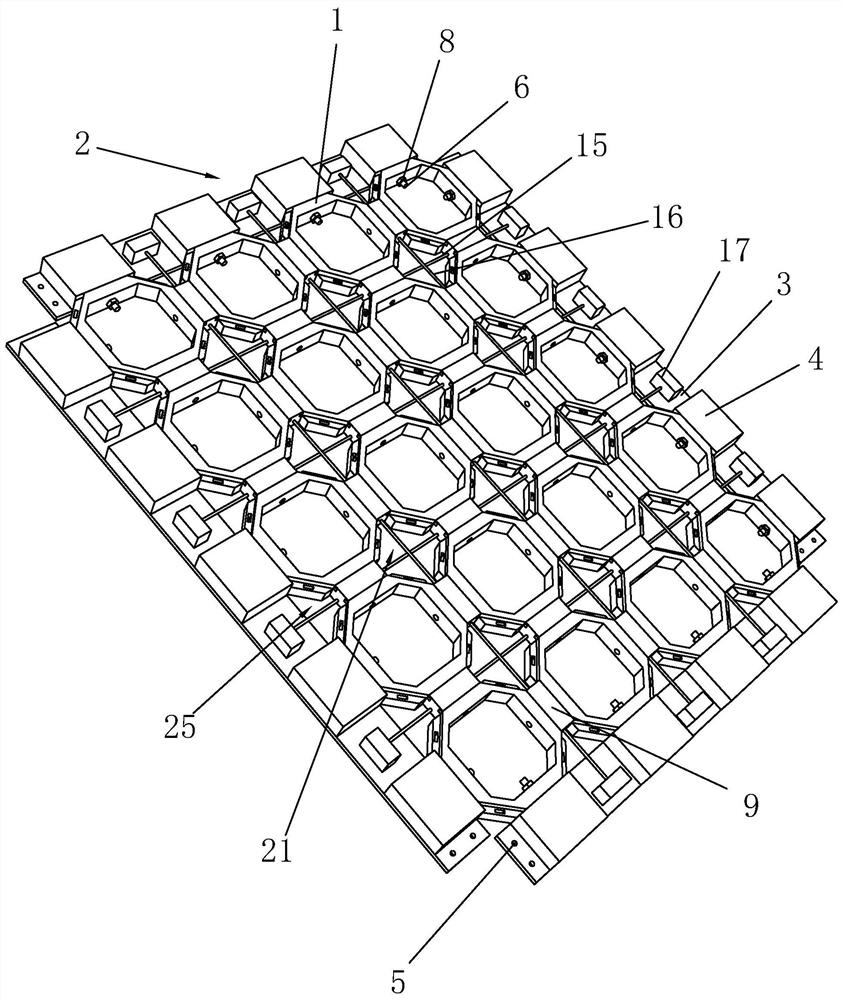

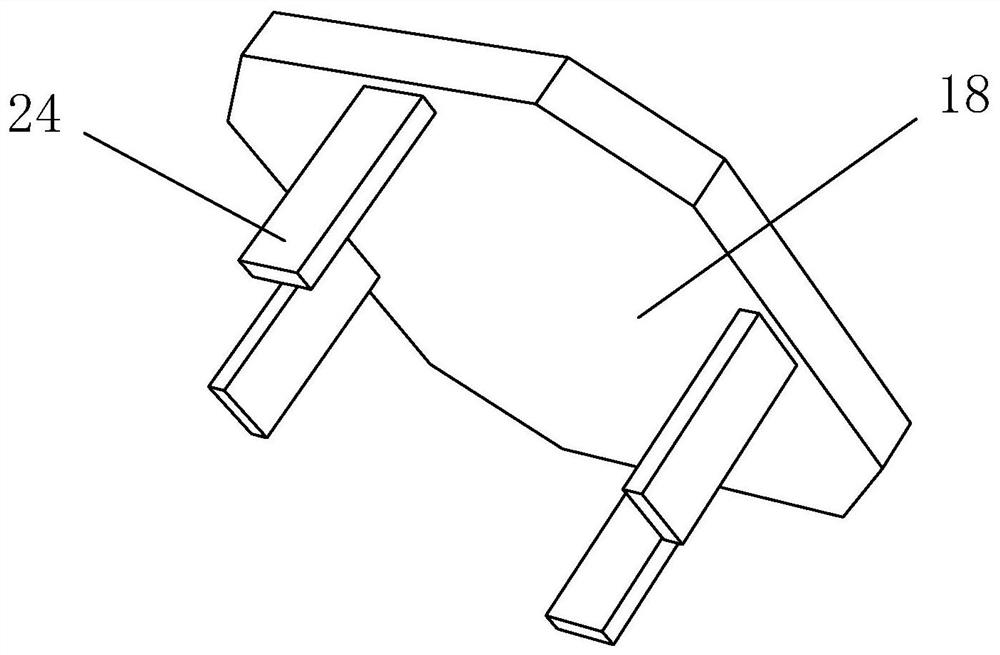

Construction method of ecological revetment block structure

ActiveCN112575741AEnsure the firmness of the installationEnsure support limit functionCoastlines protectionReceptacle cultivationEnvironmental resource managementWater flow

The invention discloses a construction method of an ecological revetment block structure. The construction method comprises the following steps of 1) construction preparation, 2) preparation of reinforcing edge strips, 3) construction of an ecological revetment, and 4) plant planting. According to the construction method, the reinforcing edge strips are arranged on the four sides of the ecologicalrevetment, reinforcing and supporting are conducted from the four sides of the ecological revetment simultaneously, the stability of the whole ecological revetment is effectively improved, thus ecological blocks are not prone to falling off, and the ecological revetment can resist scouring of water flow better; the adjacent ecological blocks are mutually clamped through positioning blocks, the positioning blocks in the same row or the same column are connected and fixed through connecting rods, indirect connecting and fixing between the transverse ecological blocks and the longitudinal ecological blocks are achieved, thus the ecological blocks are mutually combined and restrained, the structural strength of the revetment structure is improved, the ecological revetment is not prone to deforming, and the ecological blocks do not fall off; and through further reinforcing and positioning arrangement of auxiliary blocks, the structure of the whole ecological revetment is more compact and firmer.

Owner:宁波龙元盛宏生态建设工程有限公司

Formula of anticorrosive paint

The invention provides a formula of an anticorrosive paint. The anticorrosive paint is prepared by adopting water, ethylene glycol, titanium dioxide, kaolin, butyl ester and ethyl ester as main materials and adding a foam inhibitor, an antifoaming agent, a dispersing agent, a modifier and a wetting agent. The anticorrosive paint is simple in structure, convenient to prepare, relatively low in cost, free of harm, and good in anticorrosive effect; the phenomenon that the paint falls off does not easily appear, the overall security is effectively improved and the requirements of a manufacturer can be met.

Owner:镇江程灿科技服务有限公司

Manufacturing method for steel wire inhaul cable with polyurea protective materials on outer layer

ActiveCN105088946AImprove shock absorptionImprove skid resistanceBridge structural detailsBridge materialsPolymer scienceProtection layer

The invention relates to a manufacturing method for a steel wire inhaul cable with polyurea protective materials on the outer layer. The manufacturing method includes the steps that after steel wires are pretreated, steel wire combinations are molded through drying, coiling, wire dividing and coalescence, the outermost layers of the n steel wire combinations are coated with a polyurea protective coating I through the polyurea material extrusion coating work procedure I; steel wire inhaul cable bodies Ia or IIa with the polyurea protective materials on the outer layers are formed, wherein the n is larger than or equal to 1; then the steel wire inhaul cable bodies Ia or IIa are shaped through wrapping and packaging, and steel wire inhaul cable bodies Ia0 and IIa0 with the polyurea protective materials on the outer layers are formed; the manufactured steel wire inhaul cable bodies with the polyurea protective materials on the outer layers form the steel wire inhaul cable which has multiple protection layers and is provided with the polyurea protective materials on the outer layer through one or more of the PE sleeve extrusion molding working procedures I and II and polyurea material extrusion coating working procedures II and III. The steel wire inhaul cable which is manufactured with the method and provided with the polyurea protective coatings is compact in structure and antiseptic, reduces shocks, and is good in skid resistance and abrasive resistance and long in service life.

Owner:LIUZHOU OVM MASCH CO LTD

Anti-dropping type feeder line clamping device for ship

The invention relates to an anti-dropping type feeder line clamping device for a ship. The feeder line clamping device comprises a left half plastic feeder line clip and a right half plastic feeder line clip which are symmetrically arranged, arc feeder line snapping grooves are opened on inner sides of upper portions of the left half plastic feeder line clip and the right half plastic feeder line clip, lower portions of the left half plastic feeder line clip and the right half plastic feeder line clip are connected with each other through a pin shaft, and a torsion spring is sleeved on the pin shaft. The feeder line clamping device is characterized in that top ends of the left half plastic feeder line clip and the right half plastic feeder line clip correspond to lug plates, flat through holes which are mutually communicated are opened on the two lug plates, and a stainless steel tie belt penetrates through the two through holes. When a feeder line is to be tightly clamped, the left half plastic feeder line clip and the right half plastic feeder line clip are split, and the feeder line is placed in the feeder line snapping grooves to be tightly clamped by means of tight locking forces of the torsion spring; then when the stainless steel tie belt penetrates through the through holes, the whole feeder line is fixed, and the phenomenon that the feeder line drops when the left half plastic feeder line clip and the right half plastic feeder line clip are opened can be avoided; and the anti-dropping type feeder line clamping device is convenient and fast in installation and wide in using ranges, and the phenomenon that the feeder line drops is difficult to cause.

Owner:南通长青沙船舶工程有限公司

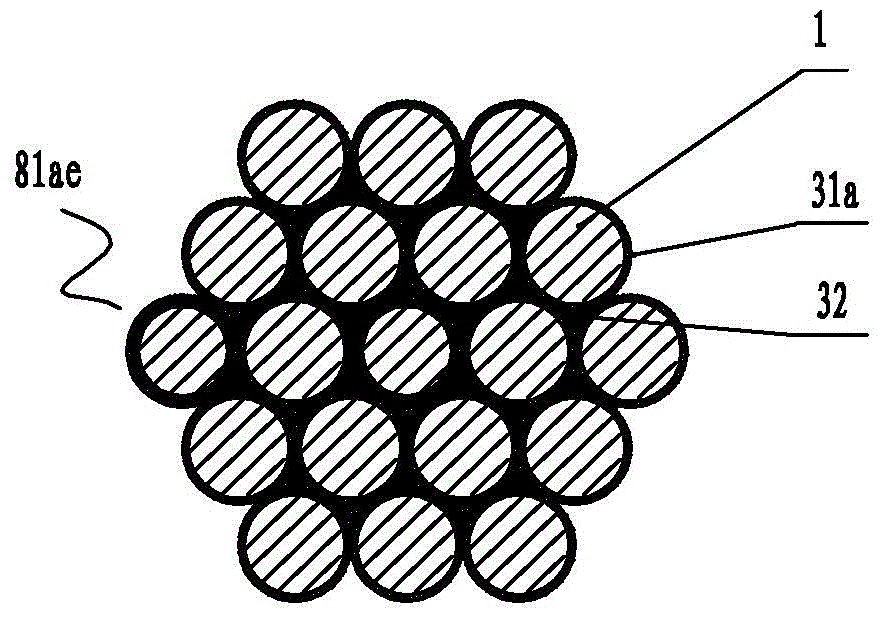

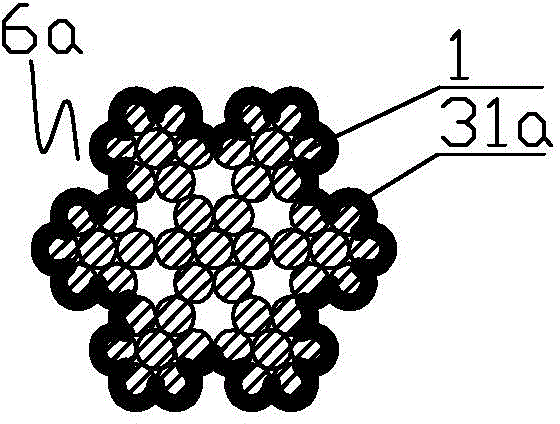

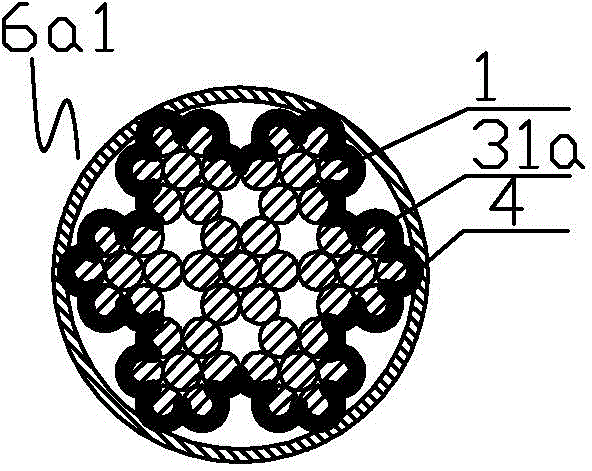

Steel strand inhaul cable with polyurea protective material on outer layer and manufacturing method of steel strand inhaul cable

ActiveCN105088950AImprove shock absorptionImprove skid resistanceRope making machinesBridge structural detailsWear resistancePolyurea

The invention relates to a steel strand inhaul cable with a polyurea protective material on an outer layer. The steel strand inhaul cable comprises a steel strand combination formed by n steel strands, the outer layer of the steel strand combination formed by the n steel strands is coated with a polyurea protective coating I to form a steel strand inhaul cable body Ia with the polyurea protective material, and the outer layer of a wrapping and packaging belt of the steel strand inhaul cable body Ia is coated with a polyurea protective coating II to form a steel strand inhaul cable body Ia0b. A manufacturing method of the steel strand inhaul cable includes the steps that a series steel strand inhaul cable which has multiple protective functions is manufactured through one or more of the polyurea material coating process I, the wrapping and packaging process, the polyurea material coating process II, the extrusion molding process, the polyurea material coating process III and the like of the steel strand combination obtained after the steps of pretreatment, drying and coalescence molding. The method is simple and convenient; the manufactured steel strand inhaul cable is good in tension-resisting strength and flexibility, high in damping and good in ageing resistance, wear resistance and damping performance; the corrosion prevention capacity of the steel strand inhaul cable can be greatly improved, and the service life of the steel strand inhaul cable can be prolonged; and the n is larger than or equal to 1.

Owner:LIUZHOU OVM MASCH CO LTD

Production method of deep-drawing zinc-iron alloy plated steel plate with ductility higher than 38% and with compact plating structure

InactiveCN105177409AGuaranteed mechanical propertiesImproved chalking resistanceHot-dipping/immersion processesAlloyArea ratio

The invention discloses a production method of a deep-drawing zinc-iron alloy plated steel plate with a compact surface plating structure. The production method comprises the steps of molten iron desulphurization, converter smelting, alloying, continuous casting, heating, rolling and alloying continuous hot galvanizing. In the alloying continuous hot galvanizing process, after galvanizing and zinc pot delivery are carried out, the cooling speed of an upstream section is controlled to be higher than or equal to 40 DEG C / s, and the cooling speed is controlled to be higher than or equal to 30 DEG C / s after alloying. The deep-drawing zinc-iron alloy plated steel plate in which zinc-iron alloy plating surface grains are fine, distribution is even in size, the plating structure is compact (the area ratio of surface holes is smaller than or equal to 5%), and the surface is free of obvious microcracks is obtained on the premise that the mechanical performance of the steel plate is guaranteed. The anti-pulverization performance of the zinc-iron alloy plated steel plate is improved, the 60-degree V bending test grade reaches the first level, and the phenomena of pulverization and falling of a plating are not likely to happen in the steel plate punching molding process; and accordingly the purposes of quality and production of zinc-iron alloy plated steel plate workpieces are achieved.

Owner:武钢集团有限公司

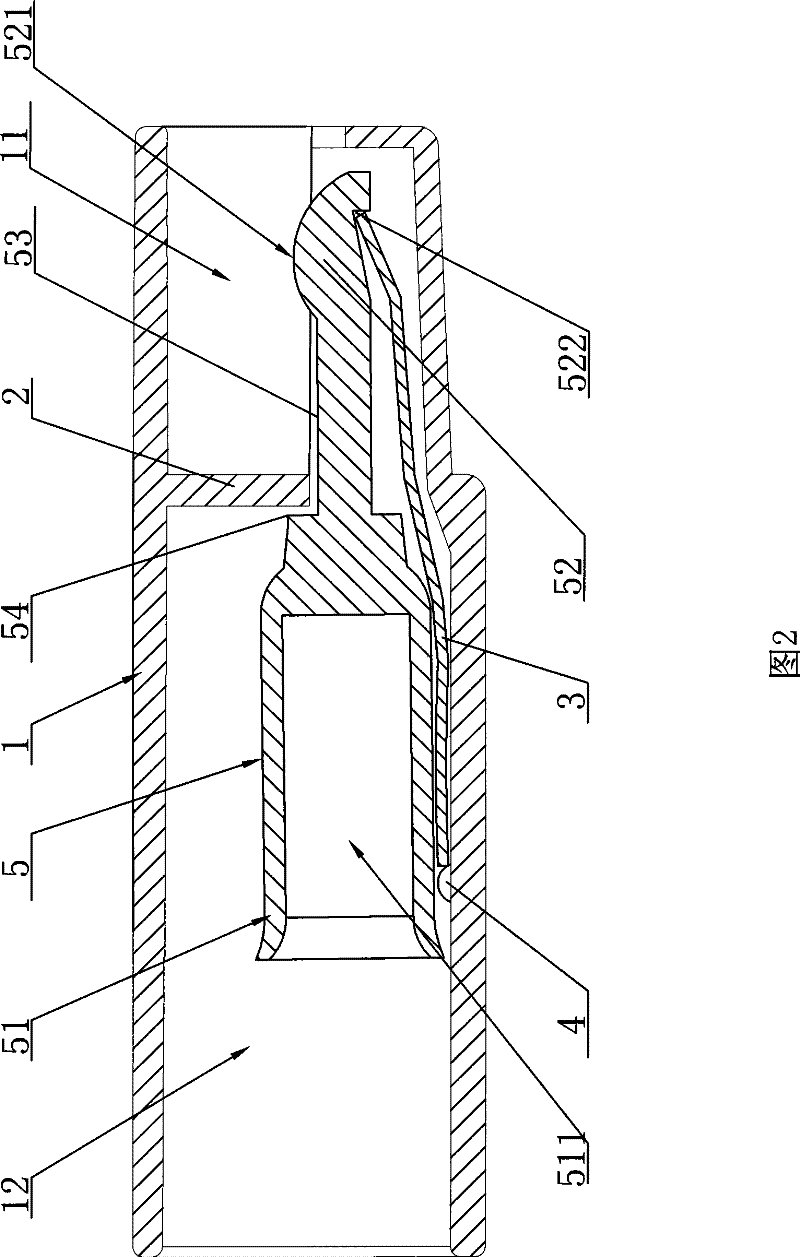

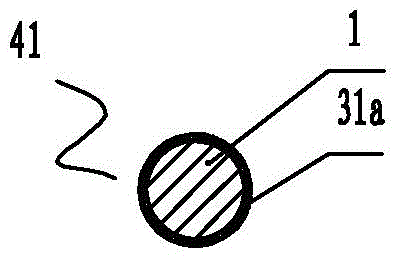

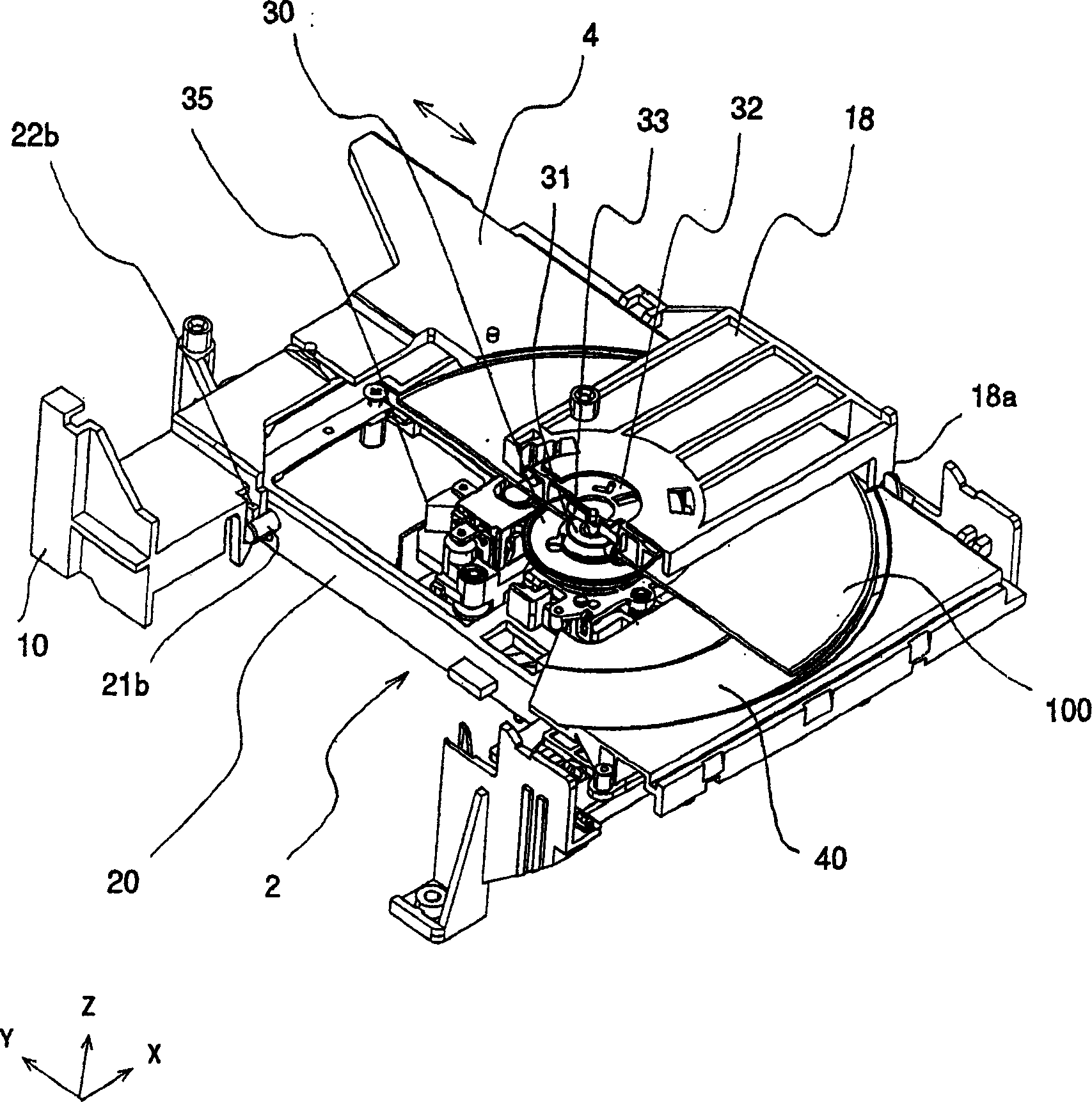

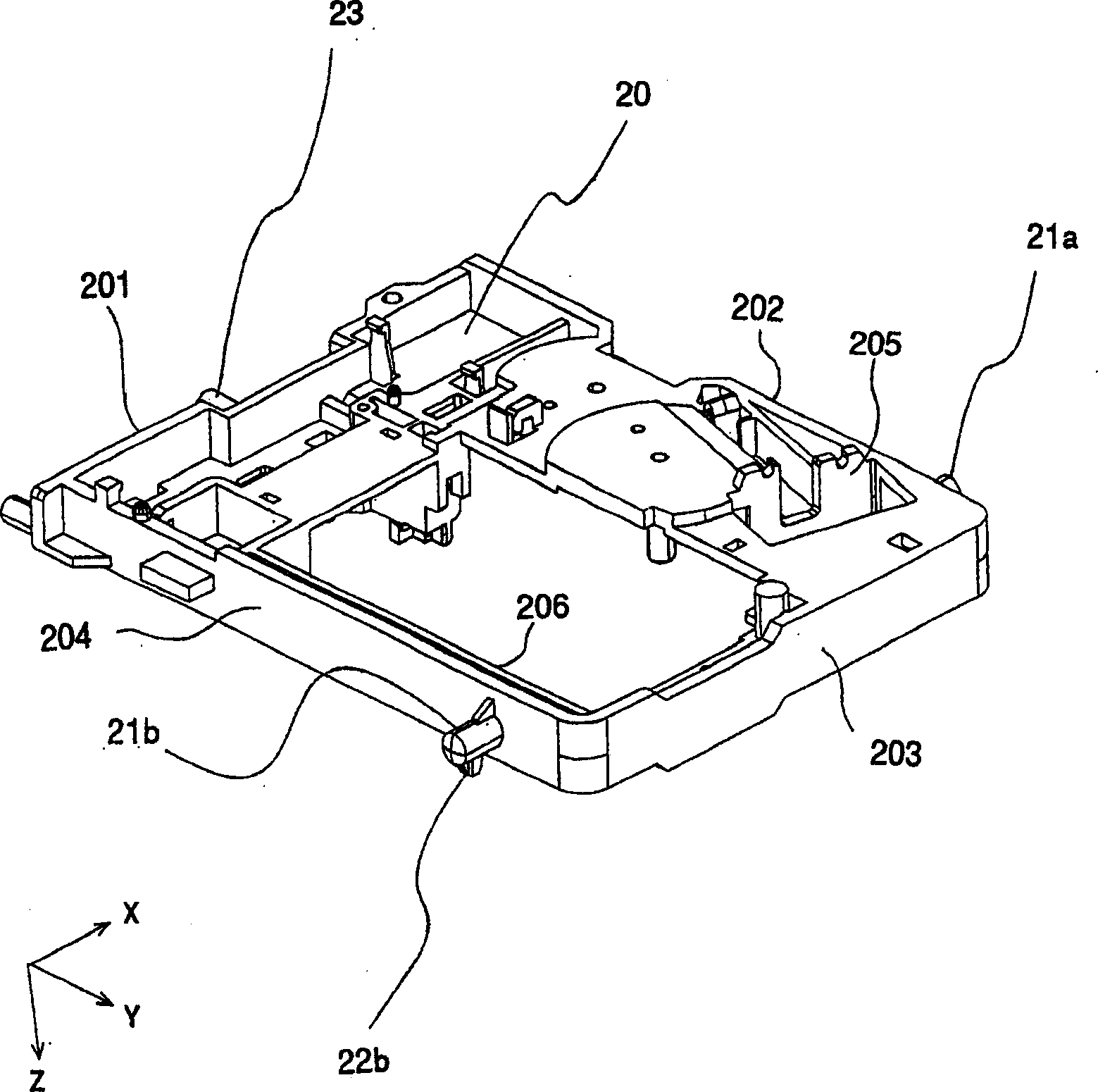

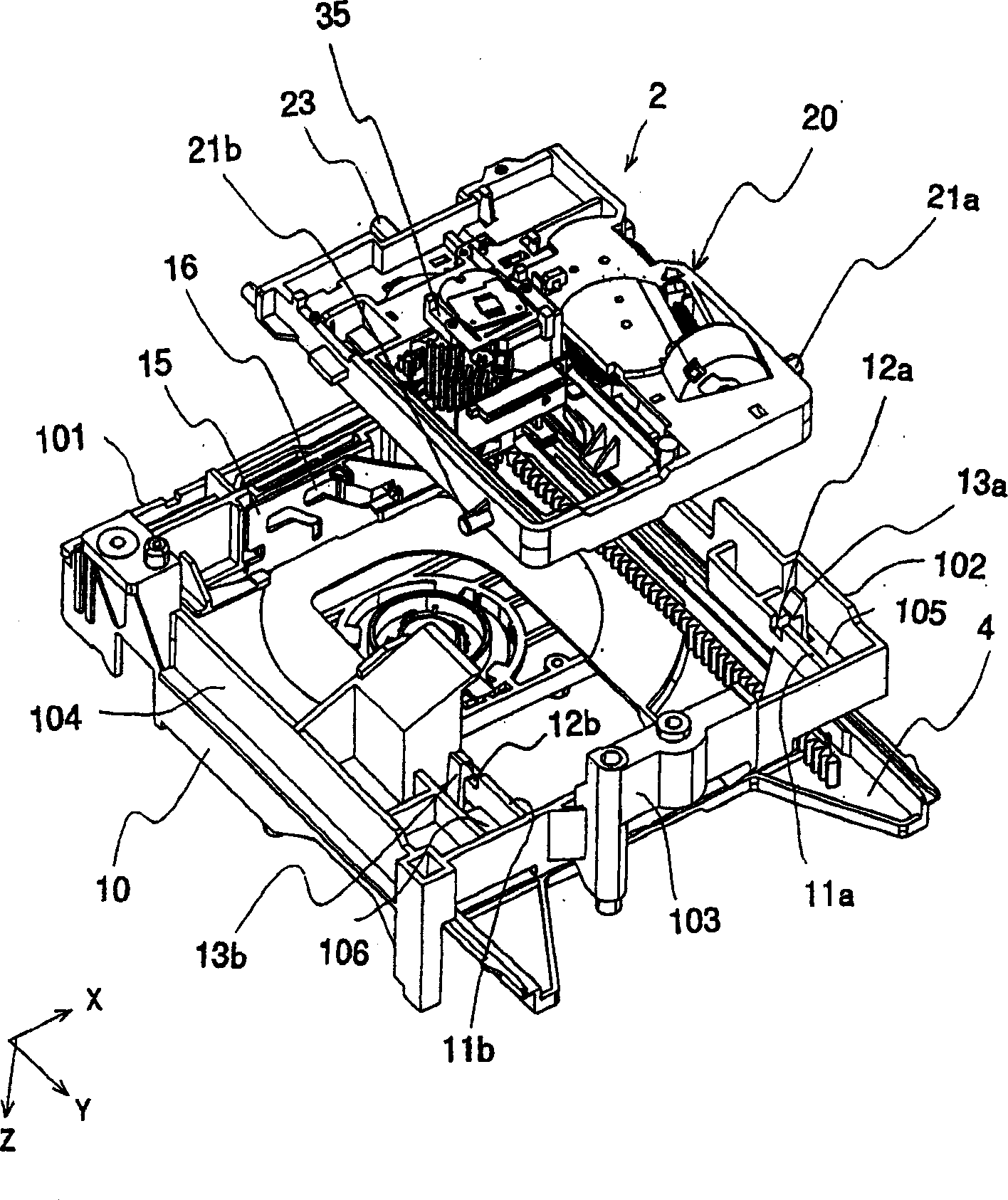

Disk device

InactiveCN1695196ANot prone to sheddingInhibit sheddingCarrier constructional parts dispositionApparatus for flat record carriersChassis

A disk device comprises a traverse chassis (20) for supporting a turntable (30) or the like, and a main chassis (10) for turnably supporting the traverse chassis (20). The traverse chassis (20) has a pair of bosses (21a, 21b) coaxial with each other, while the main chassis (10) has boss supports (1a, 1b) supporting the bosses (21a, 21b) of the traverse chassis (20). The front ends of the bosses (21a, 21b) are formed with projections (22a, 22b), which abut against the boss supports (1a, 1b), thereby inhibiting the boss supports (1a, 1b) from being deformed in the direction to move away from each other, thus preventing the bosses (21a, 21b) from falling off the boss supports (1a, 1b).

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com