Outer wall heat-preserving system

An external wall thermal insulation and thermal insulation layer technology, applied in thermal insulation, building components and other directions, can solve problems such as affecting the thermal insulation and safety performance of thermal insulation systems, high fire protection requirements for wall thermal insulation materials, and poor thermal insulation performance of rock wool thermal insulation layers. The effect of strong noise reduction and sound insulation, mildew and waterproof performance and strength improvement, and excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

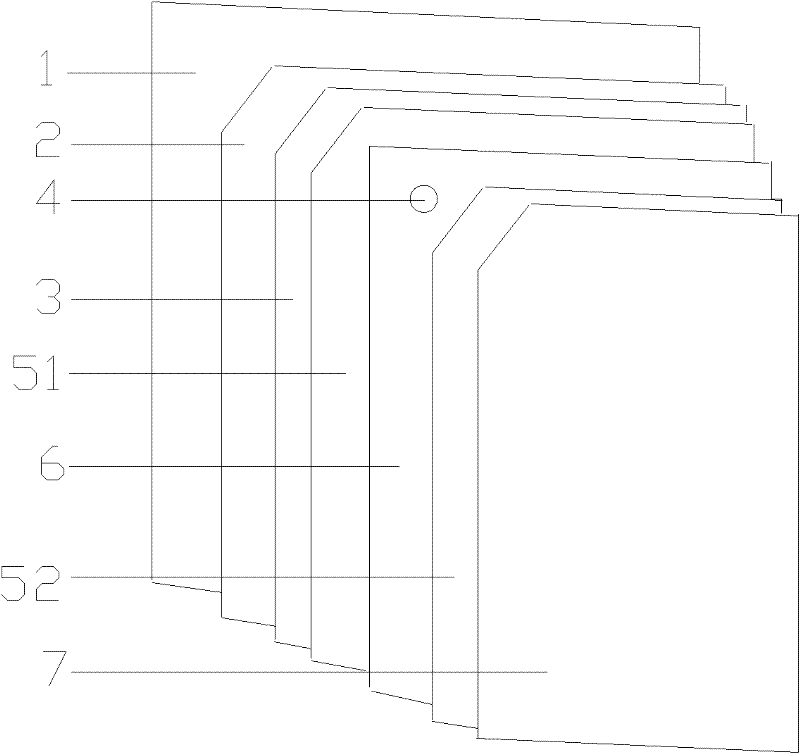

[0024] Such as figure 1 As shown, a thermal insulation composite wallboard for external walls, from the inside to the outside, consists of a glue layer 1, an insulation layer 2, an interface agent layer 3, a plastering mortar layer 51, a glass fiber mesh cloth 6, and a plastering mortar layer 52 , finishing layer 7. The inner surface of the thermal insulation layer 2 is bonded to the wall by coating the adhesive mortar layer 1, the interface agent layer 3 is coated on the outer surface of the thermal insulation layer 2, and the inner surface of the glass fiber mesh cloth 6 is bonded by the plastering mortar layer 51 On the interface agent layer 3, the outer surface is bonded to the veneer layer 7 through the plastering glue layer 52. The anchor piece 4 is an expansion ingot for fixing, installed on the outside of the glass fiber mesh cloth 6, and fixed to the wall through the insulation layer 2. Overall, the strength of the entire wall is greatly enhanced, and the durability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com