Rolling method and device for battery pole piece

A battery pole piece, pole piece technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of powder falling off, uneven particle spacing, and battery electrochemical performance deterioration, and improve safety and particle spacing. Uniform and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

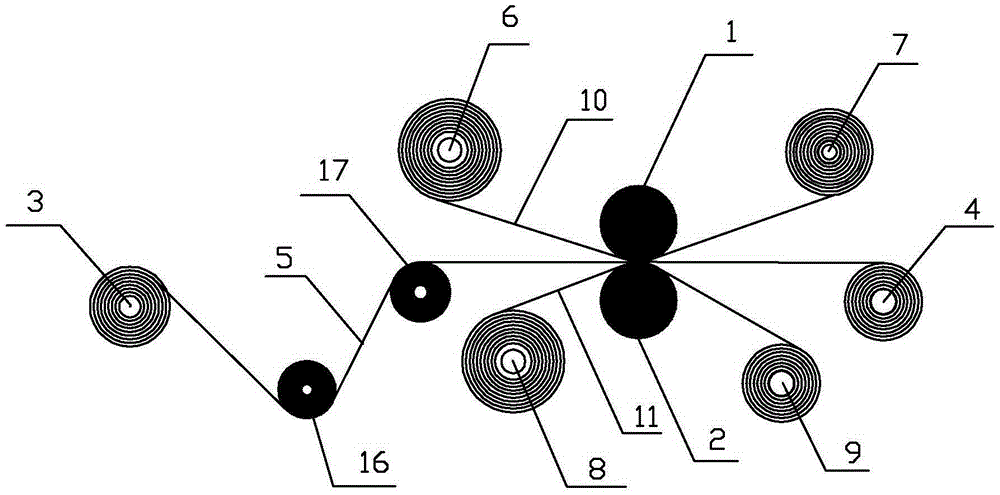

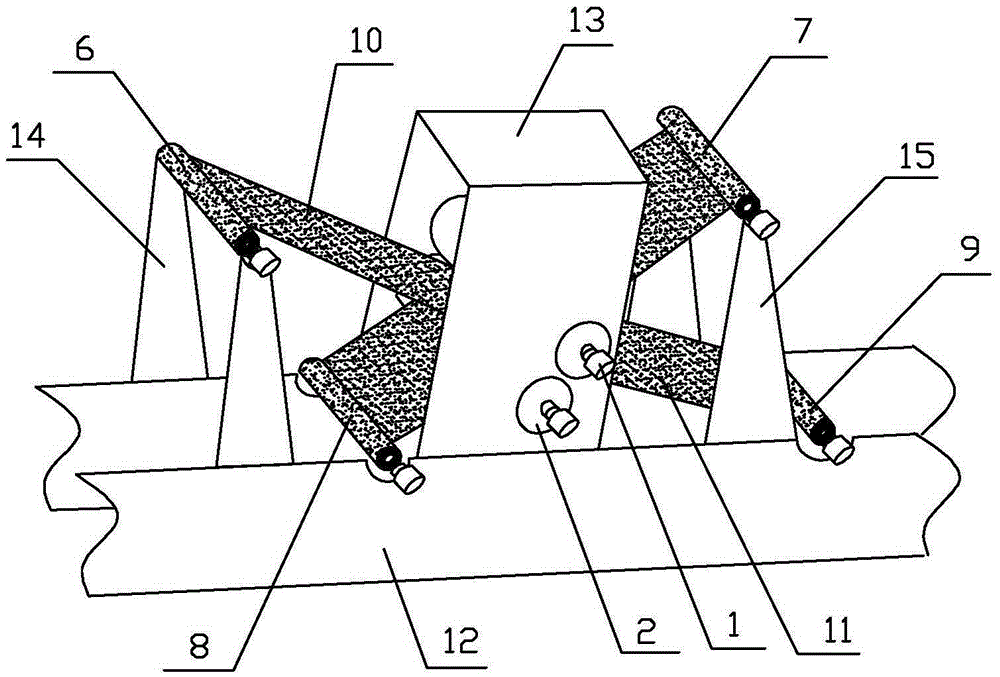

[0029] Embodiment: In the battery electrode sheet rolling method of this embodiment, the rolling of the positive electrode sheet and the negative electrode sheet both includes two rolling processes, namely primary rolling and secondary rolling. One-time rolling does not add and lower foil sheet, the pole piece roll 3 unwinds, the pole piece 5 passes between the upper roll 1 and the lower roll 2, the upper roll and the lower roll and the pole piece coated with powder on both sides The sheet 5 is directly contacted for rolling, and the rolled pole piece is wound up on the pole piece take-up roller 4 . The secondary rolling adopts the rolling method of adding foil, adding the upper foil sheet 10 and the lower foil sheet 11, the material and thickness of the upper foil sheet 10 and the lower foil sheet 11 are the same, and the upper foil sheet 10 , The lower foil sheet 11 passes between the upper roll 1 and the lower roll 2, and the upper foil sheet 10 is located on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com