Coated magnesium alloy, aluminum alloy or plastic substrate and manufacturing method thereof

A technology of substrate production and aluminum alloy, which is applied in metal material coating process, sputtering coating, vacuum evaporation coating, etc., can solve the problems of not mentioning the bonding performance, easy to be worn through, and affecting the wear resistance of the product , to achieve the effects of easy operation, improved binding force, high wear resistance and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

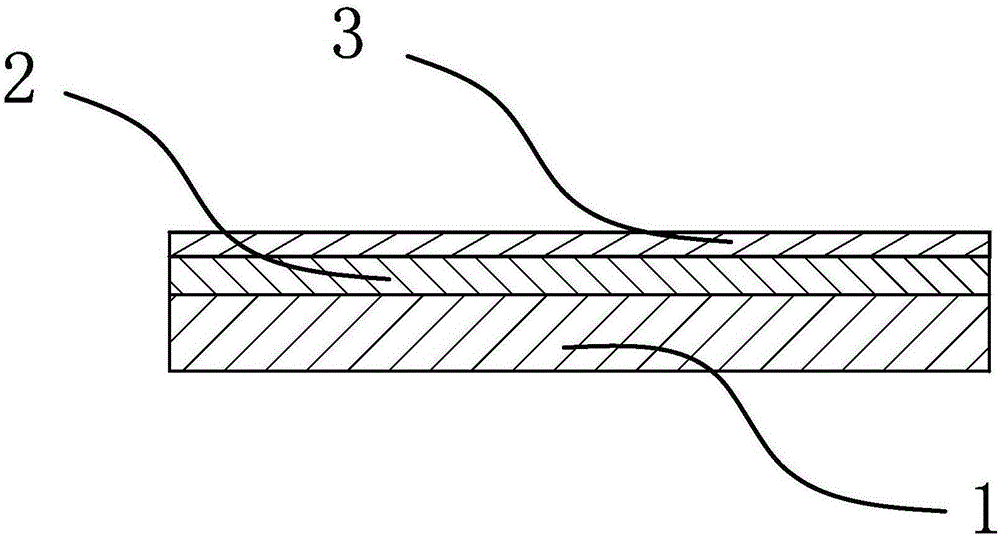

[0029] According to the required size, select the substrate 1 made of magnesium alloy, aluminum alloy or plastic for cleaning, and use weakly alkaline sodium bicarbonate aqueous solution for alkaline cleaning for 15 minutes to remove oil stains on the surface of the substrate. , then rinsed with clean water until neutral, then dried and set aside; the substrate 1 includes the front and back; then, a layer of SiO is coated on the front of the substrate 1 by a conventional method 2 Film layer 2; this film layer is used for bonding;

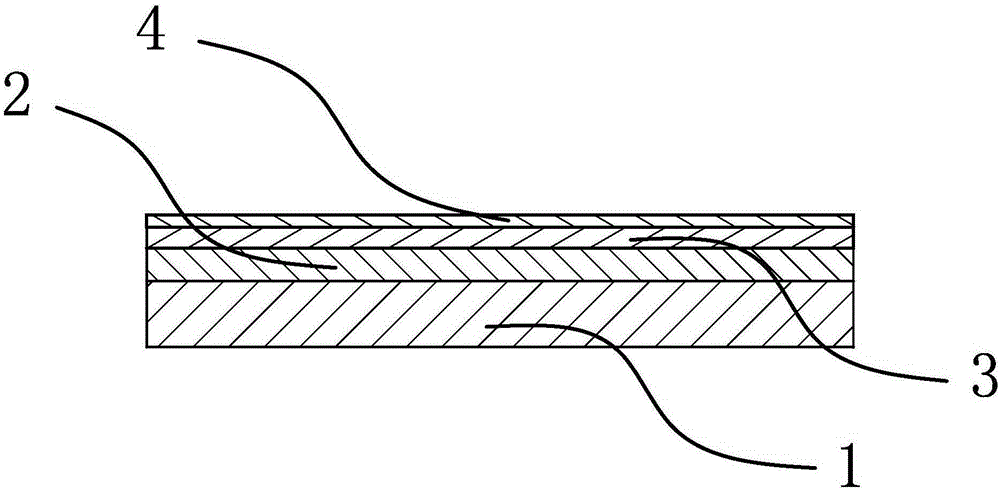

[0030] coated with SiO 2 The substrate 1 of the film layer 2 is put into the coating chamber of the vacuum coating machine, and then the coating chamber is evacuated to make the vacuum degree in the coating chamber reach 5.0x10 -5 Torr, then feed argon and oxygen, and control the flow of argon to 400 sccm, the flow of oxygen to 400 sccm, preferably, control the temperature to 150 ° C ~ 170 ° C, and open the carbon target emission source at the same...

Embodiment 2

[0032] According to the required size, select the substrate 1 made of polycarbonate for cleaning, and use a weakly alkaline sodium bicarbonate aqueous solution for alkaline cleaning for 15 minutes to remove oil stains on the surface of the substrate. After the alkaline cleaning, clean it with water Rinse to neutral, then dry, and set aside; substrate 1 includes front and back sides; then, a layer of SiO is coated on the front side of substrate 1 by vapor deposition method. 2 Film layer 2; this film layer is used for bonding;

[0033] coated with SiO 2 The substrate 1 of the film layer 2 is put into the coating chamber of the vacuum coating machine, and then the coating chamber is evacuated to make the vacuum degree in the coating chamber reach 4.5x10 -5 Torr, and then feed argon and oxygen, and control the flow of argon to 350 sccm, the flow of oxygen to 500 sccm, preferably, control the temperature to 150 ° C ~ 170 ° C, and open the carbon target emission source at the same ...

Embodiment 3

[0035] According to the required size, select the substrate 1 made of aluminum alloy for cleaning, and use a weakly alkaline sodium bicarbonate aqueous solution for alkaline cleaning for 15 minutes to remove oil stains on the surface of the substrate. After the alkaline cleaning, rinse with water To neutral, then, dry, standby; Substrate 1 includes front and back; Then, adopt one layer of SiO2 on the front of substrate 1 by vapor deposition method 2 Film layer 2; this film layer is used for bonding;

[0036] coated with SiO 2 The substrate 1 of the film layer 2 is put into the coating chamber of the vacuum coating machine, and then the coating chamber is evacuated to make the vacuum degree in the coating chamber reach 4.0x10 -5 Torr, then feed argon and oxygen, and control the flow of argon to 400sccm, the flow of oxygen to 450sccm, and open the carbon target emission source at the same time, the carbon target emission source is a graphite target emission source, and the powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com