On-line quick repair material for rotary kiln

A technology of repairing material and rotary kiln, applied in the field of refractory repairing material, can solve the problems of unusability, long time for maintenance and reduction of unit operation rate, etc., and achieve the effect of improving the service cycle, not easy to fall off, and stable repairing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

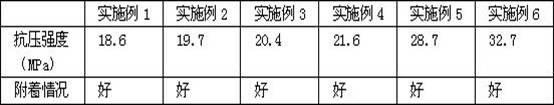

Examples

Embodiment 1

[0011] A fast online repair material for rotary kiln, its composition and weight percentage content: Al 2 O 3 : 55%, SiO 2 : 25%, MgO: 10%, Fe: 4%, Al: 3%, Fe 2 O 3 : 3%, the silica sol binder accounts for 8% of the above total.

Embodiment 2

[0013] A fast online repair material for rotary kiln, its composition and weight percentage content: Al 2 O 3 : 59%, SiO 2 : 22%, MgO: 15%, Fe: 0.01%, Al: 2.99%, Fe 2 O 3 : 1%, silica sol binder accounts for 12% of the above total.

Embodiment 3

[0015] A fast online repair material for rotary kiln, its composition and weight percentage content: Al 2 O 3 : 66%, SiO 2 : 18%, MgO: 14%, Fe: 0.8%, Al: 1%, Fe 2 O 3 : 0.2%, silica sol binder accounts for 15% of the above total.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com