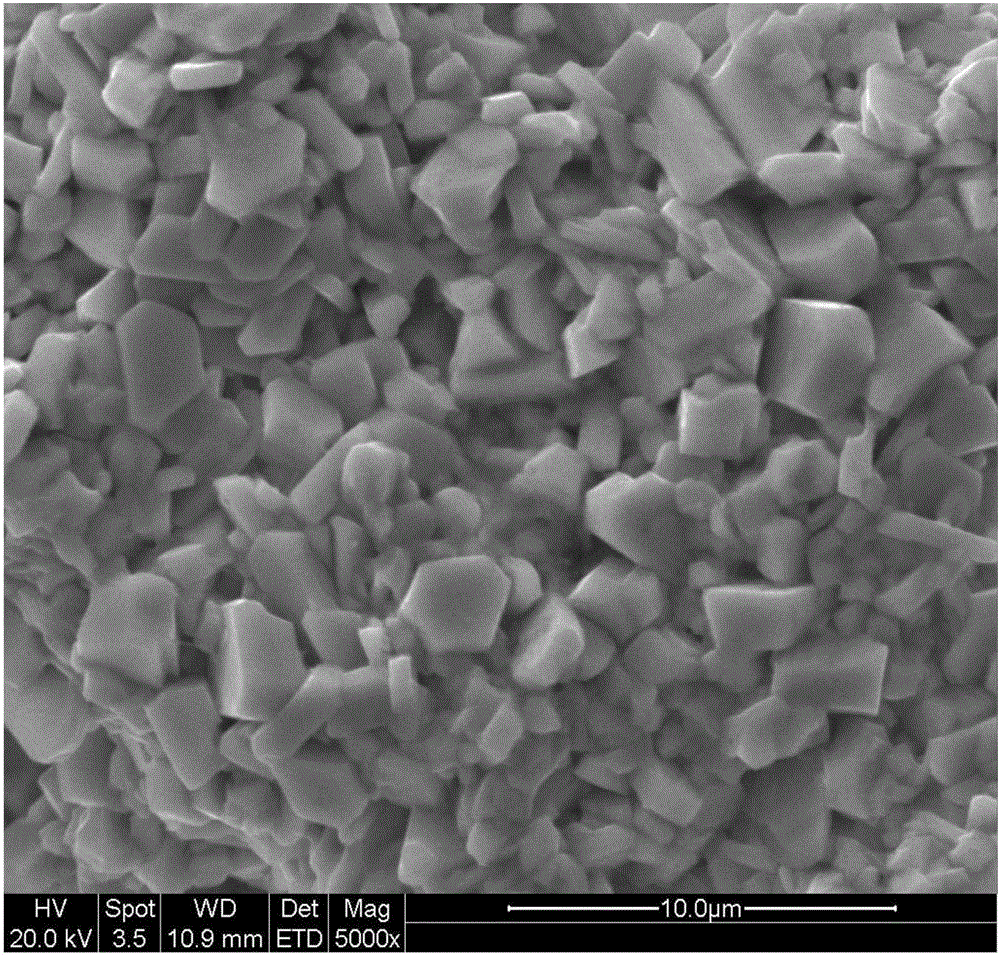

Production method of deep-drawing zinc-iron alloy plated steel plate with ductility higher than 38% and with compact plating structure

A zinc-iron alloy and coated steel technology, which is applied in the coating, hot-dip coating process, metal material coating process, etc., can solve the problems of coating peeling and pulverization, uneven grain size distribution, and coarse surface structure of the coating, etc. , to achieve the effect of solving quality and production problems, improving powder resistance, and dense coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0019] A production method of a deep-drawing zinc-iron alloy coated steel sheet with an elongation higher than 38% and a dense coating structure, comprising the following steps:

[0020] 1) Desulfurization of molten iron, converter smelting and alloying treatment;

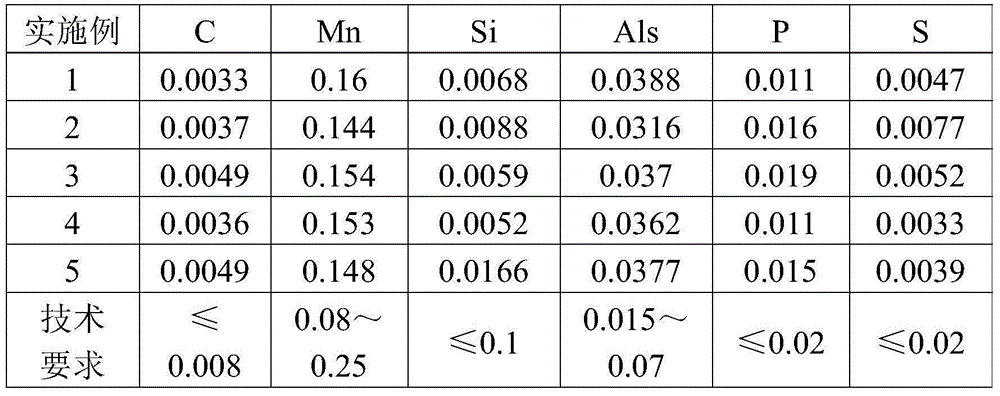

[0021] 2) Carry out continuous casting to the molten steel whose composition reaches the standard to prepare a slab. The chemical composition (wt.%) of the steel plate in Examples 1-5 is specifically shown in Table 1 below;

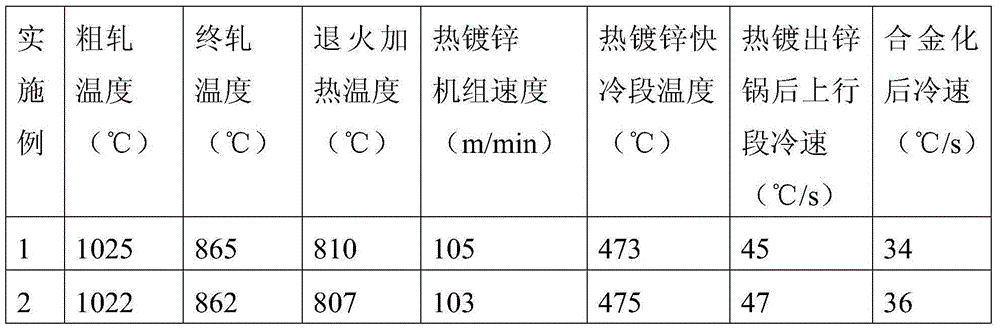

[0022] 3) Perform rough rolling of the slab, control the rough rolling temperature (RT2) at 1020-1060°C, the final rolling temperature (FT7) at 860-890°C, and the crimping temperature at 650-700°C;

[0023] 4) Cold rolling the hot-rolled plate to the required thickness specification;

[0024] 5) Carry out alloying and continuous hot-dip galvanizing treatment on the cold-rolled sheet, in which the speed of the unit is controlled at 100-130m / min, the heating temperature (P2) is controlled at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com