Composite fibre containing light catalyst, its production and polluted fluid purification

A composite fiber and fluid purification technology, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, rayon manufacturing, etc., can solve the problems of increased cost, reduced purification efficiency, and blockage in the purification process, so as to prolong the service life, not easy to fall off, The effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

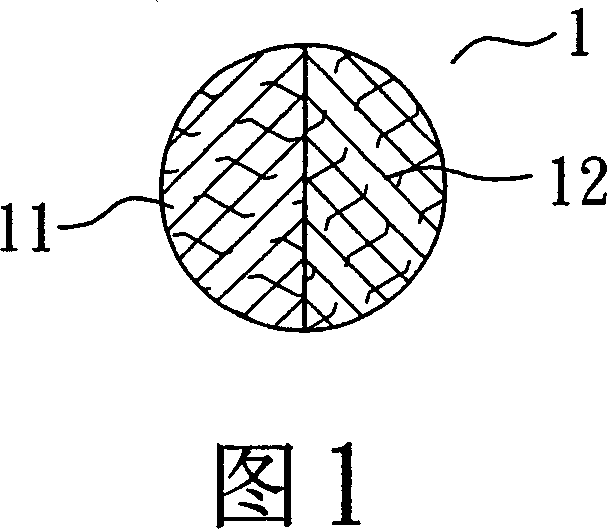

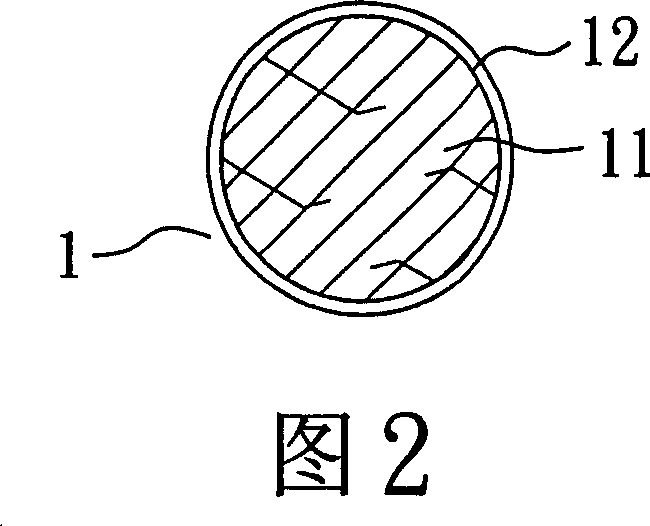

[0058] [Example 1] Preparation of composite fiber (core-sheath type) containing photocatalyst

[0059] According to the volume ratio of the first part and the second part is 70:30, and PET is used as the first part and a mixture containing PET and titanium dioxide (based on the total weight of the mixture, the weight ratio of PET and titanium dioxide is 99:1) as Second part, carry out composite spinning step again, to make the composite fiber that contains the photocatalyst with the cross-sectional diameter of 0.2mm, then this composite fiber that contains photocatalyst is cut, finally obtains the short fiber that contains photocatalyst with the length of 5mm fiber.

[0060] [Methylene blue fading test]

[0061] The short fiber containing photocatalyst that is made by this embodiment 1 is placed in the concentration of 20mL and is 10ppm methylene blue solution (methylene blue, manufactured by Japan Katayama chemical company), then irradiates ultraviolet light, to observe meth...

Embodiment 2

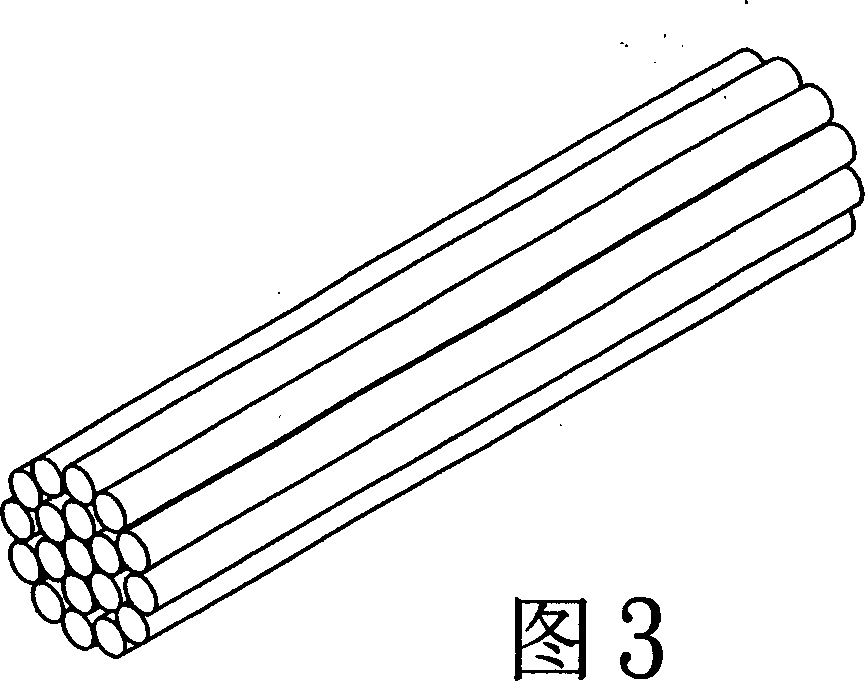

[0064] [Example 2] Production of light-guiding bundled fibers containing photocatalyst

[0065] According to the volume ratio of the first part and the second part is 80:20, and with PMMA as the first part and the mixture containing PMMA and titanium dioxide (based on the total weight of the mixture, the weight ratio of the PMMA and titanium dioxide is 99:1) as The second part is to carry out the composite spinning step again to obtain the composite fiber containing the photocatalyst with a cross-sectional diameter of 0.2mm, then the composite fiber containing the photocatalyst is bundled and cut, and finally obtained with a length of 10cm Light-guiding bundled fibers containing photocatalysts.

[0066] [Methylene blue fading test]

[0067] 50 light-guiding bundle fibers containing photocatalysts prepared in Example 2 were placed in 20 mL of methylene blue solution with a concentration of 10 ppm, and then ultraviolet light was introduced from one end of the bundle fibers resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com